ABS ISUZU TROOPER 1998 Service User Guide

[x] Cancel search | Manufacturer: ISUZU, Model Year: 1998, Model line: TROOPER, Model: ISUZU TROOPER 1998Pages: 3573, PDF Size: 60.36 MB

Page 286 of 3573

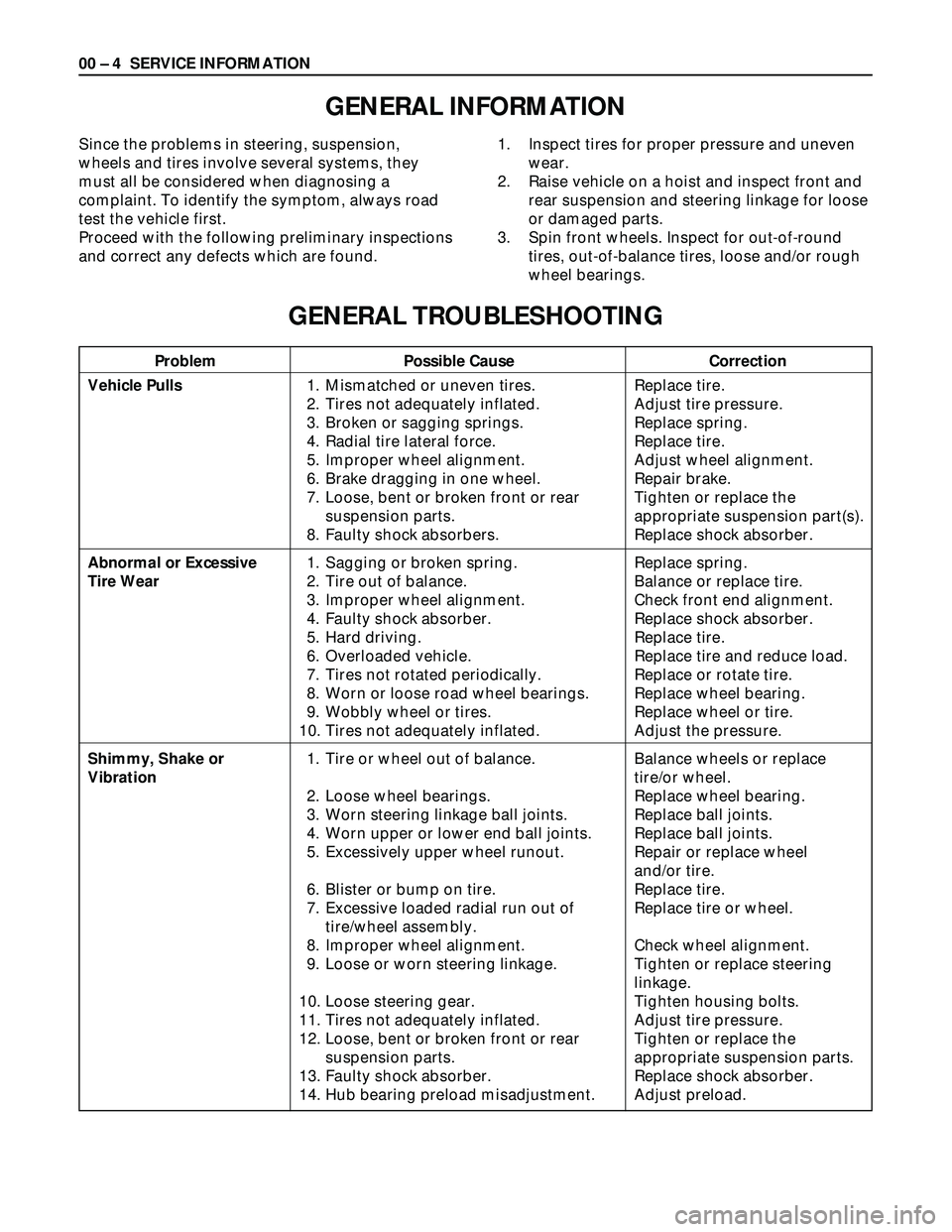

Problem Possible Cause Correction

00 – 4 SERVICE INFORMATION

GENERAL INFORMATION

Since the problems in steering, suspension,

wheels and tires involve several systems, they

must all be considered when diagnosing a

complaint. To identify the symptom, always road

test the vehicle first.

Proceed with the following preliminary inspections

and correct any defects which are found.1. Inspect tires for proper pressure and uneven

wear.

2. Raise vehicle on a hoist and inspect front and

rear suspension and steering linkage for loose

or damaged parts.

3. Spin front wheels. Inspect for out-of-round

tires, out-of-balance tires, loose and/or rough

wheel bearings.

GENERAL TROUBLESHOOTING

Vehicle Pulls

Abnormal or Excessive

Tire Wear

Shimmy, Shake or

Vibration1. Mismatched or uneven tires.

2. Tires not adequately inflated.

3. Broken or sagging springs.

4. Radial tire lateral force.

5. Improper wheel alignment.

6. Brake dragging in one wheel.

7. Loose, bent or broken front or rear

suspension parts.

8. Faulty shock absorbers.

1. Sagging or broken spring.

2. Tire out of balance.

3. Improper wheel alignment.

4. Faulty shock absorber.

5. Hard driving.

6. Overloaded vehicle.

7. Tires not rotated periodically.

8. Worn or loose road wheel bearings.

9. Wobbly wheel or tires.

10. Tires not adequately inflated.

1. Tire or wheel out of balance.

2. Loose wheel bearings.

3. Worn steering linkage ball joints.

4. Worn upper or lower end ball joints.

5. Excessively upper wheel runout.

6. Blister or bump on tire.

7. Excessive loaded radial run out of

tire/wheel assembly.

8. Improper wheel alignment.

9. Loose or worn steering linkage.

10. Loose steering gear.

11. Tires not adequately inflated.

12. Loose, bent or broken front or rear

suspension parts.

13. Faulty shock absorber.

14. Hub bearing preload misadjustment.Replace tire.

Adjust tire pressure.

Replace spring.

Replace tire.

Adjust wheel alignment.

Repair brake.

Tighten or replace the

appropriate suspension part(s).

Replace shock absorber.

Replace spring.

Balance or replace tire.

Check front end alignment.

Replace shock absorber.

Replace tire.

Replace tire and reduce load.

Replace or rotate tire.

Replace wheel bearing.

Replace wheel or tire.

Adjust the pressure.

Balance wheels or replace

tire/or wheel.

Replace wheel bearing.

Replace ball joints.

Replace ball joints.

Repair or replace wheel

and/or tire.

Replace tire.

Replace tire or wheel.

Check wheel alignment.

Tighten or replace steering

linkage.

Tighten housing bolts.

Adjust tire pressure.

Tighten or replace the

appropriate suspension parts.

Replace shock absorber.

Adjust preload.

