drain bolt INFINITI QX56 2010 Factory Owner's Guide

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2010, Model line: QX56, Model: INFINITI QX56 2010Pages: 4210, PDF Size: 81.91 MB

Page 3848 of 4210

A/T FLUID COOLERTM-153

< ON-VEHICLE MAINTENANCE >

CEF

G H

I

J

K L

M A

B

TM

N

O P

13. Flush each steel line from the cooler side back toward the A/T by spraying Transmission Cooler Cleaner in a continuous stream for 5 seconds.

14. Blow compressed air regulated to 490 - 883 kPa (5 - 9 kg/cm

2, 71 - 128 psi) through each steel line from

the cooler side back toward the A/T for 10 seconds to force out any remaining fluid.

15. Ensure all debris is removed from the steel cooler lines.

16. Ensure all debris is removed from the banjo bolts and fittings.

17. Perform A/T fluid cooler diagnosis procedure.

A/T FLUID COOLER DIAGNOSIS PROCEDURE

NOTE:

Insufficient cleaning of the cooler inlet hose exte rior may lead to inaccurate debris identification.

1. Position a drain pan under the A/T inlet and outlet fluid cooler tube to cooler hose connection.

2. Clean the exterior and tip of the cooler inlet hose.

3. Put a different color matching mark on each cooler tube to cooler hose connection to aid in assembly. CAUTION:

Use paint to make the matching mark. Do not damage the tubes or hose.

4. Disconnect the fluid cooler inle t and outlet rubber hoses from the

steel cooler tubes.

NOTE:

Replace the cooler hoses if rubber material from the hose

remains on the tube fitting.

5. Insert the extension adapter hose of a can of Transmission Cooler Cleaner (Nissan P/N 999MP-AM006) into the cooler out-

let hose.

CAUTION:

• Wear safety glasses and rubber gloves when spraying the

Transmission Cooler Cleaner.

• Spray cooler cleaner only with adequate ventilation.

• Avoid contact with eyes and skin.

• Do not breath vapors or spray mist.

6. Hold the hose and can as high as possible and spray Transmis- sion Cooler Cleaner in a continuous stream into the cooler outlet

hose until fluid flows out of the cooler inlet hose for 5 seconds.

7. Tie a common white, basket-type coffee filter to the end of the cooler inlet hose.

SCIA3830E

SCIA3831E

SCIA3833E

Revision: April 20092010 QX56

Page 3865 of 4210

TM-170

< ON-VEHICLE REPAIR >

OIL PAN

OIL PAN

Oil PanINFOID:0000000005148740

REMOVAL AND INSTALLATION

Removal

1. Drain A/T fluid. Refer to TM-150, "Changing the A/T Fluid (ATF)".

2. Remove oil pan clips (1).

3. Remove oil pan (2).

4. Remove oil pan gasket. • : Vehicle front

• : Oil pan bolts

• Drain plug (3)

5. Check foreign materials in oil pan to help determine c ause of malfunction. If the A/T fluid is very dark, has

some burned smell, or contains foreign particles, friction material (clutches, band) may need replacement.

A tacky film that will not wipe clean indicates varnish build up. Varnish can cause valves, servo, and

clutches to stick and can inhibit pump pressure.

CAUTION:

If friction material is detected, flush the transmission cooler after repair. Refer to TM-152, "

A/T

Fluid Cooler Cleaning".

6. Remove magnets from oil pan.

Installation

1. Install the oil pan magnets as shown.

AWDIA0023ZZ

SCIA5200E

SCIA5200E

Revision: April 20092010 QX56

Page 3866 of 4210

OIL PANTM-171

< ON-VEHICLE REPAIR >

CEF

G H

I

J

K L

M A

B

TM

N

O P

2. Install the oil pan and new oil pan gasket. • : Vehicle front

• : Oil pan bolts

• Clips (1)

• Drain plug (3)

CAUTION:

• Be sure the oil pan drain plug hole is located to the rear ofthe transmission assembly.

• Before installing oil pan bolts, remove any traces of old sealant from the sealing su rfaces and threaded holes.

• Do not reuse the oil pan gasket.

• Always replace the oil pan bolts as they are self-sealing.

• Partially install the oil pan bo lts in a criss-cross pattern to prevent dislocation of the gasket.

