lock ISUZU TF SERIES 2004 Workshop Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2004, Model line: TF SERIES, Model: ISUZU TF SERIES 2004Pages: 4264, PDF Size: 72.63 MB

Page 1340 of 4264

6D – 2 ENGINE ELECTRICAL

MAIN DATA AND SPECIFICATIONS

Description

Item

60A 80A

Generator

Type

AC generator with IC regulator and vacuum pump

Hitachi LR160-503E Hitachi LR180-513B

Voltage V

Drive and rotation

Ground polarity 12

V-belt, clockwise viewed from the drive pulley

Negative

Maximum output A 60 80

Engine speed ratio to 1 1.788

Maximum speed rpm 11,000

Weight with vacuum pump kg(lb) 5.8(12.8) 6.4(14.1)

Vacuum Pump

Delivery volume cm3/rev

Exhaust Characteristic

Maximum vacuum

50

-66.7 kPa (-500 mmHg) bulid up time 21 seconds or less at 1,000

rpm

7 seconds or less at 5,000 rpm

-90.7 kPa (-680 mmHg) or more

Starter Motor

Type

Solenoid controlled

Hitachi S13-555

12

2.3

8.76

300 Rated voltage V

Rated output kW

Load characteristics

Terminal voltage V

Load current A

Weight kg(Ib)

4.7 (10.4)