Page 287 of 3573

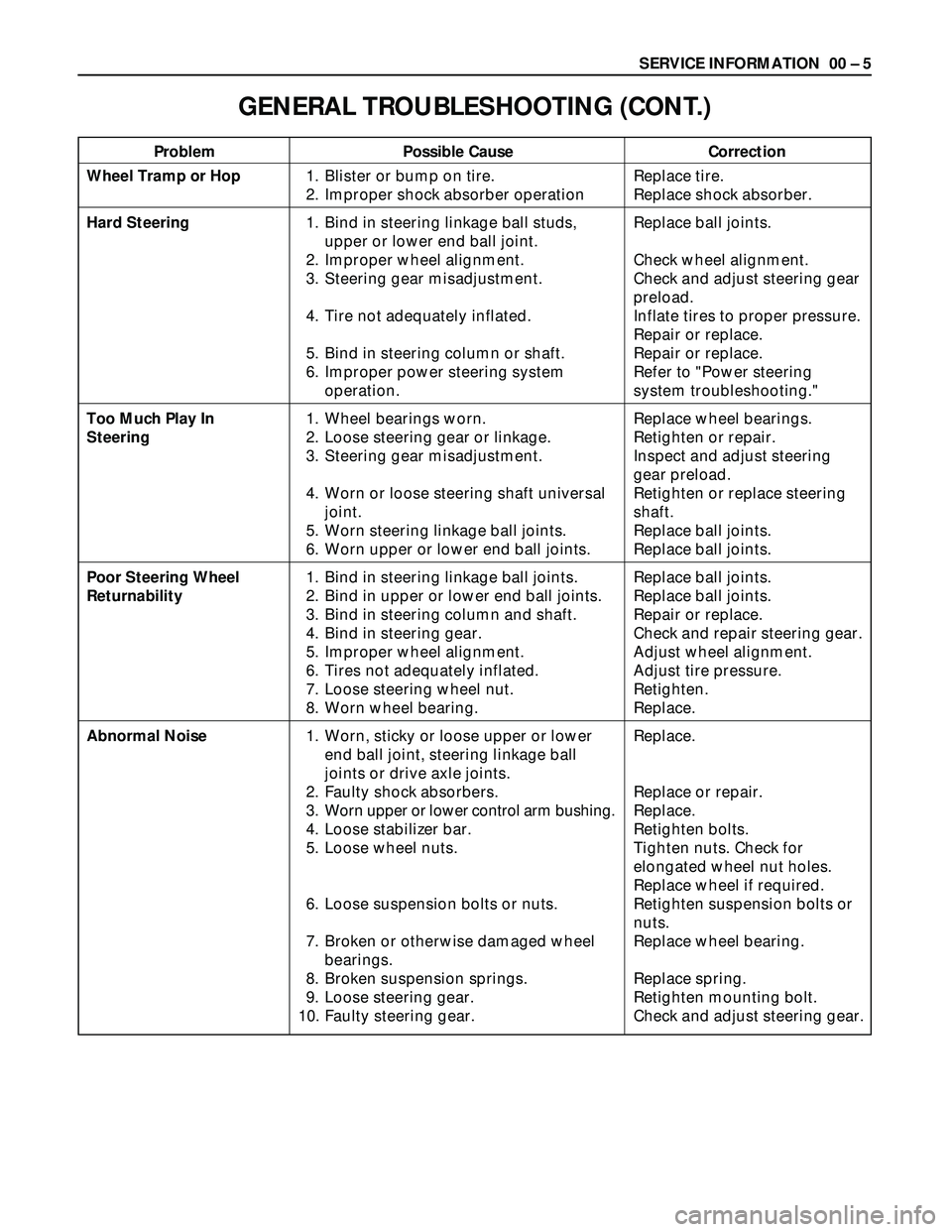

SERVICE INFORMATION 00 – 5

Problem Possible Cause Correction

GENERAL TROUBLESHOOTING (CONT.)

Wheel Tramp or Hop

Hard Steering

Too Much Play In

Steering

Poor Steering Wheel

Returnability

Abnormal Noise1. Blister or bump on tire.

2. Improper shock absorber operation

1. Bind in steering linkage ball studs,

upper or lower end ball joint.

2. Improper wheel alignment.

3. Steering gear misadjustment.

4. Tire not adequately inflated.

5. Bind in steering column or shaft.

6. Improper power steering system

operation.

1. Wheel bearings worn.

2. Loose steering gear or linkage.

3. Steering gear misadjustment.

4. Worn or loose steering shaft universal

joint.

5. Worn steering linkage ball joints.

6. Worn upper or lower end ball joints.

1. Bind in steering linkage ball joints.

2. Bind in upper or lower end ball joints.

3. Bind in steering column and shaft.

4. Bind in steering gear.

5. Improper wheel alignment.

6. Tires not adequately inflated.

7. Loose steering wheel nut.

8. Worn wheel bearing.

1. Worn, sticky or loose upper or lower

end ball joint, steering linkage ball

joints or drive axle joints.

2. Faulty shock absorbers.

3. Worn upper or lower control arm bushing.

4. Loose stabilizer bar.

5. Loose wheel nuts.

6. Loose suspension bolts or nuts.

7. Broken or otherwise damaged wheel

bearings.

8. Broken suspension springs.

9. Loose steering gear.

10. Faulty steering gear.Replace tire.

Replace shock absorber.

Replace ball joints.

Check wheel alignment.

Check and adjust steering gear

preload.

Inflate tires to proper pressure.

Repair or replace.

Repair or replace.

Refer to "Power steering

system troubleshooting."

Replace wheel bearings.

Retighten or repair.

Inspect and adjust steering

gear preload.

Retighten or replace steering

shaft.

Replace ball joints.

Replace ball joints.

Replace ball joints.

Replace ball joints.

Repair or replace.

Check and repair steering gear.

Adjust wheel alignment.

Adjust tire pressure.

Retighten.

Replace.

Replace.

Replace or repair.

Replace.

Retighten bolts.

Tighten nuts. Check for

elongated wheel nut holes.

Replace wheel if required.

Retighten suspension bolts or

nuts.

Replace wheel bearing.

Replace spring.

Retighten mounting bolt.

Check and adjust steering gear.

