air condition INFINITI QX56 2010 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2010, Model line: QX56, Model: INFINITI QX56 2010Pages: 4210, PDF Size: 81.91 MB

Page 2801 of 4210

MWI

COMBINATION METERMWI-39

< ECU DIAGNOSIS >

C

DE

F

G H

I

J

K L

M B A

O P

ECU DIAGNOSIS

COMBINATION METER

Reference ValueINFOID:0000000005146098

TERMINAL LAYOUT

PHYSICAL VALUES

WKIA5724E

Te r m i - nal Wire

color Item Condition

Reference value (V)

(Approx.)

Ignition

switch Operation or condition

3 Y/L Fuel level sensor signal — —Refer to

MWI-12, "

FUEL GAUGE : System

Description".

4 B/P Fuel level sensor ground ON —0

6 BR/W Generator ONGenerator voltage low

0

Generator voltage normal Battery voltage

10 L CAN-H —— —

11 P C A N - L —— —

13 P Air bag warning lamp in-

put ONAir bag warning lamp ON

4

Air bag warning lamp OFF 0

15 BR CK SUSP warning lamp

input —CK SUSP warning lamp

ON

0

CK SUSP warning lamp

OFF Battery voltage

20 B Ground —— 0

21 O/L Ignition switch ON or

START ON

— Battery voltage

23 W/L Washer fluid level switch ON Washer fluid level low

0

Washer fluid level normal Battery voltage

24 O/B Seat belt buckle switch

LH ONUnfastened (ON)

0

Fastened (OFF) Battery voltage

25 P/L Seat belt buckle switch

RH ONUnfastened (ON)