Page 1366 of 4264

6D – 28 ENGINE ELECTRICAL

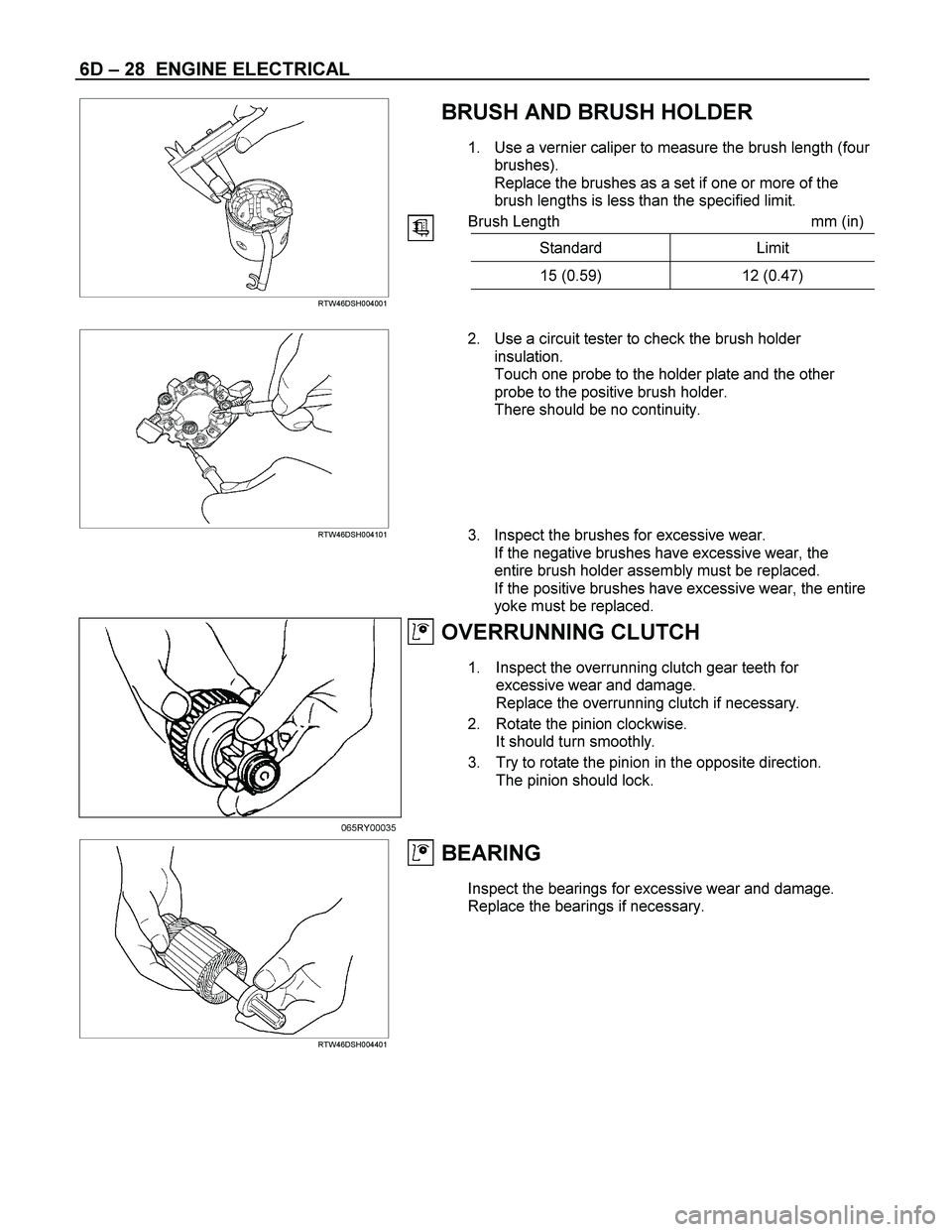

BRUSH AND BRUSH HOLDER

1. Use a vernier caliper to measure the brush length (four

brushes).

Replace the brushes as a set if one or more of the

brush lengths is less than the specified limit.

Brush Length mm (in)

Standard Limit

15 (0.59) 12 (0.47)

RTW46DSH004001

RTW46DSH004101

2. Use a circuit tester to check the brush holder

insulation.

Touch one probe to the holder plate and the other

probe to the positive brush holder.

There should be no continuity.

3. Inspect the brushes for excessive wear.

If the negative brushes have excessive wear, the

entire brush holder assembly must be replaced.

If the positive brushes have excessive wear, the entire

yoke must be replaced.

OVERRUNNING CLUTCH

1. Inspect the overrunning clutch gear teeth for

excessive wear and damage.

Replace the overrunning clutch if necessary.

2. Rotate the pinion clockwise.

It should turn smoothly.

3. Try to rotate the pinion in the opposite direction.

The pinion should lock.

065RY00035

RTW46DSH004401

BEARING

Inspect the bearings for excessive wear and damage.

Replace the bearings if necessary.

Page 1417 of 4264

4JA1/4JH1 ENGINE DRIVEABILITY AND EMISSIONS 6E–45

FUSE A ND RELAY LOCATION (LHD & RHD)

FUSE

SLOW BLOW FUSE

RELAYNo. Capacity Indication on label No. Capacity Indication on label

1——12 15A CIGER

2 10A ABS 13 15A AUDIO (+B)

3——14 20A DOOR LOCK

4 15A BACK UP 15 10A METER (+B)

5 15A METER 16 10A ROOM

6 10A TURN 17 10A ANTI THEFT

7 15A ELEC.IG 18 15A STOP

8 15A ENGINE 19 15A ACC SOCKET

9 20A FRT WIPER 20 10A STARTER

10 15A EGR 21 10A SRS

11 10A AUDIO

No. Capacity Indication on label

SBF-10 20A RR DEF

SBF-11 30A POWER WINDOW

Connector No. B-7 B-8 B-40

4JA1-TC, 4JH1-TC REAR

DEFOGGERPOWER

WINDOWACC

SOCKET

FUSE BOX

Page 1450 of 4264

6E–78 4JA1/4JH1 ENGINE DRIVEABILITY AND EMISSIONS

3. Check Bulletins and

Troubleshooting Hints

NOTE: As estimated 30 percent of successful vehicle

repairs are diagnosed with this step!

What you should do

You should have enough information gained from

preliminary checks to accurately search for a bulletin

and other related service information. Some service

manual sections provide troubleshooting hints that

match symptoms with specific complaints.

What resources you should use

You should use the following resources for assistance in

checking for bulletins and troubleshooting hints:

Printed bulletins

Access ISUZU Bulletin Web site.

Videotapes

Service manual

4. Perform Service Manual

Diagnostic Checks

What you should do

The “System Checks” in most service manual sections

and in most cells of section 8A (electrical) provide you

with:

A systematic approach to narrowing down the

possible causes of a system fault

Direction to specific diagnostic procedures in the

service manual

Assistance to identify what systems work correctly

What resources you should use

Whenever possible, you should use the following

resources to perform service manual checks:

Service manual

Technical equipment (for viewing DTCs and

analyzing data)

Digital multimeter and circuit testing tools

Other tools as needed

5a and 5b. Perform Service Manual

Diagnostic Procedures

NOTE: An estimated 40 percent of successful vehicle

repairs are diagnosed with these steps!

