lighting system ISUZU AXIOM 2002 Service Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2002, Model line: AXIOM, Model: ISUZU AXIOM 2002Pages: 2100, PDF Size: 19.35 MB

Page 1 of 2100

SECTION TABLE OF CONTENTS

GENERAL INFORMATION

0AGeneral Information

0BMaintenance and Lubrication

WORKSHOP MANUAL

HEATING, VENTILATION AND AIR

CONDITIONING

1AHVAC System

STEERING

2APower-Assisted System

AXIOM

(UPR/S)SUSPENSION

3CFront Suspension

3DRear Suspension

3EWheel and Tire System

3FIntelligent Suspension System

DRIVELINE/AXLE

4A1Differential (Front)

4A2Differential (Rear)

4B1Driveline Control System

4B2Driveline Control System (TOD)

4CDrive Shaft System

4D2Transfer Case (TOD)

FOREWORD

This manual includes special notes, impor tant points, service data,

precautions, etc. That are needed for the maintenance, adjustments,

service, removal and installation of vehicle components.

All information, illustrations and specifications contained in this manual

are based on the latest product information available at the time of

publication.

All rights are reserved to make changes at any time without notice.

Arrangement of the material is shown in the table of contents on the

right-hand side of this page. A black spot on the first page of each

section can be seen on the edge of the book below each section title.

These point to a more detailed table of contents preceding each

section.BRAKE

5ABrake Control System

5BAnti-Lock Brake System

5CPower-Assisted Brake System

5D1Parking Brake System (4´4 model)

5D2Parking Brake System (4´2 model)

ENGINE

6AEngine Mechanical

6BEngine Cooling

6CEngine Fuel

6D1Engine Electrical

6D2Ignition System

6D3Starting and Charging System

6EDriveability and Emissions

6FEngine Exhaust

6GEngine Lubrication

6HEngine Speed Control System

6JInduction

TRANSMISSION

7AAutomatic Transmission

7A1Transmission Control System

BODY AND ACCESSORIES

8ALighting System

8BWiper/Washer System

This manual applies to 2002 models.8CEnter tainment

8DWiring System

8EMeter and Gauge

8FBody Structure

8GSeats

8HSecurity and Locks

8ISun Roof/Convertible Top

8JExterior/Interior Trim

RESTRAINTS

9ASeat Belt System

9JSupplemental Restraint System (Air Bag System)

9J1Restraint Control System

CONTROL SYSTEM

10ACruise Control System

Page 114 of 2100

1A±88

HEATING, VENTILATION AND AIR CONDITIONING (HVAC)

Chart ªAº: Check of Auto Amplifier Power Supply System

StepActionValue(s)Ye sNo

1Is the fuse C±5 normal?

ÐGo to Step 2

Replace the

fuse

2Is the fuse F±7 normal?

ÐGo to Step 3

Replace the

fuse

3Disconnect the auto A/C control unit connector I±19.

Is the battery voltage applied between the harness side

connector terminal No.I32±8 and the ground?

Approx. 12VGo to Step 5Go to Step 4

4Repair an open circuit between the fuse C±5 and

terminal No.I19±8.

Is the action complete?

ÐGo to Step 4Ð

5Is there continuity between the harness side connector

terminal No.I19±16 and the ground?

ÐGo to Step 7 Go to Step 6

6Repair an open circuit between terminal No.I19±16 and

the ground No.B±9.

Is the action complete?

ÐGo to Step 5Ð

7Turn the lighting switch on.

Is the battery voltage applied between the harness side

connector terminal No.I19±12 and the ground?

Approx. 12VGo to Step 9Go to Step 8

8Repair an open circuit between the lighting switch and

terminal No.I19±12.

Is the action complete?

ÐGo to Step 7Ð

9Turn the starter switch on.

Is the battery voltage applied between the harness side

connector terminal No.I19±7 and the ground?

Approx. 12VÐGo to Step 10

10Repair an open circuit between the fuse F±7 and

terminal No.I19±7.

