warning ISUZU AXIOM 2002 Service User Guide

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2002, Model line: AXIOM, Model: ISUZU AXIOM 2002Pages: 2100, PDF Size: 19.35 MB

Page 185 of 2100

2A±34

POWER±ASSISTED STEERING SYSTEM

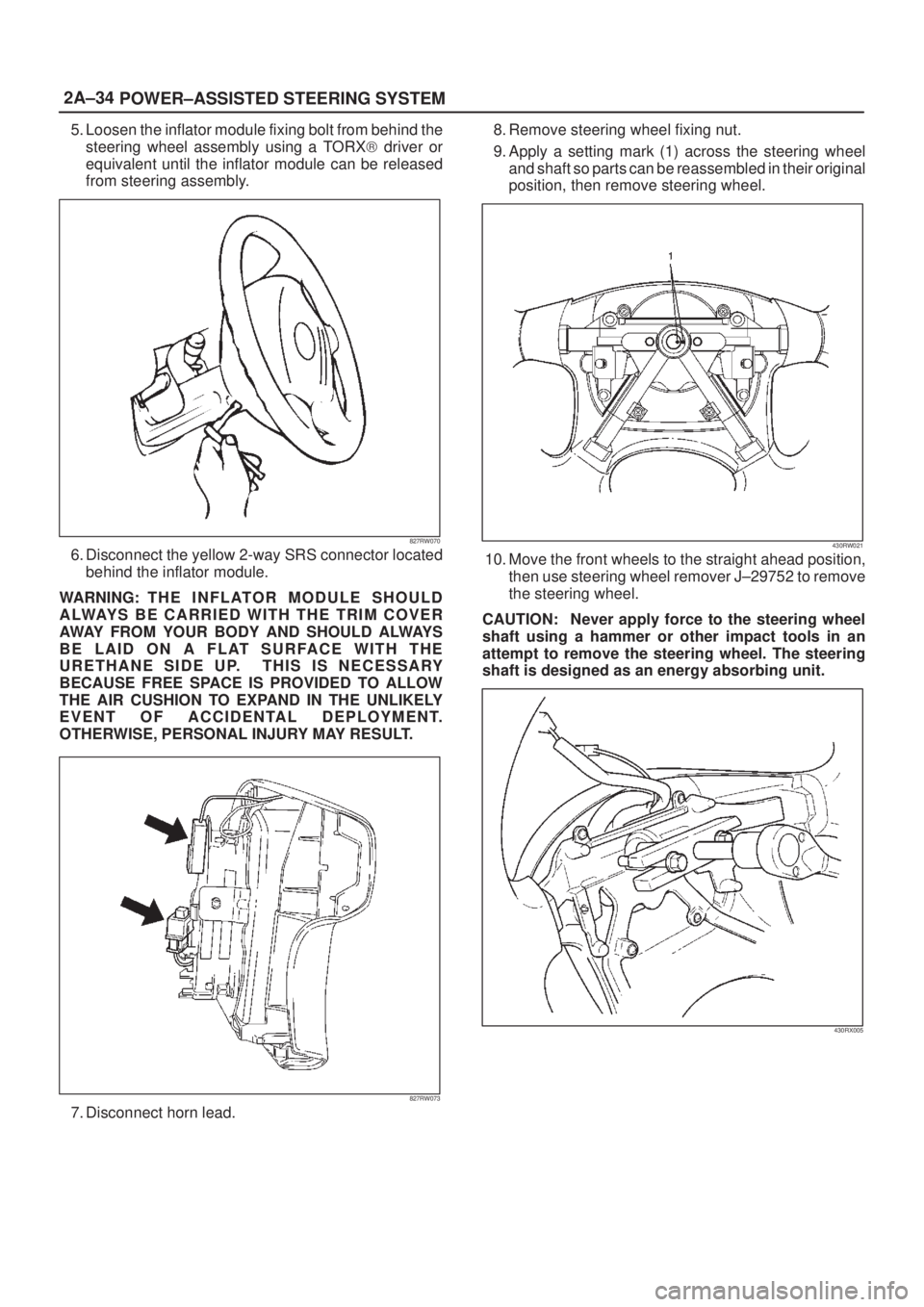

5. Loosen the inflator module fixing bolt from behind the

steering wheel assembly using a TORX) driver or

equivalent until the inflator module can be released

from steering assembly.

827RW070

6. Disconnect the yellow 2-way SRS connector located

behind the inflator module.

WARNING: T H E I N F L AT O R M O D U L E S H O U L D

ALWAYS BE CARRIED WITH THE TRIM COVER

AWAY FROM YOUR BODY AND SHOULD ALWAYS

BE LAID ON A FLAT SURFACE WITH THE

URETHANE SIDE UP. THIS IS NECESSARY

BECAUSE FREE SPACE IS PROVIDED TO ALLOW

THE AIR CUSHION TO EXPAND IN THE UNLIKELY

EVENT OF ACCIDENTAL DEPLOYMENT.

OTHERWISE, PERSONAL INJURY MAY RESULT.

