Transmission ISUZU TROOPER 1998 Service User Guide

[x] Cancel search | Manufacturer: ISUZU, Model Year: 1998, Model line: TROOPER, Model: ISUZU TROOPER 1998Pages: 3573, PDF Size: 60.36 MB

Page 131 of 3573

AIR CONDITIONING 1B Ð 5

With some compressors the differential between

the intake pressure and discharge pressure

generated while the compressor is operating is

used for lubrication instead of an oil pump.

The specified amount of the DKV-14D, DKS-15CH

and HD6 compressors oil is 150cc (4.2 Imp fl oz).

Also, compressor oil to be used varies according to

the compressor model. Be sure to avoid mixing

two or more different types of oil.

If the wrong oil is used, lubrication will be poor and

the compressor will seize or malfunction.

The magnetic clutch connector is a waterproof type.

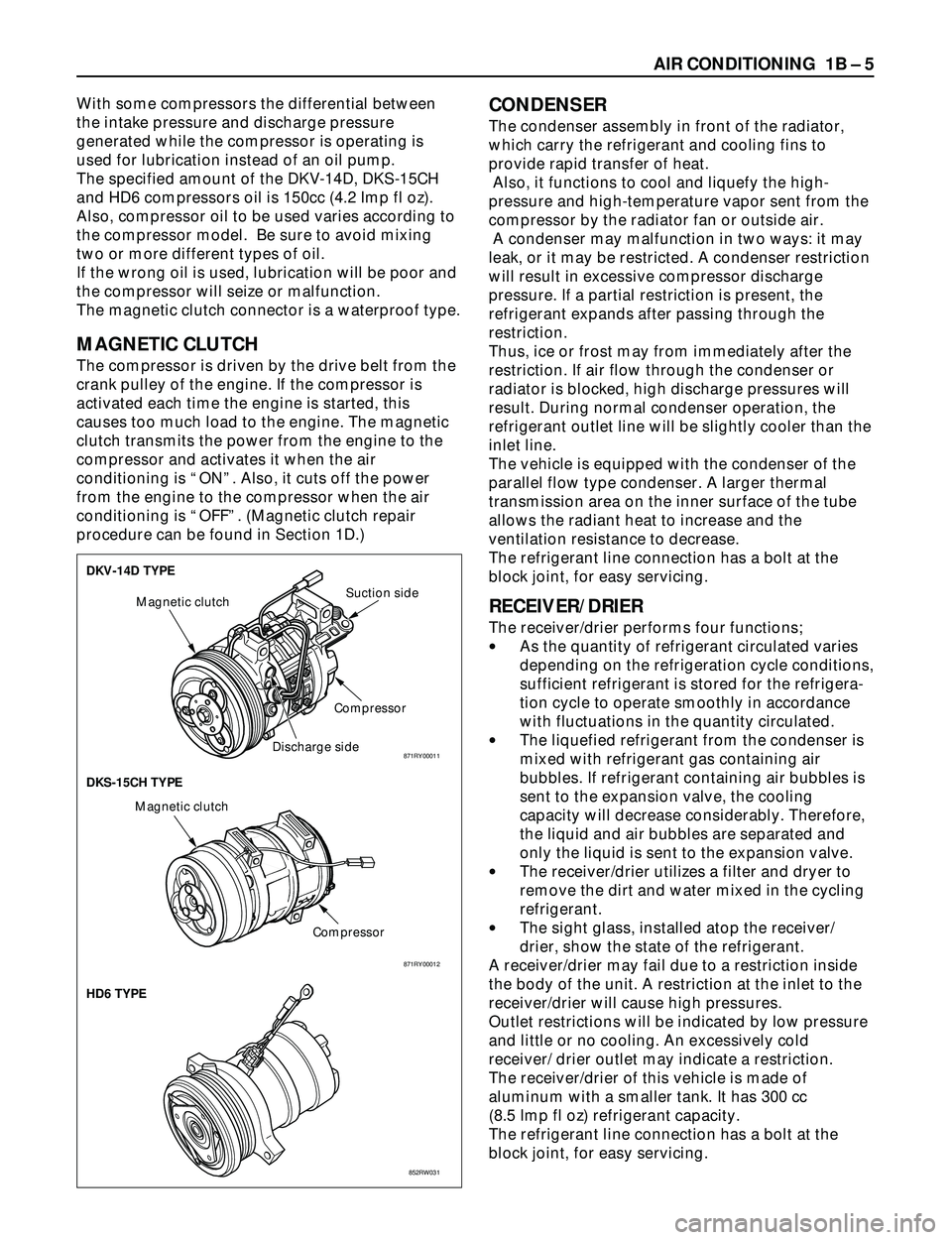

MAGNETIC CLUTCH

The compressor is driven by the drive belt from the

crank pulley of the engine. If the compressor is

activated each time the engine is started, this

causes too much load to the engine. The magnetic

clutch transmits the power from the engine to the

compressor and activates it when the air

conditioning is ÒONÓ. Also, it cuts off the power

from the engine to the compressor when the air

conditioning is ÒOFFÓ. (Magnetic clutch repair

procedure can be found in Section 1D.)

CONDENSER

The condenser assembly in front of the radiator,

which carry the refrigerant and cooling fins to

provide rapid transfer of heat.

Also, it functions to cool and liquefy the high-

pressure and high-temperature vapor sent from the

compressor by the radiator fan or outside air.

A condenser may malfunction in two ways: it may

leak, or it may be restricted. A condenser restriction

will result in excessive compressor discharge

pressure. If a partial restriction is present, the

refrigerant expands after passing through the

restriction.

Thus, ice or frost may from immediately after the

restriction. If air flow through the condenser or

radiator is blocked, high discharge pressures will

result. During normal condenser operation, the

refrigerant outlet line will be slightly cooler than the

inlet line.

The vehicle is equipped with the condenser of the

parallel flow type condenser. A larger thermal

transmission area on the inner surface of the tube

allows the radiant heat to increase and the

ventilation resistance to decrease.

The refrigerant line connection has a bolt at the

block joint, for easy servicing.

RECEIVER/DRIER

The receiver/drier performs four functions;

·As the quantity of refrigerant circulated varies

depending on the refrigeration cycle conditions,

sufficient refrigerant is stored for the refrigera-

tion cycle to operate smoothly in accordance

with fluctuations in the quantity circulated.

·The liquefied refrigerant from the condenser is

mixed with refrigerant gas containing air

bubbles. If refrigerant containing air bubbles is

sent to the expansion valve, the cooling

capacity will decrease considerably. Therefore,

the liquid and air bubbles are separated and

only the liquid is sent to the expansion valve.

·The receiver/drier utilizes a filter and dryer to

remove the dirt and water mixed in the cycling

refrigerant.