Is the action complete?

ÐVerify repairÐ

Page 393 of 2100

DRIVE LINE CONTROL SYSTEM (TOD) 4B2±14

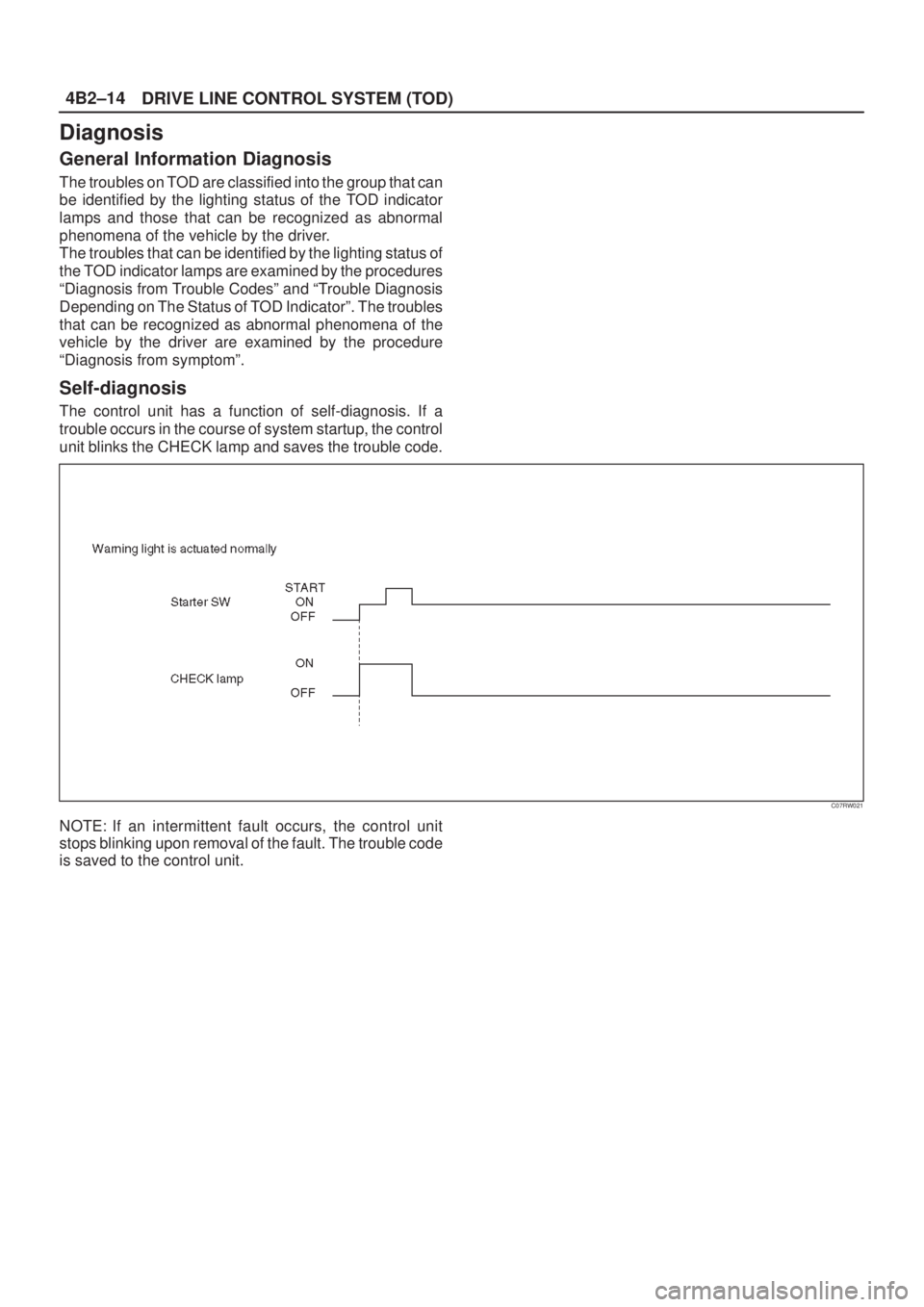

Diagnosis

General Information Diagnosis

The troubles on TOD are classified into the group that can

be identified by the lighting status of the TOD indicator

lamps and those that can be recognized as abnormal

phenomena of the vehicle by the driver.

