light ISUZU TROOPER 1998 Service Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 1998, Model line: TROOPER, Model: ISUZU TROOPER 1998Pages: 3573, PDF Size: 60.36 MB

Page 12 of 3573

PAGE BACK PAGE NEXT

THIS MALUAL INCLUDES THE FOLLOWING SECTIONS:

SECTION No. CONTRNTS

8A LIGHTING SYSTEM

8B WIPER / WASHER SYSTEM

8C ENTERTAINMENT

8D WIRING SYSTEM

8E METER AND GAUGE

8F BODY STRUCTURE

8G SEATS

8H SECURITY AND LOCKS

8I SUN ROOF/CONVERTIBLE TOP

8J EXTERIOR / INTERIOR TRIM

Page 35 of 3573

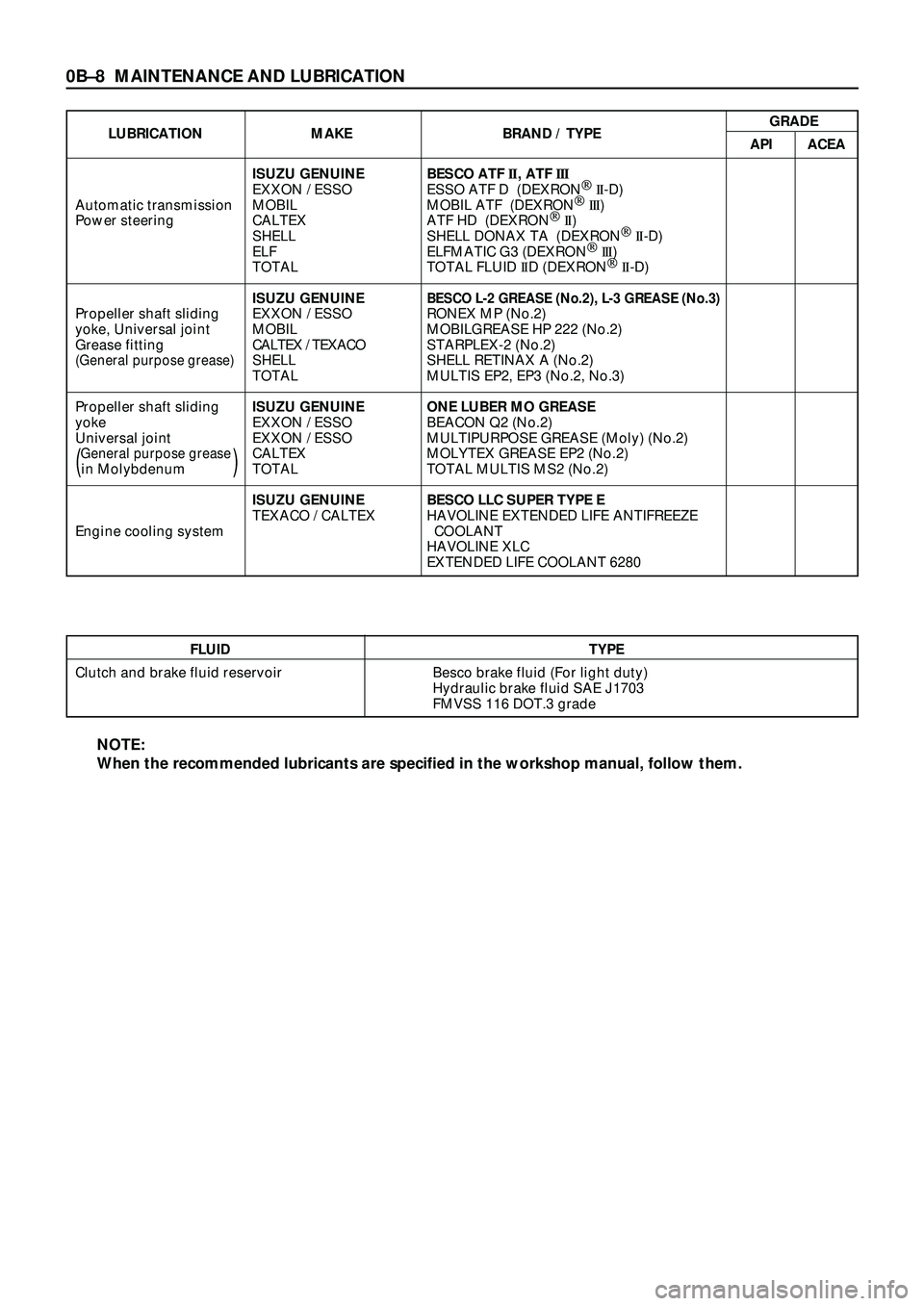

0BÐ8 MAINTENANCE AND LUBRICATION

FLUID TYPE

Clutch and brake fluid reservoir Besco brake fluid (For light duty)

Hydraulic brake fluid SAE J1703

FMVSS 116 DOT.3 grade

LUBRICATION MAKE BRAND / TYPEGRADE

API ACEA

ISUZU GENUINE BESCO ATF II, ATF III

EXXON / ESSO ESSO ATF D (DEXRONÒ

II-D)

Automatic transmission MOBIL MOBIL ATF (DEXRONÒ

III)

Power steering CALTEX ATF HD (DEXRONÒ

II)

SHELL SHELL DONAX TA (DEXRONÒ

II-D)

ELF ELFMATIC G3 (DEXRONÒ

III)

TOTAL TOTAL FLUID IID (DEXRONÒ

II-D)

ISUZU GENUINE

BESCO L-2 GREASE (No.2), L-3 GREASE (No.3)Propeller shaft sliding EXXON / ESSO RONEX MP (No.2)

yoke, Universal joint MOBIL MOBILGREASE HP 222 (No.2)

Grease fittingCALTEX / TEXACOSTARPLEX-2 (No.2)

(General purpose grease)SHELL SHELL RETINAX A (No.2)

TOTAL MULTIS EP2, EP3 (No.2, No.3)

Propeller shaft slidingISUZU GENUINE ONE LUBER MO GREASE

yoke EXXON / ESSO BEACON Q2 (No.2)

Universal joint EXXON / ESSO MULTIPURPOSE GREASE (Moly) (No.2)

General purpose greaseCALTEX MOLYTEX GREASE EP2 (No.2)(in Molybdenum)TOTAL TOTAL MULTIS MS2 (No.2)

ISUZU GENUINE BESCO LLC SUPER TYPE E

TEXACO / CALTEX HAVOLINE EXTENDED LIFE ANTIFREEZE

Engine cooling system COOLANT

HAVOLINE XLC

EXTENDED LIFE COOLANT 6280

NOTE:

When the recommended lubricants are specified in the workshop manual, follow them.