827RW073

7. Disconnect horn lead.8. Remove steering wheel fixing nut.

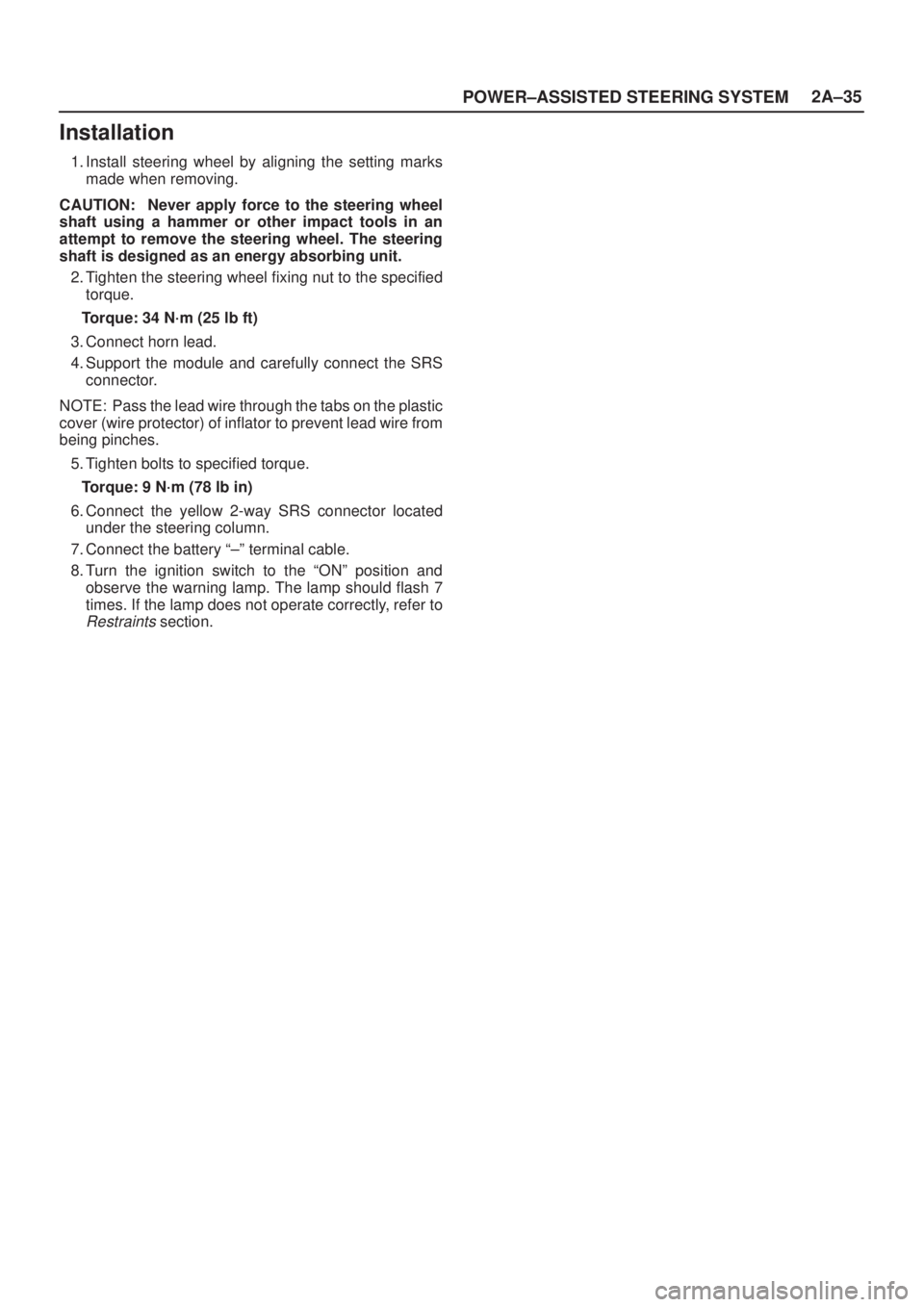

9. Apply a setting mark (1) across the steering wheel

and shaft so parts can be reassembled in their original

position, then remove steering wheel.

430RW021

10. Move the front wheels to the straight ahead position,

then use steering wheel remover J±29752 to remove

the steering wheel.

CAUTION: Never apply force to the steering wheel

shaft using a hammer or other impact tools in an

attempt to remove the steering wheel. The steering

shaft is designed as an energy absorbing unit.

430RX005

Page 186 of 2100

POWER±ASSISTED STEERING SYSTEM2A±35

Installation

1. Install steering wheel by aligning the setting marks

made when removing.

CAUTION: Never apply force to the steering wheel

shaft using a hammer or other impact tools in an

attempt to remove the steering wheel. The steering

shaft is designed as an energy absorbing unit.

2. Tighten the steering wheel fixing nut to the specified

torque.

Torque: 34 N´m (25 lb ft)

3. Connect horn lead.

4. Support the module and carefully connect the SRS

connector.

NOTE: Pass the lead wire through the tabs on the plastic

cover (wire protector) of inflator to prevent lead wire from

being pinches.

5. Tighten bolts to specified torque.

Torque: 9 N´m (78 lb in)

6. Connect the yellow 2-way SRS connector located

under the steering column.

7. Connect the battery ª±º terminal cable.

8. Turn the ignition switch to the ªONº position and

observe the warning lamp. The lamp should flash 7

times. If the lamp does not operate correctly, refer to

Restraints section.

Page 188 of 2100

POWER±ASSISTED STEERING SYSTEM2A±37

7. Loosen the inflator module fixing bolt from behind the

steering wheel assembly using a TORX) driver or

equivalent until the inflator module can be released

from steering assembly. Disconnect the yellow 2-way

SRS connector and horn lead located behind the

inflator module, then remove inflator module.

827RW070

827RW073

WARNING: T H E I N F L AT O R M O D U L E S H O U L D

ALWAYS BE CARRIED WITH THE TRIM COVER

AWAY FROM YOUR BODY AND SHOULD ALWAYS

BE LAID ON A FLAT SURFACE WITH THE

URETHANE SIDE UP. THIS IS NECESSARY

BECAUSE FREE SPACE IS PROVIDED TO ALLOW

THE AIR CUSHION TO EXPAND IN THE UNLIKELY

EVENT OF ACCIDENTAL DEPLOYMENT.

OTHERWISE, PERSONAL INJURY MAY RESULT.

