fuel filter INFINITI QX56 2011 Factory User Guide

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 2647 of 5598

CAMSHAFTEM-85

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

5. Perform the following inspection if engine oil does not

come out from valve timing control solenoid valve

oil hole of the valve timing control cover.

Remove oil filter, and then clean it. Refer to EM-61, "

Exploded View".

Clean oil groove between oil strainer and valve timing control solenoid valve. Refer to LU-5, "

Engine

Lubrication System" and LU-6, "Engine Lubrication System Schematic".

6. Remove components between valve timing control solenoid valve and camshaft sprocket, and then check each oil groove for clogging.

Clean oil groove if necessary. Refer to LU-5, "

Engine Lubrication System" and LU-6, "Engine Lubrica-

tion System Schematic".

7. After inspection, install removed parts in the reverse order.

Inspection for Leakage

The following are procedures for chec king fluid leakage, lubricant leakage.

Before starting engine, check oil/fluid levels including engine coolant and engine oil. If any are less than the

required quantity, fill them to the specified level. Refer to MA-10, "

Fluids and Lubricants".

Follow the procedure below to check for fuel leakage.

- Turn ignition switch to the “ON” position (with engi ne stopped). With fuel pressure applied to fuel piping,

check for fuel leakage at connection points.

- Start engine. With engine speed increased, check again for fuel leakage at connection points.

Run engine to check for unusual noise and vibration. NOTE:

If hydraulic pressure inside chain tensioner drops after removal/installation, slack in guide may generate a

pounding noise during and just after the engine start. However, this does not indicate a malfunction. The

noise will stop after hydraulic pressure rises.

Warm up engine thoroughly to check that there is no leak age of fuel, or any oil/fluids including engine oil and

engine coolant.

Bleed air from lines and hoses of applicable lines, such as in cooling system.

After cooling down engine, again check oil/fluid levels including engine oil and engine coolant. Refill them to

the specified level, if necessary.

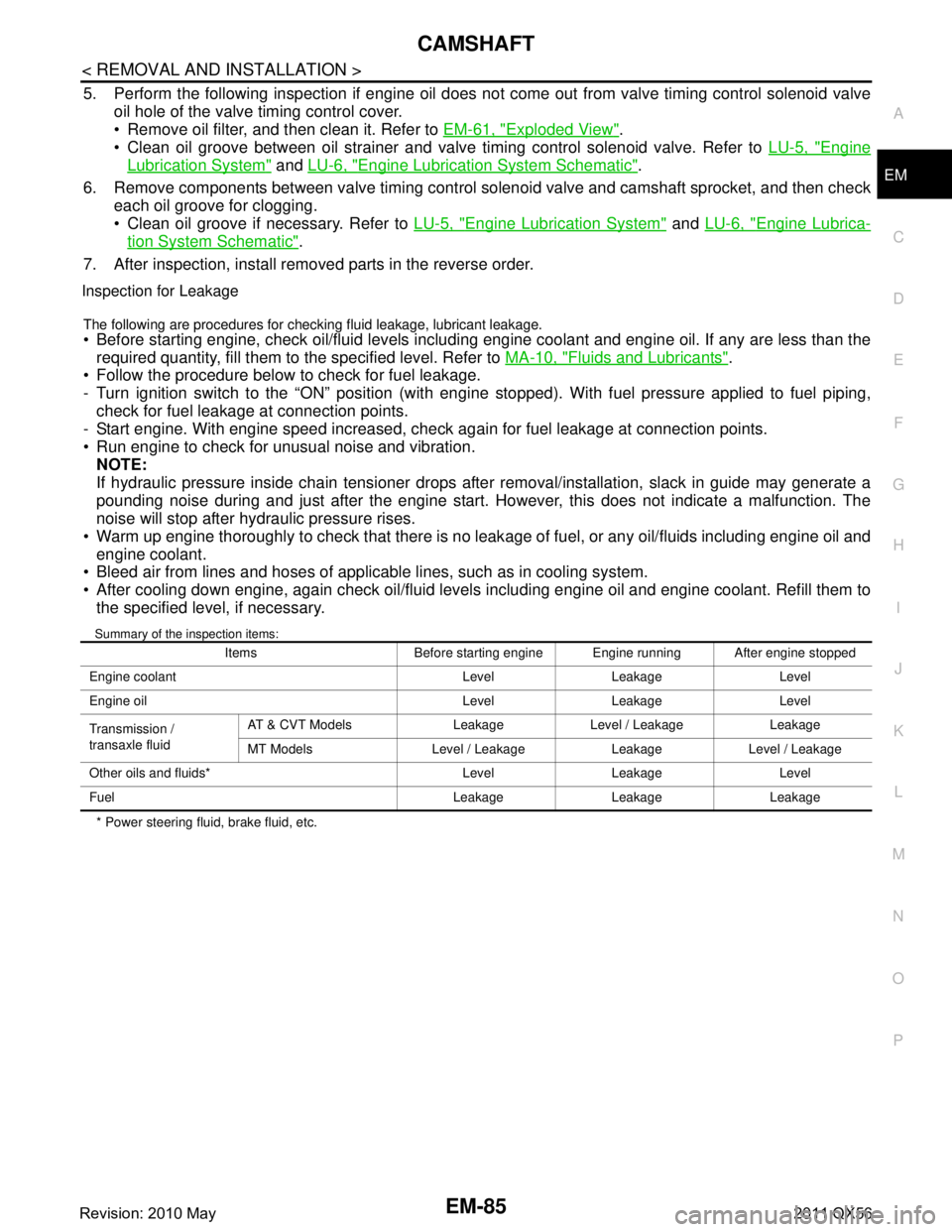

Summary of the inspection items:

