steering wheel adjustment ISUZU TROOPER 1998 Service Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 1998, Model line: TROOPER, Model: ISUZU TROOPER 1998Pages: 3573, PDF Size: 60.36 MB

Page 286 of 3573

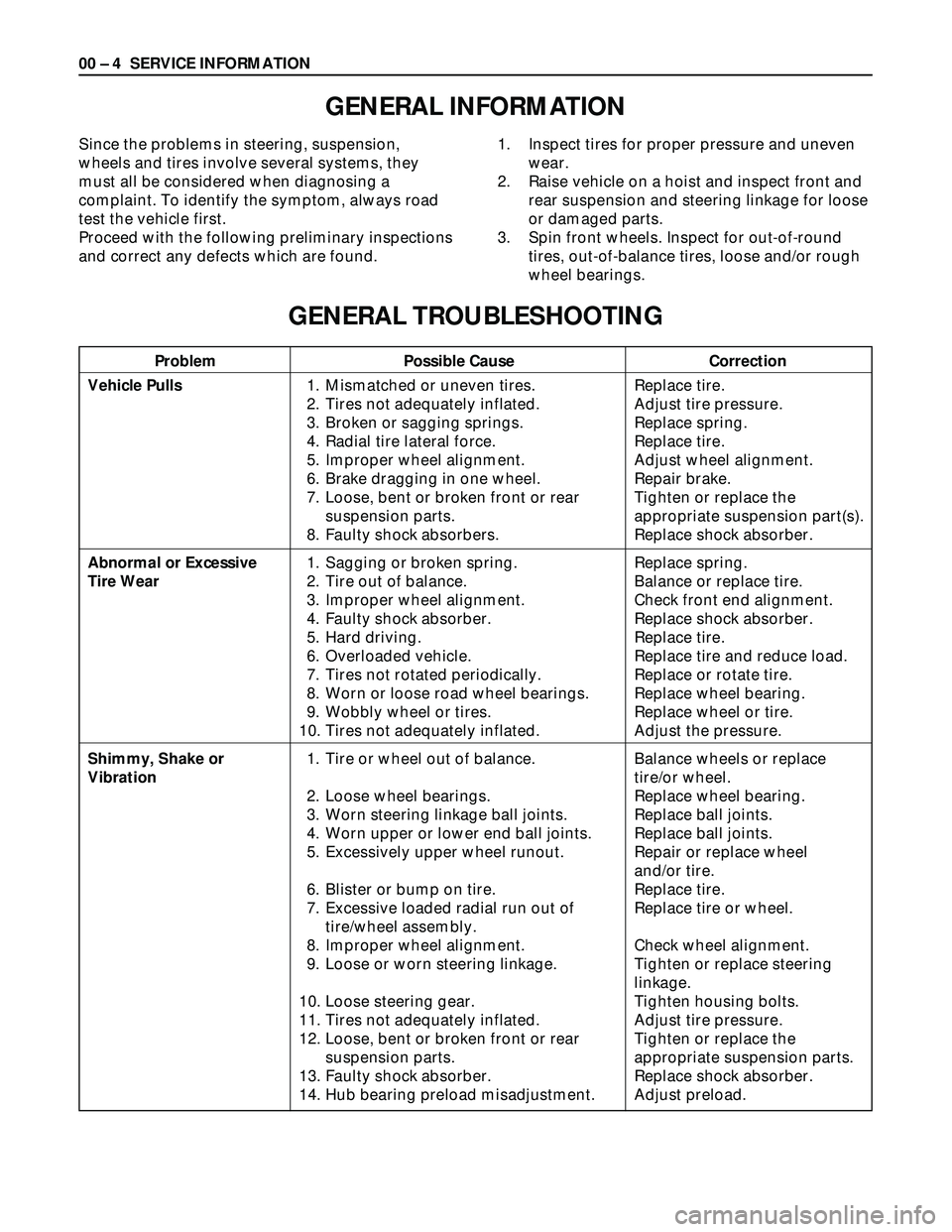

Problem Possible Cause Correction

00 – 4 SERVICE INFORMATION

GENERAL INFORMATION

Since the problems in steering, suspension,

wheels and tires involve several systems, they

must all be considered when diagnosing a

complaint. To identify the symptom, always road

test the vehicle first.

Proceed with the following preliminary inspections

and correct any defects which are found.1. Inspect tires for proper pressure and uneven

wear.

2. Raise vehicle on a hoist and inspect front and

rear suspension and steering linkage for loose

or damaged parts.

3. Spin front wheels. Inspect for out-of-round

tires, out-of-balance tires, loose and/or rough

wheel bearings.

GENERAL TROUBLESHOOTING

Vehicle Pulls

Abnormal or Excessive

Tire Wear

Shimmy, Shake or

Vibration1. Mismatched or uneven tires.

2. Tires not adequately inflated.

3. Broken or sagging springs.

4. Radial tire lateral force.

5. Improper wheel alignment.

6. Brake dragging in one wheel.

7. Loose, bent or broken front or rear

suspension parts.

8. Faulty shock absorbers.

1. Sagging or broken spring.

2. Tire out of balance.

3. Improper wheel alignment.

4. Faulty shock absorber.

5. Hard driving.

6. Overloaded vehicle.

7. Tires not rotated periodically.

8. Worn or loose road wheel bearings.

9. Wobbly wheel or tires.

10. Tires not adequately inflated.

1. Tire or wheel out of balance.

2. Loose wheel bearings.

3. Worn steering linkage ball joints.

4. Worn upper or lower end ball joints.

5. Excessively upper wheel runout.

6. Blister or bump on tire.

7. Excessive loaded radial run out of

tire/wheel assembly.

8. Improper wheel alignment.

9. Loose or worn steering linkage.

10. Loose steering gear.

11. Tires not adequately inflated.

12. Loose, bent or broken front or rear

suspension parts.

13. Faulty shock absorber.

14. Hub bearing preload misadjustment.Replace tire.

Adjust tire pressure.

Replace spring.

Replace tire.

Adjust wheel alignment.

Repair brake.

Tighten or replace the

appropriate suspension part(s).

Replace shock absorber.

Replace spring.

Balance or replace tire.

Check front end alignment.

Replace shock absorber.

Replace tire.

Replace tire and reduce load.

Replace or rotate tire.

Replace wheel bearing.

Replace wheel or tire.

Adjust the pressure.

Balance wheels or replace

tire/or wheel.

Replace wheel bearing.

Replace ball joints.

Replace ball joints.

Repair or replace wheel

and/or tire.

Replace tire.

Replace tire or wheel.

Check wheel alignment.

Tighten or replace steering

linkage.

Tighten housing bolts.

Adjust tire pressure.

Tighten or replace the

appropriate suspension parts.

