abs ISUZU TROOPER 1998 Service Owner's Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 1998, Model line: TROOPER, Model: ISUZU TROOPER 1998Pages: 3573, PDF Size: 60.36 MB

Page 368 of 3573

2A – 66 SUPPLEMENTAL RESTRAINT SYSTEM STEERING WHEEL & COLUMN

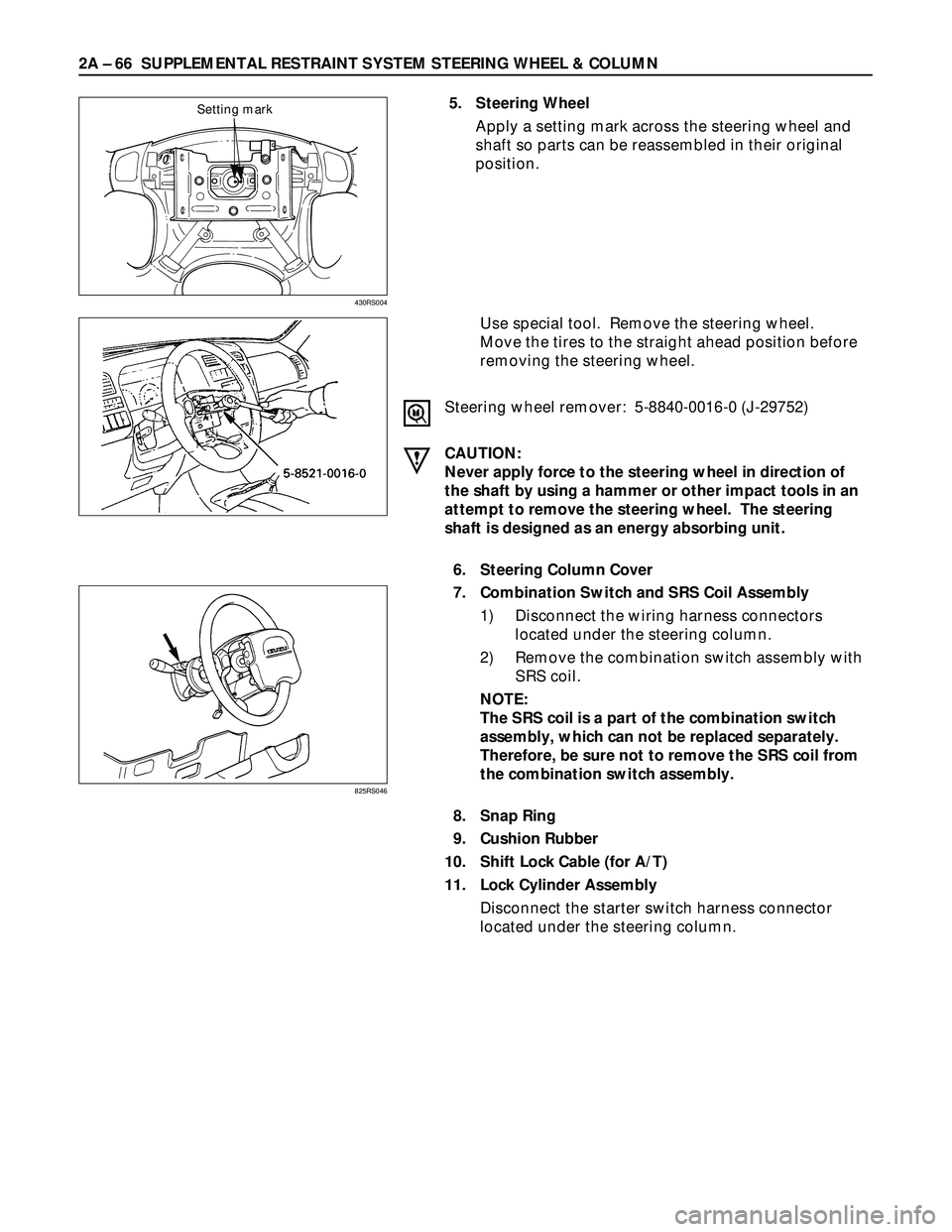

5. Steering Wheel

Apply a setting mark across the steering wheel and

shaft so parts can be reassembled in their original

position.

Use special tool. Remove the steering wheel.

Move the tires to the straight ahead position before

removing the steering wheel.

Steering wheel remover: 5-8840-0016-0 (J-29752)

CAUTION:

Never apply force to the steering wheel in direction of

the shaft by using a hammer or other impact tools in an

attempt to remove the steering wheel. The steering

shaft is designed as an energy absorbing unit.

6. Steering Column Cover

7. Combination Switch and SRS Coil Assembly

1) Disconnect the wiring harness connectors

located under the steering column.

2) Remove the combination switch assembly with

SRS coil.

NOTE:

The SRS coil is a part of the combination switch

assembly, which can not be replaced separately.

Therefore, be sure not to remove the SRS coil from

the combination switch assembly.

8. Snap Ring

9. Cushion Rubber

10. Shift Lock Cable (for A/T)

11. Lock Cylinder Assembly

Disconnect the starter switch harness connector

located under the steering column.

