flat tire INFINITI QX56 2010 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2010, Model line: QX56, Model: INFINITI QX56 2010Pages: 4210, PDF Size: 81.91 MB

Page 414 of 4210

![INFINITI QX56 2010 Factory Service Manual BCS-28

< FUNCTION DIAGNOSIS >[BCM]

DIAGNOSIS SYSTEM (BCM)

SIGNAL BUFFER : CONSULT-III Fu nction (BCM - SIGNAL BUFFER)

INFOID:0000000005146411

DATA MONITOR

ACTIVE TEST

AIR PRESSURE MONITOR

AIR PRESSURE INFINITI QX56 2010 Factory Service Manual BCS-28

< FUNCTION DIAGNOSIS >[BCM]

DIAGNOSIS SYSTEM (BCM)

SIGNAL BUFFER : CONSULT-III Fu nction (BCM - SIGNAL BUFFER)

INFOID:0000000005146411

DATA MONITOR

ACTIVE TEST

AIR PRESSURE MONITOR

AIR PRESSURE](/img/42/57032/w960_57032-413.png)

BCS-28

< FUNCTION DIAGNOSIS >[BCM]

DIAGNOSIS SYSTEM (BCM)

SIGNAL BUFFER : CONSULT-III Fu nction (BCM - SIGNAL BUFFER)

INFOID:0000000005146411

DATA MONITOR

ACTIVE TEST

AIR PRESSURE MONITOR

AIR PRESSURE MONITOR : Diagnosis DescriptionINFOID:0000000005146412

DESCRIPTION

During driving, the TPMS receives the signal transmitt ed from the transmitter installed in each wheel, when

the tire pressure becomes low. The control unit (BCM ) of this system has pressure judgment and trouble diag-

nosis functions.

When the TPMS detects low inflation pressure or another unusual symptom, the warning lamps in the combi-

nation meter comes on.

SELF DIAGNOSIS (WITH CONSULT-III)

With CONSULT-III

• Touch “SELF-DIAG RESULTS” display to show malfunction experienced since the last erasing operation. Refer to WT-11, "

CONSULT-III Function (BCM)".

SELF DIAGNOSIS (WITHOUT CONSULT-III)

Without CONSULT-III

To start the self-diagnostic results mode, ground terminal of the tire pressure warning check connector. The

malfunction location is indicated by the warning lamp flashing.

NOTE:

When the low tire warning lamp flashes 5 Hz and continues repeating it, the system is normal.

Monitor Item

[Unit] Description

OIL PRESS SW [ON/OFF] Displays the status of oil pressure switch received from IPDM E/R via CAN communication.

Test ItemOperation Description

OIL PRESSURE SW OFF OFF

ON

BCM transmits the oil pressure switch signal to the combination meter via CAN communica-

tion, which operates the oil pressure gauge in the combination meter.

SEIA0745E

Flickering

pattern Items

Diagnostic items detected when··· Check item

15 Tire pressure value (Front LH) Front LH tire pressure drops to 181 kPa (1.8 kg/cm, 25.25 psi) or less.

–

16 Tire pressure value (Front RH) Front RH tire pressure drops to 181 kPa (1.8 kg/cm, 25.25 psi) or less.

17 Tire pressure value (Rear RH) Rear RH tire pressure drops to 181 kPa (1.8 kg/cm, 25.25 psi) or less.

18 Tire pressure value (Rear LH) Rear LH tire pressure drops to 181 kPa (1.8 kg/cm, 25.25 psi) or less.

Revision: April 20092010 QX56

Page 416 of 4210

![INFINITI QX56 2010 Factory Service Manual BCS-30

< FUNCTION DIAGNOSIS >[BCM]

DIAGNOSIS SYSTEM (BCM)

AIR PRESSURE MONITOR : CONSULT-III Function

INFOID:0000000005146413

WORK SUPPORT

ID Read

The registered ID number is displayed.

ID Regist

Refe INFINITI QX56 2010 Factory Service Manual BCS-30

< FUNCTION DIAGNOSIS >[BCM]

DIAGNOSIS SYSTEM (BCM)

AIR PRESSURE MONITOR : CONSULT-III Function

INFOID:0000000005146413

WORK SUPPORT

ID Read

The registered ID number is displayed.

ID Regist

Refe](/img/42/57032/w960_57032-415.png)

BCS-30

< FUNCTION DIAGNOSIS >[BCM]

DIAGNOSIS SYSTEM (BCM)

AIR PRESSURE MONITOR : CONSULT-III Function

INFOID:0000000005146413

WORK SUPPORT

ID Read

The registered ID number is displayed.

