differential ISUZU TROOPER 1998 Service Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 1998, Model line: TROOPER, Model: ISUZU TROOPER 1998Pages: 3573, PDF Size: 60.36 MB

Page 7 of 3573

PAGE BACK PAGE NEXT

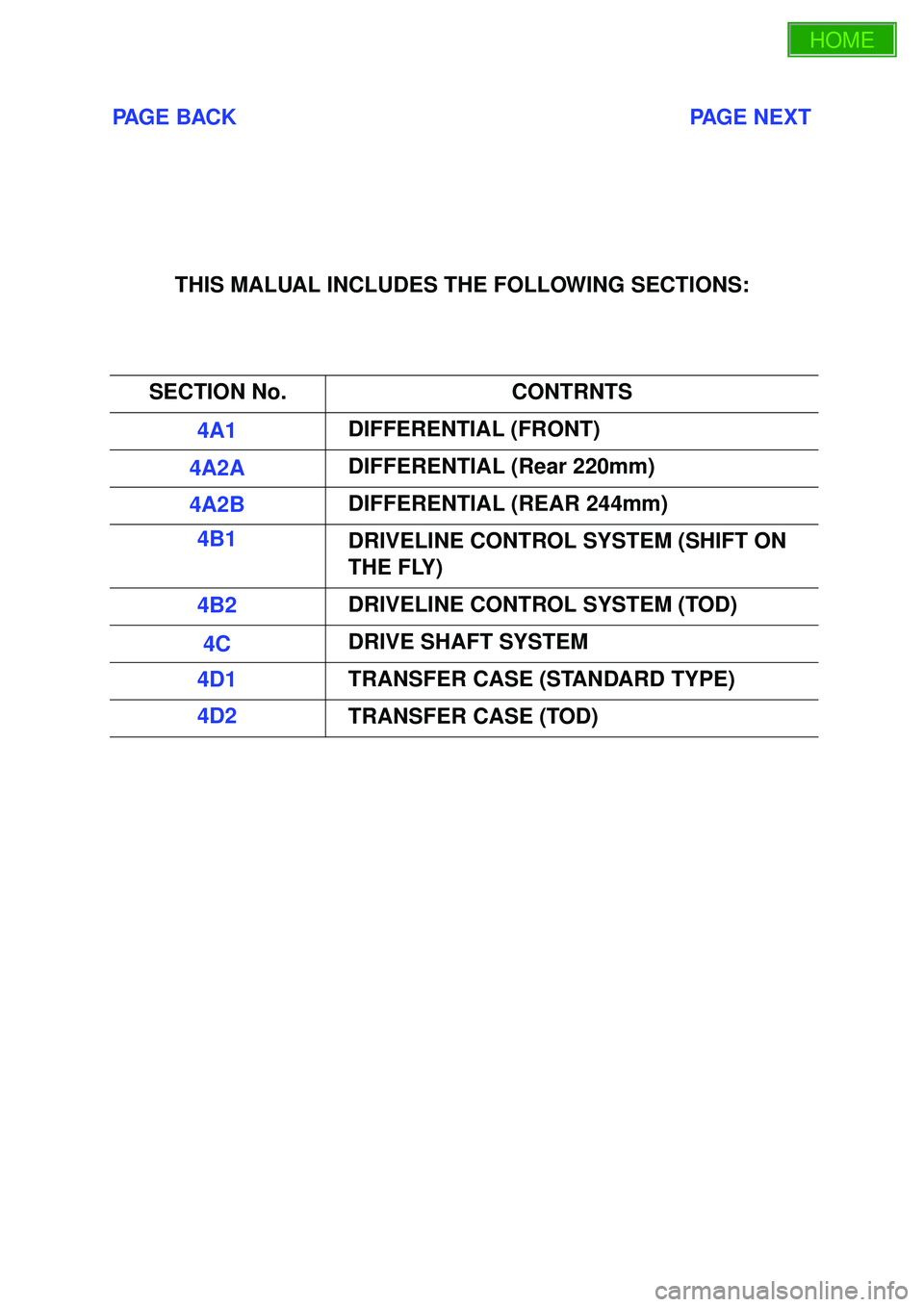

THIS MALUAL INCLUDES THE FOLLOWING SECTIONS:

SECTION No. CONTRNTS

4A1 DIFFERENTIAL (FRONT)

4A2A DIFFERENTIAL (Rear 220mm)

4A2B DIFFERENTIAL (REAR 244mm)

4B1 DRIVELINE CONTROL SYSTEM (SHIFT ON

THE FLY)

4B2 DRIVELINE CONTROL SYSTEM (TOD)

4C DRIVE SHAFT SYSTEM

4D1 TRANSFER CASE (STANDARD TYPE)

4D2 TRANSFER CASE (TOD)

Page 26 of 3573

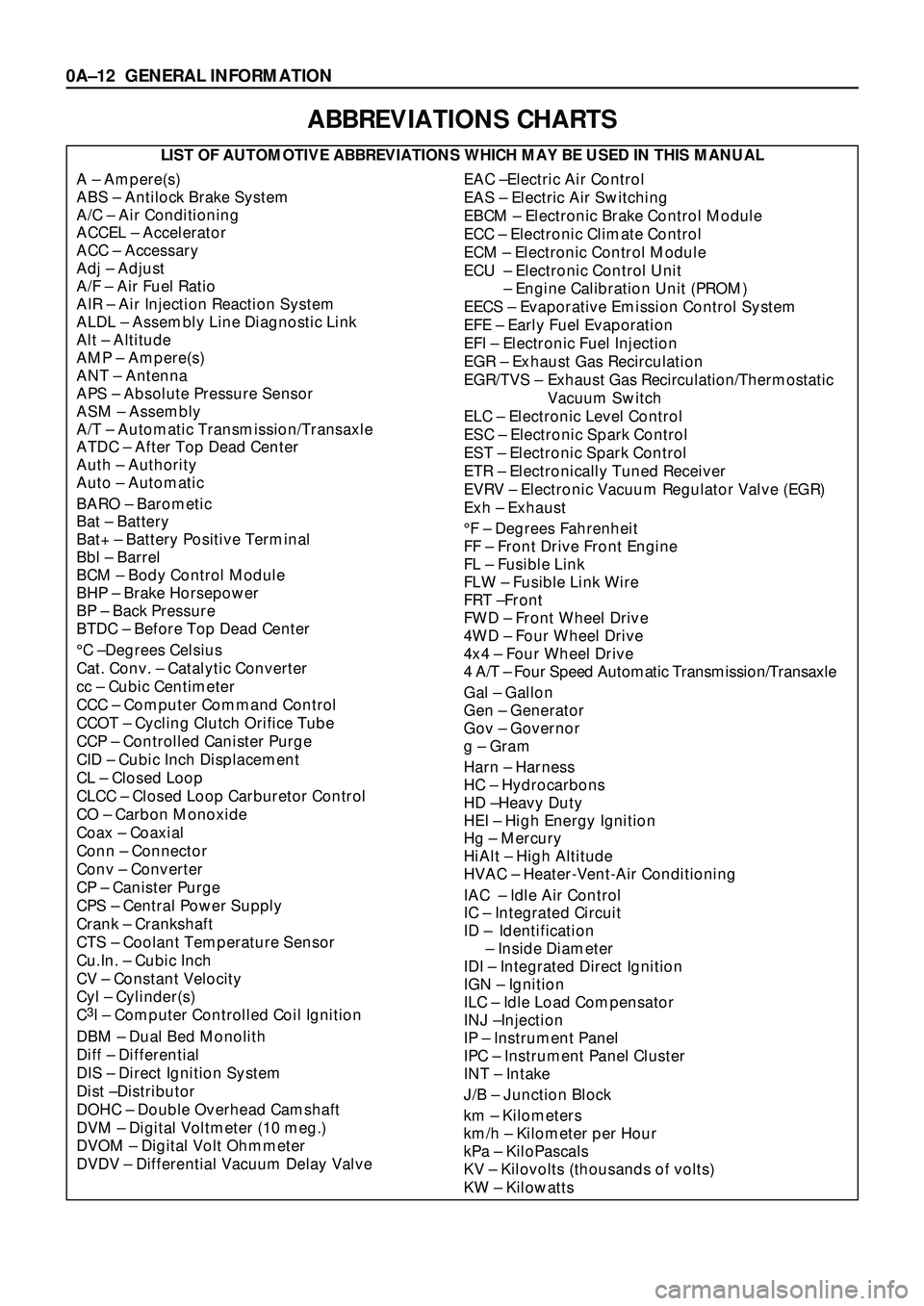

ABBREVIATIONS CHARTS

LIST OF AUTOMOTIVE ABBREVIATIONS WHICH MAY BE USED IN THIS MANUAL

A Ð Ampere(s)

