mileage ISUZU TF SERIES 2004 User Guide

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2004, Model line: TF SERIES, Model: ISUZU TF SERIES 2004Pages: 4264, PDF Size: 72.63 MB

Page 2240 of 4264

6E-244 3.5L ENGINE DRIVEABILITY AND EMISSIONS

CIRCUIT DESCRIPTION

If the ECM receives an incorrect number of pulses on

the CMP reference circuit, DTC P0341 will set.

If the ECM does not receive pulses on the CMP

reference circuit, DTC P0342 will set.

DIAGNOSTIC AIDS

An intermittent may be caused by a poor connection,

rubbed–through wire insulation or a wire broken inside

the insulation. Check for:

Poor connection —Inspect the ECM harness and

connectors for improper mating, broken locks,

improperly formed or damaged terminals, and poo

r

terminal-to-wire connection.

Damaged harness —Inspect the wiring harness fo

r

damage.

Reviewing the Failure Records vehicle mileage since

the diagnostic test last failed may help determine ho

w

often the condition that caused the DTC to be se

t

occurs. This may assist in diagnosing the condition.

Diagnostic Trouble Code (DTC) P0341(Flash Code 41) Camshaft

Position Sensor Circuit Range/Performance

Diagnostic Trouble Code (DTC) P0342 (Flash Code 41) Camshaft

Position Sensor Circuit No Signal

Step Action Value (s) Yes No

1

Was the "On-Board Diagnostic (OBD) System Check"

performed?

- Go to Step 2 Go to On Board

Diagnostic (OBD)

System Check

2

1. Connect the Tech 2.

2. Review and record the failure information.

3. Select "F0: Read DTC Infor By Priority" in "F0:

Diagnostic Trouble Code".

Is the DTC P0341 or P0342 stored as "Present

Failure"?

- Go to Step 3 Refer to

Diagnostic Aids

and Go to Step 3

3

1. Using the Tech2, ignition "On" and engine "Off".

2. Select "Clear DTC Information" with the Tech2 and

clear the DTC information.

3. Operate the vehicle and monitor the "F5: Failed

This Ignition" in "F2: DTC Information"

Was the DTC P0341 or P0342 stored in this ignition

cycle?

- Go to Step 4 Refer to

Diagnostic Aids

and Go to Step 4

4

Check any accessory parts which may cause electric

interference or magnetic interference.

Was the problem found?