The troubles that can be identified by the lighting status of

the TOD indicator lamps are examined by the procedures

ªDiagnosis from Trouble Codesº and ªTrouble Diagnosis

Depending on The Status of TOD Indicatorº. The troubles

that can be recognized as abnormal phenomena of the

vehicle by the driver are examined by the procedure

ªDiagnosis from symptomº.

Self-diagnosis

The control unit has a function of self-diagnosis. If a

trouble occurs in the course of system startup, the control

unit blinks the CHECK lamp and saves the trouble code.

C07RW021

NOTE: If an intermittent fault occurs, the control unit

stops blinking upon removal of the fault. The trouble code

is saved to the control unit.

Page 395 of 2100

DRIVE LINE CONTROL SYSTEM (TOD) 4B2±16

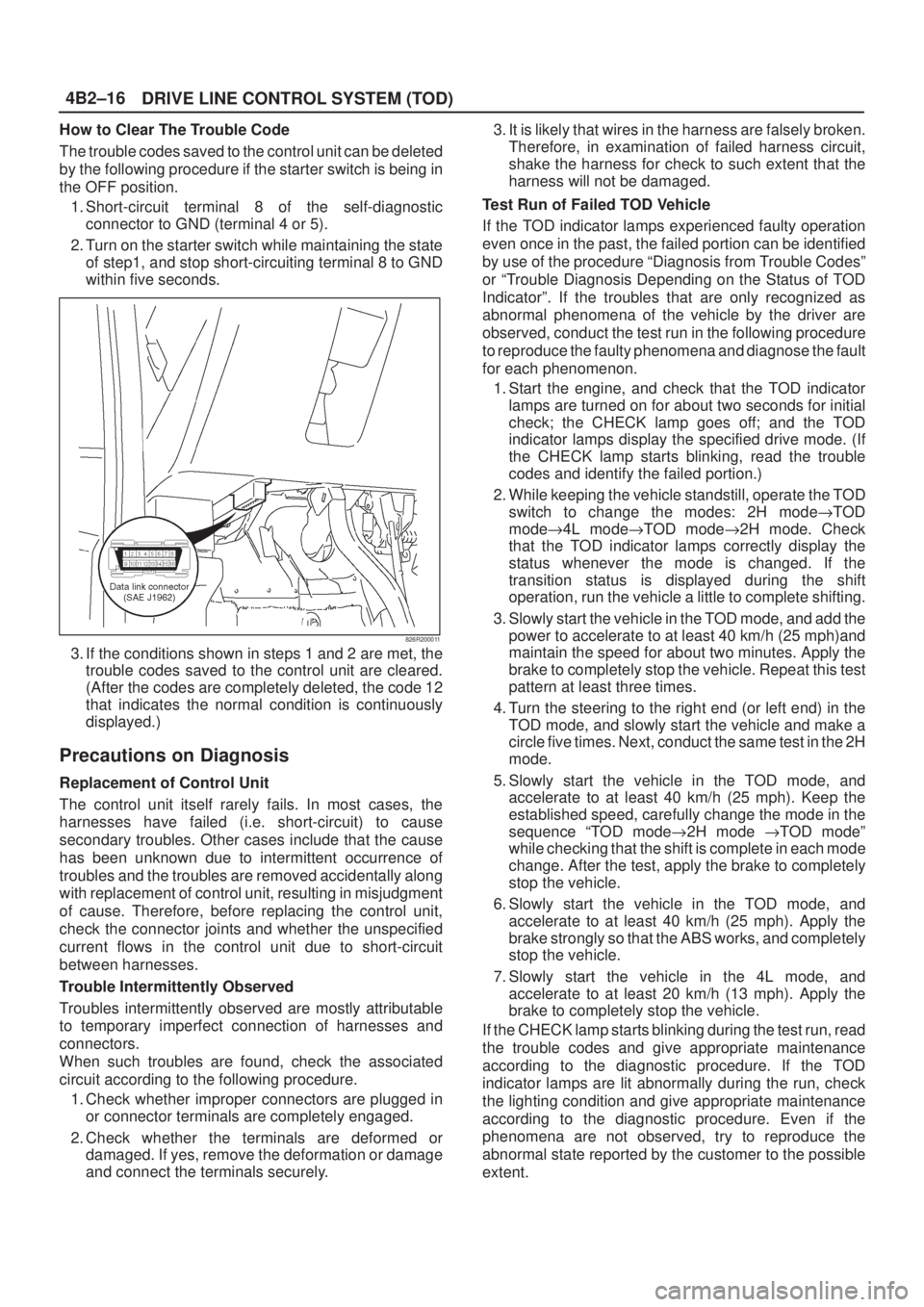

How to Clear The Trouble Code

The trouble codes saved to the control unit can be deleted

by the following procedure if the starter switch is being in

the OFF position.

1. Short-circuit terminal 8 of the self-diagnostic

connector to GND (terminal 4 or 5).

2. Turn on the starter switch while maintaining the state

of step1, and stop short-circuiting terminal 8 to GND

within five seconds.

826R200011

3. If the conditions shown in steps 1 and 2 are met, the

trouble codes saved to the control unit are cleared.

(After the codes are completely deleted, the code 12

that indicates the normal condition is continuously

displayed.)

Precautions on Diagnosis

Replacement of Control Unit

The control unit itself rarely fails. In most cases, the

harnesses have failed (i.e. short-circuit) to cause

secondary troubles. Other cases include that the cause

has been unknown due to intermittent occurrence of

troubles and the troubles are removed accidentally along

with replacement of control unit, resulting in misjudgment

of cause. Therefore, before replacing the control unit,

check the connector joints and whether the unspecified