ABS Ð Antilock Brake System

A/C Ð Air Conditioning

ACCEL Ð Accelerator

ACC Ð Accessary

Adj Ð Adjust

A/F Ð Air Fuel Ratio

AIR Ð Air Injection Reaction System

ALDL Ð Assembly Line Diagnostic Link

Alt Ð Altitude

AMP Ð Ampere(s)

ANT Ð Antenna

APS Ð Absolute Pressure Sensor

ASM Ð Assembly

A/T Ð Automatic Transmission/Transaxle

ATDC Ð After Top Dead Center

Auth Ð Authority

Auto Ð Automatic

BARO Ð Barometic

Bat Ð Battery

Bat+ Ð Battery Positive Terminal

Bbl Ð Barrel

BCM Ð Body Control Module

BHP Ð Brake Horsepower

BP Ð Back Pressure

BTDC Ð Before Top Dead Center

¡C ÐDegrees Celsius

Cat. Conv. Ð Catalytic Converter

cc Ð Cubic Centimeter

CCC Ð Computer Command Control

CCOT Ð Cycling Clutch Orifice Tube

CCP Ð Controlled Canister Purge

CID Ð Cubic Inch Displacement

CL Ð Closed Loop

CLCC Ð Closed Loop Carburetor Control

CO Ð Carbon Monoxide

Coax Ð Coaxial

Conn Ð Connector

Conv Ð Converter

CP Ð Canister Purge

CPS Ð Central Power Supply

Crank Ð Crankshaft

CTS Ð Coolant Temperature Sensor

Cu.In. Ð Cubic Inch

CV Ð Constant Velocity

Cyl Ð Cylinder(s)

C

3I Ð Computer Controlled Coil Ignition

DBM Ð Dual Bed Monolith

Diff Ð Differential

DIS Ð Direct Ignition System

Dist ÐDistributor

DOHC Ð Double Overhead Camshaft

DVM Ð Digital Voltmeter (10 meg.)

DVOM Ð Digital Volt Ohmmeter

DVDV Ð Differential Vacuum Delay Valve

EAC ÐElectric Air Control

EAS Ð Electric Air Switching

EBCM Ð Electronic Brake Control Module

ECC Ð Electronic Climate Control

ECM Ð Electronic Control Module

ECU Ð Electronic Control Unit

Ð Engine Calibration Unit (PROM)

EECS Ð Evaporative Emission Control System

EFE Ð Early Fuel Evaporation

EFI Ð Electronic Fuel Injection

EGR Ð Exhaust Gas Recirculation

EGR/TVS Ð Exhaust Gas Recirculation/Thermostatic

Vacuum Switch

ELC Ð Electronic Level Control

ESC Ð Electronic Spark Control

EST Ð Electronic Spark Control

ETR Ð Electronically Tuned Receiver

EVRV Ð Electronic Vacuum Regulator Valve (EGR)

Exh Ð Exhaust

¡F Ð Degrees Fahrenheit

FF Ð Front Drive Front Engine

FL Ð Fusible Link

FLW Ð Fusible Link Wire

FRT ÐFront

FWD Ð Front Wheel Drive

4WD Ð Four Wheel Drive

4x4 Ð Four Wheel Drive

4 A/T Ð Four Speed Automatic Transmission/Transaxle

Gal Ð Gallon

Gen Ð Generator

Gov Ð Governor

g Ð Gram

Harn Ð Harness

HC Ð Hydrocarbons

HD ÐHeavy Duty

HEI Ð High Energy Ignition

Hg Ð Mercury

HiAlt Ð High Altitude

HVAC Ð Heater-Vent-Air Conditioning

IAC Ð Idle Air Control

IC Ð Integrated Circuit

ID Ð Identification

Ð Inside Diameter

IDI Ð Integrated Direct Ignition

IGN Ð Ignition

ILC Ð Idle Load Compensator

INJ ÐInjection

IP Ð Instrument Panel

IPC Ð Instrument Panel Cluster

INT Ð Intake

J/B Ð Junction Block

km Ð Kilometers

km/h Ð Kilometer per Hour

kPa Ð KiloPascals

KV Ð Kilovolts (thousands of volts)

KW Ð Kilowatts

0AÐ12 GENERAL INFORMATION

Page 29 of 3573

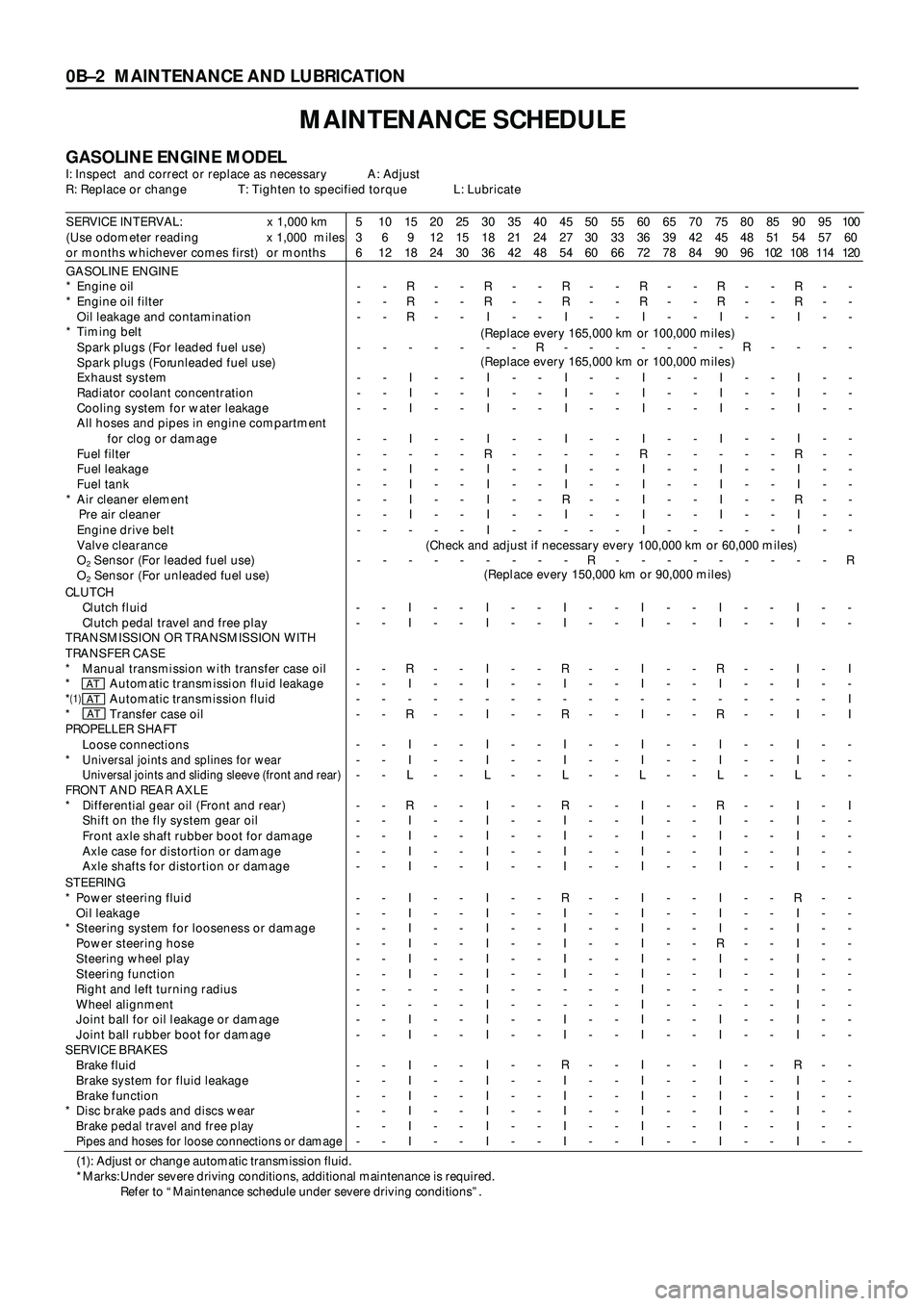

0BÐ2 MAINTENANCE AND LUBRICATION

MAINTENANCE SCHEDULE

GASOLINE ENGINE MODELI: Inspect and correct or replace as necessary A: Adjust

R: Replace or change T: Tighten to specified torque L: Lubricate

SERVICE INTERVAL: x 1,000 km

(Use odometer reading x 1,000 miles

or months whichever comes first) or months5

3

610

6

1215

9

1820

12

2425

15

3030

18

3635

21

4240

24

4845

27

5450

30

6055

33

6660

36

7265

39

7870

42

8475

45

9080

48

9685

51

10290

54

10895

57

114100

60

120

GASOLINE ENGINE

* Engine oil

* Engine oil filter

Oil leakage and contamination

* Timing belt

Spark plugs (For leaded fuel use)

