warning ISUZU TROOPER 1998 Service Manual PDF

[x] Cancel search | Manufacturer: ISUZU, Model Year: 1998, Model line: TROOPER, Model: ISUZU TROOPER 1998Pages: 3573, PDF Size: 60.36 MB

Page 1083 of 3573

6D1±4

ENGINE ELECTRICAL

4. Attach one end of the remaining cable to the negative

terminal of the booster battery.

Attach the other end of the same cable to a solid

engine ground (such as the air conditioning

compressor bracket or the generator mounting

bracket) of the vehicle with the discharged battery.

The ground connection must be at least 450 mm (18

in.) from the battery of the vehicle whose battery is

being charged.

WARNING: NEVER ATTACH THE END OF THE

JUMPER CABLE DIRECTLY TO THE NEGATIVE

TERMINAL OF THE DEAD BATTERY.

5. Start the engine of the vehicle with the good battery.

Make sure that all unnecessary electrical accessories

have been turned ªOFFº.

6. Start the engine of the vehicle with the dead battery.

7. To remove the jumper cables, follow the above

directions in reverse order.

Be sure to first disconnect the negative cable from the

vehicle with the discharged battery.

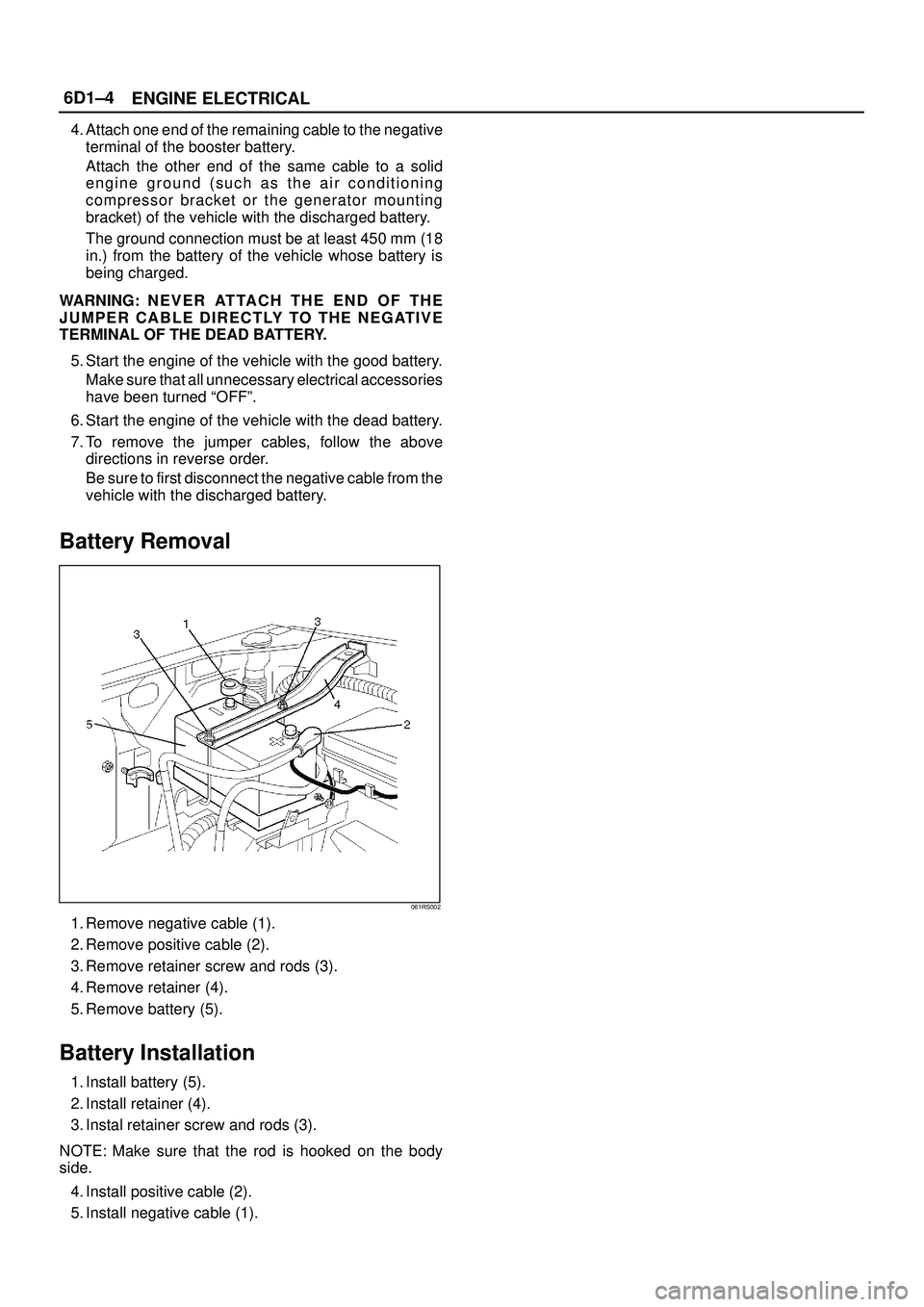

Battery Removal

061RS002

1. Remove negative cable (1).

2. Remove positive cable (2).

3. Remove retainer screw and rods (3).

4. Remove retainer (4).

5. Remove battery (5).

Battery Installation

1. Install battery (5).

2. Install retainer (4).

3. Instal retainer screw and rods (3).

NOTE: Make sure that the rod is hooked on the body

side.

4. Install positive cable (2).

5. Install negative cable (1).

Page 1086 of 3573

6D2±1

IGNITION SYSTEM

ENGINE

IGNITION SYSTEM

CONTENTS

Service Precaution 6D2±1. . . . . . . . . . . . . . . . . . . . . .

General Description 6D2±2. . . . . . . . . . . . . . . . . . . . .

Diagnosis 6D2±2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ignition Coil 6D2±3. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 6D2±3. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 6D2±3. . . . . . . . . . . . . . . . . .

Installation 6D2±3. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Spark Plug 6D2±4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . Removal 6D2±4. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 6D2±4. . . . . . . . . . . . . . . . . .