0

Fastened (OFF) Battery voltage

31 G Parking brake switch ON Parking brake applied

0

Parking brake released Battery voltage

32 P/B Brake fluid level switch ON Brake fluid level low

0

Brake fluid level normal Battery voltage

35 G/O Security indicator input OFF Security indicator ON

0

Security indicator OFF Battery voltage

Revision: April 20092010 QX56

Page 2823 of 4210

MWI

BCM (BODY CONTROL MODULE)MWI-61

< ECU DIAGNOSIS >

C

DE

F

G H

I

J

K L

M B A

O P

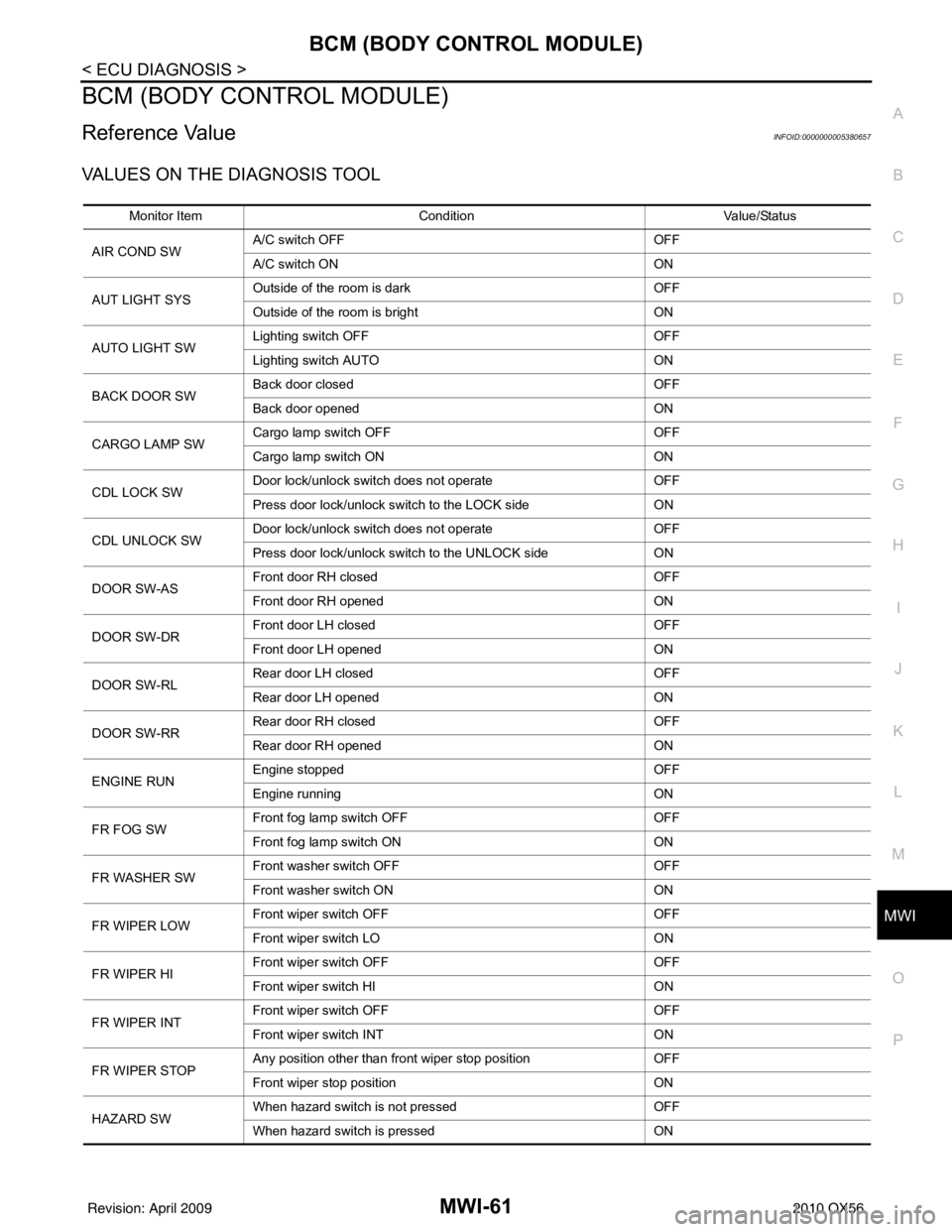

BCM (BODY CONTROL MODULE)

Reference ValueINFOID:0000000005380657

VALUES ON THE DIAGNOSIS TOOL

Monitor Item Condition Value/Status

AIR COND SW A/C switch OFF

OFF

A/C switch ON ON

AUT LIGHT SYS Outside of the room is dark

OFF

Outside of the room is bright ON

AUTO LIGHT SW Lighting switch OFF

OFF

Lighting switch AUTO ON

BACK DOOR SW Back door closed

OFF

Back door opened ON

CARGO LAMP SW Cargo lamp switch OFF

OFF

Cargo lamp switch ON ON

CDL LOCK SW Door lock/unlock switch does not operate

OFF

Press door lock/unlock switch to the LOCK side ON

CDL UNLOCK SW Door lock/unlock switch does not operate

OFF

Press door lock/unlock switch to the UNLOCK side ON

DOOR SW-AS Front door RH closed

OFF

Front door RH opened ON

DOOR SW-DR Front door LH closed

OFF

Front door LH opened ON

DOOR SW-RL Rear door LH closed

OFF

Rear door LH opened ON

DOOR SW-RR Rear door RH closed

OFF

Rear door RH opened ON

ENGINE RUN Engine stopped

OFF

Engine running ON

FR FOG SW Front fog lamp switch OFF

OFF

Front fog lamp switch ON ON

FR WASHER SW Front washer switch OFF

OFF

Front washer switch ON ON

FR WIPER LOW Front wiper switch OFF

OFF

Front wiper switch LO ON

FR WIPER HI Front wiper switch OFF

OFF

Front wiper switch HI ON

FR WIPER INT Front wiper switch OFF

OFF

Front wiper switch INT ON

FR WIPER STOP Any position other than front wiper stop position

OFF

Front wiper stop position ON

HAZARD SW When hazard switch is not pressed

OFF

When hazard switch is pressed ON

Revision: April 20092010 QX56

Page 2839 of 4210

MWI

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

MWI-77

< ECU DIAGNOSIS >

C

D E

F

G H

I

J

K L

M B A

O P

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE

ROOM)

