engine coolant ISUZU TROOPER 1998 Service User Guide

[x] Cancel search | Manufacturer: ISUZU, Model Year: 1998, Model line: TROOPER, Model: ISUZU TROOPER 1998Pages: 3573, PDF Size: 60.36 MB

Page 106 of 3573

HEATING AND VENTILATION 1A Ð 11

REMOVAL

Preparation:

·Disconnect the battery ground cable

·Drain engine coolant

1. Heater Unit

Refer to ÒHEATER UNITÓ removal procedure in this

section.

2. Case (Mode Control)

Remove the case (Mode control) from heater unit.

3. Washer and Mode Main Lever

4. Rod

5. Mode Sub-Lever

Press the tab of the sub-lever inward, and take out the

sub-lever.

6. Door Lever

Pull out the door lever while raising up the catch of

the door lever.

INSTALLATION

To install, follow the removal steps in the reverse order,

noting the following points:

1. Apply grease to mode sub-lever and to the abrasive

surface of the heater unit.

2. After installing the link unit, check to see if the link

unit operates correctly.

Page 108 of 3573

HEATING AND VENTILATION 1A Ð 13

REMOVAL

Preparation:

·Disconnect the battery ground cable

·Drain engine coolant

1. Heater Unit

Refer to ÒHEATER UNITÓ removal procedure in this

section.

2. Case (Temperature Control)

Remove the case (Temperature control) from the

heater unit.

3. Rod

4. Sub-Lever

5. Door Lever

Pull out the door lever while raising up the catch of

the door lever.

6. Clip

INSTALLATION

To install, follow the removal steps in the reverse order,

noting the following points:

1. Apply grease to sub-lever and to the abrasive surface

of the heater unit.

2. After installing the link unit, check to see if the link

unit operates correctly.

Page 221 of 3573

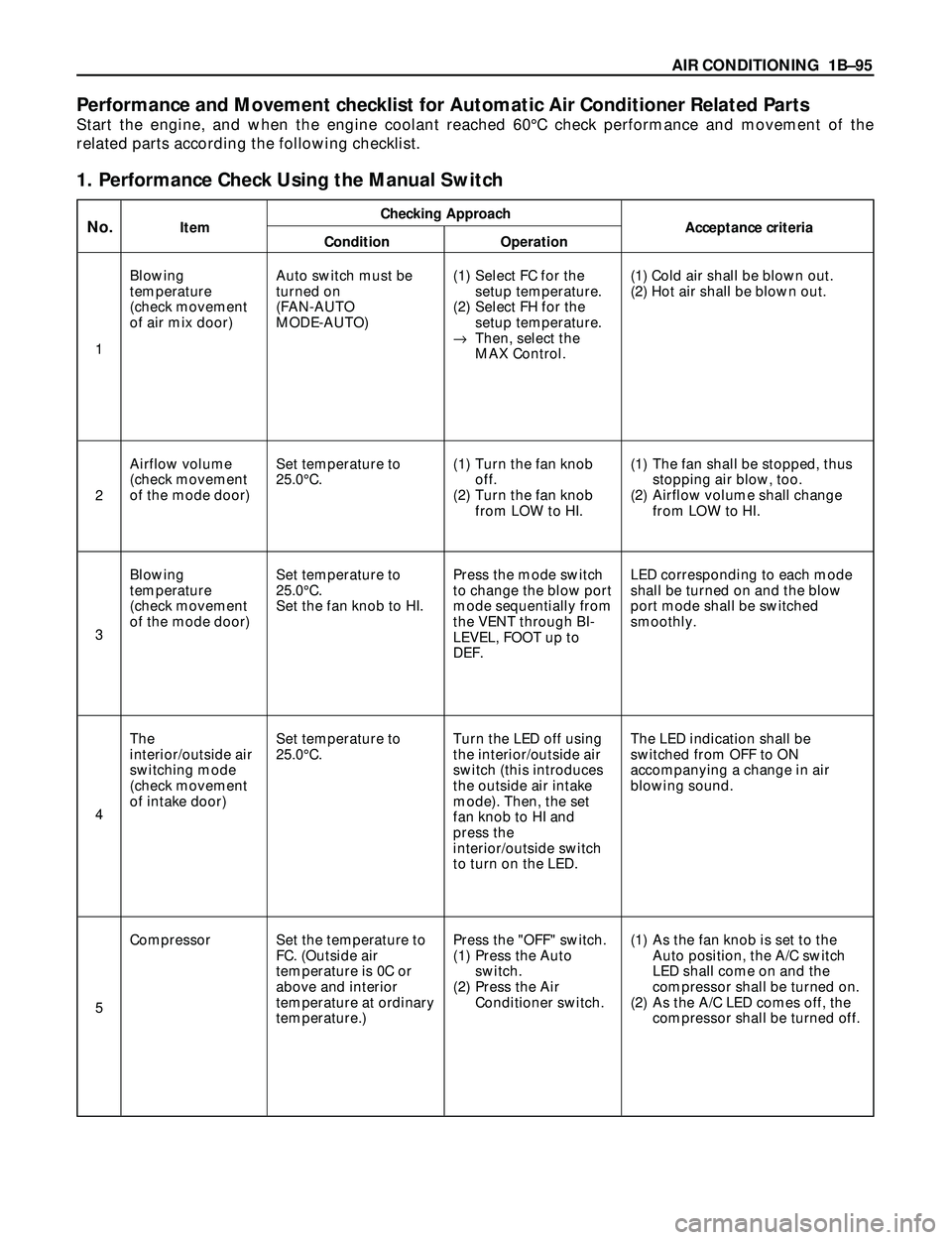

AIR CONDITIONING 1BÐ95

Performance and Movement checklist for Automatic Air Conditioner Related Parts

Start the engine, and when the engine coolant reached 60¡C check performance and movement of the

related parts according the following checklist.

1. Performance Check Using the Manual Switch

Checking ApproachNo.ItemAcceptance criteria

Condition Operation

Blowing

temperature

(check movement

of air mix door)

Airflow volume

(check movement

of the mode door)Set temperature to

25.0¡C.(1) Turn the fan knob

off.

(2) Turn the fan knob

from LOW to HI.(1) The fan shall be stopped, thus

stopping air blow, too.

(2) Airflow volume shall change

from LOW to HI.

Blowing

temperature

(check movement

of the mode door)Set temperature to

25.0¡C.

Set the fan knob to HI.Press the mode switch

to change the blow port

mode sequentially from

the VENT through BI-

LEVEL, FOOT up to

DEF.LED corresponding to each mode

shall be turned on and the blow

port mode shall be switched

smoothly.

The

interior/outside air

switching mode

(check movement

of intake door)Set temperature to

25.0¡C.Turn the LED off using

the interior/outside air

switch (this introduces

the outside air intake

mode). Then, the set

fan knob to HI and

press the

interior/outside switch

to turn on the LED.The LED indication shall be

switched from OFF to ON

accompanying a change in air

blowing sound.

Compressor Set the temperature to

FC. (Outside air

temperature is 0C or

above and interior

temperature at ordinary

temperature.)Press the "OFF" switch.

(1) Press the Auto

switch.

(2) Press the Air

Conditioner switch.(1) As the fan knob is set to the

Auto position, the A/C switch

LED shall come on and the

compressor shall be turned on.

(2) As the A/C LED comes off, the

compressor shall be turned off. Auto switch must be

turned on

(FAN-AUTO

MODE-AUTO)(1) Select FC for the

setup temperature.

(2) Select FH for the

setup temperature.

®Then, select the

MAX Control.(1) Cold air shall be blown out.

(2) Hot air shall be blown out.

1

2

3

4

5

Page 244 of 3573

1BÐ118 AIR CONDITIONING

Inspection of the Magnet Clutch System

6VE1 Engine

I-32

C-1C-3I-33

E-3E-19

12345678

9 10111213141516

1

112

123

134

145

156

167

178

189

1910

20

B-19C-25

A 2

B-361

H-14

C-19

25A

BLOWER

MOTOR

C-20

10A

A/C FL-1

80A

MAIN

Heater

Relay

1B-3610

H-13

0.3

B 0.85

W/G0.85

W/R

3.0

W

3.0

L/R

0.5

BR

1.25

B

B-19

BODY-LH3

B-36

4B-36

BATT.(+)

Blower

MotorIntake

Actuator STARTER

RELAY(1)

0.5

LG 0.5

BR0.5

BR

0.5

G/W

0.5

P/G0.5

P/G0.5

G/O

0.5

G/O

PCM

(C3-E15)

31 13

COMP-F/B 70.5

BR

0.5

BR/Y 0.3

G/B0.5

G/B0.5

BR/Y 0.5

BR

Triple

Pressure

Switch

0.5

BR

A

A/C

Thermo Relay

Auto A/C Control Unit

3X-5

16

H-1617H-16

14

I-3218I-33

1X-5

13H-24

12

H-41

2 1

C-25

C-25

4X-5X-5 2

X-57

H-16

A/C

Compressor

Relay

Magnetic

clutch

1X-7

3X-74X-72

X-7

PCM

(C-1-B14)

E-39

1

H-67

H-41

5

H-41

Engine

Coolant

Temperature

Sensor

ENGINE COOLANT

TEMPERATURE GAUGE

0.5

Y/B

0.5

Y/B

0.5

Y/B

E-1911

1

H-61

H-24

I-334

B-36X-5X-7

H-14

1

2

1

2

H-16

H-24

H-13

H-6H-41

12

3412111

362

51

4 123

45 610987654321

22212019181514131211171612345111213141567891018192021221617

6H-41

4321

8765

12 11 10 9

16 15 14 13123 4

567 8

9101112

13 14 15 16

17 18 16 15 1478 6 5

12 13 11 10 94 132

5 6 7 8

15 16 17 18 142 3 41

10 11 12 13 9A1 A2 A3 A4 A5 A6 A7 A8 A9A10 A11 A12 A13 A14 A15 A16B1 B2 B3 B4 B5 B6 B7 B8 B9B10 B11 B12 B13 B14 B15 B16E1 E2 E3 E4 E5 E6 E7 E8 E9E10 E11 E12 E13 E14 E15 E16F1 F2 F3 F4 F5 F6 F7 F8 F9F10 F11 F12 F13 F14 F15 F16

D08RY00182

Page 318 of 3573

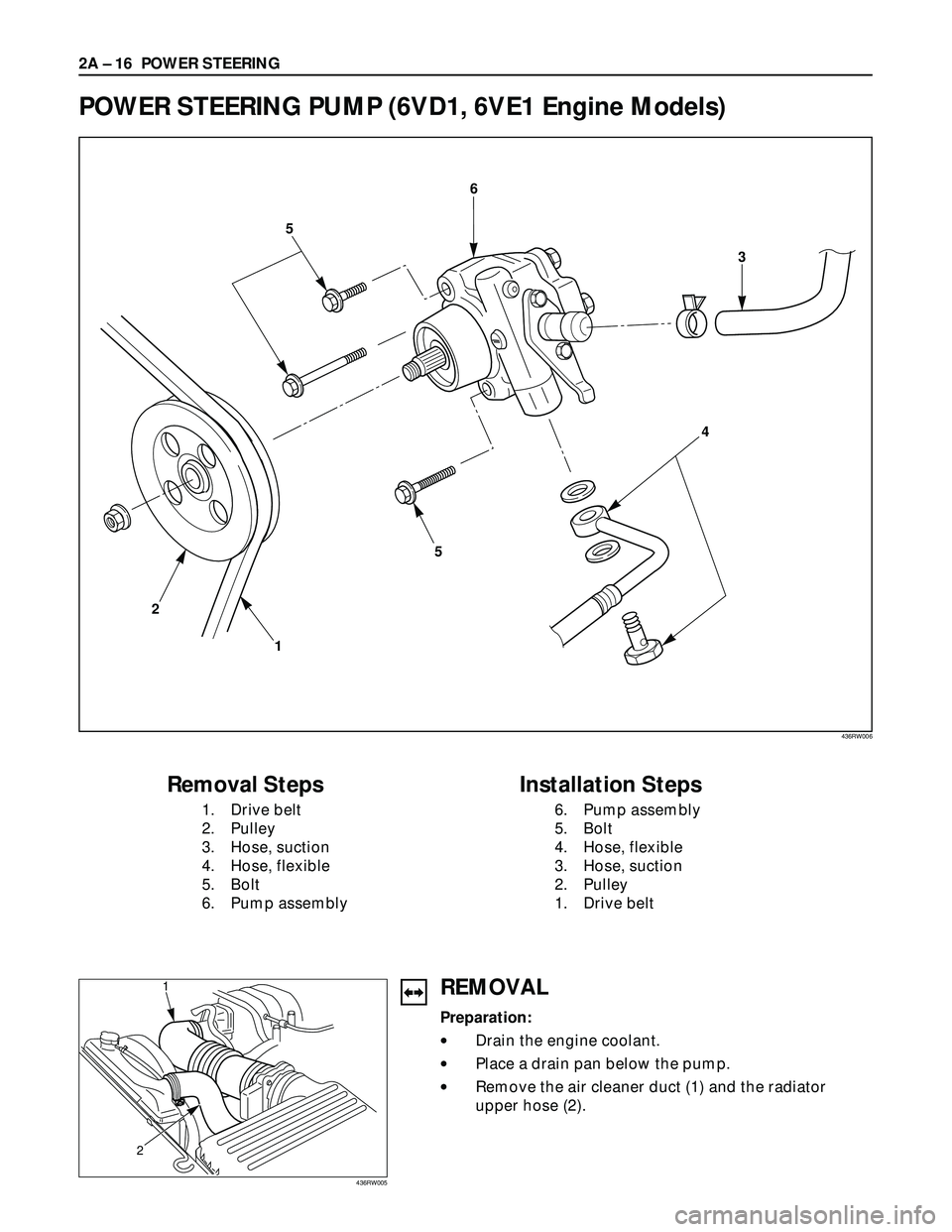

2A – 16 POWER STEERING

POWER STEERING PUMP (6VD1, 6VE1 Engine Models)

6

5

3

4

5

1 2

Removal Steps

1. Drive belt

2. Pulley

3. Hose, suction

4. Hose, flexible

5. Bolt

6. Pump assembly

Installation Steps

6. Pump assembly

5. Bolt

4. Hose, flexible

3. Hose, suction

2. Pulley

1. Drive belt

REMOVAL

Preparation:

•Drain the engine coolant.

•Place a drain pan below the pump.

•Remove the air cleaner duct (1) and the radiator

upper hose (2).

436RW006

1

2

436RW005

Page 319 of 3573

POWER STEERING 2A – 17

1. Drive Belt

2. Pulley

3. Hose, Suction

4. Hose, Flexible

5. Bolt

6. Pump Assembly

CAUTION:

When removing the pump assembly, be careful not to

damage the wiring harness under the pump housing.

INSTALLATION

6. Pump Assembly

Connect the harness under the pump housing.

5. Bolt

Pump Bolt Torque N·m(kg·m/lb·ft)

46 (4.7 / 34)

4. Hose, Flexible

Eye Bolt Torque N·m (kg·m/lb·ft)

54 (5.5 / 40)

3. Hose, Suction

2. Pulley

Install the pulley onto the power steering pump and

tighten the nut to specified torque.

Pulley Nut Torque N·m (kg·m/lb·ft)

78 (8.0 / 58)

1. Drive Belt

•Install the air cleaner duct and the radiator upper

hose.

•Refill the engine coolant.

•Fill and bleed the system. Refer to “Bleeding the

Power Steering System” in this section.

Page 962 of 3573

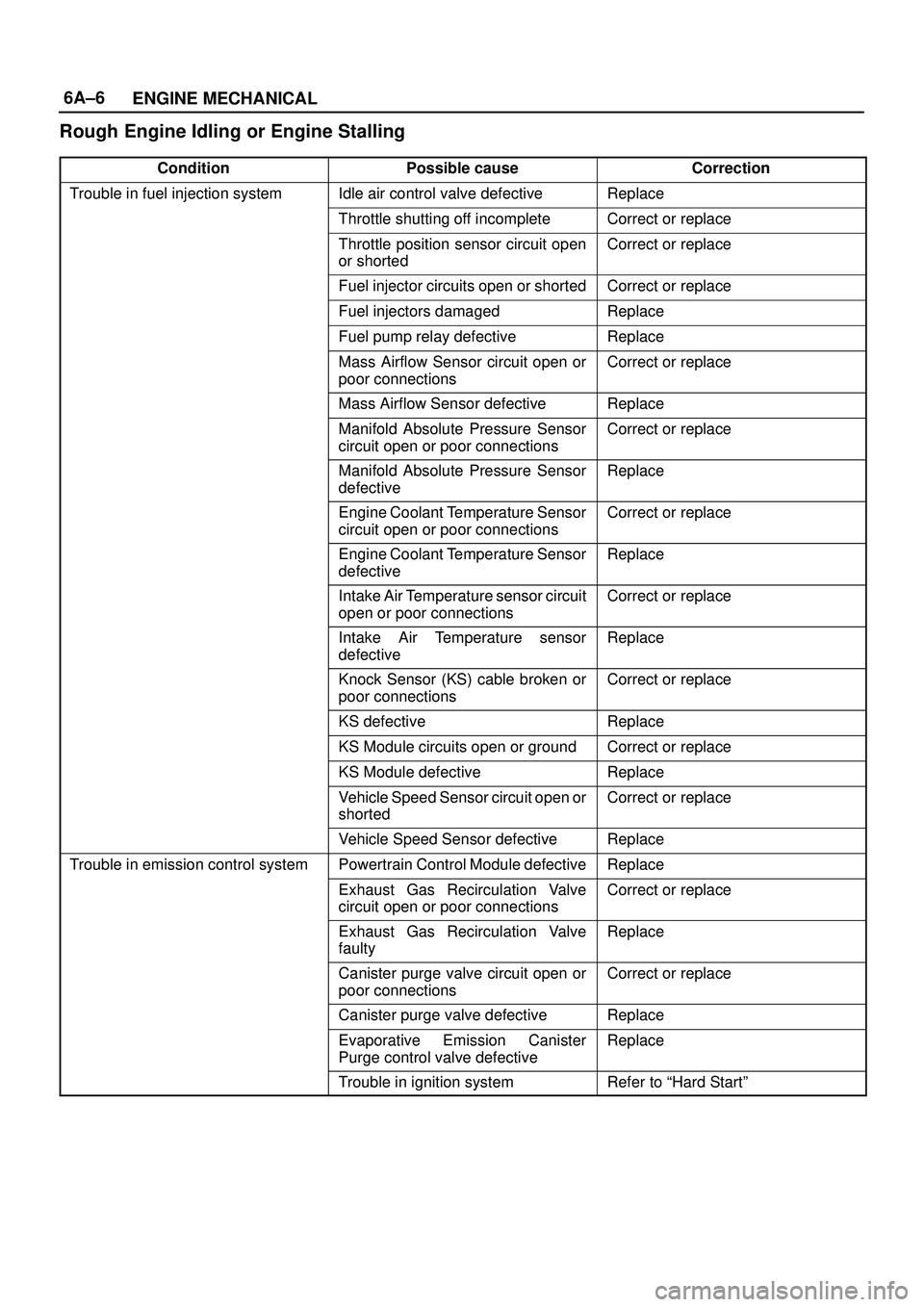

6A±6

ENGINE MECHANICAL

Rough Engine Idling or Engine Stalling

ConditionPossible causeCorrection

Trouble in fuel injection systemIdle air control valve defectiveReplace

Throttle shutting off incompleteCorrect or replace

Throttle position sensor circuit open

or shortedCorrect or replace

Fuel injector circuits open or shortedCorrect or replace

Fuel injectors damagedReplace

Fuel pump relay defectiveReplace

Mass Airflow Sensor circuit open or

poor connectionsCorrect or replace

Mass Airflow Sensor defectiveReplace

Manifold Absolute Pressure Sensor

circuit open or poor connectionsCorrect or replace

Manifold Absolute Pressure Sensor

defectiveReplace

Engine Coolant Temperature Sensor

circuit open or poor connectionsCorrect or replace

Engine Coolant Temperature Sensor

defectiveReplace

Intake Air Temperature sensor circuit

open or poor connectionsCorrect or replace

Intake Air Temperature sensor

defectiveReplace

Knock Sensor (KS) cable broken or

poor connectionsCorrect or replace

KS defectiveReplace

KS Module circuits open or groundCorrect or replace

KS Module defectiveReplace

Vehicle Speed Sensor circuit open or

shortedCorrect or replace

Vehicle Speed Sensor defectiveReplace

Trouble in emission control systemPowertrain Control Module defectiveReplace

Exhaust Gas Recirculation Valve

circuit open or poor connectionsCorrect or replace

Exhaust Gas Recirculation Valve

faultyReplace

Canister purge valve circuit open or

poor connectionsCorrect or replace

Canister purge valve defectiveReplace

Evaporative Emission Canister

Purge control valve defectiveReplace

Trouble in ignition systemRefer to ªHard Startº

Page 963 of 3573

6A±7

ENGINE MECHANICAL

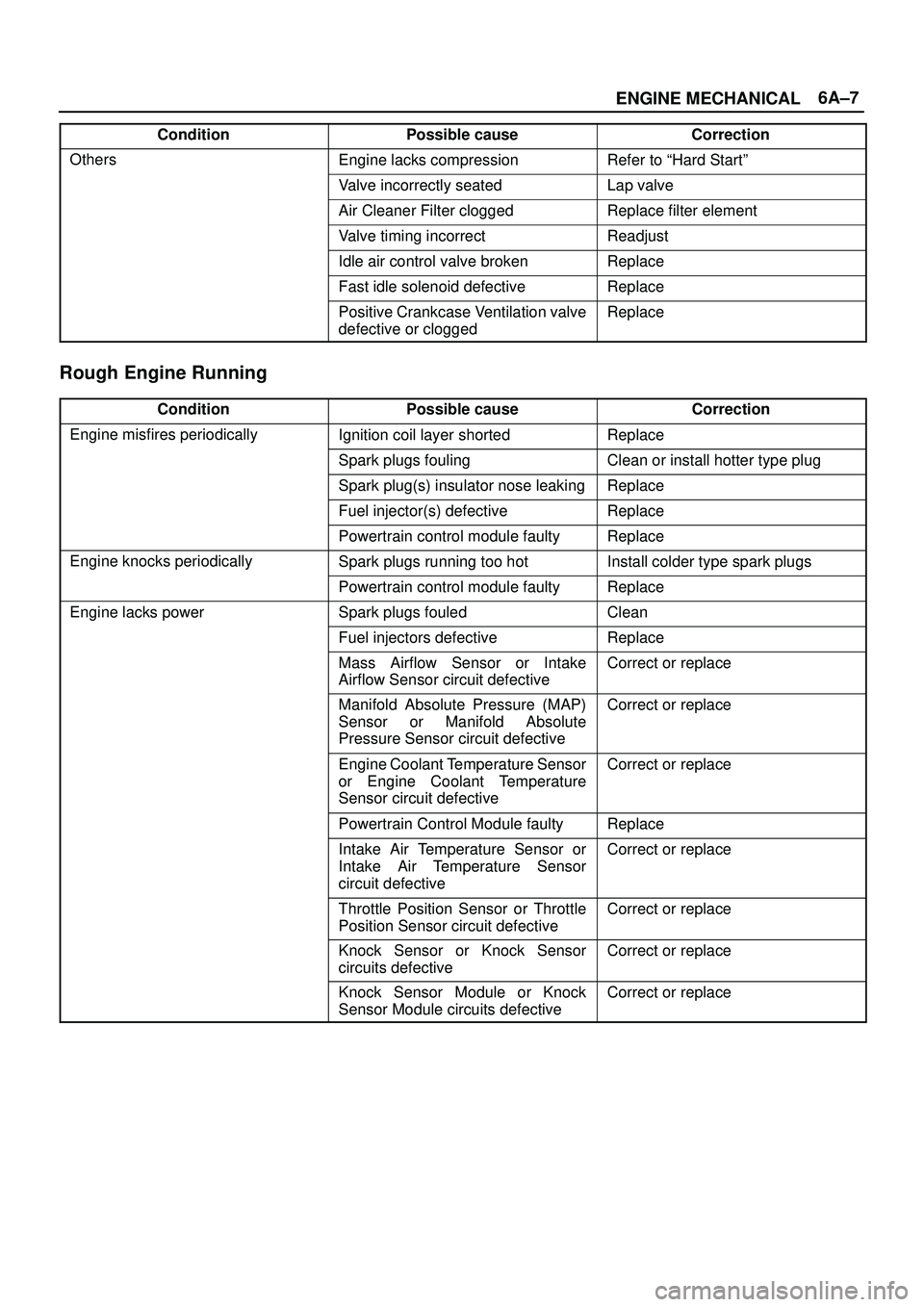

Condition CorrectionPossible cause

OthersEngine lacks compressionRefer to ªHard Startº

Valve incorrectly seatedLap valve

Air Cleaner Filter cloggedReplace filter element

Valve timing incorrectReadjust

Idle air control valve brokenReplace

Fast idle solenoid defectiveReplace

Positive Crankcase Ventilation valve

defective or cloggedReplace

Rough Engine Running

ConditionPossible causeCorrection

Engine misfires periodicallyIgnition coil layer shortedReplace

Spark plugs foulingClean or install hotter type plug

Spark plug(s) insulator nose leakingReplace

Fuel injector(s) defectiveReplace

Powertrain control module faultyReplace

Engine knocks periodicallySpark plugs running too hotInstall colder type spark plugs

Powertrain control module faultyReplace

Engine lacks powerSpark plugs fouledClean

Fuel injectors defectiveReplace

Mass Airflow Sensor or Intake

Airflow Sensor circuit defectiveCorrect or replace

Manifold Absolute Pressure (MAP)

Sensor or Manifold Absolute

Pressure Sensor circuit defectiveCorrect or replace

Engine Coolant Temperature Sensor

or Engine Coolant Temperature

Sensor circuit defectiveCorrect or replace

Powertrain Control Module faultyReplace

Intake Air Temperature Sensor or

Intake Air Temperature Sensor

circuit defectiveCorrect or replace

Throttle Position Sensor or Throttle

Position Sensor circuit defectiveCorrect or replace

Knock Sensor or Knock Sensor

circuits defectiveCorrect or replace

Knock Sensor Module or Knock

Sensor Module circuits defectiveCorrect or replace

Page 965 of 3573

6A±9

ENGINE MECHANICAL

Condition CorrectionPossible cause

Hesitation at high speedsPowertrain Control Module defectiveReplace

Throttle Position Sensor cable

broken or poor connectionsCorrect or replace

Throttle Position Sensor defectiveReplace

Engine Coolant Temperature Sensor

circuit open or shortedCorrect or replace

Engine Coolant Temperature Sensor

defectiveReplace

Mass Airflow Sensor circuit open or

poor connectionsCorrect or replace

Mass Airflow Sensor defectiveReplace

MAP Sensor cable broken or poor

connectionsCorrect or replace

MAP Sensor defectiveReplace

IAT Sensor circuit open or poor

connectionsCorrect or replace

IAT Sensor defectiveReplace

KS circuit open or poor connectionsCorrect or replace

KS defectiveReplace

KS Module circuit open or shortedCorrect or replace

KS Module defectiveReplace

Throttle valve not fully openedCheck and correct or replace

Air Cleaner Filter cloggedReplace filter element

