hood release INFINITI QX56 2010 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2010, Model line: QX56, Model: INFINITI QX56 2010Pages: 4210, PDF Size: 81.91 MB

Page 783 of 4210

ENGINE COOLING FANCO-19

< ON-VEHICLE REPAIR >

C

DE

F

G H

I

J

K L

M A

CO

NP

O

INSTALLATION

Installation is in the reverse order of removal.

• Install cooling fan with its front mark “F” facing front of engine.

INSPECTION AFTER INSTALLATION

• Check for leaks of the engine coolant. Refer to

CO-10, "Inspection".

• Start and warm up the engine. Visually make sure that there are no leaks of the engine coolant.

Removal and Installati on (Motor Driven Type)INFOID:0000000005149048

REMOVAL

1. Remove the front bumper fascia. Refer to EXT-13, "Removal and Installation".

2. Disconnect the secondary hood release cable.

3. Disconnect harness connector (A) from fan motor.

4. Remove the bolt and remove the fan grille and motor assembly.

INSTALLATION

Installation is in the reverse order of removal.

• Cooling fan is controlled by ECM. For details, refer to EC-36, "

Description".

AWBIA0668ZZ

Revision: April 20092010 QX56

Page 1069 of 4210

![INFINITI QX56 2010 Factory Service Manual HOOD

DLK-235

< ON-VEHICLE REPAIR > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

DLK

N

O P

Removal and Installation of Hood Lock ControlINFOID:0000000005147052

REMOVAL

1. Remove the bolts and INFINITI QX56 2010 Factory Service Manual HOOD

DLK-235

< ON-VEHICLE REPAIR > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

DLK

N

O P

Removal and Installation of Hood Lock ControlINFOID:0000000005147052

REMOVAL

1. Remove the bolts and](/img/42/57032/w960_57032-1068.png)

HOOD

DLK-235

< ON-VEHICLE REPAIR > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

DLK

N

O P

Removal and Installation of Hood Lock ControlINFOID:0000000005147052

REMOVAL

1. Remove the bolts and the hood lock assembly.

2. Remove the front fender protector (LH). Refer to EXT-23, "

Removal and Installation".

3. Disconnect the hood lock primary and secondary hood lock cables from the hood lock. Unclip the primary

cable from the radiator core support upper and hood ledge.

4. Remove the nuts and the secondary hood lock release assembly.

5. Remove the grommet from the dash lower, and pull the primary hood lock cable into the passenger room. CAUTION:

While pulling, be careful not to dama ge the outside of the hood lock cable.

INSTALLATION

1. Pull the hood lock cable through the dash lower hole into the engine room.

Be careful not to bend the cable too much, keeping the radius

100mm (3.94 in) or more.

2. Make sure the cable is not of fset from the positioning grommet,

and push the grommet into the dash lower hole securely.

3. Apply sealant around the grommet at * mark.

1. Hood lock assembly 2. Secondary hood lock release as-

sembly 3. Secondary hood lock cable

4. Primary hood lock cable 5. Grommet6. Hood lock release handle

WIIA0900E

PIIA0173E

Revision: April 20092010 QX56

Page 1070 of 4210

![INFINITI QX56 2010 Factory Service Manual DLK-236

< ON-VEHICLE REPAIR >[WITH INTELLIGENT KEY SYSTEM]

HOOD

4. Install the primary and secondary cables securely to the hood

lock assembly.

5. Install the hood lock and the secondary hood lock rel INFINITI QX56 2010 Factory Service Manual DLK-236

< ON-VEHICLE REPAIR >[WITH INTELLIGENT KEY SYSTEM]

HOOD

4. Install the primary and secondary cables securely to the hood

lock assembly.

5. Install the hood lock and the secondary hood lock rel](/img/42/57032/w960_57032-1069.png)

DLK-236

< ON-VEHICLE REPAIR >[WITH INTELLIGENT KEY SYSTEM]

HOOD

4. Install the primary and secondary cables securely to the hood

lock assembly.