ID Regist

Refer to WT-6, "ID Registration Procedure".

SELF-DIAG RESULTS

Operation Procedure

Refer to WT-11, "CONSULT-III Function (BCM)".

DATA MONITOR

Screen of data monitor mode is displayed. Refer to WT-11, "CONSULT-III Function (BCM)".

NOTE:

When malfunction is detected, CONSUL T-III perform REAL-TIME DIAGNOSIS.

Also, any malfunction detected while in this mode will be displayed at real time.

ACTIVE TEST

NOTE:

Before performing the self-diagnosis, be sure to register the ID, or else the actual malfunction may be different

from that displayed on CONSULT-III.

TEST ITEM LIST

THEFT ALM

THEFT ALM : CONSULT-III F unction (BCM - THEFT ALM)INFOID:0000000005370264

WORK SUPPORT

DATA MONITOR

Test item Content

WARNING LAMP This test is able to check to make sure that the warning lamp turns on.

ID REGIST WARNING This test is able to check to make su re that the buzzer sounds or the warning lamp turns on.

FLAT TIRE WARNING This test is able to check to make sure that the buzzer sounds.

HORN This test is able to check to make sure that the horn sounds.

FLASHER This test is able to check to make sure that each turn signal lamp turns on.

Test Item Description

SECURITY ALARM SET This mo de is able to confirm and change security alarm ON-OFF setting.

THEFT ALM TRG The switch which triggered vehicle security alarm is recorded. This mode is able to confirm and

erase the record of vehicle security alarm. The trigger data can be erased by touching “CLEAR” on

CONSULT-III screen.

Monitor Item

[Unit] Description

IGN ON SW [ON/OFF] Indicates ignition switch (ON) status judged from IGN signal (ignition power supply)

ACC ON SW [ON/OFF] Indicates ignition switch (ACC) status judged from ACC signal (accessory power supply)

I-KEY LOCK [ON/OFF] Indicates lock signal status received from Intelligent Key unit by CAN communication

I-KEY UNLOCK [ON/OFF] Indicates unlock si gnal status received from Intelligent Key unit by CAN communication