Spark plugs (For unleaded fuel use)

Exhaust system

Radiator coolant concentration

Cooling system for water leakage

All hoses and pipes in engine compartment

for clog or damage

Fuel filter

Fuel leakage

Fuel tank

* Air cleaner element

Pre air cleaner

Engine drive belt

Valve clearance

O

2 Sensor (For leaded fuel use)

O

2 Sensor (For unleaded fuel use)-

-

-

-

-

-

-

-

-

-

-

-

-

-

--

-

-

-

-

-

-

-

-

-

-

-

-

-

-R

R

R

-

I

I

I

I

-

I

I

I

I

-

--

-

-

-

-

-

-

-

-

-

-

-

-

-

--

-

-

-

-

-

-

-

-

-

-

-

-

-

-R

R

I

-

I

I

I

I

R

I

I

I

I

I

--

-

-

-

-

-

-

-

-

-

-

-

-

-

--

-

-

R

-

-

-

-

-

-

-

-

-

-

-R

R

I

-

I

I

I

I

-

I

I

R

I

-

--

-

-

-

-

-

-

-

-

-

-

-

-

-

R-

-

-

-

-

-

-

-

-

-

-

-

-

-

-R

R

I

-

I

I

I

I

R

I

I

I

I

I

--

-

-

-

-

-

-

-

-

-

-

-

-

-

--

-

-

-

-

-

-

-

-

-

-

-

-

-

-R

R

I

-

I

I

I

I

-

I

I

I

I

-

--

-

-

R

-

-

-

-

-

-

-

-

-

-

--

-

-

-

-

-

-

-

-

-

-

-

-

-

-R

R

I

-

I

I

I

I

R

I

I

R

I

I

--

-

-

-

-

-

-

-

-

-

-

-

-

-

--

-

-

-

-

-

-

-

-

-

-

-

-

-

R

(Replace every 165,000 km or 100,000 miles)

(Replace every 165,000 km or 100,000 miles)

(Check and adjust if necessary every 100,000 km or 60,000 miles)

(Replace every 150,000 km or 90,000 miles)

CLUTCH

Clutch fluid

Clutch pedal travel and free play

TRANSMISSION OR TRANSMISSION WITH

TRANSFER CASE

* Manual transmission with transfer case oil

* Automatic transmission fluid leakage

*

(1)Automatic transmission fluid

* Transfer case oil

PROPELLER SHAFT

Loose connections

*

Universal joints and splines for wear

Universal joints and sliding sleeve (front and rear)

FRONT AND REAR AXLE

* Differential gear oil (Front and rear)

Shift on the fly system gear oil

Front axle shaft rubber boot for damage

Axle case for distortion or damage

Axle shafts for distortion or damage-

-

-

-

-

-

-

-

-

-

-

-

-

--

-

-

-

-

-

-

-

-

-

-

-

-

-I

I

R

I

-

R

I

I

L

R

I

I

I

I-

-

-

-

-

-

-

-

-

-

-

-

-

--

-

-

-

-

-

-

-

-

-

-

-

-

-I

I

I

I

-

I

I

I

L

I

I

I

I

I-

-

-

-

-

-

-

-

-

-

-

-

-

--

-

-

-

-

-

-

-

-

-

-

-

-

-I

I

R

I

-

R

I

I

L

R

I

I

I

I-

-

-

-

-

-

-

-

-

-

-

-

-

--

-

-

-

-

-

-

-

-

-

-

-

-

-I

I

I

I

-

I

I

I

L

I

I

I

I

I-

-

-

-

-

-

-

-

-

-

-

-

-

--

-

-

-

-

-

-

-

-

-

-

-

-

-I

I

R

I

-

R

I

I

L

R

I

I

I

I-

-

-

-

-

-

-

-

-

-

-

-

-

--

-

-

-

-

-

-

-

-

-

-

-

-

-I

I

I

I

-

I

I

I

L

I

I

I

I

I-

-

-

-

-

-

-

-

-

-

-

-

-

--

-

I

-

I

I

-

-

-

I

-

-

-

-

ATATAT

STEERING

* Power steering fluid

Oil leakage

* Steering system for looseness or damage

Power steering hose

Steering wheel play

Steering function

Right and left turning radius

Wheel alignment

Joint ball for oil leakage or damage

Joint ball rubber boot for damage

SERVICE BRAKES

Brake fluid

Brake system for fluid leakage

Brake function

* Disc brake pads and discs wear

Brake pedal travel and free play

Pipes and hoses for loose connections or damage

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

--

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-I

I

I

I

I

I

-

-

I

I

I

I

I

I

I

I-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

--

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

--

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-R

I

I

I

I

I

-

-

I

I

R

I

I

I

I

I-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

--

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

--

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-I

I

I

R

I

I

-

-

I

I

I

I

I

I

I

I-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

--

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-R

I

I

I

I

I

I

I

I

I

R

I

I

I

I

I-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

--

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

(1): Adjust or change automatic transmission fluid.

*Marks: Under severe driving conditions, additional maintenance is required.

Refer to “Maintenance schedule under severe driving conditions”.