5. Install the hood lock and the secondary hood lock release assemblies.

6. Check the hood lock adjustment and hood opener operation. Refer to DLK-233, "

Fitting Adjustment".

7. Install the remaining components in the reverse order of removal.

Hood Lock Control InspectionINFOID:0000000005147053

CAUTION:

If the hood lock cable is bent or deformed, replace it.

1. Remove the front grille. Refer to EXT-17, "

Removal and Installation".

2. Make sure the secondary latch is properly engaged with the sec- ondary striker with hood's own weight by dropping it from

approx. 200 mm (7.87 in) height.

3. While operating the hood opener, carefully make sure the front end of the hood is raised by approx. 20 mm (0.79 in). Also make

sure the hood opener returns to the original position.

4. Check the hood lock lubrication condition. If necessary, apply “body grease” to the points shown in the figure.

5. Install the front grille. Refer to EXT-17, "

Removal and Installa-

tion".

Hood Stay DisposalINFOID:0000000005356855

1. Fix hood stay (1) using a vise (C).

2. Using hacksaw (A) slowly make 2 holes in the hood stay, in numerical order as shown in the figure.

CAUTION:

• When cutting a hole on hood stay, always cover a hack-saw using a shop cloth (B) to avoid scattering metal frag-

ments or oil.

• Wear eye protection (safety glasses).

• Wear gloves.

PIIA0174E

PIIA1086E

PIIA0176E

JMKIA3336ZZ

Revision: April 20092010 QX56

Page 1509 of 4210

![INFINITI QX56 2010 Factory Service Manual EC-156

< COMPONENT DIAGNOSIS >[VK56DE]

P0137, P0157 HO2S2

If not, warm up engine and go to next step when “C

OOLAN TEMP/S” indication reaches to 70°C (158° F).

7. Open engine hood.

8. Select “ INFINITI QX56 2010 Factory Service Manual EC-156

< COMPONENT DIAGNOSIS >[VK56DE]

P0137, P0157 HO2S2

If not, warm up engine and go to next step when “C

OOLAN TEMP/S” indication reaches to 70°C (158° F).

7. Open engine hood.

8. Select “](/img/42/57032/w960_57032-1508.png)

EC-156

< COMPONENT DIAGNOSIS >[VK56DE]

P0137, P0157 HO2S2

If not, warm up engine and go to next step when “C

OOLAN TEMP/S” indication reaches to 70°C (158° F).

7. Open engine hood.

8. Select “HO2S2 (B1) P1147” (for DTC P0137) or “HO2S2 (B2) P1167” (for DTC P0157) of “HO2S2” in “DTC WORK SUPPORT” mode with CONSULT-III.

9. Start engine and following the instruction of CONSULT-III. NOTE:

It will take at most 10 minutes until “COMPLETED” is displayed.

10. Make sure that “OK” is display ed after touching “SELF-DIAG RESULTS”.

If “NG” is displayed, refer to EC-156, "

Diagnosis Procedure".

If “CAN NOT BE DIAG NOSED” is displayed, perform the following.

a. Turn ignition switch OFF and leave the vehi cle in a cool place (soak the vehicle).

b. Return to step 1.

Overall Function CheckINFOID:0000000005149175

Use this procedure to check the overall function of the heated oxygen sensor 2 circuit. During this check, a 1st

trip DTC might not be confirmed.

WITH GST

1. Start engine and warm it up to the normal operating temperature.

2. Turn ignition switch OFF and wait at least 10 seconds.

3. Start engine and keep the engine speed between 3,500 and 4,000 rpm for at least 1 minute under no load.

4. Let engine idle for 1 minute.

5. Set voltmeter probes between ECM terminal 55 [HO2S2 (B1) signal] or 74\

[HO2S2 (B2) signal] and ground.

6. Check the voltage when revving up to 4,000 rpm under no load at least 10 times.

(Depress and release accelerator pedal as soon as possible.)

