transmission fluid ISUZU TROOPER 1998 Service Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 1998, Model line: TROOPER, Model: ISUZU TROOPER 1998Pages: 3573, PDF Size: 60.36 MB

Page 29 of 3573

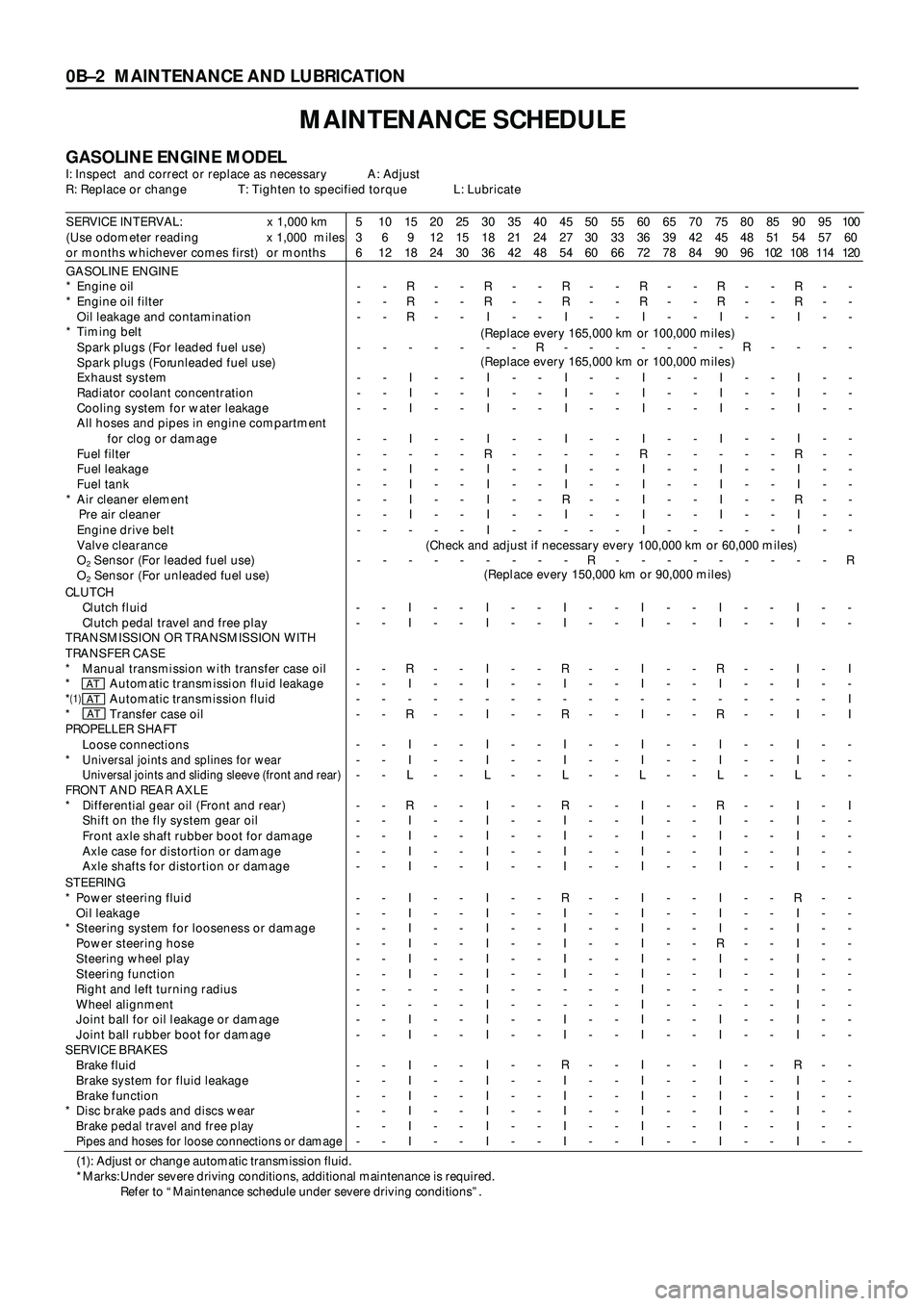

0BÐ2 MAINTENANCE AND LUBRICATION

MAINTENANCE SCHEDULE

GASOLINE ENGINE MODELI: Inspect and correct or replace as necessary A: Adjust

R: Replace or change T: Tighten to specified torque L: Lubricate

SERVICE INTERVAL: x 1,000 km

(Use odometer reading x 1,000 miles

or months whichever comes first) or months5

3

610

6

1215

9

1820

12

2425

15

3030

18

3635

21

4240

24

4845

27

5450

30

6055

33

6660

36

7265

39

7870

42

8475

45

9080

48

9685

51

10290

54

10895

57

114100

60

120

GASOLINE ENGINE

* Engine oil

* Engine oil filter

Oil leakage and contamination

* Timing belt

Spark plugs (For leaded fuel use)

Spark plugs (For unleaded fuel use)

Exhaust system

Radiator coolant concentration

Cooling system for water leakage

All hoses and pipes in engine compartment

for clog or damage

Fuel filter

Fuel leakage

Fuel tank

* Air cleaner element

Pre air cleaner

Engine drive belt

Valve clearance

O

2 Sensor (For leaded fuel use)

O

2 Sensor (For unleaded fuel use)-

-

-

-

-

-

-

-

-

-

-

-

-

-

--

-

-

-

-

-

-

-

-

-

-

-

-

-

-R

R

R

-

I

I

I

I

-

I

I

I

I

-

--

-

-

-

-

-

-

-

-

-

-

-

-

-

--

-

-

-

-

-

-

-

-

-

-

-

-

-

-R

R

I

-

I

I

I

I

R

I

I

I

I

I

--

-

-

-

-

-

-

-

-

-

-

-

-

-

--

-

-

R

-

-

-

-

-

-

-

-

-

-

-R

R

I

-

I

I

I

I

-

I

I

R

I

-

--

-

-

-

-

-

-

-

-

-

-

-

-

-

R-

-

-

-

-

-

-

-

-

-

-

-

-

-

-R

R

I

-

I

I

I

I

R

I

I

I

I

I

--

-

-

-

-

-

-

-

-

-

-

-

-

-

--

-

-

-

-

-

-

-

-

-

-

-

-

-

-R

R

I

-

I

I

I

I

-

I

I

I

I

-

--

-

-

R

-

-

-

-

-

-

-

-

-

-

--

-

-

-

-

-

-

-

-

-

-

-

-

-

-R

R

I

-

I

I

I

I

R

I

I

R

I

I

--

-

-

-

-

-

-

-

-

-

-

-

-

-

--

-

-

-

-

-

-

-

-

-

-

-

-

-

R

(Replace every 165,000 km or 100,000 miles)