Installation 6D2±4. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Crankshaft Angle Sensor 6D2±5. . . . . . . . . . . . . . . . .

Removal 6D2±5. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6D2±5. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Main Data and Specifications 6D2±6. . . . . . . . . . . . .

Service Precaution

WARNING: I F S O E Q U IPPED WITH A

SUPPLEMENTAL RESTRAINT SYSTEM (SRS),

REFER TO THE SRS COMPONENT AND WIRING

LOCATION VIEW IN ORDER TO DETERMINE

WHETHER YOU ARE PERFORMING SERVICE ON OR

NEAR THE SRS COMPONENTS OR THE SRS

WIRING. WHEN YOU ARE PERFORMING SERVICE

ON OR NEAR THE SRS COMPONENTS OR THE SRS

WIRING, REFER TO THE SRS SERVICE

INFORMATION. FAILURE TO FOLLOW WARNINGS

COULD RESULT IN POSSIBLE AIR BAG

DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU will call out those fasteners that require a

replacement after removal. ISUZU will also call out

the fasteners that require thread lockers or thread

sealant. UNLESS OTHERWISE SPECIFIED, do not

use supplemental coatings (Paints, greases, or other

corrosion inhibitors) on threaded fasteners or

fastener joint interfaces. Generally, such coatings

adversely affect the fastener torque and the joint

clamping force, and may damage the fastener. When

you install fasteners, use the correct tightening

sequence and specifications. Following these

instructions can help you avoid damage to parts and

systems.

Page 1092 of 3573

6D3±1 STARTING AND CHARGING SYSTEM

ENGINE

STARTING AND CHARGING SYSTEM

CONTENTS

Service Precaution 6D3±1. . . . . . . . . . . . . . . . . . . . . .

Starting System 6D3±2. . . . . . . . . . . . . . . . . . . . . . . . .

General Description 6D3±2. . . . . . . . . . . . . . . . . . . . .

Diagnosis 6D3±4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Starter 6D3±5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 6D3±5. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6D3±5. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Disassembled View 6D3±6. . . . . . . . . . . . . . . . . . . .

Disassembly 6D3±7. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 6D3±9. . . . . . . . . . . . . . . . . .

Reassembly 6D3±13. . . . . . . . . . . . . . . . . . . . . . . . . .

Main Data and Specifications 6D3±15. . . . . . . . . . .