825RS046

430RS004

Setting mark

Page 369 of 3573

SUPPLEMENTAL RESTRAINT SYSTEM STEERING WHEEL & COLUMN 2A – 67

INSTALLATION

11. Lock Cylinder Assembly

10. Shift Lock Cable (for A/T)

9. Cushion rubber

8. Snap ring

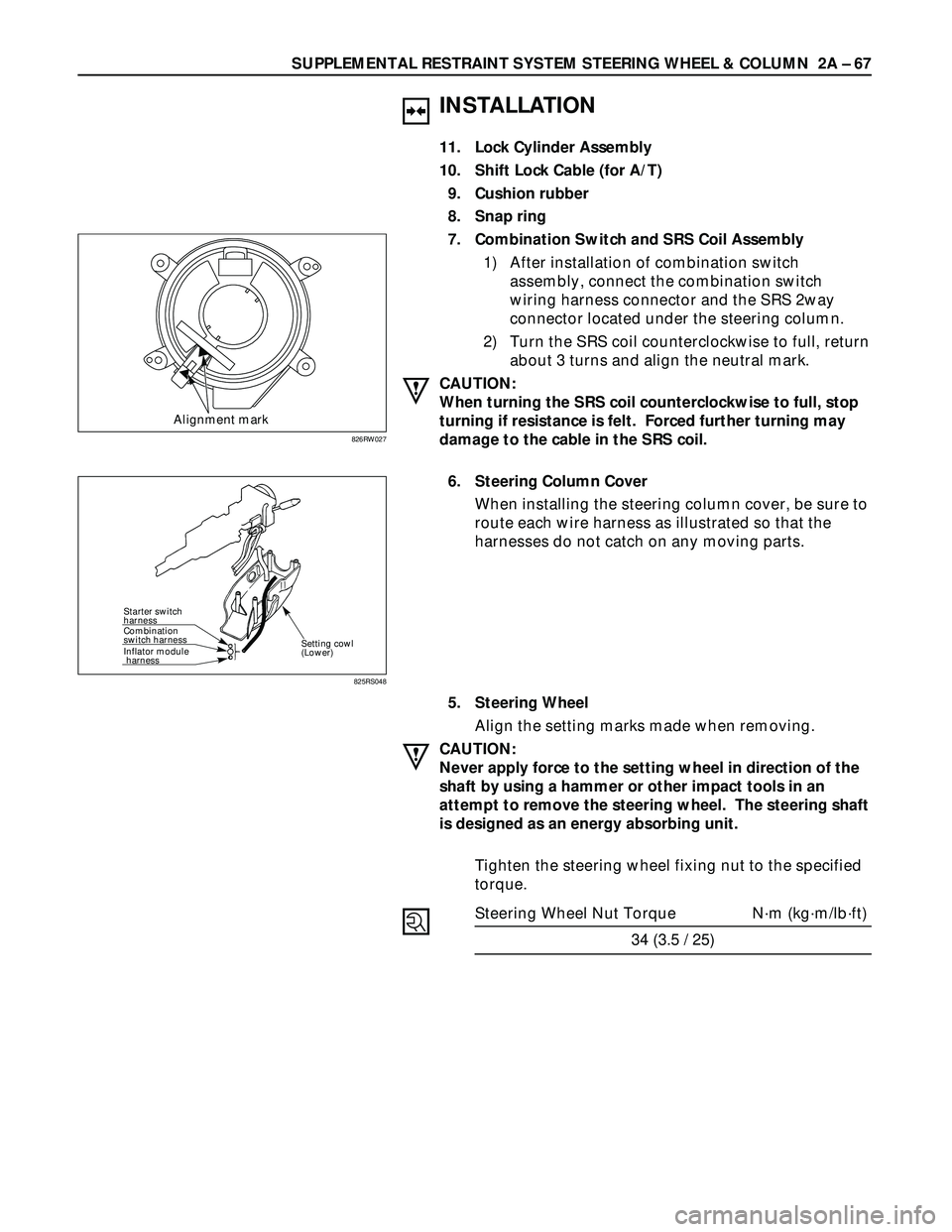

7. Combination Switch and SRS Coil Assembly

1) After installation of combination switch

assembly, connect the combination switch

wiring harness connector and the SRS 2way

connector located under the steering column.

2) Turn the SRS coil counterclockwise to full, return

about 3 turns and align the neutral mark.

CAUTION:

When turning the SRS coil counterclockwise to full, stop

turning if resistance is felt. Forced further turning may

damage to the cable in the SRS coil.

