tire pressure ISUZU TROOPER 1998 Service Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 1998, Model line: TROOPER, Model: ISUZU TROOPER 1998Pages: 3573, PDF Size: 60.36 MB

Page 30 of 3573

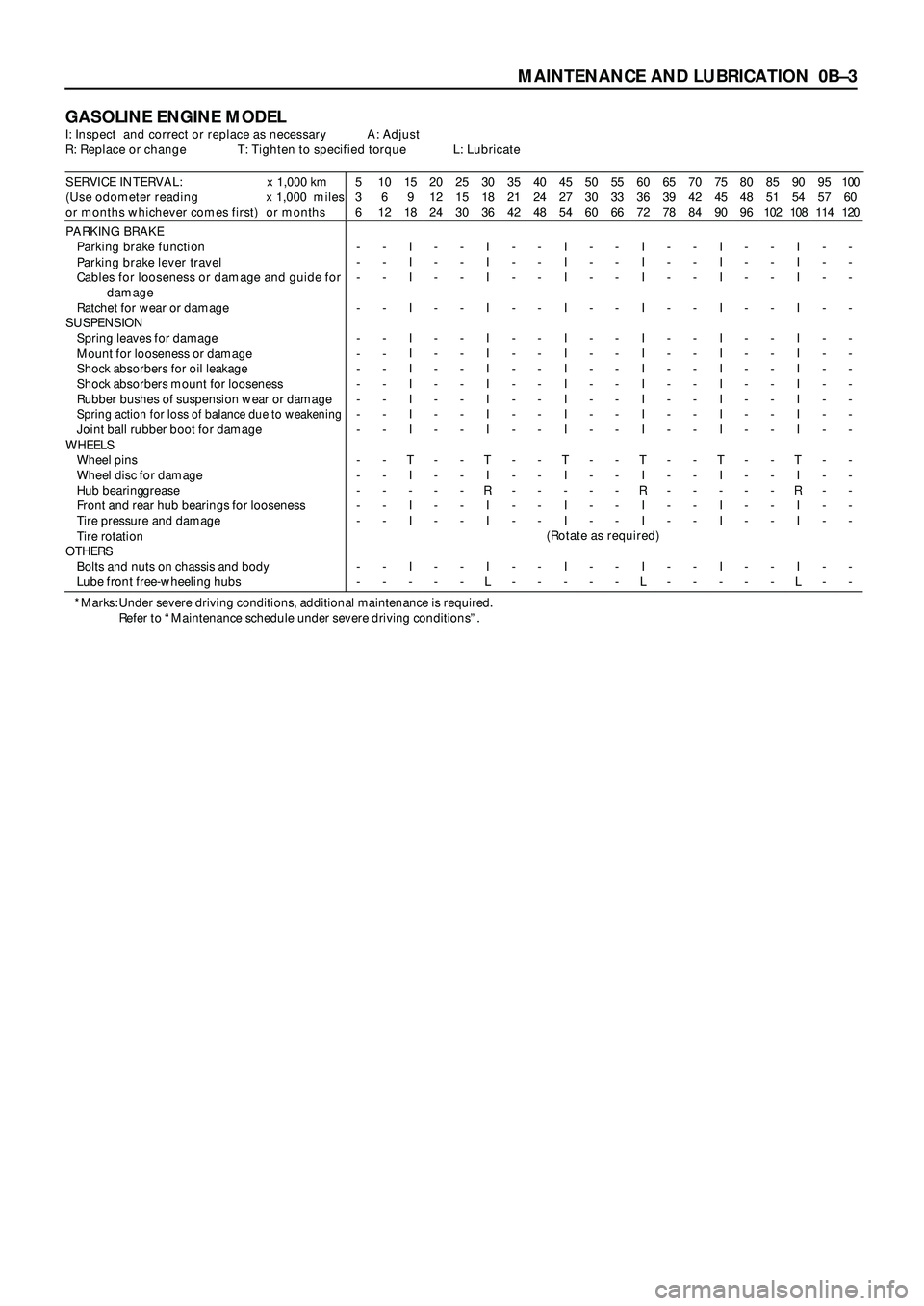

MAINTENANCE AND LUBRICATION 0BÐ3

GASOLINE ENGINE MODELI: Inspect and correct or replace as necessary A: Adjust

R: Replace or change T: Tighten to specified torque L: Lubricate

SERVICE INTERVAL: x 1,000 km

(Use odometer reading x 1,000 miles

or months whichever comes first) or months5

3

610

6

1215

9

1820

12

2425

15

3030

18

3635

21

4240

24

4845

27

5450

30

6055

33

6660

36

7265

39

7870

42

8475

45

9080

48

9685

51

10290

54

10895

57

114100

60

120

PARKING BRAKE

Parking brake function

Parking brake lever travel

Cables for looseness or damage and guide for

damage

Ratchet for wear or damage

SUSPENSION

Spring leaves for damage

Mount for looseness or damage

Shock absorbers for oil leakage

Shock absorbers mount for looseness

Rubber bushes of suspension wear or damage

Spring action for loss of balance due to weakeningJoint ball rubber boot for damage

WHEELS

Wheel pins

Wheel disc for damage

Hub bearing grease

Front and rear hub bearings for looseness

Tire pressure and damage

Tire rotation

OTHERS

Bolts and nuts on chassis and body

Lube front free-wheeling hubs-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

--

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-I

I

I

I

I

I

I

I

I

I

I

T

I

-

I

I

I

--

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

--

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-I

I

I

I

I

I

I

I

I

I

I

T

I

R

I

I

I

L-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

--

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-I

I

I

I

I

I

I

I

I

I

I

T

I

-

I

I

I

--

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

--

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-I

I

I

I

I

I

I

I

I

I

I

T

I

R

I

I

I

L-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

--

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-I

I

I

I

I

I

I

I

I

I

I

T

I

-

I

I

I

--

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

--

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-I

I

I

I

I

I

I

I

I

I

I

T

I

R

I

I

I

L-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

--

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

(Rotate as required)

*Marks: Under severe driving conditions, additional maintenance is required.

Refer to “Maintenance schedule under severe driving conditions”.