Page 288 of 3573

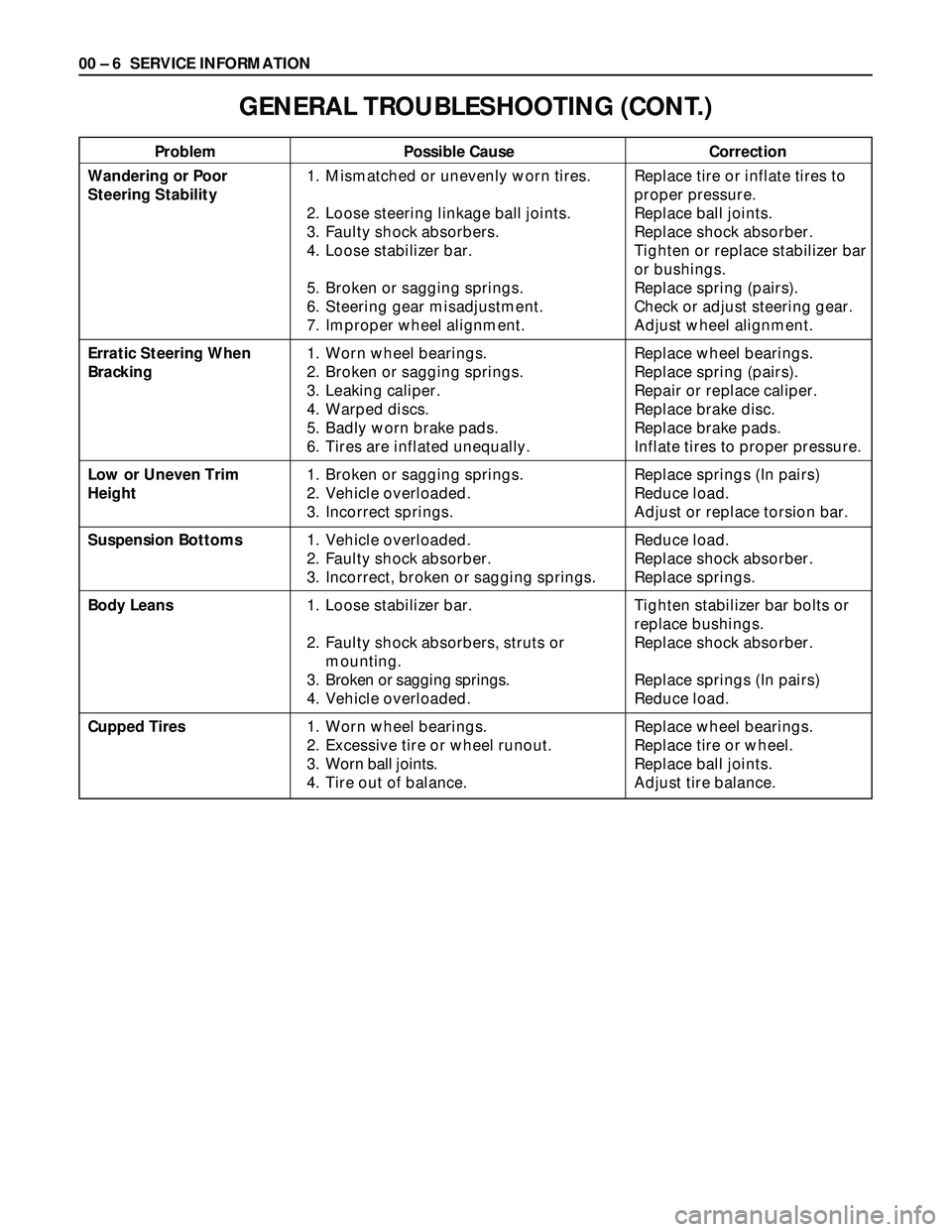

00 – 6 SERVICE INFORMATION

Problem Possible Cause Correction

GENERAL TROUBLESHOOTING (CONT.)

Wandering or Poor

Steering Stability

Erratic Steering When

Bracking

Low or Uneven Trim

Height

Suspension Bottoms

Body Leans

Cupped Tires1. Mismatched or unevenly worn tires.

2. Loose steering linkage ball joints.

3. Faulty shock absorbers.

4. Loose stabilizer bar.

5. Broken or sagging springs.

6. Steering gear misadjustment.

7. Improper wheel alignment.

1. Worn wheel bearings.

2. Broken or sagging springs.

3. Leaking caliper.

4. Warped discs.

5. Badly worn brake pads.

6. Tires are inflated unequally.

1. Broken or sagging springs.

2. Vehicle overloaded.

3. Incorrect springs.

1. Vehicle overloaded.

2. Faulty shock absorber.

3. Incorrect, broken or sagging springs.

1. Loose stabilizer bar.

2. Faulty shock absorbers, struts or

mounting.

3. Broken or sagging springs.

4. Vehicle overloaded.

1. Worn wheel bearings.

2. Excessive tire or wheel runout.

3. Worn ball joints.

4. Tire out of balance.Replace tire or inflate tires to

proper pressure.

Replace ball joints.

Replace shock absorber.

Tighten or replace stabilizer bar

or bushings.

Replace spring (pairs).

Check or adjust steering gear.

Adjust wheel alignment.

Replace wheel bearings.

Replace spring (pairs).

Repair or replace caliper.

Replace brake disc.

Replace brake pads.

Inflate tires to proper pressure.

Replace springs (In pairs)

Reduce load.

Adjust or replace torsion bar.

Reduce load.

Replace shock absorber.

Replace springs.

Tighten stabilizer bar bolts or

replace bushings.

Replace shock absorber.

Replace springs (In pairs)

Reduce load.

Replace wheel bearings.

Replace tire or wheel.

Replace ball joints.

Adjust tire balance.