827RW072

8. Apply a setting mark (1) across the steering wheel

and shaft so parts can be reassembled in their original

position. Move the front wheels to the straight ahead

position, then use steering wheel remover J±29752 to

remove the steering wheel.

430RW021

Page 190 of 2100

POWER±ASSISTED STEERING SYSTEM2A±39

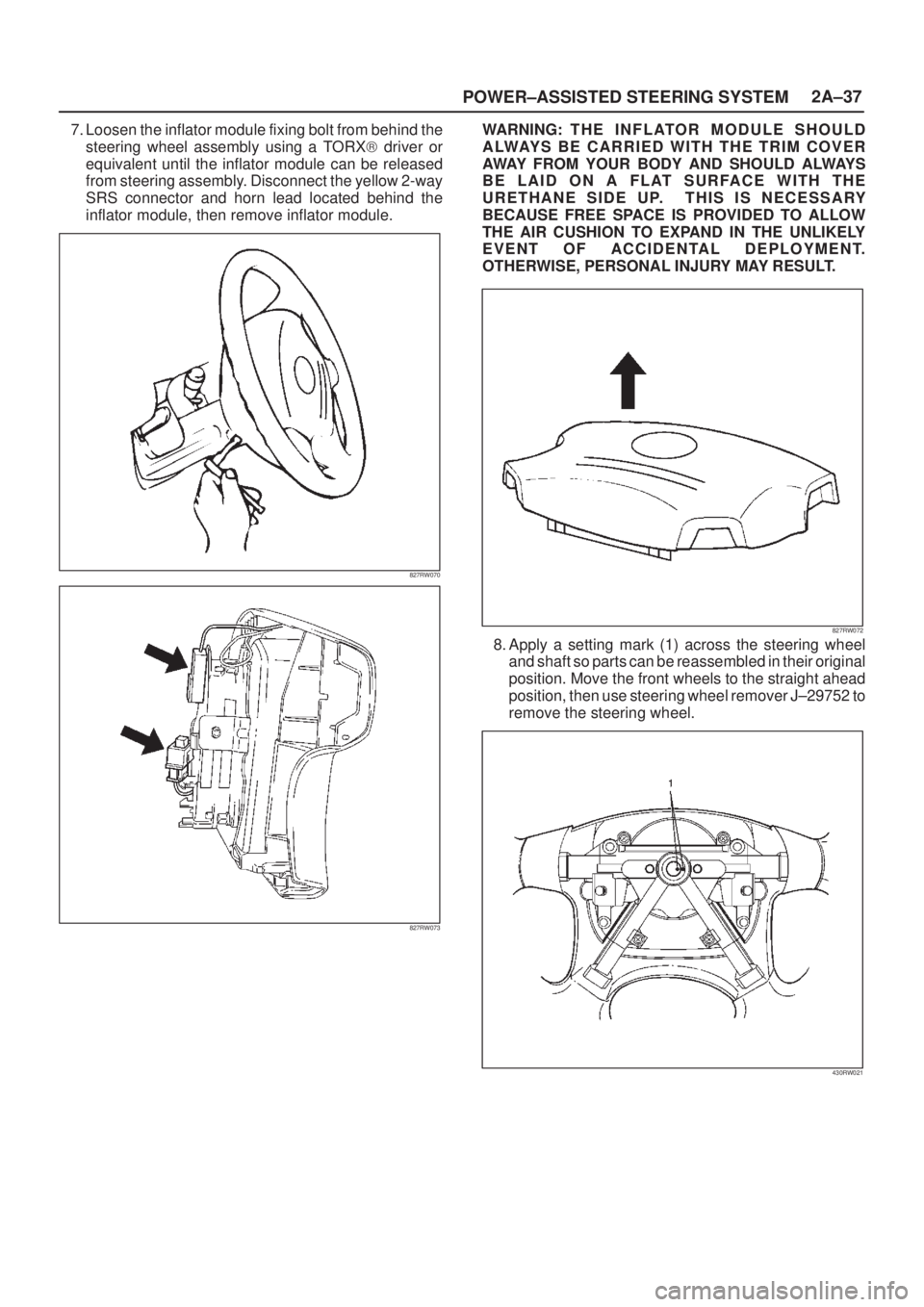

2. When installing the steering column cover, be sure to

route each wire harness as illustrated so that the

harnesses do not catch on any moving parts.