Replace shock absorber.

Adjust preload.

Page 287 of 3573

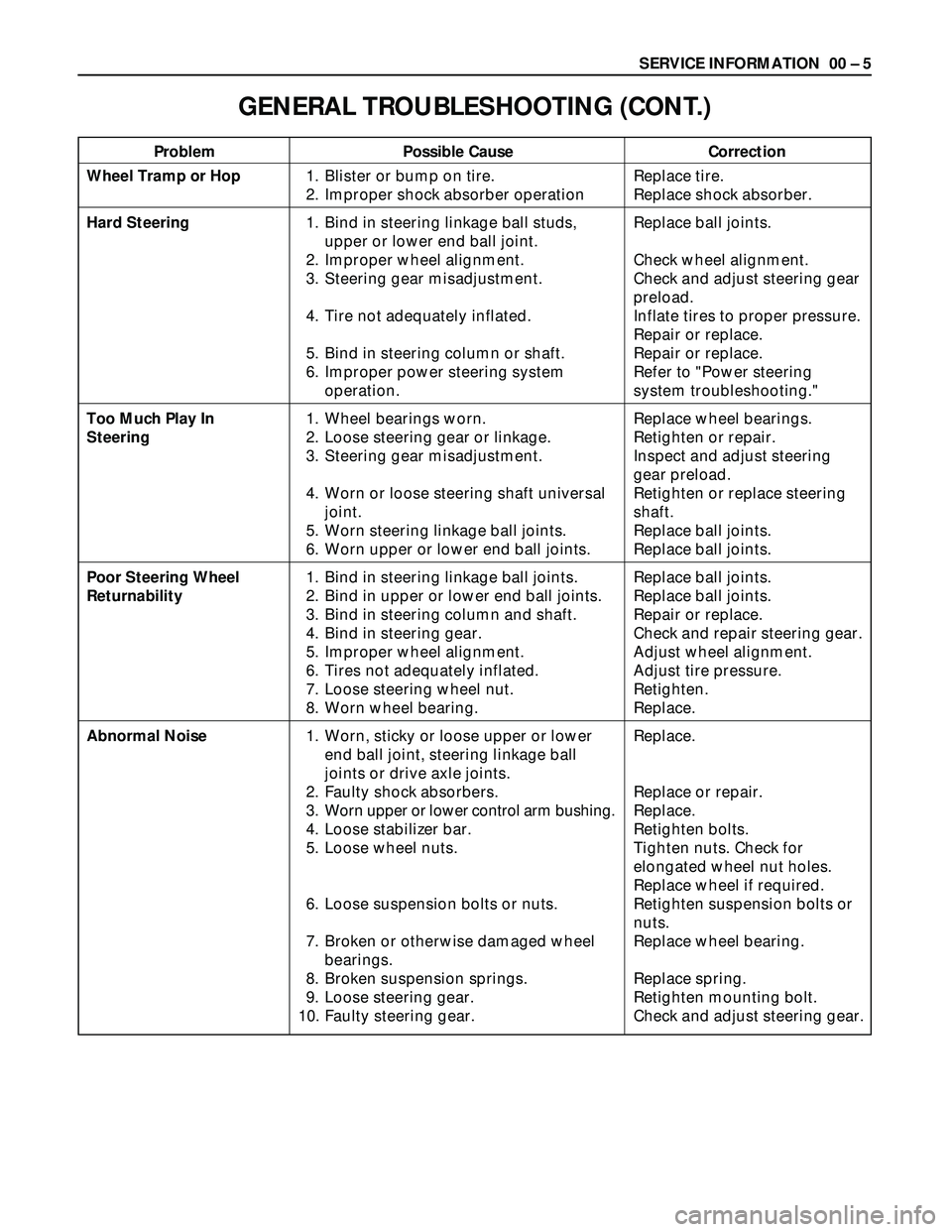

SERVICE INFORMATION 00 – 5

Problem Possible Cause Correction

GENERAL TROUBLESHOOTING (CONT.)

Wheel Tramp or Hop

Hard Steering

Too Much Play In

Steering

Poor Steering Wheel

Returnability

Abnormal Noise1. Blister or bump on tire.

2. Improper shock absorber operation

1. Bind in steering linkage ball studs,

upper or lower end ball joint.

2. Improper wheel alignment.

3. Steering gear misadjustment.

4. Tire not adequately inflated.

5. Bind in steering column or shaft.

6. Improper power steering system

operation.

1. Wheel bearings worn.

2. Loose steering gear or linkage.

3. Steering gear misadjustment.

4. Worn or loose steering shaft universal

joint.

5. Worn steering linkage ball joints.

6. Worn upper or lower end ball joints.

1. Bind in steering linkage ball joints.

2. Bind in upper or lower end ball joints.

3. Bind in steering column and shaft.

4. Bind in steering gear.

5. Improper wheel alignment.

6. Tires not adequately inflated.

7. Loose steering wheel nut.

8. Worn wheel bearing.

1. Worn, sticky or loose upper or lower

end ball joint, steering linkage ball

joints or drive axle joints.

2. Faulty shock absorbers.

3. Worn upper or lower control arm bushing.

4. Loose stabilizer bar.

5. Loose wheel nuts.

6. Loose suspension bolts or nuts.

7. Broken or otherwise damaged wheel

bearings.

8. Broken suspension springs.

9. Loose steering gear.

10. Faulty steering gear.Replace tire.

Replace shock absorber.

Replace ball joints.

Check wheel alignment.

Check and adjust steering gear

preload.

Inflate tires to proper pressure.

Repair or replace.

Repair or replace.

Refer to "Power steering

system troubleshooting."

Replace wheel bearings.

Retighten or repair.

Inspect and adjust steering

gear preload.

Retighten or replace steering

shaft.

Replace ball joints.

Replace ball joints.

Replace ball joints.

Replace ball joints.

Repair or replace.

Check and repair steering gear.

Adjust wheel alignment.

Adjust tire pressure.

Retighten.

Replace.

Replace.

Replace or repair.

Replace.

Retighten bolts.

Tighten nuts. Check for

elongated wheel nut holes.

Replace wheel if required.

Retighten suspension bolts or

nuts.

Replace wheel bearing.

Replace spring.

Retighten mounting bolt.

Check and adjust steering gear.

Page 288 of 3573

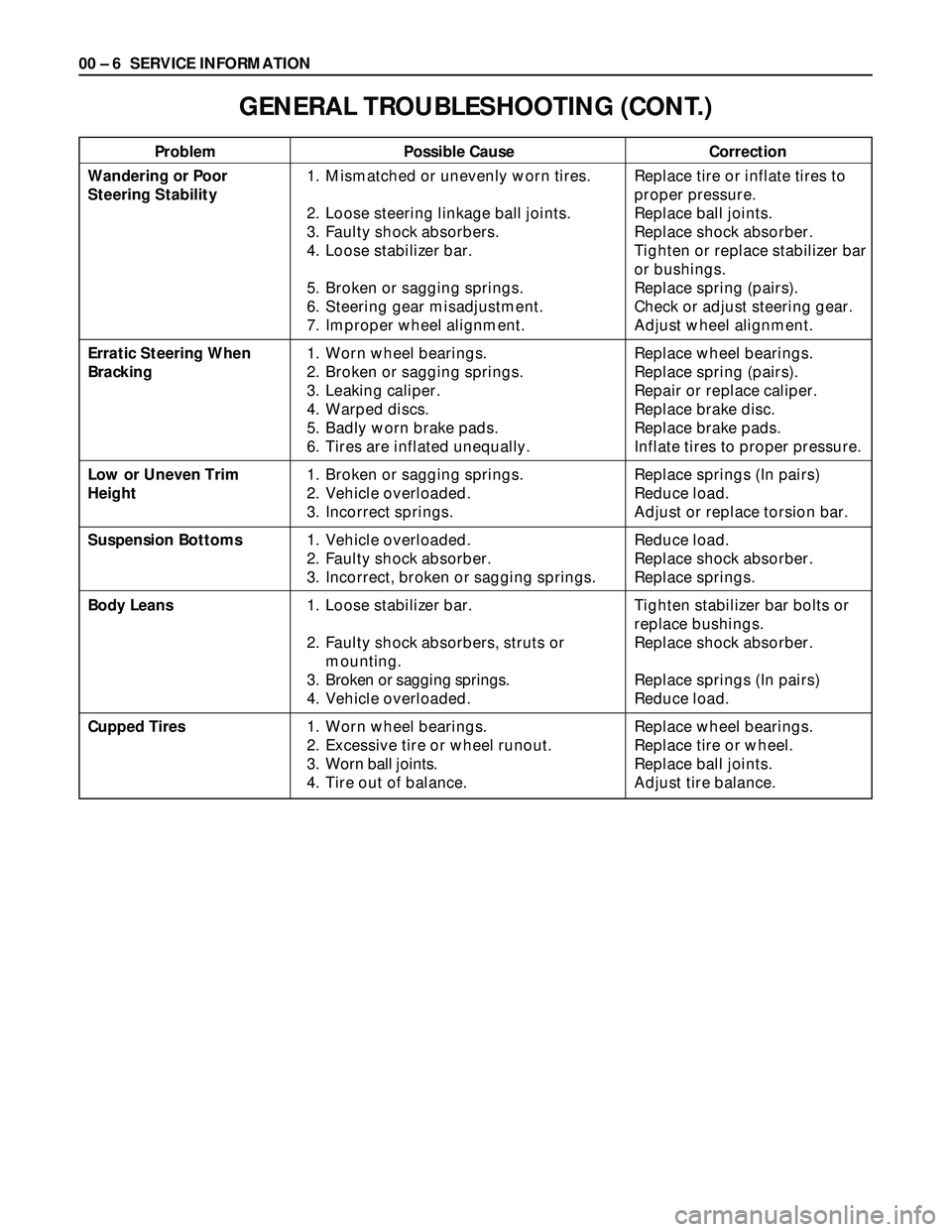

00 – 6 SERVICE INFORMATION

Problem Possible Cause Correction

GENERAL TROUBLESHOOTING (CONT.)

Wandering or Poor

Steering Stability

Erratic Steering When

Bracking

Low or Uneven Trim

Height

Suspension Bottoms

Body Leans

Cupped Tires1. Mismatched or unevenly worn tires.

2. Loose steering linkage ball joints.

3. Faulty shock absorbers.

4. Loose stabilizer bar.

5. Broken or sagging springs.

6. Steering gear misadjustment.

7. Improper wheel alignment.

1. Worn wheel bearings.

2. Broken or sagging springs.

3. Leaking caliper.

4. Warped discs.

5. Badly worn brake pads.

6. Tires are inflated unequally.

1. Broken or sagging springs.

2. Vehicle overloaded.

3. Incorrect springs.

1. Vehicle overloaded.

2. Faulty shock absorber.

3. Incorrect, broken or sagging springs.

1. Loose stabilizer bar.

2. Faulty shock absorbers, struts or

mounting.

3. Broken or sagging springs.

4. Vehicle overloaded.

1. Worn wheel bearings.

2. Excessive tire or wheel runout.

3. Worn ball joints.

4. Tire out of balance.Replace tire or inflate tires to

proper pressure.

Replace ball joints.

Replace shock absorber.

Tighten or replace stabilizer bar

or bushings.

Replace spring (pairs).

Check or adjust steering gear.

Adjust wheel alignment.

Replace wheel bearings.

Replace spring (pairs).

Repair or replace caliper.

Replace brake disc.

Replace brake pads.

Inflate tires to proper pressure.

Replace springs (In pairs)

Reduce load.

Adjust or replace torsion bar.

Reduce load.

Replace shock absorber.

Replace springs.

Tighten stabilizer bar bolts or

replace bushings.

Replace shock absorber.

Replace springs (In pairs)

Reduce load.

Replace wheel bearings.

Replace tire or wheel.

Replace ball joints.

Adjust tire balance.

Page 289 of 3573

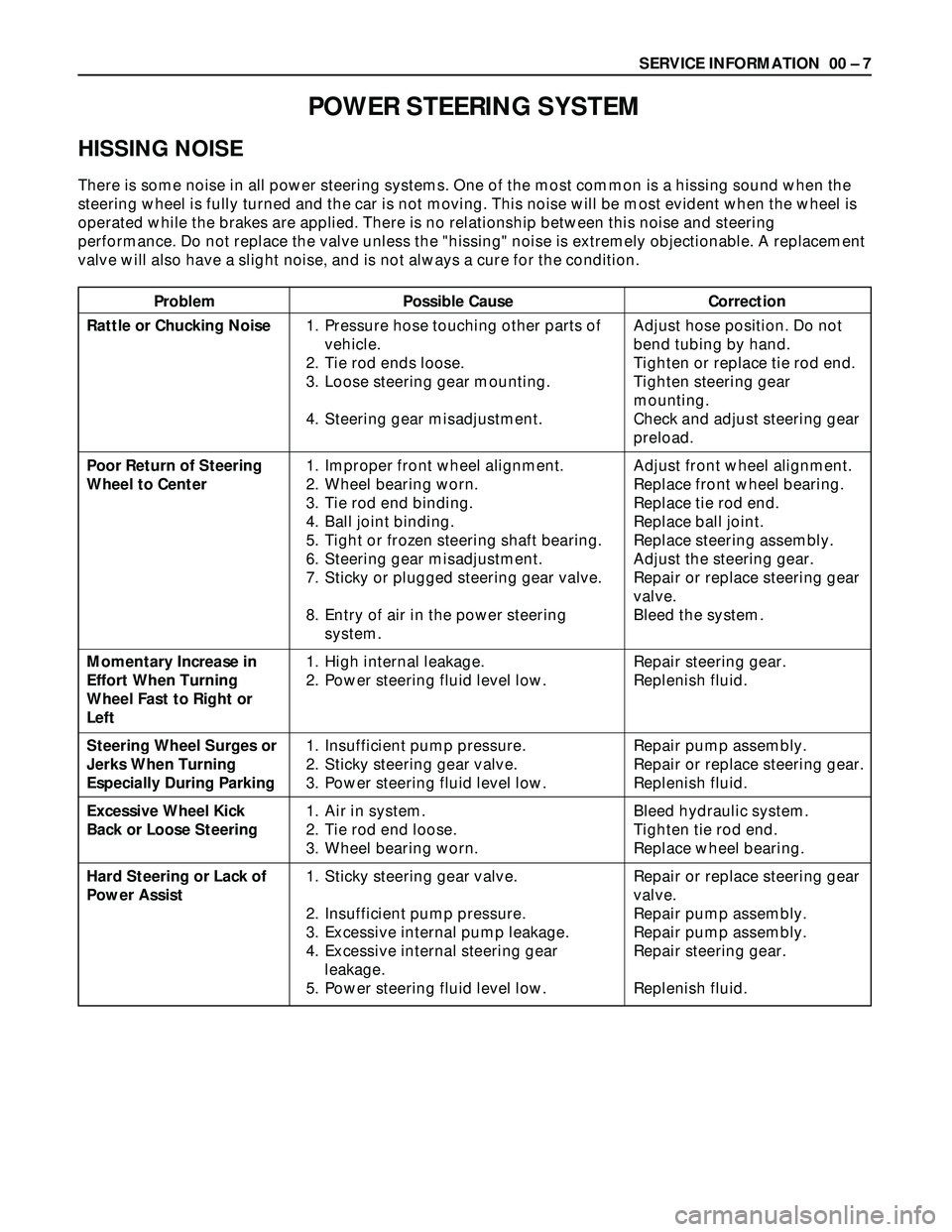

SERVICE INFORMATION 00 – 7

Problem Possible Cause Correction

POWER STEERING SYSTEM

HISSING NOISE

There is some noise in all power steering systems. One of the most common is a hissing sound when the

steering wheel is fully turned and the car is not moving. This noise will be most evident when the wheel is

operated while the brakes are applied. There is no relationship between this noise and steering

performance. Do not replace the valve unless the "hissing" noise is extremely objectionable. A replacement

valve will also have a slight noise, and is not always a cure for the condition.

Rattle or Chucking Noise

Poor Return of Steering

Wheel to Center

Momentary Increase in

Effort When Turning

Wheel Fast to Right or

Left

Steering Wheel Surges or

Jerks When Turning

Especially During Parking

Excessive Wheel Kick

Back or Loose Steering

Hard Steering or Lack of

Power Assist1. Pressure hose touching other parts of

vehicle.

2. Tie rod ends loose.

3. Loose steering gear mounting.

4. Steering gear misadjustment.

1. Improper front wheel alignment.

2. Wheel bearing worn.

3. Tie rod end binding.

4. Ball joint binding.

5. Tight or frozen steering shaft bearing.

6. Steering gear misadjustment.

7. Sticky or plugged steering gear valve.

8. Entry of air in the power steering

system.

1. High internal leakage.

2. Power steering fluid level low.

1. Insufficient pump pressure.

2. Sticky steering gear valve.

3. Power steering fluid level low.

1. Air in system.

2. Tie rod end loose.

3. Wheel bearing worn.

1. Sticky steering gear valve.

2. Insufficient pump pressure.

3. Excessive internal pump leakage.

4. Excessive internal steering gear

leakage.

5. Power steering fluid level low.Adjust hose position. Do not

bend tubing by hand.

Tighten or replace tie rod end.

Tighten steering gear

mounting.

Check and adjust steering gear

preload.

Adjust front wheel alignment.

Replace front wheel bearing.

Replace tie rod end.

Replace ball joint.

Replace steering assembly.

Adjust the steering gear.

Repair or replace steering gear

valve.

Bleed the system.

Repair steering gear.

Replenish fluid.

Repair pump assembly.

Repair or replace steering gear.

Replenish fluid.

Bleed hydraulic system.

Tighten tie rod end.

Replace wheel bearing.

Repair or replace steering gear

valve.

Repair pump assembly.

Repair pump assembly.

Repair steering gear.

Replenish fluid.

Page 296 of 3573

00 – 14 SERVICE INFORMATION

STEERING WHEEL FREE PLAY

ADJUSTMENT

INSPECTION

1. Check the amount of steering wheel play by turning

the wheel in both directions until the tires begin to

move with the front wheels properly in the straight

ahead position.

NOTE:

The wheel free play should be checked with the engine

running.

Steering Wheel Free Play mm (in)

0 – 30 (0 – 1.18)

2. Also check the steering wheel for play and looseness

in mount by moving it back and froth and sideways.

While driving, check for hard-steering, steering

shimmy and tendency to pull to one side.

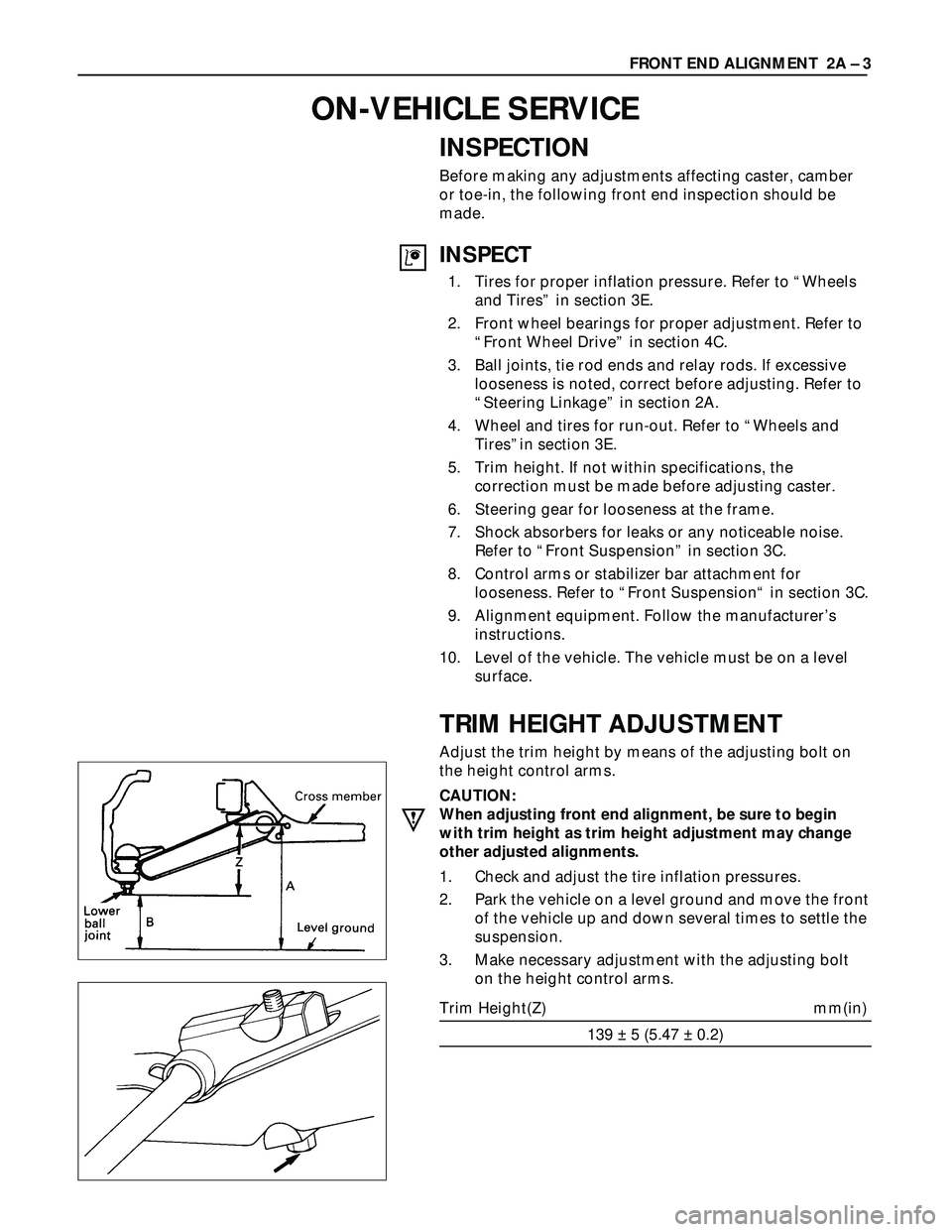

ADJUSTMENT

1. Align the front wheels properly in the straight ahead

position.

2. Loosen the lock nut on the adjusting screw of the

steering gear.

3. Turn the adjust screw clockwise to decrease free play

or counter-clockwise to increase.

4. After check of specified free play, tighten the lock nut

to specified torque.

Lock Nut Torque N·m (kg·m/lb·ft)

41 (4.2 / 30)

Page 305 of 3573

INSPECTION

Before making any adjustments affecting caster, camber

or toe-in, the following front end inspection should be

made.

INSPECT

1. Tires for proper inflation pressure. Refer to “Wheels

and Tires” in section 3E.

2. Front wheel bearings for proper adjustment. Refer to

“Front Wheel Drive” in section 4C.

3. Ball joints, tie rod ends and relay rods. If excessive

looseness is noted, correct before adjusting. Refer to

“Steering Linkage” in section 2A.

4. Wheel and tires for run-out. Refer to “Wheels and

Tires”in section 3E.

5. Trim height. If not within specifications, the

correction must be made before adjusting caster.

6. Steering gear for looseness at the frame.

7. Shock absorbers for leaks or any noticeable noise.

Refer to “Front Suspension” in section 3C.

8. Control arms or stabilizer bar attachment for

looseness. Refer to “Front Suspension“ in section 3C.

9. Alignment equipment. Follow the manufacturer’s

instructions.

10. Level of the vehicle. The vehicle must be on a level

surface.

TRIM HEIGHT ADJUSTMENT

Adjust the trim height by means of the adjusting bolt on

the height control arms.

CAUTION:

When adjusting front end alignment, be sure to begin

with trim height as trim height adjustment may change

other adjusted alignments.

1. Check and adjust the tire inflation pressures.

2. Park the vehicle on a level ground and move the front

of the vehicle up and down several times to settle the

suspension.

3. Make necessary adjustment with the adjusting bolt

on the height control arms.

Trim Height(Z) mm(in)

139 ± 5 (5.47 ± 0.2)FRONT END ALIGNMENT 2A – 3

ON-VEHICLE SERVICE

Page 307 of 3573

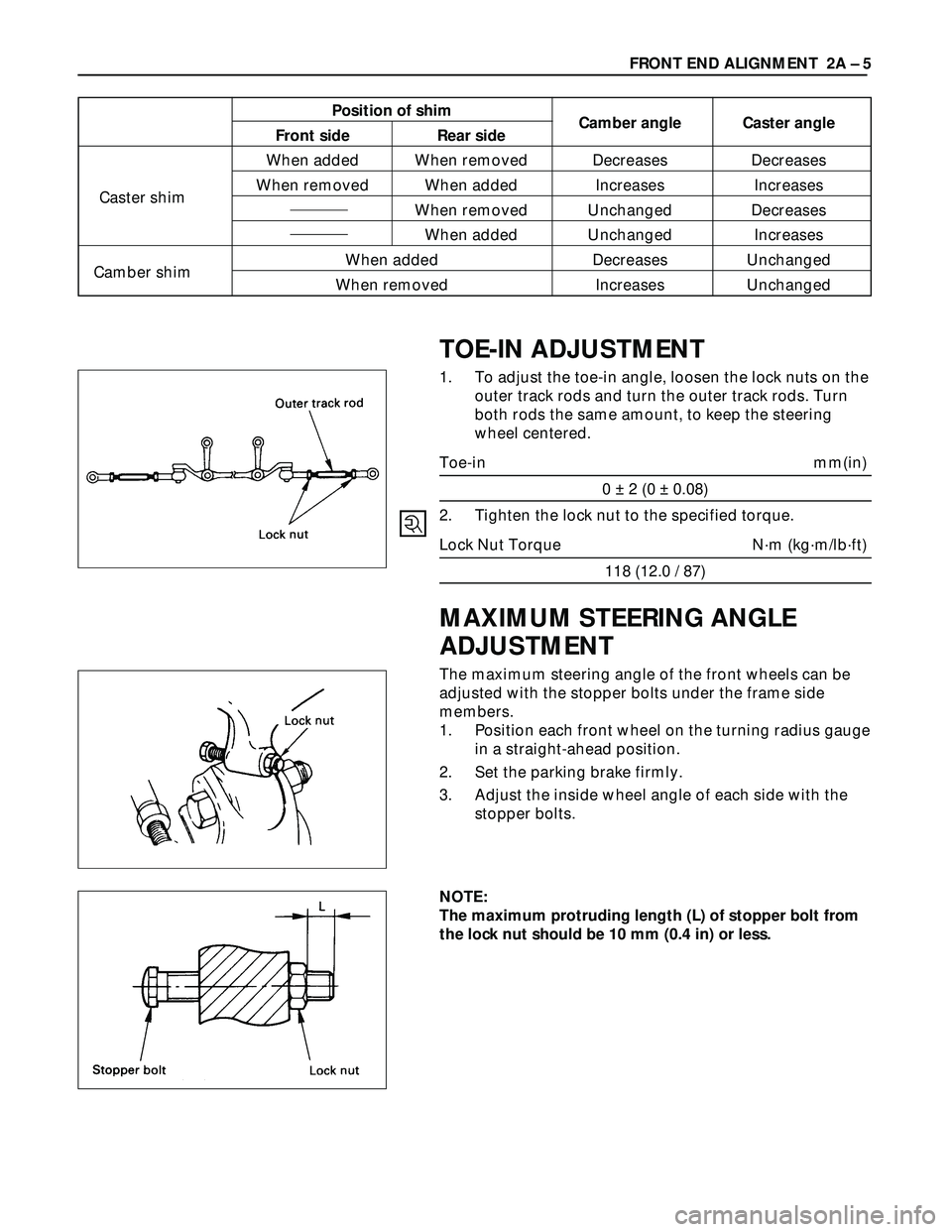

FRONT END ALIGNMENT 2A – 5

Position of shim

Camber angle Caster angle

Front side Rear side

When added When removed Decreases Decreases

When removed When added Increases Increases

Caster shim

When removed Unchanged Decreases

When added Unchanged Increases

When added Decreases Unchanged

Camber shim

When removed Increases Unchanged

TOE-IN ADJUSTMENT

1. To adjust the toe-in angle, loosen the lock nuts on the

outer track rods and turn the outer track rods. Turn

both rods the same amount, to keep the steering

wheel centered.

Toe-in mm(in)

0 ± 2 (0 ± 0.08)

2. Tighten the lock nut to the specified torque.

Lock Nut Torque N·m (kg·m/lb·ft)

118 (12.0 / 87)

MAXIMUM STEERING ANGLE

ADJUSTMENT

The maximum steering angle of the front wheels can be

adjusted with the stopper bolts under the frame side

members.

1. Position each front wheel on the turning radius gauge

in a straight-ahead position.

2. Set the parking brake firmly.

3. Adjust the inside wheel angle of each side with the

stopper bolts.

NOTE:

The maximum protruding length (L) of stopper bolt from

the lock nut should be 10 mm (0.4 in) or less.

Page 344 of 3573

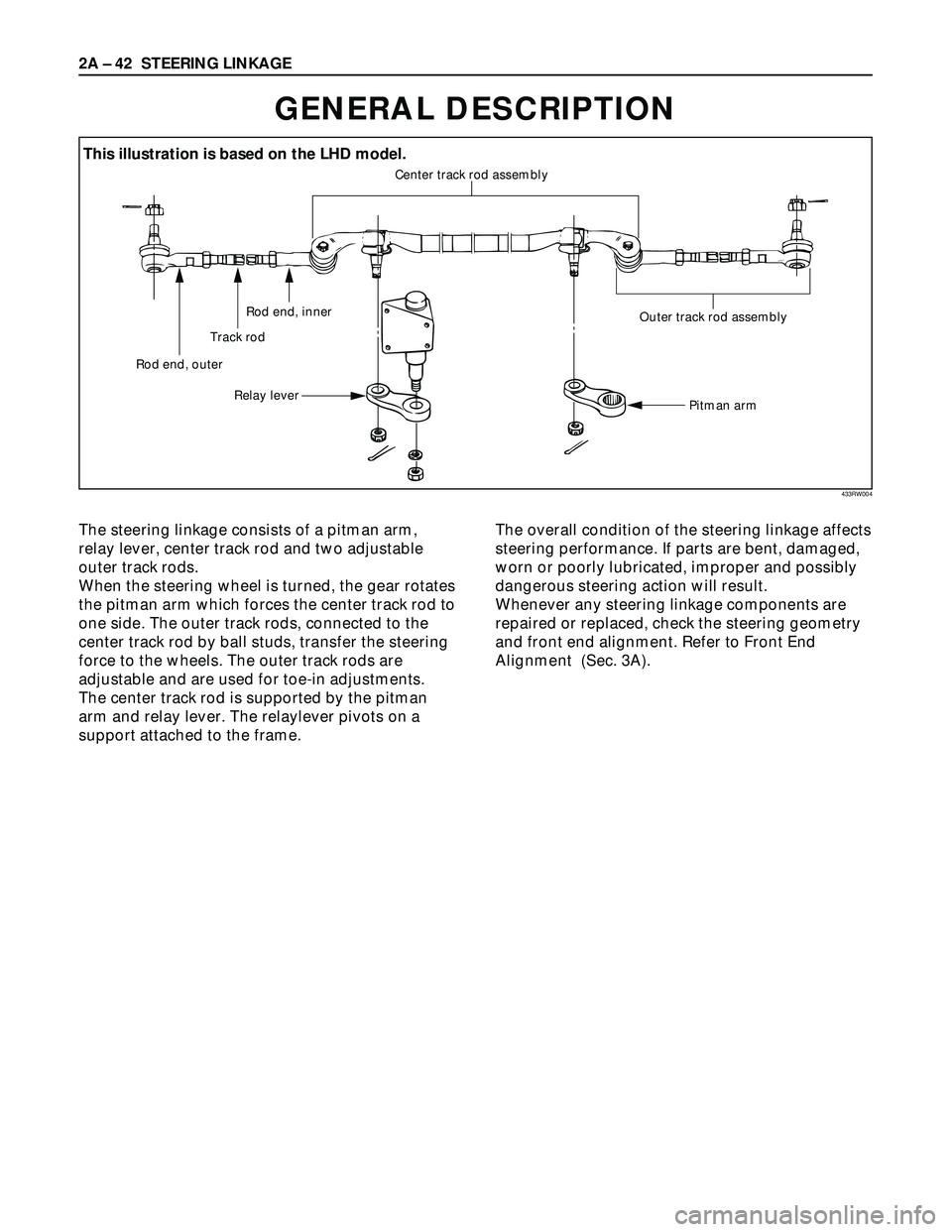

2A – 42 STEERING LINKAGE

GENERAL DESCRIPTION

Center track rod assembly

Rod end, outerTrack rodRod end, inner

Relay lever These steps are based on the LHD model.

Outer track rod assembly

Pitman arm

The steering linkage consists of a pitman arm,

relay lever, center track rod and two adjustable

outer track rods.

When the steering wheel is turned, the gear rotates

the pitman arm which forces the center track rod to

one side. The outer track rods, connected to the

center track rod by ball studs, transfer the steering

force to the wheels. The outer track rods are

adjustable and are used for toe-in adjustments.

The center track rod is supported by the pitman

arm and relay lever. The relaylever pivots on a

support attached to the frame.The overall condition of the steering linkage affects

steering performance. If parts are bent, damaged,

worn or poorly lubricated, improper and possibly

dangerous steering action will result.

Whenever any steering linkage components are

repaired or replaced, check the steering geometry

and front end alignment. Refer to Front End

Alignment (Sec. 3A).

433RW004

This illustration is based on the LHD model.

Page 439 of 3573

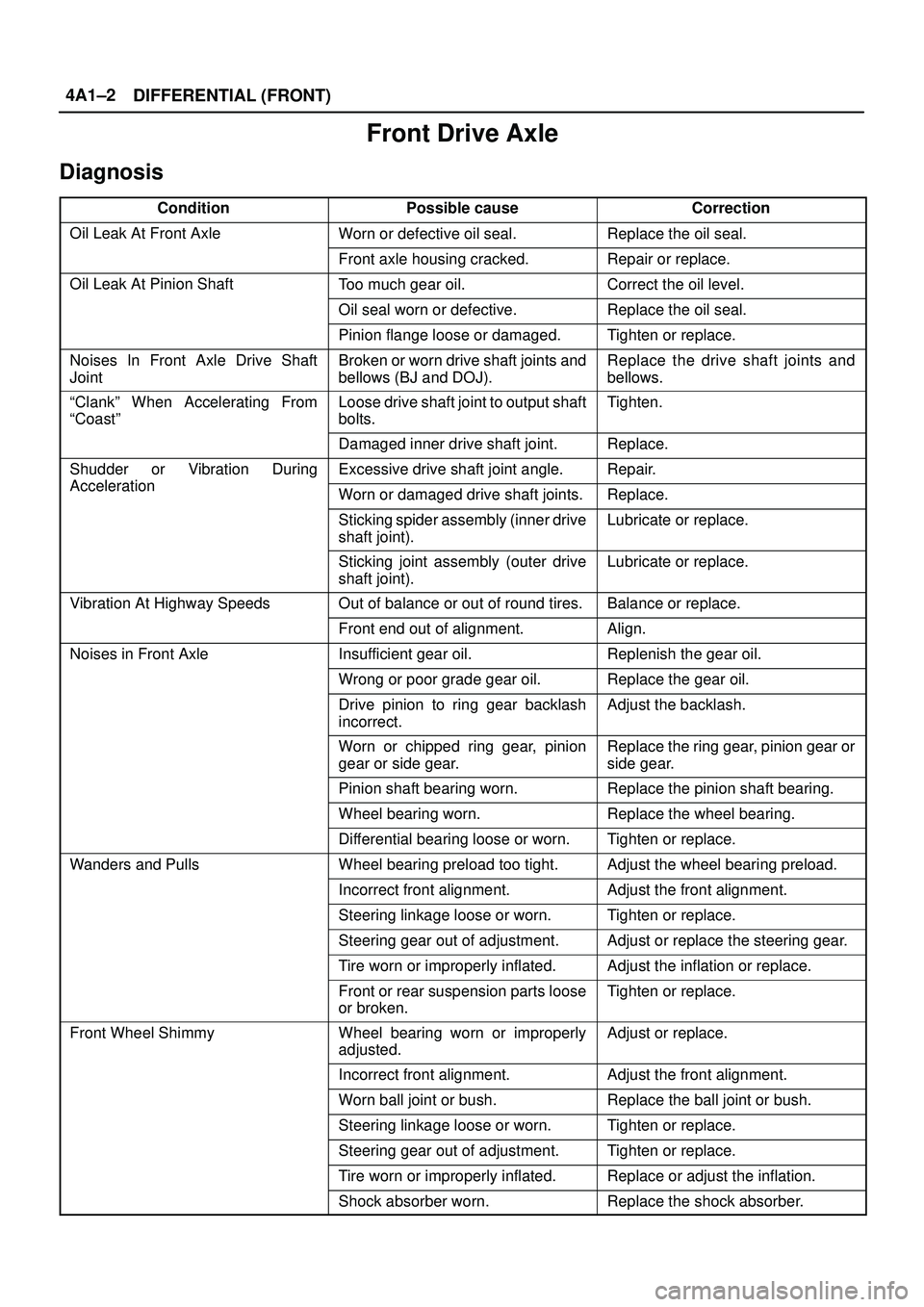

DIFFERENTIAL (FRONT) 4A1±2

Front Drive Axle

Diagnosis

ConditionPossible causeCorrection

Oil Leak At Front AxleWorn or defective oil seal.Replace the oil seal.

Front axle housing cracked.Repair or replace.

Oil Leak At Pinion ShaftToo much gear oil.Correct the oil level.

Oil seal worn or defective.Replace the oil seal.

Pinion flange loose or damaged.Tighten or replace.

Noises In Front Axle Drive Shaft

JointBroken or worn drive shaft joints and

bellows (BJ and DOJ).Replace the drive shaft joints and

bellows.

ªClankº When Accelerating From

ªCoastºLoose drive shaft joint to output shaft

bolts.Tighten.

Damaged inner drive shaft joint.Replace.

Shudder or Vibration During

Acceleration

Excessive drive shaft joint angle.Repair.

AccelerationWorn or damaged drive shaft joints.Replace.

Sticking spider assembly (inner drive

shaft joint).Lubricate or replace.

Sticking joint assembly (outer drive

shaft joint).Lubricate or replace.

Vibration At Highway SpeedsOut of balance or out of round tires.Balance or replace.

Front end out of alignment.Align.

Noises in Front AxleInsufficient gear oil.Replenish the gear oil.

Wrong or poor grade gear oil.Replace the gear oil.

Drive pinion to ring gear backlash

incorrect.Adjust the backlash.

Worn or chipped ring gear, pinion

gear or side gear.Replace the ring gear, pinion gear or

side gear.

Pinion shaft bearing worn.Replace the pinion shaft bearing.

Wheel bearing worn.Replace the wheel bearing.

Differential bearing loose or worn.Tighten or replace.

Wanders and PullsWheel bearing preload too tight.Adjust the wheel bearing preload.

Incorrect front alignment.Adjust the front alignment.

Steering linkage loose or worn.Tighten or replace.

Steering gear out of adjustment.Adjust or replace the steering gear.

Tire worn or improperly inflated.Adjust the inflation or replace.

Front or rear suspension parts loose

or broken.Tighten or replace.

Front Wheel ShimmyWheel bearing worn or improperly

adjusted.Adjust or replace.

Incorrect front alignment.Adjust the front alignment.

Worn ball joint or bush.Replace the ball joint or bush.

Steering linkage loose or worn.Tighten or replace.

Steering gear out of adjustment.Tighten or replace.

Tire worn or improperly inflated.Replace or adjust the inflation.

Shock absorber worn.Replace the shock absorber.

Page 669 of 3573

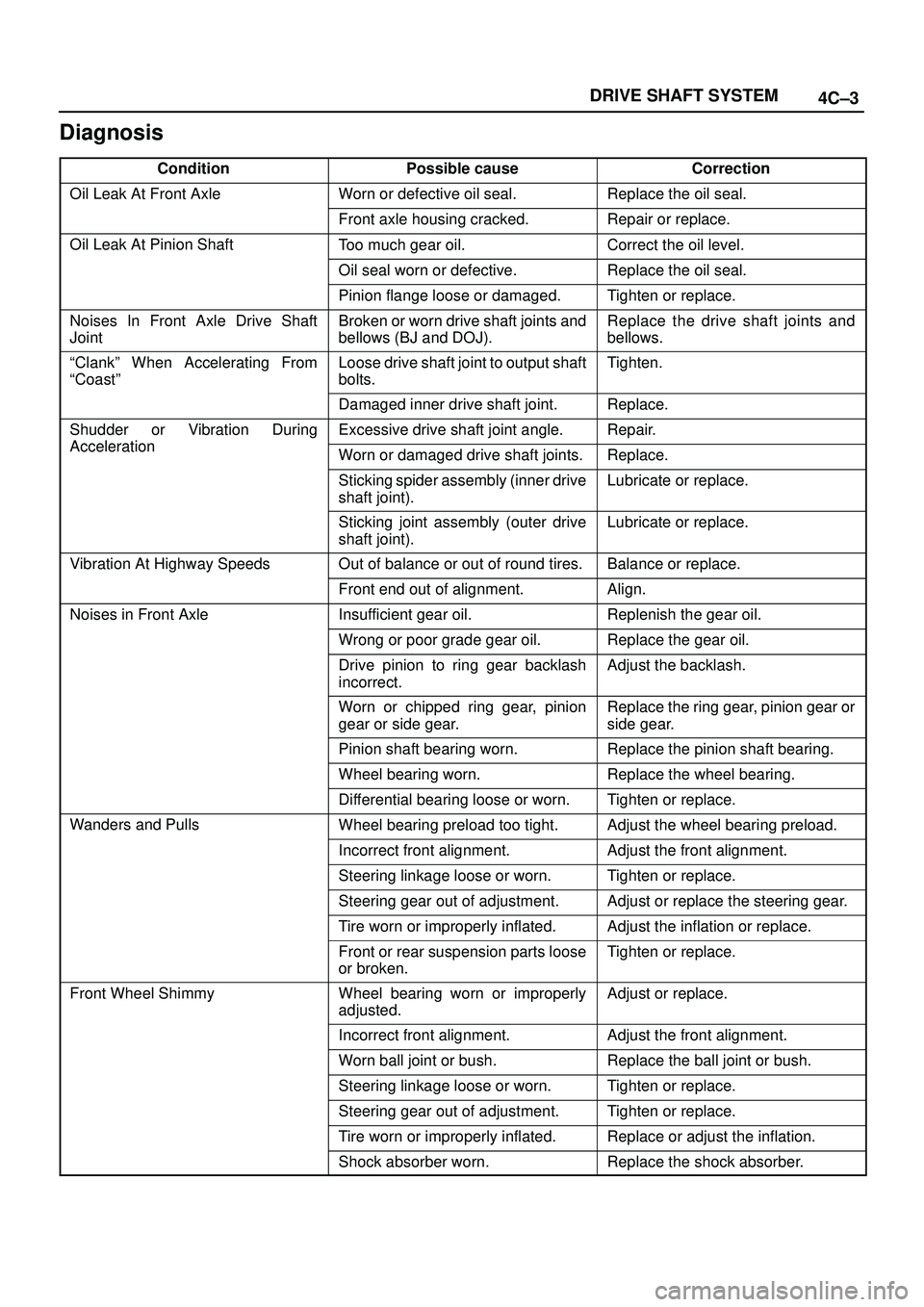

4C±3 DRIVE SHAFT SYSTEM

Diagnosis

ConditionPossible causeCorrection

Oil Leak At Front AxleWorn or defective oil seal.Replace the oil seal.

Front axle housing cracked.Repair or replace.

Oil Leak At Pinion ShaftToo much gear oil.Correct the oil level.

Oil seal worn or defective.Replace the oil seal.

Pinion flange loose or damaged.Tighten or replace.

Noises In Front Axle Drive Shaft

JointBroken or worn drive shaft joints and

bellows (BJ and DOJ).Replace the drive shaft joints and

bellows.

ªClankº When Accelerating From

ªCoastºLoose drive shaft joint to output shaft

bolts.Tighten.

Damaged inner drive shaft joint.Replace.

Shudder or Vibration During

Acceleration

Excessive drive shaft joint angle.Repair.

AccelerationWorn or damaged drive shaft joints.Replace.

Sticking spider assembly (inner drive

shaft joint).Lubricate or replace.

Sticking joint assembly (outer drive

shaft joint).Lubricate or replace.

Vibration At Highway SpeedsOut of balance or out of round tires.Balance or replace.

Front end out of alignment.Align.

Noises in Front AxleInsufficient gear oil.Replenish the gear oil.

Wrong or poor grade gear oil.Replace the gear oil.

Drive pinion to ring gear backlash

incorrect.Adjust the backlash.

Worn or chipped ring gear, pinion

gear or side gear.Replace the ring gear, pinion gear or

side gear.

Pinion shaft bearing worn.Replace the pinion shaft bearing.

Wheel bearing worn.Replace the wheel bearing.

Differential bearing loose or worn.Tighten or replace.

Wanders and PullsWheel bearing preload too tight.Adjust the wheel bearing preload.

Incorrect front alignment.Adjust the front alignment.

Steering linkage loose or worn.Tighten or replace.

Steering gear out of adjustment.Adjust or replace the steering gear.

Tire worn or improperly inflated.Adjust the inflation or replace.

Front or rear suspension parts loose

or broken.Tighten or replace.

Front Wheel ShimmyWheel bearing worn or improperly

adjusted.Adjust or replace.

Incorrect front alignment.Adjust the front alignment.

Worn ball joint or bush.Replace the ball joint or bush.

Steering linkage loose or worn.Tighten or replace.

Steering gear out of adjustment.Tighten or replace.

Tire worn or improperly inflated.Replace or adjust the inflation.

Shock absorber worn.Replace the shock absorber.