Reference ValueINFOID:0000000005380664

VALUES ON THE DIAGNOSIS TOOL

Monitor Item ConditionValue/Status

MOTOR FAN REQ Engine idle speed Changes depending on engine

coolant temperature, air conditioner

operation status, vehicle speed,

etc.0 - 100 %

A/C COMP REQ A/C switch OFF

OFF

A/C switch ON ON

TA I L & C L R R E Q Lighting switch OFF

OFF

Lighting switch 1ST, 2ND, HI or AUTO (Light is illuminated) ON

HL LO REQ Lighting switch OFF

OFF

Lighting switch 2ND HI or AUTO (Light is illuminated) ON

HL HI REQ Lighting switch OFF

OFF

Lighting switch HI ON

FR FOG REQ Lighting switch 2ND or AUTO (Light

is illuminated) Front fog lamp switch OFF OFF

• Front fog lamp switch ON

• Daytime light activated (Canada

only) ON

FR WIP REQ Ignition switch ON Front wiper switch OFF

STOP

Front wiper switch INT 1LOW

Front wiper switch LO LOW

Front wiper switch HI HI

WIP AUTO STOP Ignition switch ON Front wiper stop position

STOP P

Any position other than front wiper

stop position ACT P

WIP PROT Ignition switch ON Front wiper operates normally OFF

Front wiper stops at fail-safe opera-

tion

BLOCK

ST RLY REQ Ignition switch OFF or ACC

OFF

Ignition switch START ON

IGN RLY Ignition switch OFF or ACC

OFF

Ignition switch ON ON

RR DEF REQ Rear defogger switch OFF

OFF

Rear defogger switch ON ON

OIL P SW Ignition switch OFF, ACC or engine running

OPEN

Ignition switch ON CLOSE

DTRL REQ Daytime light system requested OFF with CONSULT-III.

OFF

Daytime light system reques ted ON with CONSULT-III. ON

HOOD SW Hood closed.

OFF

Hood open. ON

Revision: April 20092010 QX56

Page 2873 of 4210

PB-10

< ON-VEHICLE REPAIR >

PARKING BRAKE SHOE

• Check thickness of lining.

Disc Rotor Inner Diameter Inspection

• Check inner diameter insi de drum area of disc rotor.

Other Inspections

• Check shoe sliding surface on back plate for excessive wear and damage.

• Check anti-rattle pins for excessive wear and corrosion.

• Check return springs for sagging.

• Check adjuster for rough operation.

• When disassembling adjuster, apply PBC (Poly Butyl Cuprysil) grease or equivalent to the threads.

• Check either visually or with a vernier caliper to see if there is any excessive wear, cracks, or damage inside

drum area of disc rotor.

INSTALLATION

Installation is in the reverse order of removal.

• Apply brake grease to the specified points during assembly.

• Assemble adjuster so that threaded part expands when rotating it

in the direction shown by the arrow.

• Shorten adjuster by rotating it.

NOTE:

After replacing brake shoes or disc rotors, or if brakes do not function well, perform break-in operation as fol-

lows.

1. Adjust parking brake pedal stroke. Refer to PB-5, "

On-Vehicle Service".

2. Perform parking brake break-in operation by driving the vehicle forward under the following conditions: • Vehicle speed at 40 km/h (25 MPH)

• Apply parking brake with an operating forc e of 196 N (20.0 kg-f, 44.1 lb-f) set

• Apply parking brake for a period of 30 seconds

CAUTION:

• To prevent lining from getting too hot, allow a cool off period of approximately 5 minutes after every break-in operation.Standard thickness (A) : Refer to

PB-12, "

Parking

Brake".

Wear limit thickness (A) : Refer to PB-12, "

Parking

Brake".

SBR021A

Standard inner diameter : Refer to PB-12, "Park-

ing Brake".

Wear limit of inner diameter : Refer to PB-12, "

Park-

ing Brake".

SBR768A

SFIA0153E

Revision: April 20092010 QX56

Page 2878 of 4210

![INFINITI QX56 2010 Factory Service Manual PCS

DIAGNOSIS AND REPAIR WORKFLOWPCS-3

< BASIC INSPECTION > [IPDM E/R]

C

D

E

F

G H

I

J

K L

B A

O P

N

1. GET INFORMATION FOR SYMPTOM

Get the detailed information from the customer about the symptom (th INFINITI QX56 2010 Factory Service Manual PCS

DIAGNOSIS AND REPAIR WORKFLOWPCS-3

< BASIC INSPECTION > [IPDM E/R]

C

D

E

F

G H

I

J

K L

B A

O P

N

1. GET INFORMATION FOR SYMPTOM

Get the detailed information from the customer about the symptom (th](/img/42/57032/w960_57032-2877.png)

PCS

DIAGNOSIS AND REPAIR WORKFLOWPCS-3

< BASIC INSPECTION > [IPDM E/R]

C

D

E

F

G H

I

J

K L

B A

O P

N

1. GET INFORMATION FOR SYMPTOM

Get the detailed information from the customer about the symptom (the condition and the environment when

the incident/malfunction occurred).

>> GO TO 2

2. CHECK DTC

1. Check DTC.

2. Perform the following procedure if DTC is displayed.

- Record DTC and freeze frame data.

- Erase DTC.

- Study the relationship between the cause detected by DTC and the symptom described by the customer.

3. Check related service bulletins for information.

Is any symptom described and any DTC detected?

Symptom is described, DTC is displayed>>GO TO 3

Symptom is described, DTC is not displayed>>GO TO 4

Symptom is not described, DTC is displayed>>GO TO 5

3. CONFIRM THE SYMPTOM

Confirm the symptom described by the customer.

Connect CONSULT-III to the vehicle in “DATA MONI TOR” mode and check real time diagnosis results.

Verify relationship between the symptom and the condition when the symptom is detected.

>> GO TO 5

4. CONFIRM THE SYMPTOM

Confirm the symptom described by the customer.

Connect CONSULT-III to the vehicle in “DATA MONI TOR” mode and check real time diagnosis results.

Verify relationship between the symptom and the condition when the symptom is detected.

>> GO TO 6

5. PERFORM DTC CONFIRMATION PROCEDURE

Perform DTC Confirmation Procedure for the display ed DTC, and then check that DTC is detected again.

At this time, always connect CONSULT-III to the vehicle, and check diagnostic results in real time.

If two or more DTCs are detected, refer to BCS-54, "

DTCInspectionPriorityChart" and determine trouble

diagnosis order.

NOTE:

• Freeze frame data is useful if the DTC is not detected.

• Perform Component Function Check if DTC Confirmation Procedure is not included in Service Manual. This

simplified check procedure is an effective alternat ive though DTC cannot be detected during this check.

If the result of Component Function Check is NG, it is the same as the detection of DTC by DTC Confirma-

tion Procedure.

Is DTC detected?

YES >> GO TO 8

NO >> Refer to GI-38, "

Intermittent Incident".

6. PERFORM BASIC INSPECTION

Perform a basic inspection of the IPDM E/R.

Inspection End>>GO TO 7

7. DETECT MALFUNCTIONING SYSTEM BY SYMPTOM

Detect malfunctioning system according to symptom in step 4, and determine the trouble diagnosis order

based on possible causes and symptom.

>> GO TO 8

Revision: April 20092010 QX56

Page 2894 of 4210

![INFINITI QX56 2010 Factory Service Manual PCS

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

PCS-19

< ECU DIAGNOSIS > [IPDM E/R]

C

D

E

F

G H

I

J

K L

B A

O P

N

ECU DIAGNOSIS

IPDM E/R (INTELLIGENT POWER

DISTRIBUTION MODULE ENGINE INFINITI QX56 2010 Factory Service Manual PCS

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

PCS-19

< ECU DIAGNOSIS > [IPDM E/R]

C

D

E

F

G H

I

J

K L

B A

O P

N

ECU DIAGNOSIS

IPDM E/R (INTELLIGENT POWER

DISTRIBUTION MODULE ENGINE](/img/42/57032/w960_57032-2893.png)

PCS

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

PCS-19

< ECU DIAGNOSIS > [IPDM E/R]

C

D

E

F

G H

I

J

K L

B A

O P

N

ECU DIAGNOSIS

IPDM E/R (INTELLIGENT POWER

DISTRIBUTION MODULE ENGINE

ROOM)

Reference ValueINFOID:0000000005146512

VALUES ON THE DIAGNOSIS TOOL

Monitor Item ConditionValue/Status

MOTOR FAN REQ Engine idle speed Changes depending on engine

coolant temperature, air conditioner

operation status, vehicle speed,

etc.0 - 100 %

A/C COMP REQ A/C switch OFF

OFF

A/C switch ON ON

TA I L & C L R R E Q Lighting switch OFF

OFF

Lighting switch 1ST, 2ND, HI or AUTO (Light is illuminated) ON

HL LO REQ Lighting switch OFF

OFF

Lighting switch 2ND HI or AUTO (Light is illuminated) ON

HL HI REQ Lighting switch OFF

OFF

Lighting switch HI ON

FR FOG REQ Lighting switch 2ND or AUTO (Light

is illuminated) Front fog lamp switch OFF OFF

• Front fog lamp switch ON

• Daytime light activated (Canada

only) ON

FR WIP REQ Ignition switch ON Front wiper switch OFF

STOP

Front wiper switch INT 1LOW

Front wiper switch LO LOW

Front wiper switch HI HI

WIP AUTO STOP Ignition switch ON Front wiper stop position

STOP P

Any position other than front wiper

stop position ACT P

WIP PROT Ignition switch ON Front wiper operates normally OFF

Front wiper stops at fail-safe opera-

tion

BLOCK

ST RLY REQ Ignition switch OFF or ACC

OFF

Ignition switch START ON

IGN RLY Ignition switch OFF or ACC

OFF

Ignition switch ON ON

RR DEF REQ Rear defogger switch OFF

OFF

Rear defogger switch ON ON

OIL P SW Ignition switch OFF, ACC or engine running

OPEN

Ignition switch ON CLOSE

DTRL REQ Daytime light system requested OFF with CONSULT-III.

OFF

Daytime light system reques ted ON with CONSULT-III. ON

HOOD SW Hood closed.

OFF

Hood open. ON

Revision: April 20092010 QX56

Page 2913 of 4210

PG

PRECAUTIONSPG-3

< PRECAUTION >

C

DE

F

G H

I

J

K L

B A

O P

N

5. When the repair work is completed, return the ignition switch to the

″LOCK ″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of al l control units using CONSULT-III.

Precaution for Power Generation Variable Voltage Control SystemINFOID:0000000005146570

CAUTION:

For this model, the battery current sensor that is installed to the negative battery cable measures the

charging/discharging current of the battery and performs various engine controls. If an electrical com-

ponent is connected directly to the negative battery terminal, the current flowing through that compo-

nent will not be measured by the battery current sensor. This condition may cause a malfunction of

the engine control system and battery discharge m ay occur. Do not connect an electrical component

or ground wire directly to the battery terminal.

Revision: April 20092010 QX56

Page 2989 of 4210

PWC-4

< BASIC INSPECTION >

DIAGNOSIS AND REPAIR WORKFLOW

BASIC INSPECTION

DIAGNOSIS AND REPAIR WORKFLOW

Work FlowINFOID:0000000005147164

DETAILED FLOW

1. OBTAIN INFORMATION ABOUT SYMPTOM

Interview the customer to obtain the malfunction information (conditions and environment when the malfunc-

tion occurred) as much as possible when the customer brings the vehicle in.

>> GO TO 2

2. REPRODUCE THE MALFUNCTION INFORMATION

Check the malfunction on the vehicle that the customer describes.

Inspect the relation of the symptoms and the condition when the symptoms occur.

>> GO TO 3

3. IDENTIFY THE MALFUNCTIONING S YSTEM WITH “SYMPTOM DIAGNOSIS”

Use “Symptom diagnosis” from the symptom inspection re sult in step 2 and then identify where to start per-

forming the diagnosis based on possible causes and symptoms.

>> GO TO 4

4. IDENTIFY THE MALFUNCTIONING PA RTS WITH “COMPONENT DIAGNOSIS”

Perform the diagnosis with “Component diagnosis” of the applicable system.

>> GO TO 5

5. REPAIR OR REPLACE THE MALFUNCTIONING PARTS

Repair or replace the specified malfunctioning parts.

>> GO TO 6

6. FINAL CHECK

Check that malfunctions are not reproduced when obtaini ng the malfunction information from the customer,

referring to the symptom inspection result in step 2.

Are the malfunctions corrected?

YES >> Inspection End.

NO >> Refer to GI-38, "

Intermittent Incident".

Revision: April 20092010 QX56

Page 2995 of 4210

PWC-10

< FUNCTION DIAGNOSIS >

DIAGNOSIS SYSTEM (BCM)

DIAGNOSIS SYSTEM (BCM)

COMMON ITEM

COMMON ITEM : CONSULT-III Function (BCM - COMMON ITEM)INFOID:0000000005369205

APPLICATION ITEM

CONSULT-III performs the following functions via CAN communication with BCM.

SYSTEM APPLICATION

BCM can perform the following functions for each system.

NOTE:

It can perform the diagnosis modes except the following for all sub system selection items.

RETAINED PWR

Diagnosis mode Function Description

WORK SUPPORT Changes the setting for each system function.

SELF-DIAG RESULTS Displays the diagnosis results judged by BCM. Refer to BCS-54, "

DTCIndex".

CAN DIAG SUPPORT MNTR Monitors the reception status of CAN communication viewed from BCM.

DATA MONITOR The BCM input/output signals are displayed.

ACTIVE TEST The signals used to activate each device are forcibly supplied from BCM.

ECU IDENTIFICATION The BCM part number is displayed.

CONFIGURATION • Enables to read and save the vehicle specification.

• Enables to write the vehicle specification when replacing BCM.

System

Sub system selection item Diagnosis mode

WORK SUPPORT DATA MONITOR ACTIVE TEST

BCM BCM ×

Door lock DOOR LOCK ×××

Rear window defogger REAR DEFOGGER ×

Warning chime BUZZER ××

Interior room lamp timer INT LAMP ×××

Remote keyless entry system MULTI REMOTE ENT ××

Exterior lamp HEAD LAMP ×××

Wiper and washer WIPER ×××

Turn signal and hazard warning lamps FLASHER ××

Air conditioner AIR CONDITONER ×

Intelligent Key system INTELLIGENT KEY ×

Combination switch COMB SW ×

Immobilizer IMMU ××

Interior room lamp battery saver BATTERY SAVER ×××

Back door open TRUNK ××

RAP (retained accessory power) RETAINED PWR ×××

Signal buffer system SIGNAL BUFFER ××

TPMS (tire pressure monitoring sys-

tem) AIR PRESSURE MONITOR

×××

Vehicle security system THEFT ALM ×××

Panic alarm system PANIC ALARM ×

Revision: April 20092010 QX56

Page 3001 of 4210

PWC-16

< COMPONENT DIAGNOSIS >

POWER SUPPLY AND GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Check continuity between rear power window switch LH or RHconnector D203 (LH), D303 (RH) terminals 1, 7 and ground.

Is the inspection result normal?

YES >> GO TO 3

NO >> Repair or replace harness.

3. CHECK REAR POWER WINDOW SWITCH

Check rear power window switch.

Refer to PWC-16, "

REAR POWER WINDOW SWITCH : Component Inspection".

Is the inspection result normal?

YES >> Check intermittent incident. Refer to GI-38, "Intermittent Incident".

NO >> Replace rear power window switch. Refer to PWC-119, "

Removal and Installation".

REAR POWER WINDOW SWITCH : Component InspectionINFOID:0000000005147180

COMPONENT INSPECTION

1. CHECK REAR POWER WINDOW SWITCH

Check rear power window switch.

Is the inspection result normal?

YES >> Rear power window switch is OK.

NO >> Replace rear power window switch. Refer to PWC-119, "

Removal and Installation".

1 - Ground

: Continuity should exist.

7 - Ground : Continuity should exist.

LIIA2044E

Terminal Power window switch condition Continuity

25 UP

Ye s

14

14

NEUTRAL

15

24 DOWN

15

ALKIA0289ZZ

Revision: April 20092010 QX56