Charging System 6D3±18. . . . . . . . . . . . . . . . . . . . . . . . General Description 6D3±18. . . . . . . . . . . . . . . . . . . . .

General On±Vehicle Inspection 6D3±18. . . . . . . . . . .

Generator 6D3±19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 6D3±19. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection 6D3±19. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6D3±19. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Disassembled View 6D3±20. . . . . . . . . . . . . . . . . . . .

Disassembly 6D3±21. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 6D3±23. . . . . . . . . . . . . . . . . .

Reassembly 6D3±24. . . . . . . . . . . . . . . . . . . . . . . . . .

Bench Test 6D3±25. . . . . . . . . . . . . . . . . . . . . . . . . . .

Main Data and Specifications 6D3±26. . . . . . . . . . .

Service Precaution

WARNING: I F S O E Q U IPPED WITH A

SUPPLEMENTAL RESTRAINT SYSTEM (SRS),

REFER TO THE SRS COMPONENT AND WIRING

LOCATION VIEW IN ORDER TO DETERMINE

WHETHER YOU ARE PERFORMING SERVICE ON OR

NEAR THE SRS COMPONENTS OR THE SRS

WIRING. WHEN YOU ARE PERFORMING SERVICE

ON OR NEAR THE SRS COMPONENTS OR THE SRS

WIRING, REFER TO THE SRS SERVICE

INFORMATION. FAILURE TO FOLLOW WARNINGS

COULD RESULT IN POSSIBLE AIR BAG

DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU will call out those fasteners that require a

replacement after removal. ISUZU will also call out

the fasteners that require thread lockers or thread

sealant. UNLESS OTHERWISE SPECIFIED, do not

use supplemental coatings (Paints, greases, or other

corrosion inhibitors) on threaded fasteners or

fastener joint interfaces. Generally, such coatings

adversely affect the fastener torque and the joint

clamping force, and may damage the fastener. When

you install fasteners, use the correct tightening

sequence and specifications. Following these

instructions can help you avoid damage to parts and

systems.