What you should do

When directed by service manual diagnostic checks,

you must then carefully and accurately perform the

steps of diagnostic procedures to locate the fault relatedto the customer complaint.

What resources you should use

Whenever appropriate, you should use the following

resources to perform service manual diagnostic

procedures:

Service manual

Technical equipment (for analyzing diagnostic data)

Digital multimeter and circuit testing tools

Essential and special tools

5c. Technician Self Diagnoses

When there is no DTC stored and no matching

symptom for the condition identified in the service

manual, you must begin with a thorough understanding

of how the system(s) operates. Efficient use of the

service manual combined with you ex perience and a

good process of elimination will result in accurate

diagnosis of the condition.

What you should do

Step 1: Identify and understand the suspect

circuit(s)

Having completed steps 1 through 4 of the Strategy

Based Diagnostics chart, you should have enough

information to identify the system(s) or sub-system(s)

involved. Using the service manual, you should

determine and investigate the following circuit

characteristics:

Electrical:

–How is the circuit powered (power distribution

charts and/or fuse block details)?

–How is the circuit grounded (ground distribution

charts)?

–How is the circuit controlled or sensed (theory of

operation):

–If it is a switched circuit, is it normally open or

normally closed?

–Is the power switched or is the ground

switched?

–Is it a variable resistance circuit (ECT sensor

or TP sensor, for ex ample)?

–Is it a signal generating device (MAF sensor of

VSS, for example)?

–Does it rely on some mechanical/vacuum

device to operate?

Physical:

–Where are the circuit components (component

locators and wire harness routing diagrams):

–Are there areas where wires could be chafed

or pinched (brackets or frames)?

–Are there areas subjected to ex treme

temperatures?