Page 305 of 3573

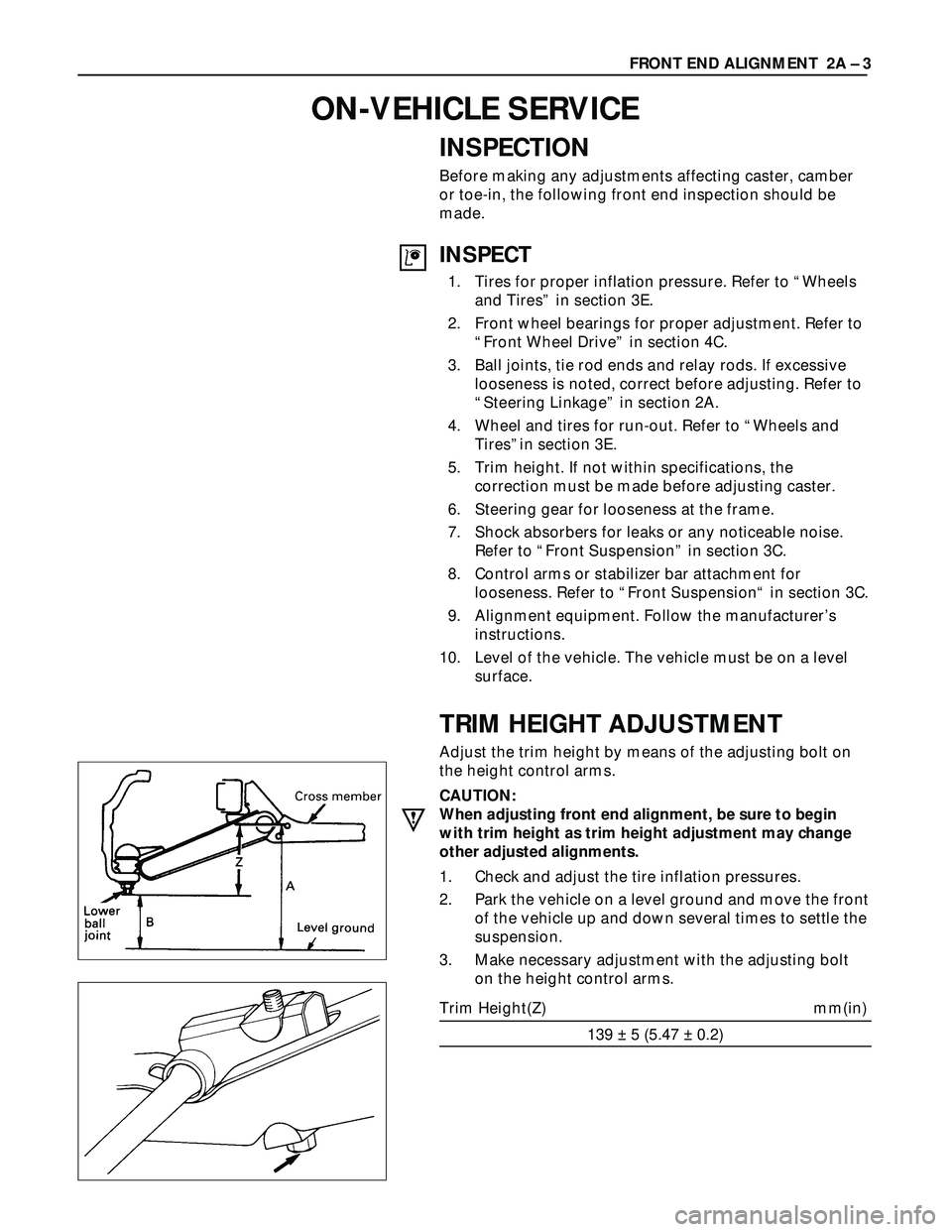

INSPECTION

Before making any adjustments affecting caster, camber

or toe-in, the following front end inspection should be

made.

INSPECT

1. Tires for proper inflation pressure. Refer to “Wheels

and Tires” in section 3E.

2. Front wheel bearings for proper adjustment. Refer to

“Front Wheel Drive” in section 4C.

3. Ball joints, tie rod ends and relay rods. If excessive

looseness is noted, correct before adjusting. Refer to

“Steering Linkage” in section 2A.

4. Wheel and tires for run-out. Refer to “Wheels and

Tires”in section 3E.

5. Trim height. If not within specifications, the

correction must be made before adjusting caster.

6. Steering gear for looseness at the frame.

7. Shock absorbers for leaks or any noticeable noise.

Refer to “Front Suspension” in section 3C.

8. Control arms or stabilizer bar attachment for

looseness. Refer to “Front Suspension“ in section 3C.

9. Alignment equipment. Follow the manufacturer’s

instructions.

10. Level of the vehicle. The vehicle must be on a level

surface.

TRIM HEIGHT ADJUSTMENT

Adjust the trim height by means of the adjusting bolt on

the height control arms.

CAUTION:

When adjusting front end alignment, be sure to begin

with trim height as trim height adjustment may change

other adjusted alignments.

1. Check and adjust the tire inflation pressures.

2. Park the vehicle on a level ground and move the front

of the vehicle up and down several times to settle the

suspension.

3. Make necessary adjustment with the adjusting bolt

on the height control arms.

Trim Height(Z) mm(in)

139 ± 5 (5.47 ± 0.2)FRONT END ALIGNMENT 2A – 3

ON-VEHICLE SERVICE

Page 354 of 3573

This steering wheel and column repair section

covers the Supplemental Restraint System (SRS)

steering column. The following repair procedures

are specific to SRS Components. When servicing a

vehicle equipped with Supplemental Restraint

System, pay close attention to all WARNINGS and

CAUTIONS.

For detailed explanation about SRS, refer to Section

9J "SUPPLEMENTAL RESTRAINT SYSTEM (SRS)"

of manual.

The steering column has three important features in

addition to the steering function:

1. The column is energy absorbing, designed to

compress in a front-end collision to minimize

the possibility of injury to the driver of the

vehicle.

2. The ignition switch and lock are mounted

conveniently on the column.

3. With the column mounted lock, the ignition

and steering operation can be locked to

prevent theft of the vehicle.

The column may be disassembled and

reassembled. To insure the energy absorbing

action, it is important that the specified screws,

bolts and nuts be used only as designated and that

they are tightened to the specified torque.

When the column is removed from the vehicle, a

sharp blow on the end of steering shaft or shift

lever, leaning on the column assembly, or dropping

the assembly could shear or loosen the fasteners

that maintain column rigidity.

WARNING

THIS VEHICLE HAS A SUPPLEMENTAL RE-

STRAINT SYSTEM (SRS).REFER TO THE SRS

COMPONENT AND WIRING LOCATION VIEW

IN ORDER TO DETERMINE WHETHER YOU ARE

PERFORMING SERVICE ON OR NEAR THE SRS

COMPONENTS OR THE SRS WIRING. WHEN

YOU ARE PERFORMING SERVICE ON OR NEAR

THE SRS COMPONENTS OR THE SRS WIRING,

REFER TO THE SRS SERVICE INFORM ATION.

FAILURE TO FOLLOW WARNINGS COULD RE-

SULT IN POSSIBLE AIR BAG DEPLOYMENT,

PERSONAL INJURY, OR OTHERWISE UN-

NEEDED SRS SYSTEM REPAIRS.

SAFE HANDLING OF INFLATOR MODULES

REQUIRES FOLLOWING THE PROCEDURES

DESCRIBED BELOW FOR BOTH LIVE AND

DEPLOYED MODULES.

SAFETY PRECAUTIONS MUST BE FOLLOWEDWHEN HANDLING A DEPLOYED AIR BAG AS-

SEMBLY (AIR BAG). AFTER DEPLOYMENT,

THE AIR BAG ASSEMBLY (AIR BAG) SURFACE

MAY CONTAIN A SMALL AMOUNT OF SODIUM

HYDROXIDE, A BY-PRODUCT OF THE DEPLOY-

MENT REACTION, THAT IS IRRITATING TO THE

SKIN AND EYES.MOST OF THE POWDER ON

THE AIR BAG ASSEMBLY (AIR BAG) IS HARM-

LESS. AS A PRECAUTION, WEAR GLOVES

AND SAFETY GLASSES WHEN HANDLING A

DEPLOYED AIR BAG ASSEMBLY, AND WASH

YOUR HANDS WITH MILD SOAP AND WATER

AFTERWARDS.

WHEN CARRYING A LIVE AIR BAG ASSEMBLY,

MAKE SURE THE BAG AND TRIM COVER ARE

POINTED AWAY FROM YOU. NEVER CARRY

AN AIR BAG ASSEMBLY BY THE WIRES OR

CONNECTOR ON THE UNDERSIDE OF MODULE.

IN THE CASE OF AN ACCIDENTAL DEPLOY-

MENT, THE BAG WILL THEN DEPLOY WITH

MINIMAL CHANCE OF INJURY. WHEN PLACING

A LIVE AIR BAG ASSEMBLY ON A BENCH OR

OTHER SURFACE, ALWAYS FACE THE BAG AND

TRIM COVER UP, AWAY FROM THE SURFACE.