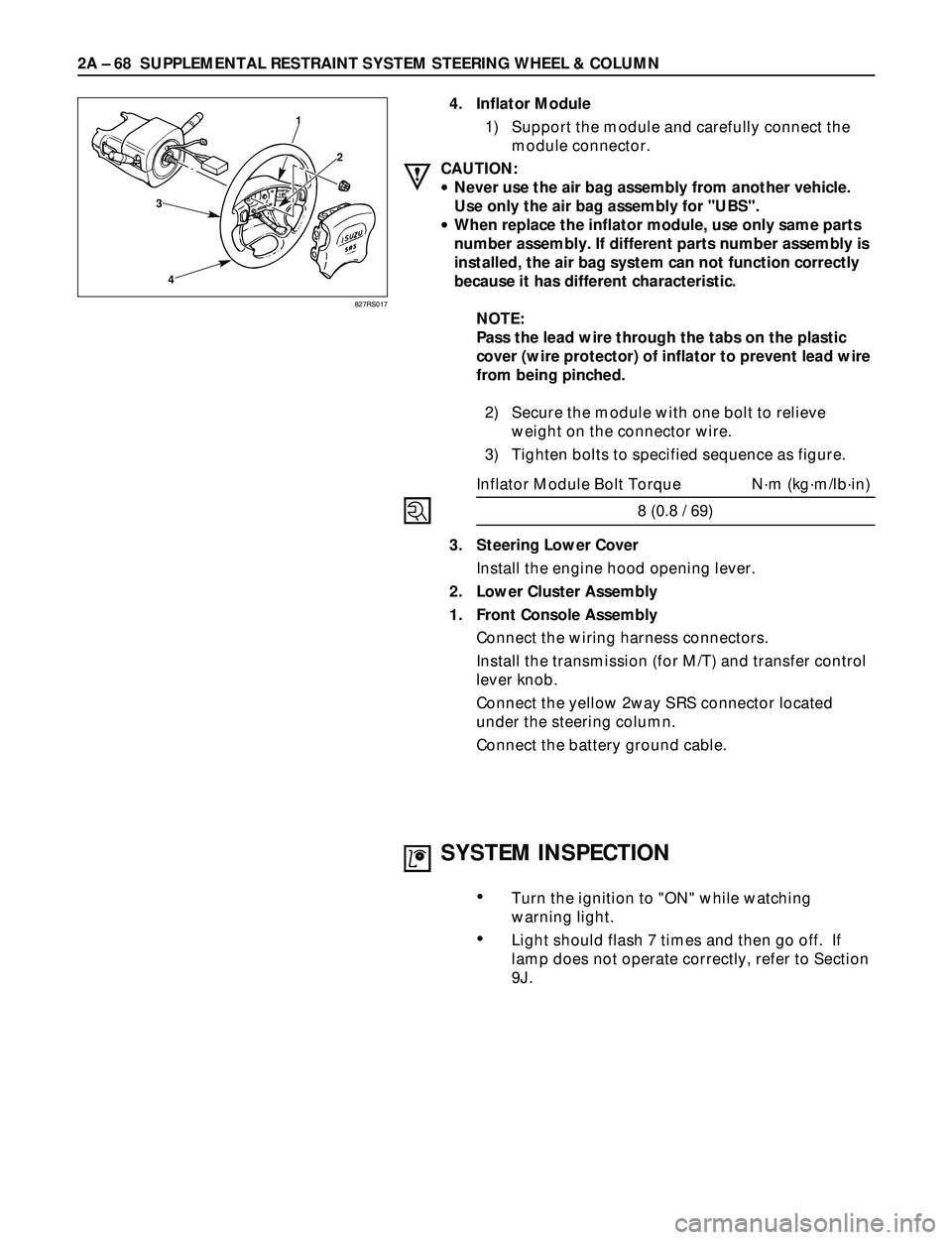

6. Steering Column Cover

When installing the steering column cover, be sure to

route each wire harness as illustrated so that the

harnesses do not catch on any moving parts.

5. Steering Wheel

Align the setting marks made when removing.

CAUTION:

Never apply force to the setting wheel in direction of the

shaft by using a hammer or other impact tools in an

attempt to remove the steering wheel. The steering shaft

is designed as an energy absorbing unit.

Tighten the steering wheel fixing nut to the specified

torque.

Steering Wheel Nut Torque N·m (kg·m/lb·ft)

34 (3.5 / 25)

Alignment mark

826RW027

Starter switch

harness

Combination

switch harness

Inflator module

harness

Setting cowl

(Lower)