Page 1459 of 4264

4JA1/4JH1 ENGINE DRIVEABILITY AND EMISSIONS 6E–87

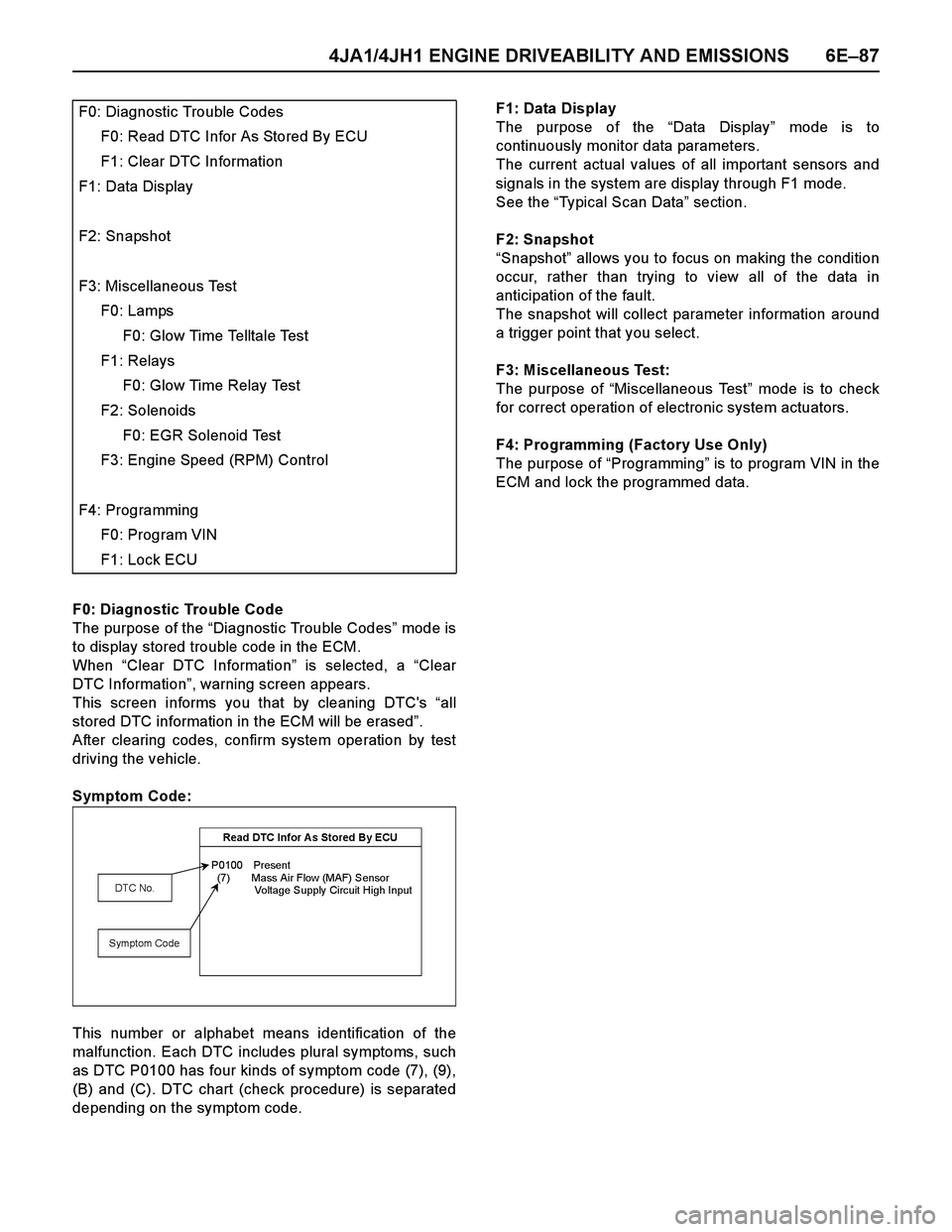

F0: Diagnostic Trouble Code

The purpose of the “Diagnostic Trouble Codes” mod e i s

to display stored trouble code in the ECM.

When “Clear DTC Information” is selected, a “Clear

DTC Information”, warning screen appears.

This screen informs you that by cleaning DTC's “all

stored DTC information in the ECM will be erased”.

After clearing codes, confirm system operation by test

driving the vehicle.

Symptom Code:

This number or alphabet means identification of the

malfunction. Each DTC includes plural symptoms, such

as DTC P0100 has four kinds of symptom code (7), (9),

(B) and (C). DTC chart (check procedure) is separated

depending on the symptom code.F1: Data Display

The purpose of the “Data Display” mode is to

continuously monitor data parameters.

The current actual values of all important sensors and

signals in the system are display through F1 mode.

See the “Typical Scan Data” section.

F2: Snapshot

“Snapshot” allows you to focus on making the condition

occur, rather than trying to view all of the data in

anticipation of the fault.

The snapshot will collect parameter information around

a trigger point that you select.

F3: Miscellaneous Test:

The purpose of “Miscellaneous Test” mode is to check

for correct operation of electronic system actuators.

F4: Programming (Factory Use Only)

The purpose of “Programming” is to program VIN in the

ECM and lock the programmed data. F0: Diagnostic Trouble Codes

F0: Read DTC Infor As Stored By ECU

F1: Clear DTC Information

F1: Data Display

F2: Snapshot

F3: Miscellaneous Test

F0: Lamps

F0: Glow Time Telltale Test

F1: Relays

F0: Glow Time Relay Test

F2: Solenoids

F0: EGR Solenoid Test

F3: Engine Speed (RPM) Control

F4: Programming

F0: Program VIN

F1: Lock ECU

Read DTC Infor A s Stored By ECU

P0100 Present

(7) Mass Air Flow (MAF) Sensor

Voltage Supply Circuit High Input

DTC No.

Symptom Code

Page 1477 of 4264

4JA1/4JH1 ENGINE DRIVEABILITY AND EMISSIONS 6E–105

ON-BOARD DIAGNOSTIC (OBD) SYSTEM CHECK

Circuit Description

The on-board diagnostic system check is the starting

point for any driveability complaint diagnosis. Before

using this procedure, perform a careful visual/physical

check of the ECM and engine grounds for cleanliness

and tightness.

The on-board diagnostic system check is an organized

approach to identifying a problem created by an

electronic engine control system malfunction.