Page 1109 of 3573

6D3±18STARTING AND CHARGING SYSTEM

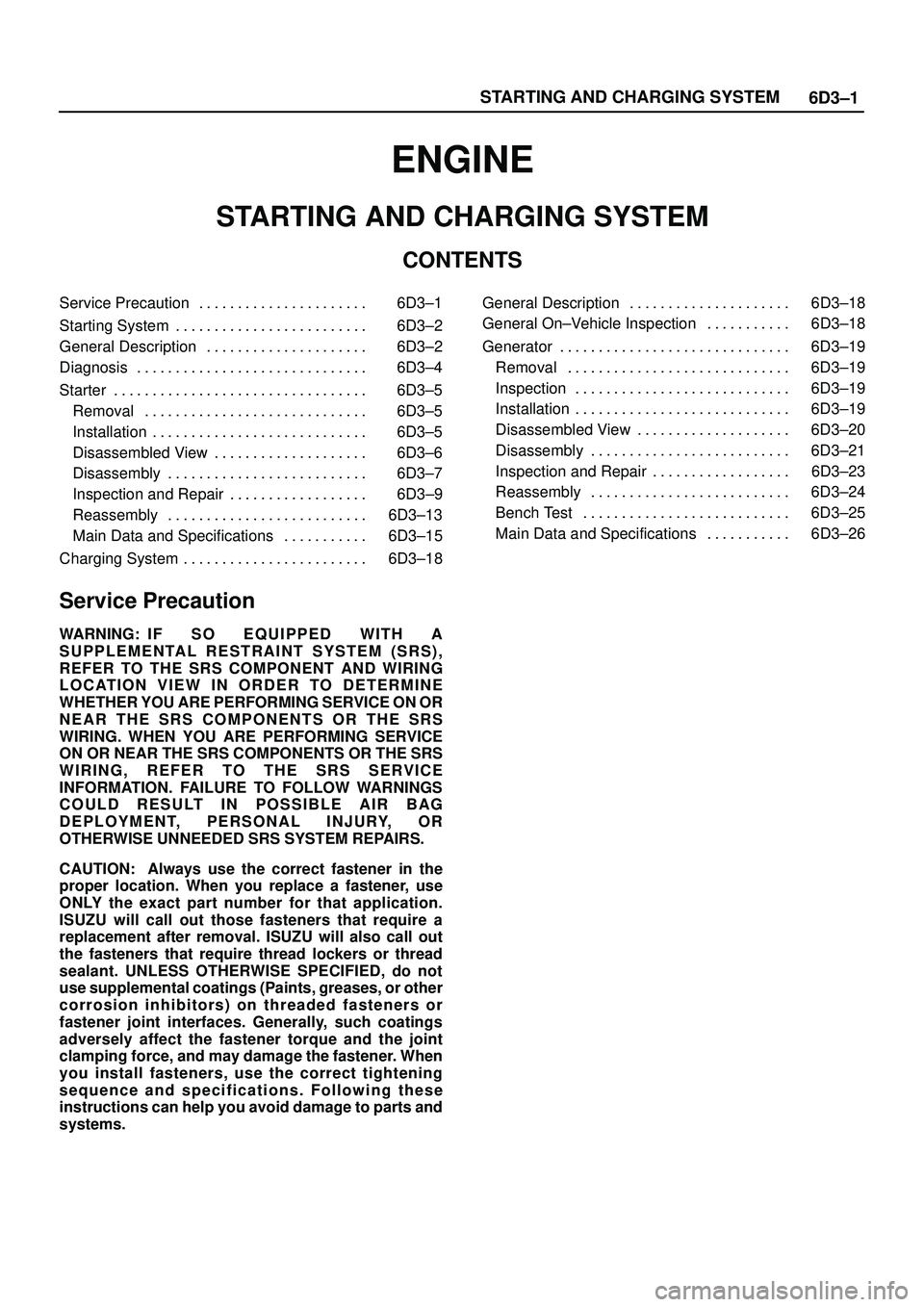

Charging System

General Description

The IC integral regulator charging system and its main

components are connected as shown in the illustration.

The regulator is a solid state type and it is mounted along

with the brush holder assembly inside the generator

installed on the rear end cover.

The generator does not require particular maintenance

such as voltage adjustment.

The rectifier connected to the stator coil has eight diodes

to transform AC voltage into DC voltage.

This DC voltage is connected to the output terminal of

generator.

General On±Vehicle Inspection

The operating condition of charging system is indicated

by the charge warning lamp. The warning lamp comes on

when the starter switch is turned to ªONº position. The

charging system operates normally if the lamp goes off

when the engine starts.

If the warning lamp shows abnormality or if undercharged

or overcharged battery condition is suspected, perform

diagnosis by checking the charging system as follows:

1. Check visually the belt and wiring connector.

2. With the engine stopped, turn the stator switch to

ªONº position and observe the warning lamp.

If lamp does not come on:

Disconnect wiring connector from generator, and

ground the terminal ªLº on connector side.

If lamp comes on:

Repair or replace the generator.

F06RW009

Page 1116 of 3573

6D3±25 STARTING AND CHARGING SYSTEM

1. Using a press with a socket wrench attached,

reassemble rotor and rear end cover assembly in the

front cover.

066RS022

2. Install pulley on the rotor.

Secure the pulley directly in the vise between two

copper plates, and tighten nut to the specified torque.

Torque: 111 N´m (11.3 Kg´m/82 lb ft)

066RS010

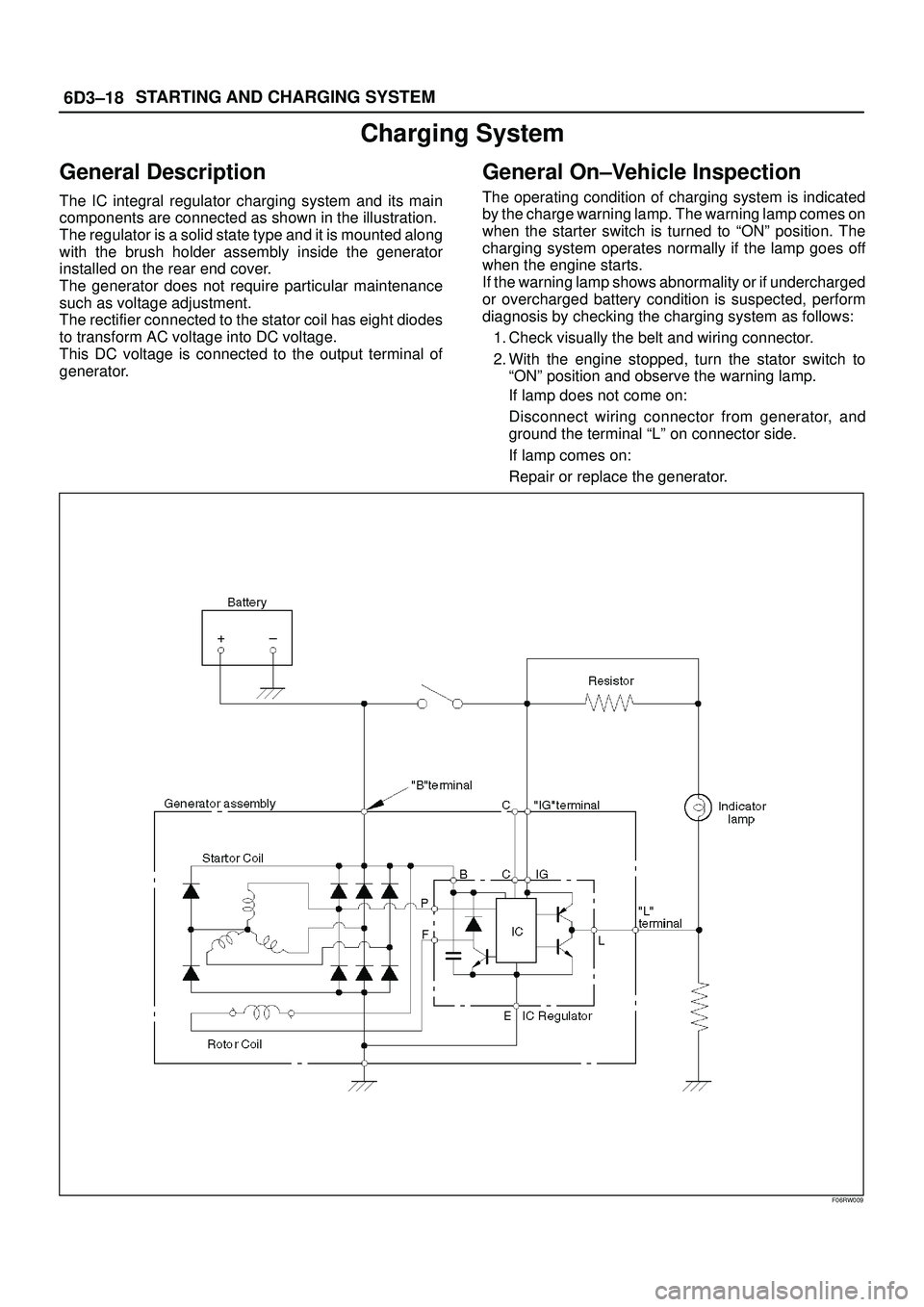

Bench Test

Conduct a bench test of the generator.

066RS023

Preparation

Remove generator from the vehicle (see ªGenerator

removalº).

1. Secure generator to the bench test equipment and

connect wires.

Terminal ªIGº for energization

Terminal ªLº for neutral (warning lamp)

Terminal ªBº for output

2. Conduct the generator characteristic test.

Characteristics of generator are shown in illustration.

Repair or replace the generator if its outputs are

abnormal.

B06RW001

Page 1415 of 3573

6E±298

ENGINE DRIVEABILITY AND EMISSIONS

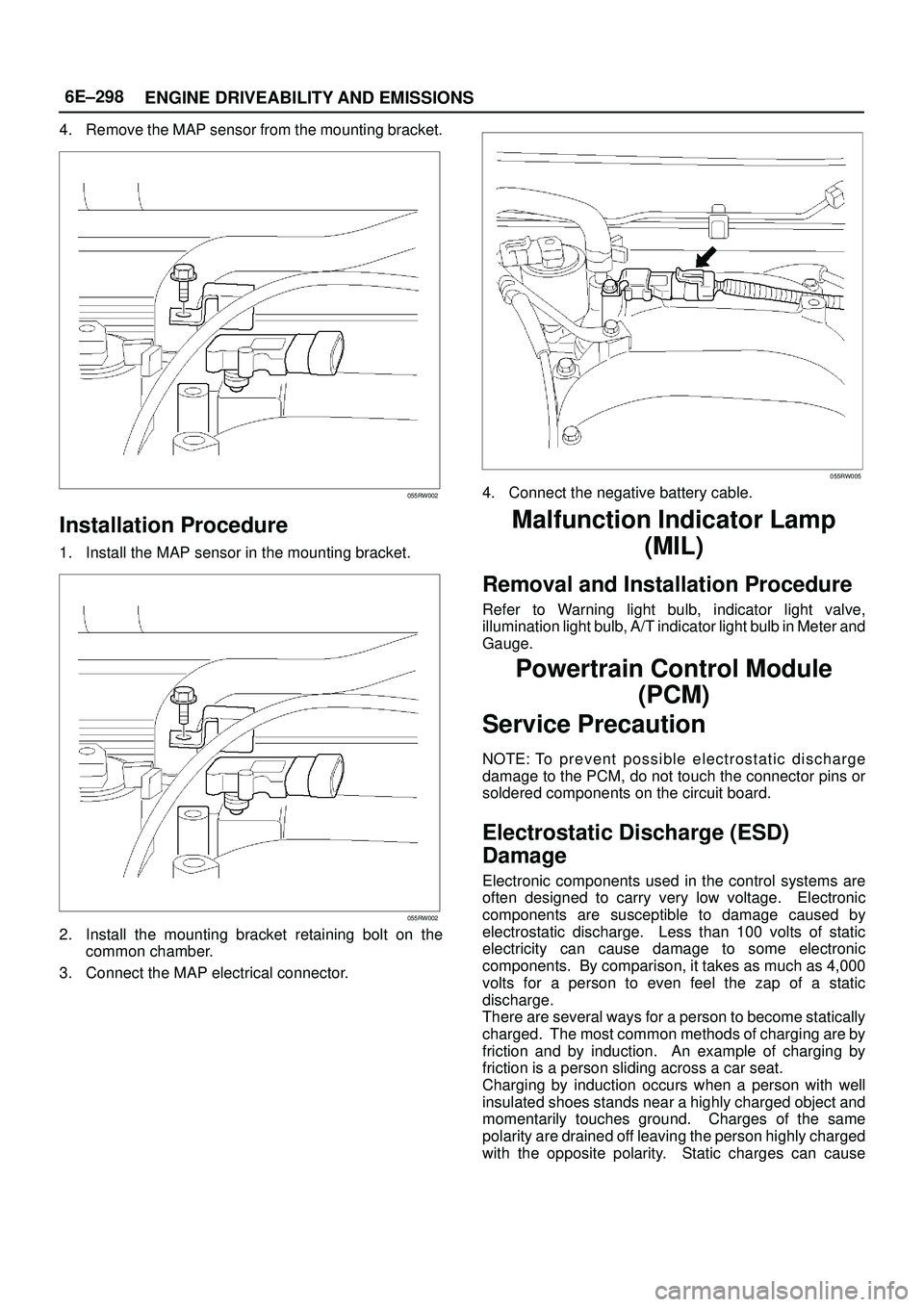

4. Remove the MAP sensor from the mounting bracket.

055RW002

Installation Procedure

1. Install the MAP sensor in the mounting bracket.

055RW002

2. Install the mounting bracket retaining bolt on the

common chamber.

3. Connect the MAP electrical connector.

055RW005

4. Connect the negative battery cable.

Malfunction Indicator Lamp

(MIL)

Removal and Installation Procedure

Refer to Warning light bulb, indicator light valve,

illumination light bulb, A/T indicator light bulb in Meter and

Gauge.

Powertrain Control Module

(PCM)

Service Precaution

NOTE: To p r e ve n t p ossible electrostatic discharge

damage to the PCM, do not touch the connector pins or

soldered components on the circuit board.

Electrostatic Discharge (ESD)

Damage

Electronic components used in the control systems are

often designed to carry very low voltage. Electronic

components are susceptible to damage caused by

electrostatic discharge. Less than 100 volts of static

electricity can cause damage to some electronic

components. By comparison, it takes as much as 4,000

volts for a person to even feel the zap of a static

discharge.

There are several ways for a person to become statically

charged. The most common methods of charging are by

friction and by induction. An example of charging by

friction is a person sliding across a car seat.