Page 31 of 3573

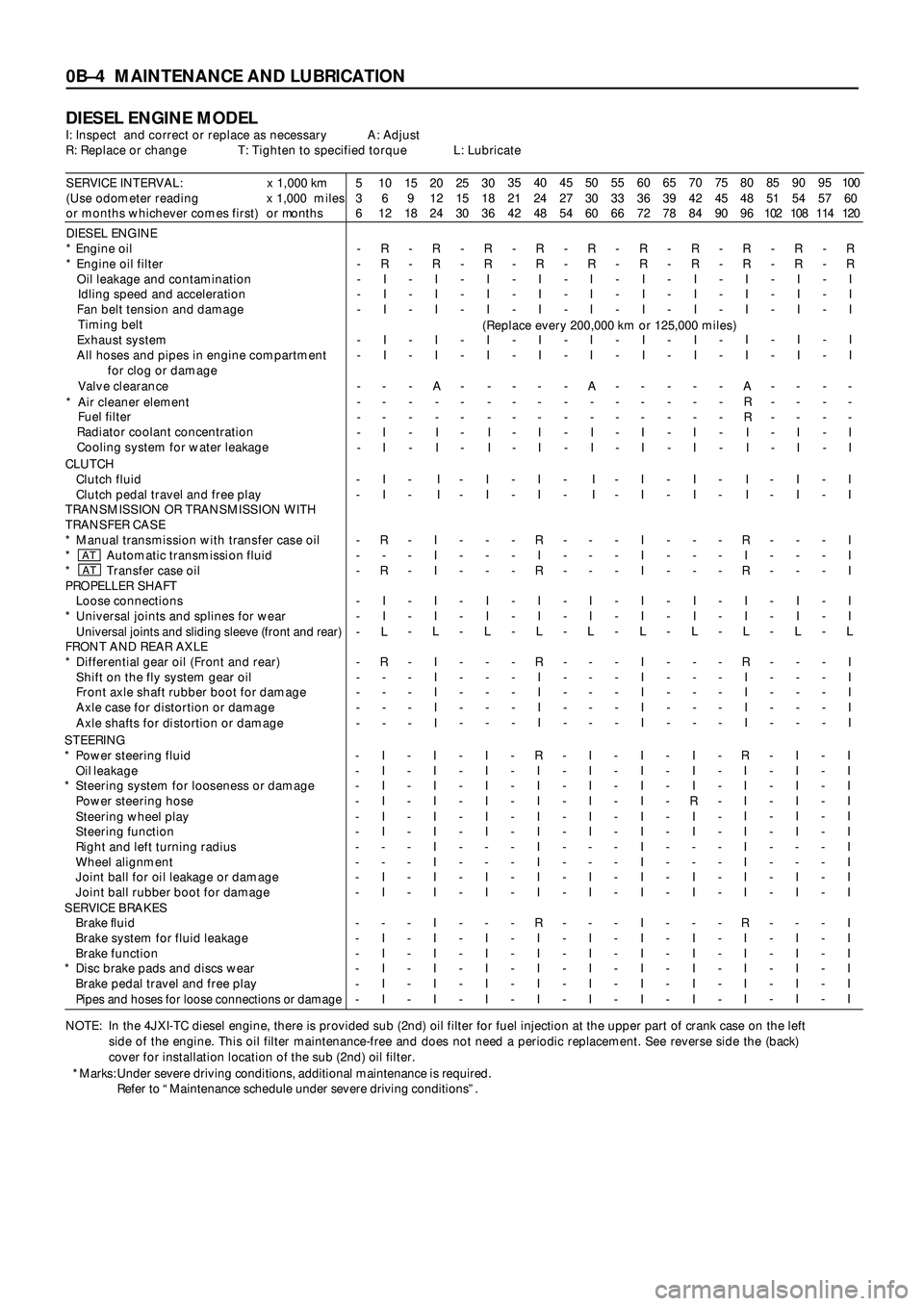

0BÐ4 MAINTENANCE AND LUBRICATION

DIESEL ENGINE MODELI: Inspect and correct or replace as necessary A: Adjust

R: Replace or change T: Tighten to specified torque L: Lubricate

SERVICE INTERVAL: x 1,000 km

(Use odometer reading x 1,000 miles

or months whichever comes first) or months5

3

610

6

1215

9

1820

12

2425

15

3030

18

3635

21

4240

24

4845

27

5450

30

6055

33

6660

36

7265

39

7870

42

8475

45

9080

48

9685

51

10290

54

10895

57

114100

60

120

DIESEL ENGINE

* Engine oil

* Engine oil filter

Oil leakage and contamination

Idling speed and acceleration

Fan belt tension and damage

Timing belt

Exhaust system

All hoses and pipes in engine compartment

for clog or damage

Valve clearance

* Air cleaner element

Fuel filter

Radiator coolant concentration

Cooling system for water leakage-

-

-

-

-

-

-

-

-

-

-

-R

R

I

I

I

I

I

-

-

-

I

I-

-

-

-

-

-

-

-

-

-

-

-R

R

I

I

I

I

I

A

-

-

I

I-

-

-

-

-

-

-

-

-

-

-

-R

R

I

I

I

I

I

-

-

-

I

I-

-

-

-

-

-

-

-

-

-

-

-R

R

I

I

I

I

I

-

-

-

I

I-

-

-

-

-

-

-

-

-

-

-

-R

R

I

I

I

I

I

A

-

-

I

I-

-

-

-

-

-

-

-

-

-

-

-R

R

I

I

I

I

I

-

-

-

I

I-

-

-

-

-

-

-

-

-

-

-

-R

R

I

I

I

I

I

-

-

-

I

I-

-

-

-

-

-

-

-

-

-

-

-R

R

I

I

I

I

I

A

R

R

I

I-

-

-

-

-

-

-

-

-

-

-

-R

R

I

I

I

I

I

-

-

-

I

I-

-

-

-

-

-

-

-

-

-

-

-R

R

I

I

I

I

I

-

-

-

I

I

NOTE: In the 4JXI-TC diesel engine, there is provided sub (2nd) oil filter for fuel injection at the upper part of crank case on the left

side of the engine. This oil filter maintenance-free and does not need a periodic replacement. See reverse side the (back)

cover for installation location of the sub (2nd) oil filter.(Replace every 200,000 km or 125,000 miles)

*Marks: Under severe driving conditions, additional maintenance is required.

Refer to “Maintenance schedule under severe driving conditions”. CLUTCH

Clutch fluid

Clutch pedal travel and free play

TRANSMISSION OR TRANSMISSION WITH

TRANSFER CASE

* Manual transmission with transfer case oil

* Automatic transmission fluid

* Transfer case oil

PROPELLER SHAFT

Loose connections

* Universal joints and splines for wear

Universal joints and sliding sleeve (front and rear)FRONT AND REAR AXLE

* Differential gear oil (Front and rear)

