center console INFINITI QX56 2010 Factory Workshop Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2010, Model line: QX56, Model: INFINITI QX56 2010Pages: 4210, PDF Size: 81.91 MB

Page 2954 of 4210

PG-44

< COMPONENT DIAGNOSIS >

HARNESS

D2 M55 W/4 : Hazard switchD5 M207 B/3 : Console power socket

D4 M56 W/16 : To M201 C4 M208 BR/20 : To M69

A3 M57 — : Body ground C5 M209 W/2 : Center console area antenna (rear)

F2 M58 B/6 : Intake door motor C4 M210 GR/2 : Center console area antenna (front)

F3 M59 BR/2 : Glove box lamp C4 M212 W/6 : Rear heated seat switch LH

G3 M60 W/6 : Fuse block (J/B) C4 M213 BR/6 : Rear heated seat switch RH

C3 M61 — : Body ground Console switch sub-harness

F4 M62 B/2 : Front blower motor D4 M251 BR/20 : To M63

D4 M63 BR/20 : To M251 D4 M252 BR/6 : Front heated seat switch RH

D4 M64 BR/24 : To M202 C4 M253 GR/6 : VDC OFF switch

F2 M65 W/4 : To M301 C3 M255 W/6 : Front heated seat switch LH

G3 M66 B/1 : To E33 C4 M256 B/2 : A/T shift selector

C3 M69 BR/20 : To M208 D4 M258 GR/8 : Tow mode switch

A2 M70 W/40 : Intelligent key unit C4 M260 W/6 : Heated steering wheel switch

A2 M71 L/4 : Heated steering relay Optical sensor sub-harness

D3 M73 BR/6 : Back-up lamp relay F1 M301 W/4 : To M65

G3 M74 BR/20 : To D102 D1 M302 B/4 : Optical sensor

G3 M75 W/10 : To D101

A3 M76 W/6 : Electric brake (pre-wiring)

E2 M77 Y/4 : Front passenger air bag module

(service replacement)

Revision: April 20092010 QX56

Page 3112 of 4210

PWO

POWER SOCKETPWO-7

< ON-VEHICLE REPAIR >

C

DE

F

G H

I

J

K L

B A

O P

N

ON-VEHICLE REPAIR

POWER SOCKET

Removal and Installation INFOID:0000000005274244

REMOVAL

1. Access both front and back of power socket assembly. Refer to

IP-15, "Exploded View" (Cluster Lid C),

IP-20, "

Exploded View" (Front Center Console), or INT-19, "Removal and Installation" (Rear Luggage

Floor Trim).

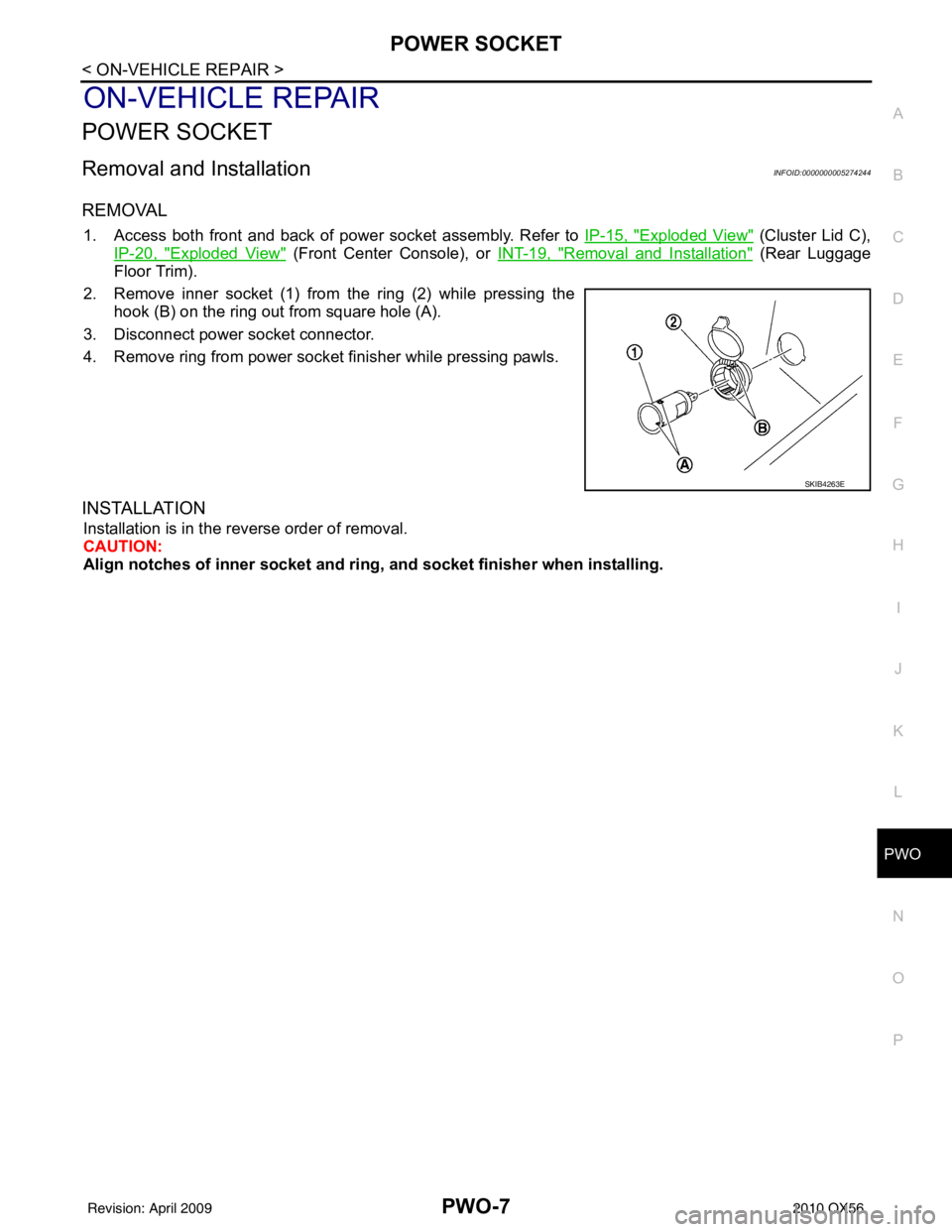

2. Remove inner socket (1) from the ring (2) while pressing the hook (B) on the ring out from square hole (A).

3. Disconnect power socket connector.

4. Remove ring from power socket finisher while pressing pawls.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

Align notches of inner socket and ring, and socket finisher when installing.

SKIB4263E

Revision: April 20092010 QX56

Page 3174 of 4210

RF-46

< SYMPTOM DIAGNOSIS >

SQUEAK AND RATTLE TROUBLE DIAGNOSES

Insulates where slight movement is present. Ideal for instrument panel applications.

SILICONE GREASE

Used in place of UHMW tape that will be visible or not fit. Will only last a few months.

SILICONE SPRAY

Use when grease cannot be applied.

DUCT TAPE

Use to eliminate movement.

CONFIRM THE REPAIR

Confirm that the cause of a noise is repaired by test driving the vehicle. Operate the vehicle under the same

conditions as when the noise originally occurred. Refer to the notes on the Diagnostic Worksheet.

Generic Squeak and Rattle TroubleshootingINFOID:0000000005286314

Refer to Table of Contents for specific component removal and installation information.

INSTRUMENT PANEL

Most incidents are caused by contact and movement between:

1. The cluster lid A and instrument panel

2. Acrylic lens and combination meter housing

3. Instrument panel to front pillar garnish

4. Instrument panel to windshield

5. Instrument panel pins

6. Wiring harnesses behind the combination meter

7. A/C defroster duct and duct joint

These incidents can usually be located by tapping or moving the components to duplicate the noise or by

pressing on the components while driving to stop the noise. Most of these incidents can be repaired by apply-

ing felt cloth tape or silicone spray (in hard to reach areas). Urethane pads can be used to insulate wiring har-

ness.

CAUTION:

Do not use silicone spray to isolate a squeak or rattle. If you saturate the ar ea with silicone, you will

not be able to recheck the repair.

CENTER CONSOLE

Components to pay attention to include:

1. Shifter assembly cover to finisher

2. A/C control unit and cluster lid C

3. Wiring harnesses behind audio and A/C control unit

The instrument panel repair and isolation pr ocedures also apply to the center console.

DOORS

Pay attention to the:

1. Finisher and inner panel making a slapping noise

2. Inside handle escutcheon to door finisher

3. Wiring harnesses tapping

4. Door striker out of alignment causing a popping noise on starts and stops

Tapping or moving the components or pressing on them wh ile driving to duplicate the conditions can isolate

many of these incidents. You can usually insulate the areas with felt cloth tape or insulator foam blocks from

the NISSAN Squeak and Rattle Kit (J-43980) to repair the noise.

TRUNK

Trunk noises are often caused by a loose jack or loose items put into the trunk by the owner.

In addition look for:

1. Trunk lid bumpers out of adjustment

2. Trunk lid striker out of adjustment

3. The trunk lid torsion bars knocking together

4. A loose license plate or bracket

Revision: April 20092010 QX56

Page 3313 of 4210

SQUEAK AND RATTLE TROUBLE DIAGNOSESSE-41

< SYMPTOM DIAGNOSIS >

C

DE

F

G H

I

K L

M A

B

SE

N

O P

SILICONE GREASE

Used instead of UHMW tape that will be visible or not fit.

Note: Will only last a few months.

SILICONE SPRAY

Use when grease cannot be applied.

DUCT TAPE

Use to eliminate movement.

CONFIRM THE REPAIR

Confirm that the cause of a noise is repaired by test driving the vehicle. Operate the vehicle under the same

conditions as when the noise originally occurred. Refer to the notes on the Diagnostic Worksheet.

Generic Squeak and Rattle TroubleshootingINFOID:0000000005147401

Refer to Table of Contents for specific component removal and installation information.

INSTRUMENT PANEL

Most incidents are caused by contact and movement between:

1. The cluster lid A and instrument panel

2. Acrylic lens and combination meter housing

3. Instrument panel to front pillar garnish

4. Instrument panel to windshield

5. Instrument panel mounting pins

6. Wiring harnesses behind the combination meter

7. A/C defroster duct and duct joint

These incidents can usually be located by tapping or moving the components to duplicate the noise or by

pressing on the components while driving to stop the noi se. Most of these incidents can be repaired by apply-

ing felt cloth tape or silicone spray (in hard to reach areas). Urethane pads can be used to insulate wiring har-

ness.

CAUTION:

Do not use silicone spray to isolate a squeak or ra ttle. If you saturate the area with silicone, you will

not be able to recheck the repair.

CENTER CONSOLE

Components to pay attention to include:

1. Shifter assembly cover to finisher

2. A/C control unit and cluster lid C

3. Wiring harnesses behind audio and A/C control unit

The instrument panel repair and isolation pr ocedures also apply to the center console.

DOORS

Pay attention to the:

1. Finisher and inner panel making a slapping noise

2. Inside handle escutcheon to door finisher

3. Wiring harnesses tapping

4. Door striker out of alignment causing a popping noise on starts and stops

Tapping or moving the components or pressing on them while driving to duplicate the conditions can isolate

many of these incidents. You can usually insulate the ar eas with felt cloth tape or insulator foam blocks from

the NISSAN Squeak and Rattle Kit (J-43980) to repair the noise.

TRUNK

Trunk noises are often caused by a loose jack or loose items put into the trunk by the owner.

In addition look for:

1. Trunk lid bumpers out of adjustment

2. Trunk lid striker out of adjustment

3. The trunk lid torsion bars knocking together

4. A loose license plate or bracket

Revision: April 20092010 QX56

Page 3361 of 4210

![INFINITI QX56 2010 Factory Workshop Manual SEC-10

< FUNCTION DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

INTELLIGENT KEY SYSTEM/ENGINE START FUNCTION

FUNCTION DIAGNOSIS

INTELLIGENT KEY SYSTEM

/ENGINE START FUNCTION

System DiagramINFOID:0000000005 INFINITI QX56 2010 Factory Workshop Manual SEC-10

< FUNCTION DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

INTELLIGENT KEY SYSTEM/ENGINE START FUNCTION

FUNCTION DIAGNOSIS

INTELLIGENT KEY SYSTEM

/ENGINE START FUNCTION

System DiagramINFOID:0000000005](/img/42/57032/w960_57032-3360.png)

SEC-10

< FUNCTION DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

INTELLIGENT KEY SYSTEM/ENGINE START FUNCTION

FUNCTION DIAGNOSIS

INTELLIGENT KEY SYSTEM

/ENGINE START FUNCTION

System DiagramINFOID:0000000005147067

System DescriptionINFOID:0000000005147068

INPUT/OUTPUT SIGNAL CHART

Intelligent Key Unit

IPDM E/R

BCM

SYSTEM DESCRIPTION

• The engine start function of Intelligent Key system is a system that makes it possible to start and stop the

engine without using the key. It verifies the electroni c ID using two-way communications when pressing the

ignition knob switch while carrying the Intelligent Key, which operates based on the results of electronic ID

verification for Intelligent Key using two-way communications between the Intelligent Key and the vehicle.

NOTE:

The driver should carry the Intelligent Key at all times.

Switch/Input signal Input signal to

Intelligent Key unit Intelligent Key unit

function Actuator/Output signal

Key switch Mechanical key

(insert/remove)

Engine start function• KEY warning lamp/buzzer

• Steering lock solenoid

• Starter relay request (to IPDM E/R)

• Inside key antenna

(Front and rear center console, over-

head console, luggage area)

• Key interlock solenoid

Ignition knob switch

Ignition knob

(push/release)

Steering lock solenoid Steering lock

(lock/unlock)

Inside key antenna

(Front and rear center console, over-

head console, luggage area) Intelligent key

(inside antenna detection

area or not.)

Switch/Input signal Input signal to

IPDM E/R IPDM E/R function

Actuator/Output signal

Transmission range switch P, N range Engine start function• Starter relay

• Starter motor

Switch/Input signal Input signal to

BCM BCM function

Actuator/Output signal

Key switch Brake

(press/release)

Engine start function• Inside key antenna

(Front and rear center console, over-

head console, luggage area)

ALKIA0925GB

Revision: April 20092010 QX56

Page 3363 of 4210

![INFINITI QX56 2010 Factory Workshop Manual SEC-12

< FUNCTION DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

INTELLIGENT KEY SYSTEM/ENGINE START FUNCTION

Component Parts Location

INFOID:0000000005147069

ALKIA0958ZZ

1. BCM M18, M20 (view with instrume INFINITI QX56 2010 Factory Workshop Manual SEC-12

< FUNCTION DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

INTELLIGENT KEY SYSTEM/ENGINE START FUNCTION

Component Parts Location

INFOID:0000000005147069

ALKIA0958ZZ

1. BCM M18, M20 (view with instrume](/img/42/57032/w960_57032-3362.png)

SEC-12

< FUNCTION DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

INTELLIGENT KEY SYSTEM/ENGINE START FUNCTION

Component Parts Location

INFOID:0000000005147069

ALKIA0958ZZ

1. BCM M18, M20 (view with instrument panel LH removed) 2. Intelligent Key unit M70

(view with instrument panel LH removed) 3. IPDM E/R

E119, E120, E122, E124

4. ECM E16 5. Key switch and ignition knob switch M12

(view with steering column removed) 6. Steering lock solenoid M15

7. Remote keyless entry receiver M25 (view with instrume nt panel RH removed) 8. A/T shift selector (park position switch)

M203

(view with center console removed) 9. Center console area antenna

(front) M210

(view with center console removed)

Revision: April 20092010 QX56

Page 3364 of 4210

![INFINITI QX56 2010 Factory Workshop Manual INTELLIGENT KEY SYSTEM/ENGINE START FUNCTIONSEC-13

< FUNCTION DIAGNOSIS > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

SEC

N

O P

Component DescriptionINFOID:0000000005147070

10. Center consol INFINITI QX56 2010 Factory Workshop Manual INTELLIGENT KEY SYSTEM/ENGINE START FUNCTIONSEC-13

< FUNCTION DIAGNOSIS > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

SEC

N

O P

Component DescriptionINFOID:0000000005147070

10. Center consol](/img/42/57032/w960_57032-3363.png)

INTELLIGENT KEY SYSTEM/ENGINE START FUNCTIONSEC-13

< FUNCTION DIAGNOSIS > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

SEC

N

O P

Component DescriptionINFOID:0000000005147070

10. Center console area antenna (rear) M209 11. Overhead console area antenna R210

(view with overhead console removed) 12. Luggage area antenna B76

(view with rear carpet removed)

13. Intelligent Key warning buzzer E25 14. Combination meter M23, M24 15. Vehicle security indicator lamp

Item Function

Intelligent Key unit Receives lock/unlock signal from re mote keyless entry receiver, and then transmits to BCM.

BCM Verifies the received signal from Intelligent Key, then informs ECM whether to allow engine start.

Remote keyless entry receiver Receives lock/unlock signal from the Intelligent Key, and then transmits to Intelligent Key unit.

Intelligent Key Transmits button operation to remote keyless entry receiver.

Steering lock solenoid Locks the steering wheel when the ignition key is off and the Intelligent Key is outside the vehicle.

Inside key antenna Detects if Intelligent Key is inside the vehicle.

Intelligent Key warning buzzer Warns the user of the lock/unlock condition and inappropriate operations with the buzzer sound.

A/T shift selector (park position

switch) Detects whether the shift lever is in park.

Revision: April 20092010 QX56

Page 3376 of 4210

![INFINITI QX56 2010 Factory Workshop Manual DIAGNOSIS SYSTEM (INTELLIGENT KEY UNIT)SEC-25

< FUNCTION DIAGNOSIS > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

SEC

N

O P

ACTIVE TEST

TRUNK SW This item is shown but not monitored.

VEHICLE INFINITI QX56 2010 Factory Workshop Manual DIAGNOSIS SYSTEM (INTELLIGENT KEY UNIT)SEC-25

< FUNCTION DIAGNOSIS > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

SEC

N

O P

ACTIVE TEST

TRUNK SW This item is shown but not monitored.

VEHICLE](/img/42/57032/w960_57032-3375.png)

DIAGNOSIS SYSTEM (INTELLIGENT KEY UNIT)SEC-25

< FUNCTION DIAGNOSIS > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

SEC

N

O P

ACTIVE TEST

TRUNK SW This item is shown but not monitored.

VEHICLE SPEED Displays the vehicle speed signal received from combination meter by numerical value

[km/h].

Monitor Item

Condition

Test itemDescription

DOOR LOCK/UNLOCK This test is able to check door lock/unlock operation.

• ALL UNLK: All door lock actuators are unlocked.

• DR UNLK: Door lock actuator

(driver side) is unlocked.

• AS UNLK: Door lock actuator (passenger side) is unlocked.

• BK UNLK: This item is indicated, but inactive.

• LOCK: All door lock actuator is locked.

ANTENNA This test is able to check Intelligent Key antenna operation.

When the following condition are met, hazard warning lamps flash.

• ROOM ANT1: Inside key antenna (front of center console) detects Intelligent Key,

when “ROOM ANT1” is selected.

• ROOM ANT2: Inside key antenna (rear luggage area) detects Intelligent Key, when “ROOM ANT2”is selected.

• ROOM ANT3: Inside key antenna (rear of center console) detects Intelligent Key,

when “ROOM ANT3” is selected.

• ROOM ANT4: Inside key antenna (roof console) detects Intelligent Key, when “ROOM ANT4”is selected.

• DRIVER ANT: Outside key antenna (driver side) detects Intelligent Key, when “DRIV- ER ANT” is selected.

• ASSIST ANT: Outside key antenna (passenger side) detects Intelligent Key, when

“ASSIST ANT” is selected.

• BK DOOR ANT: Outside key antenna (rear bumper) detects Intelligent Key, when “BK DOOR ANT” is selected.

OUTSIDE BUZZER This test is able to check Intelligent Key warning buzzer operation.

•ON

•OFF

INSIDE BUZZER This test is able to check warning chime in combination meter operation.

• TAKE OUT: Take away

warning chime sounds.

• KNOB: Ignition knob switch warning chime sounds.

• KEY: Key warning chime sounds.

•OFF

Revision: April 20092010 QX56

Page 3466 of 4210

![INFINITI QX56 2010 Factory Workshop Manual INTELLIGENT KEY SYSTEM/ENGINE START FUNCTION SYMPTOMS

SEC-115

< SYMPTOM DIAGNOSIS > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

SEC

N

O P

SYMPTOM DIAGNOSIS

INTELLIGENT KEY SYSTEM/ENGIN E STA INFINITI QX56 2010 Factory Workshop Manual INTELLIGENT KEY SYSTEM/ENGINE START FUNCTION SYMPTOMS

SEC-115

< SYMPTOM DIAGNOSIS > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

SEC

N

O P

SYMPTOM DIAGNOSIS

INTELLIGENT KEY SYSTEM/ENGIN E STA](/img/42/57032/w960_57032-3465.png)

INTELLIGENT KEY SYSTEM/ENGINE START FUNCTION SYMPTOMS

SEC-115

< SYMPTOM DIAGNOSIS > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

SEC

N

O P

SYMPTOM DIAGNOSIS

INTELLIGENT KEY SYSTEM/ENGIN E START FUNCTION SYMPTOMS

Symptom TableINFOID:0000000005147148

NOTE:

• Before performing the diagnosis in the following table, check “ SEC-4, "

Work Flow"”.

• Check that vehicle is under the condition shown in “Conditions of vehicle” before starting diagnosis, and check each symptom.

• Engine cranking is enabled when the shift lever is in the "Park" position, and in the "Neutral" position only if the brake pedal is depressed.

• If the following symptoms are detec ted, check systems shown in the “Diagnosis/service procedure” column

in this order.

CONDITIONS OF VEHICLE (OPERATING CONDITIONS)

• Engine start function is ON when setting on CONSULT-III.

• Mechanical key is not inserted in key cylinder.

• One or more of Intelligent Keys with registered Intelligent Key ID is in the vehicle.

Symptom Diagnosis/service procedureReference

page

Ignition switch does not turn on with Intelligent Key.

[LCD displays "KEY DETECTED"] 1. Check steering lock solenoid.

DLK-99

2. Replace Intelligent Key unit.SEC-120

Ignition switch does not turn on with Intelligent Key.

[LCD does not display "PUSH" with arrow toward key

cylinder] 1. Check Intelligent Key unit power supply and ground circuit.

DLK-682. Check ignition knob switch.DLK-116

3. Check key switch (BCM input).DLK-115

4. Check key switch (Intelligent Key unit input).DLK-113

5. Replace Intelligent Key unit.SEC-120

Ignition switch does not turn on with Intelligent Key.

[LCD displays " NO KEY"] 1a. Check center console area antenna (rear).

DLK-60

1b. Check luggage area antenna.DLK-62

1c. Check center console area antenna (front).DLK-64

1d. Check overhead console area antenna.DLK-68

2. Replace Intelligent Key unit.SEC-120

Ignition switch does not turn on with mechanical key1. Check key switch (BCM input).

DLK-1152. Check key switch (Intelligent Key unit input).DLK-113

Engine cannot be cranked with transmission in "Park"

or in "Neutral" position with brake pedal depressed.1. Check transmission signal.

TM-45

2. Check stop lamp switch.EXL-91

Revision: April 20092010 QX56

Page 3540 of 4210

DIAGNOSIS SENSOR UNITSR-17

< ON-VEHICLE REPAIR >

C

DE

F

G

I

J

K L

M A

B

SR

N

O P

DIAGNOSIS SENSOR UNIT

Removal and InstallationINFOID:0000000005147764

REMOVAL

WARNING:

• Before servicing the SRS, turn the ignition switch off, disconnect both battery terminals and wait at

least three minutes.

• Do not use old bolts; replace with new bolts.

• Check diagnosis sensor unit bracket to make sure it is free of deformities, dents, cracks or rust. If it

shows any visible signs of damage, replace with new one.

• Replace diagnosis sensor unit if it has been dropped or sustained an impact.

• Never use air tools or el ectric tools for servicing.

• When replacing the air bag diagnosis sensor unit, always check with the parts department for the lat-

est parts information. Installing an incorrect air bag diagnosis sensor unit may or may not cause the

air bag warning lamp to illuminate and may cause incorrect deployment of the supplemental air bags

and seat belt pre-tensioner in a collision r esulting in serious personal injury or death.

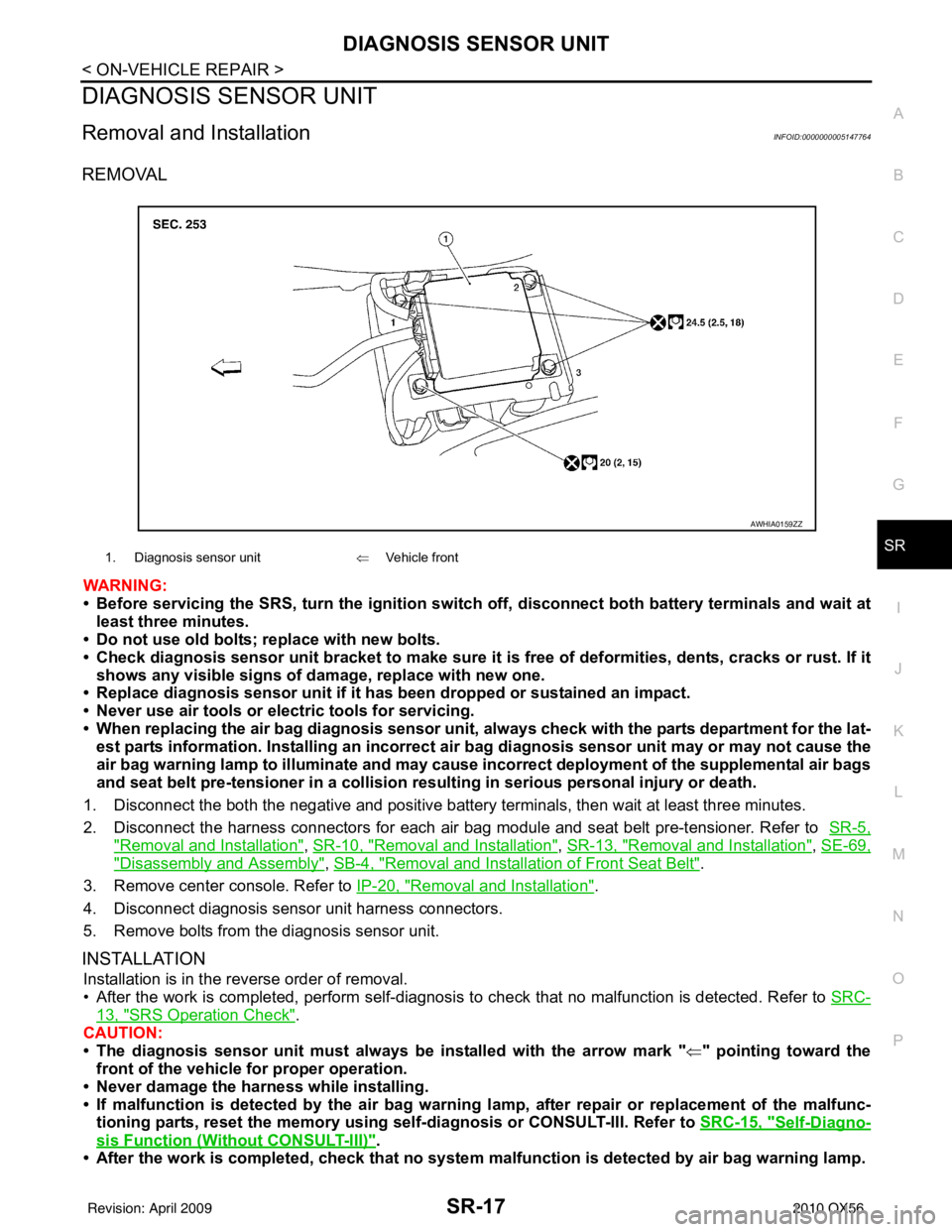

1. Disconnect the both the negative and positive battery terminals, then wait at least three minutes.

2. Disconnect the harness connectors for each air bag module and seat belt pre-tensioner. Refer to SR-5,

"Removal and Installation", SR-10, "Removal and Installation", SR-13, "Removal and Installation", SE-69,

"Disassembly and Assembly", SB-4, "Removal and Installation of Front Seat Belt".

3. Remove center console. Refer to IP-20, "

Removal and Installation".

4. Disconnect diagnosis sensor unit harness connectors.

5. Remove bolts from the diagnosis sensor unit.

INSTALLATION

Installation is in the reverse order of removal.

• After the work is completed, perform self-diagnosis to check that no malfunction is detected. Refer to SRC-

13, "SRS Operation Check".

CAUTION:

• The diagnosis sensor unit must always be installed with the arrow mark " ⇐" pointing toward the

front of the vehicle for proper operation.

• Never damage the harness while installing.

• If malfunction is detected by the air bag warnin g lamp, after repair or replacement of the malfunc-

tioning parts, reset the memory using sel f-diagnosis or CONSULT-III. Refer to SRC-15, "

Self-Diagno-

sis Function (Without CONSULT-III)".

• After the work is completed, check that no system malfunction is detected by air bag warning lamp.

1. Diagnosis sensor unit⇐Vehicle front

AWHIA0159ZZ

Revision: April 20092010 QX56