Page 131 of 3573

AIR CONDITIONING 1B Ð 5

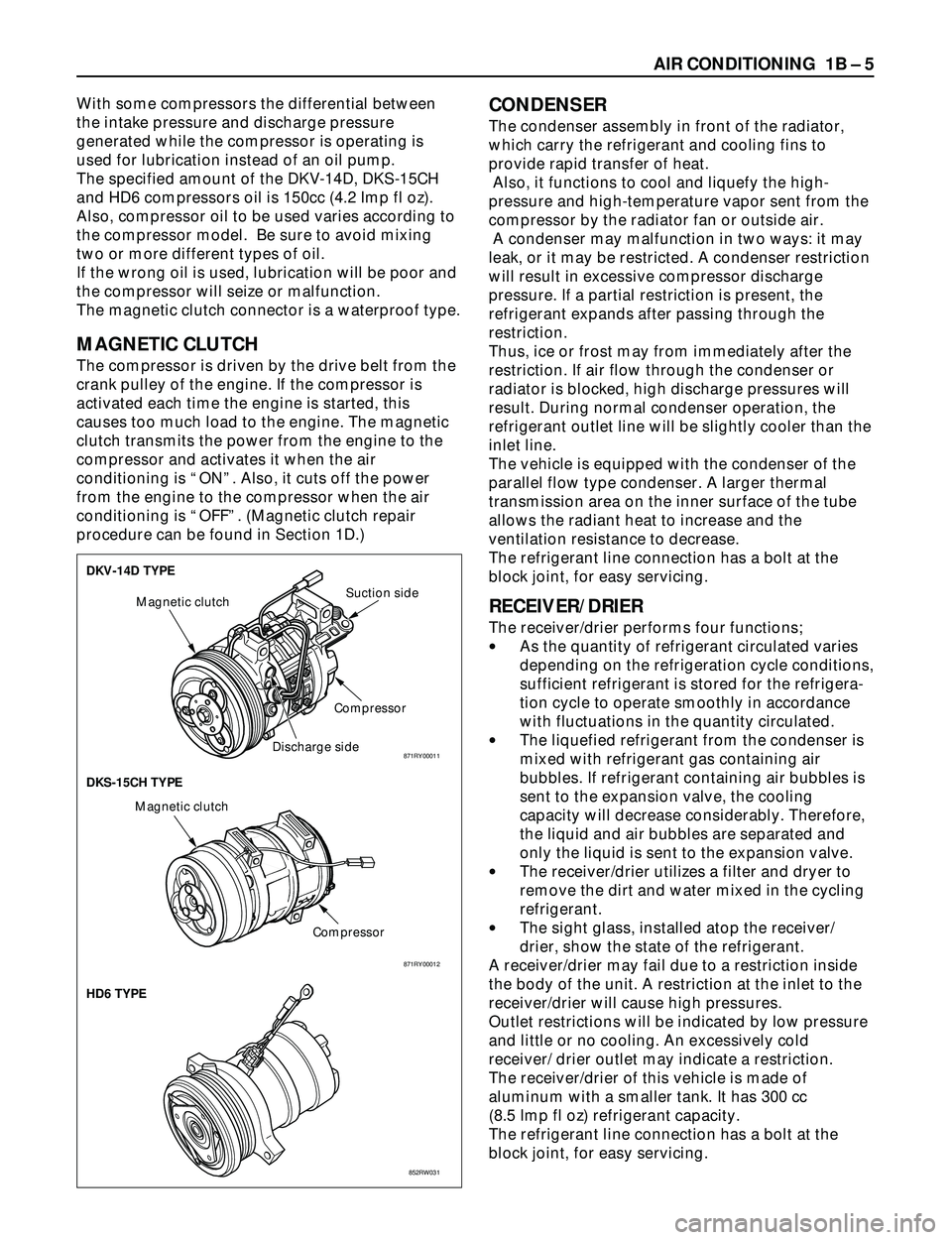

With some compressors the differential between

the intake pressure and discharge pressure

generated while the compressor is operating is

used for lubrication instead of an oil pump.

The specified amount of the DKV-14D, DKS-15CH

and HD6 compressors oil is 150cc (4.2 Imp fl oz).

Also, compressor oil to be used varies according to

the compressor model. Be sure to avoid mixing

two or more different types of oil.

If the wrong oil is used, lubrication will be poor and

the compressor will seize or malfunction.

The magnetic clutch connector is a waterproof type.

MAGNETIC CLUTCH

The compressor is driven by the drive belt from the

crank pulley of the engine. If the compressor is

activated each time the engine is started, this

causes too much load to the engine. The magnetic

clutch transmits the power from the engine to the

compressor and activates it when the air

conditioning is ÒONÓ. Also, it cuts off the power

from the engine to the compressor when the air

conditioning is ÒOFFÓ. (Magnetic clutch repair

procedure can be found in Section 1D.)

CONDENSER

The condenser assembly in front of the radiator,

which carry the refrigerant and cooling fins to

provide rapid transfer of heat.

Also, it functions to cool and liquefy the high-

pressure and high-temperature vapor sent from the

compressor by the radiator fan or outside air.

A condenser may malfunction in two ways: it may

leak, or it may be restricted. A condenser restriction

will result in excessive compressor discharge

pressure. If a partial restriction is present, the

refrigerant expands after passing through the

restriction.

Thus, ice or frost may from immediately after the

restriction. If air flow through the condenser or

radiator is blocked, high discharge pressures will

result. During normal condenser operation, the

refrigerant outlet line will be slightly cooler than the

inlet line.

The vehicle is equipped with the condenser of the

parallel flow type condenser. A larger thermal

transmission area on the inner surface of the tube

allows the radiant heat to increase and the

ventilation resistance to decrease.

The refrigerant line connection has a bolt at the

block joint, for easy servicing.

RECEIVER/DRIER

The receiver/drier performs four functions;

·As the quantity of refrigerant circulated varies

depending on the refrigeration cycle conditions,

sufficient refrigerant is stored for the refrigera-

tion cycle to operate smoothly in accordance

with fluctuations in the quantity circulated.

·The liquefied refrigerant from the condenser is

mixed with refrigerant gas containing air

bubbles. If refrigerant containing air bubbles is

sent to the expansion valve, the cooling

capacity will decrease considerably. Therefore,

the liquid and air bubbles are separated and

only the liquid is sent to the expansion valve.