825RS048

Page 370 of 3573

2A Ð 68 SUPPLEMENTAL RESTRAINT SYSTEM STEERING WHEEL & COLUMN

3

41

2

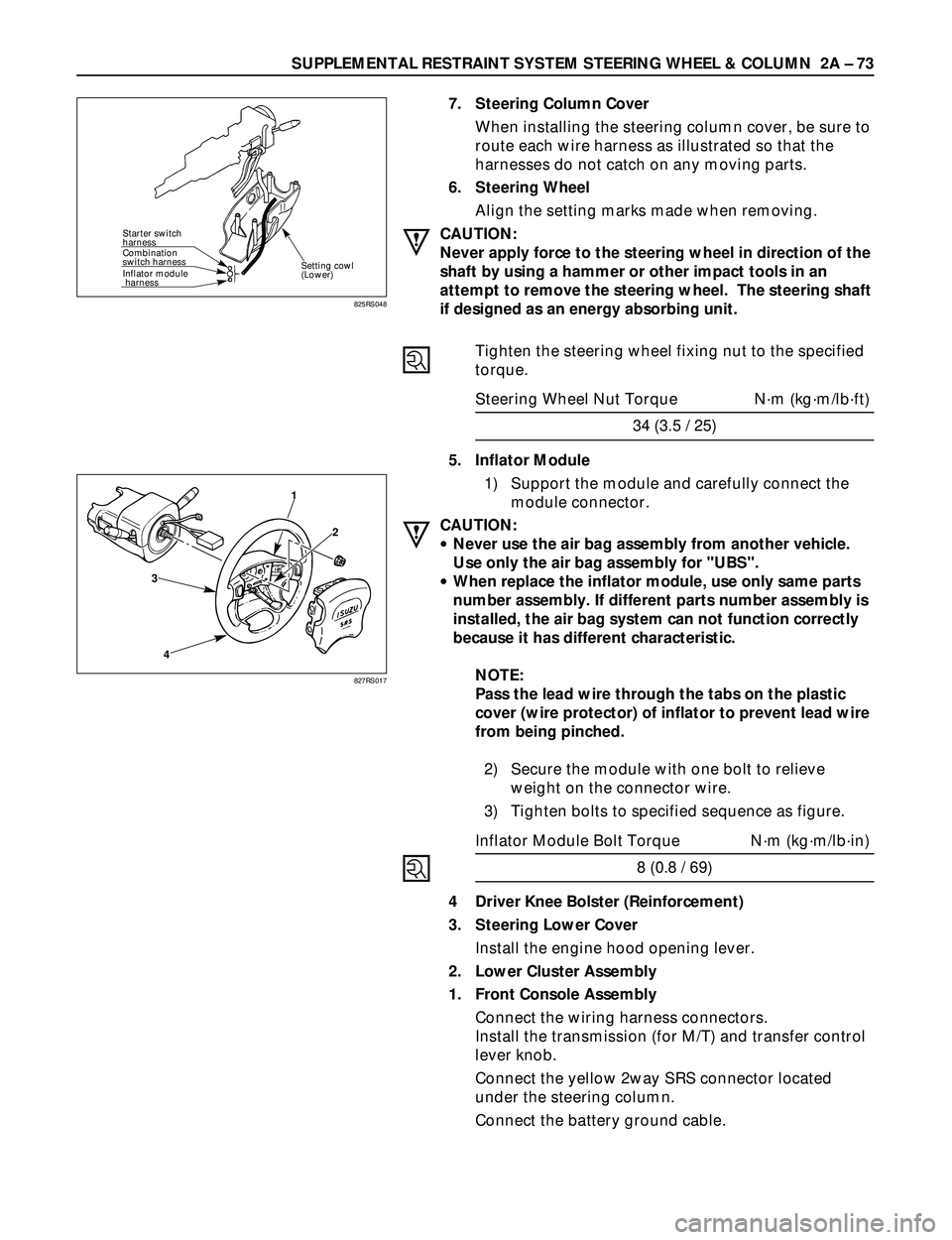

4. Inflator Module

1) Support the module and carefully connect the

module connector.

CAUTION:

·Never use the air bag assembly from another vehicle.

Use only the air bag assembly for "UBS".

·When replace the inflator module, use only same parts

number assembly. If different parts number assembly is

installed, the air bag system can not function correctly

because it has different characteristic.

NOTE:

Pass the lead wire through the tabs on the plastic

cover (wire protector) of inflator to prevent lead wire

from being pinched.

2) Secure the module with one bolt to relieve

weight on the connector wire.

3) Tighten bolts to specified sequence as figure.

Inflator Module Bolt Torque Nám (kgám/lbáin)

8 (0.8 / 69)

3. Steering Lower Cover

Install the engine hood opening lever.

2. Lower Cluster Assembly

1. Front Console Assembly

Connect the wiring harness connectors.

Install the transmission (for M/T) and transfer control

lever knob.

Connect the yellow 2way SRS connector located

under the steering column.

Connect the battery ground cable.

827RS017

SYSTEM INSPECTION

¥Turn the ignition to "ON" while watching

warning light.

¥Light should flash 7 times and then go off. If

lamp does not operate correctly, refer to Section

9J.

Page 375 of 3573

SUPPLEMENTAL RESTRAINT SYSTEM STEERING WHEEL & COLUMN 2A Ð 73

Starter switch

harness

Combination

switch harness

Inflator module

harness

Setting cowl

(Lower)

7. Steering Column Cover

When installing the steering column cover, be sure to

route each wire harness as illustrated so that the

harnesses do not catch on any moving parts.

6. Steering Wheel

Align the setting marks made when removing.

CAUTION:

Never apply force to the steering wheel in direction of the

shaft by using a hammer or other impact tools in an

attempt to remove the steering wheel. The steering shaft

if designed as an energy absorbing unit.

Tighten the steering wheel fixing nut to the specified

torque.

Steering Wheel Nut Torque Nám (kgám/lbáft)

34 (3.5 / 25)

5. Inflator Module

1) Support the module and carefully connect the

module connector.

CAUTION:

·Never use the air bag assembly from another vehicle.

Use only the air bag assembly for "UBS".

·When replace the inflator module, use only same parts

number assembly. If different parts number assembly is

installed, the air bag system can not function correctly

because it has different characteristic.

NOTE:

Pass the lead wire through the tabs on the plastic

cover (wire protector) of inflator to prevent lead wire

from being pinched.

2) Secure the module with one bolt to relieve

weight on the connector wire.

3) Tighten bolts to specified sequence as figure.

Inflator Module Bolt Torque Nám (kgám/lbáin)

8 (0.8 / 69)

4 Driver Knee Bolster (Reinforcement)

3. Steering Lower Cover

Install the engine hood opening lever.

2. Lower Cluster Assembly

1. Front Console Assembly

Connect the wiring harness connectors.

Install the transmission (for M/T) and transfer control

lever knob.

Connect the yellow 2way SRS connector located

under the steering column.

Connect the battery ground cable.