NEVER REST A STEERING COLUMN ASSEMBLY

ON THE STEERING WHEEL WITH THE AIR

BAG ASSEMBLY FACE DOWN AND COLUMN

VERTICAL.THIS IS NECESSARY SO THAT A

FREE SPACE IS PROVIDED TO ALLOW THE AIR

BAG ASSEMBLY TO EXPAND IN THE UNLIKELY

EVENT OF ACCIDENTAL DEPLOYMENT. OTHER-

WISE, PERSONAL INJURY COULD RESULT.

TO AVOID DEPLOYMENT WHEN TROUBLE

SHOOTING THE SRS SYSTEM, DO NOT USE

ELECTRICAL TEST EQUIPMENT, SUCH AS

BATTERY-POWERED OR A/C-POWERED VOLT-

METER, OHMMETER, ETC., OR ANY TYPE OF

ELECTRICAL EQUIPMENT OTHER THAN SPECI-

FIED IN THIS MANUAL. DO NOT USE A NON-

POWERED PROBE-TYPE TESTER.

INSTRUCTIONS IN THIS MANUAL MUST BE

FOLLOWED CAREFULLY, OTHERWISE PER-

SONAL INJURY MAY RESULT. 2A – 52 SUPPLEMENTAL RESTRAINT SYSTEM STEERING WHEEL & COLUMN

GENERAL DESCRIPTION

Page 357 of 3573

SUPPLEMENTAL RESTRAINT SYSTEM STEERING WHEEL & COLUMN 2A Ð 55

2. Module Connector

Disconnect the yellow 2way SRS connector located

behind the inflator module.

3. Inflator Module

827RS015

827RS016

INSPECTION AND REPAIR

WARNING

THE INFLATOR MODULE SHOULD ALWAYS BE CARRIED

WITH THE URETHANE COVER AWAY FROM YOUR BODY

AND SHOULD ALWAYS BE LAID ON A FLAT SURFACE

WITH THE URETHANE SIDE UP. THIS IS NECESSARY

BECAUSE A FREE SPACE IS PROVIDED TO ALLOW THE

AIR CUSHION TO EXPAND IN THE UNLIKELY EVENT OF

ACCIDENTAL DEPLOYMENT. OTHERWISE, PERSONAL

INJURY MAY BE RESULT.

INSTALLATION

3. Inflator Module

CAUTION:

·Never use the air bag assembly from another vehicle.

Use only the air bag assembly for "UBS".

·When replace the inflator module, use only same parts

number assembly. If different parts number assembly is

installed, the air bag system can not function correctly

because it has different characteristic.

2. Module Connector

Support the module and carefully connect the

module connector.

NOTE:

Pass the lead wire through the tabs on the plastic

cover (wire protector) of inflator to prevent lead wire

from being pinched.

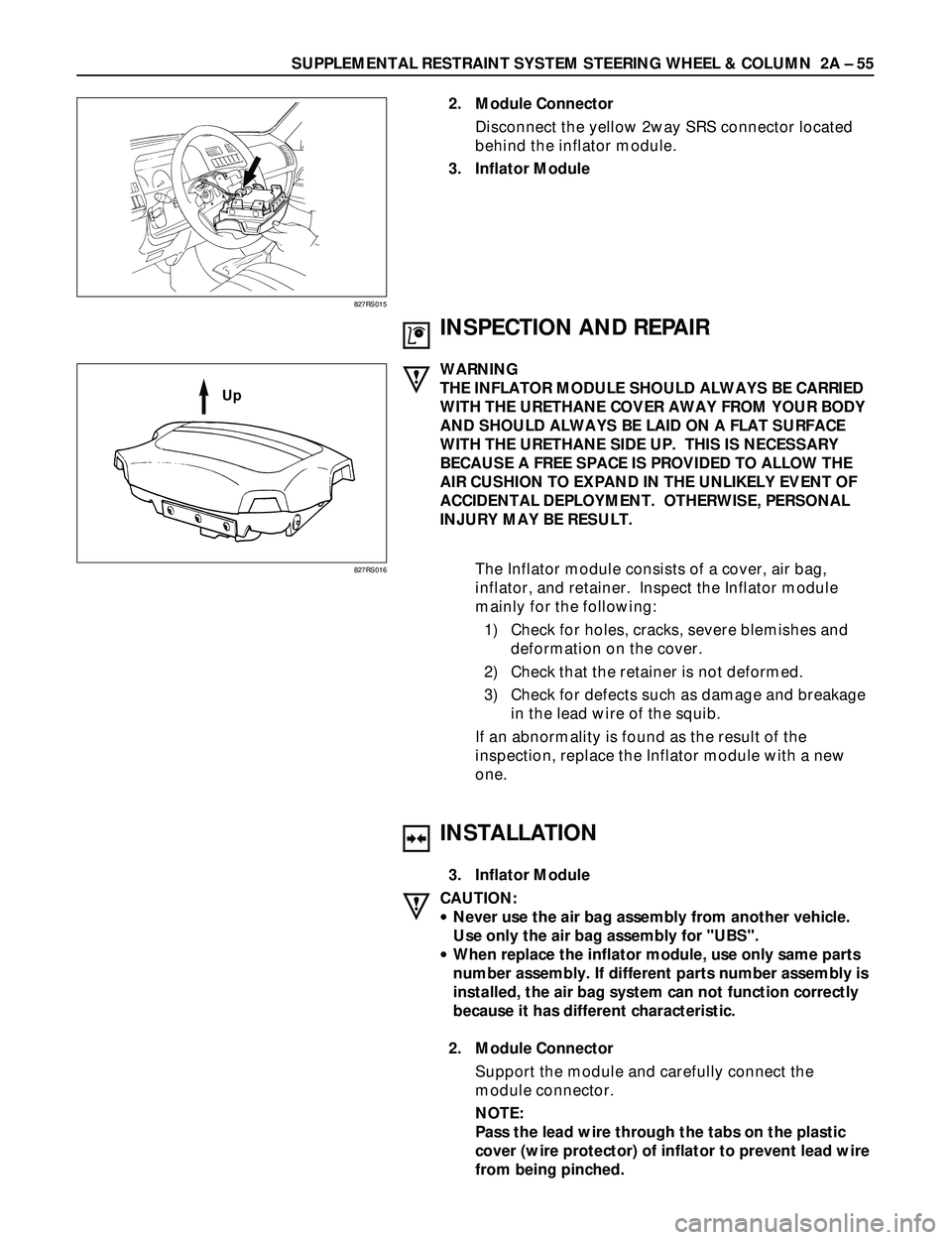

The Inflator module consists of a cover, air bag,

inflator, and retainer. Inspect the Inflator module

mainly for the following:

1) Check for holes, cracks, severe blemishes and

deformation on the cover.

2) Check that the retainer is not deformed.

3) Check for defects such as damage and breakage

in the lead wire of the squib.

If an abnormality is found as the result of the

inspection, replace the Inflator module with a new

one.