·The receiver/drier utilizes a filter and dryer to

remove the dirt and water mixed in the cycling

refrigerant.

·The sight glass, installed atop the receiver/

drier, show the state of the refrigerant.

A receiver/drier may fail due to a restriction inside

the body of the unit. A restriction at the inlet to the

receiver/drier will cause high pressures.

Outlet restrictions will be indicated by low pressure

and little or no cooling. An excessively cold

receiver/ drier outlet may indicate a restriction.

The receiver/drier of this vehicle is made of

aluminum with a smaller tank. It has 300 cc

(8.5 Imp fl oz) refrigerant capacity.

The refrigerant line connection has a bolt at the

block joint, for easy servicing.

DKV-14D TYPE

DKS-15CH TYPE

HD6 TYPE

Magnetic clutch

CompressorSuction side

Discharge side

Compressor Magnetic clutch

852RW031 871RY00012

871RY00011

Page 147 of 3573

AIR CONDITIONING 1B Ð 21

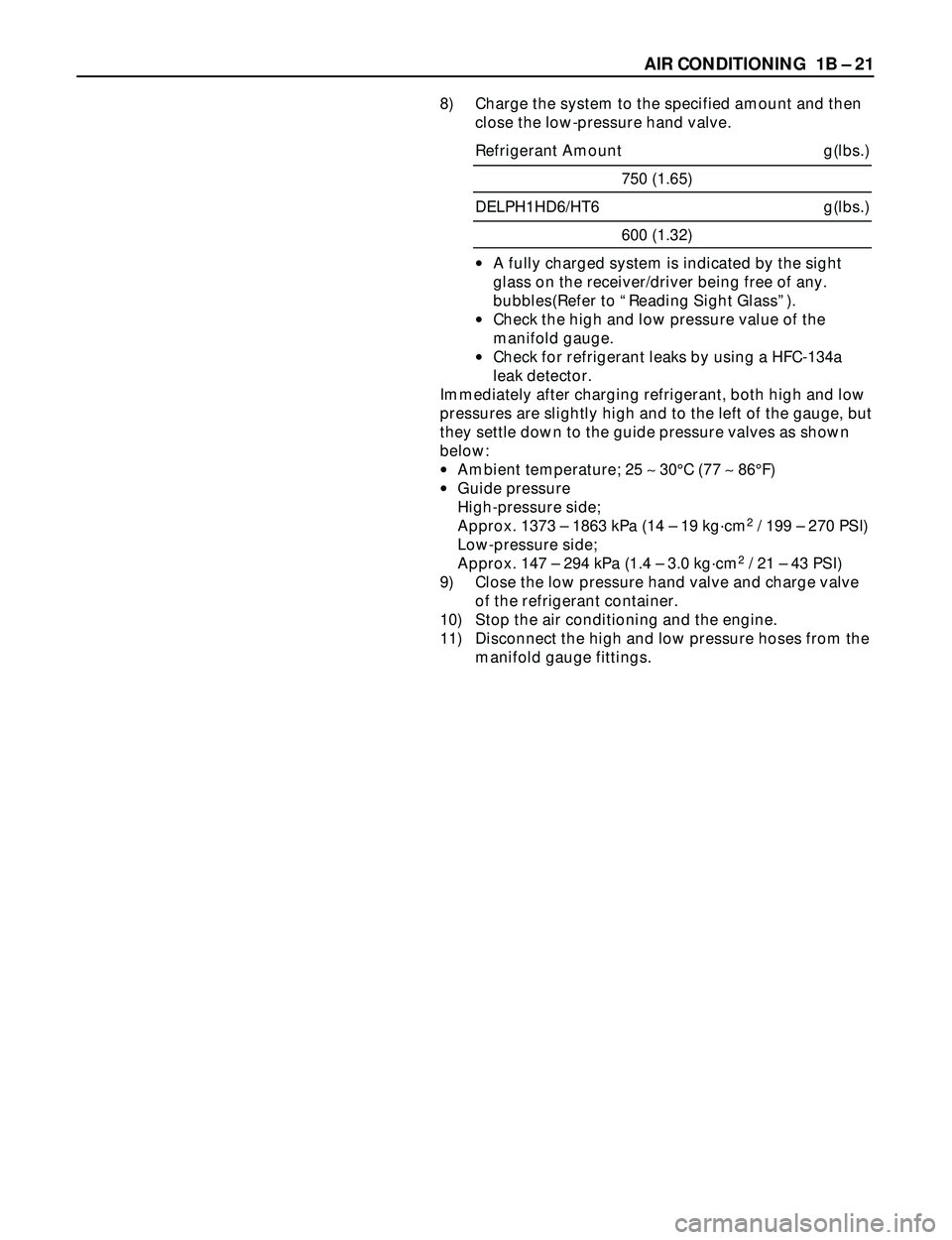

8) Charge the system to the specified amount and then

close the low-pressure hand valve.

Refrigerant Amount g(lbs.)

750 (1.65)

DELPH1HD6/HT6 g(lbs.)

600 (1.32)

·A fully charged system is indicated by the sight

glass on the receiver/driver being free of any.

bubbles(Refer to ÒReading Sight GlassÓ).

·Check the high and low pressure value of the

manifold gauge.

·Check for refrigerant leaks by using a HFC-134a

leak detector.

Immediately after charging refrigerant, both high and low

pressures are slightly high and to the left of the gauge, but

they settle down to the guide pressure valves as shown

below:

·Ambient temperature; 25 ~30¡C (77 ~86¡F)

·Guide pressure

High-pressure side;

Approx. 1373 Ð 1863 kPa (14 Ð 19 kgácm

2/ 199 Ð 270 PSI)

Low-pressure side;

Approx. 147 Ð 294 kPa (1.4 Ð 3.0 kgácm

2/ 21 Ð 43 PSI)

9) Close the low pressure hand valve and charge valve

of the refrigerant container.

10) Stop the air conditioning and the engine.

11) Disconnect the high and low pressure hoses from the

manifold gauge fittings.