Page 32 of 3573

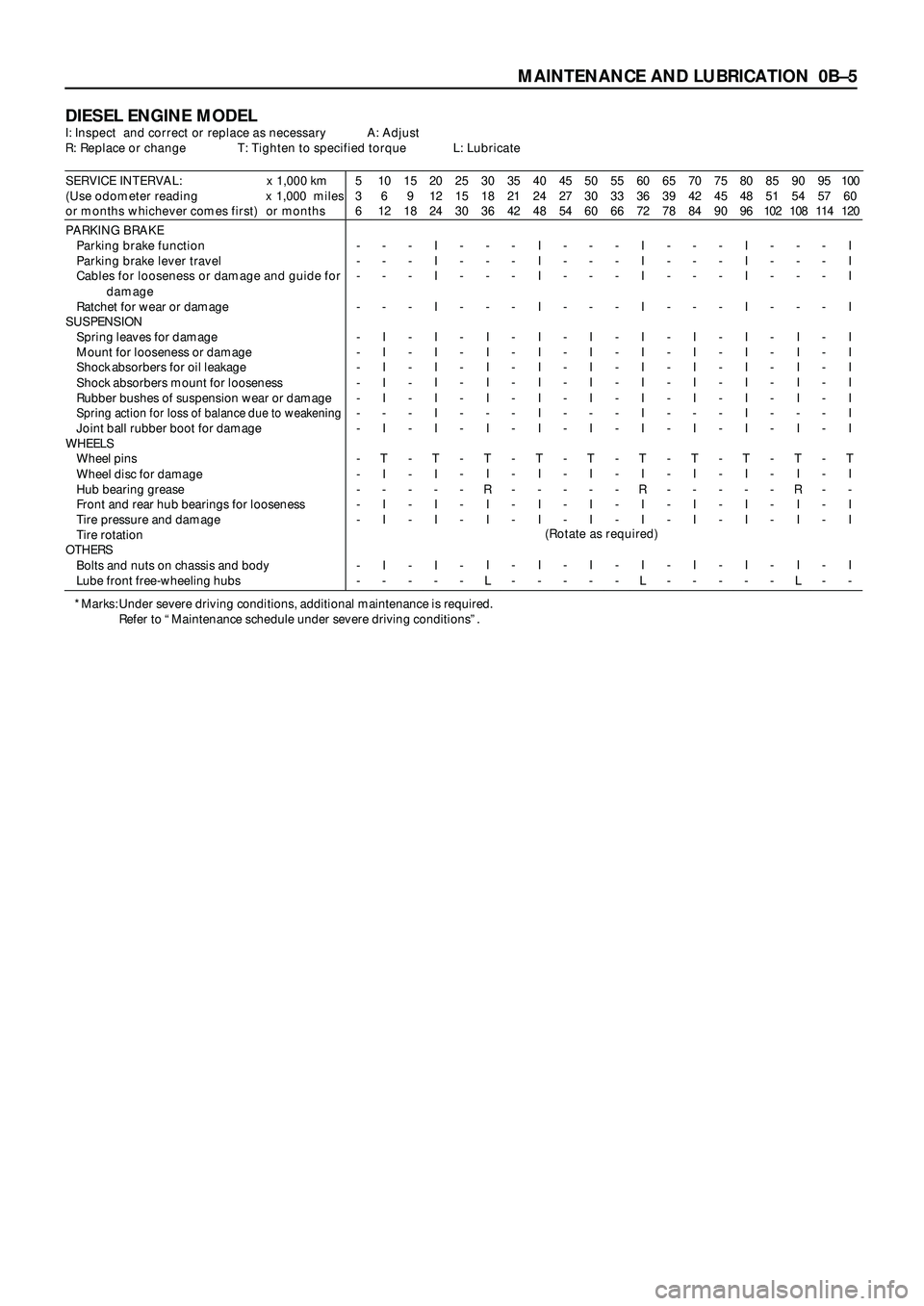

MAINTENANCE AND LUBRICATION 0BÐ5

DIESEL ENGINE MODELI: Inspect and correct or replace as necessary A: Adjust

R: Replace or change T: Tighten to specified torque L: Lubricate

SERVICE INTERVAL: x 1,000 km

(Use odometer reading x 1,000 miles

or months whichever comes first) or months5

3

610

6

1215

9

1820

12

2425

15

3030

18

3635

21

4240

24

4845

27

5450

30

6055

33

6660

36

7265

39

7870

42

8475

45

9080

48

9685

51

10290

54

10895

57

114100

60

120

PARKING BRAKE

Parking brake function

Parking brake lever travel

Cables for looseness or damage and guide for

damage

Ratchet for wear or damage

SUSPENSION

Spring leaves for damage

Mount for looseness or damage

Shock absorbers for oil leakage

Shock absorbers mount for looseness

Rubber bushes of suspension wear or damage

Spring action for loss of balance due to weakeningJoint ball rubber boot for damage

WHEELS

Wheel pins

Wheel disc for damage

Hub bearing grease

Front and rear hub bearings for looseness

Tire pressure and damage

Tire rotation

OTHERS

Bolts and nuts on chassis and body

Lube front free-wheeling hubs-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

--

-

-

-

I

I

I

I

I

-

I

T

I

-

I

I

I

--

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-I

I

I

I

I

I

I

I

I

I

I

T

I

-

I

I

I

--

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

--

-

-

-

I

I

I

I

I

-

I

T

I

R

I

I

I

L-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-I

I

I

I

I

I

I

I

I

I

I

T

I

-

I

I

I

--

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

--

-

-

-

I

I

I

I

I

-

I

T

I

-

I

I

I

--

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-I

I

I

I

I

I

I

I

I

I

I

T

I

R

I

I

I

L-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

--

-

-

-

I

I

I

I

I

-

I

T

I

-

I

I

I

--

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-I

I

I

I

I

I

I

I

I

I

I

T

I

-

I

I

I

--

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

--

-

-

-

I

I

I

I

I

-

I

T

I

R

I

I

I

L-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-I

I

I

I

I

I

I

I

I

I

I

T

I

-

I

I

I

-

(Rotate as required)

*Marks: Under severe driving conditions, additional maintenance is required.

Refer to “Maintenance schedule under severe driving conditions”.