current flows in the control unit due to short-circuit

between harnesses.

Trouble Intermittently Observed

Troubles intermittently observed are mostly attributable

to temporary imperfect connection of harnesses and

connectors.

When such troubles are found, check the associated

circuit according to the following procedure.

1. Check whether improper connectors are plugged in

or connector terminals are completely engaged.

2. Check whether the terminals are deformed or

damaged. If yes, remove the deformation or damage

and connect the terminals securely.3. It is likely that wires in the harness are falsely broken.

Therefore, in examination of failed harness circuit,

shake the harness for check to such extent that the

harness will not be damaged.

Test Run of Failed TOD Vehicle

If the TOD indicator lamps experienced faulty operation

even once in the past, the failed portion can be identified

by use of the procedure ªDiagnosis from Trouble Codesº

or ªTrouble Diagnosis Depending on the Status of TOD

Indicatorº. If the troubles that are only recognized as

abnormal phenomena of the vehicle by the driver are

observed, conduct the test run in the following procedure

to reproduce the faulty phenomena and diagnose the fault

for each phenomenon.

1. Start the engine, and check that the TOD indicator

lamps are turned on for about two seconds for initial

check; the CHECK lamp goes off; and the TOD

indicator lamps display the specified drive mode. (If

the CHECK lamp starts blinking, read the trouble

codes and identify the failed portion.)

2. While keeping the vehicle standstill, operate the TOD

switch to change the modes: 2H mode"TOD

mode"4L mode"TOD mode"2H mode. Check

that the TOD indicator lamps correctly display the

status whenever the mode is changed. If the

transition status is displayed during the shift

operation, run the vehicle a little to complete shifting.