* Power steering fluid, brake fluid, etc. Items Before starting engine Engine running After engine stopped

Engine coolant Level Leakage Level

Engine oil Level Leakage Level

Transmission /

transaxle fluid AT & CVT Models Leakage Level / Leakage Leakage

MT Models Level / Leakage Leakage Level / Leakage

Other oils and fluids* Level Leakage Level

Fuel Leakage Leakage Leakage

Revision: 2010 May2011 QX56

Page 2930 of 5598

FL-1

ENGINE

C

DE

F

G H

I

J

K L

M

SECTION FL

A

FL

N

O P

CONTENTS

FUEL SYSTEM

PRECAUTION ................ ...............................2

PRECAUTIONS .............................................. .....2

General Precautions ........................................... ......2

PREPARATION ............................................3

PREPARATION .............................................. .....3

Special Service Tool ........................................... ......3

Commercial Service Tools ........................................3

PERIODIC MAINTENANCE ..........................4

FUEL SYSTEM ............................................... .....4

Inspection ............................................................ ......4

Quick Connector .......................................................4

REMOVAL AND INSTALLATION ................5

FUEL LEVEL SENSOR UNIT, FUEL FILTER

AND FUEL PUMP ASSEMBLY ..................... .....

5

Exploded View .................................................... ......5

Removal and Installation ..................................... .....5

Inspection .................................................................7

FUEL TANK ..................................... ..................8

Exploded View ..................................................... .....8

Removal and Installation ..........................................8

Inspection .................................................................9

EVAP CANISTER ..............................................10

Exploded View .........................................................10

Hydraulic Layout ......................................................10

Removal and Installation .........................................12

Disassembly and Assembly .....................................12

Inspection ................................................................12

SERVICE DATA AND SPECIFICATIONS

(SDS) ............... .............................................

13

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................