·The sight glass, installed atop the receiver/

drier, show the state of the refrigerant.

A receiver/drier may fail due to a restriction inside

the body of the unit. A restriction at the inlet to the

receiver/drier will cause high pressures.

Outlet restrictions will be indicated by low pressure

and little or no cooling. An excessively cold

receiver/ drier outlet may indicate a restriction.

The receiver/drier of this vehicle is made of

aluminum with a smaller tank. It has 300 cc

(8.5 Imp fl oz) refrigerant capacity.

The refrigerant line connection has a bolt at the

block joint, for easy servicing.

DKV-14D TYPE

DKS-15CH TYPE

HD6 TYPE

Magnetic clutch

CompressorSuction side

Discharge side

Compressor Magnetic clutch

852RW031 871RY00012

871RY00011

Page 363 of 3573

SUPPLEMENTAL RESTRAINT SYSTEM STEERING WHEEL & COLUMN 2A – 61

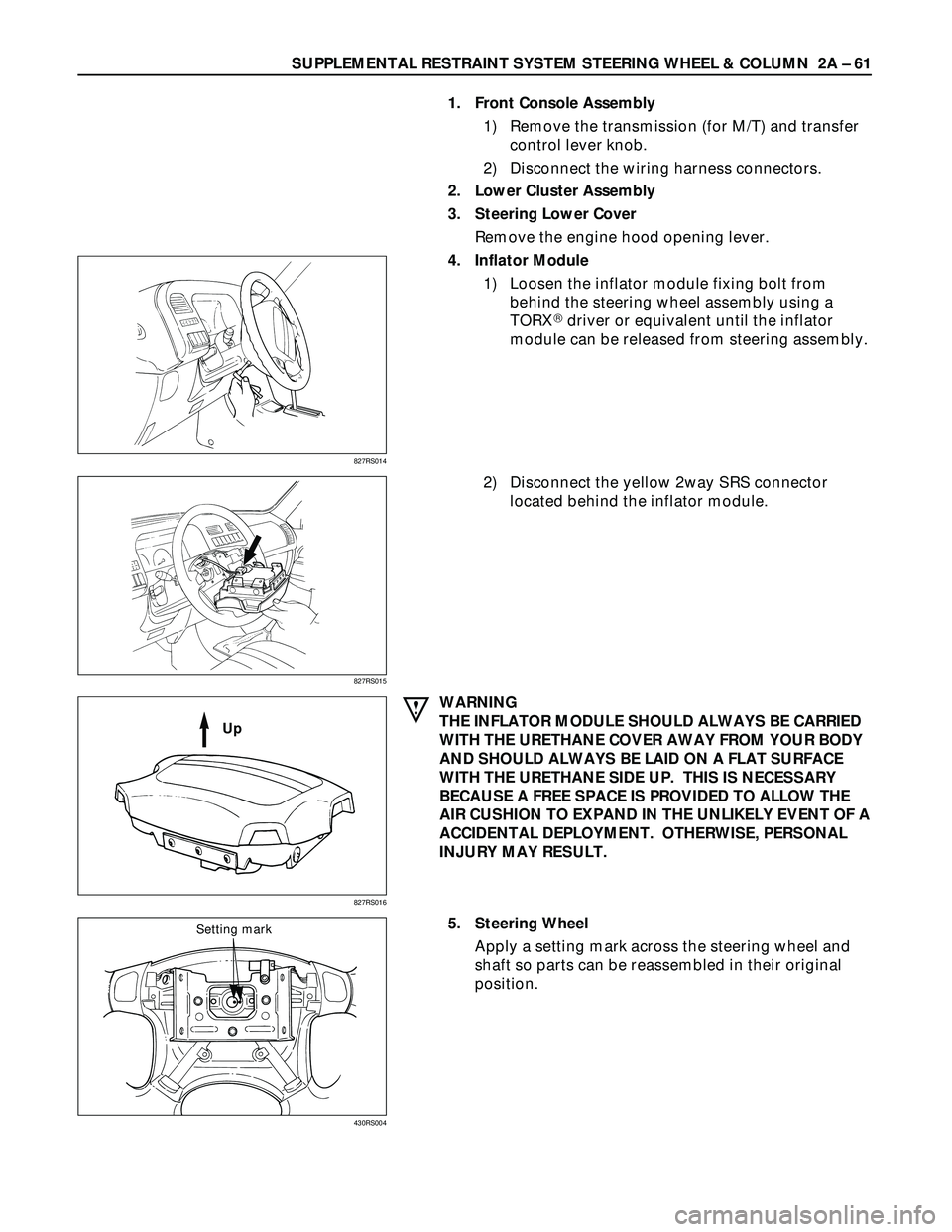

1. Front Console Assembly

1) Remove the transmission (for M/T) and transfer

control lever knob.

2) Disconnect the wiring harness connectors.

2. Lower Cluster Assembly

3. Steering Lower Cover

Remove the engine hood opening lever.

4. Inflator Module

1) Loosen the inflator module fixing bolt from

behind the steering wheel assembly using a

TORX

driver or equivalent until the inflator

module can be released from steering assembly.

2) Disconnect the yellow 2way SRS connector

located behind the inflator module.

WARNING

THE INFLATOR MODULE SHOULD ALWAYS BE CARRIED

WITH THE URETHANE COVER AWAY FROM YOUR BODY

AND SHOULD ALWAYS BE LAID ON A FLAT SURFACE

WITH THE URETHANE SIDE UP. THIS IS NECESSARY

BECAUSE A FREE SPACE IS PROVIDED TO ALLOW THE

AIR CUSHION TO EXPAND IN THE UNLIKELY EVENT OF A

ACCIDENTAL DEPLOYMENT. OTHERWISE, PERSONAL

INJURY MAY RESULT.

5. Steering Wheel

Apply a setting mark across the steering wheel and

shaft so parts can be reassembled in their original

position.