Page 286 of 3573

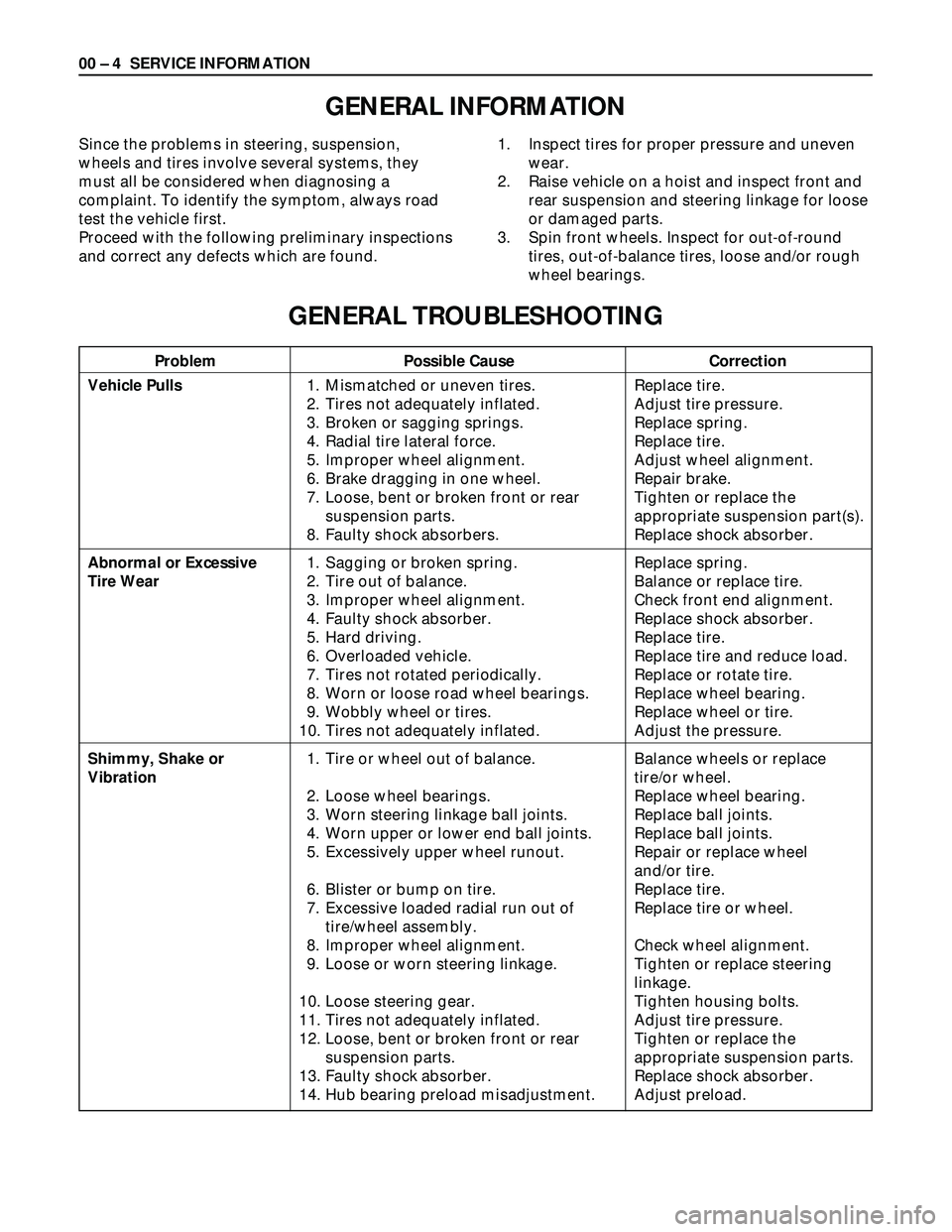

Problem Possible Cause Correction

00 – 4 SERVICE INFORMATION

GENERAL INFORMATION

Since the problems in steering, suspension,

wheels and tires involve several systems, they

must all be considered when diagnosing a

complaint. To identify the symptom, always road

test the vehicle first.

Proceed with the following preliminary inspections

and correct any defects which are found.1. Inspect tires for proper pressure and uneven

wear.

2. Raise vehicle on a hoist and inspect front and

rear suspension and steering linkage for loose

or damaged parts.

3. Spin front wheels. Inspect for out-of-round

tires, out-of-balance tires, loose and/or rough

wheel bearings.

GENERAL TROUBLESHOOTING

Vehicle Pulls

Abnormal or Excessive

Tire Wear

Shimmy, Shake or

Vibration1. Mismatched or uneven tires.

2. Tires not adequately inflated.

3. Broken or sagging springs.

4. Radial tire lateral force.

5. Improper wheel alignment.

6. Brake dragging in one wheel.

7. Loose, bent or broken front or rear

suspension parts.

8. Faulty shock absorbers.

1. Sagging or broken spring.

2. Tire out of balance.

3. Improper wheel alignment.

4. Faulty shock absorber.

5. Hard driving.

6. Overloaded vehicle.

7. Tires not rotated periodically.

8. Worn or loose road wheel bearings.

9. Wobbly wheel or tires.

10. Tires not adequately inflated.

1. Tire or wheel out of balance.

2. Loose wheel bearings.

3. Worn steering linkage ball joints.

4. Worn upper or lower end ball joints.

5. Excessively upper wheel runout.

6. Blister or bump on tire.

7. Excessive loaded radial run out of

tire/wheel assembly.

8. Improper wheel alignment.

9. Loose or worn steering linkage.

10. Loose steering gear.

11. Tires not adequately inflated.

12. Loose, bent or broken front or rear

suspension parts.

13. Faulty shock absorber.

14. Hub bearing preload misadjustment.Replace tire.

Adjust tire pressure.

Replace spring.

Replace tire.

Adjust wheel alignment.

Repair brake.

Tighten or replace the

appropriate suspension part(s).

Replace shock absorber.

Replace spring.

Balance or replace tire.

Check front end alignment.

Replace shock absorber.

Replace tire.

Replace tire and reduce load.

Replace or rotate tire.

Replace wheel bearing.

Replace wheel or tire.

Adjust the pressure.

Balance wheels or replace

tire/or wheel.

Replace wheel bearing.

Replace ball joints.

Replace ball joints.

Repair or replace wheel

and/or tire.

Replace tire.

Replace tire or wheel.

Check wheel alignment.

Tighten or replace steering

linkage.

Tighten housing bolts.

Adjust tire pressure.

Tighten or replace the

appropriate suspension parts.

Replace shock absorber.

Adjust preload.