Up

Page 360 of 3573

2A – 58 SUPPLEMENTAL RESTRAINT SYSTEM STEERING WHEEL & COLUMN

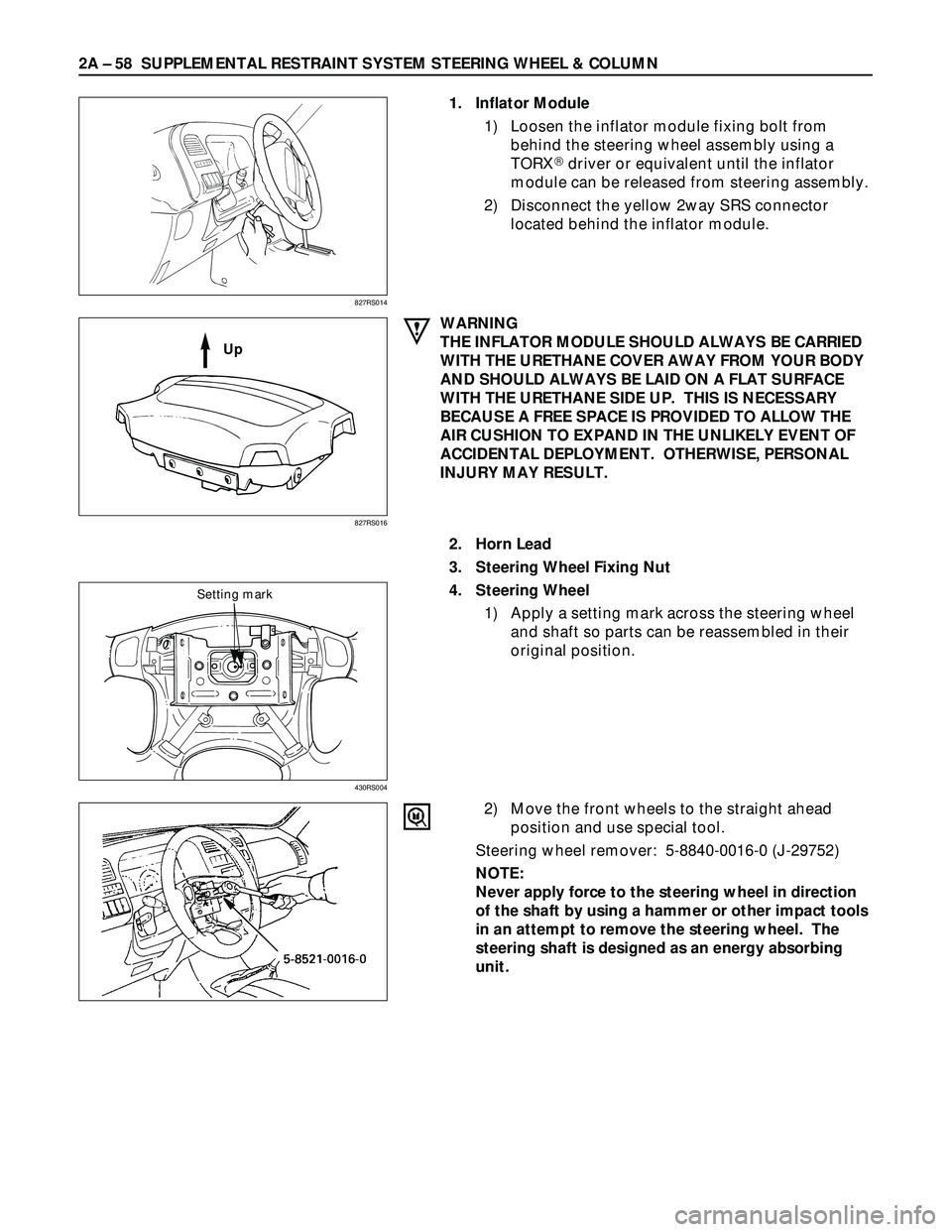

1. Inflator Module

1) Loosen the inflator module fixing bolt from

behind the steering wheel assembly using a

TORX

driver or equivalent until the inflator

module can be released from steering assembly.

2) Disconnect the yellow 2way SRS connector

located behind the inflator module.

WARNING

THE INFLATOR MODULE SHOULD ALWAYS BE CARRIED

WITH THE URETHANE COVER AWAY FROM YOUR BODY

AND SHOULD ALWAYS BE LAID ON A FLAT SURFACE

WITH THE URETHANE SIDE UP. THIS IS NECESSARY

BECAUSE A FREE SPACE IS PROVIDED TO ALLOW THE

AIR CUSHION TO EXPAND IN THE UNLIKELY EVENT OF

ACCIDENTAL DEPLOYMENT. OTHERWISE, PERSONAL

INJURY MAY RESULT.

2. Horn Lead

3. Steering Wheel Fixing Nut

4. Steering Wheel

1) Apply a setting mark across the steering wheel

and shaft so parts can be reassembled in their

original position.

2) Move the front wheels to the straight ahead

position and use special tool.

Steering wheel remover: 5-8840-0016-0 (J-29752)

NOTE:

Never apply force to the steering wheel in direction

of the shaft by using a hammer or other impact tools

in an attempt to remove the steering wheel. The

steering shaft is designed as an energy absorbing

unit.

827RS014

827RS016

430RS004

Up

Setting mark

Page 361 of 3573

SUPPLEMENTAL RESTRAINT SYSTEM STEERING WHEEL & COLUMN 2A Ð 59

INSTALLATION

4. Steering Wheel

Align the setting marks made when removing.

CAUTION:

Never apply force to the setting wheel in direction of the

shaft by using a hammer or other impact tools in an

attempt to install the steering wheel. The setting shaft is

designed as an energy absorbing unit.

3. Steering Wheel Fixing Nut

Steering Wheel Nut Torque Nám (kgám/lbáft)

34 (3.5 / 25)

2. Horn Lead

1. Inflator Module

1) Support the module and carefully connect the

module connector.

CAUTION:

·Never use the air bag assembly from another vehicle.

Use only the air bag assembly for "UBS".

·When replace the inflator module, use only same parts

number assembly. If different parts number assembly is

installed, the air bag system can not function correctly

because it has different characteristic.

NOTE:

Pass the lead wire through the tabs on the plastic

cover (wire protector) of inflator to prevent lead wire

from being pinches.