Shift on the fly system gear oil

Front axle shaft rubber boot for damage

Axle case for distortion or damage

Axle shafts for distortion or damage-

-

-

-

-

-

-

-

-

-

-

-

-I

I

R

-

R

I

I

L

R

-

-

-

--

-

-

-

-

-

-

-

-

-

-

-

-I

I

I

I

I

I

I

L

I

I

I

I

I-

-

-

-

-

-

-

-

-

-

-

-

-I

I

-

-

-

I

I

L

-

-

-

-

--

-

-

-

-

-

-

-

-

-

-

-

-I

I

R

I

R

I

I

L

R

I

I

I

I-

-

-

-

-

-

-

-

-

-

-

-

-I

I

-

-

-

I

I

L

-

-

-

-

--

-

-

-

-

-

-

-

-

-

-

-

-I

I

I

I

I

I

I

L

I

I

I

I

I-

-

-

-

-

-

-

-

-

-

-

-

-I

I

-

-

-

I

I

L

-

-

-

-

--

-

-

-

-

-

-

-

-

-

-

-

-I

I

R

I

R

I

I

L

R

I

I

I

I-

-

-

-

-

-

-

-

-

-

-

-

-I

I

-

-

-

I

I

L

-

-

-

-

--

-

-

-

-

-

-

-

-

-

-

-

-I

I

I

I

I

I

I

L

I

I

I

I

I

ATAT

STEERING

* Power steering fluid

Oil leakage

* Steering system for looseness or damage

Power steering hose

Steering wheel play

Steering function

Right and left turning radius

Wheel alignment

Joint ball for oil leakage or damage

Joint ball rubber boot for damage

SERVICE BRAKES

Brake fluid

Brake system for fluid leakage

Brake function

* Disc brake pads and discs wear

Brake pedal travel and free play

Pipes and hoses for loose connections or damage

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-I

I

I

I

I

I

-

-

I

I

-

I

I

I

I

I-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-I

I

I

I

I

I

-

-

I

I

-

I

I

I

I

I-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-R

I

I

I

I

I

I

I

I

I

R

I

I

I

I

I-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-I

I

I

I

I

I

-

-

I

I

-

I

I

I

I

I-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-I

I

I

R

I

I

-

-

I

I

-

I

I

I

I

I-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-R

I

I

I

I

I

I

I

I

I

R

I

I

I

I

I-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-I

I

I

I

I

I

-

-

I

I

-

I

I

I

I

I-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

Page 33 of 3573

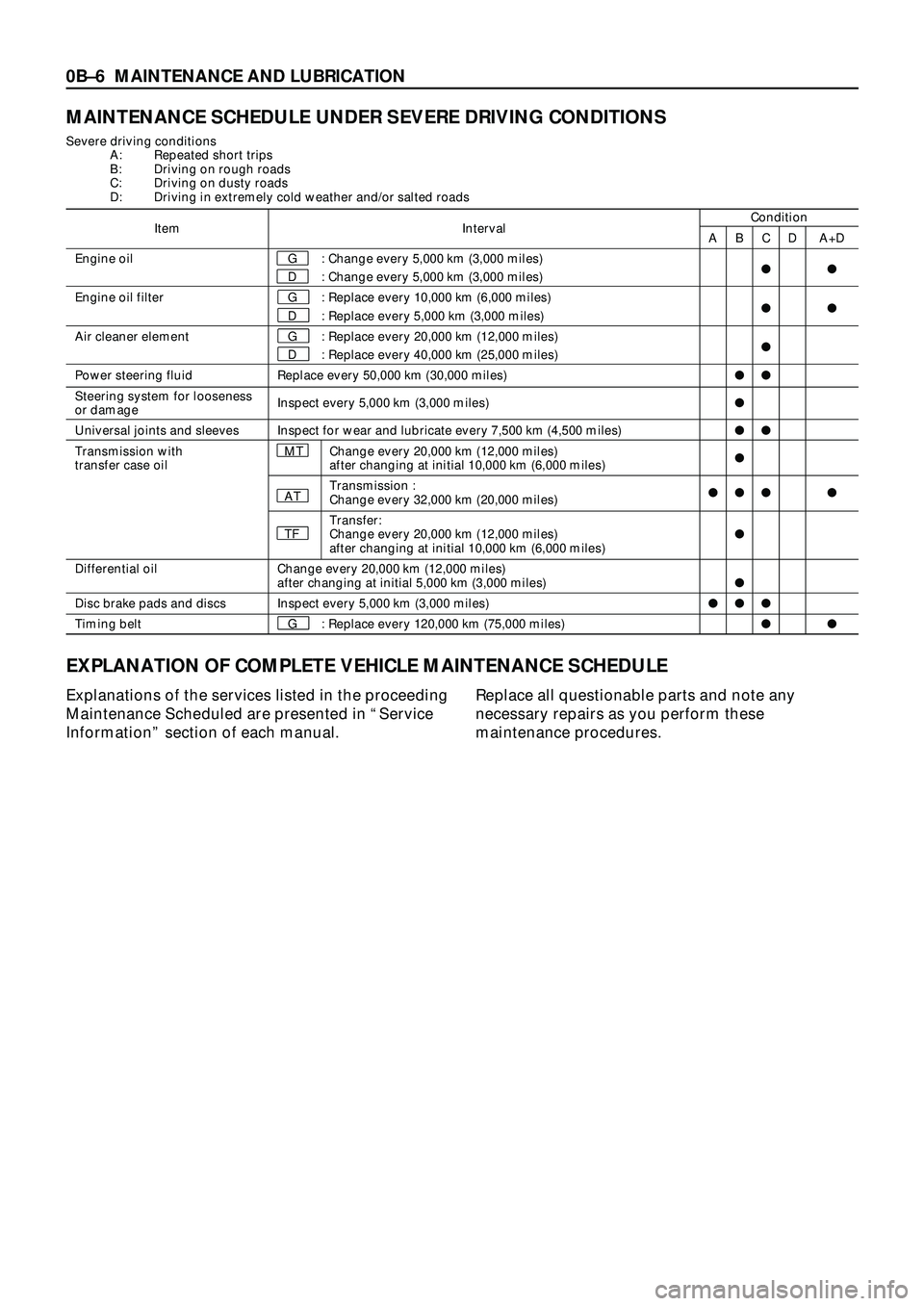

0BÐ6 MAINTENANCE AND LUBRICATION

Item IntervalCondition

ABCD A+D

Engine oil G : Change every 5,000 km (3,000 miles)

D : Change every 5,000 km (3,000 miles) ll

Engine oil filter G : Replace every 10,000 km (6,000 miles)

D : Replace every 5,000 km (3,000 miles) ll

Air cleaner element G : Replace every 20,000 km (12,000 miles)

D : Replace every 40,000 km (25,000 miles)l

Power steering fluid Replace every 50,000 km (30,000 miles)ll

Steering system for looseness

or damage Inspect every 5,000 km (3,000 miles)l

Universal joints and sleeves Inspect for wear and lubricate every 7,500 km (4,500 miles)ll

Transmission with MT Change every 20,000 km (12,000 miles)

transfer case oil after changing at initial 10,000 km (6,000 miles)l

Transmission :

AT

Change every 32,000 km (20,000 miles) lll l

Transfer:

TF Change every 20,000 km (12,000 miles)

after changing at initial 10,000 km (6,000 miles)l

Differential oil Change every 20,000 km (12,000 miles)

after changing at initial 5,000 km (3,000 miles) l

Disc brake pads and discs Inspect every 5,000 km (3,000 miles)lll

Timing belt G : Replace every 120,000 km (75,000 miles)ll

EXPLANATION OF COMPLETE VEHICLE MAINTENANCE SCHEDULE

Explanations of the services listed in the proceeding

Maintenance Scheduled are presented in ÒService

InformationÓ section of each manual.Replace all questionable parts and note any

necessary repairs as you perform these

maintenance procedures.

MAINTENANCE SCHEDULE UNDER SEVERE DRIVING CONDITIONS

Severe driving conditions

A: Repeated short trips

B: Driving on rough roads

C: Driving on dusty roads

D: Driving in extremely cold weather and/or salted roads

Page 34 of 3573

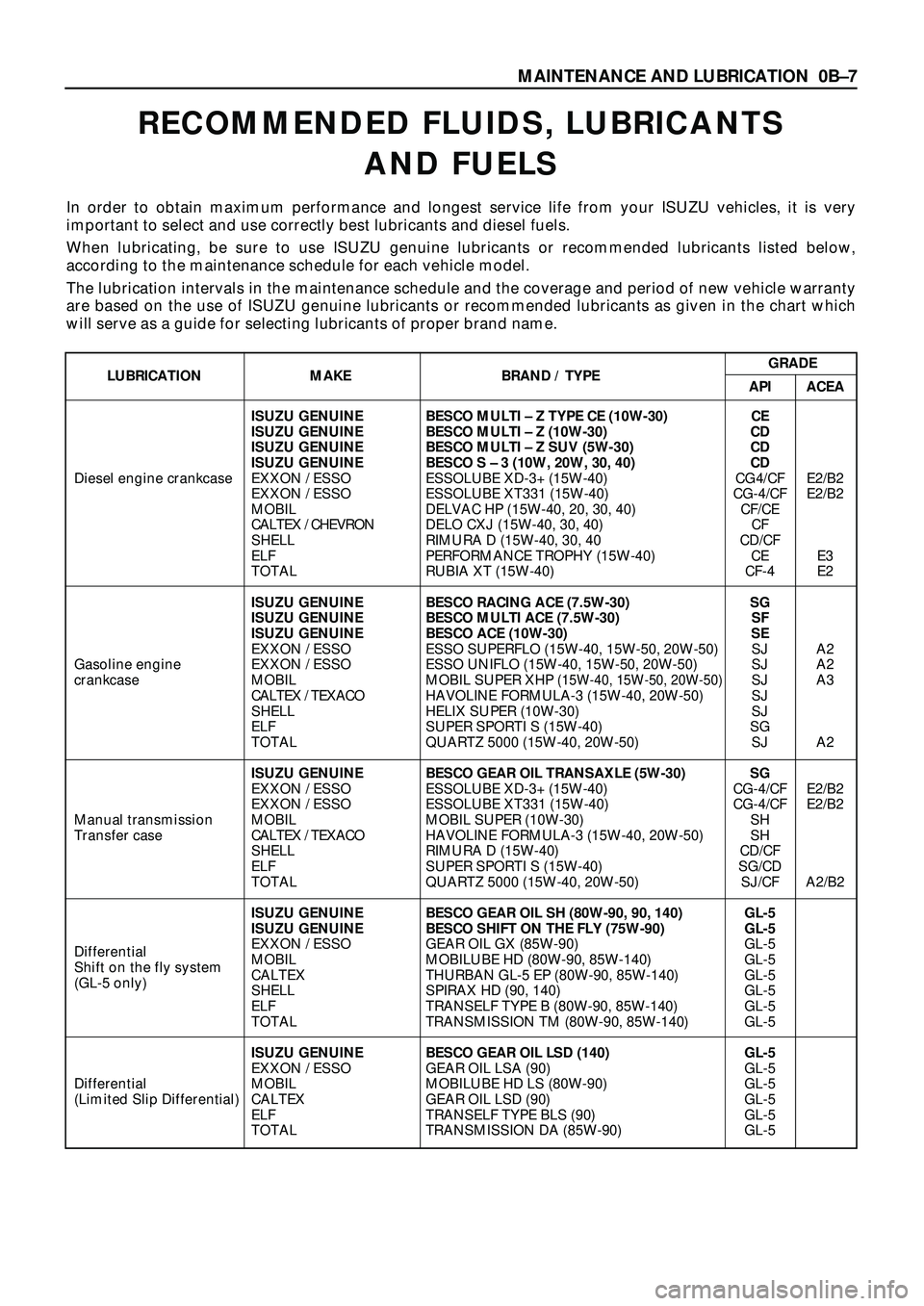

MAINTENANCE AND LUBRICATION 0BÐ7

RECOMMENDED FLUIDS, LUBRICANTS

AND FUELS

In order to obtain maximum performance and longest service life from your ISUZU vehicles, it is very

important to select and use correctly best lubricants and diesel fuels.

When lubricating, be sure to use ISUZU genuine lubricants or recommended lubricants listed below,

according to the maintenance schedule for each vehicle model.

The lubrication intervals in the maintenance schedule and the coverage and period of new vehicle warranty

are based on the use of ISUZU genuine lubricants or recommended lubricants as given in the chart which

will serve as a guide for selecting lubricants of proper brand name.