3. Slowly start the vehicle in the TOD mode, and add the

power to accelerate to at least 40 km/h (25 mph)and

maintain the speed for about two minutes. Apply the

brake to completely stop the vehicle. Repeat this test

pattern at least three times.

4. Turn the steering to the right end (or left end) in the

TOD mode, and slowly start the vehicle and make a

circle five times. Next, conduct the same test in the 2H

mode.

5. Slowly start the vehicle in the TOD mode, and

accelerate to at least 40 km/h (25 mph). Keep the

established speed, carefully change the mode in the

sequence ªTOD mode"2H mode "TOD modeº

while checking that the shift is complete in each mode

change. After the test, apply the brake to completely

stop the vehicle.

6. Slowly start the vehicle in the TOD mode, and

accelerate to at least 40 km/h (25 mph). Apply the

brake strongly so that the ABS works, and completely

stop the vehicle.

7. Slowly start the vehicle in the 4L mode, and

accelerate to at least 20 km/h (13 mph). Apply the

brake to completely stop the vehicle.

If the CHECK lamp starts blinking during the test run, read

the trouble codes and give appropriate maintenance

according to the diagnostic procedure. If the TOD

indicator lamps are lit abnormally during the run, check

the lighting condition and give appropriate maintenance

according to the diagnostic procedure. Even if the

phenomena are not observed, try to reproduce the

abnormal state reported by the customer to the possible

extent.