Charging by induction occurs when a person with well

insulated shoes stands near a highly charged object and

momentarily touches ground. Charges of the same

polarity are drained off leaving the person highly charged

with the opposite polarity. Static charges can cause

Page 1472 of 3573

6F±1 ENGINE EXHAUST

ENGINE

ENGINE EXHAUST

CONTENTS

Service Precaution 6F±1. . . . . . . . . . . . . . . . . . . . . .

General Description 6F±2. . . . . . . . . . . . . . . . . . . . .

Front Exhaust Pipe 6F±4. . . . . . . . . . . . . . . . . . . . . .

Front Exhaust Pipe and Associated Parts 6F±4.

Removal 6F±4. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6F±4. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Three Way Catalytic Converter 6F±5. . . . . . . . . . . .

Removal 6F±5. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6F±5. . . . . . . . . . . . . . . . . . . . . . . . . . . . Exhaust Silencer 6F±6. . . . . . . . . . . . . . . . . . . . . . . .

Exhaust Silencer and Associated Parts 6F±6. . .

Removal 6F±6. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6F±6. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rear Exhaust pipe 6F±7. . . . . . . . . . . . . . . . . . . . . . .

Rear Exhaust pipe and Associated Parts 6F±7.

Removal 6F±7. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6F±7. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Main Data and Specifications 6F±8. . . . . . . . . . . . .

Service Precaution

WARNING: I F S O E Q U IPPED WITH A

SUPPLEMENTAL RESTRAINT SYSTEM (SRS),

REFER TO THE SRS COMPONENT AND WIRING

LOCATION VIEW IN ORDER TO DETERMINE

WHETHER YOU ARE PERFORMING SERVICE ON OR

NEAR THE SRS COMPONENTS OR THE SRS

WIRING. WHEN YOU ARE PERFORMING SERVICE

ON OR NEAR THE SRS COMPONENTS OR THE SRS

WIRING, REFER TO THE SRS SERVICE

INFORMATION. FAILURE TO FOLLOW WARNINGS

COULD RESULT IN POSSIBLE AIR BAG

DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU will call out those fasteners that require a

replacement after removal. ISUZU will also call out

the fasteners that require thread lockers or thread

sealant. UNLESS OTHERWISE SPECIFIED, do not

use supplemental coatings (Paints, greases, or other

corrosion inhibitors) on threaded fasteners or

fastener joint interfaces. Generally, such coatings

adversely affect the fastener torque and the joint

clamping force, and may damage the fastener. When

you install fasteners, use the correct tightening

sequence and specifications. Following these

instructions can help you avoid damage to parts and

systems.

Page 1480 of 3573

6G±1 ENGINE LUBRICATION

ENGINE

ENGINE LUBRICATION

CONTENTS

Service Precaution 6G±1. . . . . . . . . . . . . . . . . . . . . .

General Description 6G±2. . . . . . . . . . . . . . . . . . . . .

Oil Pump 6G±3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Oil Pump and Associated Parts 6G±3. . . . . . . . . .

Oil Pump and Associated Parts 6G±3. . . . . . . . . .

Inspection and Repair 6G±4. . . . . . . . . . . . . . . . . .

Reassembly 6G±5. . . . . . . . . . . . . . . . . . . . . . . . . .

Oil Pan and Crankcase 6G±7. . . . . . . . . . . . . . . . . .

Removal 6G±7. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6G±7. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Oil Pump 6G±10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Removal 6G±10. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6G±10. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Oil Pump Oil Seal 6G±12. . . . . . . . . . . . . . . . . . . . . . .

Removal 6G±12. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6G±12. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Oil Filter 6G±13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 6G±13. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6G±13. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Main Data and Specification 6G±14. . . . . . . . . . . . . .