825RS048

3

41

2

827RS017

Page 378 of 3573

2A – 76 SUPPLEMENTAL RESTRAINT SYSTEM STEERING WHEEL & COLUMN

GENERAL DESCRIPTION

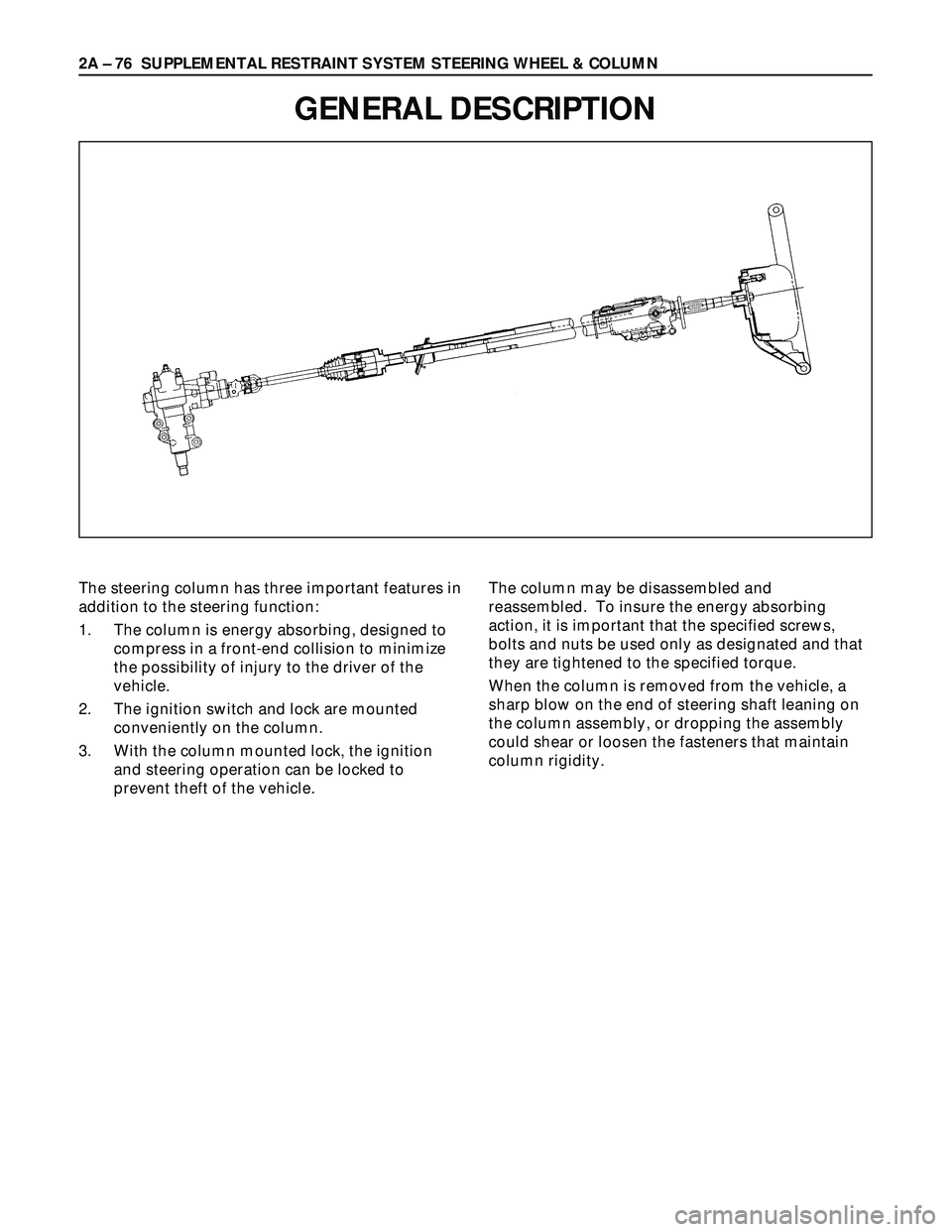

The steering column has three important features in

addition to the steering function:

1. The column is energy absorbing, designed to

compress in a front-end collision to minimize

the possibility of injury to the driver of the

vehicle.

2. The ignition switch and lock are mounted

conveniently on the column.

3. With the column mounted lock, the ignition

and steering operation can be locked to

prevent theft of the vehicle.The column may be disassembled and

reassembled. To insure the energy absorbing

action, it is important that the specified screws,

bolts and nuts be used only as designated and that

they are tightened to the specified torque.

When the column is removed from the vehicle, a

sharp blow on the end of steering shaft leaning on

the column assembly, or dropping the assembly

could shear or loosen the fasteners that maintain

column rigidity.