825RW017

Legend

(1) Steering Column Cover

(2) Starter Switch Harness

(3) Combination Switch Harness

(4) Inflator Module Harness

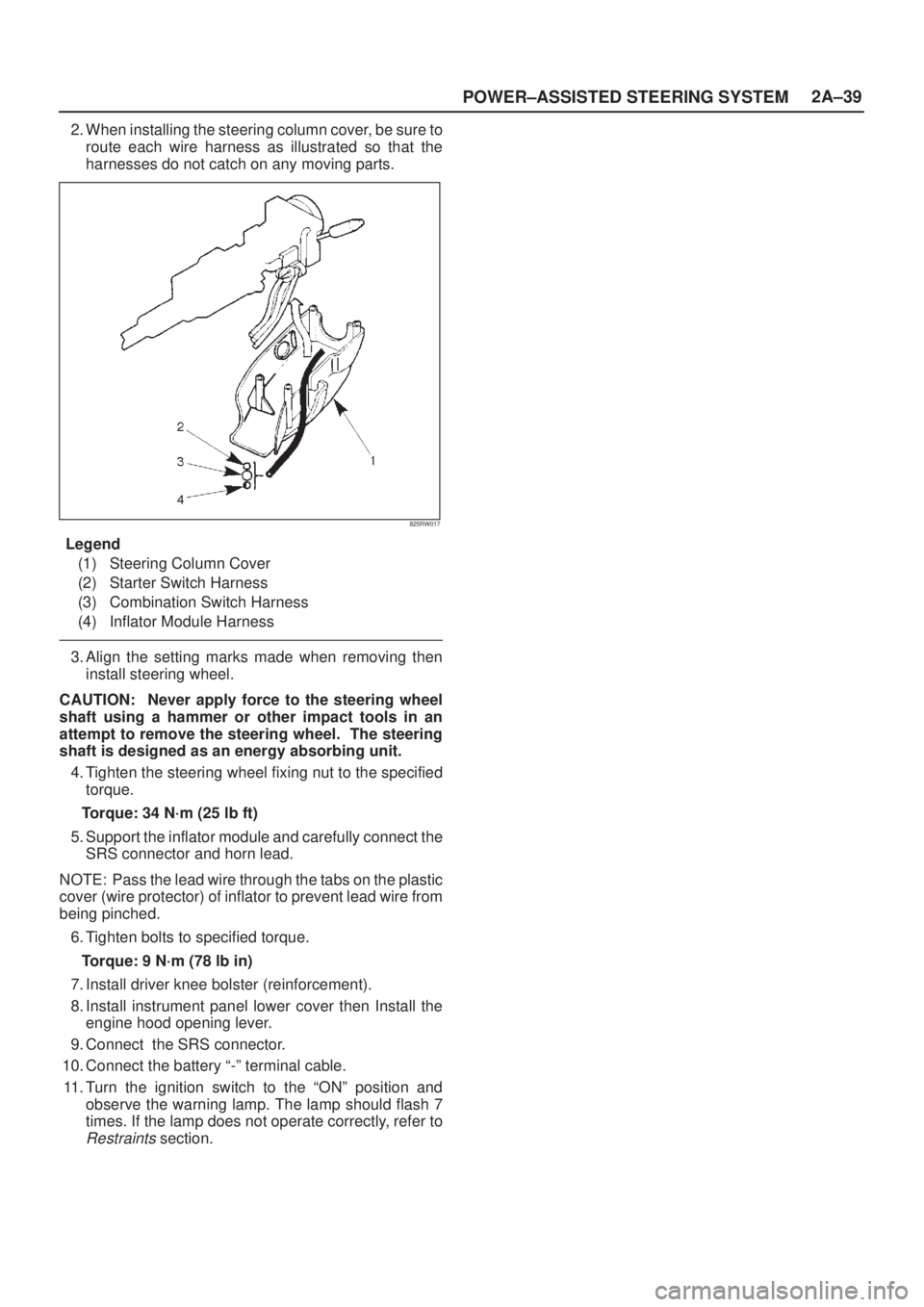

3. Align the setting marks made when removing then

install steering wheel.

CAUTION: Never apply force to the steering wheel

shaft using a hammer or other impact tools in an

attempt to remove the steering wheel. The steering

shaft is designed as an energy absorbing unit.

4. Tighten the steering wheel fixing nut to the specified

torque.

Torque: 34 N´m (25 lb ft)

5. Support the inflator module and carefully connect the

SRS connector and horn lead.

NOTE: Pass the lead wire through the tabs on the plastic

cover (wire protector) of inflator to prevent lead wire from

being pinched.

6. Tighten bolts to specified torque.

Torque: 9 N´m (78 lb in)

7. Install driver knee bolster (reinforcement).

8. Install instrument panel lower cover then Install the

engine hood opening lever.

9. Connect the SRS connector.

10. Connect the battery ª-º terminal cable.

11. Turn the ignition switch to the ªONº position and

observe the warning lamp. The lamp should flash 7

times. If the lamp does not operate correctly, refer to

Restraints section.