(Replace every 165,000 km or 100,000 miles)

(Check and adjust if necessary every 100,000 km or 60,000 miles)

(Replace every 150,000 km or 90,000 miles)

CLUTCH

Clutch fluid

Clutch pedal travel and free play

TRANSMISSION OR TRANSMISSION WITH

TRANSFER CASE

* Manual transmission with transfer case oil

* Automatic transmission fluid leakage

*

(1)Automatic transmission fluid

* Transfer case oil

PROPELLER SHAFT

Loose connections

*

Universal joints and splines for wear

Universal joints and sliding sleeve (front and rear)

FRONT AND REAR AXLE

* Differential gear oil (Front and rear)

Shift on the fly system gear oil

Front axle shaft rubber boot for damage

Axle case for distortion or damage

Axle shafts for distortion or damage-

-

-

-

-

-

-

-

-

-

-

-

-

--

-

-

-

-

-

-

-

-

-

-

-

-

-I

I

R

I

-

R

I

I

L

R

I

I

I

I-

-

-

-

-

-

-

-

-

-

-

-

-

--

-

-

-

-

-

-

-

-

-

-

-

-

-I

I

I

I

-

I

I

I

L

I

I

I

I

I-

-

-

-

-

-

-

-

-

-

-

-

-

--

-

-

-

-

-

-

-

-

-

-

-

-

-I

I

R

I

-

R

I

I

L

R

I

I

I

I-

-

-

-

-

-

-

-

-

-

-

-

-

--

-

-

-

-

-

-

-

-

-

-

-

-

-I

I

I

I

-

I

I

I

L

I

I

I

I

I-

-

-

-

-

-

-

-

-

-

-

-

-

--

-

-

-

-

-

-

-

-

-

-

-

-

-I

I

R

I

-

R

I

I

L

R

I

I

I

I-

-

-

-

-

-

-

-

-

-

-

-

-

--

-

-

-

-

-

-

-

-

-

-

-

-

-I

I

I

I

-

I

I

I

L

I

I

I

I

I-

-

-

-

-

-

-

-

-

-

-

-

-

--

-

I

-

I

I

-

-

-

I

-

-

-

-

ATATAT

STEERING

* Power steering fluid

Oil leakage

* Steering system for looseness or damage

Power steering hose

Steering wheel play

Steering function

Right and left turning radius

Wheel alignment

Joint ball for oil leakage or damage

Joint ball rubber boot for damage

SERVICE BRAKES

Brake fluid

Brake system for fluid leakage

Brake function

* Disc brake pads and discs wear

Brake pedal travel and free play

Pipes and hoses for loose connections or damage

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

--

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-I

I

I

I

I

I

-

-

I

I

I

I

I

I

I

I-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

--

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

--

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-R

I

I

I

I

I

-

-

I

I

R

I

I

I

I

I-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

--

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

--

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-I

I

I

R

I

I

-

-

I

I

I

I

I

I

I

I-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

--

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-R

I

I

I

I

I

I

I

I

I

R

I

I

I

I

I-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

--

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

(1): Adjust or change automatic transmission fluid.

*Marks: Under severe driving conditions, additional maintenance is required.

Refer to “Maintenance schedule under severe driving conditions”.