Page 380 of 3573

2A – 78 SUPPLEMENTAL RESTRAINT SYSTEM STEERING WHEEL & COLUMN

INSTALLATION

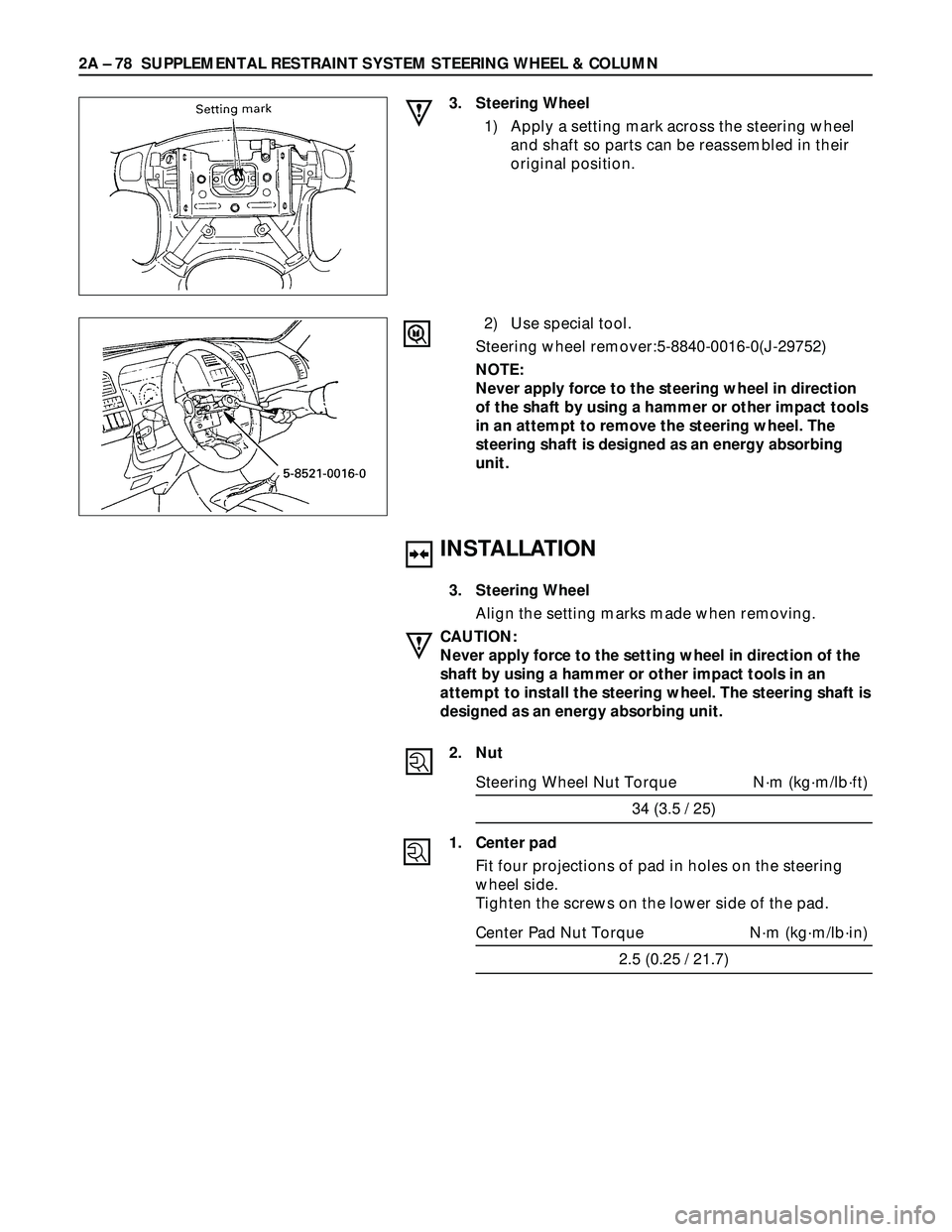

3. Steering Wheel

Align the setting marks made when removing.

CAUTION:

Never apply force to the setting wheel in direction of the

shaft by using a hammer or other impact tools in an

attempt to install the steering wheel. The steering shaft is

designed as an energy absorbing unit.

2. Nut

Steering Wheel Nut Torque N·m (kg·m/lb·ft)

34 (3.5 / 25)

1. Center pad

Fit four projections of pad in holes on the steering

wheel side.

Tighten the screws on the lower side of the pad.

Center Pad Nut Torque N·m (kg·m/lb·in)

2.5 (0.25 / 21.7) 3. Steering Wheel

1) Apply a setting mark across the steering wheel

and shaft so parts can be reassembled in their

original position.

2) Use special tool.

Steering wheel remover:5-8840-0016-0(J-29752)

NOTE:

Never apply force to the steering wheel in direction

of the shaft by using a hammer or other impact tools

in an attempt to remove the steering wheel. The

steering shaft is designed as an energy absorbing

unit.