827RS014

827RS015

827RS016

Up

430RS004

Setting mark

Page 365 of 3573

SUPPLEMENTAL RESTRAINT SYSTEM STEERING WHEEL & COLUMN 2A Ð 63

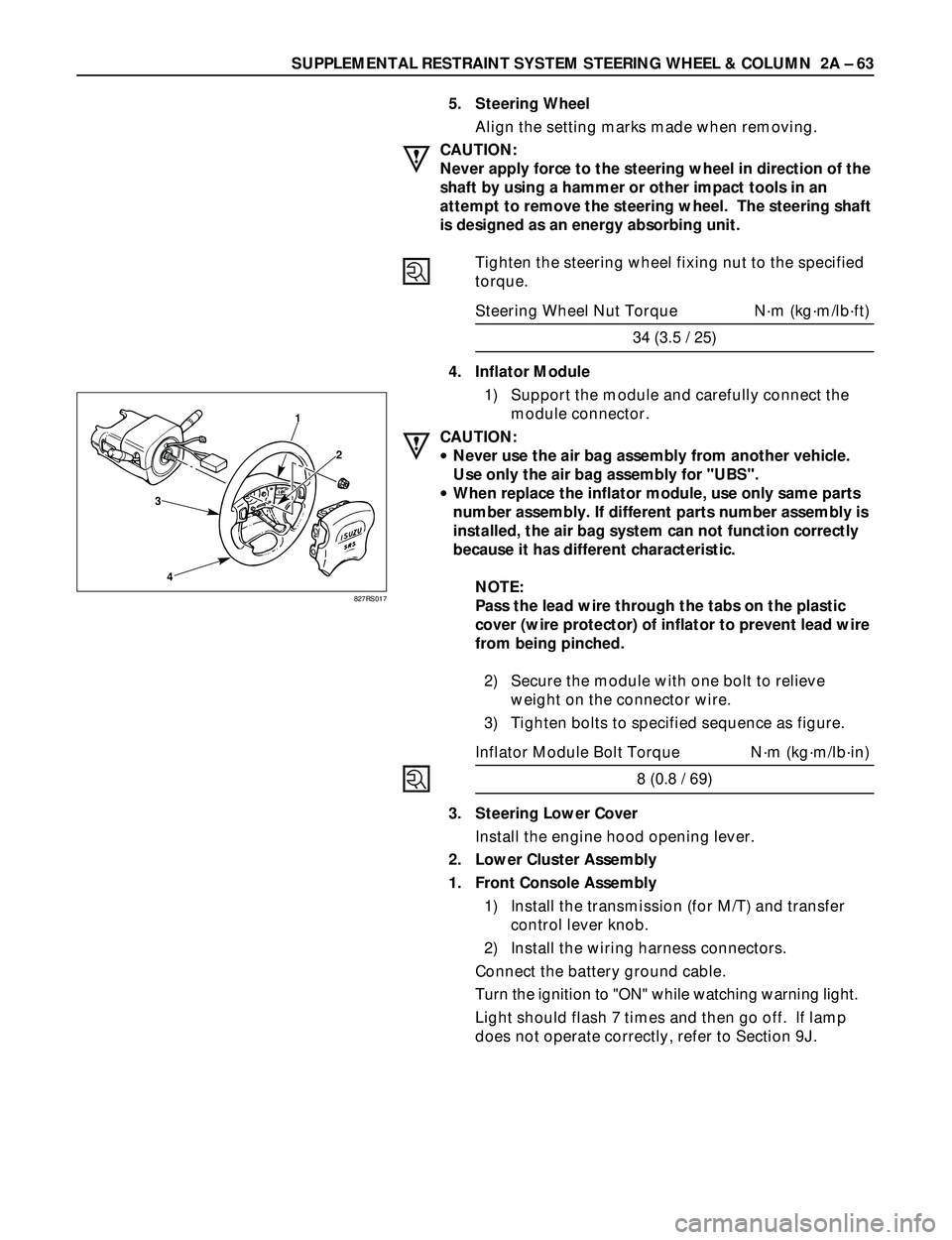

5. Steering Wheel

Align the setting marks made when removing.

CAUTION:

Never apply force to the steering wheel in direction of the

shaft by using a hammer or other impact tools in an

attempt to remove the steering wheel. The steering shaft

is designed as an energy absorbing unit.

Tighten the steering wheel fixing nut to the specified

torque.

Steering Wheel Nut Torque Nám (kgám/lbáft)

34 (3.5 / 25)

4. Inflator Module

1) Support the module and carefully connect the

module connector.

CAUTION:

·Never use the air bag assembly from another vehicle.

Use only the air bag assembly for "UBS".

·When replace the inflator module, use only same parts

number assembly. If different parts number assembly is

installed, the air bag system can not function correctly

because it has different characteristic.

NOTE:

Pass the lead wire through the tabs on the plastic

cover (wire protector) of inflator to prevent lead wire

from being pinched.

2) Secure the module with one bolt to relieve

weight on the connector wire.

3) Tighten bolts to specified sequence as figure.

Inflator Module Bolt Torque Nám (kgám/lbáin)

8 (0.8 / 69)

3. Steering Lower Cover

Install the engine hood opening lever.

2. Lower Cluster Assembly

1. Front Console Assembly

1) Install the transmission (for M/T) and transfer

control lever knob.

2) Install the wiring harness connectors.

Connect the battery ground cable.

Turn the ignition to "ON" while watching warning light.

Light should flash 7 times and then go off. If lamp

does not operate correctly, refer to Section 9J.

3

41

2

827RS017

Page 367 of 3573

SUPPLEMENTAL RESTRAINT SYSTEM STEERING WHEEL & COLUMN 2A – 65

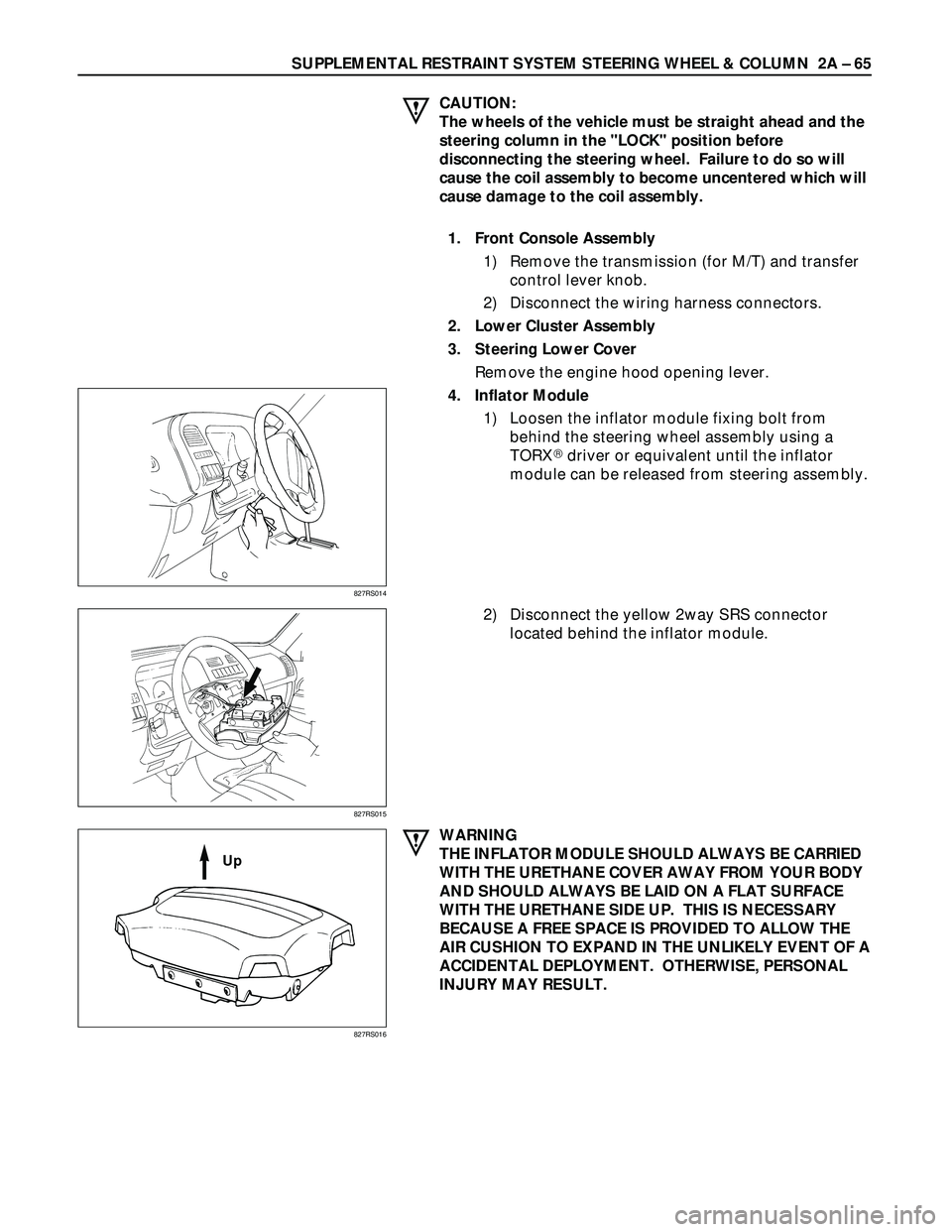

CAUTION:

The wheels of the vehicle must be straight ahead and the

steering column in the "LOCK" position before

disconnecting the steering wheel. Failure to do so will

cause the coil assembly to become uncentered which will

cause damage to the coil assembly.

1. Front Console Assembly

1) Remove the transmission (for M/T) and transfer

control lever knob.

2) Disconnect the wiring harness connectors.

2. Lower Cluster Assembly

3. Steering Lower Cover

Remove the engine hood opening lever.

4. Inflator Module

1) Loosen the inflator module fixing bolt from

behind the steering wheel assembly using a

TORX

driver or equivalent until the inflator

module can be released from steering assembly.

2) Disconnect the yellow 2way SRS connector

located behind the inflator module.

WARNING

THE INFLATOR MODULE SHOULD ALWAYS BE CARRIED

WITH THE URETHANE COVER AWAY FROM YOUR BODY

AND SHOULD ALWAYS BE LAID ON A FLAT SURFACE

WITH THE URETHANE SIDE UP. THIS IS NECESSARY

BECAUSE A FREE SPACE IS PROVIDED TO ALLOW THE

AIR CUSHION TO EXPAND IN THE UNLIKELY EVENT OF A

ACCIDENTAL DEPLOYMENT. OTHERWISE, PERSONAL

INJURY MAY RESULT.

827RS014

827RS015

827RS016

Up

Page 370 of 3573

2A Ð 68 SUPPLEMENTAL RESTRAINT SYSTEM STEERING WHEEL & COLUMN

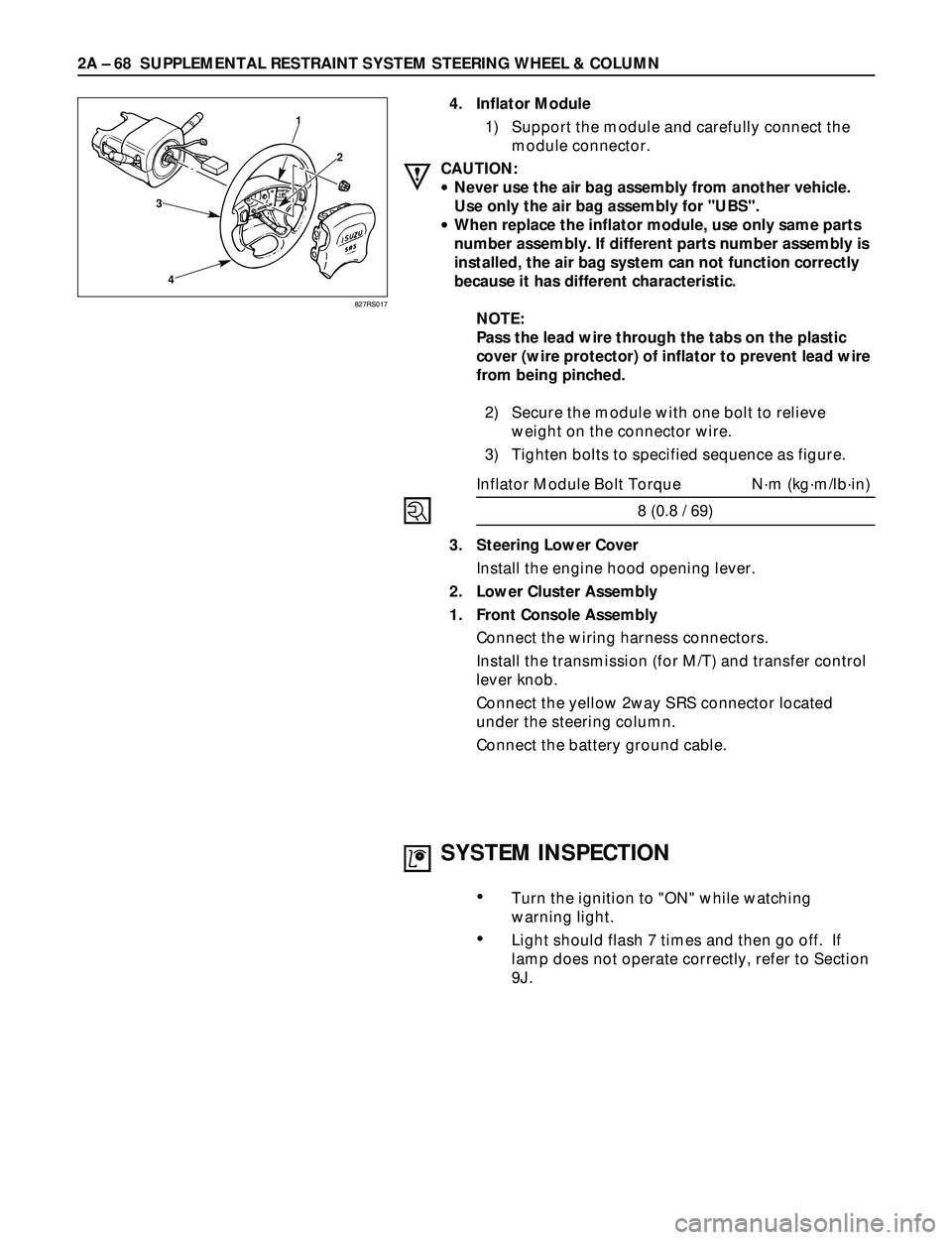

3

41

2

4. Inflator Module

1) Support the module and carefully connect the

module connector.

CAUTION:

·Never use the air bag assembly from another vehicle.

Use only the air bag assembly for "UBS".

·When replace the inflator module, use only same parts

number assembly. If different parts number assembly is

installed, the air bag system can not function correctly

because it has different characteristic.

NOTE:

Pass the lead wire through the tabs on the plastic

cover (wire protector) of inflator to prevent lead wire

from being pinched.

2) Secure the module with one bolt to relieve

weight on the connector wire.

3) Tighten bolts to specified sequence as figure.

Inflator Module Bolt Torque Nám (kgám/lbáin)

8 (0.8 / 69)

3. Steering Lower Cover

Install the engine hood opening lever.

2. Lower Cluster Assembly

1. Front Console Assembly

Connect the wiring harness connectors.

Install the transmission (for M/T) and transfer control

lever knob.

Connect the yellow 2way SRS connector located

under the steering column.

Connect the battery ground cable.

827RS017

SYSTEM INSPECTION

¥Turn the ignition to "ON" while watching

warning light.

¥Light should flash 7 times and then go off. If

lamp does not operate correctly, refer to Section

9J.

Page 372 of 3573

2A – 70 SUPPLEMENTAL RESTRAINT SYSTEM STEERING WHEEL & COLUMN

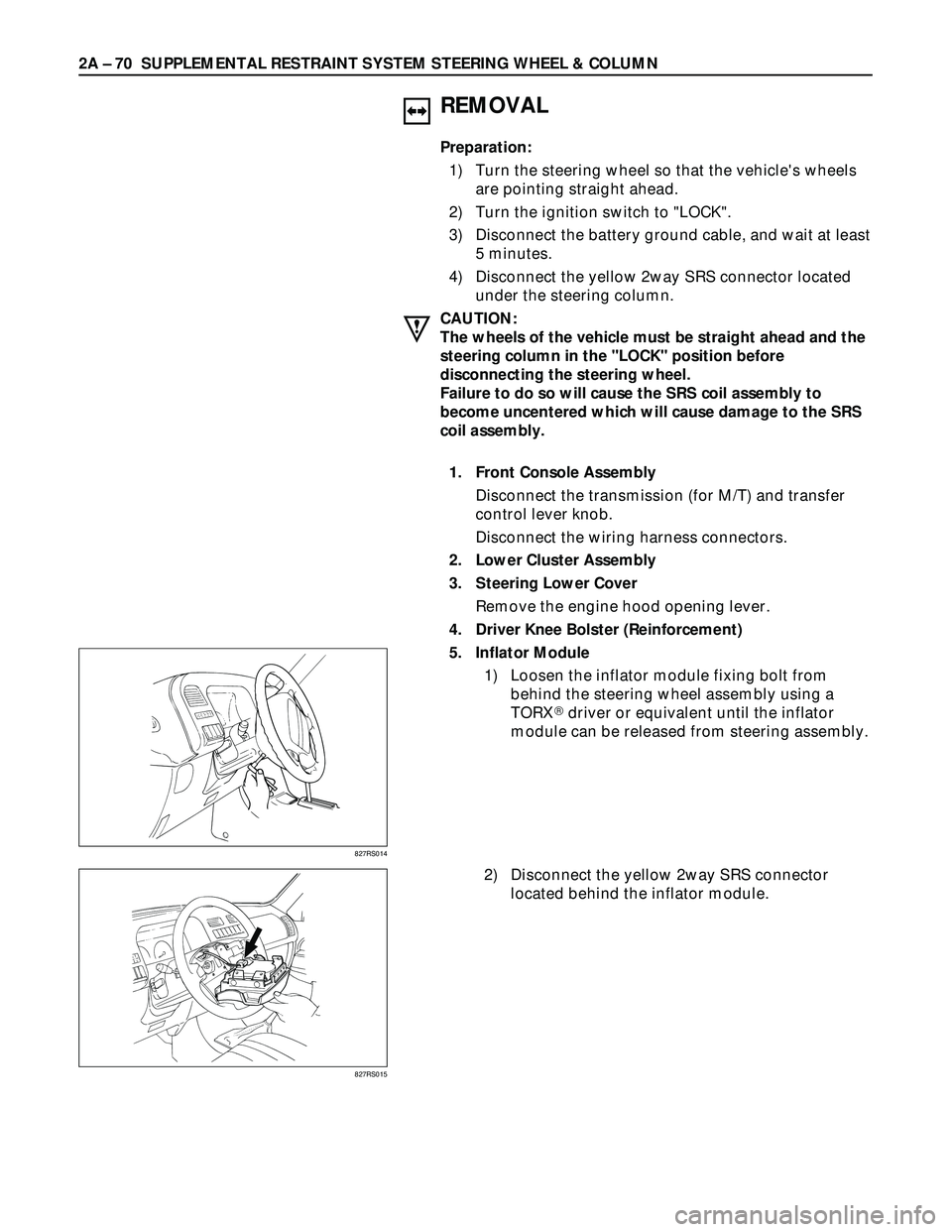

REMOVAL

Preparation:

1) Turn the steering wheel so that the vehicle's wheels

are pointing straight ahead.

2) Turn the ignition switch to "LOCK".

3) Disconnect the battery ground cable, and wait at least

5 minutes.

4) Disconnect the yellow 2way SRS connector located

under the steering column.

CAUTION:

The wheels of the vehicle must be straight ahead and the

steering column in the "LOCK" position before

disconnecting the steering wheel.

Failure to do so will cause the SRS coil assembly to

become uncentered which will cause damage to the SRS

coil assembly.

1. Front Console Assembly

Disconnect the transmission (for M/T) and transfer

control lever knob.

Disconnect the wiring harness connectors.

2. Lower Cluster Assembly

3. Steering Lower Cover

Remove the engine hood opening lever.

4. Driver Knee Bolster (Reinforcement)

5. Inflator Module

1) Loosen the inflator module fixing bolt from

behind the steering wheel assembly using a

TORX

driver or equivalent until the inflator

module can be released from steering assembly.

2) Disconnect the yellow 2way SRS connector

located behind the inflator module.

827RS014

827RS015

Page 375 of 3573

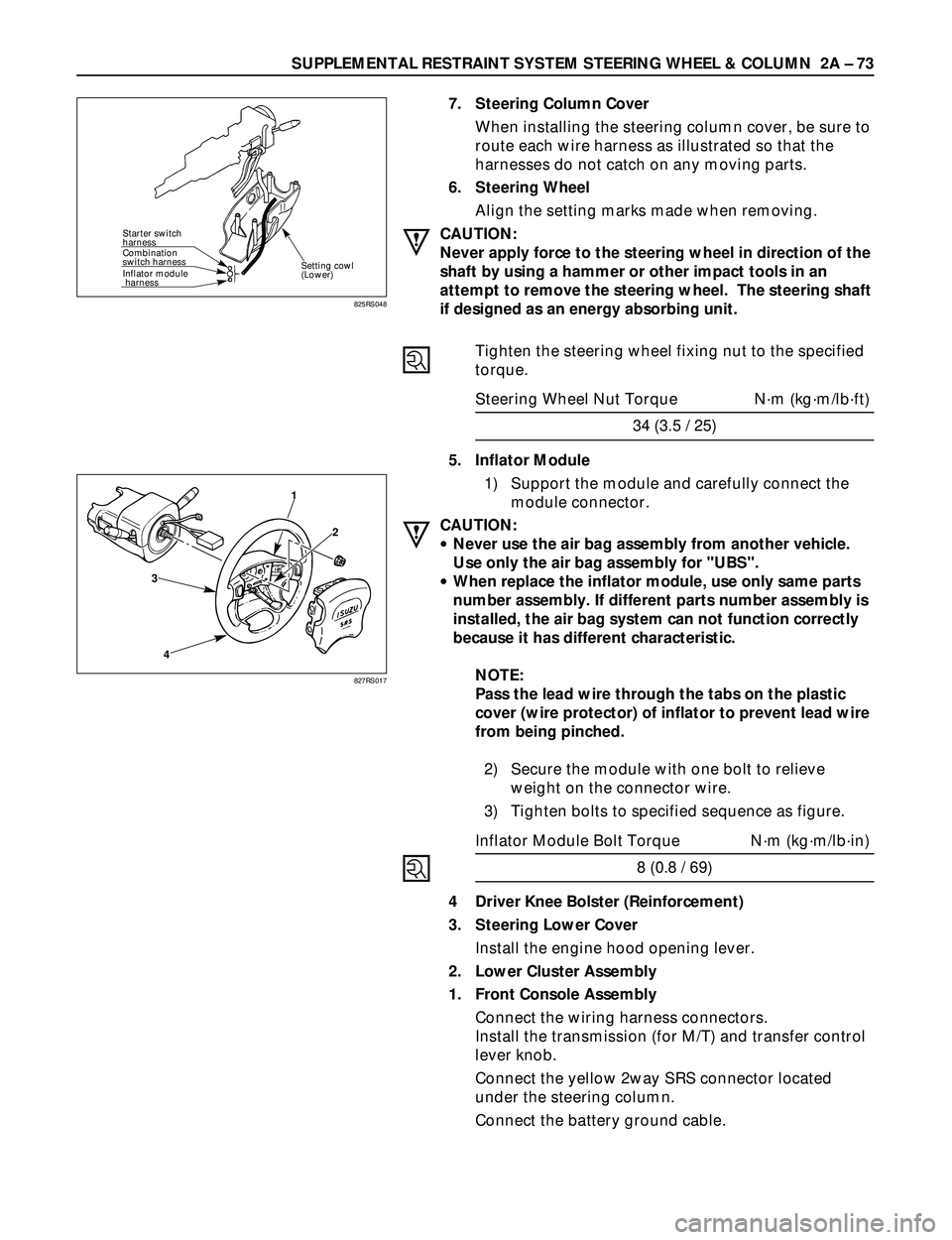

SUPPLEMENTAL RESTRAINT SYSTEM STEERING WHEEL & COLUMN 2A Ð 73

Starter switch

harness

Combination

switch harness

Inflator module

harness

Setting cowl

(Lower)

7. Steering Column Cover

When installing the steering column cover, be sure to

route each wire harness as illustrated so that the

harnesses do not catch on any moving parts.

6. Steering Wheel

Align the setting marks made when removing.

CAUTION:

Never apply force to the steering wheel in direction of the

shaft by using a hammer or other impact tools in an

attempt to remove the steering wheel. The steering shaft

if designed as an energy absorbing unit.

Tighten the steering wheel fixing nut to the specified

torque.

Steering Wheel Nut Torque Nám (kgám/lbáft)

34 (3.5 / 25)

5. Inflator Module

1) Support the module and carefully connect the

module connector.

CAUTION:

·Never use the air bag assembly from another vehicle.

Use only the air bag assembly for "UBS".

·When replace the inflator module, use only same parts

number assembly. If different parts number assembly is

installed, the air bag system can not function correctly

because it has different characteristic.

NOTE:

Pass the lead wire through the tabs on the plastic

cover (wire protector) of inflator to prevent lead wire

from being pinched.

2) Secure the module with one bolt to relieve

weight on the connector wire.

3) Tighten bolts to specified sequence as figure.

Inflator Module Bolt Torque Nám (kgám/lbáin)

8 (0.8 / 69)

4 Driver Knee Bolster (Reinforcement)

3. Steering Lower Cover

Install the engine hood opening lever.

2. Lower Cluster Assembly

1. Front Console Assembly

Connect the wiring harness connectors.

Install the transmission (for M/T) and transfer control

lever knob.

Connect the yellow 2way SRS connector located

under the steering column.

Connect the battery ground cable.