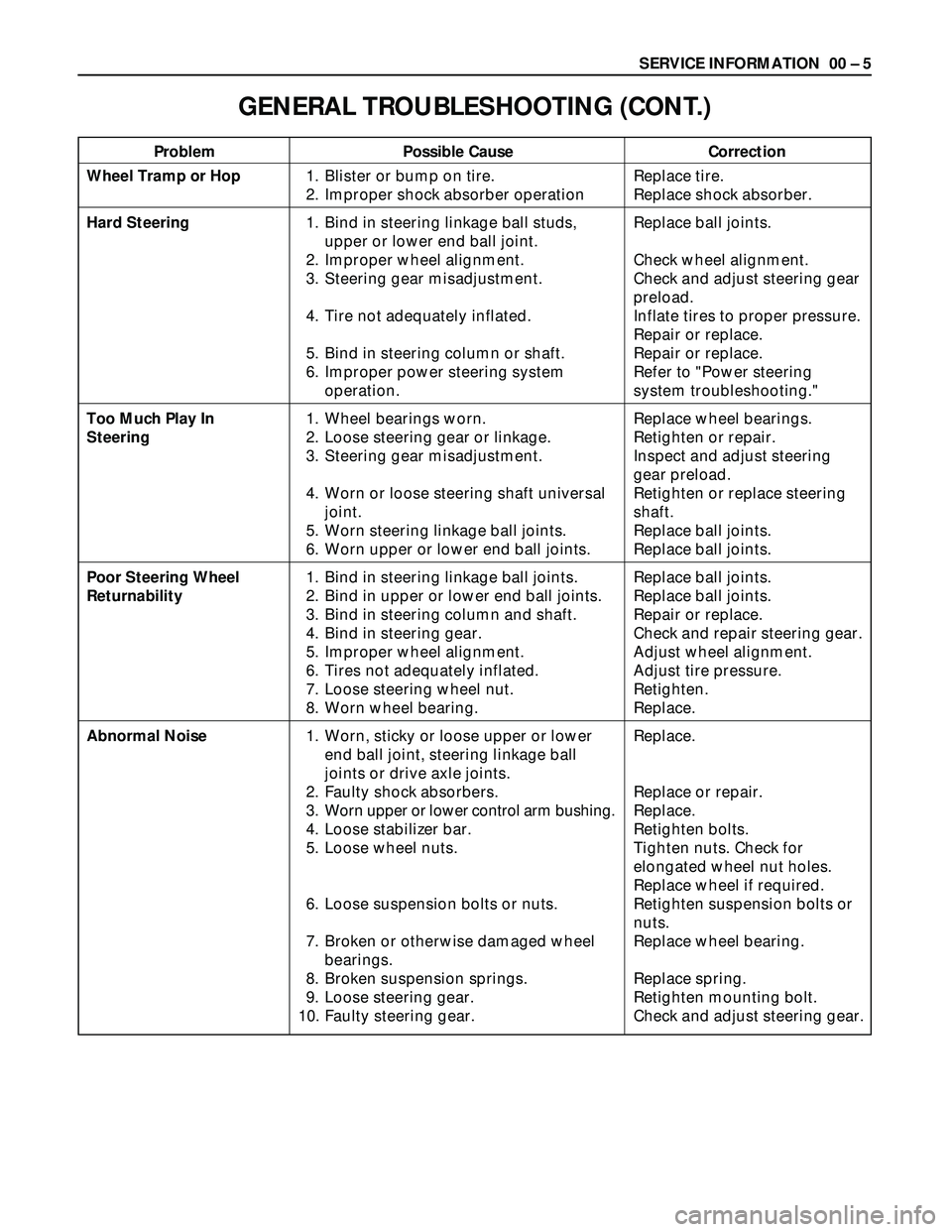

Page 287 of 3573

SERVICE INFORMATION 00 – 5

Problem Possible Cause Correction

GENERAL TROUBLESHOOTING (CONT.)

Wheel Tramp or Hop

Hard Steering

Too Much Play In

Steering

Poor Steering Wheel

Returnability

Abnormal Noise1. Blister or bump on tire.

2. Improper shock absorber operation

1. Bind in steering linkage ball studs,

upper or lower end ball joint.

2. Improper wheel alignment.

3. Steering gear misadjustment.

4. Tire not adequately inflated.

5. Bind in steering column or shaft.

6. Improper power steering system

operation.

1. Wheel bearings worn.

2. Loose steering gear or linkage.

3. Steering gear misadjustment.

4. Worn or loose steering shaft universal

joint.

5. Worn steering linkage ball joints.

6. Worn upper or lower end ball joints.

1. Bind in steering linkage ball joints.

2. Bind in upper or lower end ball joints.

3. Bind in steering column and shaft.

4. Bind in steering gear.

5. Improper wheel alignment.

6. Tires not adequately inflated.

7. Loose steering wheel nut.

8. Worn wheel bearing.

1. Worn, sticky or loose upper or lower

end ball joint, steering linkage ball

joints or drive axle joints.

2. Faulty shock absorbers.

3. Worn upper or lower control arm bushing.

4. Loose stabilizer bar.

5. Loose wheel nuts.

6. Loose suspension bolts or nuts.

7. Broken or otherwise damaged wheel

bearings.

8. Broken suspension springs.

9. Loose steering gear.

10. Faulty steering gear.Replace tire.

Replace shock absorber.

Replace ball joints.

Check wheel alignment.

Check and adjust steering gear

preload.

Inflate tires to proper pressure.

Repair or replace.

Repair or replace.

Refer to "Power steering

system troubleshooting."

Replace wheel bearings.

Retighten or repair.

Inspect and adjust steering

gear preload.

Retighten or replace steering

shaft.

Replace ball joints.

Replace ball joints.

Replace ball joints.

Replace ball joints.

Repair or replace.

Check and repair steering gear.

Adjust wheel alignment.

Adjust tire pressure.

Retighten.

Replace.

Replace.

Replace or repair.

Replace.

Retighten bolts.

Tighten nuts. Check for

elongated wheel nut holes.

Replace wheel if required.

Retighten suspension bolts or

nuts.

Replace wheel bearing.

Replace spring.

Retighten mounting bolt.

Check and adjust steering gear.