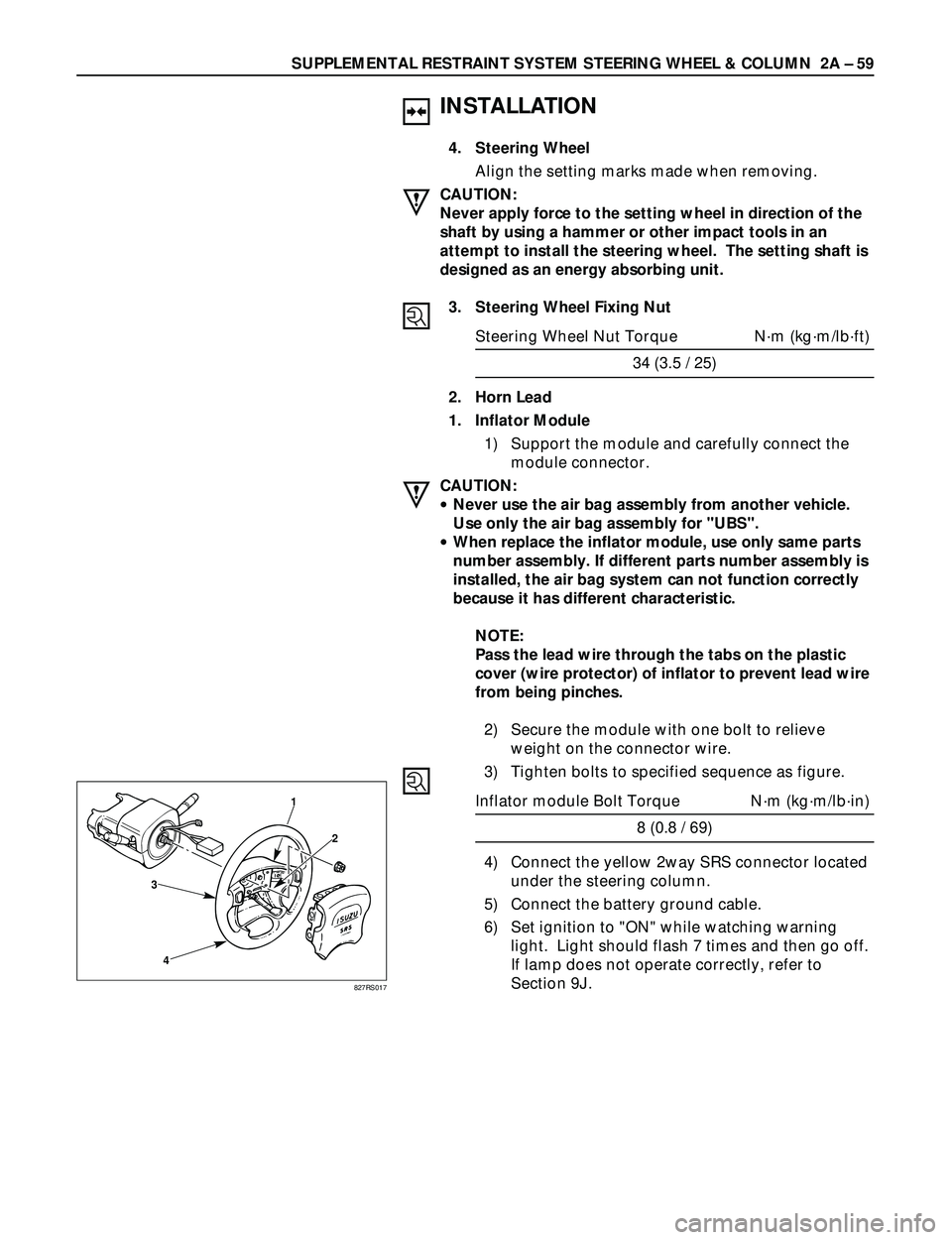

2) Secure the module with one bolt to relieve

weight on the connector wire.

3) Tighten bolts to specified sequence as figure.

Inflator module Bolt Torque Nám (kgám/lbáin)

8 (0.8 / 69)

4) Connect the yellow 2way SRS connector located

under the steering column.

5) Connect the battery ground cable.

6) Set ignition to "ON" while watching warning

light. Light should flash 7 times and then go off.

If lamp does not operate correctly, refer to

Section 9J.

3

41

2

827RS017

Page 364 of 3573

2A Ð 62 SUPPLEMENTAL RESTRAINT SYSTEM STEERING WHEEL & COLUMN

Use special tool. Remove the steering wheel.

Move the tires to the straight ahead position before

removing the steering wheel.

Steering wheel remover: 5-8840-0016-0 (J-29752)

CAUTION:

Never apply force to the steering wheel in direction of the

shaft by using a hammer or other impact tools in an

attempt to remove the steering wheel. The steering shaft

is designed as an energy absorbing unit.

6. Steering Column Cover

7. Combination Switch and SRS Coil Assembly

1) Disconnect the wiring harness connectors

located under the steering column.

2) Remove the combination switch assembly with

SRS coil.

NOTE:

The SRS coil is a part of the combination switch

assembly, which can not be replaced separately.

Therefore, be sure not to remove the SRS coil from

the combination switch assembly.