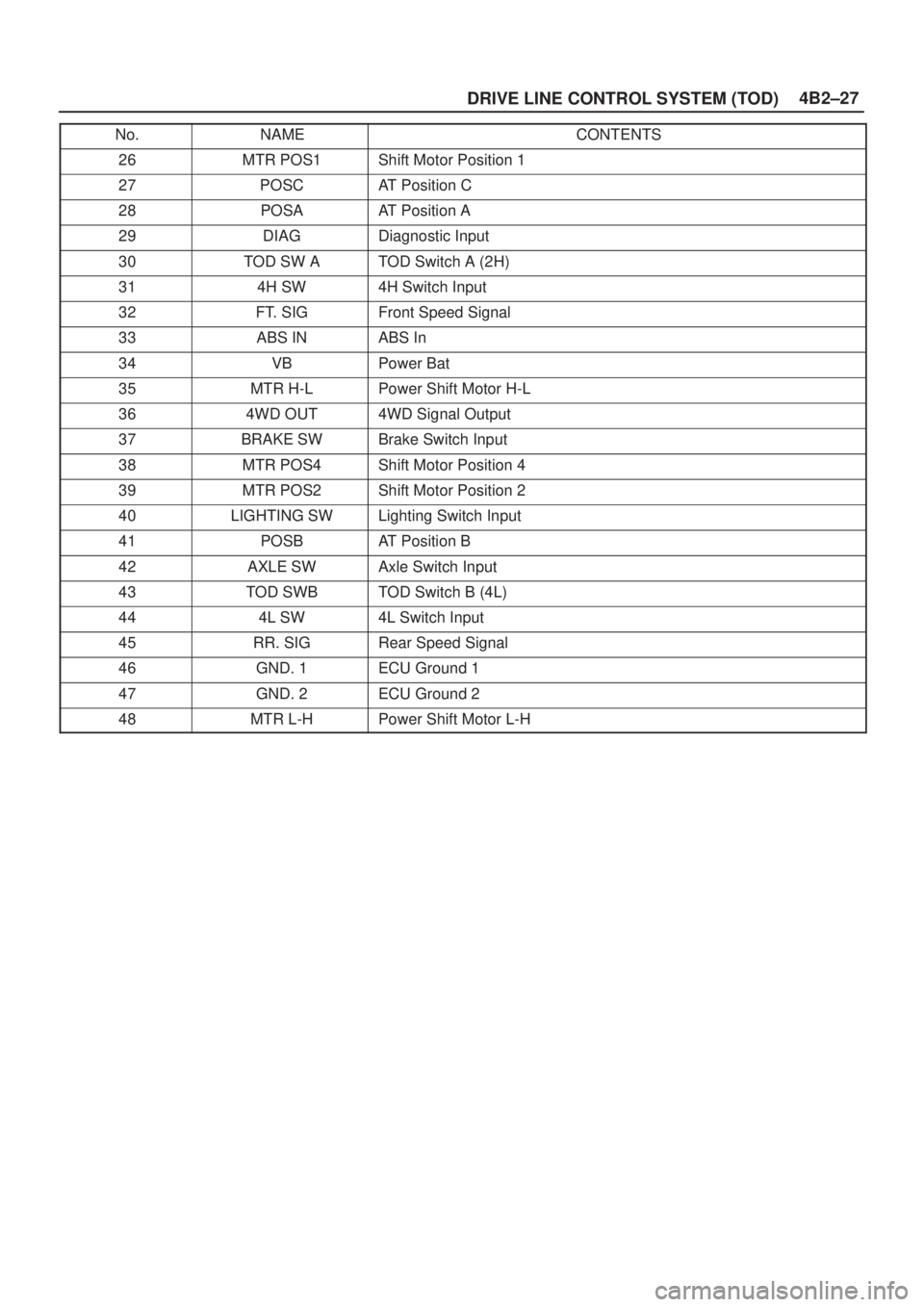

Page 406 of 2100

4B2±27

DRIVE LINE CONTROL SYSTEM (TOD)

No. CONTENTSNAME

26MTR POS1Shift Motor Position 1

27POSCAT Position C

28POSAAT Position A

29DIAGDiagnostic Input

30TOD SW ATOD Switch A (2H)

314H SW4H Switch Input

32FT. SIGFront Speed Signal

33ABS INABS In

34VBPower Bat

35MTR H-LPower Shift Motor H-L

364WD OUT4WD Signal Output

37BRAKE SWBrake Switch Input

38MTR POS4Shift Motor Position 4

39MTR POS2Shift Motor Position 2

40LIGHTING SWLighting Switch Input

41POSBAT Position B

42AXLE SWAxle Switch Input

43TOD SWBTOD Switch B (4L)

444L SW4L Switch Input

45RR. SIGRear Speed Signal

46GND. 1ECU Ground 1

47GND. 2ECU Ground 2

48MTR L-HPower Shift Motor L-H

Page 479 of 2100

DRIVE LINE CONTROL SYSTEM (TOD) 4B2±100

Chart HLighting switch circuit

Function of circuitReads in the status of lighting switch, and reduces the indicator at night.

Fail conditionEven if the lighting switch is pressed on and off, brightness does not change.

Indicator lamp state

TOD switch positionAll position (exsample TOD mode)

D04R200009

Page 480 of 2100

4B2±101

DRIVE LINE CONTROL SYSTEM (TOD)

StepActionYe sNo

11. Turn on the starter switch.

2. Turn off the lighting switch.

Is 0V observed between the EUC terminal 40 and 47?

Go to Step 2

Lighting switch

battery circuit

short. Repair the

circuit.

Go to

Step 4

2Turn lighting switch ªONº.

Is the battery voltage observed between ECU terminal 40 and 47?

Go to Step 3

Wires are broken

in lighting switch

circuit. Repair the

circuit.

Go to

Step 4

3While the lighting switch is pressed on and off, does the

brightness of the indicator change?The phenomenon

is not

reproduced.

Refer to

ªTroubles

intermittently

observedº

The ECU has

failed. Replace

the ECU.

Go to

Step 4

4Check that all the parts are mounted.

Is this step complete?

Verify the repair.Go to Step 4

Page 655 of 2100

5A±36BRAKE CONTROL SYSTEM

Diagnosis By ªABSº Warning Light

Illumination Pattern

In the event that there is abnormality in the ªABSº warning

light illumination pattern while the key is in the ON position

or if the warning light is actuated while driving, refer to the

flow chart below for the correct diagnostic procedure.

No.