Page 288 of 3573

00 – 6 SERVICE INFORMATION

Problem Possible Cause Correction

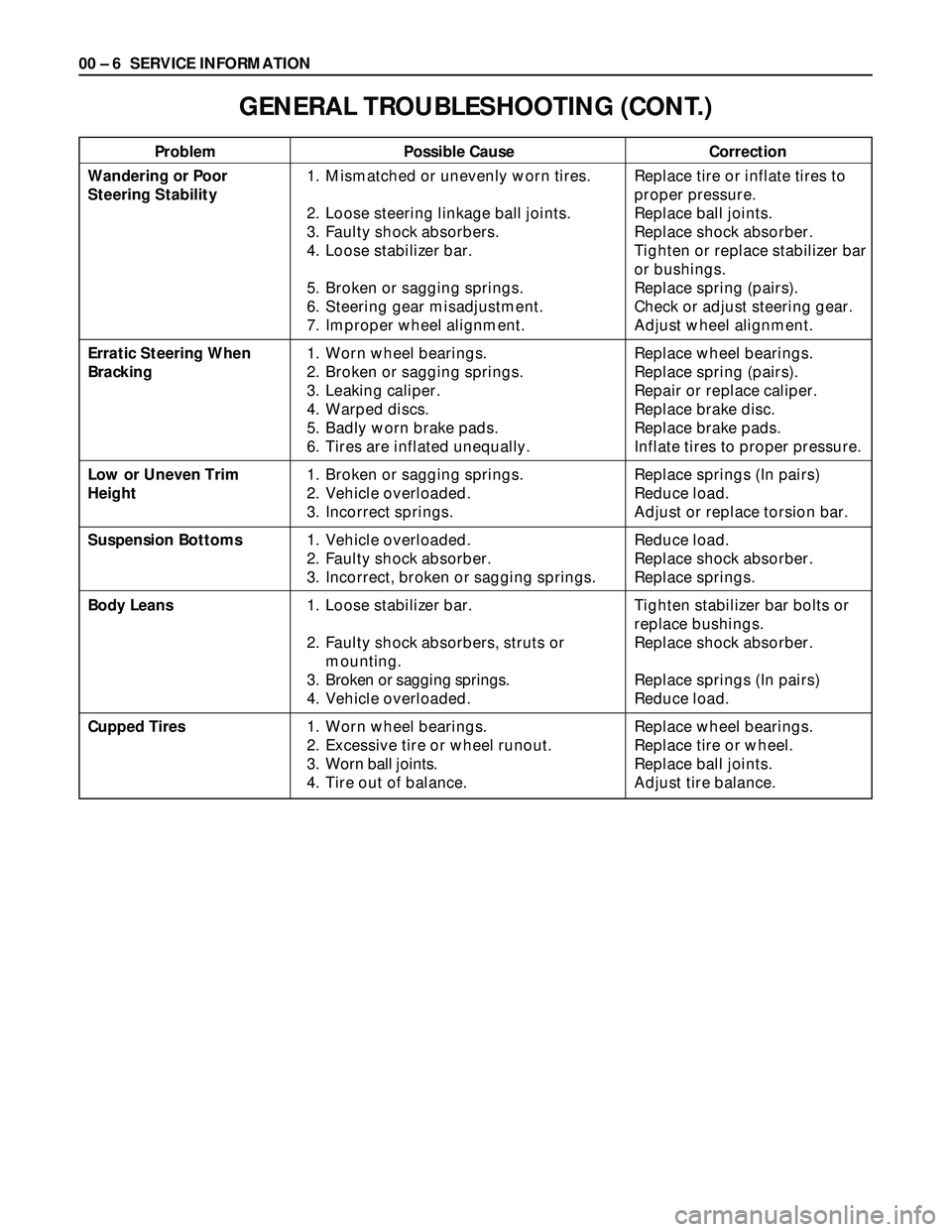

GENERAL TROUBLESHOOTING (CONT.)

Wandering or Poor

Steering Stability

Erratic Steering When

Bracking

Low or Uneven Trim

Height

Suspension Bottoms

Body Leans

Cupped Tires1. Mismatched or unevenly worn tires.

2. Loose steering linkage ball joints.

3. Faulty shock absorbers.

4. Loose stabilizer bar.

5. Broken or sagging springs.

6. Steering gear misadjustment.

7. Improper wheel alignment.

1. Worn wheel bearings.

2. Broken or sagging springs.

3. Leaking caliper.

4. Warped discs.

5. Badly worn brake pads.

6. Tires are inflated unequally.

1. Broken or sagging springs.

2. Vehicle overloaded.

3. Incorrect springs.

1. Vehicle overloaded.

2. Faulty shock absorber.

3. Incorrect, broken or sagging springs.

1. Loose stabilizer bar.

2. Faulty shock absorbers, struts or

mounting.

3. Broken or sagging springs.

4. Vehicle overloaded.

1. Worn wheel bearings.

2. Excessive tire or wheel runout.

3. Worn ball joints.

4. Tire out of balance.Replace tire or inflate tires to

proper pressure.

Replace ball joints.

Replace shock absorber.

Tighten or replace stabilizer bar

or bushings.

Replace spring (pairs).

Check or adjust steering gear.

Adjust wheel alignment.

Replace wheel bearings.

Replace spring (pairs).

Repair or replace caliper.

Replace brake disc.

Replace brake pads.

Inflate tires to proper pressure.

Replace springs (In pairs)

Reduce load.

Adjust or replace torsion bar.

Reduce load.

Replace shock absorber.

Replace springs.

Tighten stabilizer bar bolts or

replace bushings.

Replace shock absorber.

Replace springs (In pairs)

Reduce load.

Replace wheel bearings.

Replace tire or wheel.

Replace ball joints.

Adjust tire balance.

Page 305 of 3573

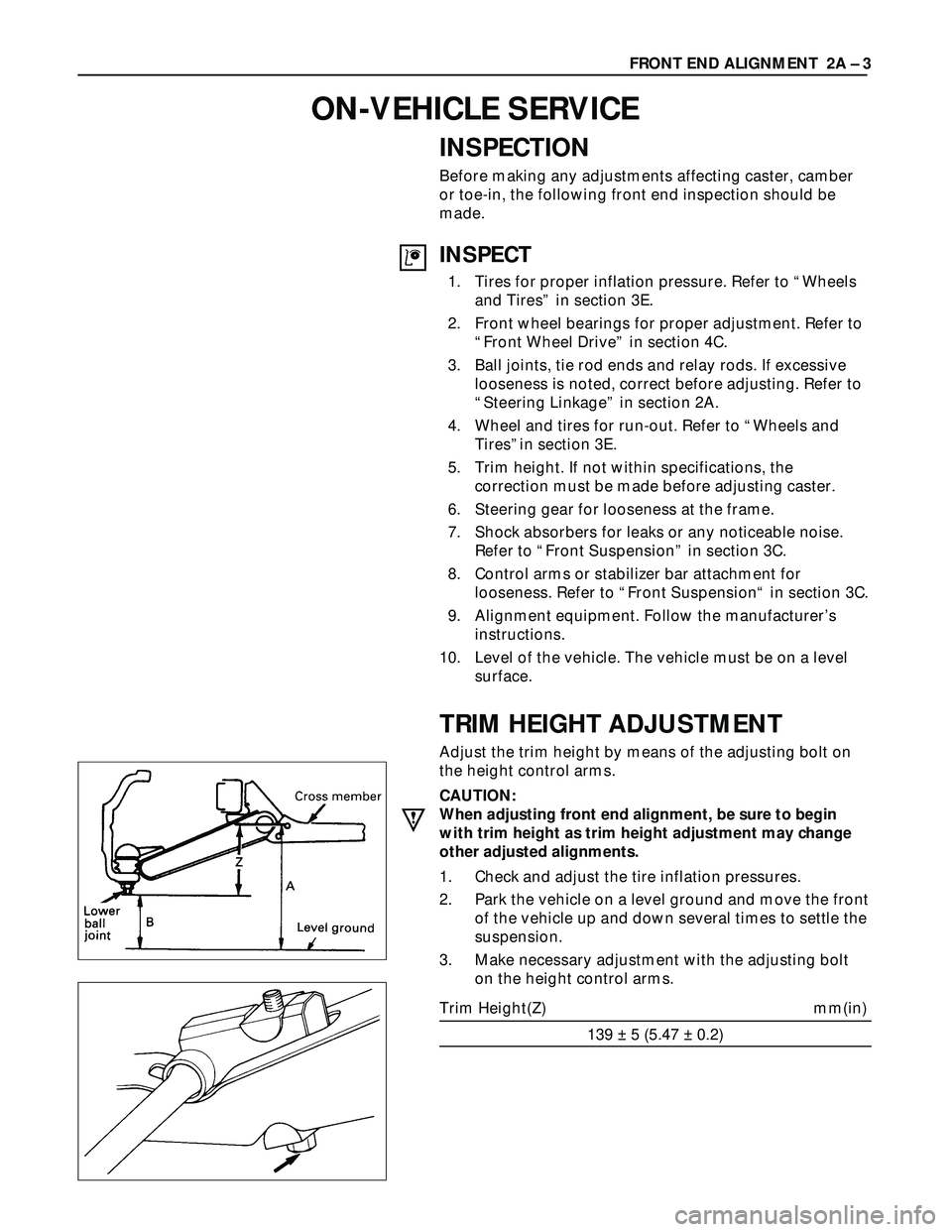

INSPECTION

Before making any adjustments affecting caster, camber

or toe-in, the following front end inspection should be

made.

INSPECT

1. Tires for proper inflation pressure. Refer to “Wheels

and Tires” in section 3E.