Page 148 of 3573

1B Ð 22 AIR CONDITIONING

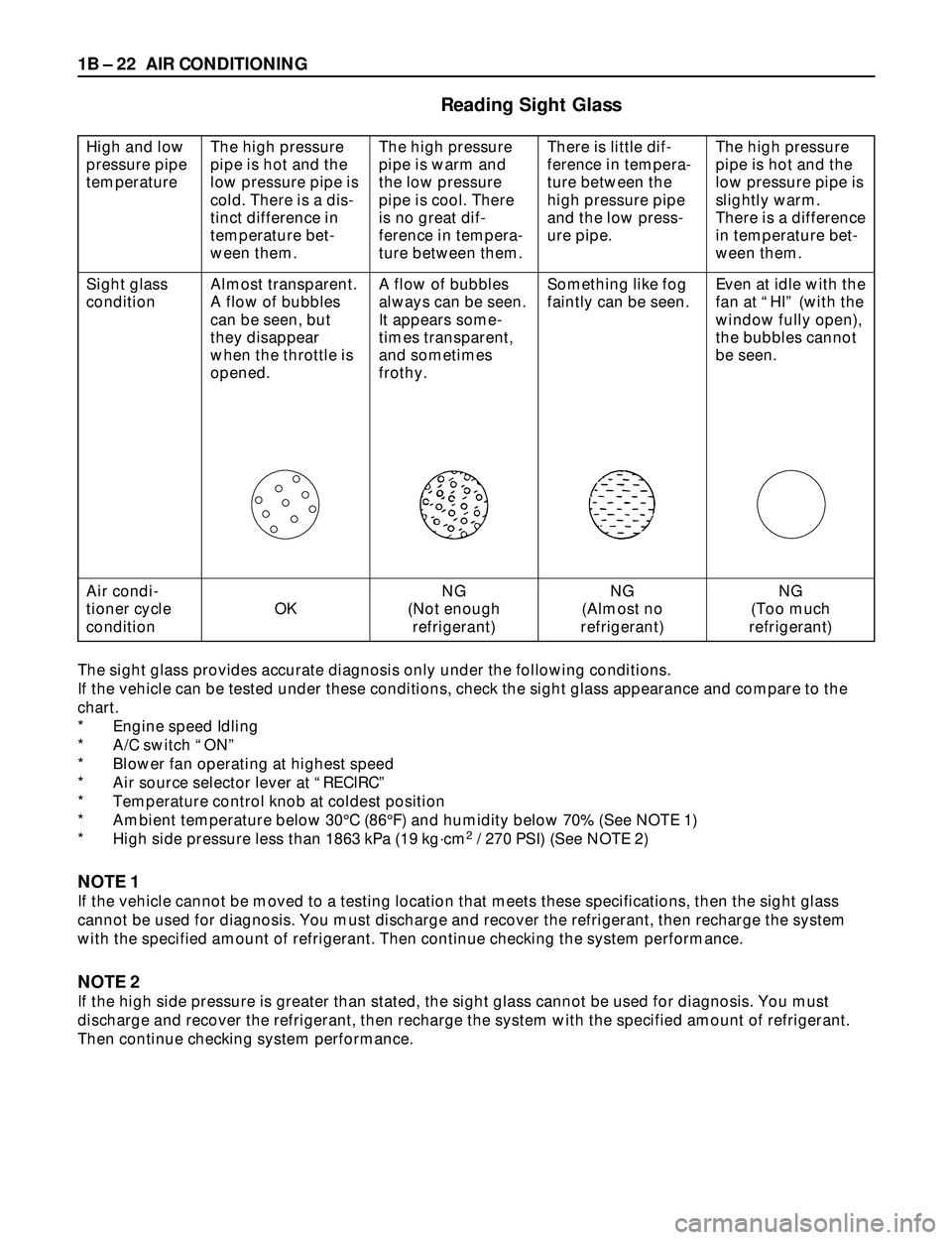

Almost transparent.

A flow of bubbles

can be seen, but

they disappear

when the throttle is

opened.

The sight glass provides accurate diagnosis only under the following conditions.

If the vehicle can be tested under these conditions, check the sight glass appearance and compare to the

chart.

* Engine speed Idling

* A/C switch ÒONÓ

* Blower fan operating at highest speed

* Air source selector lever at ÒRECIRCÓ

* Temperature control knob at coldest position

* Ambient temperature below 30¡C (86¡F) and humidity below 70% (See NOTE 1)

* High side pressure less than 1863 kPa (19 kgácm

2/ 270 PSI) (See NOTE 2)

NOTE 1

If the vehicle cannot be moved to a testing location that meets these specifications, then the sight glass

cannot be used for diagnosis. You must discharge and recover the refrigerant, then recharge the system

with the specified amount of refrigerant. Then continue checking the system performance.

NOTE 2

If the high side pressure is greater than stated, the sight glass cannot be used for diagnosis. You must

discharge and recover the refrigerant, then recharge the system with the specified amount of refrigerant.

Then continue checking system performance.

Reading Sight Glass

High and low

pressure pipe

temperature

Sight glass

condition

Air condi-

tioner cycle

condition

The high pressure

pipe is hot and the

low pressure pipe is

cold. There is a dis-

tinct difference in

temperature bet-

ween them.

OK

The high pressure

pipe is warm and

the low pressure

pipe is cool. There

is no great dif-

ference in tempera-

ture between them.

A flow of bubbles

always can be seen.

It appears some-

times transparent,

and sometimes

frothy.

NG

(Not enough

refrigerant)

There is little dif-

ference in tempera-

ture between the

high pressure pipe

and the low press-

ure pipe.

Something like fog

faintly can be seen.

NG

(Almost no

refrigerant)

The high pressure

pipe is hot and the

low pressure pipe is

slightly warm.

There is a difference

in temperature bet-

ween them.

Even at idle with the

fan at ÒHIÓ (with the

window fully open),

the bubbles cannot

be seen.

NG

(Too much

refrigerant)