3. Install new oil pan bolts and clips tighten in numerical order as shown.

4. Install drain plug with new gasket to oil pan and tighten to speci- fication.

CAUTION:

Do not reuse the drain plug gasket.

5. Refill the A/T with fluid and check for fluid leakage. Refer to TM-

148, "Checking the A/T Fluid (ATF)".

AWDIA0023ZZ

Oil pan bolts : 7.9 N·m (0.81 kg-m, 70 in-lb)

Drain plug : 34 N·m (3.5 kg-m, 25 ft-lb)

SCIA4113E

Revision: April 20092010 QX56

Page 3867 of 4210

TM-172

< ON-VEHICLE REPAIR >

CONTROL VALVE WITH TCM

CONTROL VALVE WITH TCM

Control Valve with TCM and A/T Fluid Temperature Sensor 2 and PlugINFOID:0000000005148741

COMPONENTS

CONTROL VALVE WITH TCM REMOVAL AND INSTALLATION

Removal

1. Disconnect negative battery terminal.

2. Drain A/T fluid. Refer to TM-150, "

Changing the A/T Fluid (ATF)".

3. Disconnect A/T assembly harness connector.

1. Transmission 2. Snap ring3. Sub-harness

4. Control valve with TCM 5. Bracket 6. A/T fluid temperature sensor 2

7. Oil pan gasket 8. Brackets9. Oil pan bolt

10. Oil pan 11. Magnet12. Drain plug

13. Drain plug gasket 14. Terminal cord assembly 15. O-ring

16. O-ring 17. Plug

A/T fluid temperature sensor 2 (A) can be changed to plug (B), depending on vehicles.

JSDIA1314GB

Revision: April 20092010 QX56

Page 3882 of 4210

TRANSMISSION ASSEMBLYTM-187

< REMOVAL AND INSTALLATION >

CEF

G H

I

J

K L

M A

B

TM

N

O P

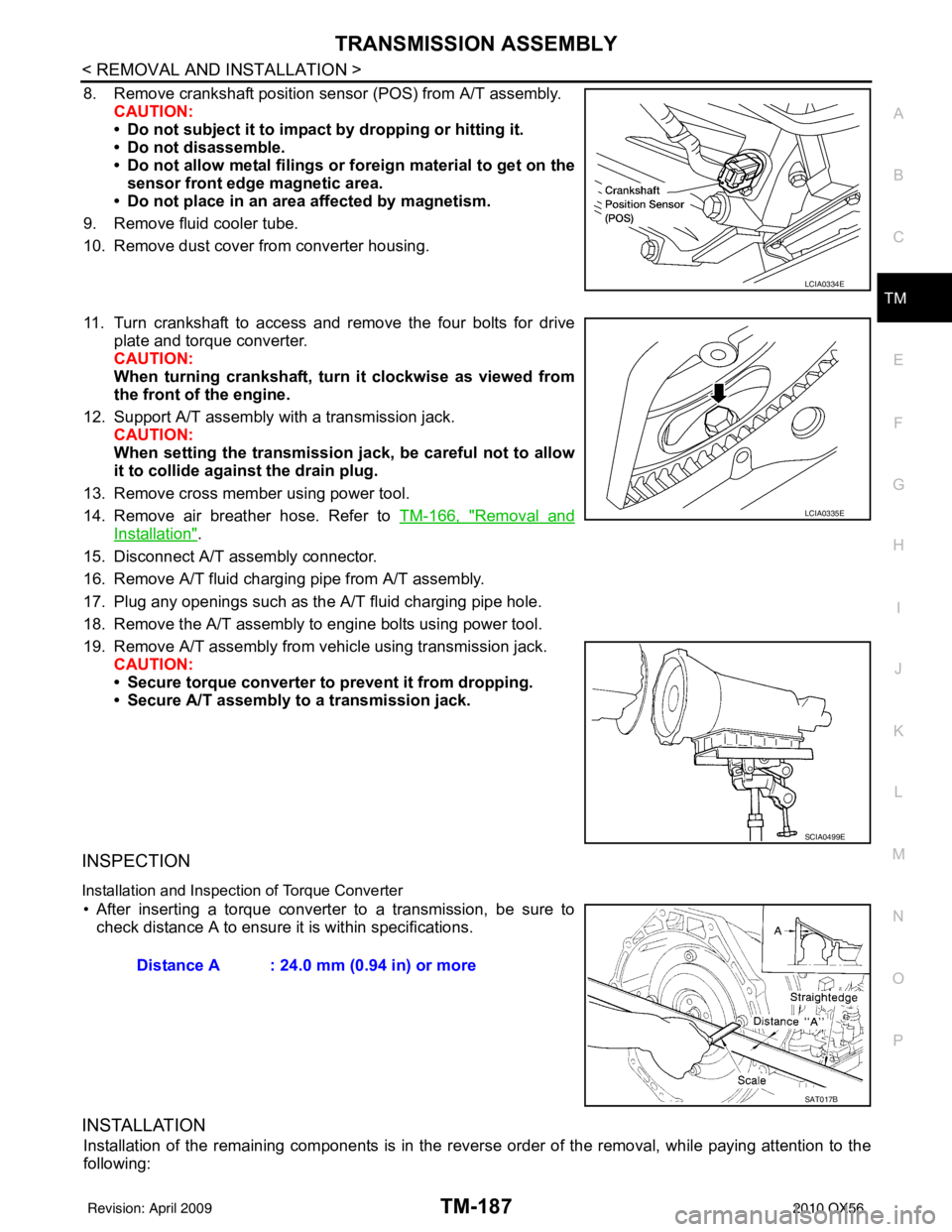

8. Remove crankshaft position sens or (POS) from A/T assembly.

CAUTION:

• Do not subject it to impact by dropping or hitting it.

• Do not disassemble.

• Do not allow metal filings or foreign material to get on the

sensor front edge magnetic area.

• Do not place in an area affected by magnetism.

9. Remove fluid cooler tube.

10. Remove dust cover from converter housing.

11. Turn crankshaft to access and remove the four bolts for drive plate and torque converter.

CAUTION:

When turning crankshaft, turn it clockwise as viewed from

the front of the engine.

12. Support A/T assembly with a transmission jack. CAUTION:

When setting the transmission jack, be careful not to allow

it to collide agai nst the drain plug.

13. Remove cross member using power tool.

14. Remove air breather hose. Refer to TM-166, "

Removal and

Installation".

15. Disconnect A/T assembly connector.

16. Remove A/T fluid charging pipe from A/T assembly.

17. Plug any openings such as the A/T fluid charging pipe hole.

18. Remove the A/T assembly to engine bolts using power tool.

19. Remove A/T assembly from vehicle using transmission jack. CAUTION:

• Secure torque converter to prevent it from dropping.

• Secure A/T assembly to a transmission jack.

INSPECTION

Installation and Inspection of Torque Converter

• After inserting a torque converter to a transmission, be sure to check distance A to ensure it is within specifications.

INSTALLATION

Installation of the remaining components is in the revers e order of the removal, while paying attention to the

following:

LCIA0334E

LCIA0335E

SCIA0499E

Distance A : 24.0 mm (0.94 in) or more

SAT017B

Revision: April 20092010 QX56

Page 3885 of 4210

TM-190

< REMOVAL AND INSTALLATION >

TRANSMISSION ASSEMBLY

8. Remove crankshaft position sensor (POS) from A/T assembly.CAUTION:

• Do not subject it to impact by dropping or hitting it.

• Do not disassemble.

• Do not allow metal filings or fo reign material to get on the

sensor front edge magnetic area.

• Do not place in an area affected by magnetism.

9. Remove A/T fluid cooler tube from A/T assembly.

10. Remove dust cover from converter housing.

11. Turn crankshaft, and remove the four bolts for drive plate and torque converter.

CAUTION:

When turning crankshaft, turn it clockwise as viewed from

the front of the engine.

12. Support A/T assembly using transmission jack and Tool. CAUTION:

When setting the transmission jack, be careful not to allow it to collide against the drain plug.

NOTE:

The actual special service tool may differ from tool shown.

13. Remove cross member using power tool.

14. Tilt the transmission slightly to keep the cl earance between body and transmission, then disconnect air

breather hose from A/T fluid charging pipe.

15. Remove air breather hose. Refer to TM-166, "

Removal and Installation".

16. Disconnect A/T assembly connector and transfer unit connector.

17. Remove A/T fluid charging pipe.

18. Plug any openings such as the fluid charging pipe hole.

19. Remove A/T assembly to engine bolts using power tool.

20. Remove A/T assembly with transfer from vehicle. CAUTION:

• Secure torque converter to prevent it from dropping.

• Secure A/T assembly to transmission jack.

21. Remove transfer from A/T assembly. Refer to TM-188,

"Removal and Installation (4WD)".

INSPECTION

Installation and Inspection of Torque Converter

LCIA0334E

LCIA0335E

Tool number : — (J-47002)

SCIA2203E

Revision: April 20092010 QX56

Page 3891 of 4210

TM-196

< DISASSEMBLY AND ASSEMBLY >

OVERHAUL

4WD

16. Bearing race17. Needle bearing18. Manual plate

19. Parking rod 20. Manual shaft oil seal 21. Manual shaft

22. O-ring 23. Band servo anchor end pin 24. Detent spring

25. Spacer 26. Seal ring27. Snap ring

28. Return spring 29. O-ring30. Servo assembly

31. Snap ring 32. Sub-harness33. Control valve with TCM

34. Bracket 35. A/T fluid temperature sensor 2 36. Oil pan gasket

37. Brackets 38. Oil pan bolt39. Oil pan

40. Magnets 41. Drain plug42. Drain plug gasket

43. A/T assemblt harness connector 44. O-ring 45. Retaining pin

46. Transmission case 47. O-ring48. Plug

A/T fluid temperature sensor 2 (A) can be changed to plug (B), depending on vehicles.

*: Apply Genuine Anaerobic Liquid Gasket or equivalent.

Revision: April 20092010 QX56

Page 3893 of 4210

TM-198

< DISASSEMBLY AND ASSEMBLY >

OVERHAUL

19. Parking rod20. Manual shaft oil seal 21. Manual shaft

22. O-ring 23. Band servo anchor end pin 24. Detent spring

25. Spacer 26. Seal rings 27. Return spring

28. O-ring 29. Servo assembly 30. Snap ring

31. Snap ring 32. Sub-harness 33. Control valve with TCM

34. Bracket 35. A/T fluid temperature sensor 2 36. Oil pan gasket

37. Brackets 38. Oil pan bolt 39. Oil pan

40. Magnets 41. Drain plug 42. Drain plug gasket

43. A/T assembly harness con- nector 44. O-ring

45. Retaining pin

46. Transmission case 47. O-ring 48. Plug

A/T fluid temperature sensor 2 (A) can be changed to plug (B), depending on vehicles.

Revision: April 20092010 QX56

Page 3899 of 4210

TM-204

< DISASSEMBLY AND ASSEMBLY >

DISASSEMBLY

DISASSEMBLY

DisassemblyINFOID:0000000005148748

CAUTION:

Do not disassemble parts behind Drum Support. Refer to TM-8, "

Cross-Sectional View (2WD models)".

1. Drain A/T fluid through drain plug.

2. Remove torque converter by holding it firmly and turing while pulling straight out.

3. Check torque converter one-way clutch using a check tool as shown.

a. Insert a check tool into the groove of bearing support built into one-way clutch outer race.

b. While holding bearing support with a check tool, rotate one-way clutch spline using suitable tool.

c. Make sure that inner race rotates clockwise only. If not, replace torque converter assembly.

4. Remove bolts and converter housing from transmission case. CAUTION:

Do not scratch converter housing.

• Self-sealing bolt (A)

SCIA5010E

SCIA3171E

WCIA0662E

Revision: April 20092010 QX56

Page 3979 of 4210

HEATER & COOLING UNIT ASSEMBLYVTL-17

< ON-VEHICLE REPAIR >

C

DE

F

G H

J

K L

M A

B

VTL

N

O P

Rear A/C System

NOTE:

Refer to HA-5, "

Precaution for Refrigerant Connection".

Removal and InstallationINFOID:0000000005147613

FRONT HEATER AND COOLING UNIT ASSEMBLY

Removal

7. High-pressure flexible hose 8. Low-pressure flexible hose 9. Low-pressure service valve

10. Low-pressure pipe 11. Expansion valve (front) 12. Drain hose

AWIIA0134GB

1. Rear heater and cooling unit assembly 2. Rear A/C pipes 3. Rear A/C heater core pipes

4. Rear heater core hose 5. Rear blower motor6. Underfloor rear A/C pipes

7. Underfloor rear heater core pipes A. Bolt torque specification B. Leak checking order (l - r)

C. Tightening torque D. Wrench sizeE. O-ring size

Front

NOTE: The O-ring size 8 is the high-side and the O-ring size 16 is the low-side.

Revision: April 20092010 QX56