Diagnostic Aids

An intermittent may be caused by a poor connection,

rubbed-through wire insulation or a wire broken inside

the insulation. Check for poor connections or a

damaged harness. Inspect the ECM harness and

connector for improper mating, broken locks, improperly

formed or damaged terminals, poor terminal-to-wireconnection, and damaged harness.

Test Description

Number(s) below refer the step number(s) on the

Diagnostic Chart:

1. The Check Engine Lamp (MIL) should be ON steady

with the ignition “On”, engine “Off”. If not, “No Check

Engine Lamp (MIL)” chart should be used to isolate the

malfunction.

2. Checks the Class 2 data circuit and ensures that the

ECM is able to transmit serial data.

3. This test ensures that the ECM is capable of

controlling the Check Engine Lamp (MIL) and the Check

Engine Lamp (MIL) driver circuit is not shorted to

ground circuit.

4. If the engine will not start, “Engine Cranks But Will

Not Run” chart should be used to diagnose the fault.

Page 1481 of 4264

4JA1/4JH1 ENGINE DRIVEABILITY AND EMISSIONS 6E–109

NO CHECK ENGINE LAMP (MIL)

Circuit Description

The check engine lamp should be illuminated and

steady for about five seconds with the ignition “ON” and

the engine stopped. Ignition feed voltage is supplied to

the check engine lamp bulb through the meter fuse.

The Engine Control Module (ECM) turns the check

engine lamp “ON” by grounding the check engine lamp

driver circuit.

Diagnostic Aids

An intermittent check engine lamp may be cased by a

poor connection, rubbed-through wire insulation, or awire broken inside the insulation. Check for the

following items:

Inspect the ECM harness and connections for

improper mating, broken locks, improperly formed or

damaged terminals, poor terminal-to-wire connection,

and damaged harness.

If the engine runs OK, check for a faulty light bulb, an

open in the check engine lamp driver circuit, or an

open in the instrument cluster ignition feed.

If the engine cranks but will not run, check for an

open ECM ignition or battery feed, or a poor ECM to

engine ground.

Page 1484 of 4264

6E–112 4JA1/4JH1 ENGINE DRIVEABILITY AND EMISSIONS

CHECK ENGINE LAMP (MIL) “ON” STEADY

Circuit description

The check engine lamp should always be illuminated

and steady for about five seconds with ignition “ON” and

the engine stopped. Ignition feed voltage is supplied

directly to the check engine lamp indicator. The Engine

Control Module (ECM) turns the check engine lamp

“ON” by grounding the check engine lamp driver circuit.

The check engine lamp should not remain “ON” with the

engine running and no DTC(s) set. A steady check

engine lamp with the engine running and no DTC(s)

suggests a short to ground in the check engine lamp

driver circuit.

Diagnostic Aids

An intermittent may be caused by a poor connection,

rubbed-through wire insulation, or a wire broken inside

the insulation. Check for the following items:

Poor connection or damaged harness – Inspect the

ECM harness and connectors for improper mating,

broken locks, improperly formed or damaged

terminals, poor terminal-to-wire connection, and

damaged harness.

Page 1501 of 4264

4JA1/4JH1 ENGINE DRIVEABILITY AND EMISSIONS 6E–129

Condition for setting the DTC and action taken when the DTC sets

Circuit Description

The mass air flow (MAF) sensor is part of the intake air

system. It is fitted between the air cleaner and

turbocharger and measure the mass air flowing into the

engine.

The mass air flow (MAF) sensor element measures the

partial air mass through a measurement duct on the

sensor housing.

The ECM monitors the MAF sensor supply voltage and

MAF sensor output voltage. The supply voltage is out of

range, DTC P0100 (Symptom Code 7) or P0100

(Symptom Code 9) will be stored. The output voltage

ex cessively high or low, DTC P0100 (Symptom Code B)

or P0100 (Symptom Code C) will be stored.

Diagnostic Aids

An intermittent may be caused by the following:

Poor connections.

Misrouted harness.

Rubbed through wire insulation.

Broken wire inside the insulation.

Check for the following conditions:

Poor connection at ECM-Inspect harness connectors

for backed out terminals, improper mating, broken

locks, improperly formed or damaged terminals, and

poor terminal to wire connection.