The voltage should be above 0.58 V at least once during

this procedure.

If the voltage can be confirmed in step 6, step 7 is not nec-

essary.

7. Keep vehicle at idling for 10 minutes, then check the voltage. Or check the voltage when coasting from 80 km/h (50 MPH) in D

position.

The voltage should be above 0.58V at least once during this

procedure.

8. If NG, go to EC-156, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000005149176

1.CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF.

2. Loosen and retighten three ground screws on the body. Refer to EC-85, "

Ground Inspection".

OK or NG

OK >> GO TO 2.

PBIB2054E

BBIA0354E

Revision: April 20092010 QX56

Page 1521 of 4210

![INFINITI QX56 2010 Factory Service Manual EC-168

< COMPONENT DIAGNOSIS >[VK56DE]

P0139, P0159 HO2S2

If not, warm up engine and go to next step when “C

OOLAN TEMP/S” indication reaches to 70°C (158° F).

7. Open engine hood.

8. Select “ INFINITI QX56 2010 Factory Service Manual EC-168

< COMPONENT DIAGNOSIS >[VK56DE]

P0139, P0159 HO2S2

If not, warm up engine and go to next step when “C

OOLAN TEMP/S” indication reaches to 70°C (158° F).

7. Open engine hood.

8. Select “](/img/42/57032/w960_57032-1520.png)

EC-168

< COMPONENT DIAGNOSIS >[VK56DE]

P0139, P0159 HO2S2

If not, warm up engine and go to next step when “C

OOLAN TEMP/S” indication reaches to 70°C (158° F).

7. Open engine hood.

8. Select “HO2S2 (B1) P0139” or “HO2S2 (B2) P0159” of “HO2S2” in “DTC WORK SUPPORT” mode with CONSULT-III.

9. Following the instruction of CONSULT-III. NOTE:

It will take at most 10 minutes until “COMPLETED” is displayed.

10. Make sure that “OK” is display ed after touching “SELF-DIAG RESULTS”.

If “NG” is displayed, refer to EC-168, "

Diagnosis Procedure".

If “CAN NOT BE DIAG NOSED” is displayed, perform the following.

a. Turn ignition switch OFF and leave the vehi cle in a cool place (soak the vehicle).

b. Return to step 1.

Overall Function CheckINFOID:0000000005149187

Use this procedure to check the overall function of the heated oxygen sensor 2 circuit. During this check, a 1st

trip DTC might not be confirmed.

WITH GST

1. Start engine and warm it up to the normal operating temperature.

2. Turn ignition switch OFF and wait at least 10 seconds.

3. Start engine and keep the engine speed between 3,500 and 4,000 rpm for at least 1 minute under no load.

4. Let engine idle for 1 minute.

5. Set voltmeter probes between ECM terminal 55 [HO2S2 (B1) signal] or 74\

[HO2S2 (B2) signal] and ground.

6. Check the voltage when revving up to 4,000 rpm under no load at least 10 times.

(Depress and release accelerator pedal as soon as possible.)

A change of voltage should be more than 0.12 V for 1 sec-

ond during this procedure.

If the voltage can be confirmed in step 6, step 7 is not nec-

essary.

7. Keep vehicle at idling for 10 minutes, then check the voltage. Or check the voltage when coasting from 80 km/h (50 MPH) in D

position.

A change of voltage should be more than 0.12 V for 1 sec-

ond during this procedure.

8. If NG, go to EC-168, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000005149188

1.CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF.

2. Loosen and retighten three ground screws on the body. Refer to EC-85, "

Ground Inspection".

OK or NG

OK >> GO TO 2.