13

Fuel Tank ............................................................. ....13

Revision: 2010 May2011 QX56

Page 2934 of 5598

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY

FL-5

< REMOVAL AND INSTALLATION >

C

D E

F

G H

I

J

K L

M A

FL

NP

O

REMOVAL AND INSTALLATION

FUEL LEVEL SENSOR UNIT, FUEL FI

LTER AND FUEL PUMP ASSEMBLY

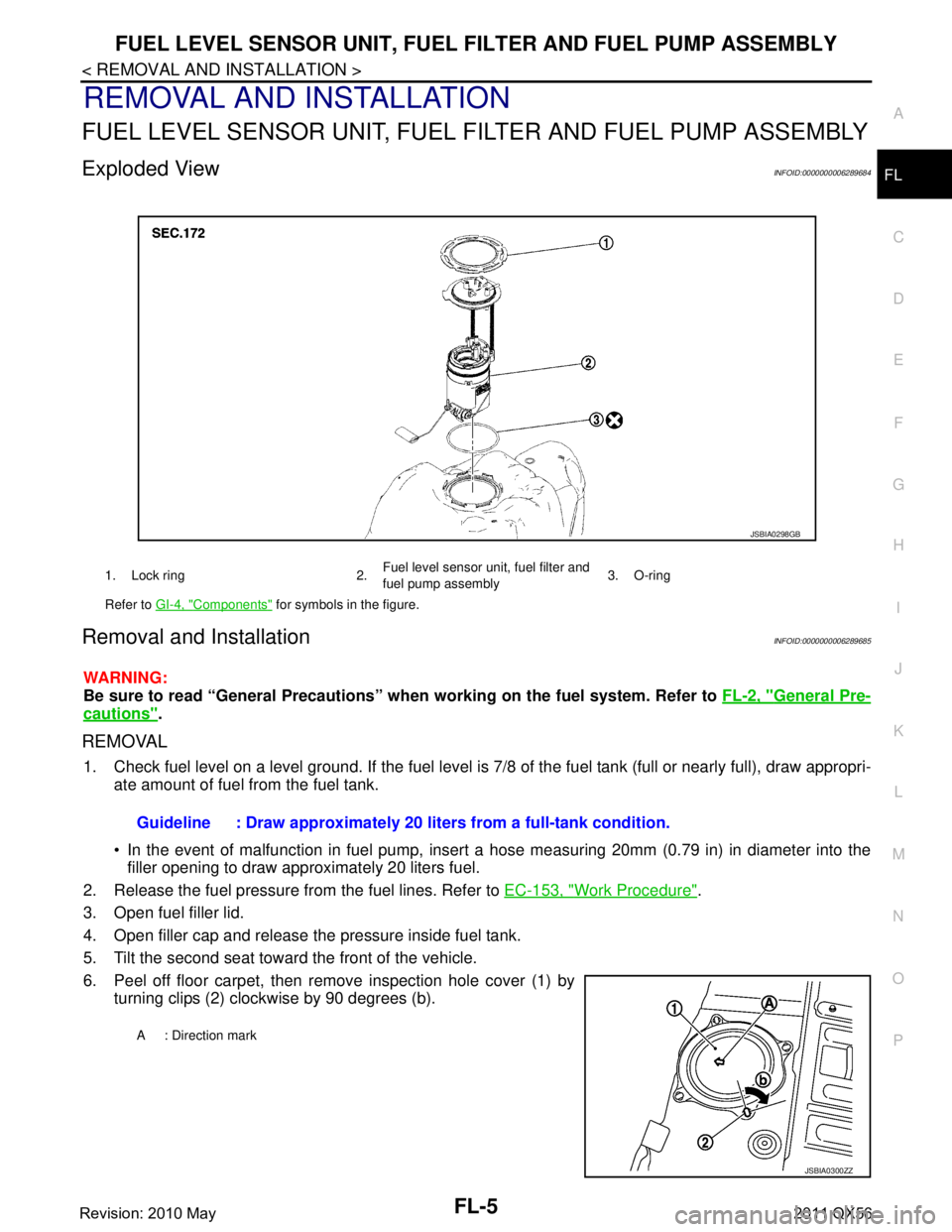

Exploded ViewINFOID:0000000006289684

Removal and InstallationINFOID:0000000006289685

WARNING:

Be sure to read “General Precautions” wh en working on the fuel system. Refer to FL-2, "

General Pre-

cautions".

REMOVAL

1. Check fuel level on a level ground. If the fuel level is 7/8 of the fuel tank (full or nearly full), draw appropri-

ate amount of fuel from the fuel tank.

In the event of malfunction in fuel pump, insert a hose measuring 20mm (0.79 in) in diameter into the

filler opening to draw approximately 20 liters fuel.

2. Release the fuel pressure from the fuel lines. Refer to EC-153, "

Work Procedure".

3. Open fuel filler lid.

4. Open filler cap and release the pressure inside fuel tank.

5. Tilt the second seat toward the front of the vehicle.

6. Peel off floor carpet, then remove inspection hole cover (1) by turning clips (2) clockwise by 90 degrees (b).

1. Lock ring 2. Fuel level sensor unit, fuel filter and

fuel pump assembly3. O-ring

Refer to GI-4, "

Components" for symbols in the figure.

JSBIA0298GB

Guideline : Draw approximately 20 li ters from a full-tank condition.