Damaged harness-Inspect the wiring harness for

damage. If the harness appears to be OK, observe

the “Mass Air Flow” display on the Tech2 while

moving connectors and wiring harness related to the

sensor.

Diagnostic Trouble Code (DTC) P0100 (Symptom Code 7) (Flash Code 65)

Mass Air Flow (MAF) Sensor Voltage Supply Circuit High Input

Flash

CodeCodeSymptom

CodeMIL DTC Name DTC Setting Condition Fail-Safe (Back Up)

65 P0100 7 ON Ma ss Air Flo w (MAF) Senso r

Voltage Supply Circuit High

InputMAF sensor power supply

voltage is more than 5.2V.ECM uses ma ss a ir flo w

1600mg/strk & EGR 10% co n-

ditions as substitute.

9 ON Mass Air Flow (MAF) Sensor

Voltage Supply Circuit Low

InputMAF sensor power supply

voltage is below 4.6V.

B ON Mass Air Flow (MAF) Sensor

Output Circuit Low Input1. Engine speed is between

600rpm and 5000rpm.

2. MAF se nsor o utput is

below -33.7mg/strk.

C ON Mass Air Flow (MAF) Sensor

Output Circuit High Input1. Engine speed is between

600rpm and 5000rpm.

2. MAF sensor output is more

tha n 1378mg/strk (4JA1-TC)

o r 1784mg/strk (4JH1-TC).

Step Action Value(s) Yes No

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2Go to On Board

Diagnostic

(OBD) System

Check

2 1. Connect the Tech 2.

2. Review and record the failure information.

3. Select “F0: Read DTC Infor As Stored By ECU” in

“F0: Diagnostic Trouble Codes”.

Is the DTC P0100 (Symptom Code 7) stored as

“Present Failure”?—Go to Step 3Refer to

Diagnostic Aids

and Go to Step

3

Page 1513 of 4264

4JA1/4JH1 ENGINE DRIVEABILITY AND EMISSIONS 6E–141

Condition for setting the DTC and action taken when the DTC sets

Circuit description

The ECM monitors altitude from the barometric

pressure sensor. To apply specified vacuum pressure to

the turbocharger wastegate valve, ECM sends control

signal to the wastegate control solenoid depending on

altitude.

Then, apply vacuum pressure to the turbocharger

wastegate valve is monitored by the ECM form the

vacuum pressure sensor output signal. The ECM

controls wastegate control solenoid based on signal

from vacuum pressure sensor output.

The output voltage ex cessively high or low, DTC P0105

(Symptom Code 1) or P0105 (Symptom Code 2) will be

stored.

The supply voltage is out of range, DTC P0105

(Symptom Code 7) or P0105 (Symptom Code 9) will be

stored.

Diagnostic Aids

An intermittent may be caused by the following:

Poor connections.

Misrouted harness.

Rubbed through wire insulation.

Broken wire inside insulation.

Check for the following conditions:

Poor connection at ECM-Inspect harness connectors

for backed out terminals, improper mating, broken

locks, improperly formed or damaged terminals, and

poor terminal to wire connection.

Damaged harness-Inspect the wiring harness for

damage. If the harness appears to be OK, observe

the DTC P0105 display on the Tech 2 while moving

connectors and wiring harnesses. A change in the

display will indicate the location of the fault.

Flash

CodeCode Symptom

CodeMIL DTC Name DTC Setting Condition Fail-Safe (Back Up)

34 P0105 1 ON Vacuum Pressure Sensor

Circuit High InputVacuum sensor output

voltage is more than 4.4V.1. Fuel injection quantity is

r e d u c e d .

2. ECM use 615hpa

conditio ns for

turbo cha rge r wa ste gate

contro l. 2 ON Vacuum Pressure Sensor

Circuit Low InputVacuum sensor output

voltage is below 0.5V.

7 ON Vacuum Pressure Sensor

Volta ge Supply Circuit High

InputVacuum senso r po wer supply

voltage is more than 5.2V.1. Fuel injection quantity is

r e d u c e d .

2. ECM use vacuum sensor

output voltage 5.0V

condition as substitute. 9 ON Vacuum Pressure Sensor

Volta ge Supply Circuit Lo w

InputVacuum senso r po wer supply

voltage is below 4.5V.