ConditionªABSº Warning Light Illumination PatternDiagnostic

1Warning light is

actuated normallyNormal

2Warning light is not litWarning light lighting circuit

trouble"Go to Chart B-1

3Warning light remains

ONDiagnostic trouble codes are

stored.

Display diagnostic trouble

codes and diagnose on a

code basis according to the

flow charts.

4Warning light is

actuated while drivingDiagnostic trouble codes are

stored.

Display diagnostic trouble

codes and diagnose on a

code basis according to the

flow charts.

5Warning light goes at

12 km/h (8 mph) or

higher (After repairing

the faulty part)Even after repairing the

faulty part the warning light

(W/L) dose not go out if

vehicle is at a stop.

Turn the ignition switch to the

ON position and drive the

vehicle at 12 km/h (8 mph) or

higher to make sure that the

warning light goes out.

Page 1777 of 2100

LIGHTING SYSTEM8A±1

AXIOM

BODY AND ACCESSORIES

CONTENTS

Lighting System 8A. . . . . . . . . . . . . . . . . . . . . . . . .

Wiper / Washer System 8B. . . . . . . . . . . . . . . . . .

Entertainment 8C. . . . . . . . . . . . . . . . . . . . . . . . . . .

Wiring System 8D. . . . . . . . . . . . . . . . . . . . . . . . . .

Meter and Gauge 8E. . . . . . . . . . . . . . . . . . . . . . . Body Structure 8F. . . . . . . . . . . . . . . . . . . . . . . . . .

Seats 8G. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Security and Locks 8H. . . . . . . . . . . . . . . . . . . . . .

Sunroof / Convertible Top 8I. . . . . . . . . . . . . . . .

Exterior / Interior Trim 8J. . . . . . . . . . . . . . . . . . . .

LIGHTING SYSTEM

CONTENTS

Service Precaution 8A±2. . . . . . . . . . . . . . . . . . . . . .

Headlight Bulb 8A±3. . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 8A±3. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8A±3. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Headlight Assembly 8A±4. . . . . . . . . . . . . . . . . . . . .

Removal 8A±4. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8A±4. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Headlight Adjustment 8A±4. . . . . . . . . . . . . . . . . .

Side Marker Light Bulb 8A±6. . . . . . . . . . . . . . . . . . .

Removal 8A±6. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8A±6. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Taillight Bulb 8A±7. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 8A±7. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8A±7. . . . . . . . . . . . . . . . . . . . . . . . . . . .

License Plate Light Bulb 8A±8. . . . . . . . . . . . . . . . . .

Removal 8A±8. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8A±8. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Stoplight Bulb 8A±8. . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal and Installation 8A±8. . . . . . . . . . . . . . .

High Mounted Stoplight Assembly 8A±9. . . . . . . . .

Removal 8A±9. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8A±9. . . . . . . . . . . . . . . . . . . . . . . . . . . .

High Mounted Stoplight Bulb 8A±9. . . . . . . . . . . . . .

Removal 8A±9. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8A±9. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Backup Light Bulb 8A±10. . . . . . . . . . . . . . . . . . . . . . .

Removal 8A±10. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8A±10. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Turn Signal Light Bulb 8A±10. . . . . . . . . . . . . .

Removal and Installation 8A±10. . . . . . . . . . . . . . .

Rear Turn Signal Light Bulb 8A±11. . . . . . . . . . . . . .

Removal 8A±11. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8A±11. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dome Light Bulb 8A±11. . . . . . . . . . . . . . . . . . . . . . . .

Removal 8A±11. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8A±11. . . . . . . . . . . . . . . . . . . . . . . . . . . . Map Light Bulb 8A±12. . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 8A±12. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8A±12. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Courtesy Light Bulb 8A±12. . . . . . . . . . . . . . . . . . . . . .

Removal 8A±12. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8A±12. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Luggage Room Light Bulb 8A±13. . . . . . . . . . . . . . . .