Page 193 of 2100

2A±42

POWER±ASSISTED STEERING SYSTEM

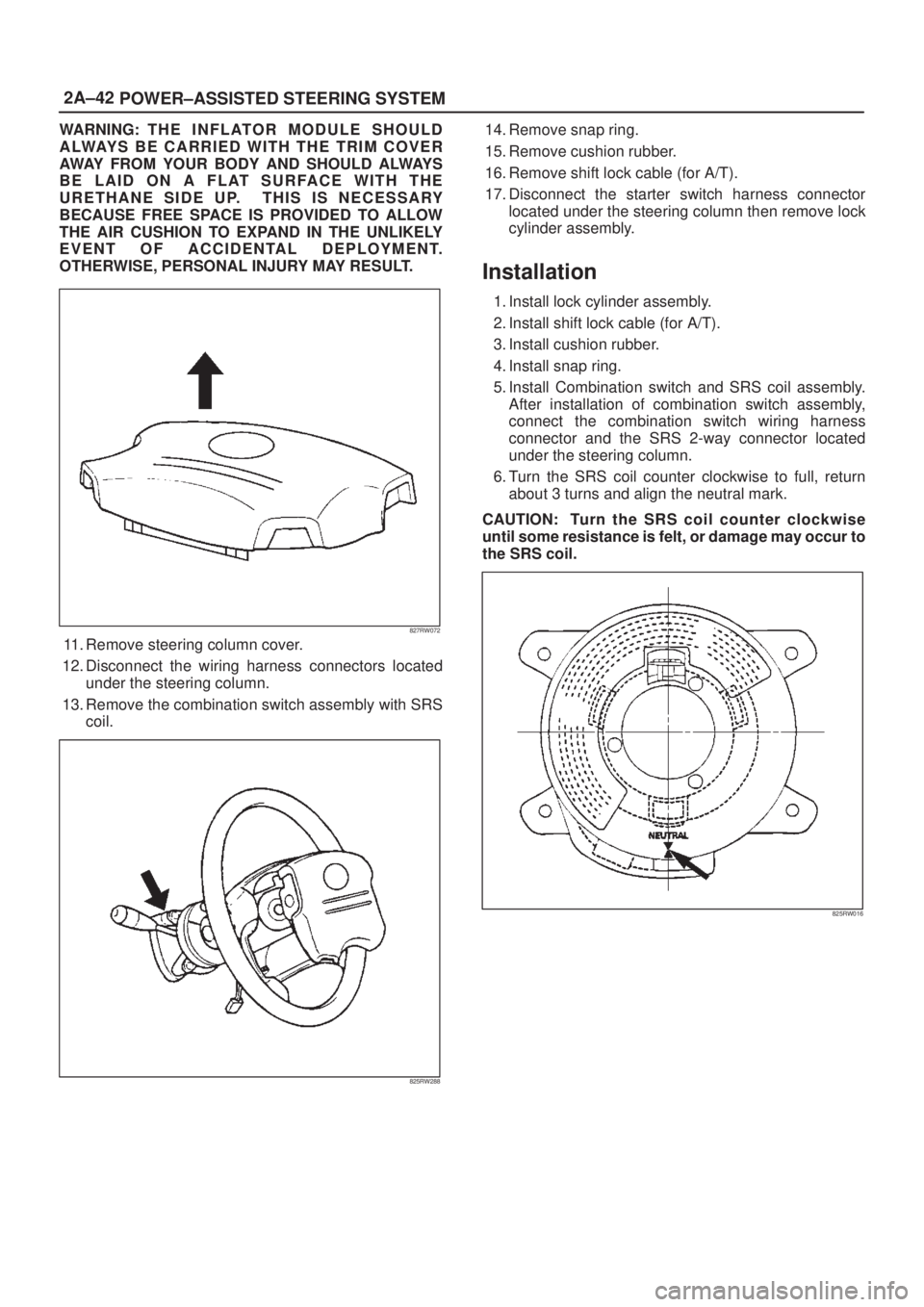

WARNING: T H E I N F L AT O R M O D U L E S H O U L D

ALWAYS BE CARRIED WITH THE TRIM COVER

AWAY FROM YOUR BODY AND SHOULD ALWAYS

BE LAID ON A FLAT SURFACE WITH THE

URETHANE SIDE UP. THIS IS NECESSARY

BECAUSE FREE SPACE IS PROVIDED TO ALLOW

THE AIR CUSHION TO EXPAND IN THE UNLIKELY

EVENT OF ACCIDENTAL DEPLOYMENT.

OTHERWISE, PERSONAL INJURY MAY RESULT.

827RW072

11. Remove steering column cover.

12. Disconnect the wiring harness connectors located

under the steering column.

13. Remove the combination switch assembly with SRS

coil.

825RW288

14. Remove snap ring.

15. Remove cushion rubber.

16. Remove shift lock cable (for A/T).

17. Disconnect the starter switch harness connector

located under the steering column then remove lock

cylinder assembly.

Installation

1. Install lock cylinder assembly.

2. Install shift lock cable (for A/T).

3. Install cushion rubber.

4. Install snap ring.

5. Install Combination switch and SRS coil assembly.

After installation of combination switch assembly,

connect the combination switch wiring harness

connector and the SRS 2-way connector located

under the steering column.

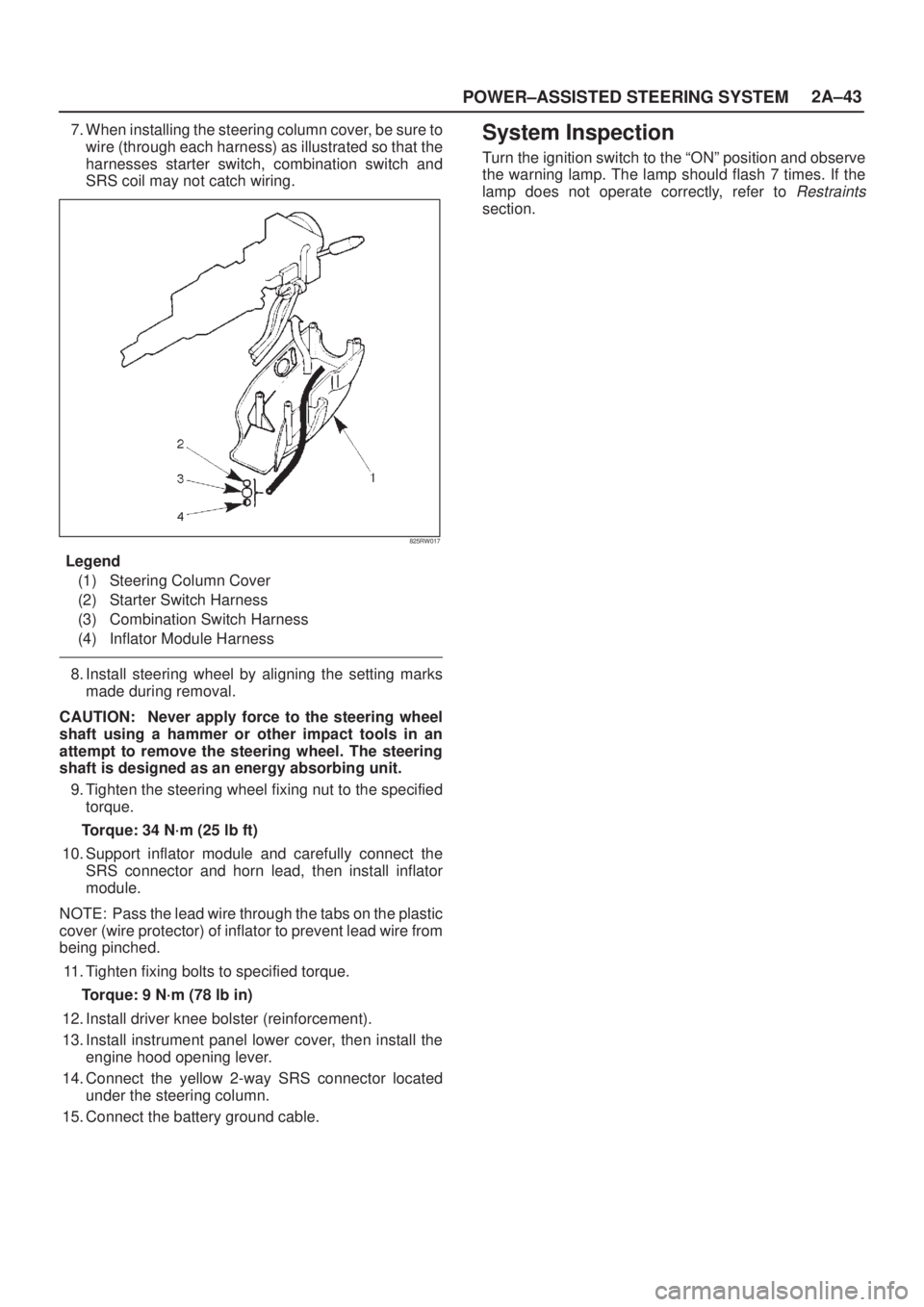

6. Turn the SRS coil counter clockwise to full, return

about 3 turns and align the neutral mark.

CAUTION: Turn the SRS coil counter clockwise

until some resistance is felt, or damage may occur to

the SRS coil.

825RW016

Page 194 of 2100

POWER±ASSISTED STEERING SYSTEM2A±43

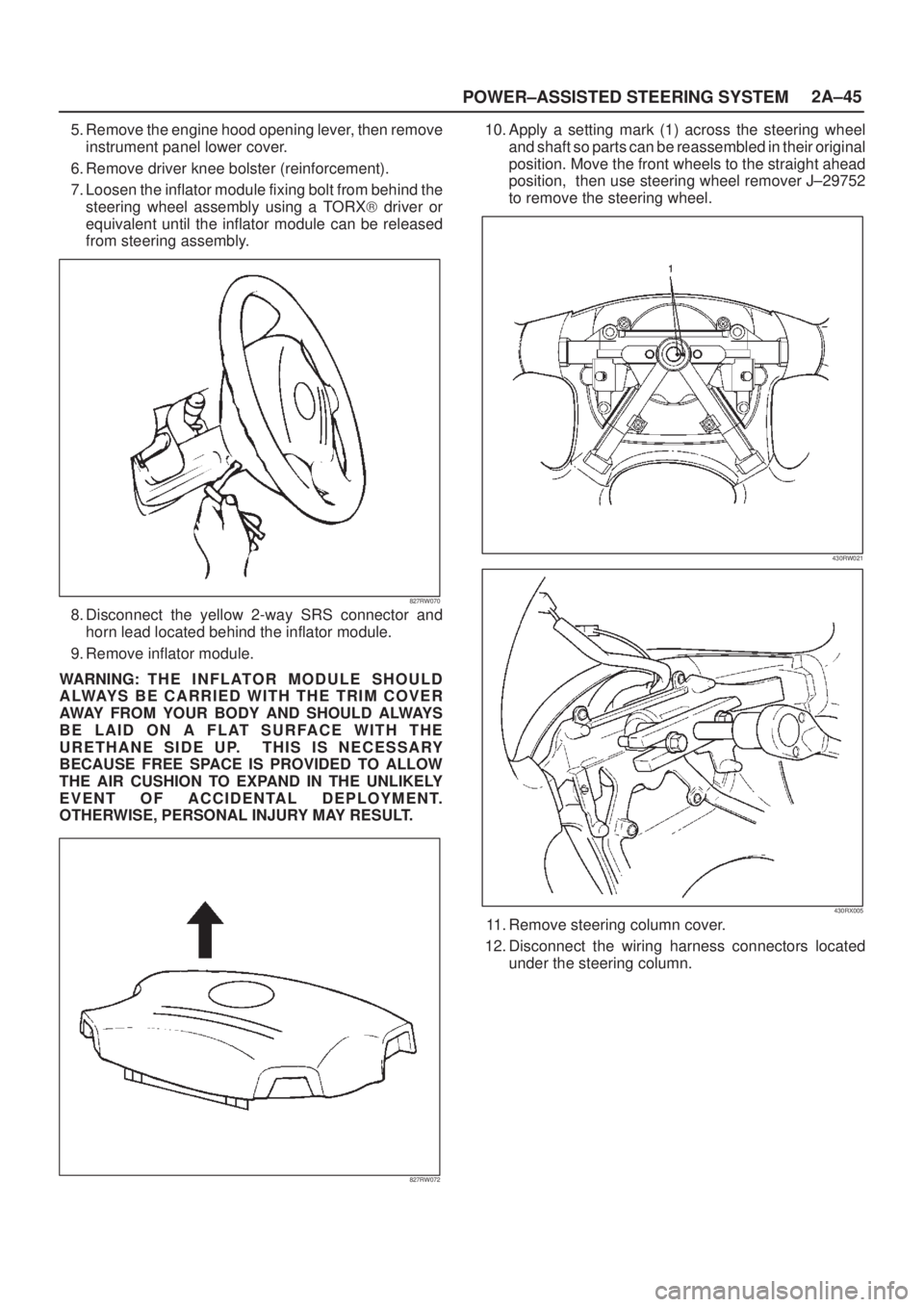

7. When installing the steering column cover, be sure to

wire (through each harness) as illustrated so that the

harnesses starter switch, combination switch and

SRS coil may not catch wiring.

825RW017

Legend

(1) Steering Column Cover

(2) Starter Switch Harness

(3) Combination Switch Harness

(4) Inflator Module Harness

8. Install steering wheel by aligning the setting marks

made during removal.

CAUTION: Never apply force to the steering wheel

shaft using a hammer or other impact tools in an

attempt to remove the steering wheel. The steering

shaft is designed as an energy absorbing unit.

9. Tighten the steering wheel fixing nut to the specified

torque.

Torque: 34 N´m (25 lb ft)

10. Support inflator module and carefully connect the

SRS connector and horn lead, then install inflator

module.

NOTE: Pass the lead wire through the tabs on the plastic

cover (wire protector) of inflator to prevent lead wire from

being pinched.

11. Tighten fixing bolts to specified torque.

Torque: 9 N´m (78 lb in)

12. Install driver knee bolster (reinforcement).

13. Install instrument panel lower cover, then install the

engine hood opening lever.

14. Connect the yellow 2-way SRS connector located

under the steering column.

15. Connect the battery ground cable.

System Inspection

Turn the ignition switch to the ªONº position and observe

the warning lamp. The lamp should flash 7 times. If the

lamp does not operate correctly, refer to

Restraints

section.

Page 196 of 2100

POWER±ASSISTED STEERING SYSTEM2A±45

5. Remove the engine hood opening lever, then remove

instrument panel lower cover.

6. Remove driver knee bolster (reinforcement).

7. Loosen the inflator module fixing bolt from behind the

steering wheel assembly using a TORX) driver or

equivalent until the inflator module can be released

from steering assembly.

827RW070

8. Disconnect the yellow 2-way SRS connector and

horn lead located behind the inflator module.

9. Remove inflator module.

WARNING: T H E I N F L AT O R M O D U L E S H O U L D

ALWAYS BE CARRIED WITH THE TRIM COVER

AWAY FROM YOUR BODY AND SHOULD ALWAYS

BE LAID ON A FLAT SURFACE WITH THE

URETHANE SIDE UP. THIS IS NECESSARY

BECAUSE FREE SPACE IS PROVIDED TO ALLOW

THE AIR CUSHION TO EXPAND IN THE UNLIKELY

EVENT OF ACCIDENTAL DEPLOYMENT.

OTHERWISE, PERSONAL INJURY MAY RESULT.

827RW072

10. Apply a setting mark (1) across the steering wheel

and shaft so parts can be reassembled in their original

position. Move the front wheels to the straight ahead

position, then use steering wheel remover J±29752

to remove the steering wheel.

430RW021

430RX005

11. Remove steering column cover.

12. Disconnect the wiring harness connectors located

under the steering column.

Page 200 of 2100

POWER±ASSISTED STEERING SYSTEM2A±49

13. Install steering wheel and align the setting marks

made when removing.

CAUTION: Never apply force to the steering wheel

shaft using a hammer or other impact tools in an

attempt to remove the steering wheel. The steering

shaft is designed as an energy absorbing unit.

14. Tighten the steering wheel fixing nut to the specified

torque.

Torque: 34 N´m (25 lb ft)

15. Support the module and carefully connect the module

connector and horn lead, then install inflator module.

NOTE: Pass the lead wire through the tabs on the plastic

cover (wire protector) of inflator to prevent lead wire from

being pinched.

16. Tighten bolts to specified torque.

Torque: 9 N´m (78 lb in)

17. Install driver knee bolster (reinforcement).

18. Install instrument panel lower cover.

19. Install the engine hood opening lever.

20. Connect the yellow 2-way SRS connector and horn

lead located under the steering column.

21. Connect the battery ground cable.

System Inspection

Turn the ignition switch ªONº and observe if the warning

lamp flashes 7 times. If the warning lamp does not

operate correctly, refer to

Restraints section.

Page 202 of 2100

FRONT SUSPENSION3C±1

AXIOM

SUSPENSION

CONTENTS

Front Suspension 3C±1. . . . . . . . . . . . . . . . . . . . . . .

Rear Suspension 3D±1. . . . . . . . . . . . . . . . . . . . . . . .

Wheel and Tire System 3E±1. . . . . . . . . . . . . . . . . . Intelligent Suspension Control 3F±1. . . . . . . . . . . .

FRONT SUSPENSION

CONTENTS

Service Precaution 3C±1. . . . . . . . . . . . . . . . . . . . . .

General Description 3C±2. . . . . . . . . . . . . . . . . . . . .

Diagnosis 3C±2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Shock Absorber 3C±5. . . . . . . . . . . . . . . . . . . . . . . . .

Shock Absorber and Associated Parts 3C±5. . . .

Removal 3C±5. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 3C±5. . . . . . . . . . . . . . . . . .

Installation 3C±5. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Stabilizer Bar 3C±6. . . . . . . . . . . . . . . . . . . . . . . . . . .

Stabilizer Bar and Associated Parts 3C±6. . . . . .

Removal 3C±6. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 3C±6. . . . . . . . . . . . . . . . . .

Installation 3C±6. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Torsion Bar 3C±7. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Torsion Bar and Associated Parts 3C±7. . . . . . . .

Removal 3C±7. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 3C±8. . . . . . . . . . . . . . . . . .

Installation 3C±8. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Knuckle 3C±10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Knuckle and Associated Parts 3C±10. . . . . . . . . . .

Removal 3C±10. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 3C±11. . . . . . . . . . . . . . . . . .

Installation 3C±11. . . . . . . . . . . . . . . . . . . . . . . . . . . . Upper Control Arm 3C±13. . . . . . . . . . . . . . . . . . . . . .

Upper Control Arm and Associated Parts 3C±13.

Removal 3C±13. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 3C±14. . . . . . . . . . . . . . . . . .

Installation 3C±14. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lower Control Arm 3C±16. . . . . . . . . . . . . . . . . . . . . .

Lower Control Arm and Associated Parts 3C±16.

Removal 3C±16. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 3C±17. . . . . . . . . . . . . . . . . .

Installation 3C±18. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Upper Ball Joint 3C±19. . . . . . . . . . . . . . . . . . . . . . . . .

Upper Ball Joint and Associated Parts 3C±19. . . .

Removal 3C±19. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 3C±20. . . . . . . . . . . . . . . . . .

Installation 3C±20. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lower Ball Joint 3C±21. . . . . . . . . . . . . . . . . . . . . . . . .

Lower Ball Joint and Associated Parts 3C±21. . . .

Removal 3C±21. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 3C±22. . . . . . . . . . . . . . . . . .

Installation 3C±22. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Main Data and Specifications 3C±23. . . . . . . . . . . . .

Special Tools 3C±25. . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Precaution

WARNING: THIS VEHICLE HAS A SUPPLEMENTAL

RESTRAINT SYSTEM (SRS). REFER TO THE SRS

COMPONENT AND WIRING LOCATION VIEW IN

ORDER TO DETERMINE WHETHER YOU ARE

PERFORMING SERVICE ON OR NEAR THE SRS

COMPONENTS OR THE SRS WIRING. WHEN YOU

ARE PERFORMING SERVICE ON OR NEAR THE SRS

COMPONENTS OR THE SRS WIRING, REFER TO

THE SRS SERVICE INFORMATION. FAILURE TO

FOLLOW WARNINGS COULD RESULT IN POSSIBLE

AIR BAG DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU will call out those fasteners that require a

replacement after removal. ISUZU will also call out

the fasteners that require thread lockers or thread

sealant. UNLESS OTHERWISE SPECIFIED, do not

use supplemental coatings (Paints, greases, or other

corrosion inhibitors) on threaded fasteners or

fastener joint interfaces. Generally, such coatings

adversely affect the fastener torque and the joint

clamping force, and may damage the fastener. When

you install fasteners, use the correct tightening

sequence and specifications. Following these

instructions can help you avoid damage to parts and

systems.

Page 227 of 2100

REAR SUSPENSION3D±1

AXIOM (Vehicles Produced Before July/31/2001)

SUSPENSION

REAR SUSPENSION

CONTENTS

Service Precaution 3D±1. . . . . . . . . . . . . . . . . . . . . .

General Description 3D±1. . . . . . . . . . . . . . . . . . . . .

Diagnosis 3D±2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Coil Spring 3D±5. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Coil Spring and Associated Parts 3D±5. . . . . . . .

Removal 3D±5. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 3D±6. . . . . . . . . . . . . . . . . .

Installation 3D±6. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Shock Absorber 3D±7. . . . . . . . . . . . . . . . . . . . . . . . .

Shock Absorber and Associated Parts 3D±7. . . .

Removal 3D±7. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 3D±7. . . . . . . . . . . . . . . . . .

Installation 3D±7. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Trailing Link 3D±8. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Trailing Link and Associated Parts 3D±8. . . . . . .

Removal 3D±8. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 3D±8. . . . . . . . . . . . . . . . . .

Installation 3D±9. . . . . . . . . . . . . . . . . . . . . . . . . . . . Upper Link 3D±10. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Upper Link and Associated Parts 3D±10. . . . . . . .

Removal 3D±10. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 3D±10. . . . . . . . . . . . . . . . . .

Installation 3D±11. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lateral Rod 3D±12. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lateral Rod and Associated Parts 3D±12. . . . . . .

Removal 3D±12. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 3D±12. . . . . . . . . . . . . . . . . .

Installation 3D±13. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Stabilizer Bar 3D±14. . . . . . . . . . . . . . . . . . . . . . . . . . .

Stabilizer Bar and Associated Parts 3D±14. . . . . .

Removal 3D±14. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 3D±14. . . . . . . . . . . . . . . . . .

Installation 3D±15. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Main Data and Specifications 3D±16. . . . . . . . . . . . .

Special Tools 3D±18. . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Precaution

WARNING: THIS VEHICLE HAS A SUPPLEMENTAL

RESTRAINT SYSTEM (SRS). REFER TO THE SRS

COMPONENT AND WIRING LOCATION VIEW IN

ORDER TO DETERMINE WHETHER YOU ARE

PERFORMING SERVICE ON OR NEAR THE SRS

COMPONENTS OR THE SRS WIRING. WHEN YOU

ARE PERFORMING SERVICE ON OR NEAR THE SRS

COMPONENTS OR THE SRS WIRING, REFER TO

THE SRS SERVICE INFORMATION. FAILURE TO

FOLLOW WARNINGS COULD RESULT IN POSSIBLE

AIR BAG DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU will call out those fasteners that require a

replacement after removal. ISUZU will also call out

the fasteners that require thread lockers or thread

sealant. UNLESS OTHERWISE SPECIFIED, do not

use supplemental coatings (Paints, greases, or other

corrosion inhibitors) on threaded fasteners or

fastener joint interfaces. Generally, such coatings

adversely affect the fastener torque and the joint

clamping force, and may damage the fastener. When

you install fasteners, use the correct tightening

sequence and specifications. Following these

instructions can help you avoid damage to parts and

systems.

General Description

The rear suspension is a 5-link, coil spring type

suspension with a stabilizer bar, consisting of two trailing

links, two upper links, lateral rod, shock absorber, and

stabilizer. In this suspension, the links are specially

arranged to enable the rear axle to move freely, thereby

expanding suspension stroke, reducing friction, and

improving lateral rigidity and roll control. All these result in

improved stability, riding comfort, and rough road

maneuverability.

Each link connects the axle housing with the frame

through a runner bushing. The axle housing is supported

by the trailing links and upper links longitudinally and by

the lateral rod latitudinally.