light ISUZU TROOPER 1998 Service Manual PDF

[x] Cancel search | Manufacturer: ISUZU, Model Year: 1998, Model line: TROOPER, Model: ISUZU TROOPER 1998Pages: 3573, PDF Size: 60.36 MB

Page 906 of 3573

5C – 28 POWER ASSISTED BRAKE SYSTEM

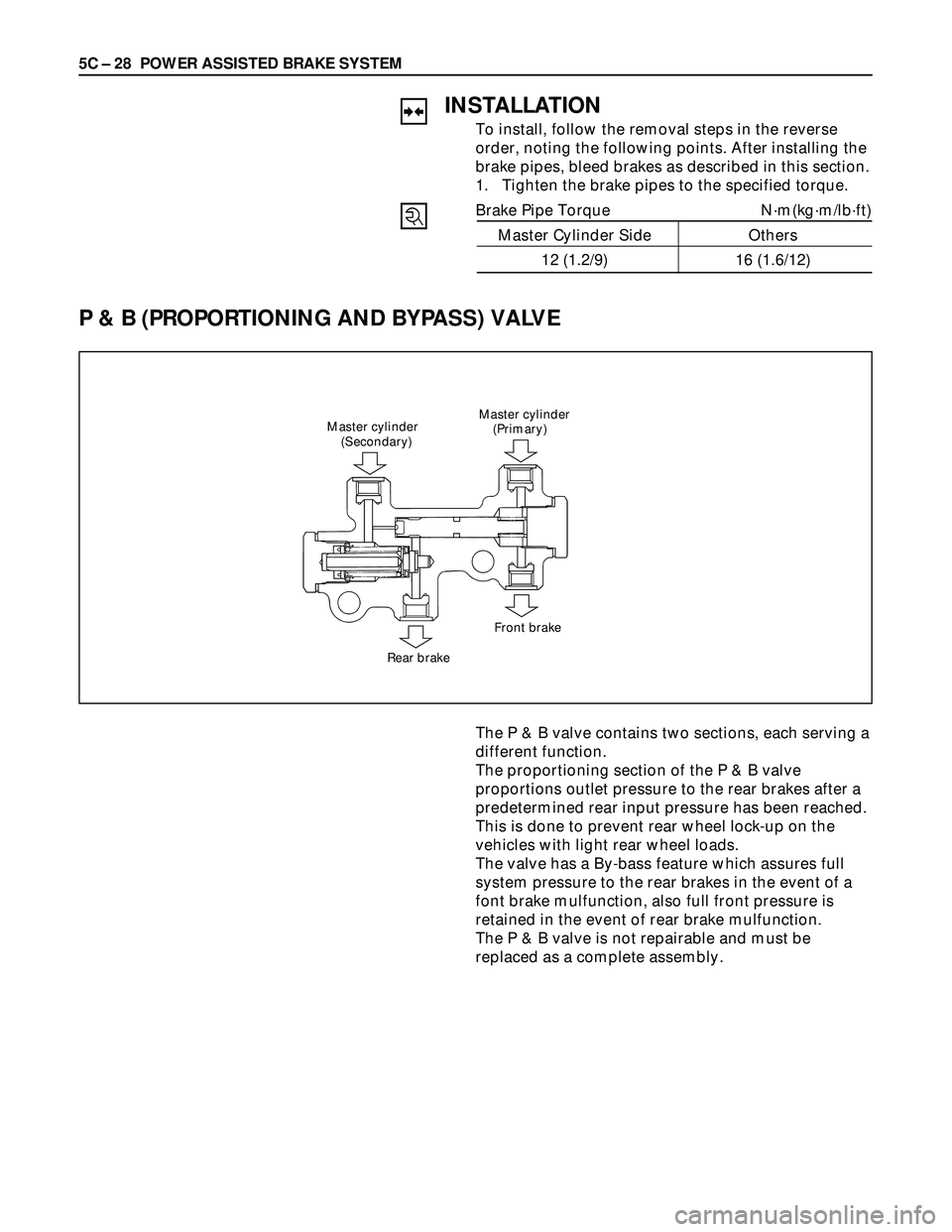

P & B (PROPORTIONING AND BYPASS) VALVE

Master cylinder

(Primary) Master cylinder

(Secondary)

Rear brakeFront brake

INSTALLATION

To install, follow the removal steps in the reverse

order, noting the following points. After installing the

brake pipes, bleed brakes as described in this section.

1. Tighten the brake pipes to the specified torque.

Brake Pipe Torque N·m(kg·m/lb·ft)

Master Cylinder Side Others

12 (1.2/9) 16 (1.6/12)

The P & B valve contains two sections, each serving a

different function.

The proportioning section of the P & B valve

proportions outlet pressure to the rear brakes after a

predetermined rear input pressure has been reached.

This is done to prevent rear wheel lock-up on the

vehicles with light rear wheel loads.

The valve has a By-bass feature which assures full

system pressure to the rear brakes in the event of a

font brake mulfunction, also full front pressure is

retained in the event of rear brake mulfunction.

The P & B valve is not repairable and must be

replaced as a complete assembly.

Page 912 of 3573

5C – 34 POWER ASSISTED BRAKE SYSTEM

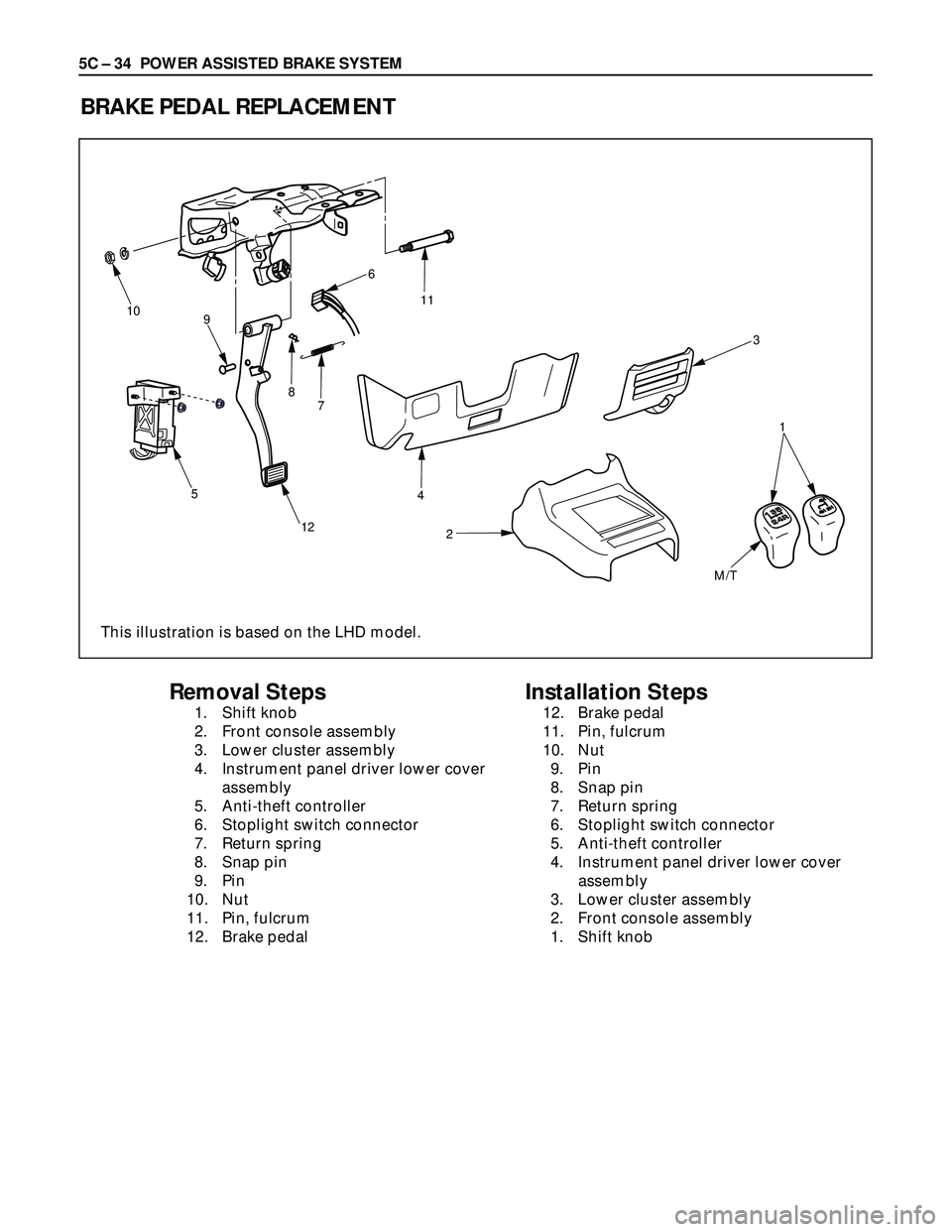

BRAKE PEDAL REPLACEMENT

10

9

5

124

2 7 86

11

3

1

M/T

Removal Steps

1. Shift knob

2. Front console assembly

3. Lower cluster assembly

4. Instrument panel driver lower cover

assembly

5. Anti-theft controller

6. Stoplight switch connector

7. Return spring

8. Snap pin

9. Pin

10. Nut

11. Pin, fulcrum

12. Brake pedal

Installation Steps

12. Brake pedal

11. Pin, fulcrum

10. Nut

9. Pin

8. Snap pin

7. Return spring

6. Stoplight switch connector

5. Anti-theft controller

4. Instrument panel driver lower cover

assembly

3. Lower cluster assembly

2. Front console assembly

1. Shift knob

This illustration is based on the LHD model.

Page 913 of 3573

POWER ASSISTED BRAKE SYSTEM 5C – 35

REMOVAL

1. Shift Knob

2. Front Console Assembly

3. Lower Cluster Assembly

4. Instrument Panel Driver Lower Cover Assembly

5. Anti-theft Controller

6. Stoplight switch Connector

7. Return Spring

8. Snap Pin

9. Pin

10. Nut

11. Pin, Fulcrum

12. Brake Pedal

INSTALLATION

12. Brake Pedal

11. Pin, Fulcrum

•Apply grease to the entire circumference of the

fulcrum pin.

10. Nut

Bolt and Nut Torque N·m (kg·m / lb·ft)

33 (3.3 / 24)

9. Pin

•Apply grease to the entire circumference of the

push rod pin.

8. Snap Pin

•Adjust pedal free travel. Refer to “Brake Pedal

Adjustment” previously in this section.

7. Return Spring

6. Stoplight Switch Connector

5. Anti-theft Connector

4. Instrument Panel Driver Lower Cover Assembly

3. Lower Cluster Assembly

2. Front Console Assembly

1. Shift Knob

Page 914 of 3573

5C – 36 POWER ASSISTED BRAKE SYSTEM

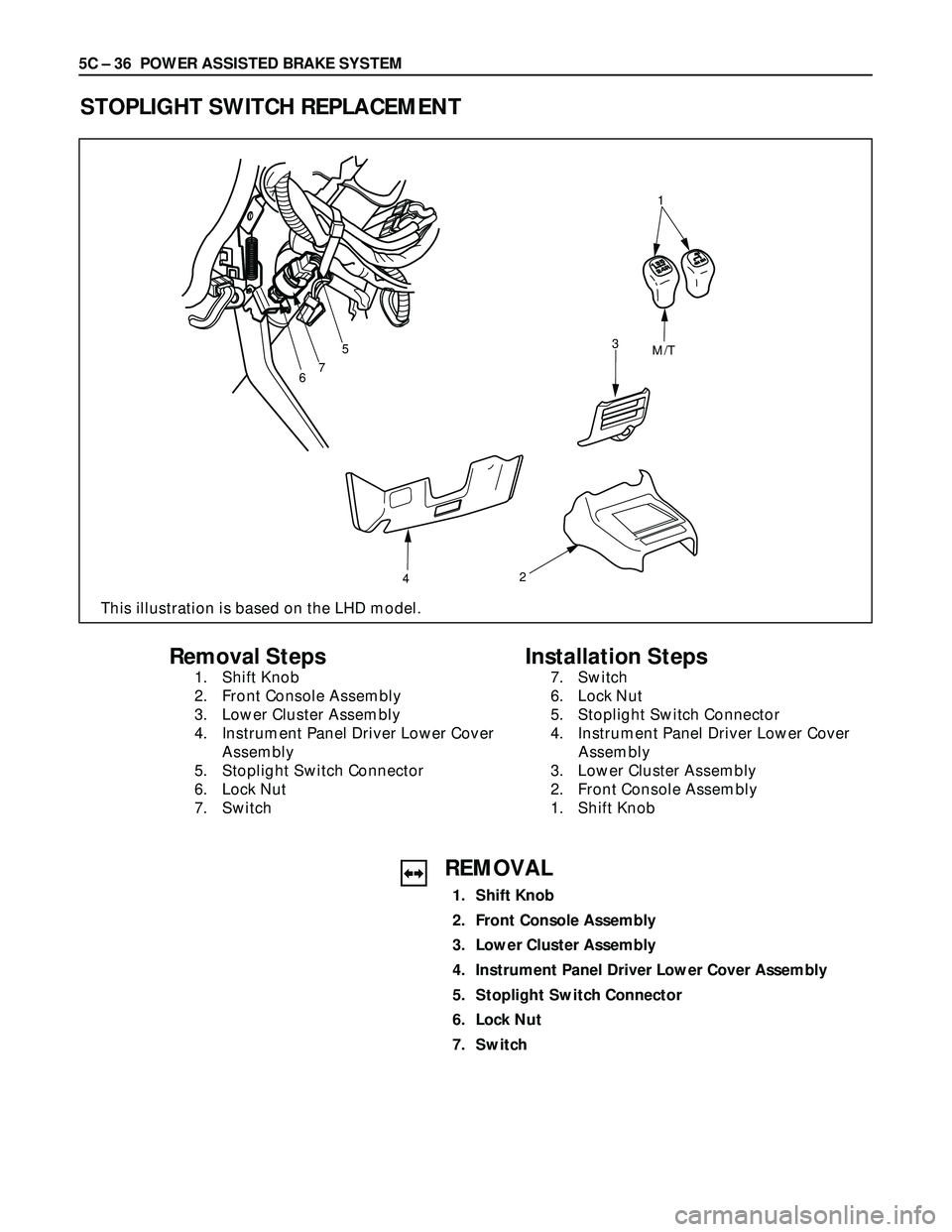

STOPLIGHT SWITCH REPLACEMENT

675

423

M/T1

Removal Steps

1. Shift Knob

2. Front Console Assembly

3. Lower Cluster Assembly

4. Instrument Panel Driver Lower Cover

Assembly

5. Stoplight Switch Connector

6. Lock Nut

7. Switch

Installation Steps

7. Switch

6. Lock Nut

5. Stoplight Switch Connector

4. Instrument Panel Driver Lower Cover

Assembly

3. Lower Cluster Assembly

2. Front Console Assembly

1. Shift Knob

REMOVAL

1. Shift Knob

2. Front Console Assembly

3. Lower Cluster Assembly

4. Instrument Panel Driver Lower Cover Assembly

5. Stoplight Switch Connector

6. Lock Nut

7. Switch

This illustration is based on the LHD model.

Page 915 of 3573

POWER ASSISTED BRAKE SYSTEM 5C – 37

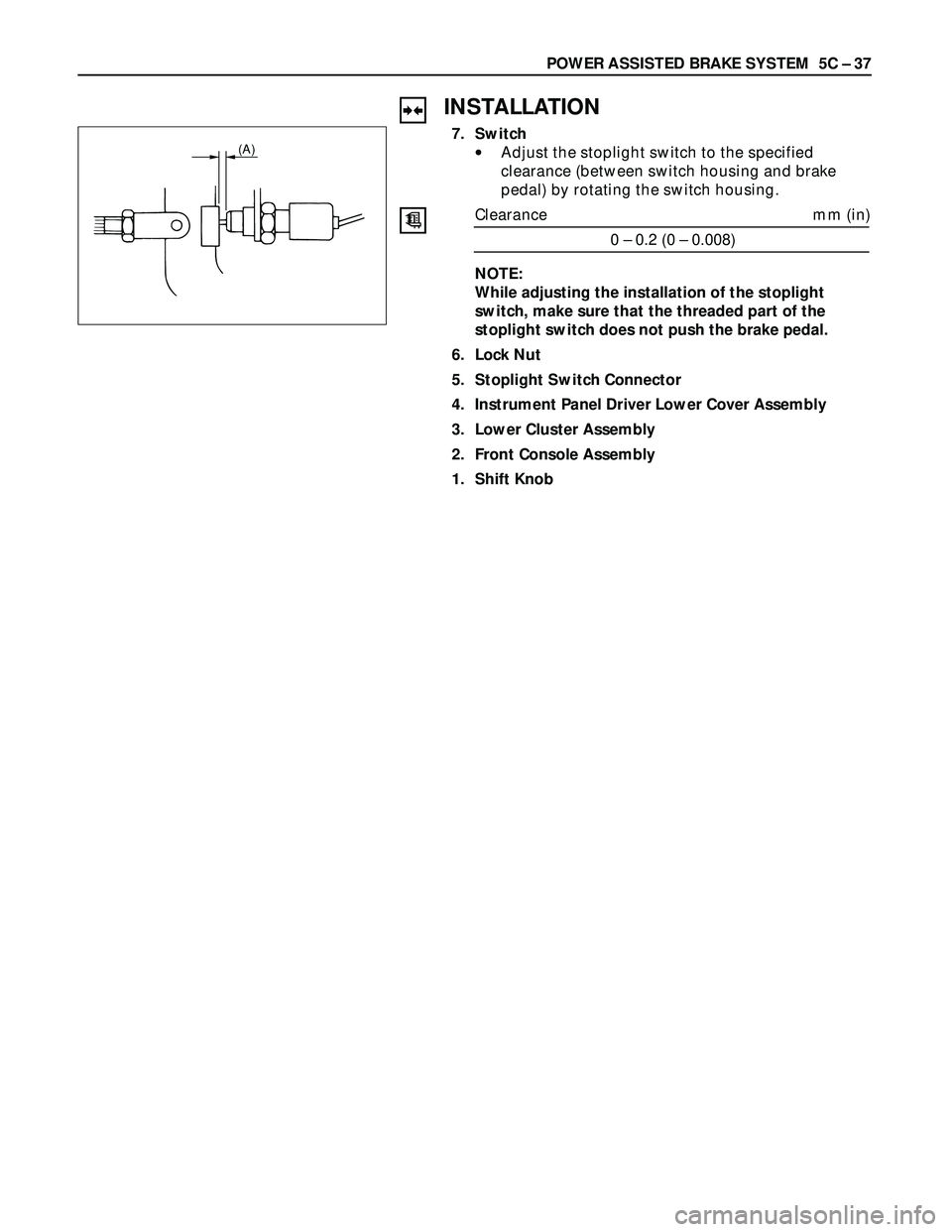

INSTALLATION

7. Switch

•Adjust the stoplight switch to the specified

clearance (between switch housing and brake

pedal) by rotating the switch housing.

Clearance mm (in)

0 – 0.2 (0 – 0.008)

NOTE:

While adjusting the installation of the stoplight

switch, make sure that the threaded part of the

stoplight switch does not push the brake pedal.

6. Lock Nut

5. Stoplight Switch Connector

4. Instrument Panel Driver Lower Cover Assembly

3. Lower Cluster Assembly

2. Front Console Assembly

1. Shift Knob(A)

Page 948 of 3573

PARKING BRAKES 5D Ð 3

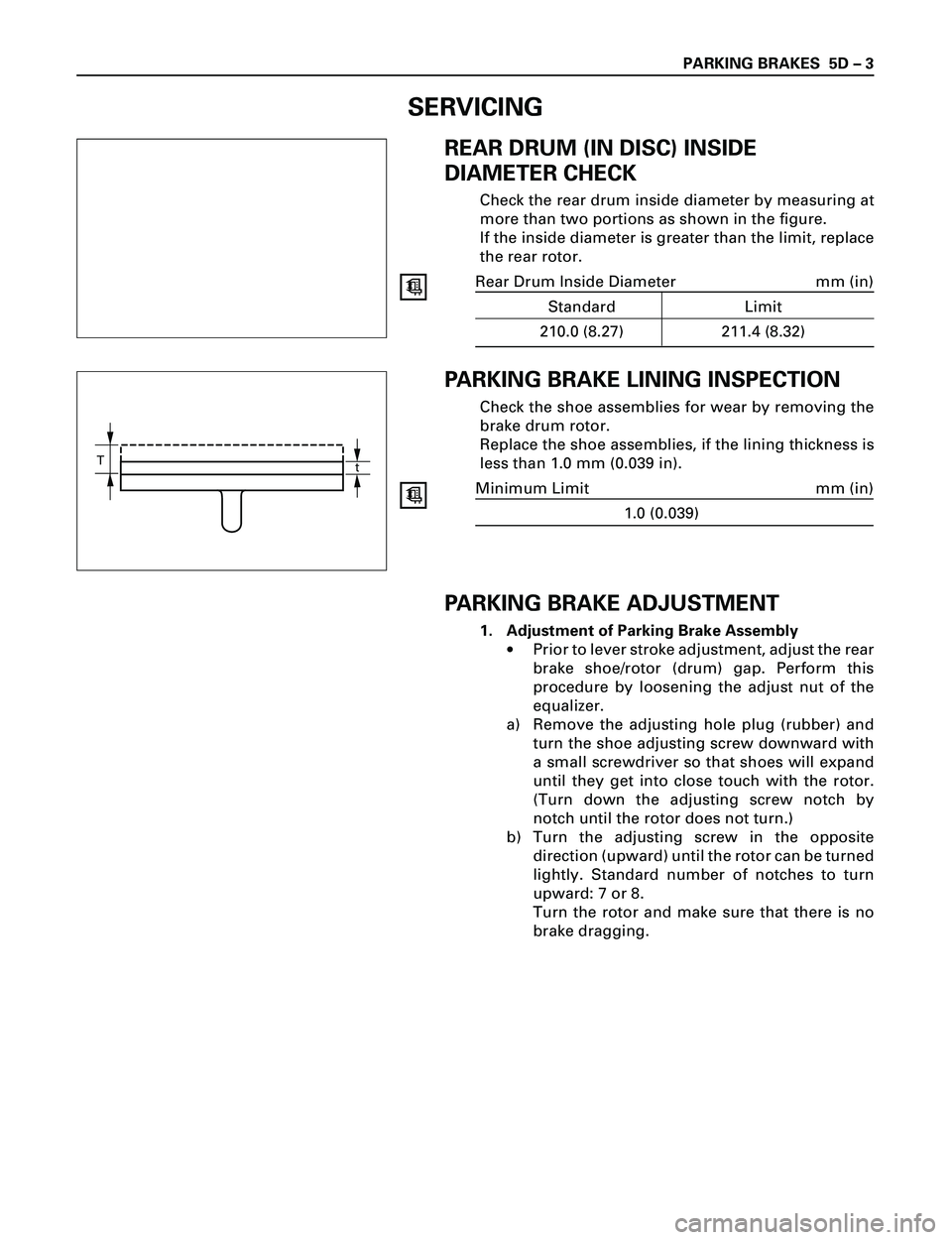

REAR DRUM (IN DISC) INSIDE

DIAMETER CHECK

Check the rear drum inside diameter by measuring at

more than two portions as shown in the figure.

If the inside diameter is greater than the limit, replace

the rear rotor.

Rear Drum Inside Diameter mm (in)

Standard Limit

210.0 (8.27) 211.4 (8.32)

PARKING BRAKE LINING INSPECTION

Check the shoe assemblies for wear by removing the

brake drum rotor.

Replace the shoe assemblies, if the lining thickness is

less than 1.0 mm (0.039 in).

Minimum Limit mm (in)

1.0 (0.039)

PARKING BRAKE ADJUSTMENT

1. Adjustment of Parking Brake Assembly

·Prior to lever stroke adjustment, adjust the rear

brake shoe/rotor (drum) gap. Perform this

procedure by loosening the adjust nut of the

equalizer.

a) Remove the adjusting hole plug (rubber) and

turn the shoe adjusting screw downward with

a small screwdriver so that shoes will expand

until they get into close touch with the rotor.

(Turn down the adjusting screw notch by

notch until the rotor does not turn.)

b) Turn the adjusting screw in the opposite

direction (upward) until the rotor can be turned

lightly. Standard number of notches to turn

upward: 7 or 8.

Turn the rotor and make sure that there is no

brake dragging.

T

t

SERVICING

Page 951 of 3573

5D Ð 6 PARKING BRAKES

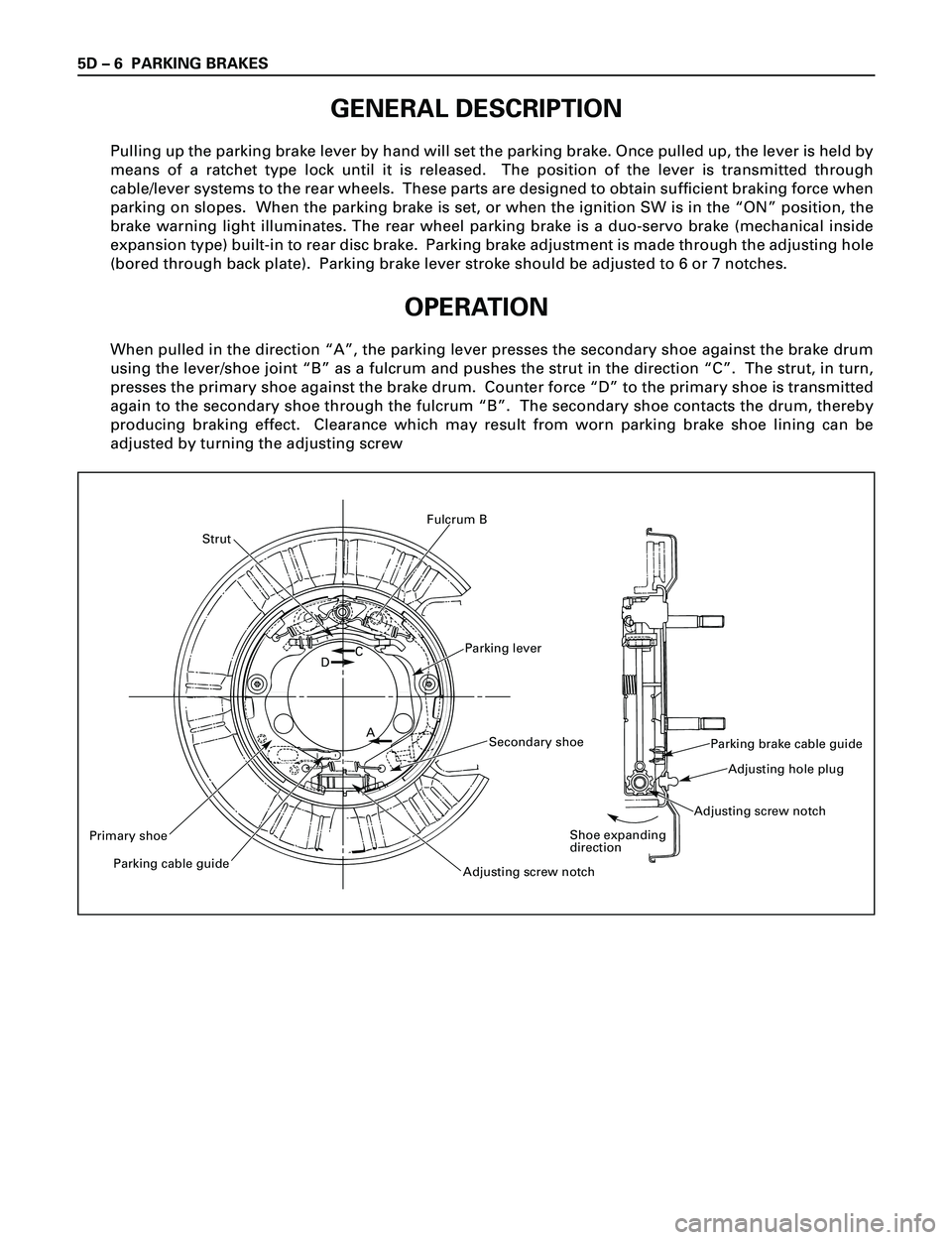

GENERAL DESCRIPTION

Pulling up the parking brake lever by hand will set the parking brake. Once pulled up, the lever is held by

means of a ratchet type lock until it is released. The position of the lever is transmitted through

cable/lever systems to the rear wheels. These parts are designed to obtain sufficient braking force when

parking on slopes. When the parking brake is set, or when the ignition SW is in the ÒONÓ position, the

brake warning light illuminates. The rear wheel parking brake is a duo-servo brake (mechanical inside

expansion type) built-in to rear disc brake. Parking brake adjustment is made through the adjusting hole

(bored through back plate). Parking brake lever stroke should be adjusted to 6 or 7 notches.

OPERATION

When pulled in the direction ÒAÓ, the parking lever presses the secondary shoe against the brake drum

using the lever/shoe joint ÒBÓ as a fulcrum and pushes the strut in the direction ÒCÓ. The strut, in turn,

presses the primary shoe against the brake drum. Counter force ÒDÓ to the primary shoe is transmitted

again to the secondary shoe through the fulcrum ÒBÓ. The secondary shoe contacts the drum, thereby

producing braking effect. Clearance which may result from worn parking brake shoe lining can be

adjusted by turning the adjusting screw

Parking lever

Strut

Primary shoe

Parking cable guide

Adjusting screw notch

Secondary shoe

DC

A

Fulcrum B

Parking brake cable guide

Adjusting hole plug

Adjusting screw notch

Shoe expanding

direction

Page 960 of 3573

6A±4

ENGINE MECHANICAL

Engine Diagnosis

Hard Starting

1. Starting Motor Does Not Turn Over

Troubleshooting Procedure

Turn on headlights and starter switch.

Condition

Possible causeCorrection

Headlights go out or dim

considerably

Battery run down or under chargedRecharge or replace battery

considerablyTerminals poorly connectedClean battery posts and terminals

and connect properly

Starting motor coil circuit shortedOverhaul or replace

Starting motor defectiveOverhaul or replace

2. Ignition Trouble Ð Starting Motor Turns Over But Engine Does Not Start

Spark Test

Disconnect an igniton coil from any spark plug. Connect

the spark plug tester 5±8840±0607±0, start the engine,

and check if a spark is generated in the spark plug tester.

Before starting the engine, make sure that the spark plugtester is properly grounded. To avoid electrical shock, do

not touch the part where insulation of the igniton coil is

broken while the engine is running.

Condition

Possible causeCorrection

Spark jumps across gapSpark plug defectiveClean, adjust spark gap or replace

Ignition timing incorrectRefer to Ignition System

Fuel not reaching fuel injector(s) or

engineRefer to item 3 (Trouble in fuel

system)

Valve timing incorrectAdjust

Engine lacks compressionRefer to item 4 (Engine lacks

compression)

No sparking takes placeIgnition coil disconnected or brokenConnect properly or replace

Electronic Ignition System with

moduleReplace

Poor connections in engine harnessCorrect

Powertrain Control Module cable

disconnected or defectiveCorrect or replace

3. Trouble In Fuel System

Condition

Possible causeCorrection

Starting motor turns over and spark

occurs but engine does not start

Fuel tank emptyFill

occurs but engine does not start.Water in fuel systemClean

Fuel filter cloggedReplace filter

Fuel pipe cloggedClean or replace

Fuel pump defectiveReplace

Fuel pump circuit openCorrect or replace

Evaporative Emission Control

System circuit cloggedCorrect or replace

Multiport Fuel Injection System faultyRefer to ªElectronic Fuel Injectionº

section

Page 968 of 3573

6A±12

ENGINE MECHANICAL

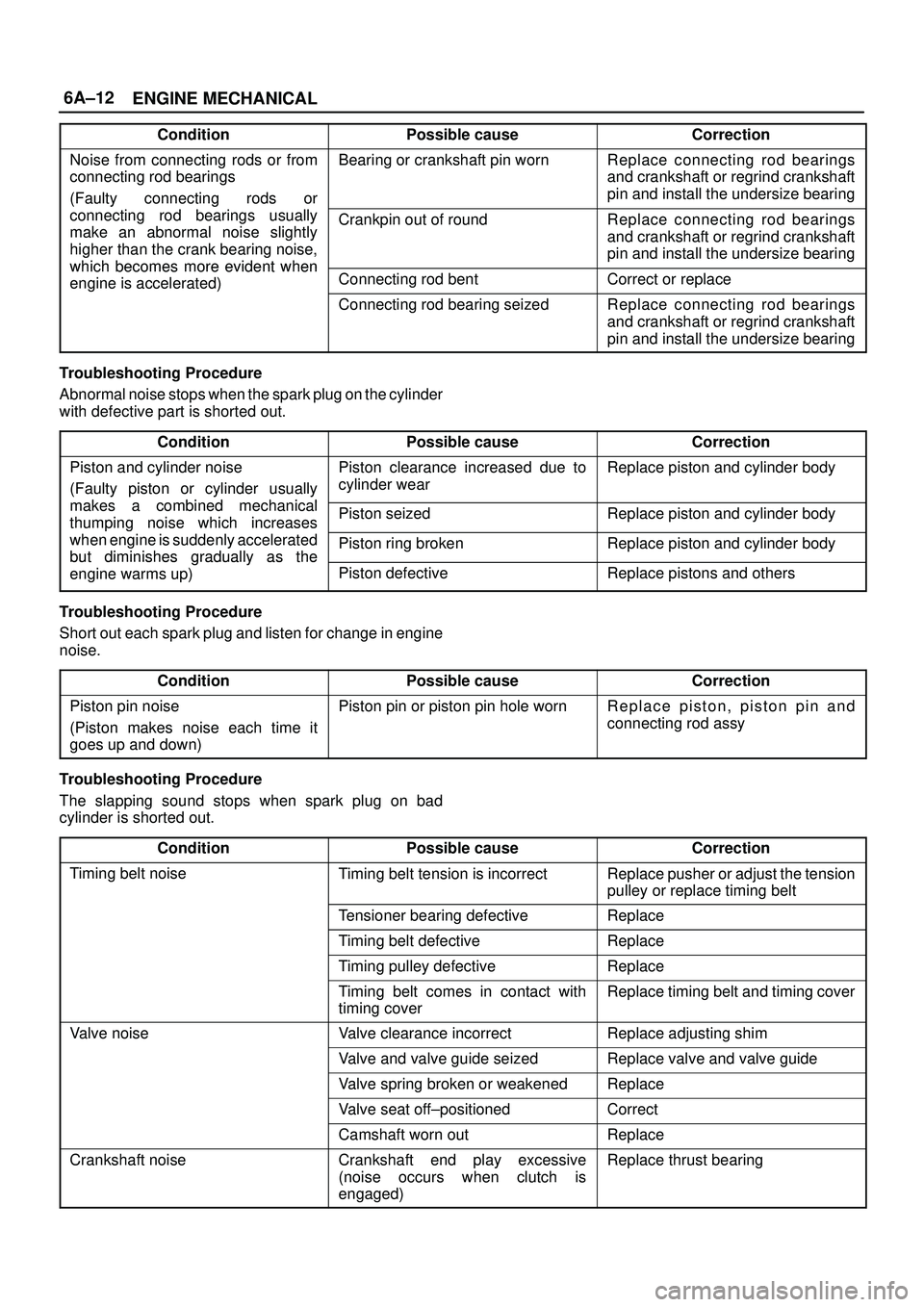

ConditionPossible causeCorrection

Noise from connecting rods or from

connecting rod bearings

(Faulty connecting rods orBearing or crankshaft pin wornReplace connecting rod bearings

and crankshaft or regrind crankshaft

pin and install the undersize bearing

yg

connecting rod bearings usually

make an abnormal noise slightly

higher than the crank bearing noise,

which becomes more evident when

Crankpin out of roundReplace connecting rod bearings

and crankshaft or regrind crankshaft

pin and install the undersize bearing

which becomes more evident when

engine is accelerated)Connecting rod bentCorrect or replaceg)

Connecting rod bearing seizedReplace connecting rod bearings

and crankshaft or regrind crankshaft

pin and install the undersize bearing

Troubleshooting Procedure

Abnormal noise stops when the spark plug on the cylinder

with defective part is shorted out.

Condition

Possible causeCorrection

Piston and cylinder noise

(Faulty piston or cylinder usually

k bid hil

Piston clearance increased due to

cylinder wearReplace piston and cylinder body

makes a combined mechanical

thumping noise which increasesPiston seizedReplace piston and cylinder bodyg

when engine is suddenly accelerated

but diminishes

gradually as thePiston ring brokenReplace piston and cylinder bodybut diminishes gradually as the

engine warms up)Piston defectiveReplace pistons and others

Troubleshooting Procedure

Short out each spark plug and listen for change in engine

noise.

Condition

Possible causeCorrection

Piston pin noise

(Piston makes noise each time it

goes up and down)Piston pin or piston pin hole wornReplace piston, piston pin and

connecting rod assy

Troubleshooting Procedure

The slapping sound stops when spark plug on bad

cylinder is shorted out.

Condition

Possible causeCorrection

Timing belt noiseTiming belt tension is incorrectReplace pusher or adjust the tension

pulley or replace timing belt

Tensioner bearing defectiveReplace

Timing belt defectiveReplace

Timing pulley defectiveReplace

Timing belt comes in contact with

timing coverReplace timing belt and timing cover

Valve noiseValve clearance incorrectReplace adjusting shim

Valve and valve guide seizedReplace valve and valve guide

Valve spring broken or weakenedReplace

Valve seat off±positionedCorrect

Camshaft worn outReplace

Crankshaft noiseCrankshaft end play excessive

(noise occurs when clutch is

engaged)Replace thrust bearing

Page 985 of 3573

6A±29

ENGINE MECHANICAL

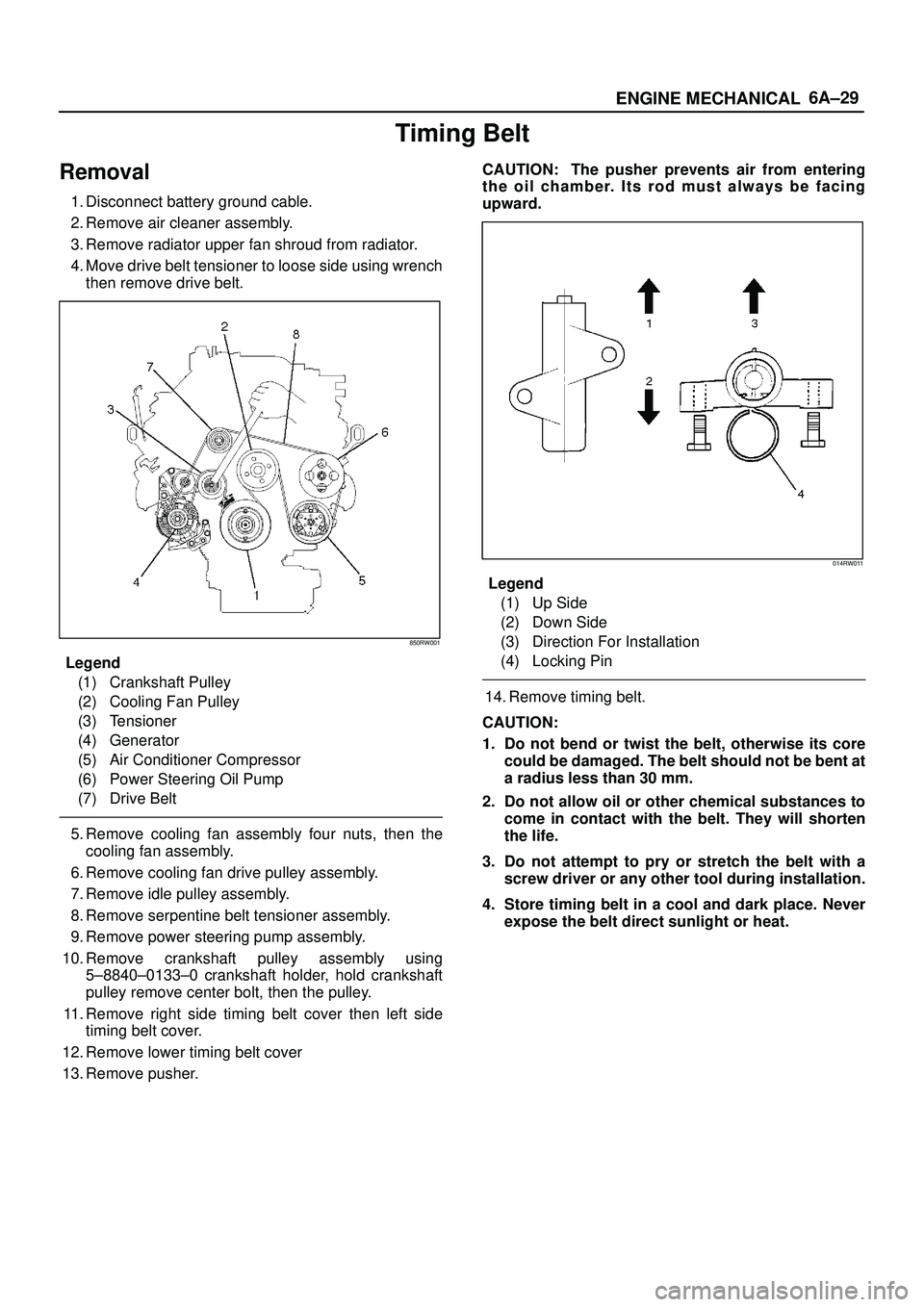

Timing Belt

Removal

1. Disconnect battery ground cable.

2. Remove air cleaner assembly.

3. Remove radiator upper fan shroud from radiator.

4. Move drive belt tensioner to loose side using wrench

then remove drive belt.

850RW001

Legend

(1) Crankshaft Pulley

(2) Cooling Fan Pulley

(3) Tensioner

(4) Generator

(5) Air Conditioner Compressor

(6) Power Steering Oil Pump

(7) Drive Belt

5. Remove cooling fan assembly four nuts, then the

cooling fan assembly.

6. Remove cooling fan drive pulley assembly.

7. Remove idle pulley assembly.

8. Remove serpentine belt tensioner assembly.

9. Remove power steering pump assembly.

10. Remove crankshaft pulley assembly using

5±8840±0133±0 crankshaft holder, hold crankshaft

pulley remove center bolt, then the pulley.

11. Remove right side timing belt cover then left side

timing belt cover.

12. Remove lower timing belt cover

13. Remove pusher.CAUTION: The pusher prevents air from entering

the oil chamber. Its rod must always be facing

upward.

014RW011

Legend

(1) Up Side

(2) Down Side

(3) Direction For Installation

(4) Locking Pin

14. Remove timing belt.

CAUTION:

1. Do not bend or twist the belt, otherwise its core

could be damaged. The belt should not be bent at

a radius less than 30 mm.

2. Do not allow oil or other chemical substances to

come in contact with the belt. They will shorten

the life.

3. Do not attempt to pry or stretch the belt with a

screw driver or any other tool during installation.

4. Store timing belt in a cool and dark place. Never

expose the belt direct sunlight or heat.