Page 31 of 3573

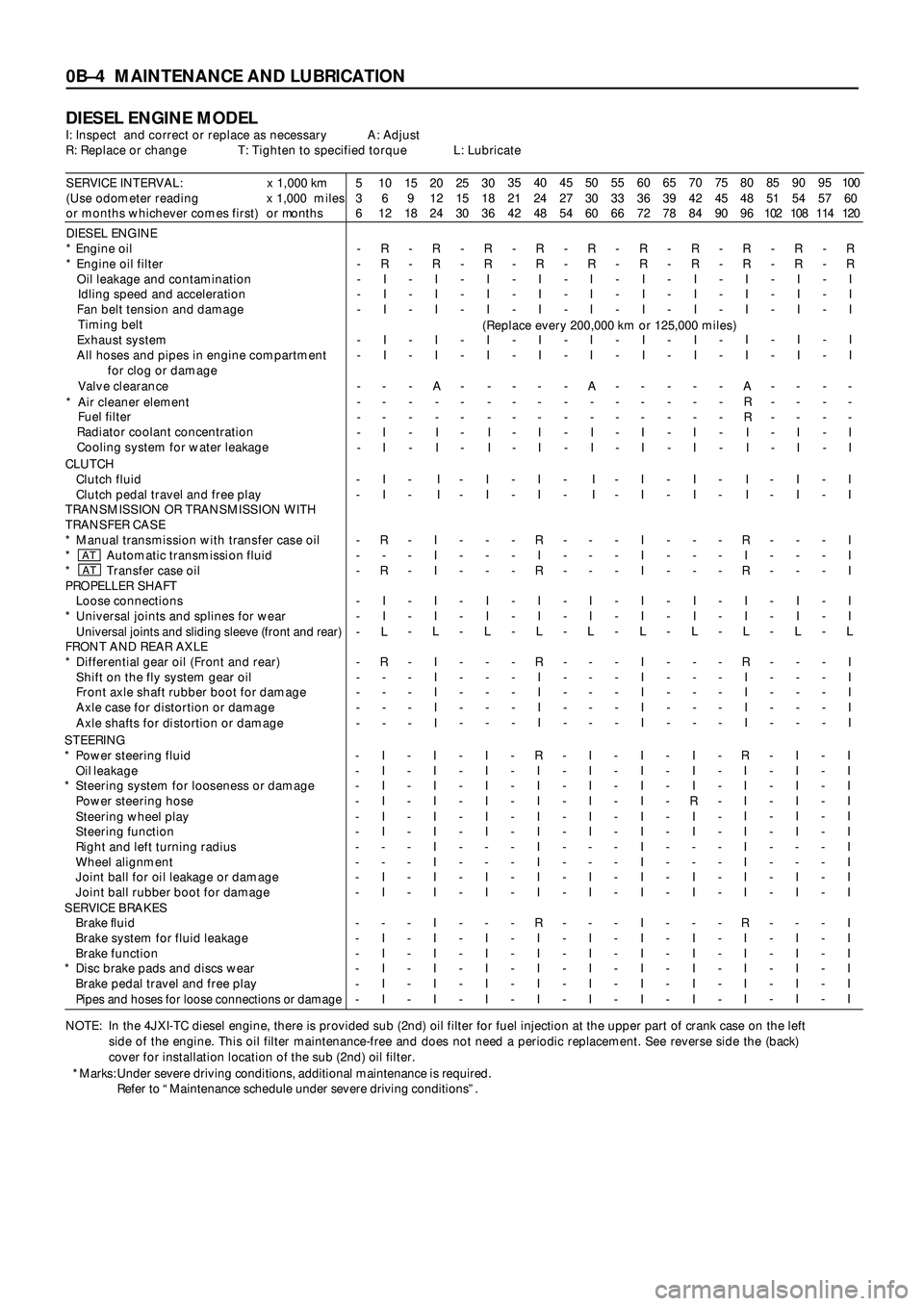

0BÐ4 MAINTENANCE AND LUBRICATION

DIESEL ENGINE MODELI: Inspect and correct or replace as necessary A: Adjust

R: Replace or change T: Tighten to specified torque L: Lubricate

SERVICE INTERVAL: x 1,000 km

(Use odometer reading x 1,000 miles

or months whichever comes first) or months5

3

610

6

1215

9

1820

12

2425

15

3030

18

3635

21

4240

24

4845

27

5450

30

6055

33

6660

36

7265

39

7870

42

8475

45

9080

48

9685

51

10290

54

10895

57

114100

60

120

DIESEL ENGINE

* Engine oil

* Engine oil filter

Oil leakage and contamination

Idling speed and acceleration

Fan belt tension and damage

Timing belt

Exhaust system

All hoses and pipes in engine compartment

for clog or damage

Valve clearance

* Air cleaner element

Fuel filter

Radiator coolant concentration

Cooling system for water leakage-

-

-

-

-

-

-

-

-

-

-

-R

R

I

I

I

I

I

-

-

-

I

I-

-

-

-

-

-

-

-

-

-

-

-R

R

I

I

I

I

I

A

-

-

I

I-

-

-

-

-

-

-

-

-

-

-

-R

R

I

I

I

I

I

-

-

-

I

I-

-

-

-

-

-

-

-

-

-

-

-R

R

I

I

I

I

I

-

-

-

I

I-

-

-

-

-

-

-

-

-

-

-

-R

R

I

I

I

I

I

A

-

-

I

I-

-

-

-

-

-

-

-

-

-

-

-R

R

I

I

I

I

I

-

-

-

I

I-

-

-

-

-

-

-

-

-

-

-

-R

R

I

I

I

I

I

-

-

-

I

I-

-

-

-

-

-

-

-

-

-

-

-R

R

I

I

I

I

I

A

R

R

I

I-

-

-

-

-

-

-

-

-

-

-

-R

R

I

I

I

I

I

-

-

-

I

I-

-

-

-

-

-

-

-

-

-

-

-R

R

I

I

I

I

I

-

-

-

I

I

NOTE: In the 4JXI-TC diesel engine, there is provided sub (2nd) oil filter for fuel injection at the upper part of crank case on the left

side of the engine. This oil filter maintenance-free and does not need a periodic replacement. See reverse side the (back)

cover for installation location of the sub (2nd) oil filter.(Replace every 200,000 km or 125,000 miles)

*Marks: Under severe driving conditions, additional maintenance is required.

Refer to “Maintenance schedule under severe driving conditions”. CLUTCH

Clutch fluid

Clutch pedal travel and free play

TRANSMISSION OR TRANSMISSION WITH

TRANSFER CASE

* Manual transmission with transfer case oil

* Automatic transmission fluid

* Transfer case oil

PROPELLER SHAFT

Loose connections

* Universal joints and splines for wear

Universal joints and sliding sleeve (front and rear)FRONT AND REAR AXLE

* Differential gear oil (Front and rear)

Shift on the fly system gear oil

Front axle shaft rubber boot for damage

Axle case for distortion or damage

Axle shafts for distortion or damage-

-

-

-

-

-

-

-

-

-

-

-

-I

I

R

-

R

I

I

L

R

-

-

-

--

-

-

-

-

-

-

-

-

-

-

-

-I

I

I

I

I

I

I

L

I

I

I

I

I-

-

-

-

-

-

-

-

-

-

-

-

-I

I

-

-

-

I

I

L

-

-

-

-

--

-

-

-

-

-

-

-

-

-

-

-

-I

I

R

I

R

I

I

L

R

I

I

I

I-

-

-

-

-

-

-

-

-

-

-

-

-I

I

-

-

-

I

I

L

-

-

-

-

--

-

-

-

-

-

-

-

-

-

-

-

-I

I

I

I

I

I

I

L

I

I

I

I

I-

-

-

-

-

-

-

-

-

-

-

-

-I

I

-

-

-

I

I

L

-

-

-

-

--

-

-

-

-

-

-

-

-

-

-

-

-I

I

R

I

R

I

I

L

R

I

I

I

I-

-

-

-

-

-

-

-

-

-

-

-

-I

I

-

-

-

I

I

L

-

-

-

-

--

-

-

-

-

-

-

-

-

-

-

-

-I

I

I

I

I

I

I

L

I

I

I

I

I

ATAT

STEERING

* Power steering fluid

Oil leakage

* Steering system for looseness or damage

Power steering hose

Steering wheel play

Steering function

Right and left turning radius

Wheel alignment

Joint ball for oil leakage or damage

Joint ball rubber boot for damage

SERVICE BRAKES

Brake fluid

Brake system for fluid leakage

Brake function

* Disc brake pads and discs wear

Brake pedal travel and free play

Pipes and hoses for loose connections or damage

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-I

I

I

I

I

I

-

-

I

I

-

I

I

I

I

I-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-I

I

I

I

I

I

-

-

I

I

-

I

I

I

I

I-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-R

I

I

I

I

I

I

I

I

I

R

I

I

I

I

I-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-I

I

I

I

I

I

-

-

I

I

-

I

I

I

I

I-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-I

I

I

R

I

I

-

-

I

I

-

I

I

I

I

I-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-R

I

I

I

I

I

I

I

I

I

R

I

I

I

I

I-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-I

I

I

I

I

I

-

-

I

I

-

I

I

I

I

I-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

Page 33 of 3573

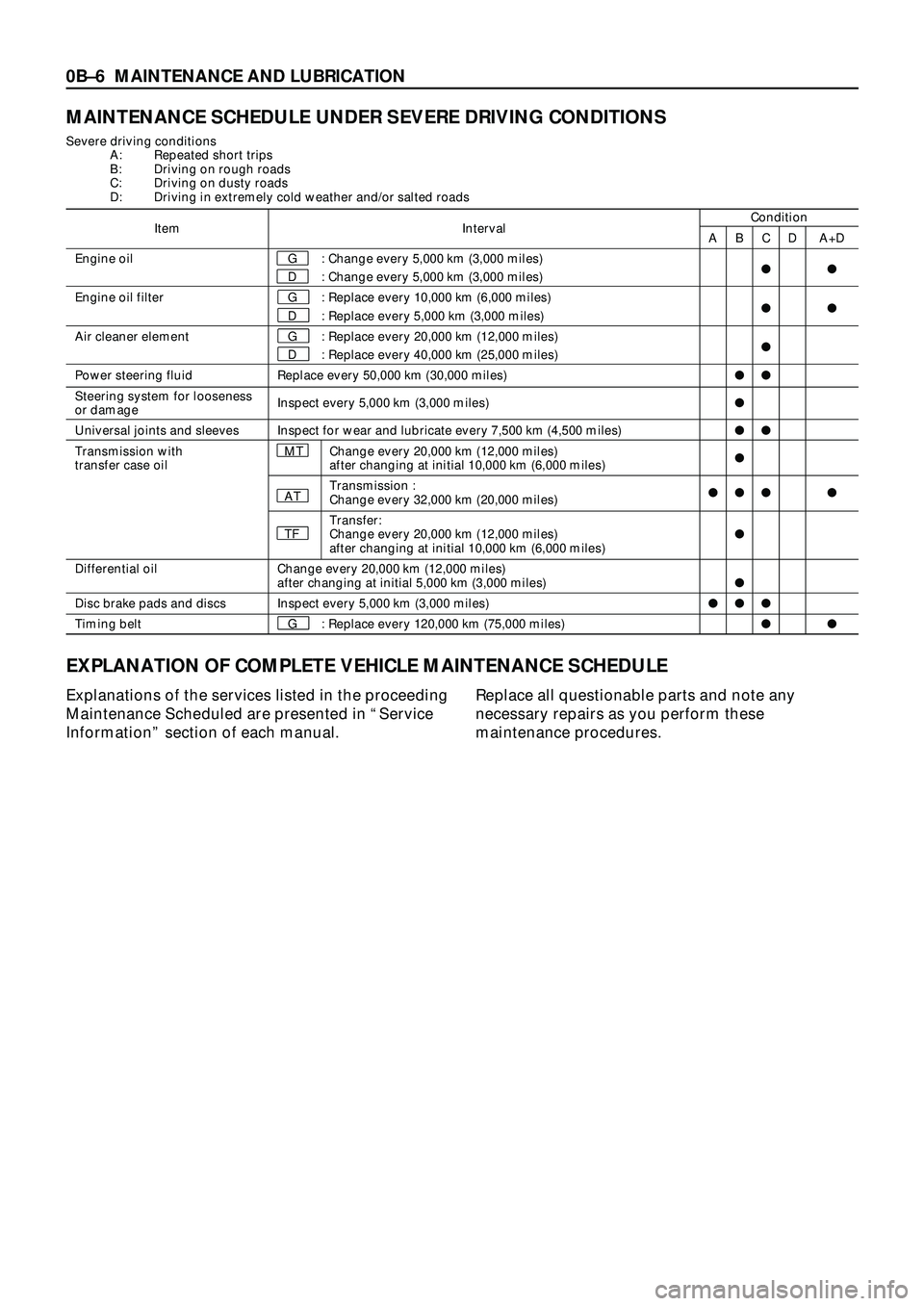

0BÐ6 MAINTENANCE AND LUBRICATION

Item IntervalCondition

ABCD A+D

Engine oil G : Change every 5,000 km (3,000 miles)

D : Change every 5,000 km (3,000 miles) ll

Engine oil filter G : Replace every 10,000 km (6,000 miles)

D : Replace every 5,000 km (3,000 miles) ll

Air cleaner element G : Replace every 20,000 km (12,000 miles)

D : Replace every 40,000 km (25,000 miles)l

Power steering fluid Replace every 50,000 km (30,000 miles)ll

Steering system for looseness

or damage Inspect every 5,000 km (3,000 miles)l

Universal joints and sleeves Inspect for wear and lubricate every 7,500 km (4,500 miles)ll

Transmission with MT Change every 20,000 km (12,000 miles)

transfer case oil after changing at initial 10,000 km (6,000 miles)l

Transmission :

AT

Change every 32,000 km (20,000 miles) lll l

Transfer:

TF Change every 20,000 km (12,000 miles)

after changing at initial 10,000 km (6,000 miles)l

Differential oil Change every 20,000 km (12,000 miles)

after changing at initial 5,000 km (3,000 miles) l

Disc brake pads and discs Inspect every 5,000 km (3,000 miles)lll

Timing belt G : Replace every 120,000 km (75,000 miles)ll

EXPLANATION OF COMPLETE VEHICLE MAINTENANCE SCHEDULE

Explanations of the services listed in the proceeding

Maintenance Scheduled are presented in ÒService

InformationÓ section of each manual.Replace all questionable parts and note any

necessary repairs as you perform these

maintenance procedures.

MAINTENANCE SCHEDULE UNDER SEVERE DRIVING CONDITIONS

Severe driving conditions

A: Repeated short trips

B: Driving on rough roads

C: Driving on dusty roads

D: Driving in extremely cold weather and/or salted roads

Page 34 of 3573

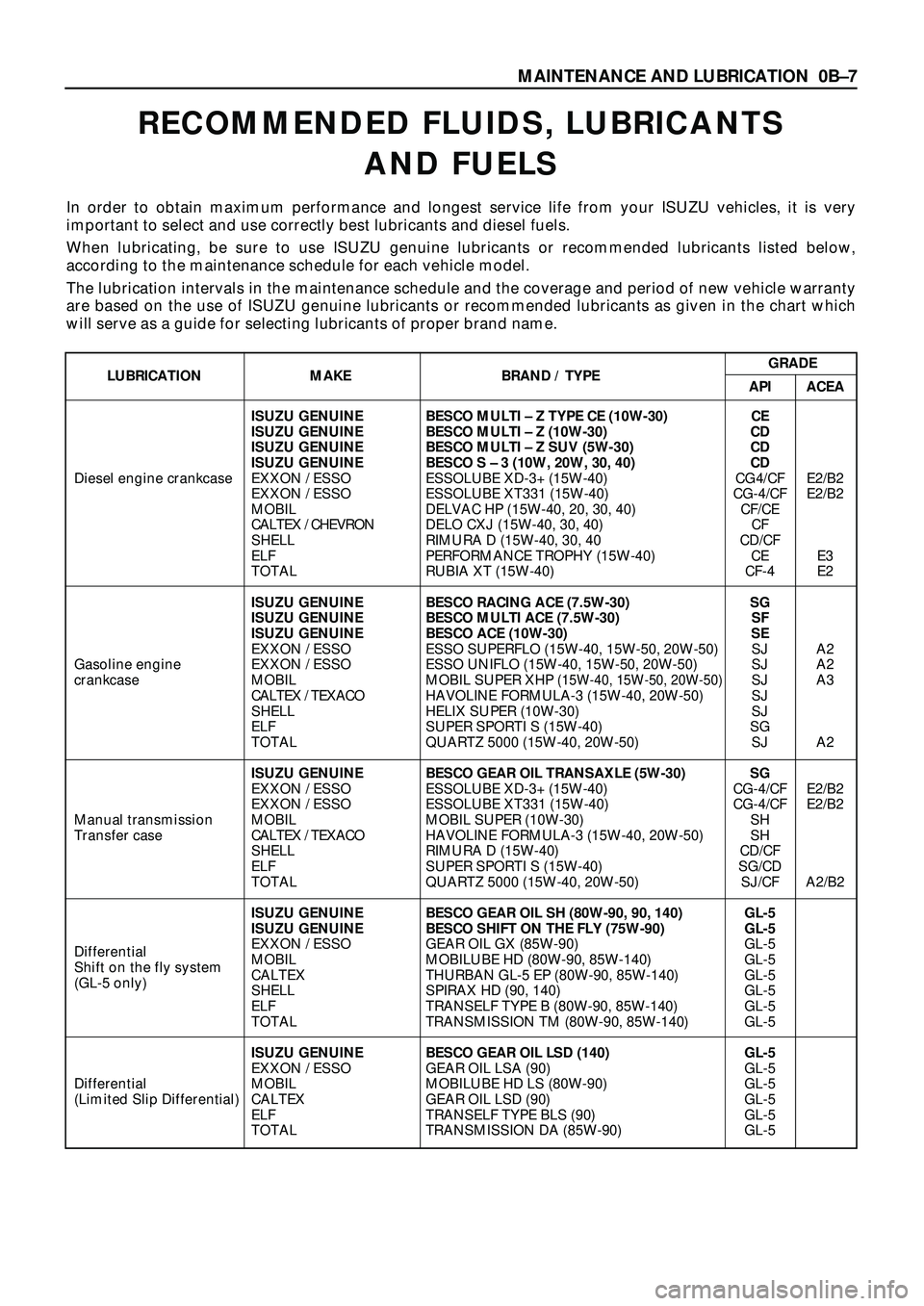

MAINTENANCE AND LUBRICATION 0BÐ7

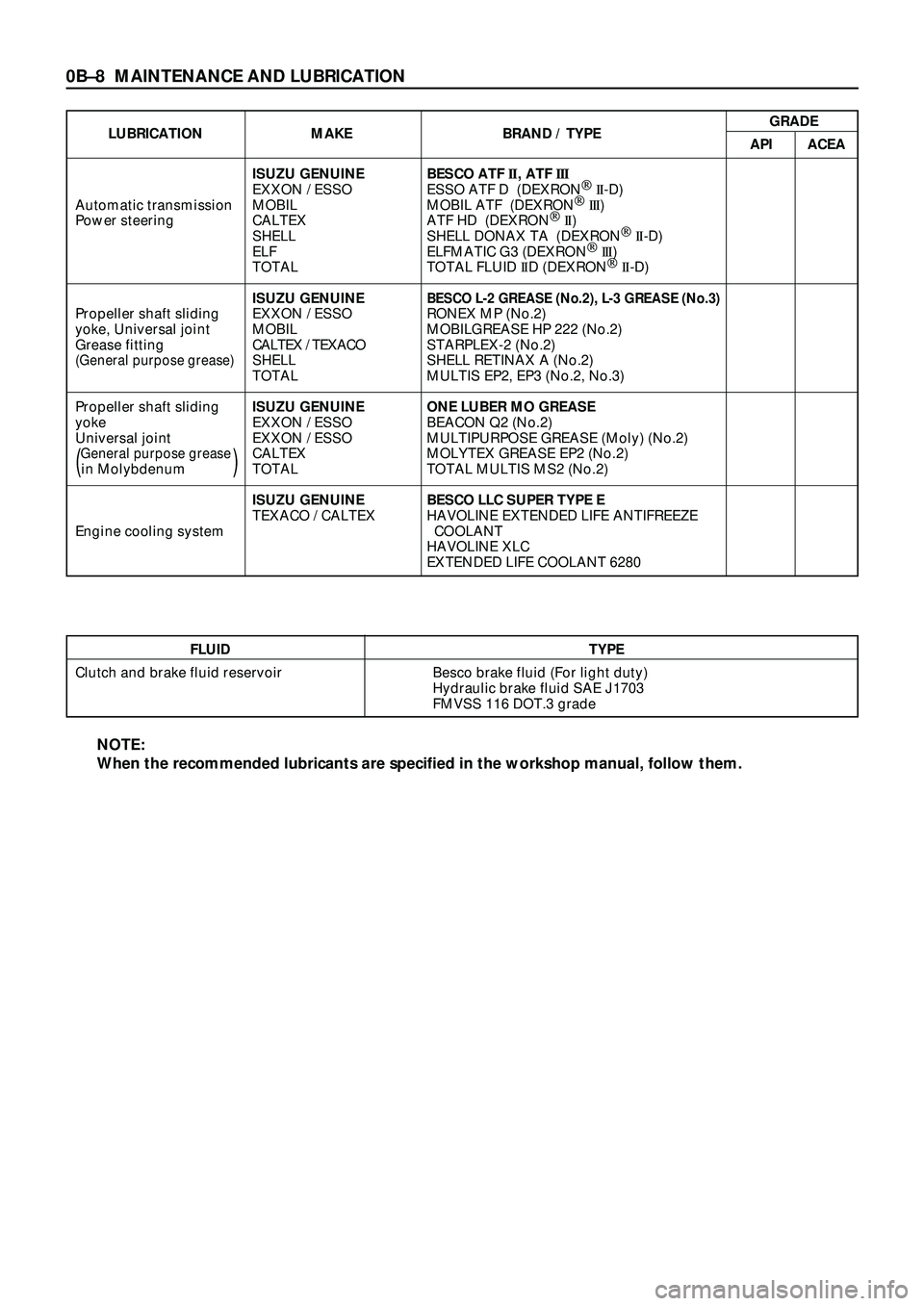

RECOMMENDED FLUIDS, LUBRICANTS

AND FUELS

In order to obtain maximum performance and longest service life from your ISUZU vehicles, it is very

important to select and use correctly best lubricants and diesel fuels.

When lubricating, be sure to use ISUZU genuine lubricants or recommended lubricants listed below,

according to the maintenance schedule for each vehicle model.

The lubrication intervals in the maintenance schedule and the coverage and period of new vehicle warranty

are based on the use of ISUZU genuine lubricants or recommended lubricants as given in the chart which

will serve as a guide for selecting lubricants of proper brand name.

LUBRICATION MAKE BRAND / TYPEGRADE

API ACEA

ISUZU GENUINE BESCO MULTI Ð Z TYPE CE (10W-30) CE

ISUZU GENUINE BESCO MULTI Ð Z (10W-30) CD

ISUZU GENUINE BESCO MULTI Ð Z SUV (5W-30) CD

ISUZU GENUINE BESCO S Ð 3 (10W, 20W, 30, 40) CD

Diesel engine crankcase EXXON / ESSO ESSOLUBE XD-3+ (15W-40) CG4/CF E2/B2

EXXON / ESSO ESSOLUBE XT331 (15W-40) CG-4/CF E2/B2

MOBIL DELVAC HP (15W-40, 20, 30, 40) CF/CE

CALTEX / CHEVRONDELO CXJ (15W-40, 30, 40) CF

SHELL RIMURA D (15W-40, 30, 40 CD/CF

ELF PERFORMANCE TROPHY (15W-40) CE E3

TOTAL RUBIA XT (15W-40) CF-4 E2

ISUZU GENUINE BESCO RACING ACE (7.5W-30) SG

ISUZU GENUINE BESCO MULTI ACE (7.5W-30) SF

ISUZU GENUINE BESCO ACE (10W-30) SE

EXXON / ESSO ESSO SUPERFLO (15W-40, 15W-50, 20W-50) SJ A2

Gasoline engine EXXON / ESSO ESSO UNIFLO (15W-40, 15W-50, 20W-50) SJ A2

crankcase MOBIL MOBIL SUPER XHP

(15W-40, 15W-50, 20W-50)SJ A3

CALTEX / TEXACOHAVOLINE FORMULA-3 (15W-40, 20W-50) SJ

SHELL HELIX SUPER (10W-30) SJ

ELF SUPER SPORTI S (15W-40) SG

TOTAL QUARTZ 5000 (15W-40, 20W-50) SJ A2

ISUZU GENUINE BESCO GEAR OIL TRANSAXLE (5W-30) SG

EXXON / ESSO ESSOLUBE XD-3+ (15W-40) CG-4/CF E2/B2

EXXON / ESSO ESSOLUBE XT331 (15W-40) CG-4/CF E2/B2

Manual transmission MOBIL MOBIL SUPER (10W-30) SH

Transfer caseCALTEX / TEXACOHAVOLINE FORMULA-3 (15W-40, 20W-50) SH

SHELL RIMURA D (15W-40) CD/CF

ELF SUPER SPORTI S (15W-40) SG/CD

TOTAL QUARTZ 5000 (15W-40, 20W-50) SJ/CF A2/B2

ISUZU GENUINE BESCO GEAR OIL SH (80W-90, 90, 140) GL-5

ISUZU GENUINE BESCO SHIFT ON THE FLY (75W-90) GL-5

DifferentialEXXON / ESSO GEAR OIL GX (85W-90) GL-5

Shift on the fly systemMOBIL MOBILUBE HD (80W-90, 85W-140) GL-5

(GL-5 only)CALTEX THURBAN GL-5 EP (80W-90, 85W-140) GL-5

SHELL SPIRAX HD (90, 140) GL-5

ELF TRANSELF TYPE B (80W-90, 85W-140) GL-5

TOTAL TRANSMISSION TM (80W-90, 85W-140) GL-5

ISUZU GENUINE BESCO GEAR OIL LSD (140) GL-5

EXXON / ESSO GEAR OIL LSA (90) GL-5

Differential MOBIL MOBILUBE HD LS (80W-90) GL-5

(Limited Slip Differential) CALTEX GEAR OIL LSD (90) GL-5

ELF TRANSELF TYPE BLS (90) GL-5

TOTAL TRANSMISSION DA (85W-90) GL-5

Page 35 of 3573

0BÐ8 MAINTENANCE AND LUBRICATION

FLUID TYPE

Clutch and brake fluid reservoir Besco brake fluid (For light duty)

Hydraulic brake fluid SAE J1703

FMVSS 116 DOT.3 grade

LUBRICATION MAKE BRAND / TYPEGRADE

API ACEA

ISUZU GENUINE BESCO ATF II, ATF III

EXXON / ESSO ESSO ATF D (DEXRONÒ

II-D)

Automatic transmission MOBIL MOBIL ATF (DEXRONÒ

III)

Power steering CALTEX ATF HD (DEXRONÒ

II)

SHELL SHELL DONAX TA (DEXRONÒ

II-D)

ELF ELFMATIC G3 (DEXRONÒ

III)

TOTAL TOTAL FLUID IID (DEXRONÒ

II-D)

ISUZU GENUINE

BESCO L-2 GREASE (No.2), L-3 GREASE (No.3)Propeller shaft sliding EXXON / ESSO RONEX MP (No.2)

yoke, Universal joint MOBIL MOBILGREASE HP 222 (No.2)

Grease fittingCALTEX / TEXACOSTARPLEX-2 (No.2)

(General purpose grease)SHELL SHELL RETINAX A (No.2)

TOTAL MULTIS EP2, EP3 (No.2, No.3)

Propeller shaft slidingISUZU GENUINE ONE LUBER MO GREASE

yoke EXXON / ESSO BEACON Q2 (No.2)

Universal joint EXXON / ESSO MULTIPURPOSE GREASE (Moly) (No.2)

General purpose greaseCALTEX MOLYTEX GREASE EP2 (No.2)(in Molybdenum)TOTAL TOTAL MULTIS MS2 (No.2)

ISUZU GENUINE BESCO LLC SUPER TYPE E

TEXACO / CALTEX HAVOLINE EXTENDED LIFE ANTIFREEZE

Engine cooling system COOLANT

HAVOLINE XLC

EXTENDED LIFE COOLANT 6280

NOTE:

When the recommended lubricants are specified in the workshop manual, follow them.

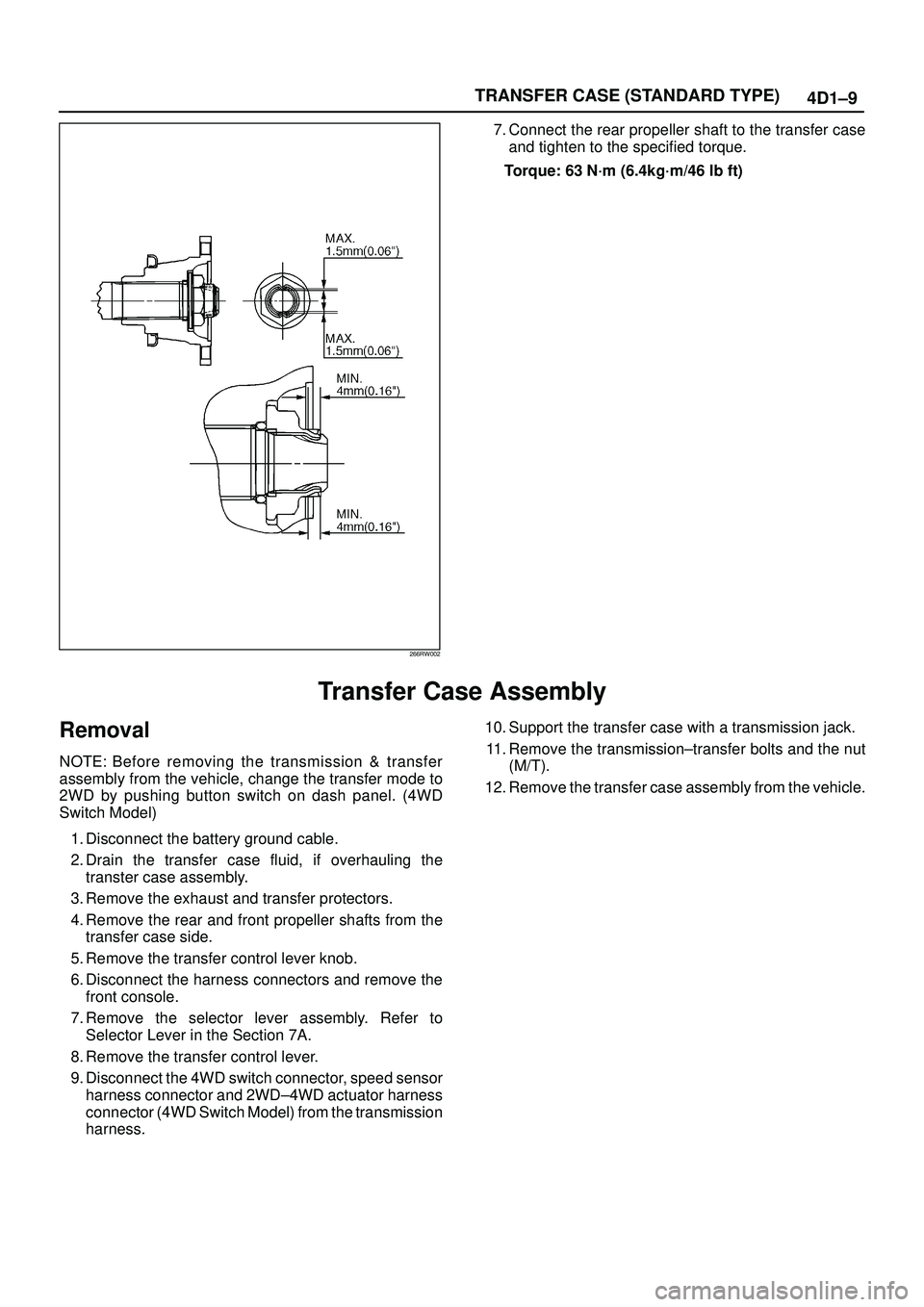

Page 730 of 3573

TRANSFER CASE (STANDARD TYPE)

4D1±9

266RW002

7. Connect the rear propeller shaft to the transfer case

and tighten to the specified torque.

Torque: 63 N´m (6.4kg´m/46 lb ft)

Transfer Case Assembly

Removal

NOTE: Before removing the transmission & transfer

assembly from the vehicle, change the transfer mode to

2WD by pushing button switch on dash panel. (4WD

Switch Model)

1. Disconnect the battery ground cable.

2. Drain the transfer case fluid, if overhauling the

transter case assembly.

3. Remove the exhaust and transfer protectors.

4. Remove the rear and front propeller shafts from the

transfer case side.

5. Remove the transfer control lever knob.

6. Disconnect the harness connectors and remove the

front console.

7. Remove the selector lever assembly. Refer to

Selector Lever in the Section 7A.

8. Remove the transfer control lever.

9. Disconnect the 4WD switch connector, speed sensor

harness connector and 2WD±4WD actuator harness

connector (4WD Switch Model) from the transmission

harness.10. Support the transfer case with a transmission jack.

11. Remove the transmission±transfer bolts and the nut

(M/T).

12. Remove the transfer case assembly from the vehicle.

Page 847 of 3573

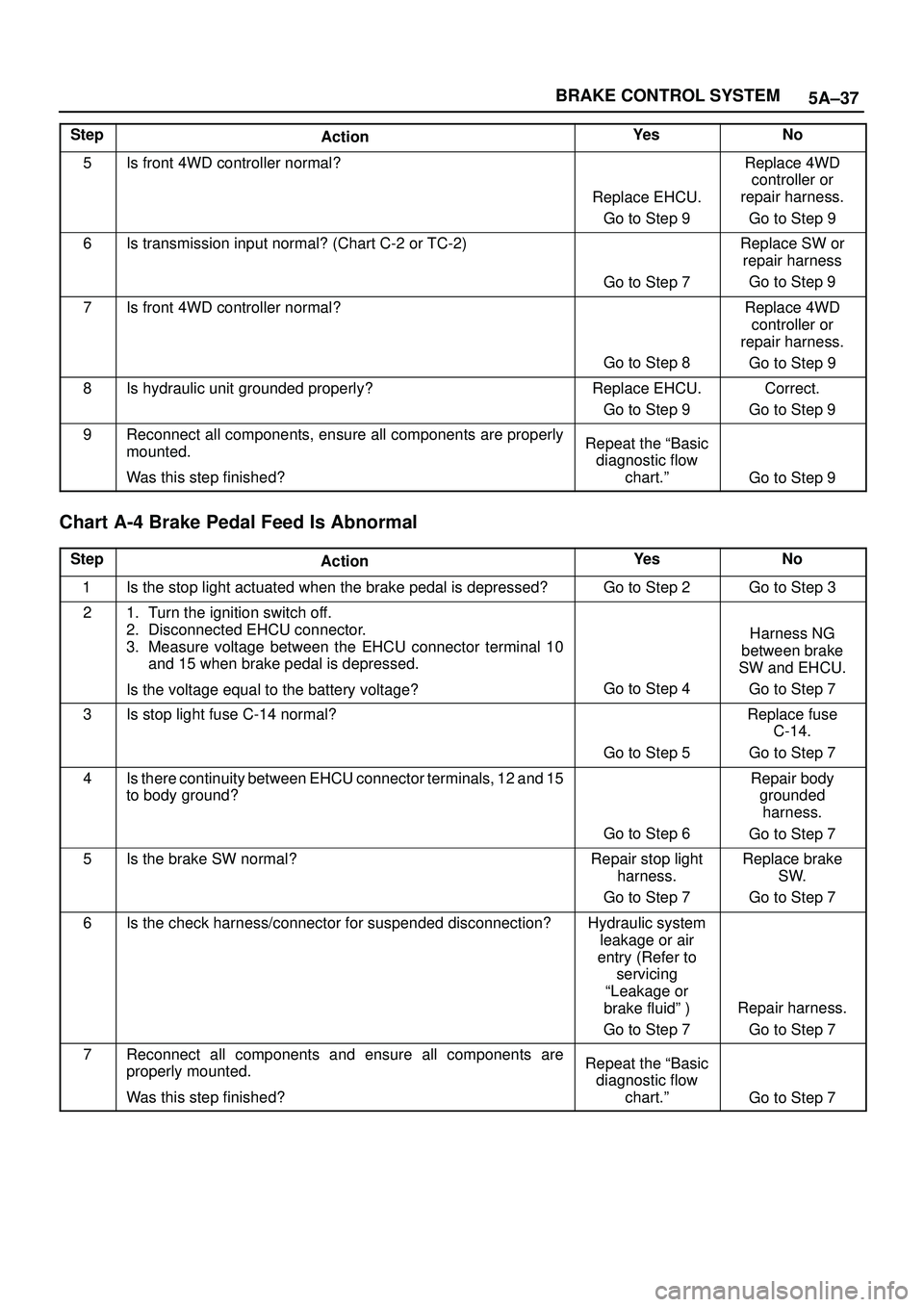

5A±37 BRAKE CONTROL SYSTEM

StepNo Ye s

Action

5Is front 4WD controller normal?

Replace EHCU.

Go to Step 9

Replace 4WD

controller or

repair harness.

Go to Step 9

6Is transmission input normal? (Chart C-2 or TC-2)

Go to Step 7

Replace SW or

repair harness

Go to Step 9

7Is front 4WD controller normal?

Go to Step 8

Replace 4WD

controller or

repair harness.

Go to Step 9

8Is hydraulic unit grounded properly?Replace EHCU.

Go to Step 9Correct.

Go to Step 9

9Reconnect all components, ensure all components are properly

mounted.

Was this step finished?Repeat the ªBasic

diagnostic flow

chart.º

Go to Step 9

Chart A-4 Brake Pedal Feed Is Abnormal

StepActionYe sNo

1Is the stop light actuated when the brake pedal is depressed?Go to Step 2Go to Step 3

21. Turn the ignition switch off.

2. Disconnected EHCU connector.

3. Measure voltage between the EHCU connector terminal 10

and 15 when brake pedal is depressed.

Is the voltage equal to the battery voltage?

Go to Step 4

Harness NG

between brake

SW and EHCU.

Go to Step 7

3Is stop light fuse C-14 normal?

Go to Step 5

Replace fuse

C-14.

Go to Step 7

4Is there continuity between EHCU connector terminals, 12 and 15

to body ground?

Go to Step 6

Repair body

grounded

harness.

Go to Step 7

5Is the brake SW normal?Repair stop light

harness.

Go to Step 7Replace brake

SW.

Go to Step 7

6Is the check harness/connector for suspended disconnection?Hydraulic system

leakage or air

entry (Refer to

servicing

ªLeakage or

brake fluidº )

Go to Step 7

Repair harness.

Go to Step 7

7Reconnect all components and ensure all components are

properly mounted.

Was this step finished?Repeat the ªBasic

diagnostic flow

chart.º

Go to Step 7

Page 881 of 3573

POWER ASSISTED BRAKE SYSTEM 5C – 3

BRAKE SYSTEM DIAGNOSIS

ROAD TESTING THE BRAKES

Brake Test

Brakes should be tested on a dry, clean, reasonably

smooth and level roadway. A true test of brake

performance cannot be made if the roadway is wet,

greasy or covered with loose dirt so that all tires do

not grip the road equally. Testing will also be

adversely affected if the roadway is crowned so as to

throw the weight of the vehicle toward wheels on one

side or if the roadway is so rough that wheels tend to

bounce. Test the brakes at different vehicle speeds

with both light and heavy pedal pressure; however,

avoid locking the wheels and sliding the tires. Locked

wheels and sliding tires do not indicate brake

efficiency, since heavily braked but turning wheels

will stop the vehicle in less distance than locked

wheels. More tire-to-road friction is present with a

heavily braked turning tire then with a sliding tire.

The standard brake system is designed and balanced

to avoid locking the wheels except at very high

deceleration levels.

It is designed this way because the shortest stopping

distance and best control is achieved without brake

lock-up.

Because of high deceleration capability, a firmer pedal

may be felt at higher deceleration levels.

External Conditions That Affect Brake

Performance

1. