sensor INFINITI QX56 2010 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2010, Model line: QX56, Model: INFINITI QX56 2010Pages: 4210, PDF Size: 81.91 MB

Page 3267 of 4210

![INFINITI QX56 2010 Factory Service Manual SUSPENSION CONTROL UNITSCS-35

< ECU DIAGNOSIS >

C

DF

G H

I

J

K L

M A

B

SCS

N

O P

Compressor relay [C1802] • Driving transistor for compressor relay is OFF and monitor

voltage continues at a high le INFINITI QX56 2010 Factory Service Manual SUSPENSION CONTROL UNITSCS-35

< ECU DIAGNOSIS >

C

DF

G H

I

J

K L

M A

B

SCS

N

O P

Compressor relay [C1802] • Driving transistor for compressor relay is OFF and monitor

voltage continues at a high le](/img/42/57032/w960_57032-3266.png)

SUSPENSION CONTROL UNITSCS-35

< ECU DIAGNOSIS >

C

DF

G H

I

J

K L

M A

B

SCS

N

O P

Compressor relay [C1802] • Driving transistor for compressor relay is OFF and monitor

voltage continues at a high level for more than 10 seconds.

• Driving transistor for compressor relay is ON and monitor voltage continues at a low level for more than 5 seconds. SCS-10, "DiagnosisProcedure".

Exhaust solenoid [C1803] • Driving transistor for exhaust valve solenoid is OFF and

monitor voltage continues at a high level for more than 10

seconds.

• Driving transistor for exhaust valve solenoid is ON and mon- itor voltage continues at a low level for more than 5 seconds. SCS-11,

"DiagnosisProcedure".

Vehicle height adjusting malfunc-

tion (compressor)[C1804] Continuous compressor relay ON time is more than 120 sec-

onds. SCS-12,

"DiagnosisProcedure".

Vehicle height adjusting malfunc-

tion (exhaust solenoid)[C1805] Continuous exhaust valve solenoid ON time is more than 120

seconds. SCS-13,

"DiagnosisProcedure".

Vehicle height sensor locking mal-

function [C1806] Output sensor voltage variation

±0.02V is more than 100 sec-

onds when vehicle height range is normal. SCS-14, "

Diagnosis Proce-

dure".

Sensor 5V malfunction [C1807] Sensor reference voltage is less than 0.8V or more than 6V for

20 seconds. SCS-15,

"DiagnosisProcedure"

Integral time malfunction by sup-

plying air [C1808]A suspension air compressor ON request has been in effect

for 180 seconds and the suspension air compressor has not

activated during that time. SCS-16,

"DiagnosisProcedure".

Revision: April 20092010 QX56

Page 3268 of 4210

SCS-36

< SYMPTOM DIAGNOSIS >

SUSPENSION CONTROL SYSTEM

SYMPTOM DIAGNOSIS

SUSPENSION CONTROL SYSTEM

Symptom TableINFOID:0000000005148193

AIR LEVELIZER

SymptomPossible causeReference page

Inoperative • Suspension control unit

• Compressor motor relay

• Suspension air compressorSCS-37, "

Diagnosis Proce-

dure"

System does not raise • Suspension control unit

• Height sensor

• Compressor motor relay

• Suspension air compressor

• Leak in system

• Restriction in systemSCS-38, "Diagnosis Proce-

dure"

System does not lower

• Suspension control unit

• Height sensor

• Compressor motor relay

• Suspension air compressor

• Restriction in systemSCS-39, "Diagnosis Proce-

dure"

CK SUSP indicator lamp always ON with key ON

• CK SUSP indicator la

mp control circuit

• Suspension control unit SCS-26, "Description"

Revision: April 20092010 QX56

Page 3269 of 4210

SUSPENSION CONTROL SYSTEM INOPERATIVESCS-37

< SYMPTOM DIAGNOSIS >

C

DF

G H

I

J

K L

M A

B

SCS

N

O P

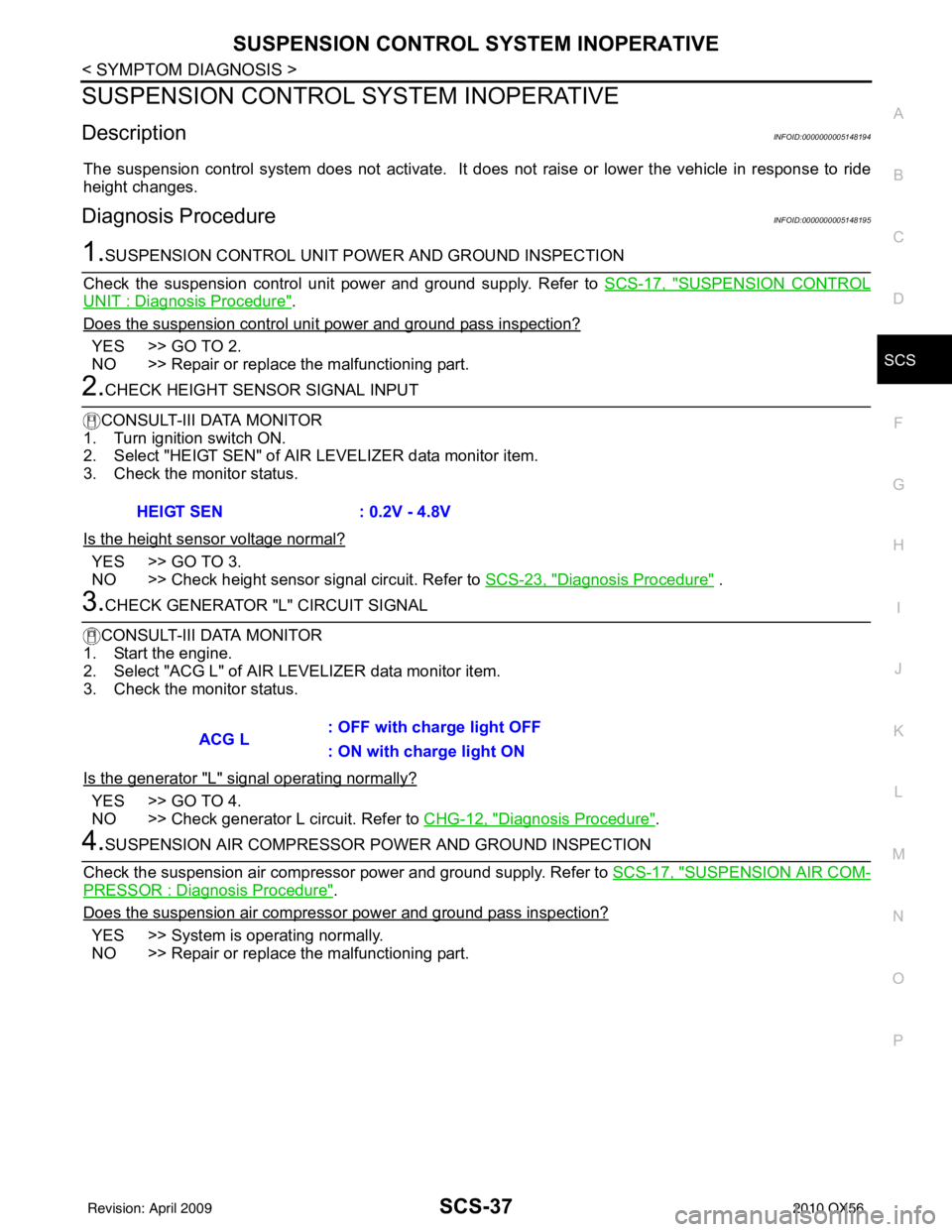

SUSPENSION CONTROL SYSTEM INOPERATIVE

DescriptionINFOID:0000000005148194

The suspension control system does not activate. It does not raise or lower the vehicle in response to ride

height changes.

Diagnosis ProcedureINFOID:0000000005148195

1.SUSPENSION CONTROL UNIT PO WER AND GROUND INSPECTION

Check the suspension control unit power and ground supply. Refer to SCS-17, "

SUSPENSION CONTROL

UNIT : Diagnosis Procedure".

Does the suspension control uni t power and ground pass inspection?

YES >> GO TO 2.

NO >> Repair or replace the malfunctioning part.

2.CHECK HEIGHT SENSOR SIGNAL INPUT

CONSULT-III DATA MONITOR

1. Turn ignition switch ON.

2. Select "HEIGT SEN" of AI R LEVELIZER data monitor item.

3. Check the monitor status.

Is the height sensor voltage normal?

YES >> GO TO 3.

NO >> Check height sensor signal circuit. Refer to SCS-23, "

Diagnosis Procedure" .

3.CHECK GENERATOR "L" CIRCUIT SIGNAL

CONSULT-III DATA MONITOR

1. Start the engine.

2. Select "ACG L" of AIR LEVELIZER data monitor item.

3. Check the monitor status.

Is the generator "L" signal operating normally?

YES >> GO TO 4.

NO >> Check generator L circuit. Refer to CHG-12, "

Diagnosis Procedure".

4.SUSPENSION AIR COMPRESSOR POWER AND GROUND INSPECTION

Check the suspension air compressor power and ground supply. Refer to SCS-17, "

SUSPENSION AIR COM-

PRESSOR : Diagnosis Procedure".

Does the suspension air compress or power and ground pass inspection?

YES >> System is operating normally.

NO >> Repair or replace the malfunctioning part.HEIGT SEN : 0.2V - 4.8V

ACG L

: OFF with charge light OFF

: ON with charge light ON

Revision: April 20092010 QX56

Page 3270 of 4210

SCS-38

< SYMPTOM DIAGNOSIS >

SUSPENSION CONTROL SYSTEM DOES NOT RAISE

SUSPENSION CONTROL SYSTEM DOES NOT RAISE

DescriptionINFOID:0000000005148196

The suspension control system does not raise t he vehicle in accordance with ride height changes.

Diagnosis ProcedureINFOID:0000000005148197

1.SUSPENSION CONTROL UNIT POWER AND GROUND INSPECTION

Check the suspension control unit power and ground supply. Refer to SCS-17, "

SUSPENSION CONTROL

UNIT : Diagnosis Procedure".

Does the suspension control unit power and ground pass inspection?

YES >> GO TO 2.

NO >> Repair or replace the malfunctioning part.

2.CHECK HEIGHT SENSOR SIGNAL INPUT

CONSULT-III DATA MONITOR

1. Turn ignition ON.

2. Select "HEIGT SEN" of AI R LEVELIZER data monitor item.

3. Check the monitor status.

Is the height sensor voltage normal?

YES >> GO TO 3.

NO >> Check height sensor signal circuit. Refer to SCS-23, "

Diagnosis Procedure" .

3.SUSPENSION AIR COMPRESSOR POWER AND GROUND INSPECTION

Check the suspension air compressor power and ground supply. Refer to SCS-17, "

SUSPENSION AIR COM-

PRESSOR : Diagnosis Procedure".

Does the suspension air compressor power and ground pass inspection?

YES >> Inspect for a weak compressor, leak or restri ction in the system. Repair or replace malfunctioning

part.

NO >> Repair or replace the malfunctioning part. HEIGT SEN

: 0.2V - 4.8V

Revision: April 20092010 QX56

Page 3271 of 4210

SUSPENSION CONTROL SYSTEM DOES NOT LOWER

SCS-39

< SYMPTOM DIAGNOSIS >

C

D F

G H

I

J

K L

M A

B

SCS

N

O P

SUSPENSION CONTROL SYST EM DOES NOT LOWER

DescriptionINFOID:0000000005148198

The suspension control system does not lower the vehicle in accordance with ride height changes.

Diagnosis ProcedureINFOID:0000000005148199

1.SUSPENSION CONTROL UNIT POWER AND GROUND INSPECTION

Check the suspension control unit power and ground supply. Refer to SCS-17, "

SUSPENSION CONTROL

UNIT : Diagnosis Procedure".

Does the suspension control uni t power and ground pass inspection?

YES >> GO TO 2.

NO >> Repair or replace the malfunctioning part.

2.CHECK HEIGHT SENSOR SIGNAL INPUT

CONSULT-III DATA MONITOR

1. Turn ignition ON.

2. Select "HEIGT SEN" of AI R LEVELIZER data monitor item.

3. Check the monitor status.

Is the height sensor voltage normal?

YES >> GO TO 3.

NO >> Check height sensor signal circuit. Refer to SCS-23, "

Diagnosis Procedure" .

3.EXHAUST VALVE SOLENOID CIRCUIT INSPECTION

Check the exhaust valve solenoid circuit. Refer to SCS-24, "

Component Function Check".

Does the exhaust valve solenoi d circuit pass inspection?

YES >> Inspect for a restriction in the system. repair or replace the malfunctioning part.

NO >> Repair or replace the malfunctioning part.HEIGT SEN : 0.2V - 4.8V

Revision: April 20092010 QX56

Page 3272 of 4210

SCS-40

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005383225

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SR and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution for Rear SuspensionINFOID:0000000005148201

• When installing the rubber bushings, the final ti ghtening must be done under unladen condition and with the

tires on level ground. Oil will shorten the life of the r ubber bushings, so wipe off any spilled oil immediately.

• Unladen condition means the fuel tank, engine coolant and lubricants are at the full specification. The spare tire, jack, hand tools, and mats are in their designated positions.

• After installing suspension components, check the wheel alignment.

• Caulking nuts are not reusable. Always use new caulking nuts for installation. New caulking nuts are pre-

oiled, do not apply any additional lubrication.

Revision: April 20092010 QX56

Page 3317 of 4210

PRECAUTIONSSE-45

< PRECAUTION >

C

DE

F

G H

I

K L

M A

B

SE

N

O P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005256398

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SR and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Un it or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or el ectric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers, always switch the Ignition OFF, disconnect the battery, and wait at least 3 minutes before performing any service.

Precaution Necessary for Steering Wheel Rotation After Battery Disconnect

INFOID:0000000005402593

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecti ng both battery cables with the ignition knob in the

″ LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS , an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery power is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be

rotated.

4. Perform the necessary repair operation.

Revision: April 20092010 QX56

Page 3323 of 4210

FRONT SEATSE-51

< ON-VEHICLE REPAIR >

C

DE

F

G H

I

K L

M A

B

SE

N

O P

Removal and InstallationINFOID:0000000005147410

REMOVAL

CAUTION:

• When removing or installing the seat trim, handle it carefully to keep dirt out and avoid damage.

• Before removing the front seat, turn the ignition switch off, disconnect both battery cables and wait

at least 3 minutes.

• When checking the power seat circuit for continuity using a circuit tester, do not confuse its connec-

tor with the side air bag module connector. Su ch an error may cause the air bag to deploy.

• Do not drop, tilt, or bump the side air bag modul e while installing the seat. Always handle it with

care.

• After front side air bag module inflat es, front seatback assembly must be replaced.

• Front passenger seat is equipped with an Occupant Classification System sensor and control mod-

ule. Do not disassemble front passenger seat cushion assembly or remove the trim as this will affect

the Occupant Classificatio n System calibration.

• Always replace passenger seat cushion as an assembly.

1. Slide the seat until the four body mounting bolts are visible and a tool can be inserted.

NOTE:

• If disassembling the seat after removal, set the front/rear cushion lifters to the top position.

2. Disconnect both battery cables and wait at least 3 minutes.

3. Remove the outer pedestal finisher.

4. Disconnect the side air bag module harness connector.

5. Remove the four body mounting bolts.

6. Disconnect the power seat harness connectors and remove the seat from the vehicle.

CAUTION:

When removing and installing the seat, use shop cloths to protect the vehicle from damage.

INSTALLATION

Installation is in the reverse order of removal.

19. Outer pedestal finisher20. Seat cushion outer finisher21. Seat cushion assembly

22. Power seat switch escutcheon 23. Slide switch knob 24. Recliner switch knob

25. Seatback assembly 26. Headrest holder27. Seat slide/ recline switch

28. Power lumbar switch

Revision: April 20092010 QX56

Page 3341 of 4210

FRONT SEATSE-69

< DISASSEMBLY AND ASSEMBLY >

C

DE

F

G H

I

K L

M A

B

SE

N

O P

Disassembly and AssemblyINFOID:0000000005256345

SEATBACK TRIM AND PAD

Disassembly

CAUTION:

• Only complete seatback assemblies can be replaced on vehicles equipped with side air bags.

• When removing or installing the seat trim, handle it carefully to keep dirt out and avoid damage.

1. Remove the seatback assembly. Refer to SE-51, "

Removal and Installation".

2. Remove the headrest.

3. From inside of the seatback, squeeze the headrest holder tabs

at the base of the stay pipe and pull the up to remove.

NOTE:

Before installing the headrest holder, check its orientation (front/

rear and right/left).

4. Remove the snap ring and the lumbar support lever knob (if equipped).

5. Remove the seatback trim and pad assembly.

6. Remove the hog rings to separate the seatback trim from the pad.

Assembly

Assembly is in the reverse order of disassembly.

SEAT CUSHION TRIM AND PAD

Disassembly

CAUTION:

• Front passenger seat is equipped with an Occupant Classification System sensor and control mod-

ule. Do not disassemble front passenger seat cushion assembly or remove the trim as this will affect

the Occupant Classificatio n System calibration.

• Always replace passenger seat cushion as an assembly.

• When removed, the passenger seat cushion must al ways be placed pan side UP to prevent damage.

• During installation, the wire harness clips must be reinstalled in the holes they were originally in. Do

not add additional clips.

• The Occupant Classification System control module can only be replaced as part of the seat cushion

assembly.

19. Outer pedestal finisher 20. Seat cushion outer finisher21. Seat cushion assembly

22. Power seat switch escutcheon 23. Slide switch knob 24. Recliner switch knob

25. Seatback assembly 26. Headrest holder27. Seat slide/ recline switch

28. Power lumbar switch

LRS023

PIIA1156E

Revision: April 20092010 QX56

Page 3412 of 4210

![INFINITI QX56 2010 Factory Service Manual BCM (BODY CONTROL MODULE)SEC-61

< ECU DIAGNOSIS > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

SEC

N

O P

LIGHT SW 1ST Lighting switch OFF OFF

Lighting switch 1st

ON

HEAD LAMP SW1 Headlamp swi INFINITI QX56 2010 Factory Service Manual BCM (BODY CONTROL MODULE)SEC-61

< ECU DIAGNOSIS > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

SEC

N

O P

LIGHT SW 1ST Lighting switch OFF OFF

Lighting switch 1st

ON

HEAD LAMP SW1 Headlamp swi](/img/42/57032/w960_57032-3411.png)

BCM (BODY CONTROL MODULE)SEC-61

< ECU DIAGNOSIS > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

SEC

N

O P

LIGHT SW 1ST Lighting switch OFF OFF

Lighting switch 1st

ON

HEAD LAMP SW1 Headlamp switch OFF

OFF

Headlamp switch 1st ON

HEAD LAMP SW2 Headlamp switch OFF

OFF

Headlamp switch 1st ON

HI BEAM SW High beam switch OFF

OFF

High beam switch HI ON

IGN ON SW Ignition switch OFF or ACC

OFF

Ignition switch ON ON

IGN SW CAN Ignition switch OFF or ACC

OFF

Ignition switch ON ON

INT VOLUME Wiper intermittent dial is in a dial position 1 - 7 1 - 7

I-KEY LOCK LOCK button of Intelligent Key is not pressed

OFF

LOCK button of Intelligent Key is pressed ON

I-KEY UNLOCK UNLOCK button of Intelligent Key is not pressed

OFF

UNLOCK button of Intelligent Key is pressed ON

KEY CYL LK-SW Door key cylinder LOCK position

ON

Door key cylinder other than LOCK position OF

KEY CYL UN-SW Door key cylinder UNLOCK position

ON

Door key cylinder other than UNLOCK position ON

KEY ON SW Mechanical key is removed from key cylinder

OFF

Mechanical key is inserted to key cylinder ON

OIL PRESS SW • Ignition switch OFF or ACC

• Engine running

OFF

Ignition switch ON ON

OPTICAL SENSOR Bright outside of the vehicle

Close to 5V

Dark outside of the vehicle Close to 0V

PASSING SW Other than lighting switch PASS

OFF

Lighting switch PASS ON

PUSH SW Return to ignition switch to LOCK position

OFF

Press ignition switch ON

REAR DEF SW Rear window defogger switch OFF

OFF

Rear window defogger switch ON ON

RR WASHER SW Rear washer switch OFF

OFF

Rear washer switch ON ON

RR WIPER INT Rear wiper switch OFF

OFF

Rear wiper switch INT ON

RR WIPER ON Rear wiper switch OFF

OFF

Rear wiper switch ON ON

RR WIPER STOP Rear wiper stop position

OFF

Other than rear wiper stop position ON

RR WIPER STP2 Rear wiper stop position

OFF

Other than rear wiper stop position ON

Monitor Item

Condition Value/Status

Revision: April 20092010 QX56