LUBRICATION MAKE BRAND / TYPEGRADE

API ACEA

ISUZU GENUINE BESCO MULTI Ð Z TYPE CE (10W-30) CE

ISUZU GENUINE BESCO MULTI Ð Z (10W-30) CD

ISUZU GENUINE BESCO MULTI Ð Z SUV (5W-30) CD

ISUZU GENUINE BESCO S Ð 3 (10W, 20W, 30, 40) CD

Diesel engine crankcase EXXON / ESSO ESSOLUBE XD-3+ (15W-40) CG4/CF E2/B2

EXXON / ESSO ESSOLUBE XT331 (15W-40) CG-4/CF E2/B2

MOBIL DELVAC HP (15W-40, 20, 30, 40) CF/CE

CALTEX / CHEVRONDELO CXJ (15W-40, 30, 40) CF

SHELL RIMURA D (15W-40, 30, 40 CD/CF

ELF PERFORMANCE TROPHY (15W-40) CE E3

TOTAL RUBIA XT (15W-40) CF-4 E2

ISUZU GENUINE BESCO RACING ACE (7.5W-30) SG

ISUZU GENUINE BESCO MULTI ACE (7.5W-30) SF

ISUZU GENUINE BESCO ACE (10W-30) SE

EXXON / ESSO ESSO SUPERFLO (15W-40, 15W-50, 20W-50) SJ A2

Gasoline engine EXXON / ESSO ESSO UNIFLO (15W-40, 15W-50, 20W-50) SJ A2

crankcase MOBIL MOBIL SUPER XHP

(15W-40, 15W-50, 20W-50)SJ A3

CALTEX / TEXACOHAVOLINE FORMULA-3 (15W-40, 20W-50) SJ

SHELL HELIX SUPER (10W-30) SJ

ELF SUPER SPORTI S (15W-40) SG

TOTAL QUARTZ 5000 (15W-40, 20W-50) SJ A2

ISUZU GENUINE BESCO GEAR OIL TRANSAXLE (5W-30) SG

EXXON / ESSO ESSOLUBE XD-3+ (15W-40) CG-4/CF E2/B2

EXXON / ESSO ESSOLUBE XT331 (15W-40) CG-4/CF E2/B2

Manual transmission MOBIL MOBIL SUPER (10W-30) SH

Transfer caseCALTEX / TEXACOHAVOLINE FORMULA-3 (15W-40, 20W-50) SH

SHELL RIMURA D (15W-40) CD/CF

ELF SUPER SPORTI S (15W-40) SG/CD

TOTAL QUARTZ 5000 (15W-40, 20W-50) SJ/CF A2/B2

ISUZU GENUINE BESCO GEAR OIL SH (80W-90, 90, 140) GL-5

ISUZU GENUINE BESCO SHIFT ON THE FLY (75W-90) GL-5

DifferentialEXXON / ESSO GEAR OIL GX (85W-90) GL-5

Shift on the fly systemMOBIL MOBILUBE HD (80W-90, 85W-140) GL-5

(GL-5 only)CALTEX THURBAN GL-5 EP (80W-90, 85W-140) GL-5

SHELL SPIRAX HD (90, 140) GL-5

ELF TRANSELF TYPE B (80W-90, 85W-140) GL-5

TOTAL TRANSMISSION TM (80W-90, 85W-140) GL-5

ISUZU GENUINE BESCO GEAR OIL LSD (140) GL-5

EXXON / ESSO GEAR OIL LSA (90) GL-5

Differential MOBIL MOBILUBE HD LS (80W-90) GL-5

(Limited Slip Differential) CALTEX GEAR OIL LSD (90) GL-5

ELF TRANSELF TYPE BLS (90) GL-5

TOTAL TRANSMISSION DA (85W-90) GL-5

Page 85 of 3573

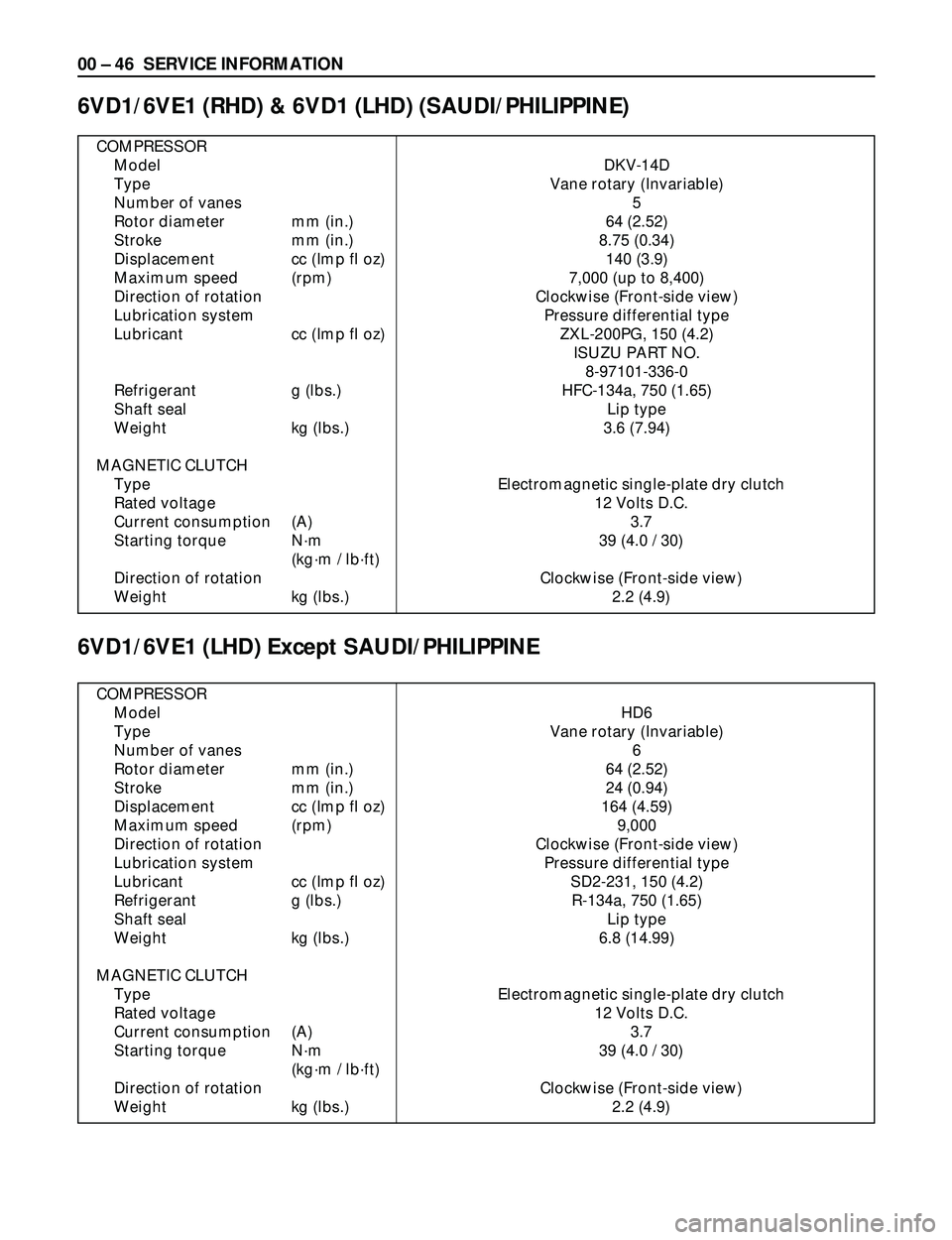

00 Ð 46 SERVICE INFORMATION

COMPRESSOR

Model DKV-14D

Type Vane rotary (Invariable)

Number of vanes 5

Rotor diameter mm (in.) 64 (2.52)

Stroke mm (in.) 8.75 (0.34)

Displacement cc (Imp fl oz) 140 (3.9)

Maximum speed (rpm) 7,000 (up to 8,400)

Direction of rotation Clockwise (Front-side view)

Lubrication system Pressure differential type

Lubricant cc (Imp fl oz) ZXL-200PG, 150 (4.2)

ISUZU PART NO.

8-97101-336-0

Refrigerant g (lbs.) HFC-134a, 750 (1.65)

Shaft seal Lip type

Weight kg (lbs.) 3.6 (7.94)

MAGNETIC CLUTCH

Type Electromagnetic single-plate dry clutch

Rated voltage 12 Volts D.C.