I-KEY TRUNK [ON/OFF] Indicates condit ion of back door opener switch

TRNK OPNR SW [ON/OFF] Indicates switch status of back door opener switch

TRNK OPN MNTR [ON/OFF] Indicates switch status of back door latch

Revision: April 20092010 QX56

Page 475 of 4210

BR-30

< ON-VEHICLE REPAIR >

FRONT DISC BRAKE

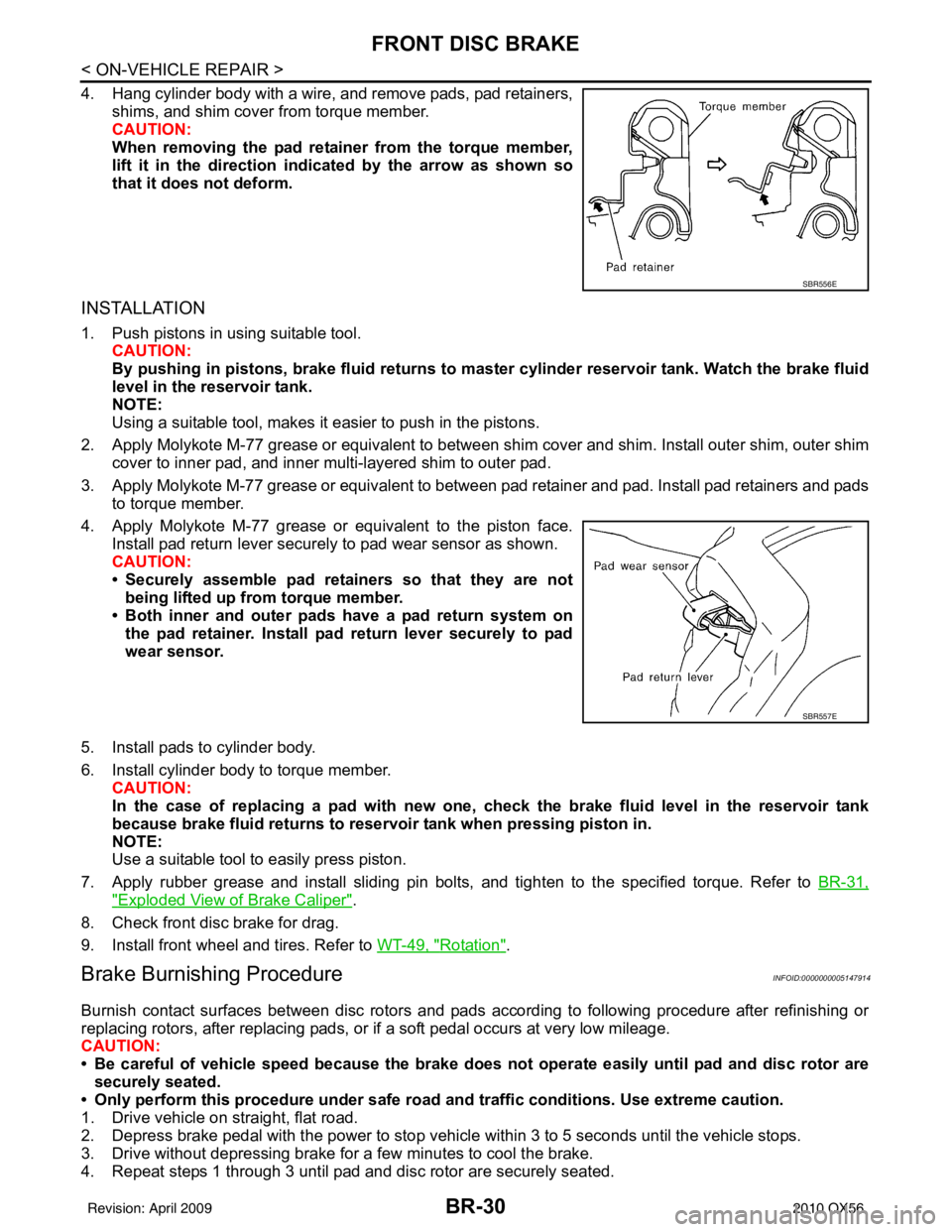

4. Hang cylinder body with a wire, and remove pads, pad retainers,shims, and shim cover from torque member.

CAUTION:

When removing the pad retainer from the torque member,

lift it in the direction indi cated by the arrow as shown so

that it does not deform.

INSTALLATION

1. Push pistons in using suitable tool.

CAUTION:

By pushing in pistons, brake fluid returns to m aster cylinder reservoir tank. Watch the brake fluid

level in the reservoir tank.

NOTE:

Using a suitable tool, makes it easier to push in the pistons.

2. Apply Molykote M-77 grease or equivalent to between shim cover and shim. Install outer shim, outer shim cover to inner pad, and inner multi-layered shim to outer pad.

3. Apply Molykote M-77 grease or equivalent to between pad retainer and pad. Install pad retainers and pads to torque member.

4. Apply Molykote M-77 grease or equivalent to the piston face. Install pad return lever securely to pad wear sensor as shown.

CAUTION:

• Securely assemble pad retainers so that they are not

being lifted up from torque member.

• Both inner and outer pads have a pad return system on

the pad retainer. Install pad return lever securely to pad

wear sensor.

5. Install pads to cylinder body.

6. Install cylinder body to torque member. CAUTION:

In the case of replacing a pad with new one, ch eck the brake fluid level in the reservoir tank

because brake fluid returns to reservoir tank when pressing piston in.

NOTE:

Use a suitable tool to easily press piston.

7. Apply rubber grease and install sliding pin bolts, and tighten to the specified torque. Refer to BR-31,

"Exploded View of Brake Caliper".

8. Check front disc brake for drag.

9. Install front wheel and tires. Refer to WT-49, "

Rotation".

Brake Burnishing ProcedureINFOID:0000000005147914

Burnish contact surfaces between disc rotors and pads according to following procedure after refinishing or

replacing rotors, after replacing pads, or if a soft pedal occurs at very low mileage.

CAUTION:

• Be careful of vehicle speed because the brake does not operate easily until pad and disc rotor are

securely seated.

• Only perform this procedure under safe road and traffic conditions. Use extreme caution.

1. Drive vehicle on straight, flat road.

2. Depress brake pedal with the power to stop vehicle within 3 to 5 seconds until the vehicle stops.

3. Drive without depressing brake for a few minutes to cool the brake.

4. Repeat steps 1 through 3 until pad and disc rotor are securely seated.

SBR556E

SBR557E

Revision: April 20092010 QX56

Page 480 of 4210

REAR DISC BRAKEBR-35

< ON-VEHICLE REPAIR >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

2. Apply Molykote M-77 grease to knuckle slide where brake pad contacts and to the outer multi-layered

shim, pad retainers and inner shim.

CAUTION:

Do not get grease on the brake pads or brake rotor friction surfaces.

3. Install pads, shims, cover and retainers to cylinder body.

4. Apply rubber grease to the sliding sleeves and install cylinder body, sliding sleeves and sliding pin bolts and tighten to specification. Refer to BR-35, "

Exploded View of Brake Caliper".

5. Check rear disc brake for drag.

6. Install rear wheel and tires. Refer to WT-49, "

Rotation".

Brake Burnishing ProcedureINFOID:0000000005147919

Burnish contact surfaces between disc rotors and pads according to following procedure after refinishing or

replacing rotors, after replacing pads, or if a soft pedal occurs at very low mileage.

CAUTION:

• Be careful of vehicle speed because the brake does not operate easily until pad and disc rotor are securely seated.

• Only perform this procedure under safe road and traffic conditions. Use extreme caution.

1. Drive vehicle on straight, flat road.

2. Depress brake pedal with the power to stop vehicle within 3 to 5 seconds until the vehicle stops.

3. Drive without depressing brake for a few minutes to cool the brake.

4. Repeat steps 1 through 3 until pad and disc rotor are securely seated.

Exploded View of Brake CaliperINFOID:0000000005147920

1. Union bolt 2. Brake hose 3. Copper washer

4. Cap 5. Bleed valve 6. Sliding pin bolt

7. Cylinder body 8. Piston seal 9. Piston

10. Piston boot 11. Knuckle slide 12. Sliding sleeve boot

AWFIA0423GB

Revision: April 20092010 QX56

Page 521 of 4210

![INFINITI QX56 2010 Factory Service Manual C1101, C1102, C1103, C1104 WHEEL SENSOR-1

BRC-29

< COMPONENT DIAGNOSIS > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

NOTE:

The green POWER indicator should illuminate. If the POWER indicator does INFINITI QX56 2010 Factory Service Manual C1101, C1102, C1103, C1104 WHEEL SENSOR-1

BRC-29

< COMPONENT DIAGNOSIS > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

NOTE:

The green POWER indicator should illuminate. If the POWER indicator does](/img/42/57032/w960_57032-520.png)

C1101, C1102, C1103, C1104 WHEEL SENSOR-1

BRC-29

< COMPONENT DIAGNOSIS > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

NOTE:

The green POWER indicator should illuminate. If the POWER indicator does not illuminate, replace the

battery in the ABS active wheel sensor tester before proceeding.

3. Spin the wheel of the vehicle by hand and observe the red SENSOR indicator on the ABS active wheel

sensor tester. The red SENSOR indicator should flash on and off to indicate an output signal.

NOTE:

If the red SENSOR indicator illuminates but does not flash, reverse the polarity of the tester leads and

retest.

Does the ABS active wheel s ensor tester detect a signal?

YES >> GO TO 3

NO >> Replace the wheel sensor. Refer to BRC-114, "

Removal and Installation".

3.CHECK TIRES

Check the inflation pressure, wear and size of each tire.

Is the inspection result normal?

YES >> GO TO 4

NO >> Adjust tire pressure or replace tire(s).

4.CHECK WHEEL BEARINGS

Check wheel bearing axial end play. Refer to FA X - 6 , "

On-Vehicle Inspection and Service" (front) or RAX-6,

"On-Vehicle Inspection and Service" (rear).

Is the inspection result normal?

YES >> GO TO 5

NO >> Repair or replace as necessary. Refer to FAX-7, "

Removal and Installation" (front) or RAX-8,

"Removal and Installation" (rear).

5.CHECK WIRING HARNESS FOR SHORT CIRCUIT

1. Disconnect ABS actuator and electric unit (control unit) connec- tor and wheel sensor connector of malfunction code.

2. Check continuity between wheel sensor connector terminals

and ground.

Is the inspection result normal?

YES >> GO TO 6

NO >> Repair the circuit.

6.CHECK WIRING HARNESS FOR OPEN CIRCUIT

Check continuity between ABS actuator and electric unit (control unit) connector and the malfunctioning wheel

sensor connector.

Is the inspection result normal?

Continuity should not exist.

AWFIA0188ZZ

Wheel sensor ABS actuator and

electric unit (control unit) Wheel sensor

Continuity

Connector Terminal Connector Terminal

Front LH

E12545

E18 1

Ye s

46

2

Front RH 34

E117 1

33 2

Rear LH 37

C11 2

36 1

Rear RH 42

C10 2

43 1

Revision: April 20092010 QX56

Page 524 of 4210

![INFINITI QX56 2010 Factory Service Manual BRC-32

< COMPONENT DIAGNOSIS >[VDC/TCS/ABS]

C1105, C1106, C1107,

C1108 WHEEL SENSOR-2

NO >> Repair or replace as necessary.

2.CHECK WHEEL SENSOR OUTPUT SIGNAL

1. Connect ABS active wheel sensor teste INFINITI QX56 2010 Factory Service Manual BRC-32

< COMPONENT DIAGNOSIS >[VDC/TCS/ABS]

C1105, C1106, C1107,

C1108 WHEEL SENSOR-2

NO >> Repair or replace as necessary.

2.CHECK WHEEL SENSOR OUTPUT SIGNAL

1. Connect ABS active wheel sensor teste](/img/42/57032/w960_57032-523.png)

BRC-32

< COMPONENT DIAGNOSIS >[VDC/TCS/ABS]

C1105, C1106, C1107,

C1108 WHEEL SENSOR-2

NO >> Repair or replace as necessary.

2.CHECK WHEEL SENSOR OUTPUT SIGNAL

1. Connect ABS active wheel sensor tester (J-45741) to wheel sensor using appropriate adapter.

2. Turn on the ABS active wheel sensor tester power switch. NOTE:

The green POWER indicator should illuminate. If the POWER indicator does not illuminate, replace the

battery in the ABS active wheel sensor tester before proceeding.

3. Spin the wheel of the vehicle by hand and observe the red SENSOR indicator on the ABS active wheel

sensor tester. The red SENSOR indicator should flash on and off to indicate an output signal.

NOTE:

If the red SENSOR indicator illuminates but does not flash, reverse the polarity of the tester leads and

retest.

Does the ABS active wheel sensor tester detect a signal?

YES >> GO TO 3

NO >> Replace the wheel sensor. Refer to BRC-114, "

Removal and Installation".

3.CHECK TIRES

Check the inflation pressure, wear and size of each tire.

Is the inspection result normal?

YES >> GO TO 4

NO >> Adjust tire pressure or replace tire(s).

4.CHECK WHEEL BEARINGS

Check wheel bearing axial end play. Refer to FAX-6, "

On-Vehicle Inspection and Service" (front) or RAX-6,

"On-Vehicle Inspection and Service" (rear).

Is the inspection result normal?

YES >> GO TO 5

NO >> Repair or replace as necessary. Refer to FA X - 7 , "

Removal and Installation" (front) or RAX-8,

"Removal and Installation" (rear).

5.CHECK WIRING HARNESS FOR SHORT CIRCUIT

1. Disconnect ABS actuator and elec tric unit (control unit) connec-

tor and wheel sensor connector of malfunction code.

2. Check continuity between wheel sensor connector terminals and ground.

Is the inspection result normal?

YES >> GO TO 6

NO >> Repair the circuit.

6.CHECK WIRING HARNESS FOR OPEN CIRCUIT

Check continuity between ABS actuator and electric unit (control unit) connecto r and the malfunctioning wheel

sensor connector. Continuity should not exist.

AWFIA0188ZZ

Revision: April 20092010 QX56

Page 535 of 4210

![INFINITI QX56 2010 Factory Service Manual C1115 WHEEL SENSORBRC-43

< COMPONENT DIAGNOSIS > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

3.CHECK TIRES

Check the inflation pressure, wear and size of each tire.

Is the inspection result normal INFINITI QX56 2010 Factory Service Manual C1115 WHEEL SENSORBRC-43

< COMPONENT DIAGNOSIS > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

3.CHECK TIRES

Check the inflation pressure, wear and size of each tire.

Is the inspection result normal](/img/42/57032/w960_57032-534.png)

C1115 WHEEL SENSORBRC-43

< COMPONENT DIAGNOSIS > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

3.CHECK TIRES

Check the inflation pressure, wear and size of each tire.

Is the inspection result normal?

YES >> GO TO 4

NO >> Adjust tire pressure or replace tire(s).

4.CHECK WHEEL BEARINGS

Check wheel bearing axial end play. Refer to FA X - 6 , "

On-Vehicle Inspection and Service" (front) or RAX-6,

"On-Vehicle Inspection and Service" (rear).

Is the inspection result normal?

YES >> GO TO 5

NO >> Repair or replace as necessary. Refer to FAX-7, "

Removal and Installation" (front) or RAX-8,

"Removal and Installation" (rear).

5.CHECK WIRING HARNESS FOR SHORT CIRCUIT

1. Disconnect ABS actuator and electric unit (control unit) connec- tor and wheel sensor connector of malfunction code.

2. Check continuity between wheel sensor connector terminals and ground.

Is the inspection result normal?

YES >> GO TO 6

NO >> Repair the circuit.

6.CHECK WIRING HARNESS FOR OPEN CIRCUIT

Check continuity between ABS actuator and electric unit (control unit) connector and the malfunctioning wheel

sensor connector.

Is the inspection result normal?

YES >> Replace the ABS actuator and elec tric unit (control unit). Refer to BRC-116, "Removal and Instal-

lation".

NO >> Repair the circuit.

Component InspectionINFOID:0000000005194909

1.CHECK DATA MONITOR

On “DATA MONITOR”, select “FR LH SENSOR”, “FR RH SENSOR”, “RR LH SENSOR”, and “RR RH SEN-

SOR”, and check the vehicle speed. Continuity should not exist.

AWFIA0188ZZ

Wheel sensor

ABS actuator and

electric unit (control unit) Wheel sensor

Continuity

Connector Terminal Connector Terminal

Front LH

E12545

E18 1

Ye s

46

2

Front RH 34

E117 1

33 2

Rear LH 37

C11 2

36 1

Rear RH 42

C10 2

43 1

Revision: April 20092010 QX56

Page 2121 of 4210

ADJUSTMENT AND INSPECTIONEXL-145

< ON-VEHICLE REPAIR >

C

DE

F

G H

I

J

K

M A

B

EXL

N

O P

ON-VEHICLE REPAIR

ADJUSTMENT AND INSPECTION

HEADLAMP

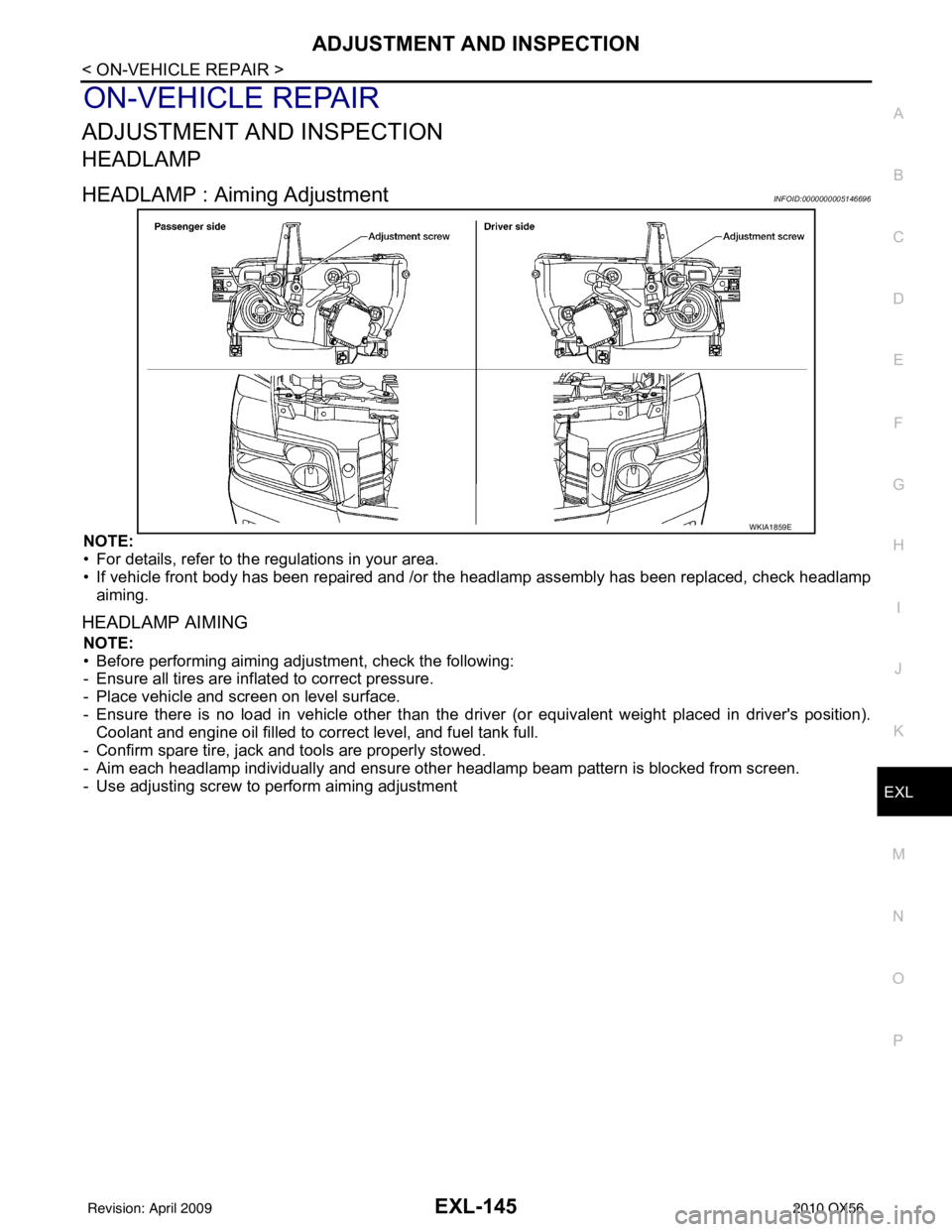

HEADLAMP : Aiming AdjustmentINFOID:0000000005146696

NOTE:

• For details, refer to the regulations in your area.

• If vehicle front body has been repaired and /or the headlamp assembly has been replaced, check headlamp

aiming.

HEADLAMP AIMING

NOTE:

• Before performing aiming adjustment, check the following:

- Ensure all tires are inflated to correct pressure.

- Place vehicle and screen on level surface.

- Ensure there is no load in vehicle other than the driver (or equivalent weight placed in driver's position). Coolant and engine oil filled to correct level, and fuel tank full.

- Confirm spare tire, jack and tools are properly stowed.

- Aim each headlamp individually and ensure other headlamp beam pattern is blocked from screen.

- Use adjusting screw to perform aiming adjustment

WKIA1859E

Revision: April 20092010 QX56

Page 2122 of 4210

EXL-146

< ON-VEHICLE REPAIR >

ADJUSTMENT AND INSPECTION

NOTE:

Basic illuminating area for adjustment should be within the range shown on the aiming chart. Adjust head-

lamps accordingly.

LOW BEAM AND HIGH BEAM

1. Turn headlamp low beam on.

2. Use adjusting screw to perform aiming adjustment.

FRONT FOG LAMP

FRONT FOG LAMP : Aiming AdjustmentINFOID:0000000005146697

The fog lamp is a semi-sealed beam type which uses a replaceable halogen bulb. Before performing aiming

adjustment, make sure of the following.

• Keep all tires inflated to correct pressure.

• Place vehicle on level ground.

A. RightB. Left C. Center of headlamp bulb (H-V point)

D. Cutoff line E. ScreenF. Aim evaluation segment

G. Step H. Horizontal center line of headlamp J. 103 mm (4.06 in.)

K. 37 mm (1.46 in.) L. 7.62 m (25 ft.) M. 399 mm (15.71 in.)

N. 133 mm (5.24 in.) P. 53.2 mm (2.09 in.)Q. 466 mm (18.35 in.)

R. 200 mm (7.87 in.) S. RH headlamp aiming screen T. LH headlamp aiming screen

V. Vertical center line

LKIA0809E

Revision: April 20092010 QX56

Page 2205 of 4210

FSU-6

< ON-VEHICLE MAINTENANCE >

ON-VEHICLE SERVICE

ON-VEHICLE MAINTENANCE

ON-VEHICLE SERVICE

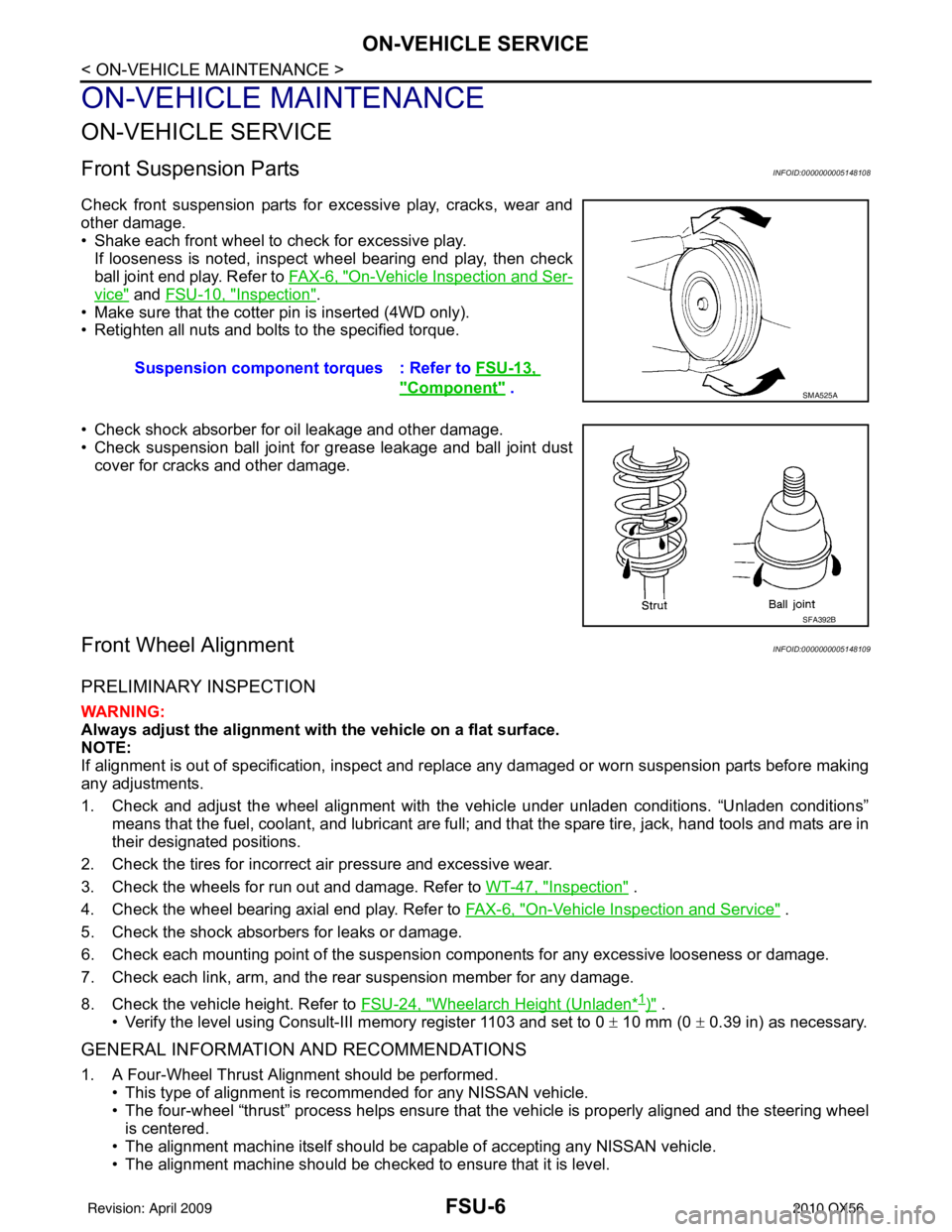

Front Suspension PartsINFOID:0000000005148108

Check front suspension parts for excessive play, cracks, wear and

other damage.

• Shake each front wheel to check for excessive play.If looseness is noted, inspect wheel bearing end play, then check

ball joint end play. Refer to FA X - 6 , "

On-Vehicle Inspection and Ser-

vice" and FSU-10, "Inspection".

• Make sure that the cotter pin is inserted (4WD only).

• Retighten all nuts and bolts to the specified torque.

• Check shock absorber for oil leakage and other damage.

• Check suspension ball joint for grease leakage and ball joint dust cover for cracks and other damage.

Front Wheel AlignmentINFOID:0000000005148109

PRELIMINARY INSPECTION

WARNING:

Always adjust the alignment with the vehicle on a flat surface.

NOTE:

If alignment is out of specificat ion, inspect and replace any damaged or worn suspension parts before making

any adjustments.

1. Check and adjust the wheel alignment with the vehicle under unladen conditions. “Unladen conditions”

means that the fuel, coolant, and lubricant are full; and that the spare tire, jack, hand tools and mats are in

their designated positions.

2. Check the tires for incorrect air pressure and excessive wear.

3. Check the wheels for run out and damage. Refer to WT-47, "

Inspection" .

4. Check the wheel bearing axial end play. Refer to FA X - 6 , "

On-Vehicle Inspection and Service" .

5. Check the shock absorbers for leaks or damage.

6. Check each mounting point of the suspension components for any excessive looseness or damage.

7. Check each link, arm, and the rear suspension member for any damage.

8. Check the vehicle height. Refer to FSU-24, "

Wheelarch Height (Unladen*1)" .

• Verify the level using Consult-III memory register 1103 and set to 0 ± 10 mm (0 ± 0.39 in) as necessary.

GENERAL INFORMATION AND RECOMMENDATIONS

1. A Four-Wheel Thrust Alignment should be performed.

• This type of alignment is recommended for any NISSAN vehicle.

• The four-wheel “thrust” process helps ensure that the vehicle is properly aligned and the steering wheel

is centered.

• The alignment machine itself should be ca pable of accepting any NISSAN vehicle.

• The alignment machine should be checked to ensure that it is level. Suspension component

torques : Refer to FSU-13,

"Component" . SMA525A

SFA392B

Revision: April 20092010 QX56