A : Direction mark

JSBIA0300ZZ

Revision: 2010 May2011 QX56

Page 2935 of 5598

FL-6

< REMOVAL AND INSTALLATION >

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY

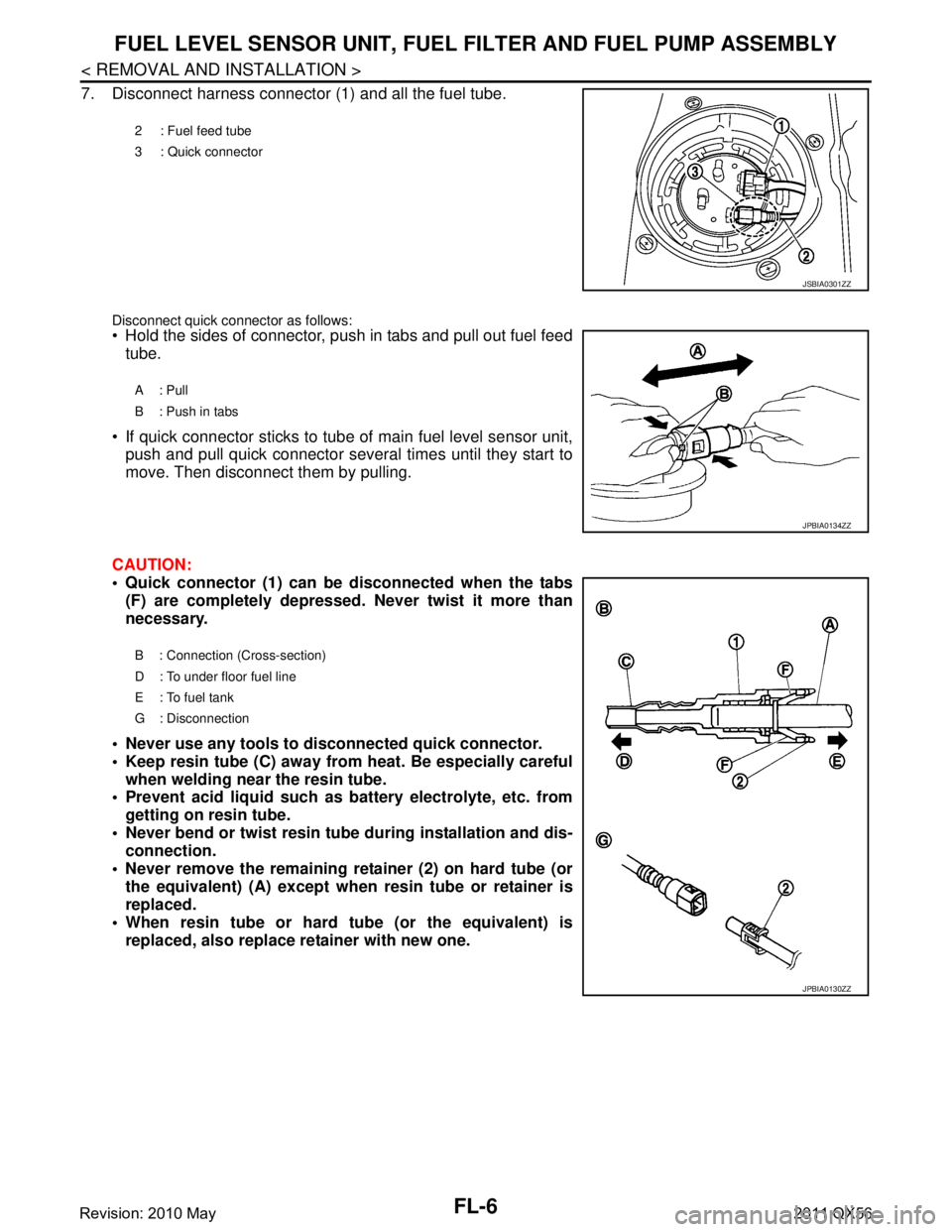

7. Disconnect harness connector (1) and all the fuel tube.

Disconnect quick connector as follows: Hold the sides of connector, push in tabs and pull out fuel feed

tube.

If quick connector sticks to tube of main fuel level sensor unit, push and pull quick connector several times until they start to

move. Then disconnect them by pulling.

CAUTION:

Quick connector (1) can be disconnected when the tabs (F) are completely depressed. Never twist it more than

necessary.

Never use any tools to di sconnected quick connector.

Keep resin tube (C) away from heat. Be especially careful when welding near the resin tube.

Prevent acid liquid such as battery electrolyte, etc. from

getting on resin tube.

Never bend or twist resin tube during installation and dis- connection.

Never remove the remaining retainer (2) on hard tube (or the equivalent) (A) except when resin tube or retainer is

replaced.

When resin tube or hard tube (or the equivalent) is replaced, also replace retainer with new one.

2 : Fuel feed tube

3 : Quick connector

JSBIA0301ZZ

A: Pull

B : Push in tabs

JPBIA0134ZZ

B : Connection (Cross-section)