Power supply voltage too lowCheck and correct or replace

Page 966 of 3573

6A±10

ENGINE MECHANICAL

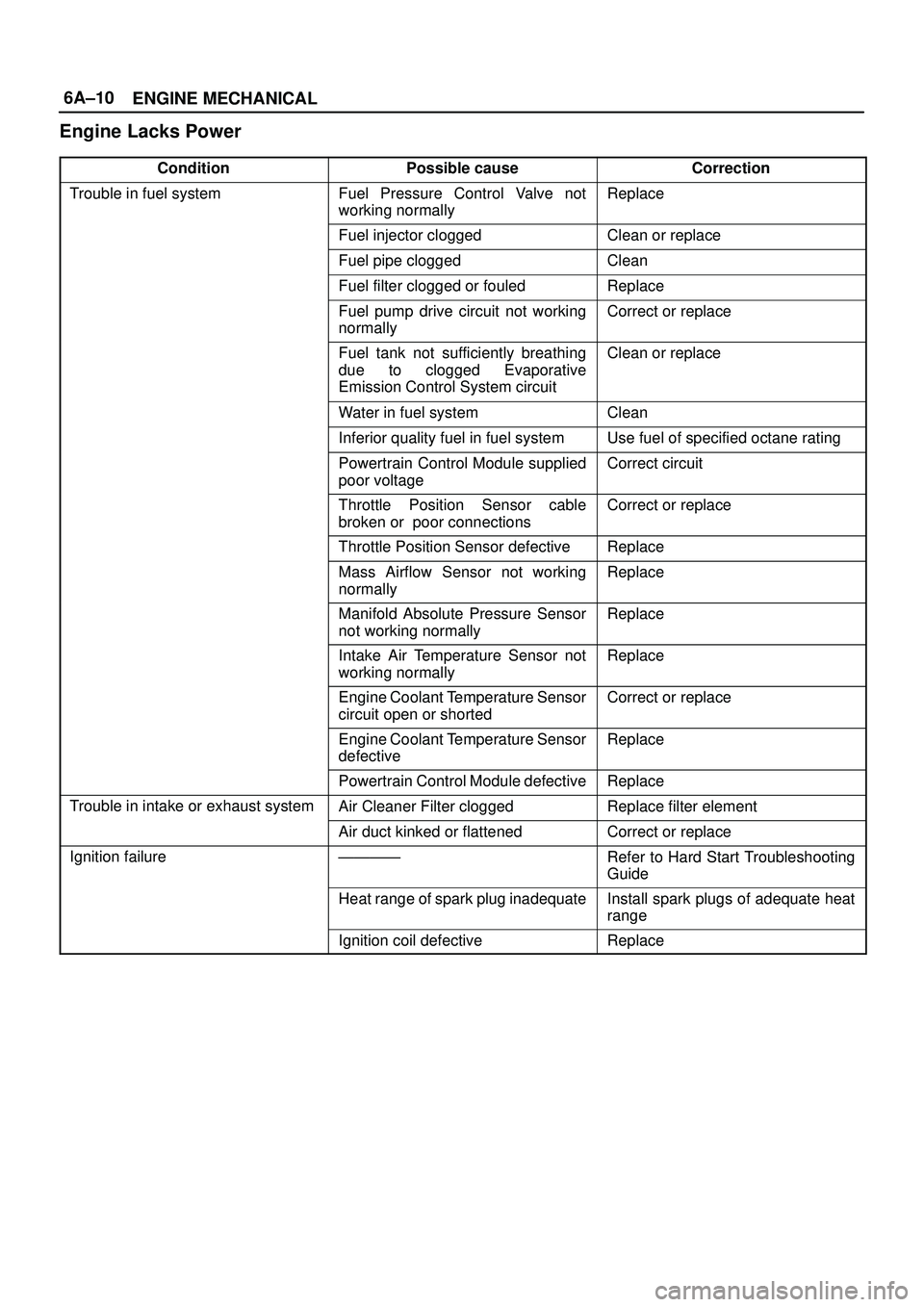

Engine Lacks Power

ConditionPossible causeCorrection

Trouble in fuel systemFuel Pressure Control Valve not

working normallyReplace

Fuel injector cloggedClean or replace

Fuel pipe cloggedClean

Fuel filter clogged or fouledReplace

Fuel pump drive circuit not working

normallyCorrect or replace

Fuel tank not sufficiently breathing

due to clogged Evaporative

Emission Control System circuitClean or replace

Water in fuel systemClean

Inferior quality fuel in fuel systemUse fuel of specified octane rating

Powertrain Control Module supplied

poor voltageCorrect circuit

Throttle Position Sensor cable

broken or poor connectionsCorrect or replace

Throttle Position Sensor defectiveReplace

Mass Airflow Sensor not working

normallyReplace

Manifold Absolute Pressure Sensor

not working normallyReplace

Intake Air Temperature Sensor not

working normallyReplace

Engine Coolant Temperature Sensor

circuit open or shortedCorrect or replace

Engine Coolant Temperature Sensor

defectiveReplace

Powertrain Control Module defectiveReplace

Trouble in intake or exhaust systemAir Cleaner Filter cloggedReplace filter element

Air duct kinked or flattenedCorrect or replace

Ignition failureÐÐÐÐRefer to Hard Start Troubleshooting

Guide

Heat range of spark plug inadequateInstall spark plugs of adequate heat

range

Ignition coil defectiveReplace