Page 382 of 3573

2A – 80 SUPPLEMENTAL RESTRAINT SYSTEM STEERING WHEEL & COLUMN

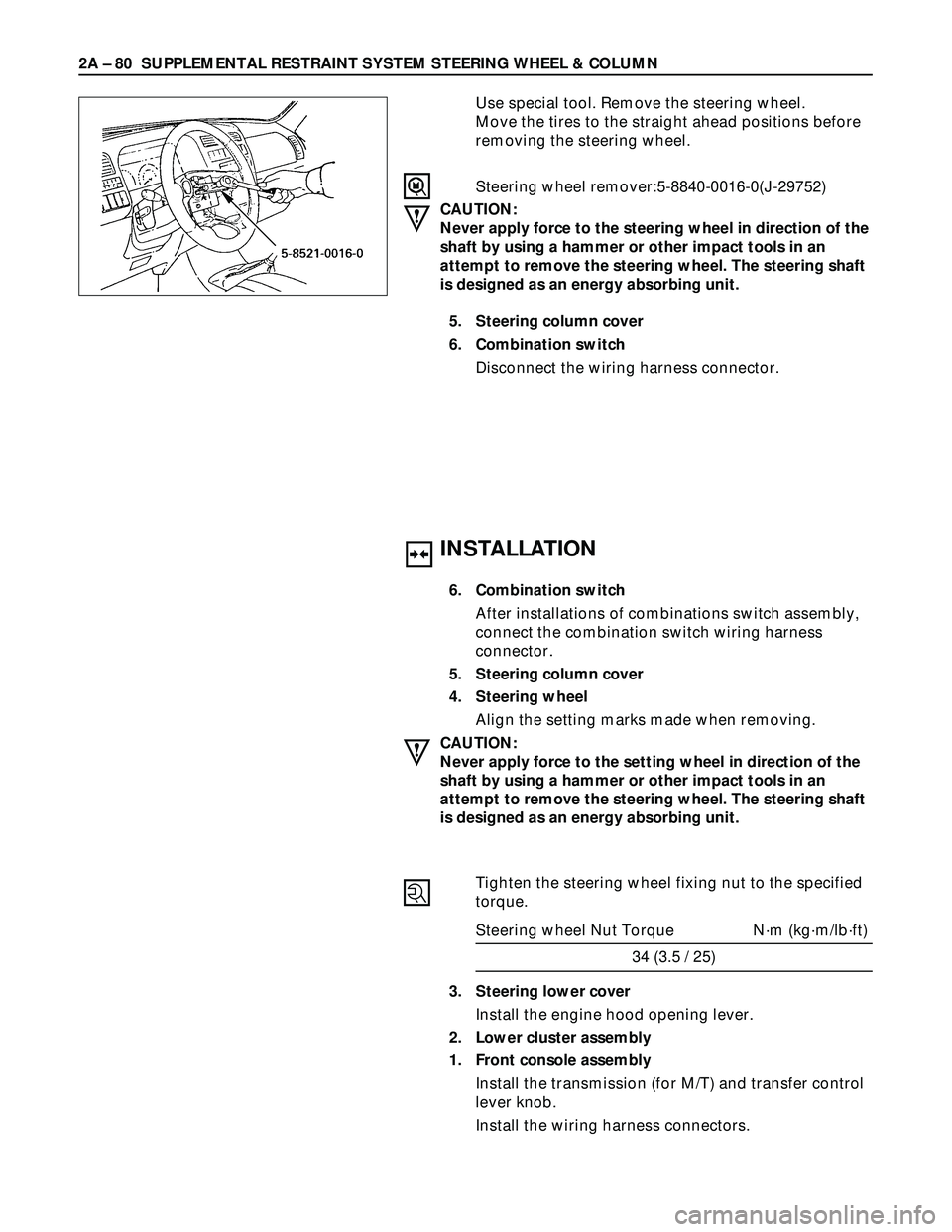

INSTALLATION

6. Combination switch

After installations of combinations switch assembly,

connect the combination switch wiring harness

connector.

5. Steering column cover

4. Steering wheel

Align the setting marks made when removing.

CAUTION:

Never apply force to the setting wheel in direction of the

shaft by using a hammer or other impact tools in an

attempt to remove the steering wheel. The steering shaft

is designed as an energy absorbing unit.

Tighten the steering wheel fixing nut to the specified

torque.

Steering wheel Nut Torque N·m (kg·m/lb·ft)

34 (3.5 / 25)

3. Steering lower cover

Install the engine hood opening lever.

2. Lower cluster assembly

1. Front console assembly

Install the transmission (for M/T) and transfer control

lever knob.

Install the wiring harness connectors. Use special tool. Remove the steering wheel.

Move the tires to the straight ahead positions before

removing the steering wheel.

Steering wheel remover:5-8840-0016-0(J-29752)

CAUTION:

Never apply force to the steering wheel in direction of the

shaft by using a hammer or other impact tools in an

attempt to remove the steering wheel. The steering shaft

is designed as an energy absorbing unit.

5. Steering column cover

6. Combination switch

Disconnect the wiring harness connector.