825RS046

INSTALLATION

Alignment mark

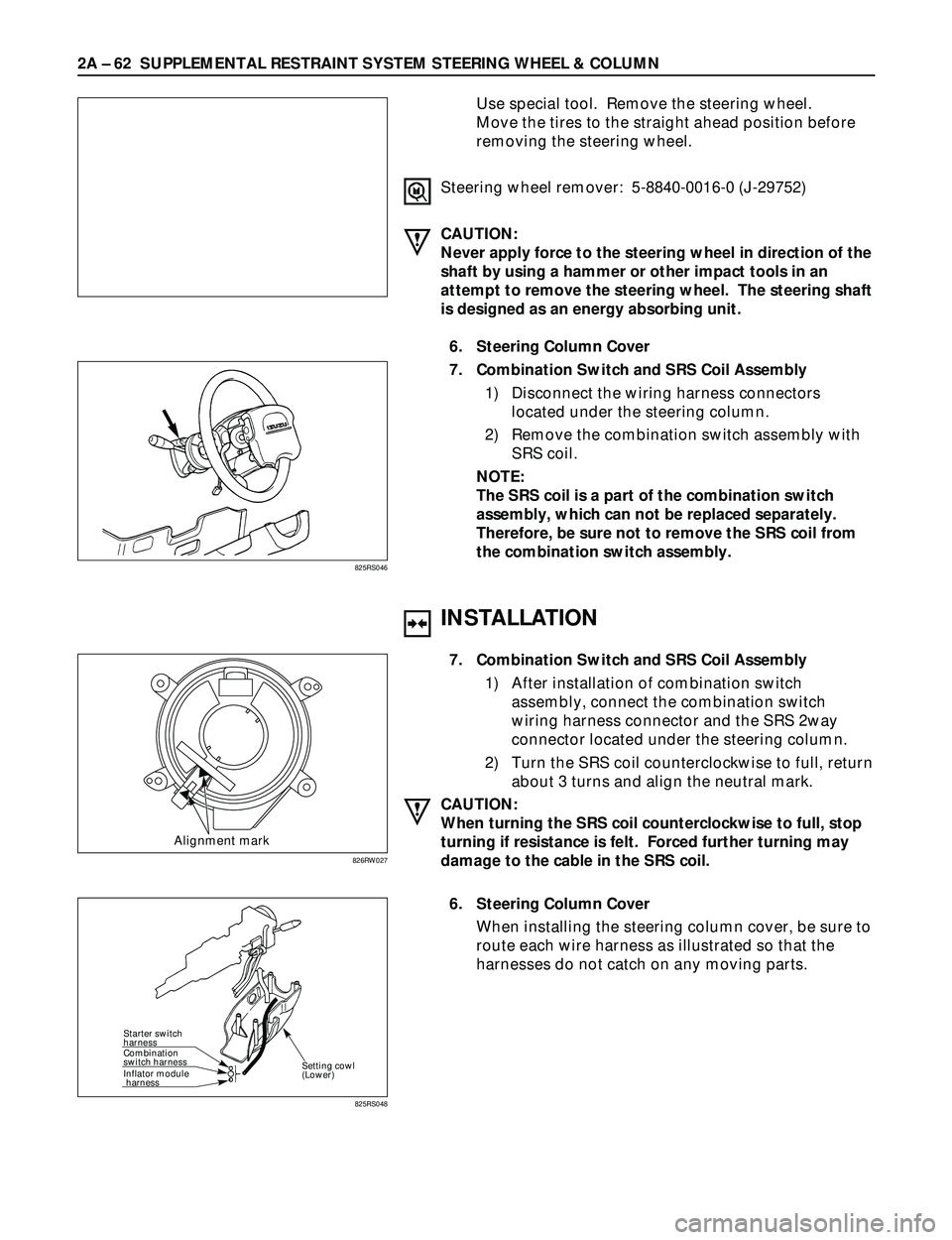

7. Combination Switch and SRS Coil Assembly

1) After installation of combination switch

assembly, connect the combination switch

wiring harness connector and the SRS 2way

connector located under the steering column.

2) Turn the SRS coil counterclockwise to full, return

about 3 turns and align the neutral mark.

CAUTION:

When turning the SRS coil counterclockwise to full, stop

turning if resistance is felt. Forced further turning may

damage to the cable in the SRS coil.

826RW027

Starter switch

harness

Combination

switch harness

Inflator module

harness

Setting cowl

(Lower)

6. Steering Column Cover

When installing the steering column cover, be sure to

route each wire harness as illustrated so that the

harnesses do not catch on any moving parts.

825RS048

Page 365 of 3573

SUPPLEMENTAL RESTRAINT SYSTEM STEERING WHEEL & COLUMN 2A Ð 63

5. Steering Wheel

Align the setting marks made when removing.

CAUTION:

Never apply force to the steering wheel in direction of the

shaft by using a hammer or other impact tools in an

attempt to remove the steering wheel. The steering shaft

is designed as an energy absorbing unit.

Tighten the steering wheel fixing nut to the specified

torque.

Steering Wheel Nut Torque Nám (kgám/lbáft)

34 (3.5 / 25)

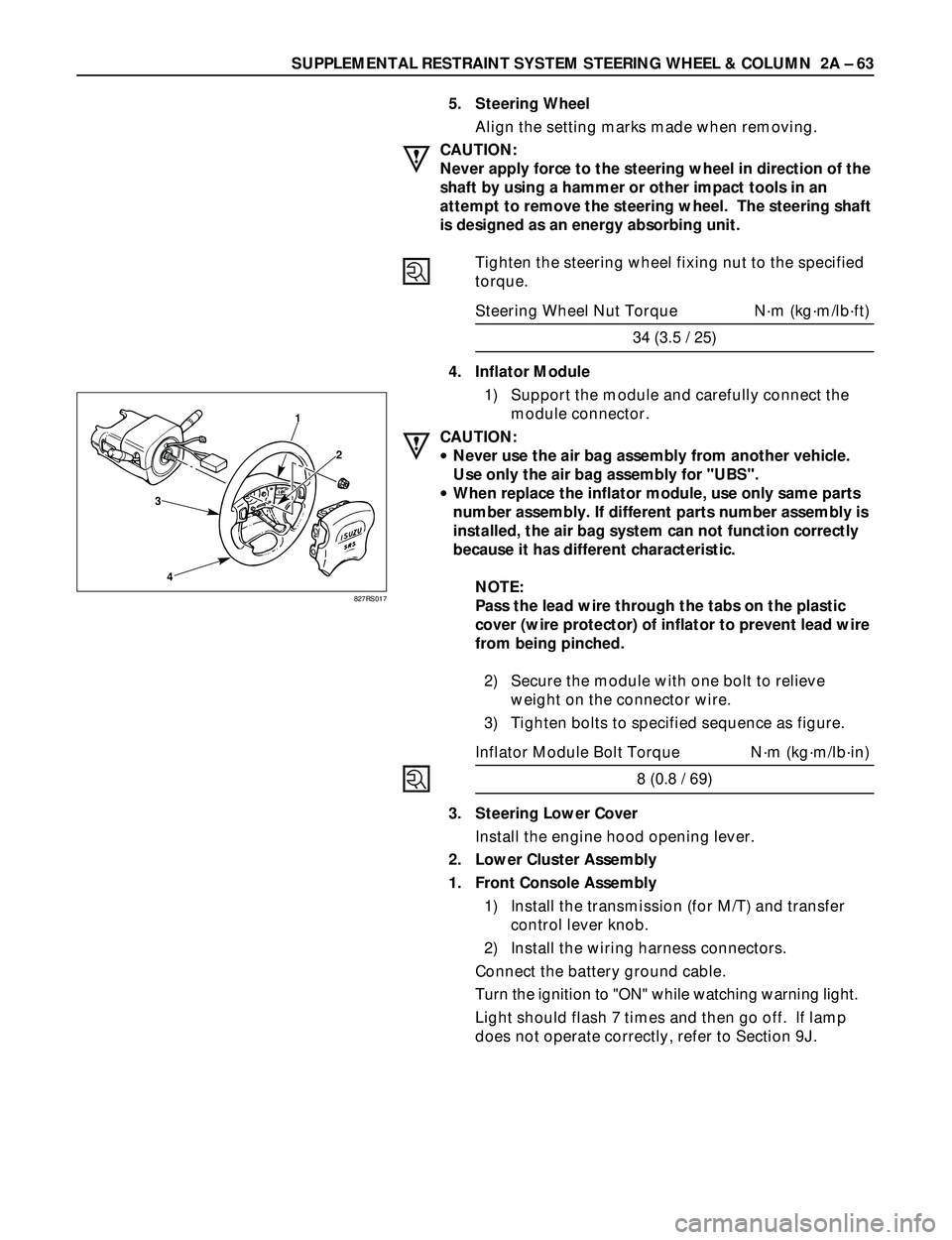

4. Inflator Module

1) Support the module and carefully connect the

module connector.

CAUTION:

·Never use the air bag assembly from another vehicle.

Use only the air bag assembly for "UBS".

·When replace the inflator module, use only same parts

number assembly. If different parts number assembly is

installed, the air bag system can not function correctly

because it has different characteristic.

NOTE:

Pass the lead wire through the tabs on the plastic

cover (wire protector) of inflator to prevent lead wire

from being pinched.

2) Secure the module with one bolt to relieve

weight on the connector wire.

3) Tighten bolts to specified sequence as figure.

Inflator Module Bolt Torque Nám (kgám/lbáin)

8 (0.8 / 69)

3. Steering Lower Cover

Install the engine hood opening lever.

2. Lower Cluster Assembly

1. Front Console Assembly

1) Install the transmission (for M/T) and transfer

control lever knob.

2) Install the wiring harness connectors.

Connect the battery ground cable.

Turn the ignition to "ON" while watching warning light.

Light should flash 7 times and then go off. If lamp

does not operate correctly, refer to Section 9J.

3

41

2

827RS017