- Remove the

accessory parts

and verify repair Go to Step 5

Page 2246 of 4264

6E-250 3.5L ENGINE DRIVEABILITY AND EMISSIONS

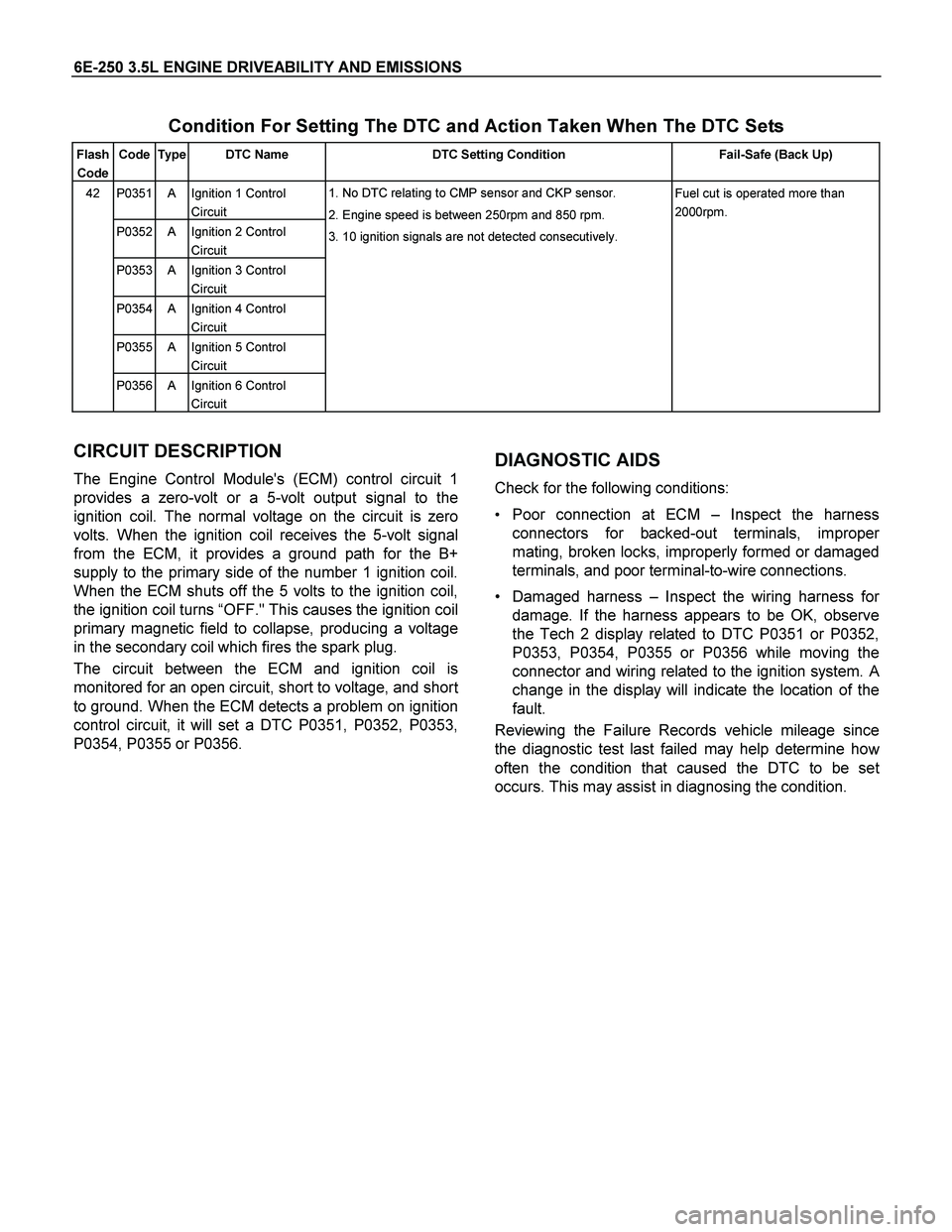

Condition For Setting The DTC and Action Taken When The DTC Sets

Flash

Code Code Type DTC Name DTC Setting Condition Fail-Safe (Back Up)

P0351 A Ignition 1 Control

Circuit

P0352 A Ignition 2 Control

Circuit

P0353 A Ignition 3 Control

Circuit

P0354 A Ignition 4 Control

Circuit

P0355 A Ignition 5 Control

Circuit

42

P0356 A Ignition 6 Control

Circuit 1. No DTC relating to CMP sensor and CKP sensor.

2. Engine speed is between 250rpm and 850 rpm.

3. 10 ignition signals are not detected consecutively. Fuel cut is operated more than

2000rpm.

CIRCUIT DESCRIPTION

The Engine Control Module's (ECM) control circuit 1

provides a zero-volt or a 5-volt output signal to the

ignition coil. The normal voltage on the circuit is zero

volts. When the ignition coil receives the 5-volt signal

from the ECM, it provides a ground path for the B+

supply to the primary side of the number 1 ignition coil.

When the ECM shuts off the 5 volts to the ignition coil,

the ignition coil turns “OFF." This causes the ignition coil

primary magnetic field to collapse, producing a voltage

in the secondary coil which fires the spark plug.

The circuit between the ECM and ignition coil is

monitored for an open circuit, short to voltage, and shor

t

to ground. When the ECM detects a problem on ignition

control circuit, it will set a DTC P0351, P0352, P0353,

P0354, P0355 or P0356.

DIAGNOSTIC AIDS

Check for the following conditions:

Poor connection at ECM – Inspect the harness

connectors for backed-out terminals, imprope

r

mating, broken locks, improperly formed or damaged

terminals, and poor terminal-to-wire connections.

Damaged harness –Inspect the wiring harness fo

r

damage. If the harness appears to be OK, observe

the Tech 2 display related to DTC P0351 or P0352,

P0353, P0354, P0355 or P0356 while moving the

connector and wiring related to the ignition system.

A

change in the display will indicate the location of the

fault.

Reviewing the Failure Records vehicle mileage since

the diagnostic test last failed may help determine ho

w

often the condition that caused the DTC to be set

occurs. This may assist in diagnosing the condition.

Page 2271 of 4264

3.5L ENGINE DRIVEABILITY AND EMISSIONS 6E-275

CIRCUIT DESCRIPTION

The canister purge solenoid valve is controlled by the

Engine Train Control Module (ECM).

At an appropriate time, the EVAP canister purge

solenoid is “ON," allowing engine vacuum to draw a

small vacuum on the entire evaporative emissions

system.

DIAGNOSTIC AIDS

An intermittent may be caused by the following:

Poor connections.

Mis routed harness.

Rubbed through wire insulation.

Broken wire inside the insulation.

Check for the following conditions:

Poor connection at ECM-Inspect harness connectors

for backed out terminals, improper mating, broken

locks, improperly formed or damaged terminals, and

poor terminal to wire connection.

Damaged harness-Inspect the wiring harness fo

r

damage. If the harness appears to be OK, observe

the EVAP purge solenoid display on the Tech 2 while

moving connectors and wiring harnesses related to

the sensor.

A change in the display will indicate the location o

f

the fault. If DTC P0444 or P0445 cannot be

duplicated, the information included in the Failure

Records data can be useful in determined vehicle

mileage since the DTC was last set.

If it is determined that the DTC occurs intermittently,

performing the DTC P0444 or P0445 Diagnostic

Chart may isolate the cause of the fault.

Diagnostic Trouble Code (DTC) P0444 EVAP Purge Solenoid

Valve Circuit Low Voltage

Diagnostic Trouble Code (DTC) P0445 EVAP Purge Solenoid

Valve Circuit High Voltage

Step Action Value (s) Yes No

1

Was the "On-Board Diagnostic (OBD) System Check"

performed?

- Go to Step 2 Go to On Board

Diagnostic (OBD)

System Check

2

1. Connect the Tech 2.

2. Review and record the failure information.

3. Select "F0: Read DTC Infor By Priority" in "F0:

Diagnostic Trouble Code".

Is the DTC P0444 or P0445 stored as "Present

Failure"?

- Go to Step 3 Refer to

Diagnostic Aids

and Go to Step 3

3

1. Using the Tech2, ignition "On" and engine "Off".

2. Select "Clear DTC Information" with the Tech2 and

clear the DTC information.

3. Operate the vehicle and monitor the "F5: Failed

This Ignition" in "F2: DTC Information"

Was the DTC P0444 or P0445 stored in this ignition

cycle?

- Go to Step 4 Refer to

Diagnostic Aids

and Go to Step 4

Page 2441 of 4264

ENGINE MECHANICAL (C24SE) 6A-21

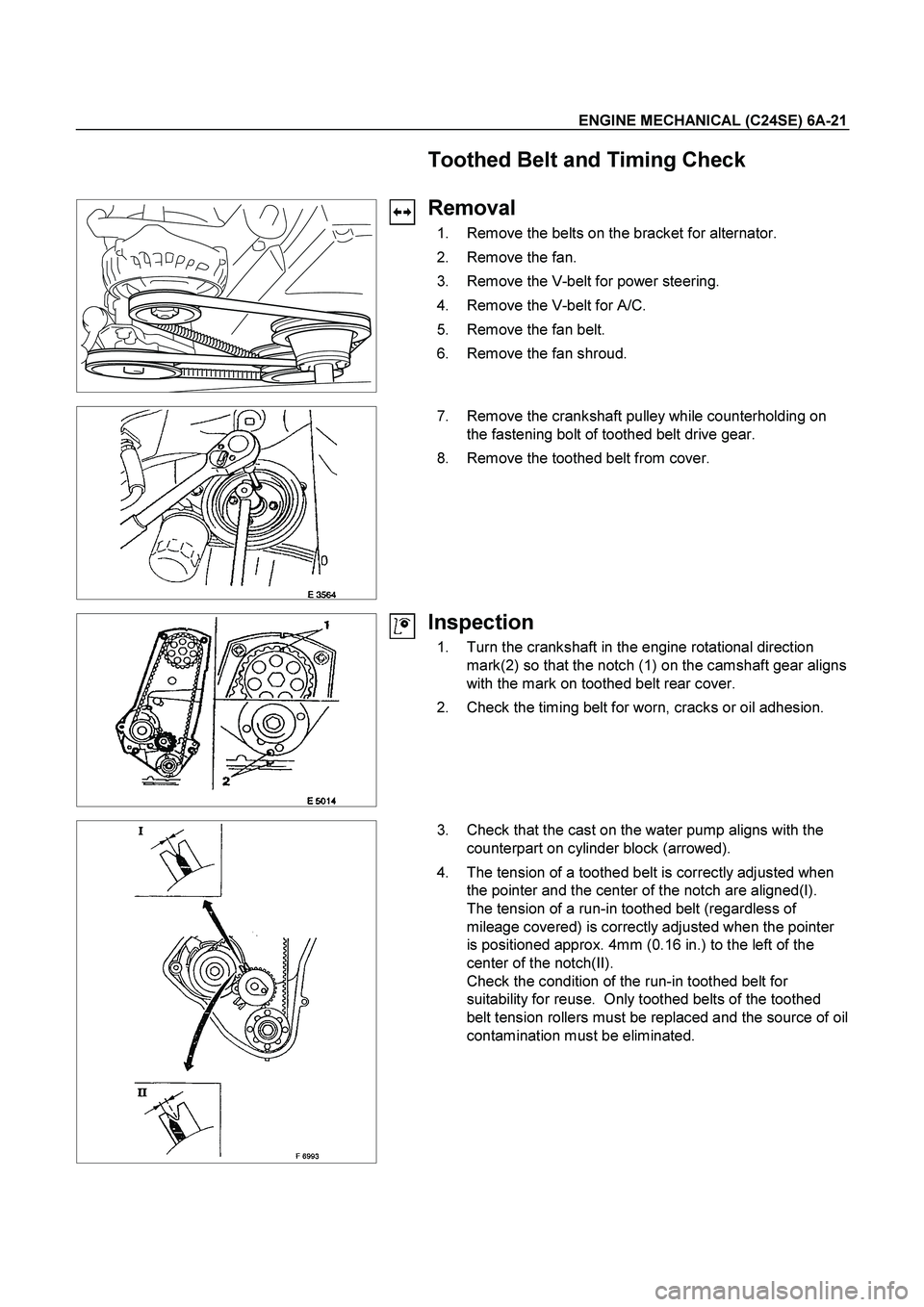

Toothed Belt and Timing Check

Removal

1. Remove the belts on the bracket for alternator.

2. Remove the fan.

3. Remove the V-belt for power steering.

4. Remove the V-belt for A/C.

5. Remove the fan belt.

6. Remove the fan shroud.

7. Remove the crankshaft pulley while counterholding on

the fastening bolt of toothed belt drive gear.

8. Remove the toothed belt from cover.

Inspection

1. Turn the crankshaft in the engine rotational direction

mark(2) so that the notch (1) on the camshaft gear aligns

with the mark on toothed belt rear cover.

2. Check the timing belt for worn, cracks or oil adhesion.

3. Check that the cast on the water pump aligns with the

counterpart on cylinder block (arrowed).

4. The tension of a toothed belt is correctly adjusted when

the pointer and the center of the notch are aligned(I).

The tension of a run-in toothed belt (regardless of

mileage covered) is correctly adjusted when the pointer

is positioned approx. 4mm (0.16 in.) to the left of the

center of the notch(II).

Check the condition of the run-in toothed belt for

suitability for reuse. Only toothed belts of the toothed

belt tension rollers must be replaced and the source of oil

contamination must be eliminated.