Page 384 of 3573

2A – 82 SUPPLEMENTAL RESTRAINT SYSTEM STEERING WHEEL & COLUMN

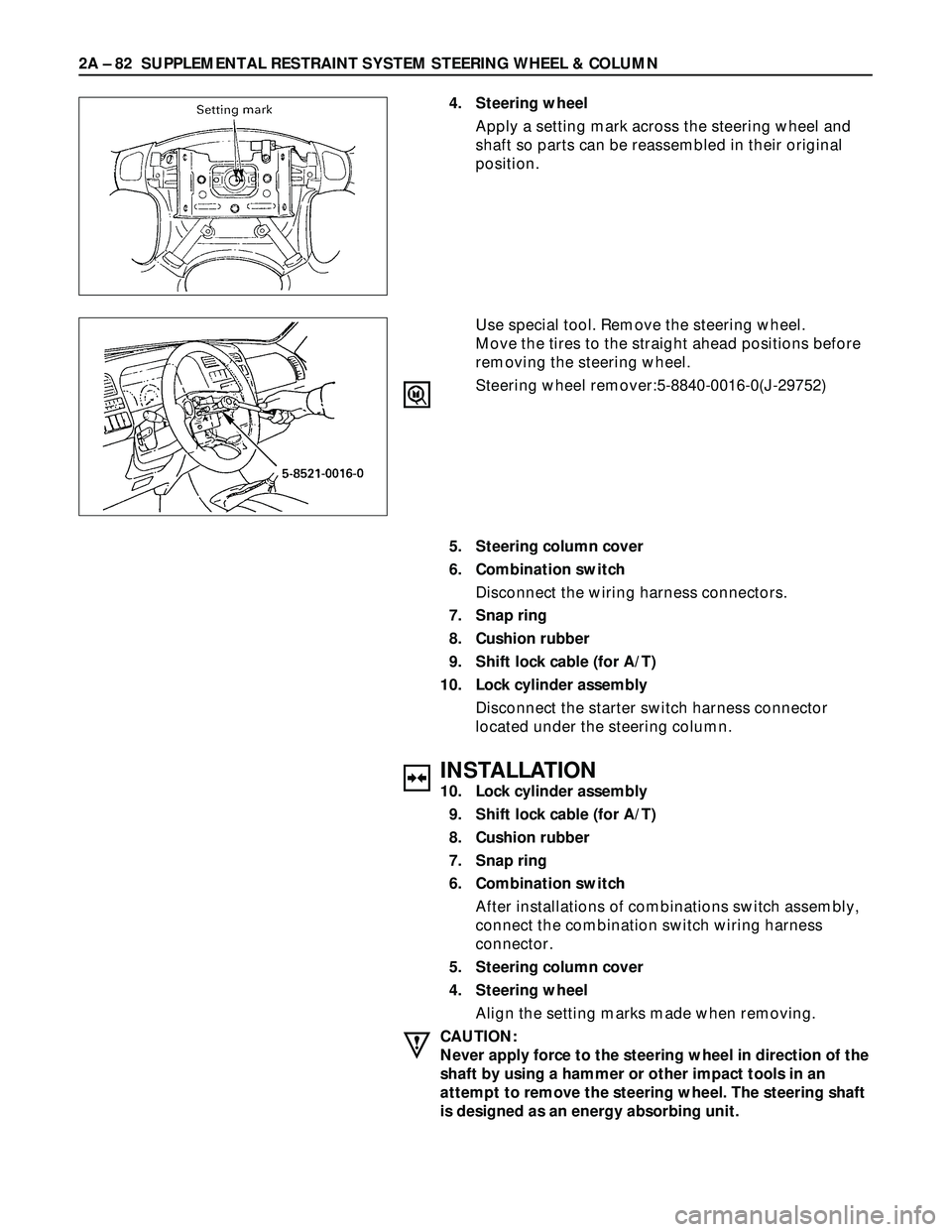

5. Steering column cover

6. Combination switch

Disconnect the wiring harness connectors.

7. Snap ring

8. Cushion rubber

9. Shift lock cable (for A/T)

10. Lock cylinder assembly

Disconnect the starter switch harness connector

located under the steering column.

INSTALLATION

10. Lock cylinder assembly

9. Shift lock cable (for A/T)

8. Cushion rubber

7. Snap ring

6. Combination switch

After installations of combinations switch assembly,

connect the combination switch wiring harness

connector.

5. Steering column cover

4. Steering wheel

Align the setting marks made when removing.

CAUTION:

Never apply force to the steering wheel in direction of the

shaft by using a hammer or other impact tools in an

attempt to remove the steering wheel. The steering shaft

is designed as an energy absorbing unit.4. Steering wheel

Apply a setting mark across the steering wheel and

shaft so parts can be reassembled in their original

position.

Use special tool. Remove the steering wheel.

Move the tires to the straight ahead positions before

removing the steering wheel.

Steering wheel remover:5-8840-0016-0(J-29752)

Page 388 of 3573

2A – 86 SUPPLEMENTAL RESTRAINT SYSTEM STEERING WHEEL & COLUMN

INSTALLATION

11. Steering column assembly

Align the setting marks on the universal joint and

steering shaft made during removal.

Tighten the steering column fixing bolt (dash panel)

to the specified torque.

Steering Column Bolt Torque N·m (kg·m/lb·ft)

19 (1.9 / 14)

Tighten the steering column fixing bolt ( pedal

bracket) to the specified torque.

Steering Column Bolt Torque N·m (kg·m/lb·ft)

17 (1.7 / 13)

Tighten the universal joint to the specified torque.

Universal Joint Torque N·m (kg·m/lb·ft)

25 (2.5 / 18)

10. Lock cylinder assembly

9. Shift lock cable (for A/T)

8. Cushion rubber

7. Snap ring

6. Combination switch

After installation of combination switch assembly,

connect the combination switch wiring harness

connector.

5. Steering column cover

4. Steering wheel

Align the setting marks made when removing.

CAUTION:

Never apply force to the steering wheel in direction of the

shaft by using a hammer or other impact tools in an

attempt to remove the steering wheel. The steering shaft

is designed as an energy absorbing unit.

Tighten the steering wheel fixing nut to the specified

torque.

Steering wheel Nut Torque N·m (kg·m/lb·ft)

34 (3.5 / 25)

3. Steering lower cover

Install the engine hood opening lever.

2. Lower cluster assembly

1. Front console assembly

Connect the wiring harness connectors.

Install the transmission (for M/T) and transfer control

Page 389 of 3573

FRONT SUSPENSION 3C – 1

SECTION 3C

FRONT SUSPENSION

CONTENTS

PAGE

General Description ........................................................................................................ 3C – 2

On-Vehicle Service .......................................................................................................... 3C – 3

Shock Absorber ........................................................................................................... 3C – 3

Stabilizer Bar ............................................................................................................... 3C – 5

Torsion Bar .................................................................................................................. 3C – 7

Knuckle ........................................................................................................................ 3C – 10

Upper Control Arm ..................................................................................................... 3C – 14

Lower Control Arm ..................................................................................................... 3C – 18

Upper Ball Joint .......................................................................................................... 3C – 22

Lower Ball Joint .......................................................................................................... 3C – 25