Current consumption (A) 3.7

Starting torque Nám 39 (4.0 / 30)

(kgám / lbáft)

Direction of rotation Clockwise (Front-side view)

Weight kg (lbs.) 2.2 (4.9)

6VD1/6VE1 (RHD) & 6VD1 (LHD) (SAUDI/PHILIPPINE)

6VD1/6VE1 (LHD) Except SAUDI/PHILIPPINE

COMPRESSOR

Model HD6

Type Vane rotary (Invariable)

Number of vanes 6

Rotor diameter mm (in.) 64 (2.52)

Stroke mm (in.) 24 (0.94)

Displacement cc (Imp fl oz) 164 (4.59)

Maximum speed (rpm) 9,000

Direction of rotation Clockwise (Front-side view)

Lubrication system Pressure differential type

Lubricant cc (Imp fl oz) SD2-231, 150 (4.2)

Refrigerant g (lbs.) R-134a, 750 (1.65)

Shaft seal Lip type

Weight kg (lbs.) 6.8 (14.99)

MAGNETIC CLUTCH

Type Electromagnetic single-plate dry clutch

Rated voltage 12 Volts D.C.

Current consumption (A) 3.7

Starting torque Nám 39 (4.0 / 30)

(kgám / lbáft)

Direction of rotation Clockwise (Front-side view)

Weight kg (lbs.) 2.2 (4.9)

Page 86 of 3573

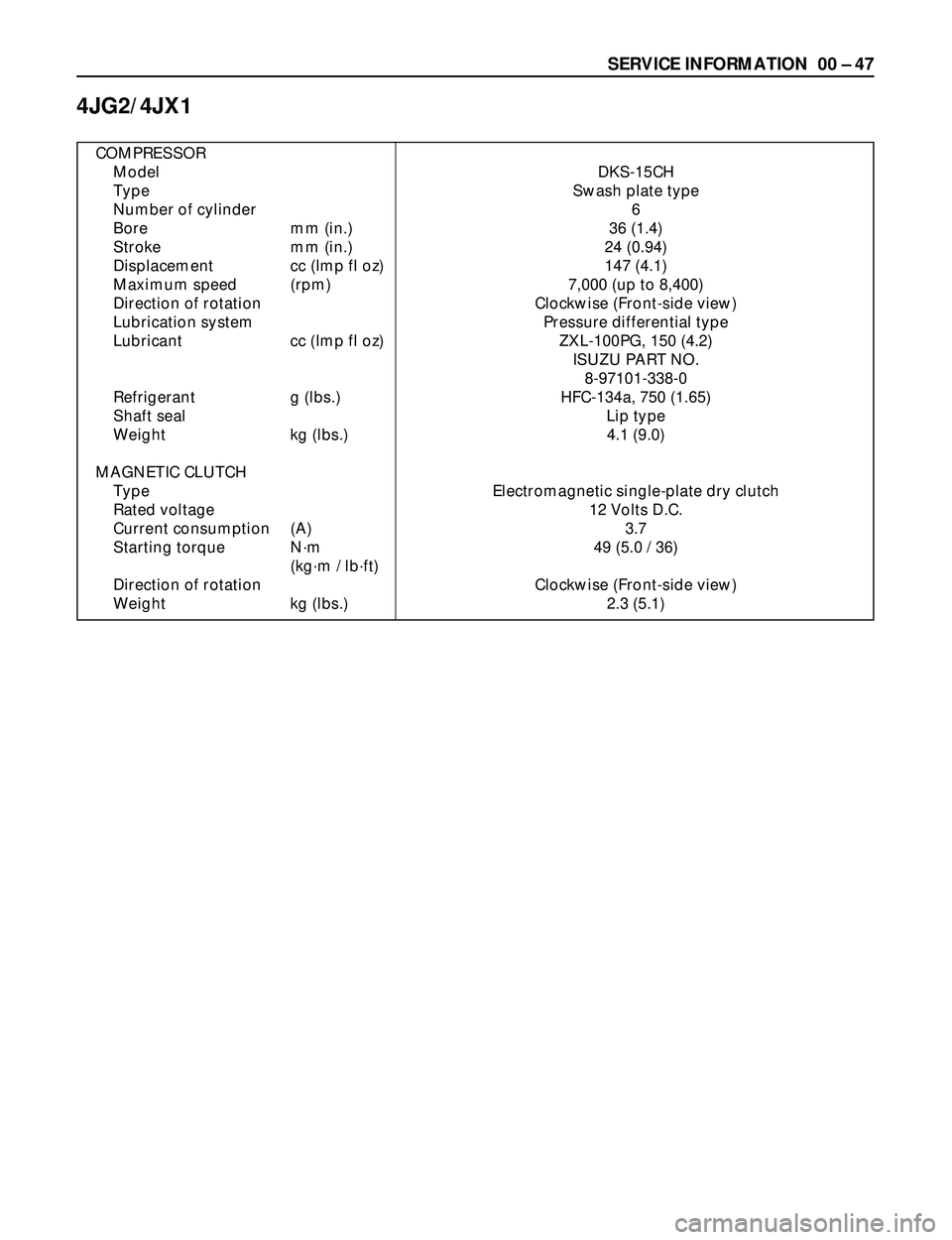

SERVICE INFORMATION 00 Ð 47

4JG2/4JX1

COMPRESSOR

Model DKS-15CH

Type Swash plate type

Number of cylinder 6

Bore mm (in.) 36 (1.4)

Stroke mm (in.) 24 (0.94)

Displacement cc (Imp fl oz) 147 (4.1)

Maximum speed (rpm) 7,000 (up to 8,400)

Direction of rotation Clockwise (Front-side view)

Lubrication system Pressure differential type

Lubricant cc (Imp fl oz) ZXL-100PG, 150 (4.2)

ISUZU PART NO.

8-97101-338-0

Refrigerant g (lbs.) HFC-134a, 750 (1.65)

Shaft seal Lip type

Weight kg (lbs.) 4.1 (9.0)

MAGNETIC CLUTCH

Type Electromagnetic single-plate dry clutch

Rated voltage 12 Volts D.C.

Current consumption (A) 3.7

Starting torque Nám 49 (5.0 / 36)

(kgám / lbáft)

Direction of rotation Clockwise (Front-side view)

Weight kg (lbs.) 2.3 (5.1)