Removal 8A±13. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8A±13. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Shift Lever Illumination Light Bulb (A/T) 8A±13. . . .

Removal 8A±13. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8A±13. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Vanity Mirror Illumination Light Bulb 8A±14. . . . . . . .

Removal 8A±14. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8A±14. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Switch Unit Assembly Illumination

Light Bulb (Power/Winter & Intelligent

Suspension Switch) 8A±14. . . . . . . . . . . . . . . . . . . . .

Removal 8A±14. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8A±14. . . . . . . . . . . . . . . . . . . . . . . . . . . .

TOD Switch Illumination Light Bulb 8A±15. . . . . . . .

Removal 8A±15. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8A±15. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cruise Control Main Switch Illumination

Light Bulb 8A±15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 8A±15. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8A±15. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rear Wiper and Washer Switch Illumination

Light Bulb 8A±16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 8A±16. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8A±16. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Seat Heater Switch Illumination Light Bulb 8A±16. .

Removal 8A±16. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8A±16. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Starter Switch 8A±17. . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal and Installation 8A±17. . . . . . . . . . . . . . .

Lighting Switch (Combination Switch) 8A±17. . . . . .

Page 1778 of 2100

8A±2LIGHTING SYSTEM

Removal and Installation 8A±17. . . . . . . . . . . . . . .

Dimmer´Passing Switch

(Combination Switch) 8A±17. . . . . . . . . . . . . . . . . . .

Removal and Installation 8A±17. . . . . . . . . . . . . . .

Front Door Switch 8A±17. . . . . . . . . . . . . . . . . . . . . . .

Removal 8A±17. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8A±17. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rear Door Switch 8A±18. . . . . . . . . . . . . . . . . . . . . . .

Removal 8A±18. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8A±18. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tailgate Lock Switch 8A±18. . . . . . . . . . . . . . . . . . . . .

Removal 8A±18. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8A±18. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Key Remind Switch (Starter Switch) 8A±19. . . . . . . Removal and Installation 8A±19. . . . . . . . . . . . . . .

Hazard Warning Light Switch 8A±19. . . . . . . . . . . . .

Removal 8A±19. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8A±19. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Stoplight Switch 8A±20. . . . . . . . . . . . . . . . . . . . . . . . .

Removal and Installation 8A±20. . . . . . . . . . . . . . .

Turn Signal Light Switch

(Combination Switch) 8A±20. . . . . . . . . . . . . . . . . . .

Removal and Installation 8A±20. . . . . . . . . . . . . . .

Illumination Controller 8A±20. . . . . . . . . . . . . . . . . . . .

Removal 8A±20. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8A±20. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Main Data and Specifications 8A±21. . . . . . . . . . . . .

Service Precaution

WARNING: THIS VEHICLE HAS A SUPPLEMENTAL

RESTRAINT SYSTEM (SRS). REFER TO THE SRS

COMPONENT AND WIRING LOCATION VIEW IN

ORDER TO DETERMINE WHETHER YOU ARE

PERFORMING SERVICE ON OR NEAR THE SRS

COMPONENTS OR THE SRS WIRING. WHEN YOU

ARE PERFORMING SERVICE ON OR NEAR THE SRS

COMPONENTS OR THE SRS WIRING, REFER TO

THE SRS SERVICE INFORMATION. FAILURE TO

FOLLOW WARNINGS COULD RESULT IN POSSIBLE

AIR BAG DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU will call out those fasteners that require a

replacement after removal. ISUZU will also call out

the fasteners that require thread lockers or thread

sealant. UNLESS OTHERWISE SPECIFIED, do not

use supplemental coatings (Paints, greases, or other

corrosion inhibitors) on threaded fasteners or

fasteners joint interfaces. Generally, such coatings

adversely affect the fastener torque and the joint

clamping force, and may damage the fasteners.

When you install fasteners, use the correct

tightening sequence and specifications. Following

these instructions can help you avoid damage to

parts and systems.