D : To under floor fuel line

E : To fuel tank

G : Disconnection

JPBIA0130ZZ

Revision: 2010 May2011 QX56

Page 2936 of 5598

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY

FL-7

< REMOVAL AND INSTALLATION >

C

D E

F

G H

I

J

K L

M A

FL

NP

O

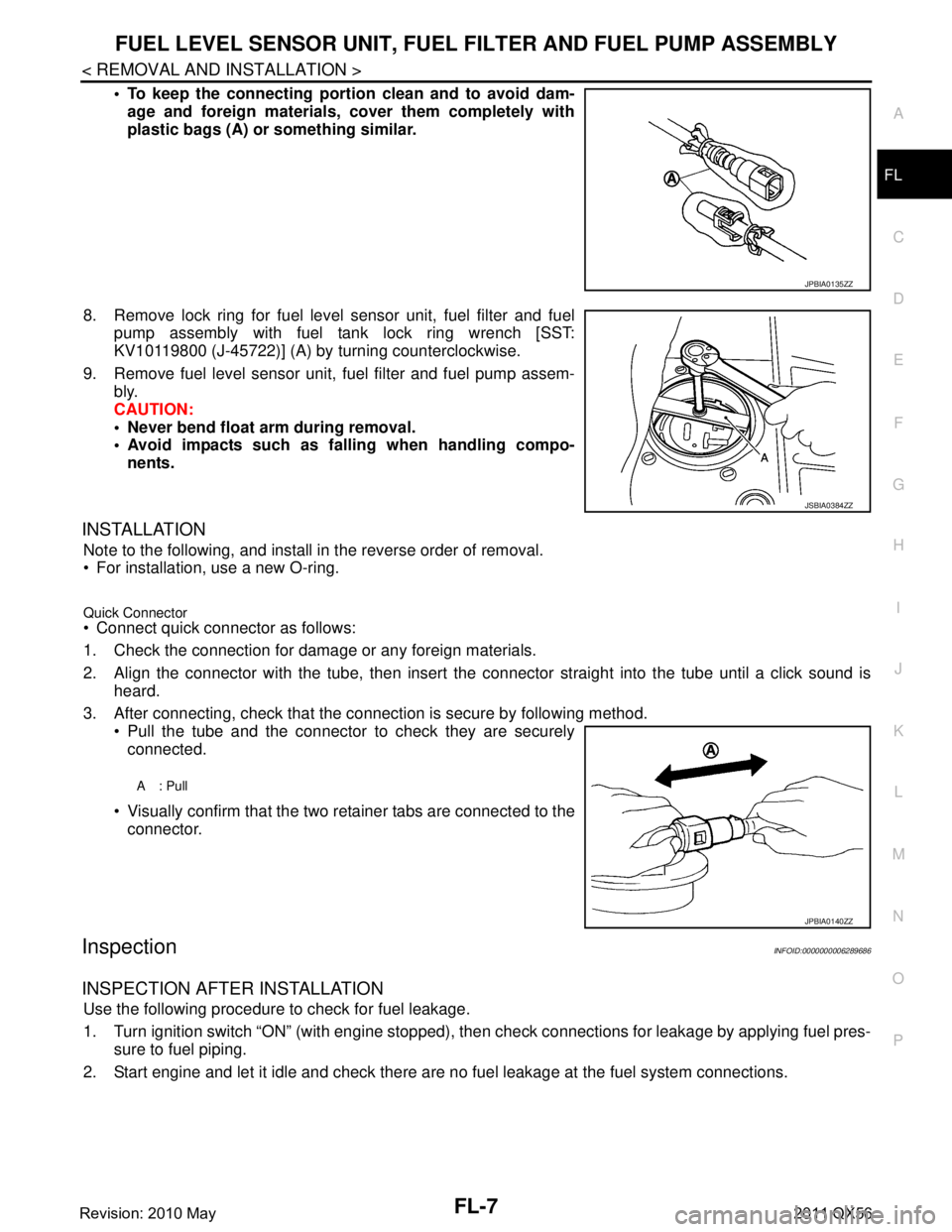

To keep the connecting portio

n clean and to avoid dam-

age and foreign materials, cover them completely with

plastic bags (A) or something similar.

8. Remove lock ring for fuel level sensor unit, fuel filter and fuel pump assembly with fuel tank lock ring wrench [SST:

KV10119800 (J-45722)] (A) by turning counterclockwise.

9. Remove fuel level sensor unit, fuel filter and fuel pump assem- bly.

CAUTION:

Never bend float arm during removal.

Avoid impacts such as fa lling when handling compo-

nents.

INSTALLATION

Note to the following, and install in the reverse order of removal.

For installation, use a new O-ring.

Quick Connector Connect quick connector as follows:

1. Check the connection for damage or any foreign materials.

2. Align the connector with the tube, then insert the connector straight into the tube until a click sound is

heard.

3. After connecting, check that the connection is secure by following method. Pull the tube and the connector to check they are securely

connected.

Visually confirm that the two retainer tabs are connected to the connector.

InspectionINFOID:0000000006289686

INSPECTION AFTER INSTALLATION

Use the following procedure to check for fuel leakage.

1. Turn ignition switch “ON” (with engine stopped), then check connections for leakage by applying fuel pres-

sure to fuel piping.

2. Start engine and let it idle and check there are no fuel leakage at the fuel system connections.

JPBIA0135ZZ

JSBIA0384ZZ

A: Pull

JPBIA0140ZZ

Revision: 2010 May2011 QX56

Page 2937 of 5598

FL-8

< REMOVAL AND INSTALLATION >

FUEL TANK

FUEL TANK

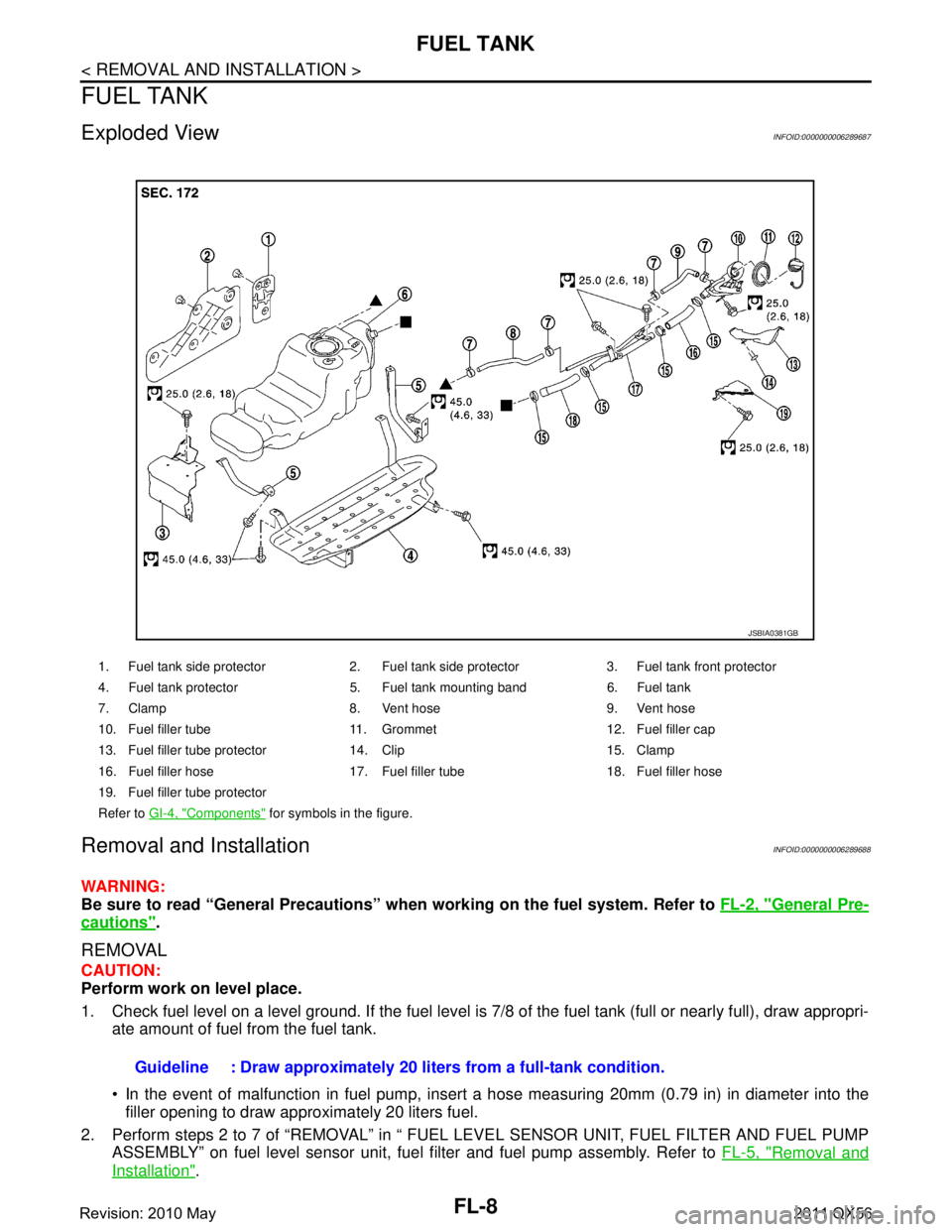

Exploded ViewINFOID:0000000006289687

Removal and InstallationINFOID:0000000006289688

WARNING:

Be sure to read “General Precautions” when working on the fuel system. Refer to FL-2, "

General Pre-

cautions".

REMOVAL

CAUTION:

Perform work on level place.

1. Check fuel level on a level ground. If the fuel level is 7/8 of the fuel tank (full or nearly full), draw appropri-

ate amount of fuel from the fuel tank.

In the event of malfunction in fuel pump, insert a hose measuring 20mm (0.79 in) in diameter into the

filler opening to draw approximately 20 liters fuel.

2. Perform steps 2 to 7 of “REMOVAL” in “ FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY” on fuel level sensor unit, fuel filter and fuel pump assembly. Refer to FL-5, "

Removal and

Installation".

1. Fuel tank side protector 2. Fuel tank side protector 3. Fuel tank front protector

4. Fuel tank protector 5. Fuel tank mounting band 6. Fuel tank

7. Clamp 8. Vent hose 9. Vent hose

10. Fuel filler tube 11. Grommet 12. Fuel filler cap

13. Fuel filler tube protector 14. Clip 15. Clamp

16. Fuel filler hose 17. Fuel filler tube 18. Fuel filler hose

19. Fuel filler tube protector

Refer to GI-4, "

Components" for symbols in the figure.

JSBIA0381GB

Guideline : Draw approximately 20 li ters from a full-tank condition.

Revision: 2010 May2011 QX56

Page 2995 of 5598

PRECAUTIONSGI-31

< PRECAUTION >

C

DE

F

G H

I

J

K L

M B

GI

N

O P

Dispose of used oil and used oil filters through authorized waste disposal contractors to licensed waste dis-

posal sites, or to the waste oil reclamation trade. If in doubt, contact the local authority for advice on disposal

facilities.

It is illegal to pour used oil on to the ground, dow n sewers or drains, or into water sources.

The regulations concerning po llution vary between regions.

Air ConditioningINFOID:0000000006280875

Use an approved refrigerant recovery unit any time t he air conditioning system must be discharged. Refer to

HA section “REFRIGERANT” fo r specific instructions.

FuelINFOID:0000000006280876

INFINITI recommends the use of unleaded premium gasoli ne with an octane rating of at least 91 AKI (Anti-

Knock Index) number (Research octane number 96).

If unleaded premium gasoline is not available, unleaded r egular gasoline with an octane rating of at least 87

AKI number (Research octane number 91), can be used. In such case, engine performance may be decrease.

CAUTION:

Using a fuel other than that specified could ad versely affect the emission control system, and may

also affect warranty coverage.

Under no circumstances should a leaded gasoline be used, because this will damage the three-way

catalyst.

Do not use E-85 fuel in the vehicle . The vehicle is not designed to run on E-85 fuel. Using E-85 fuel

can damage the fuel system components and is not covered by the INFINITI vehicle limited warranty.

Revision: 2010 May2011 QX56

Page 3671 of 5598

MA-1

MAINTENANCE

C

DE

F

G H

I

J

K L

M B

MA

SECTION MA

N

O A

CONTENTS

MAINTENANCE

PREPARATION .............

...............................3

PREPARATION .............................................. .....3

Special Service Tool ........................................... ......3

Commercial Service Tool ..........................................3

PERIODIC MAINTENANCE ..........................4

GENERAL MAINTENANCE ........................... .....4

Explanation of General Maintenance .................. ......4

PERIODIC MAINTENANCE ................................6

Introduction of Periodic Maintenance .................. ......6

Schedule 1 ................................................................6

Schedule 2 ................................................................8

RECOMMENDED FLUIDS AND LUBRI-

CANTS ................................................................

10

Fluids and Lubricants .......................................... ....10

Engine Oil Recommendation ..................................10

Anti-Freeze Coolant Mixture Ratio ..........................11

ENGINE MAINTENANCE ...................................12

DRIVE BELTS ....................................................... ....12

DRIVE BELTS : Exploded View ..............................12

DRIVE BELTS : Checking .......................................12

DRIVE BELTS : Tension Adjustment .....................12

ENGINE COOLANT ............................................... ....12

ENGINE COOLANT : Inspection .............................12

ENGINE COOLANT : Draining ................................13

ENGINE COOLANT : Refilling ................................13

ENGINE COOLANT : Flushing ...............................15

RESERVOIR TANK CAP ..........................................15

RESERVOIR TANK CAP : Inspection ................. ....15

RADIATOR ............................................................ ....16

RADIATOR : Inspection ..........................................16

FUEL LINES .......................................................... ....16

FUEL LINES : Inspection ........................................17

AIR CLEANER FILTER ......................................... ....17

AIR CLEANER FILTER : Removal and Installation

....

17

ENGINE OIL ........................................................... ....17

ENGINE OIL : Draining ............................................17

ENGINE OIL : Refilling ............................................17

OIL FILTER ............................................................ ....18

OIL FILTER : Removal and Installation ...................18

SPARK PLUG ........................................................ ....18

SPARK PLUG : Removal and Installation ...............19

SPARK PLUG : Inspection ......................................19

EVAP VAPOR LINES ............................................ ....20

EVAP VAPOR LINES : Inspection ...........................20

CHASSIS MAINTENANCE ...............................21

EXHAUST SYSTEM . ..................................................21

EXHAUST SYSTEM : Inspec tion ............................21

A/T FLUID .............................................................. ....21

A/T FLUID : Inspection ............................................21

TRANSFER FLUID ................................................ ....21

TRANSFER FLUID : Inspection ..............................21

TRANSFER FLUID : Draining .................................21

TRANSFER FLUID : Refilling ..................................22

FRONT PROPELLER SHAFT: 2F P15 ................. ....22

FRONT PROPELLER SHAFT: 2F P15 : Inspec-

tion ...........................................................................

22

REAR PROPELLER SHAFT: 2F P26 .................... ....23

REAR PROPELLER SHAFT: 2F P26 : Inspection ....23

REAR PROPELLER SHAFT: 2S1410 ................... ....23

REAR PROPELLER SHAFT: 2S1410 : Inspection ....23

FRONT DIFFERENTIAL GEAR OIL: R180A ........ ....24

FRONT DIFFERENTIAL GEAR OIL: R180A : In-

spection ...................................................................

24

Revision: 2010 May2011 QX56

Page 3676 of 5598

MA-6

< PERIODIC MAINTENANCE >

PERIODIC MAINTENANCE

PERIODIC MAINTENANCE

Introduction of Periodic MaintenanceINFOID:0000000006287729

Two different maintenance schedules are provided, and should be used, depending upon the conditions in

which the vehicle is mainly operated. After 60,000 miles (96,000 km) or 48 months, continue the periodic

maintenance at the same mileage/time intervals.

Schedule 1INFOID:0000000006287730

EMISSION CONTROL SYSTEM

Abbreviations: R = Replace. I = Inspec t. Correct or replace if necessary. [ ]: At the mileage intervals only

Schedule 1Follow Periodic Maintenance Schedule 1 if the driving habits frequently include

one or more of the following driving conditions:

Repeated short trips of less than 5 miles (8 km).

Repeated short trips of less than 10 miles (16 km) with outside temperatures

remaining below freezing.

Operating in hot weather in stop-and-go “rush hour” traffic.

Extensive idling and/or low speed driving for long distances, such as police, taxi

or door-to-door delivery use.

Driving in dusty conditions.

Driving on rough, muddy, or salt spread roads.

Towing a trailer, using a camper or a car-top carrier. Emission Control Sys-

tem Maintenance

MA-6Chassis and Body

Maintenance

Schedule 2 Follow Periodic Maintenance Schedule 2 if none of driving conditions shown in

Schedule 1 apply to the driving habits. Emission Control Sys-

tem Maintenance

MA-8

Chassis and Body

Maintenance

MAINTENANCE OPERATION MAINTENANCE INTERVAL

Reference

Section -

Page or -

Content Title

Perform at number of miles,

kilometers or months, which-

ever comes first. Miles x 1,000

(km x 1,000) Months 3.75

(6)3 7.50

(12) 6 11 . 2 5

(18) 9 15

(24) 12 18.75

(30)15 22.5

(36) 18 26.25

(42)21 30

(48) 24

Drive belts NOTE (1) MA-12

Air cleaner filter NOTE (2) [R]MA-17

EVAP vapor linesI*MA-20

Fuel lines I*MA-17

Fuel filter NOTE (3) —

Engine coolant* NOTE (4) MA-13

Engine oil R R R R R R R RMA-17

Engine oil filter (Use genuine

NISSAN engine oil filter or

equivalent.)R R RRRRR R

MA-18

Spark plugs (Iridium-tipped

type)Replace every 105,000 miles (168,000 km).

MA-19

Intake & exhaust valve clear-

ance*NOTE (5)

EM-12

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Reference

Section -

Page or -

Content Title

Perform at number of miles,

kilometers or months, which-

ever comes first. Miles x 1,000

(km x 1,000) Months 33.75

(54)27 37.5

(60) 30 41.25

(66)33 45

(72) 36 48.75

(78)39 52.5

(84) 42 56.25

(90)45 60

(96) 48

Drive belts NOTE (1) I* MA-12

Air cleaner filter NOTE (2) [R]MA-17

EVAP vapor linesI*MA-20

Fuel lines I*MA-17

Revision: 2010 May2011 QX56

Page 3677 of 5598

PERIODIC MAINTENANCEMA-7

< PERIODIC MAINTENANCE >

C

DE

F

G H

I

J

K L

M B

MA

N

O A

NOTE:

(1) After 60,000 miles (96,000 km) or 48 months, inspect every 15,000 miles (24,000 km) or 12 months. Replace the drive belts i

f found

damaged or if the auto belt tensioner reading reaches the maximum limit.

(2) If operating mainly in dusty conditions, more frequent maintenance may be required.

(3) Maintenance-free item. For service procedures, refer to FL section.

(4) First replacement interval is 105,000 miles (168,000 km) or 84 months. After first replacement, replace every 75,000 miles (120,000

km) or 60 months. Use only Genu ine NISSAN Long Life Antifreeze/Coo lant (blue) or equivalent with proper mixture ratio of 50% anti-

freeze and 50% demineralized or distilled water. Mixing any other type of coolant or the use of non-distilled water will reduce the life

expectancy of the factory-fill coolant.

(5) Periodic maintenance is not required. However, if valve noise increases, inspect valve clearance.

* Maintenance items and intervals with “*” are recommended by INFINITI for reliable vehicle operation. The owner need not perfo rm

such maintenance in order to maintain the emission warranty or manufacturer recall liability. Other maintenance items and inter vals are

required.

CHASSIS AND BODY

Abbreviations: R = Replace. I = Inspec t. Correct or replace if necessary.

Fuel filter NOTE (3) —

Engine coolant* NOTE (4) MA-13

Engine oil R R R R R R R RMA-17

Engine oil filter (Use genuine

NISSAN engine oil filter or

equivalent.)R R RRRRRR

MA-18

Spark plugs (Iridium-tipped

type)Replace every 105,000 miles (168,000 km).

MA-19

Intake & exhaust valve clear-

ance*NOTE (5)

EM-12

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Reference

Section -

Page or -

Content Title

Perform at number of miles,

kilometers or months, which-

ever comes first. Miles x 1,000

(km x 1,000)

Months 33.75

(54)

27 37.5

(60)

30 41.25

(66)

33 45

(72)

36 48.75

(78)

39 52.5

(84)

42 56.25

(90)

45 60

(96)

48

MAINTENANCE OPERATION MAINTENANCE INTERVAL

Reference

Section -

Page or - Con- tent Title

Perform at number of miles,

kilometers or months,

whichever comes first. Miles x 1,000

(km x 1,000)

Months 3.75

(6)

3 7.50

(12)

6 11 . 2 5

(18)

9 15

(24)

12 18.75

(30)

15 22.5

(36)

18 26.25

(42)

21 30

(48)

24

Brake lines & cables I I MA-28

Brake fluid R RMA-28

Brake pads & rotors I I I IMA-30

BR-16

BR-18

BR-16

BR-18

Transfer fluid & differential

gear oil

NOTE (1) I I MA-21MA-24

MA-25

Automatic transmission flu-

id

NOTE (2)

—

Steering gear & linkage,

axle & suspension parts IIII

MA-31

MA-32

Tire rotation NOTE (3) MA-4WT-63

Drive shaft boots and pro-

peller shaft (4WD models) IIII MA-33MA-22

MA-23

MA-23

Revision: 2010 May2011 QX56