825RS048

3

41

2

827RS017

Page 381 of 3573

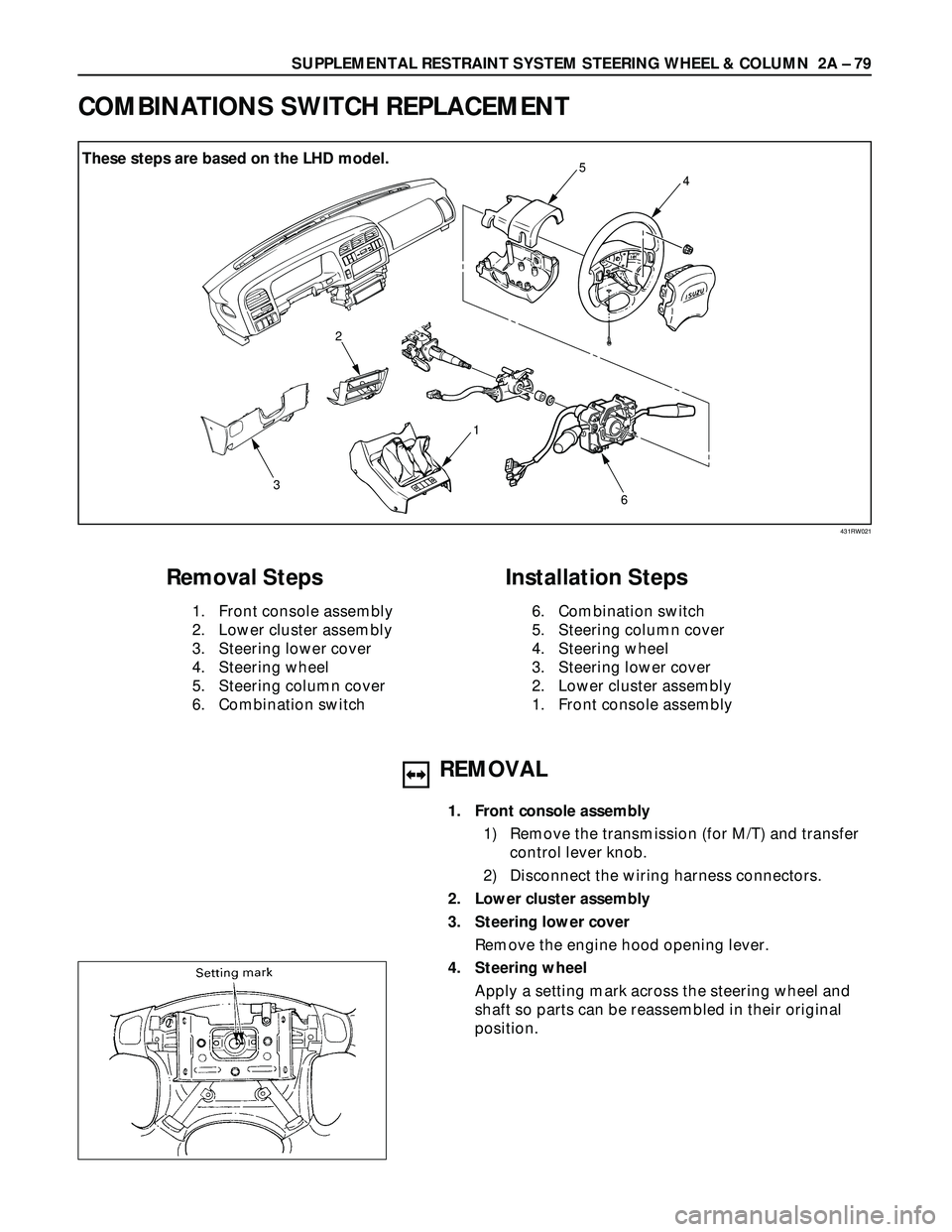

SUPPLEMENTAL RESTRAINT SYSTEM STEERING WHEEL & COLUMN 2A – 79

4

1 2

6

3

5 These steps are based on the LHD model.

Removal Steps

1. Front console assembly

2. Lower cluster assembly

3. Steering lower cover

4. Steering wheel

5. Steering column cover

6. Combination switch

Installation Steps

6. Combination switch

5. Steering column cover

4. Steering wheel

3. Steering lower cover

2. Lower cluster assembly

1. Front console assembly

REMOVAL

1. Front console assembly

1) Remove the transmission (for M/T) and transfer

control lever knob.

2) Disconnect the wiring harness connectors.

2. Lower cluster assembly

3. Steering lower cover

Remove the engine hood opening lever.

4. Steering wheel

Apply a setting mark across the steering wheel and

shaft so parts can be reassembled in their original

position.

COMBINATIONS SWITCH REPLACEMENT

431RW021

These steps are based on the LHD model.

Page 382 of 3573

2A – 80 SUPPLEMENTAL RESTRAINT SYSTEM STEERING WHEEL & COLUMN

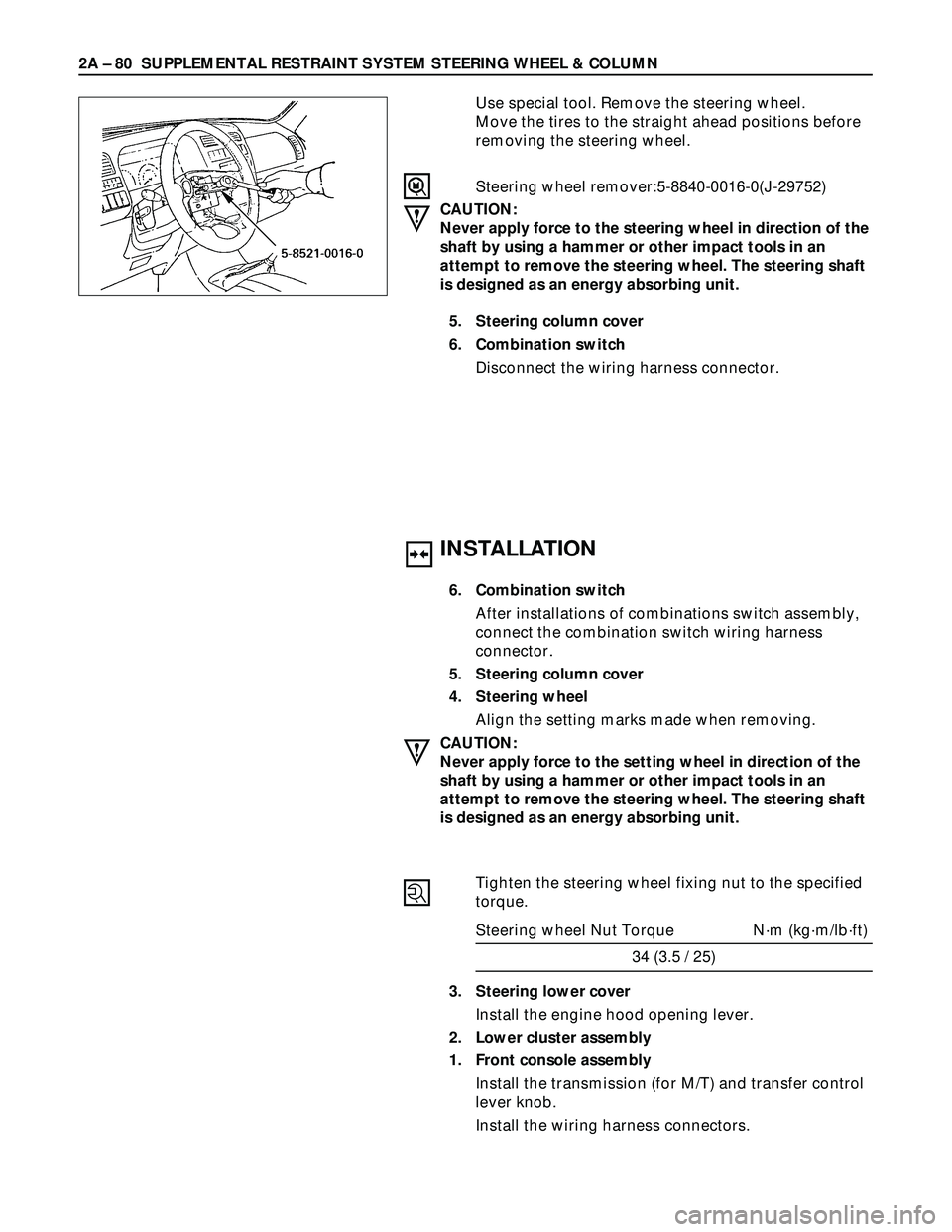

INSTALLATION

6. Combination switch

After installations of combinations switch assembly,

connect the combination switch wiring harness

connector.