2. Front wheel bearings for proper adjustment. Refer to

“Front Wheel Drive” in section 4C.

3. Ball joints, tie rod ends and relay rods. If excessive

looseness is noted, correct before adjusting. Refer to

“Steering Linkage” in section 2A.

4. Wheel and tires for run-out. Refer to “Wheels and

Tires”in section 3E.

5. Trim height. If not within specifications, the

correction must be made before adjusting caster.

6. Steering gear for looseness at the frame.

7. Shock absorbers for leaks or any noticeable noise.

Refer to “Front Suspension” in section 3C.

8. Control arms or stabilizer bar attachment for

looseness. Refer to “Front Suspension“ in section 3C.

9. Alignment equipment. Follow the manufacturer’s

instructions.

10. Level of the vehicle. The vehicle must be on a level

surface.

TRIM HEIGHT ADJUSTMENT

Adjust the trim height by means of the adjusting bolt on

the height control arms.

CAUTION:

When adjusting front end alignment, be sure to begin

with trim height as trim height adjustment may change

other adjusted alignments.

1. Check and adjust the tire inflation pressures.

2. Park the vehicle on a level ground and move the front

of the vehicle up and down several times to settle the

suspension.

3. Make necessary adjustment with the adjusting bolt

on the height control arms.

Trim Height(Z) mm(in)

139 ± 5 (5.47 ± 0.2)FRONT END ALIGNMENT 2A – 3

ON-VEHICLE SERVICE

Page 433 of 3573

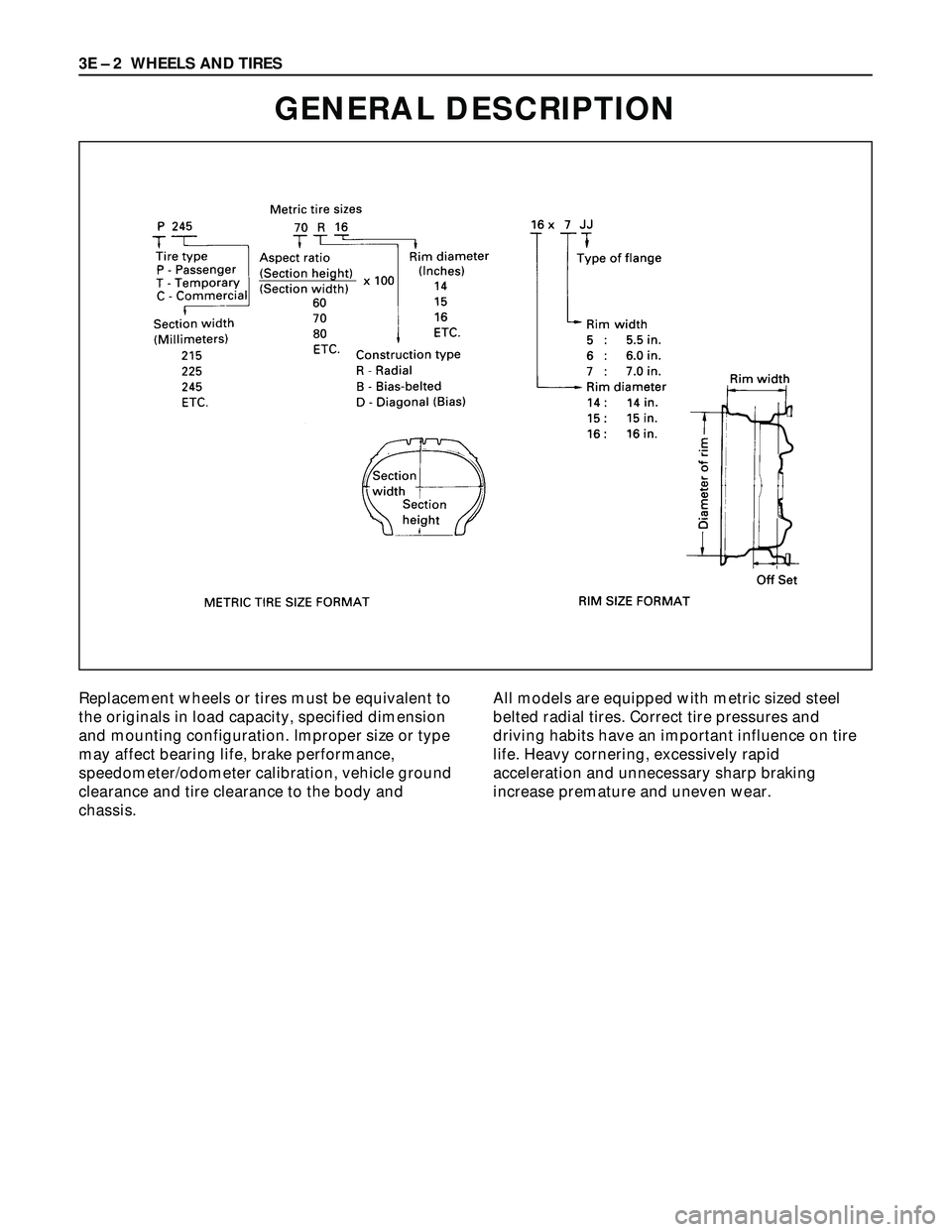

3E – 2 WHEELS AND TIRES

GENERAL DESCRIPTION

Replacement wheels or tires must be equivalent to

the originals in load capacity, specified dimension

and mounting configuration. Improper size or type

may affect bearing life, brake performance,

speedometer/odometer calibration, vehicle ground

clearance and tire clearance to the body and

chassis.All models are equipped with metric sized steel

belted radial tires. Correct tire pressures and

driving habits have an important influence on tire

life. Heavy cornering, excessively rapid

acceleration and unnecessary sharp braking

increase premature and uneven wear.

Page 435 of 3573

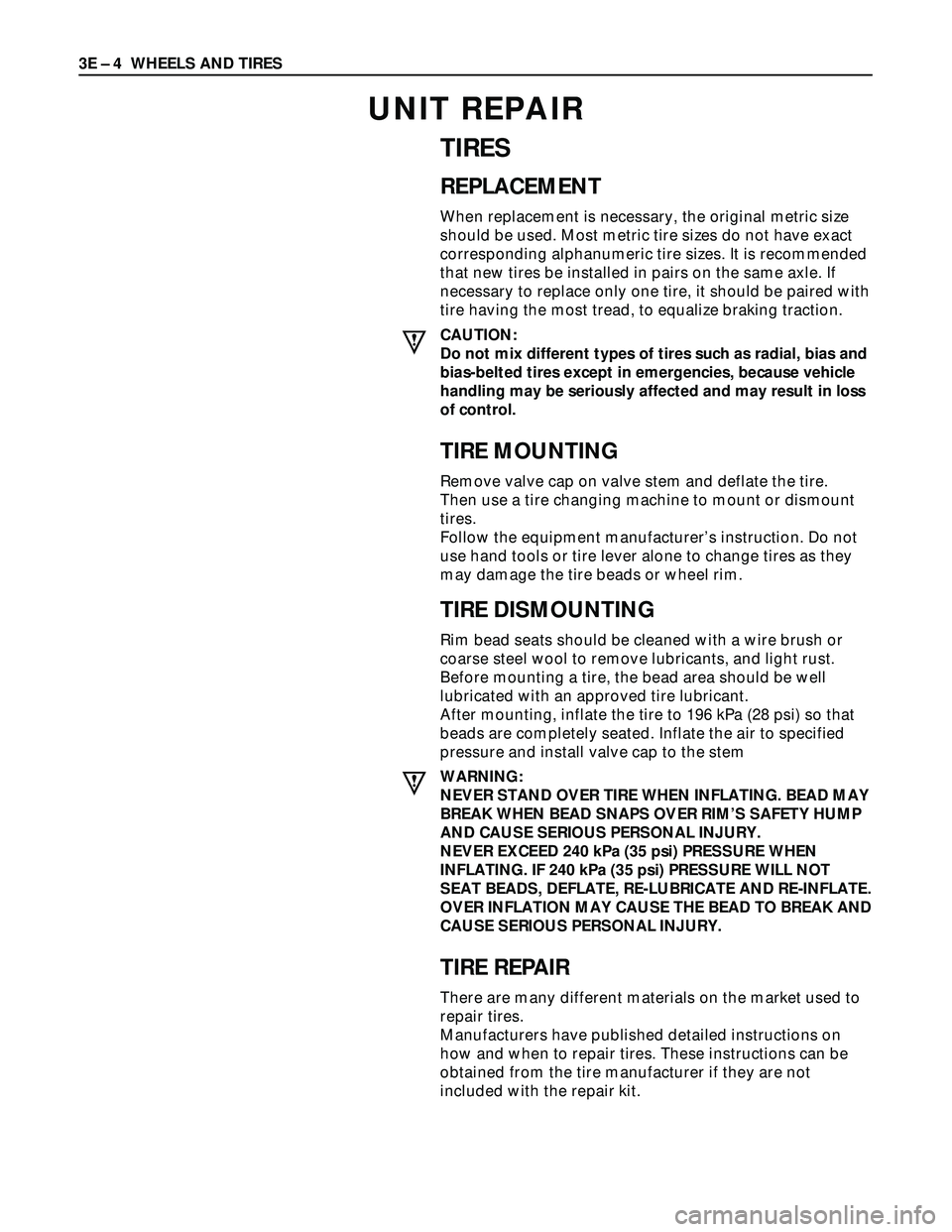

3E – 4 WHEELS AND TIRES

TIRES

REPLACEMENT

When replacement is necessary, the original metric size

should be used. Most metric tire sizes do not have exact

corresponding alphanumeric tire sizes. It is recommended

that new tires be installed in pairs on the same axle. If

necessary to replace only one tire, it should be paired with

tire having the most tread, to equalize braking traction.

CAUTION:

Do not mix different types of tires such as radial, bias and

bias-belted tires except in emergencies, because vehicle

handling may be seriously affected and may result in loss

of control.

TIRE MOUNTING

Remove valve cap on valve stem and deflate the tire.

Then use a tire changing machine to mount or dismount

tires.

Follow the equipment manufacturer’s instruction. Do not

use hand tools or tire lever alone to change tires as they

may damage the tire beads or wheel rim.

TIRE DISMOUNTING

Rim bead seats should be cleaned with a wire brush or

coarse steel wool to remove lubricants, and light rust.

Before mounting a tire, the bead area should be well

lubricated with an approved tire lubricant.

After mounting, inflate the tire to 196 kPa (28 psi) so that

beads are completely seated. Inflate the air to specified

pressure and install valve cap to the stem

WARNING:

NEVER STAND OVER TIRE WHEN INFLATING. BEAD MAY

BREAK WHEN BEAD SNAPS OVER RIM’S SAFETY HUMP

AND CAUSE SERIOUS PERSONAL INJURY.

NEVER EXCEED 240 kPa (35 psi) PRESSURE WHEN

INFLATING. IF 240 kPa (35 psi) PRESSURE WILL NOT

SEAT BEADS, DEFLATE, RE-LUBRICATE AND RE-INFLATE.

OVER INFLATION MAY CAUSE THE BEAD TO BREAK AND

CAUSE SERIOUS PERSONAL INJURY.

TIRE REPAIR

There are many different materials on the market used to

repair tires.

Manufacturers have published detailed instructions on

how and when to repair tires. These instructions can be

obtained from the tire manufacturer if they are not

included with the repair kit.