Page 131 of 3573

AIR CONDITIONING 1B Ð 5

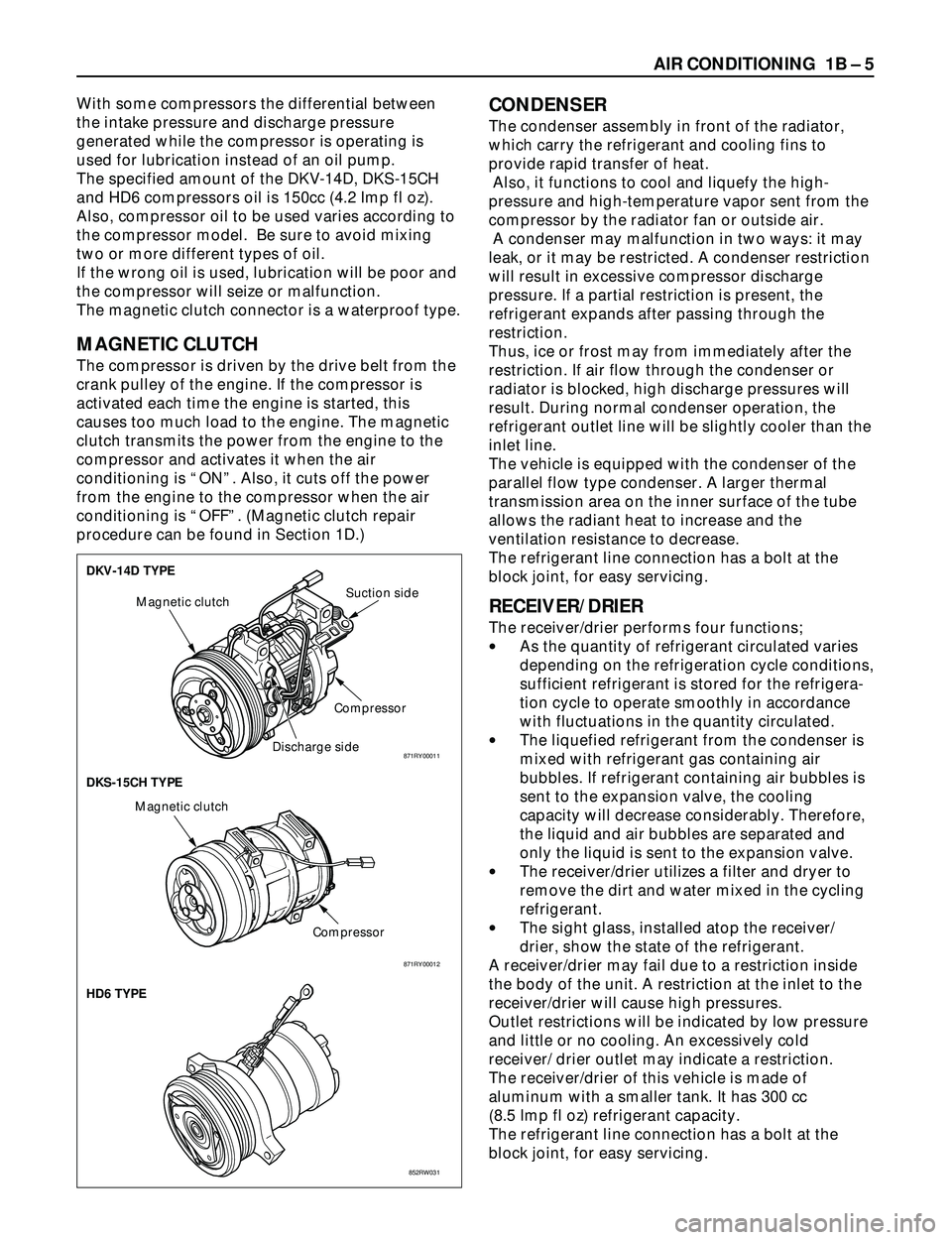

With some compressors the differential between

the intake pressure and discharge pressure

generated while the compressor is operating is

used for lubrication instead of an oil pump.

The specified amount of the DKV-14D, DKS-15CH

and HD6 compressors oil is 150cc (4.2 Imp fl oz).

Also, compressor oil to be used varies according to

the compressor model. Be sure to avoid mixing

two or more different types of oil.

If the wrong oil is used, lubrication will be poor and

the compressor will seize or malfunction.

The magnetic clutch connector is a waterproof type.

MAGNETIC CLUTCH

The compressor is driven by the drive belt from the

crank pulley of the engine. If the compressor is

activated each time the engine is started, this

causes too much load to the engine. The magnetic

clutch transmits the power from the engine to the

compressor and activates it when the air

conditioning is ÒONÓ. Also, it cuts off the power

from the engine to the compressor when the air

conditioning is ÒOFFÓ. (Magnetic clutch repair

procedure can be found in Section 1D.)

CONDENSER

The condenser assembly in front of the radiator,

which carry the refrigerant and cooling fins to

provide rapid transfer of heat.

Also, it functions to cool and liquefy the high-

pressure and high-temperature vapor sent from the

compressor by the radiator fan or outside air.

A condenser may malfunction in two ways: it may

leak, or it may be restricted. A condenser restriction

will result in excessive compressor discharge

pressure. If a partial restriction is present, the

refrigerant expands after passing through the

restriction.

Thus, ice or frost may from immediately after the

restriction. If air flow through the condenser or

radiator is blocked, high discharge pressures will

result. During normal condenser operation, the

refrigerant outlet line will be slightly cooler than the

inlet line.

The vehicle is equipped with the condenser of the

parallel flow type condenser. A larger thermal

transmission area on the inner surface of the tube

allows the radiant heat to increase and the

ventilation resistance to decrease.

The refrigerant line connection has a bolt at the

block joint, for easy servicing.

RECEIVER/DRIER

The receiver/drier performs four functions;

·As the quantity of refrigerant circulated varies

depending on the refrigeration cycle conditions,

sufficient refrigerant is stored for the refrigera-

tion cycle to operate smoothly in accordance

with fluctuations in the quantity circulated.

·The liquefied refrigerant from the condenser is

mixed with refrigerant gas containing air

bubbles. If refrigerant containing air bubbles is

sent to the expansion valve, the cooling

capacity will decrease considerably. Therefore,

the liquid and air bubbles are separated and

only the liquid is sent to the expansion valve.

·The receiver/drier utilizes a filter and dryer to

remove the dirt and water mixed in the cycling

refrigerant.

·The sight glass, installed atop the receiver/

drier, show the state of the refrigerant.

A receiver/drier may fail due to a restriction inside

the body of the unit. A restriction at the inlet to the

receiver/drier will cause high pressures.

Outlet restrictions will be indicated by low pressure

and little or no cooling. An excessively cold

receiver/ drier outlet may indicate a restriction.

The receiver/drier of this vehicle is made of

aluminum with a smaller tank. It has 300 cc

(8.5 Imp fl oz) refrigerant capacity.

The refrigerant line connection has a bolt at the

block joint, for easy servicing.

DKV-14D TYPE

DKS-15CH TYPE

HD6 TYPE

Magnetic clutch

CompressorSuction side

Discharge side

Compressor Magnetic clutch

852RW031 871RY00012

871RY00011

Page 259 of 3573

COMPRESSOR OVERHAUL 1D Ð 3

solvent, and dried with dry air. Use only lint free

cloths to wipe parts.

The operations described below are based on

bench overhaul with compressor removed from the

car, except as noted. They have been prepared in

order of accessibility of the components. When the

compressor is removed from the car for servicing,

the oil remaining in the compressor should be

discarded and new refrigerant oil added to the

compressor.

Magnetic clutch assembly repair procedures require

that the system be discharged of refrigerant. (Refer

to Section 1B for ÒREFRIGERANT RECOVERYÓ.)

Compressor malfunction will appear in one of four

ways: noise, seizure, leakage or low discharge

pressure. Resonant compressor noises are not

cause for alarm; however, irregular noise or rattles

may indicate broken parts or excessive clearances

due to wear. To check seizure, de-energize the

magnetic clutch and check to see if the drive plate

can be rotated. If rotation is impossible, the

compressor is seized. Low discharge pressure may

be due to a faulty internal seal of the compressor,

or a restriction in the compressor. Low discharge

pressure may also be due to an insufficient

refrigerant charge or a restriction elsewhere in the

system. These possibilities should be checked prior

to servicing the compressor. If the compressor is

inoperative, but is not seized, check to see if current

is being supplied to the magnetic clutch coil

terminals.

The compressor has vanes built into a rotor which

is mounted on a shaft.

When the shaft rotates, the vanes built into the

cylinder block assembly are opened by centrifugal

force.

This changes the volume of the space formed by

the rotor and cylinder, resulting in the intake and

compression of the refrigerant gas. The discharge

valve and the valve stopper, which protects the

discharge valve, are built into the cylinder block

assembly. There is no suction valve but a shaft seal

is installed between the shaft and head; a trigger

valve, which applies back pressure to the vanes, is

installed in the cylinder block and a refrigerant gas

temperature sensor is installed in the front head.

The specified quantity of compressor oil is

contained in the compressor to lubricate the various

parts using the refrigerant gas discharge pressure.

6VD1 engine is equipped with an invariable

capacity five-vane rotary compressor (DKV-14D

Type).

The compressor sucks and compresses refrigerant

by the rotation of the vane installed to the shaft,

and always discharges a fixed amount of refrigerant

independent of the load of refrigerant.The thermo sensor is installed to the front head of

the compressor to protect it by stopping its

operation when the refrigerant gas is insufficient or

when the temperature get abnormally high.

·OFF ..... 160 ±5¡C (320.0 ±9.0¡F)

·ON ..... 135 ±5¡C (275.0 ±9.0¡F)

4JG2 Engine are provided with a swash plate type

compressor (DKS-15CH Type)

Swash plate compressors have a swash (slanted)

plate mounted on the shaft. When the shaft turns,

the rotation of the swash plate is converted to

reciprocating piston motion which sucks in and

compresses the refrigerant gas.

Shaft seal (Lip type) is installed between the valve

plate and shaft & cylinder head to prevent

refrigerant gas leaks. A specified amount of

compressor oil is contained in the oil pan.

This oil is supplied to the cylinders, bearings, etc.,

by an oil pump which is connected to the swash

plate shaft.

With some compressors the differential between

the intake pressure and discharge pressure

generated while the compressor is operating is

used for lubrication instead of an oil pump.

Three pistons are arranged at 120g intervals around

the center of the swash plate shaft. These pistons

are connected to the ends of the swash plate

through shoe disks and balls.

The rotation of the swash plate causes

reciprocating movement of the piston inside the

cylinders, with each piston operating as two

cylinders. Because of that, the compressor operates

as though it has 6 cylinders.

The specified amount of the compressors oil is

150cc (4.2 Imp fl oz).

Also, compressor oil to be used varies according to

the compressor model. Be sure to avoid mixing two

or more different types of oil.

If the wrong oil is used, lubrication will be poor and

the compressor will seize or malfunction.