5. Steering column cover

4. Steering wheel

Align the setting marks made when removing.

CAUTION:

Never apply force to the setting wheel in direction of the

shaft by using a hammer or other impact tools in an

attempt to remove the steering wheel. The steering shaft

is designed as an energy absorbing unit.

Tighten the steering wheel fixing nut to the specified

torque.

Steering wheel Nut Torque N·m (kg·m/lb·ft)

34 (3.5 / 25)

3. Steering lower cover

Install the engine hood opening lever.

2. Lower cluster assembly

1. Front console assembly

Install the transmission (for M/T) and transfer control

lever knob.

Install the wiring harness connectors. Use special tool. Remove the steering wheel.

Move the tires to the straight ahead positions before

removing the steering wheel.

Steering wheel remover:5-8840-0016-0(J-29752)

CAUTION:

Never apply force to the steering wheel in direction of the

shaft by using a hammer or other impact tools in an

attempt to remove the steering wheel. The steering shaft

is designed as an energy absorbing unit.

5. Steering column cover

6. Combination switch

Disconnect the wiring harness connector.

Page 383 of 3573

SUPPLEMENTAL RESTRAINT SYSTEM STEERING WHEEL & COLUMN 2A – 81

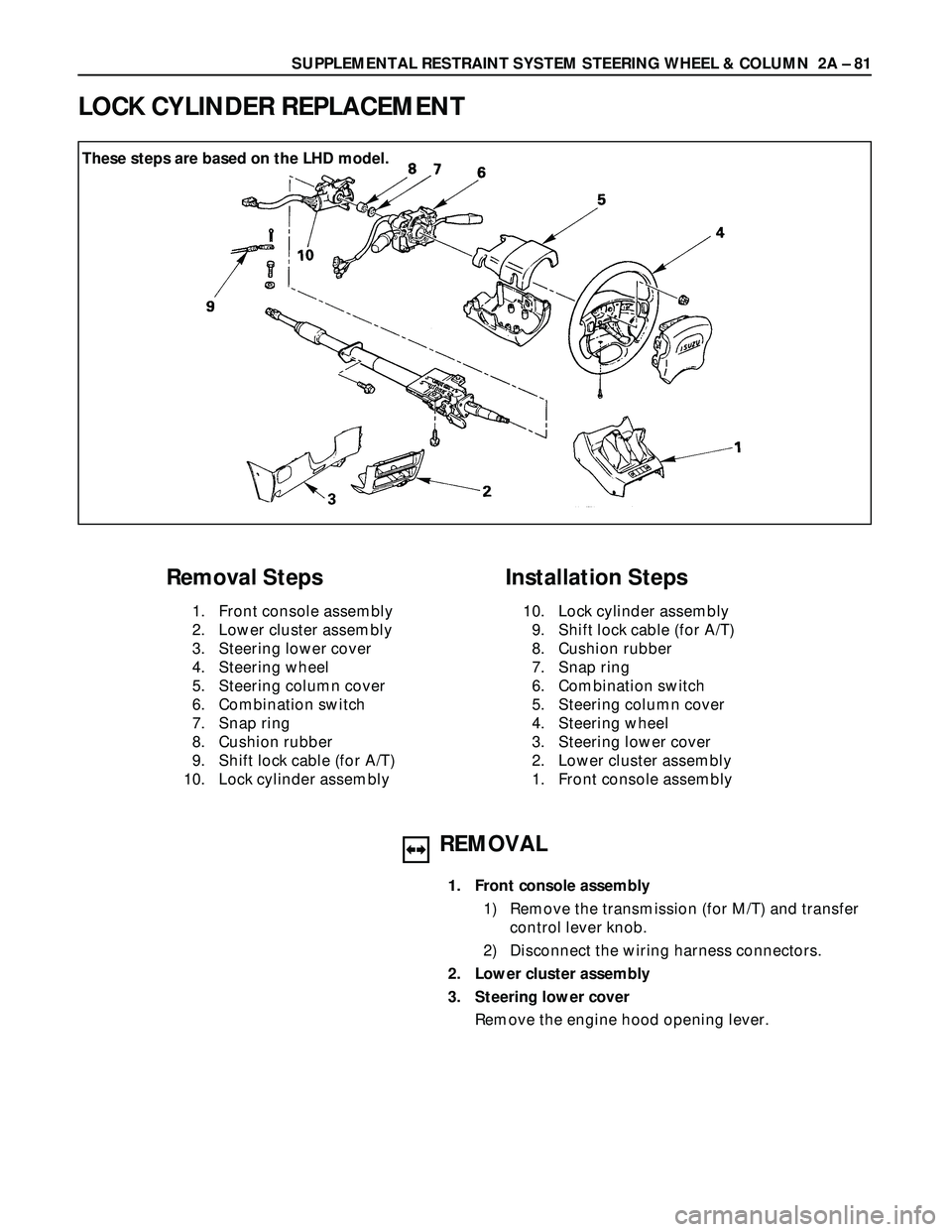

These steps are based on the LHD model.

REMOVAL

1. Front console assembly

1) Remove the transmission (for M/T) and transfer

control lever knob.

2) Disconnect the wiring harness connectors.

2. Lower cluster assembly

3. Steering lower cover

Remove the engine hood opening lever.

LOCK CYLINDER REPLACEMENT

Removal Steps

1. Front console assembly

2. Lower cluster assembly

3. Steering lower cover

4. Steering wheel

5. Steering column cover

6. Combination switch

7. Snap ring

8. Cushion rubber

9. Shift lock cable (for A/T)

10. Lock cylinder assembly

Installation Steps

10. Lock cylinder assembly

9. Shift lock cable (for A/T)

8. Cushion rubber

7. Snap ring

6. Combination switch

5. Steering column cover

4. Steering wheel

3. Steering lower cover

2. Lower cluster assembly

1. Front console assembly