Page 219 of 3573

AIR CONDITIONING 1BÐ93

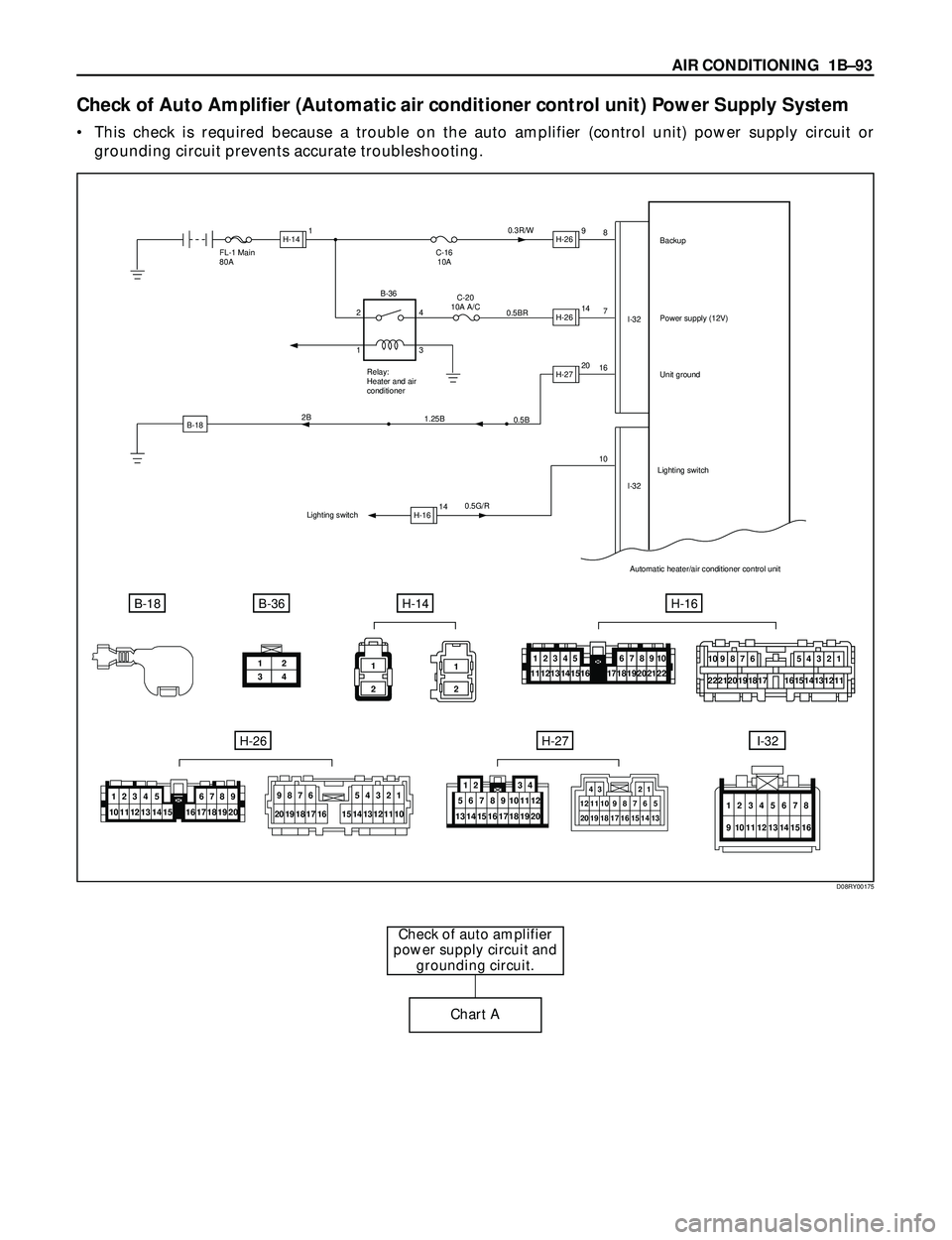

Check of Auto Amplifier (Automatic air conditioner control unit) Power Supply System

¥ This check is required because a trouble on the auto amplifier (control unit) power supply circuit or

grounding circuit prevents accurate troubleshooting.

Check of auto amplifier

power supply circuit and

grounding circuit.

Chart A

B-18

FL-1 Main

80A

0.5G/R16

107 8

I-32

I-32 C-16

10A0.3R/W

0.5BRBackup

Power supply (12V)

Unit ground

Automatic heater/air conditioner control unit

B-18B-36H-14

C-20

10A A/C

Relay:

Heater and air

conditioner

0.5B

1.25B 2B

Lighting switchLighting switch

H-141H-269

H-2614

H-2720

H-1614 2

14

3 B-36

12

34

H-16

H-26H-27I-32

1

2

1

2

10987654321

222120191815141312111716

12345111213141567891018192021221617

10 11 12 13 14 151234 5

17 18 19 206789

16

9876

20 19 18 17 165

14 154

133

122

111

10

20 12

19 11

18 10

179

168

157

146

13512 34

43 21

12111098765

13 14 15 16 17 18 19 20

12345678

9 10111213141516

D08RY00175

Page 220 of 3573

1BÐ94 AIR CONDITIONING

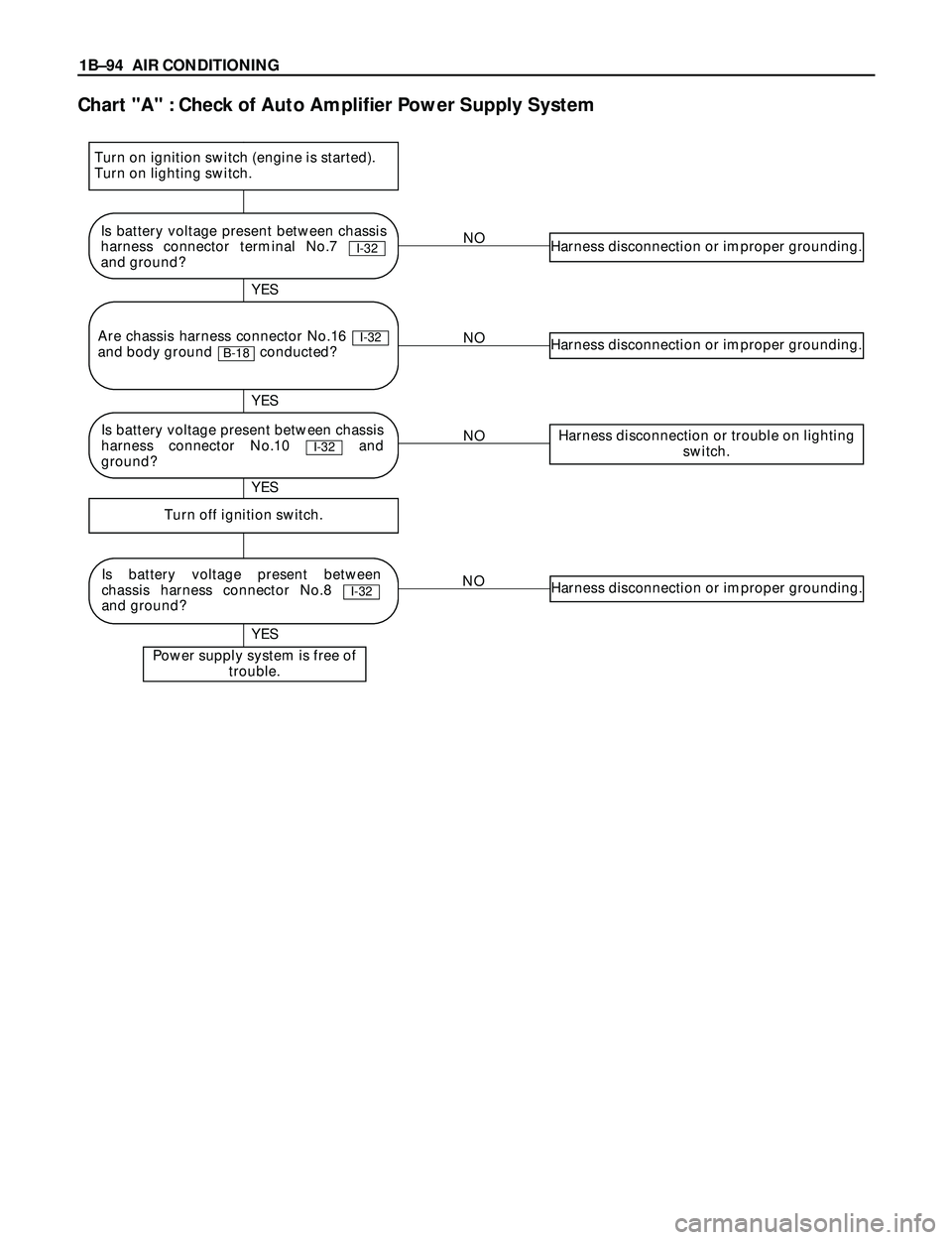

Chart "A" : Check of Auto Amplifier Power Supply System

NOHarness disconnection or improper grounding.

NOHarness disconnection or improper grounding.

NOHarness disconnection or trouble on lighting

switch.

NOHarness disconnection or improper grounding.

Turn off ignition switch.

Power supply system is free of

trouble.

YES YES

YES YES

Is battery voltage present between chassis

harness connector terminal No.7

and ground?

I-32

Is battery voltage present between

chassis harness connector No.8

and ground?

I-32

Are chassis harness connector No.16

and body ground conducted?

B-18I-32

Turn on ignition switch (engine is started).

Turn on lighting switch.

Is battery voltage present between chassis

harness connector No.10 and

ground?

I-32

Page 223 of 3573

AIR CONDITIONING 1BÐ97

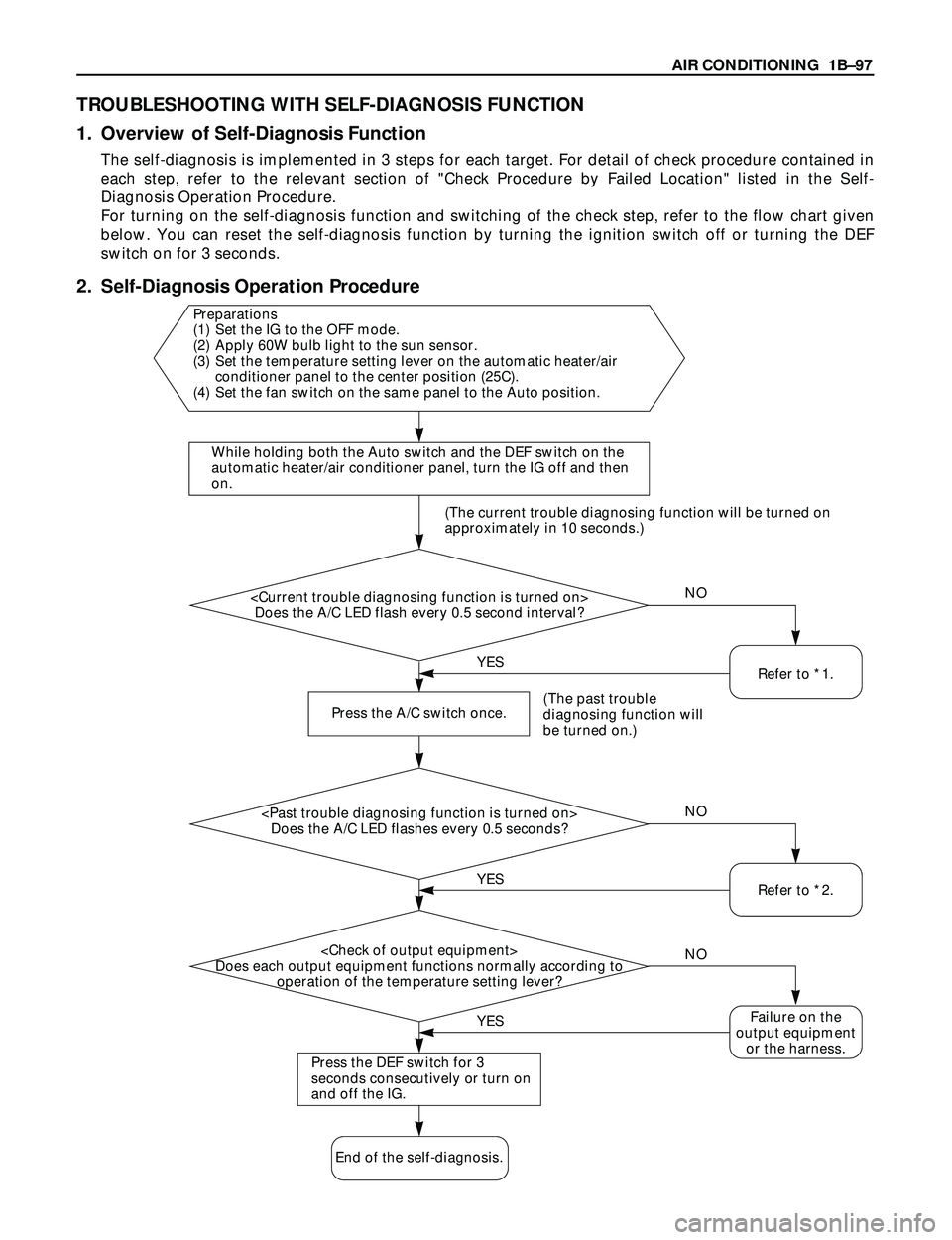

TROUBLESHOOTING WITH SELF-DIAGNOSIS FUNCTION

1. Overview of Self-Diagnosis Function

The self-diagnosis is implemented in 3 steps for each target. For detail of check procedure contained in

each step, refer to the relevant section of "Check Procedure by Failed Location" listed in the Self-

Diagnosis Operation Procedure.

For turning on the self-diagnosis function and switching of the check step, refer to the flow chart given

below. You can reset the self-diagnosis function by turning the ignition switch off or turning the DEF

switch on for 3 seconds.

2. Self-Diagnosis Operation Procedure

While holding both the Auto switch and the DEF switch on the

automatic heater/air conditioner panel, turn the IG off and then

on.

Does the A/C LED flash every 0.5 second interval?

Press the A/C switch once.

(The past trouble

diagnosing function will

be turned on.)

Does the A/C LED flashes every 0.5 seconds?

Does each output equipment functions normally according to

operation of the temperature setting lever?

Press the DEF switch for 3

seconds consecutively or turn on

and off the IG.

Failure on the

output equipment

or the harness.

Preparations

(1) Set the IG to the OFF mode.

(2) Apply 60W bulb light to the sun sensor.

(3) Set the temperature setting lever on the automatic heater/air

conditioner panel to the center position (25C).

(4) Set the fan switch on the same panel to the Auto position.

End of the self-diagnosis.(The current trouble diagnosing function will be turned on

approximately in 10 seconds.)

YESNO

YESNO

NO

YES

Refer to *1.

Refer to *2.

Page 224 of 3573

1BÐ98 AIR CONDITIONING

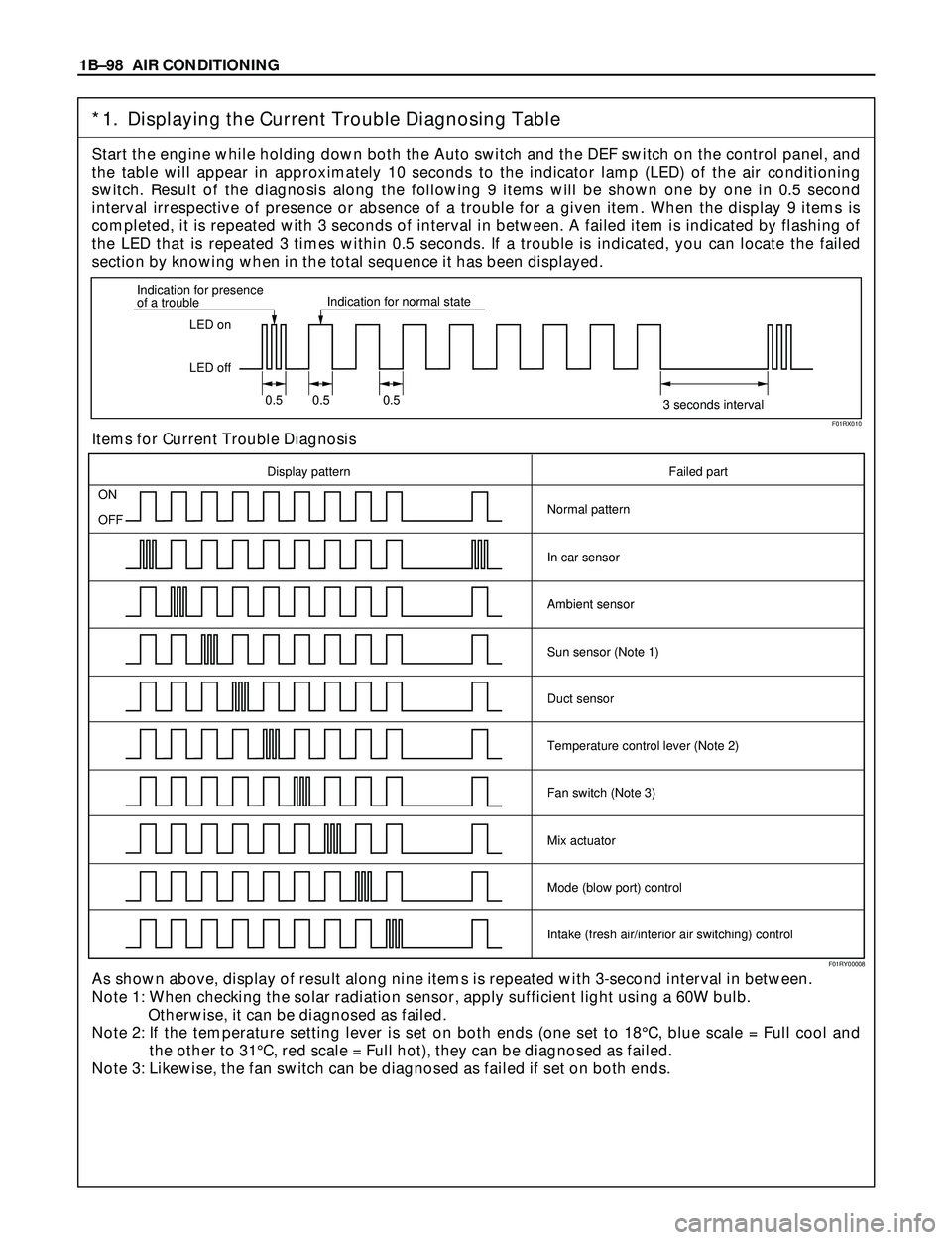

*1. Displaying the Current Trouble Diagnosing Table

Start the engine while holding down both the Auto switch and the DEF switch on the control panel, and

the table will appear in approximately 10 seconds to the indicator lamp (LED) of the air conditioning

switch. Result of the diagnosis along the following 9 items will be shown one by one in 0.5 second

interval irrespective of presence or absence of a trouble for a given item. When the display 9 items is

completed, it is repeated with 3 seconds of interval in between. A failed item is indicated by flashing of

the LED that is repeated 3 times within 0.5 seconds. If a trouble is indicated, you can locate the failed

section by knowing when in the total sequence it has been displayed.

Items for Current Trouble Diagnosis

As shown above, display of result along nine items is repeated with 3-second interval in between.

Note 1: When checking the solar radiation sensor, apply sufficient light using a 60W bulb.

Otherwise, it can be diagnosed as failed.

Note 2: If the temperature setting lever is set on both ends (one set to 18¡C, blue scale = Full cool and

the other to 31¡C, red scale = Full hot), they can be diagnosed as failed.

Note 3: Likewise, the fan switch can be diagnosed as failed if set on both ends.