UNIT REPAIR

Page 436 of 3573

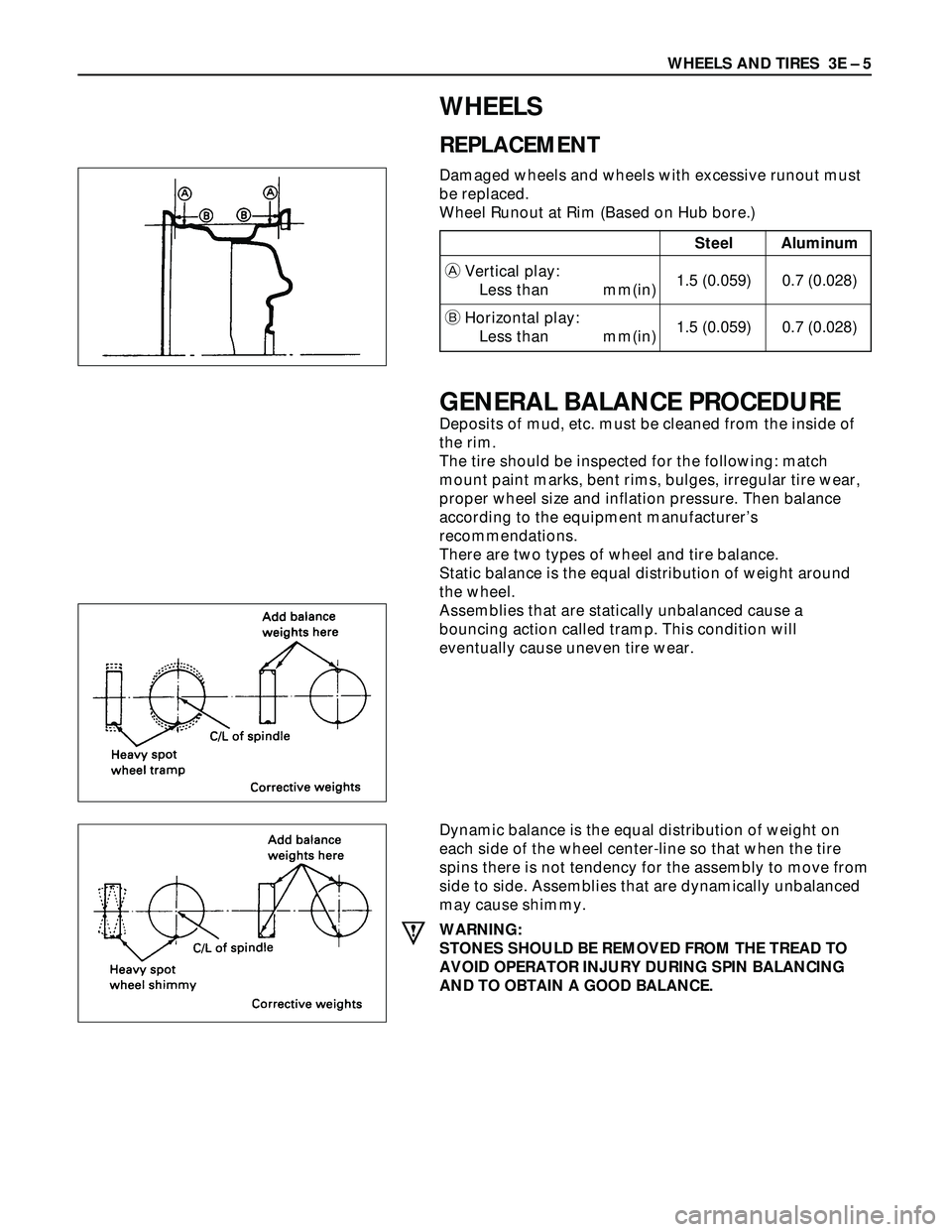

WHEELS AND TIRES 3E – 5

WHEELS

REPLACEMENT

Damaged wheels and wheels with excessive runout must

be replaced.

Wheel Runout at Rim (Based on Hub bore.)

GENERAL BALANCE PROCEDURE

Deposits of mud, etc. must be cleaned from the inside of

the rim.

The tire should be inspected for the following: match

mount paint marks, bent rims, bulges, irregular tire wear,

proper wheel size and inflation pressure. Then balance

according to the equipment manufacturer’s

recommendations.

There are two types of wheel and tire balance.

Static balance is the equal distribution of weight around

the wheel.

Assemblies that are statically unbalanced cause a

bouncing action called tramp. This condition will

eventually cause uneven tire wear.

Dynamic balance is the equal distribution of weight on

each side of the wheel center-line so that when the tire

spins there is not tendency for the assembly to move from

side to side. Assemblies that are dynamically unbalanced

may cause shimmy.

WARNING:

STONES SHOULD BE REMOVED FROM THE TREAD TO

AVOID OPERATOR INJURY DURING SPIN BALANCING

AND TO OBTAIN A GOOD BALANCE.

Steel Aluminum

AVertical play:

Less than mm(in)1.5 (0.059) 0.7 (0.028)

BHorizontal play:

Less than mm(in)1.5 (0.059) 0.7 (0.028)

Page 470 of 3573

DIFFERENTIAL (REAR 220mm)

4A2A±3

Diagnosis

Many noises that seem to come from the rear axle

actually originate from other sources such as tires, road

surface, wheel bearings, engine, transmission, muffler, or

body drumming. Investigate to find the source of the

noise before disassembling the rear axle. Rear axles, like

any other mechanical device, are not absolutely quiet but

should be considered quiet unless some abnormal noise

is present.

To make a systematic check for axle noise, observe the

following:

1. Select a level asphalt road to reduce tire noise and

body drumming.

2. Check rear axle lubricant level to assure correct level,

and then drive the vehicle far enough to thoroughly

warm up the rear axle lubricant.

3. Note the speed at which noise occurs. Stop the

vehicle and put the transmission in neutral. Run the

engine speed slowly up and down to determine if the

noise is caused by exhaust, muffler noise, or other

engine conditions.

4. Tire noise changes with different road surfaces; axle

noises do not. Temporarily inflate all tires to 344 kPa

(3.5kg/cm

2, 50 psi) (for test purposes only). This will

change noise caused by tires but will not affect noise

caused by the rear axle.

Rear axle noise usually stops when coasting at

speeds under 48 km/h (30 mph); however, tire noise

continues with a lower tone. Rear axle noise usually

changes when comparing pull and coast, but tire

noise stays about the same.

Distinguish between tire noise and rear axle noise by

noting if the noise changes with various speeds or

sudden acceleration and deceleration. Exhaust and

axle noise vary under these conditions, while tire

noise remains constant and is more pronounced at

speeds of 32 to 48 km/h (20 to 30 mph). Further check

for tire noise by driving the vehicle over smooth

pavements or dirt roads (not gravel) with the tires at

normal pressure. If the noise is caused by tires, it will

change noticeably with changes in road surface.

5. Loose or rough front wheel bearings will cause noise

which may be confused with rear axle noise; however,

front wheel bearing noise does not change when

comparing drive and coast. Light application of the

brake while holding vehicle speed steady will often

cause wheel bearing noise to diminish. Front wheel

bearings may be checked for noise by jacking up the

wheels and spinning them or by shaking the wheels to

determine if bearings are loose.

6. Rear suspension rubber bushings and spring

insulators dampen out rear axle noise when correctly

installed. Check to see that there is no link or rod

loosened or metal±to±metal contact.

7. Make sure that there is no metal±to±metal contact

between the floor and the frame.

After the noise has been determined to be in the axle, the

type of axle noise should be determined, in order to make

any necessary repairs.

Gear Noise

Gear noise (whine) is audible from 32 to 89 km/h (20 to 55

mph) under four driving conditions.

1. Driving under acceleration or heavy pull.

2. Driving under load or under constant speed.

3. When using enough throttle to keep the vehicle from

driving the engine while the vehicle slows down

gradually (engine still pulls slightly).

4. When coasting with the vehicle in gear and the throttle

closed. The gear noise is usually more noticeable

between 48 and 64 km/h (30 and 40 mph) and 80 and

89 km/h (50 and 55 mph).

Bearing Noise

Bad bearings generally produce a rough growl or grating

sound, rather than the whine typical of gear noise.

Bearing noise frequently ªwow±wowsº at bearing rpm,

indicating a bad pinion or rear axle side bearing. This

noise can be confused with rear wheel bearing noise.

Rear Wheel Bearing Noise

Rear wheel bearing noise continues to be heard while

coasting at low speed with transmission in neutral. Noise

may diminish by gentle braking. Jack up the rear wheels,

spin them by hand and listen for noise at the hubs.

Replace any faulty wheel bearings.

Knock At Low Speeds

Low speed knock can be caused by worn universal joints

or a side gear hub counter bore in the cage that is worn

oversize. Inspect and replace universal joints or cage and

side gears as required.

Backlash Clunk

Excessive clunk on acceleration and deceleration can be

caused by a worn rear axle pinion shaft, a worn cage,

excessive clearance between the axle and the side gear

splines, excessive clearance between the side gear hub

and the counterbore in the cage, worn pinion and side

gear teeth, worn thrust washers, or excessive drive pinion

and ring gear backlash. Remove worn parts and replace

as required. Select close±fitting parts when possible.

Adjust pinion and ring gear backlash.