Special Tool 6G±15. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Precaution

WARNING: I F S O E Q U IPPED WITH A

SUPPLEMENTAL RESTRAINT SYSTEM (SRS),

REFER TO THE SRS COMPONENT AND WIRING

LOCATION VIEW IN ORDER TO DETERMINE

WHETHER YOU ARE PERFORMING SERVICE ON OR

NEAR THE SRS COMPONENTS OR THE SRS

WIRING. WHEN YOU ARE PERFORMING SERVICE

ON OR NEAR THE SRS COMPONENTS OR THE SRS

WIRING, REFER TO THE SRS SERVICE

INFORMATION. FAILURE TO FOLLOW WARNINGS

COULD RESULT IN POSSIBLE AIR BAG

DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU will call out those fasteners that require a

replacement after removal. ISUZU will also call out

the fasteners that require thread lockers or thread

sealant. UNLESS OTHERWISE SPECIFIED, do not

use supplemental coatings (Paints, greases, or other

corrosion inhibitors) on threaded fasteners or

fastener joint interfaces. Generally, such coatings

adversely affect the fastener torque and the joint

clamping force, and may damage the fastener. When

you install fasteners, use the correct tightening

sequence and specifications. Following these

instructions can help you avoid damage to parts and

systems.

Page 1495 of 3573

6H±1 ENGINE SPEED CONTROL SYSTEM

ENGINE

ENGINE SPEED CONTROL SYSTEM

CONTENTS

Service Precaution 6H±1. . . . . . . . . . . . . . . . . . . . . .

Accelerator Pedal Control Cable 6H±2. . . . . . . . . .

Removal 6H±2. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection 6H±2. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6H±2. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjustment 6H±2. . . . . . . . . . . . . . . . . . . . . . . . . . . Accelerator Pedal 6H±3. . . . . . . . . . . . . . . . . . . . . . .

Accelerator Pedal and Associated Parts 6H±3. .

Removal 6H±3. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6H±3. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjustment 6H±3. . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Precaution

WARNING: I F S O E Q U IPPED WITH A

SUPPLEMENTAL RESTRAINT SYSTEM (SRS),

REFER TO THE SRS COMPONENT AND WIRING

LOCATION VIEW IN ORDER TO DETERMINE

WHETHER YOU ARE PERFORMING SERVICE ON OR

NEAR THE SRS COMPONENTS OR THE SRS

WIRING. WHEN YOU ARE PERFORMING SERVICE

ON OR NEAR THE SRS COMPONENTS OR THE SRS

WIRING, REFER TO THE SRS SERVICE

INFORMATION. FAILURE TO FOLLOW WARNINGS

COULD RESULT IN POSSIBLE AIR BAG

DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU will call out those fasteners that require a

replacement after removal. ISUZU will also call out

the fasteners that require thread lockers or thread

sealant. UNLESS OTHERWISE SPECIFIED, do not

use supplemental coatings (Paints, greases, or other

corrosion inhibitors) on threaded fasteners or

fastener joint interfaces. Generally, such coatings

adversely affect the fastener torque and the joint

clamping force, and may damage the fastener. When

you install fasteners, use the correct tightening

sequence and specifications. Following these

instructions can help you avoid damage to parts and

systems.

Page 1499 of 3573

INDUCTION6J±1

ENGINE

INDUCTION

CONTENTS

Service Precaution 6J±1. . . . . . . . . . . . . . . . . . . . . .

Air Cleaner Element 6J±2. . . . . . . . . . . . . . . . . . . . .

Removal 6J±2. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection 6J±2. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6J±2. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Precaution

WARNING: I F S O E Q U IPPED WITH A

SUPPLEMENTAL RESTRAINT SYSTEM

(SRS),REFER TO THE SRS COMPONENT AND

WIRING LOCATION VIEW IN ORDER TO DETERMINE

WHETHER YOU ARE PERFORMING SERVICE ON OR

NEAR THE SRS COMPONENTS OR THE SRS

WIRING. WHEN YOU ARE PERFORMING SERVICE

ON OR NEAR THE SRS COMPONENTS OR THE SRS

WIRING, REFER TO THE SRS SERVICE

INFORMATION. FAILURE TO FOLLOW WARNINGS

COULD RESULT IN POSSIBLE AIR BAG

DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU will call out those fasteners that require a

replacement after removal. ISUZU will also call out

the fasteners that require thread lockers or thread

sealant. UNLESS OTHERWISE SPECIFIED, do not

use supplemental coatings (Paints, greases, or other

corrosion inhibitors) on threaded fasteners or

fastener joint interfaces. Generally, such coatings

adversely affect the fastener torque and the joint

clamping force, and may damage the fastener. When

you install fasteners, use the correct tightening

sequence and specifications. Following these

instructions can help you avoid damage to parts and

systems.