LED on

LED off Indication for presence

of a troubleIndication for normal state

0.5 0.5 0.5

3 seconds interval

ON

OFF

Display pattern Failed part

Normal pattern

In car sensor

Ambient sensor

Sun sensor (Note 1)

Duct sensor

Temperature control lever (Note 2)

Fan switch (Note 3)

Mix actuator

Mode (blow port) control

Intake (fresh air/interior air switching) control

F01RX010

F01RY00008

Page 274 of 3573

1D Ð 18 COMPRESSOR OVERHAUL

HD6 TYPE COMPRESSOR

Metric Thread Size Information

Compressor to mounting bracket bolts (Front)

M10´ 1.5 Ð 6H

Compressor to mounting bracket bolts (Rear)

M8´ 1.25 Ð 6H

Suction-discharge port screw

M10´ 1.5 Ð 6HCompressor shaft

M9´ 1.25 Ð 6H

Internal hub-clutch drive assembly

M22´ 1.5 Ð 6H

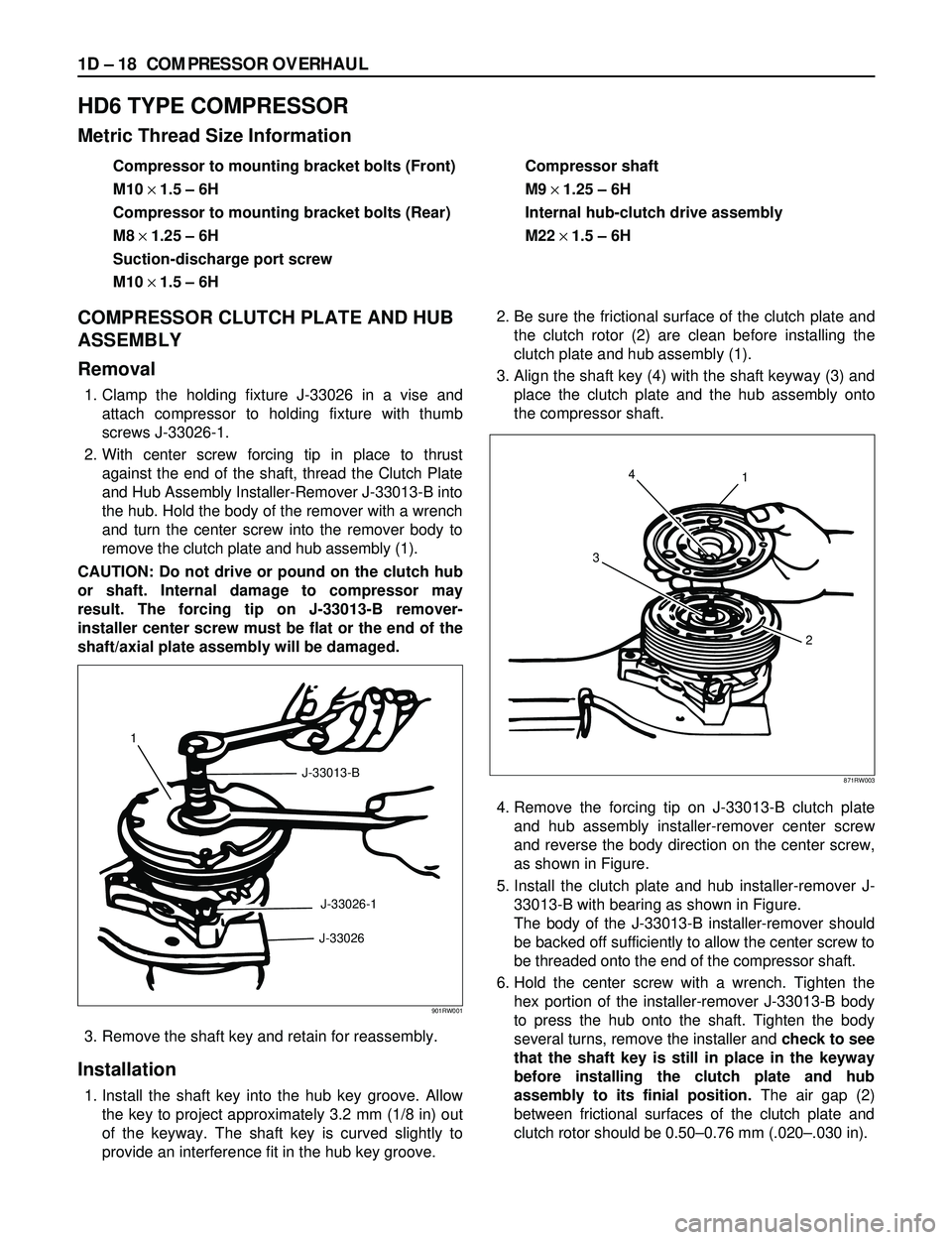

COMPRESSOR CLUTCH PLATE AND HUB

ASSEMBLY

Removal

1. Clamp the holding fixture J-33026 in a vise and

attach compressor to holding fixture with thumb

screws J-33026-1.

2. With center screw forcing tip in place to thrust

against the end of the shaft, thread the Clutch Plate

and Hub Assembly Installer-Remover J-33013-B into

the hub. Hold the body of the remover with a wrench

and turn the center screw into the remover body to

remove the clutch plate and hub assembly (1).

CAUTION: Do not drive or pound on the clutch hub

or shaft. Internal damage to compressor may

result. The forcing tip on J-33013-B remover-

installer center screw must be flat or the end of the

shaft/axial plate assembly will be damaged.

3. Remove the shaft key and retain for reassembly.

Installation

1. Install the shaft key into the hub key groove. Allow

the key to project approximately 3.2 mm (1/8 in) out

of the keyway. The shaft key is curved slightly to

provide an interference fit in the hub key groove.2. Be sure the frictional surface of the clutch plate and

the clutch rotor (2) are clean before installing the

clutch plate and hub assembly (1).

3. Align the shaft key (4) with the shaft keyway (3) and

place the clutch plate and the hub assembly onto

the compressor shaft.

4. Remove the forcing tip on J-33013-B clutch plate

and hub assembly installer-remover center screw

and reverse the body direction on the center screw,

as shown in Figure.

5. Install the clutch plate and hub installer-remover J-

33013-B with bearing as shown in Figure.

The body of the J-33013-B installer-remover should

be backed off sufficiently to allow the center screw to

be threaded onto the end of the compressor shaft.

6. Hold the center screw with a wrench. Tighten the

hex portion of the installer-remover J-33013-B body

to press the hub onto the shaft. Tighten the body

several turns, remove the installer and check to see

that the shaft key is still in place in the keyway

before installing the clutch plate and hub

assembly to its finial position.The air gap (2)

between frictional surfaces of the clutch plate and

clutch rotor should be 0.50Ð0.76 mm (.020Ð.030 in).

1

J-33013-B

J-33026-1

J-33026

901RW001

4

31

2

871RW003