PBIB2054E

BBIA0354E

Revision: April 20092010 QX56

Page 1562 of 4210

![INFINITI QX56 2010 Factory Service Manual P0420, P0430 THREE WAY CATALYST FUNCTIONEC-209

< COMPONENT DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

P0420, P0430 THREE WAY CATALYST FUNCTION

On Board Diagnosis LogicINFOID:0000000005149229 INFINITI QX56 2010 Factory Service Manual P0420, P0430 THREE WAY CATALYST FUNCTIONEC-209

< COMPONENT DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

P0420, P0430 THREE WAY CATALYST FUNCTION

On Board Diagnosis LogicINFOID:0000000005149229](/img/42/57032/w960_57032-1561.png)

P0420, P0430 THREE WAY CATALYST FUNCTIONEC-209

< COMPONENT DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

P0420, P0430 THREE WAY CATALYST FUNCTION

On Board Diagnosis LogicINFOID:0000000005149229

The ECM monitors the switching

frequency ratio of air fuel sensor

(A/F) sensor 1 and heated oxygen sensor 2.

A three way catalyst (manifold) with high oxygen storage capacity

will indicate a low switching frequency of heated oxygen sensor 2.

As oxygen storage capacity decreases, the heated oxygen sensor 2

switching frequency will increase.

When the frequency ratio of air fuel ratio (A/F) sensor 1 and heated

oxygen sensor 2 approaches a specified limit value, the three way

catalyst (manifold) malfunction is diagnosed.

DTC Confirmation ProcedureINFOID:0000000005149230

NOTE:

If DTC Confirmation Procedure has been previously conducted, always perform the following procedure

before conducting the next step.

1. Turn ignition switch OFF and wait at least 10 seconds.

2. Turn ignition switch ON.

3. Turn ignition switch OFF and wait at least 10 seconds.

WITH CONSULT-III

TESTING CONDITION:

Do not hold engine speed for more than the specified minutes below.

1. Turn ignition switch ON and select “DATA MONITOR” mode with CONSULT-III.

2. Start engine and warm it up to the normal operating temperature.

3. Turn ignition switch OFF and wait at least 10 seconds.

4. Start engine and keep the engine speed between 3,500 and 4,000 rpm for at least 1 minute under no load.

5. Let engine idle for 1 minute.

6. Make sure that “COOLAN TEMP/S” indicates more than 70 °C (158° F).

If not, warm up engine and go to next step when “COOLAN TEMP/S” indication reaches to 70°C (158° F).

7. Open engine hood.

8. Select “DTC & SRT CONFIRMATION” then “SRT WORK SUPPORT” mode with CONSULT-III.

9. Rev engine up to 2,000 to 3,000 rpm and hold it for 3 consecutive minutes then release the accelerator pedal completely.

If “INCMP” of “CATALYST” changed to “CMPLT”, go to step 12.

10. Wait 5 seconds at idle.

11. Rev engine up to 2,000 to 3,000 rpm and maintain it unt il “INCMP” of “CATALYST” changes to “CMPLT” (It

will take approximately 5 minutes).

If not “CMPLT”, stop engine and cool it down to less than 70 °C (158° F) and then retest from step 1.

12. Select “SELF-DIAG RESU LTS” mode with CONSULT-III.

PBIB2055E

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0420

0420

(Bank 1) Catalyst system efficien-

cy below threshold • Three way catalyst (manifold) does not oper-

ate properly.

• Three way catalyst (manifold) does not have enough oxygen storage capacity. • Three way catalyst (manifold)

• Exhaust tube

• Intake air leaks

• Fuel injector

• Fuel injector leaks

• Spark plug

• Improper ignition timing

P0430

0430

(Bank 2)

Revision: April 20092010 QX56

Page 1630 of 4210

![INFINITI QX56 2010 Factory Service Manual P0506 ISC SYSTEMEC-277

< COMPONENT DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

P0506 ISC SYSTEM

DescriptionINFOID:0000000005149303

NOTE:

If DTC P0506 is displayed with ot

her DTC, first perfo INFINITI QX56 2010 Factory Service Manual P0506 ISC SYSTEMEC-277

< COMPONENT DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

P0506 ISC SYSTEM

DescriptionINFOID:0000000005149303

NOTE:

If DTC P0506 is displayed with ot

her DTC, first perfo](/img/42/57032/w960_57032-1629.png)

P0506 ISC SYSTEMEC-277

< COMPONENT DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

P0506 ISC SYSTEM

DescriptionINFOID:0000000005149303

NOTE:

If DTC P0506 is displayed with ot

her DTC, first perform the trouble diagnosis for the other DTC.

The ECM controls the engine idle speed to a specified level through the fine adjustment of the air, which is let

into the intake manifold, by operating the electric thrott le control actuator. The operating of the throttle valve is

varied to allow for optimum control of the engine idli ng speed. The crankshaft position sensor (POS) detects

the actual engine speed and sends a signal to the ECM.

The ECM controls the electric throttle control actuator so that the engine speed coincides with the target value

memorized in the ECM. The target engine speed is the lowest speed at which the engine can operate steadily.

The optimum value stored in the ECM is determined by taking into consideration various engine conditions,

such as during warming up, deceleration, and engine load (air conditioner, power steering and cooling fan

operation, etc.).

On Board Diagnosis LogicINFOID:0000000005149304

DTC Confirmation ProcedureINFOID:0000000005149305

NOTE:

• If DTC Confirmation Procedure has been previously conducted, always perform the following procedure before conducting the next step.

1. Turn ignition switch OFF and wait at least 10 seconds.

2. Turn ignition switch ON.

3. Turn ignition switch OFF and wait at least 10 seconds.

• If the target idle speed is ou t of the specified value, perform EC-18, "

Idle Air Volume Learning",

before conducting DTC Confirmation Procedure. For the target idle speed, refer to the EC-497, "

Idle

Speed and Ignition Timing".

TESTING CONDITION:

• Before performing the following procedure, confirm that battery voltage is more than 11V at idle.

• Always perform the test at a temperature above −10° C (14° F).

1. Open engine hood.

2. Start engine and warm it up to normal operating temperature.

3. Turn ignition switch OFF and wait at least 10 seconds.

4. Start engine and run it for at least 1 minute at idle speed.

5. Check 1st trip DTC.

6. If 1st trip DTC is detected, go to EC-277, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000005149306

1.CHECK INTAKE AIR LEAK

1. Start engine and let it idle.

2. Listen for an intake air leak after the mass air flow sensor.

OK or NG

OK >> GO TO 2.

NG >> Discover air leak location and repair.

2.REPLACE ECM

1. Stop engine.

2. Replace ECM.

3. Perform initialization of IVIS(NATS) system and registration of all IVIS(NATS) ignition key IDs. Refer to SEC-9, "

ECM RE-COMMUNICATING FUNCTION : Special Repair Requirement".

4. Perform EC-17, "

VIN Registration".

5. Perform EC-18, "

Accelerator Pedal Released Position Learning".

DTC No. Trouble diagnosis name DTC detecting conditionPossible cause

P0506

0506 Idle speed control system

RPM lower than expected The idle speed is less than the target idle speed

by 100 rpm or more. • Electric throttle control actuator

• Intake air leak

Revision: April 20092010 QX56

Page 1930 of 4210

ENGINE ASSEMBLYEM-79

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

1. Release the fuel pressure. Refer to

EC-489, "Fuel Pressure Check".

2. Drain the engine coolant. Refer to CO-11, "

Changing Engine Coolant".

3. Drain the engine oil. Refer to LU-9, "

Changing Engine Oil".

4. Partially drain the A/T fluid. Refer to TM-150, "

Changing the A/T Fluid (ATF)".

5. Disconnect the battery negative and positive terminal. Refer to PG-74, "

Removal and Installation".

6. Remove the engine hood. Refer to DLK-234, "

Removal and Installation of Hood Assembly".

7. Remove the cowl extension. Refer to EXT-18, "

Removal and Installation".

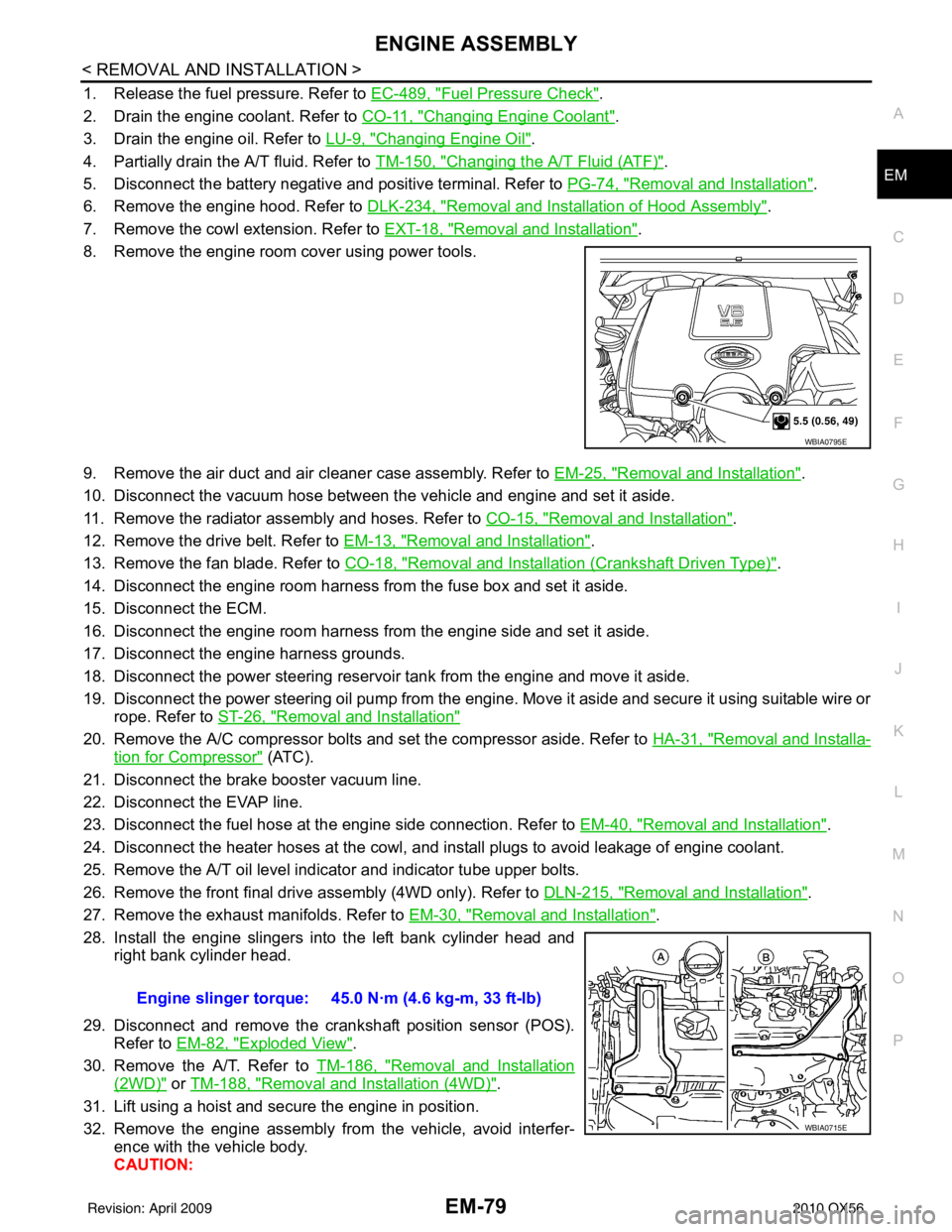

8. Remove the engine room cover using power tools.

9. Remove the air duct and air cleaner case assembly. Refer to EM-25, "

Removal and Installation".

10. Disconnect the vacuum hose between the vehicle and engine and set it aside.

11. Remove the radiator assembly and hoses. Refer to CO-15, "

Removal and Installation".

12. Remove the drive belt. Refer to EM-13, "

Removal and Installation".

13. Remove the fan blade. Refer to CO-18, "

Removal and Installation (Crankshaft Driven Type)".

14. Disconnect the engine room harness from the fuse box and set it aside.

15. Disconnect the ECM.

16. Disconnect the engine room harness from the engine side and set it aside.

17. Disconnect the engine harness grounds.

18. Disconnect the power steering reservoir t ank from the engine and move it aside.

19. Disconnect the power steering oil pump from the engine. Move it aside and secure it using suitable wire or rope. Refer to ST-26, "

Removal and Installation"

20. Remove the A/C compressor bolts and set the compressor aside. Refer to HA-31, "Removal and Installa-

tion for Compressor" (ATC).

21. Disconnect the brake booster vacuum line.

22. Disconnect the EVAP line.

23. Disconnect the fuel hose at the engine side connection. Refer to EM-40, "

Removal and Installation".

24. Disconnect the heater hoses at the cowl, and in stall plugs to avoid leakage of engine coolant.

25. Remove the A/T oil level indicator and indicator tube upper bolts.

26. Remove the front final drive assembly (4WD only). Refer to DLN-215, "

Removal and Installation".

27. Remove the exhaust manifolds. Refer to EM-30, "

Removal and Installation".

28. Install the engine slingers into the left bank cylinder head and right bank cylinder head.

29. Disconnect and remove the crankshaft position sensor (POS). Refer to EM-82, "

Exploded View".

30. Remove the A/T. Refer to TM-186, "

Removal and Installation

(2WD)" or TM-188, "Removal and Installation (4WD)".

31. Lift using a hoist and secure the engine in position.

32. Remove the engine assembly from the vehicle, avoid interfer- ence with the vehicle body.

CAUTION:

WBIA0795E

Engine slinger torque: 45.0 N·m (4.6 kg-m, 33 ft-lb)

WBIA0715E

Revision: April 20092010 QX56

Page 2153 of 4210

EXT-18

< SERVICE INFORMATION >

COWL TOP

COWL TOP

Removal and InstallationINFOID:0000000005147321

REMOVAL

1. Remove the right and left wiper arms. Refer to WW-79, "Front Wiper Arms".

2. Remove the cowl top seal. • Release the plastics clips on the cowl top seal which go through the cowl tops LH and RH and the cowltop extension.

3. Remove the cowl top covers LH and RH. • Release the plastic clips under the cowl top covers attaching to grommets on hoodledge.

• Disconnect the washer tubes from the wa sher nozzles under the cowl top covers.

4. Remove the cowl top extension brackets LH and RH. • Disconnect the wiper motor harness from the cowl top extension bracket LH.

• The cowl top extension bracket LH must be removed prior to the removal of the wiper motor and con-

necting rod assembly.

5. Remove the wiper motor and connecting rod linkage. Refer to WW-80, "

Wiper Motor and Linkage".

1. Clip CG1042. Clip C103 3. Cowl top cover RH

4. Cowl top seal 5. Drain tube6. Cowl top extension bracket RH

7. Cowl top extension 8. Cowl top extension bracket LH 9. Cowl top cover LH

WIIA0955E

Revision: April 20092010 QX56

Page 2235 of 4210

GI-12

< HOW TO USE THIS MANUAL >

HOW TO READ WIRING DIAGRAMS

• ignition switch is “OFF”,

• doors, hood and trunk lid/back door are closed,

• pedals are not depressed, and

• parking brake is released.

MULTIPLE SWITCH

The continuity of multiple switch is described in two ways as shown below.

• The switch chart is used in schematic diagrams.

• The switch diagram is used in wiring diagrams.

SGI860

JSAIA0017GB

Revision: April 20092010 QX56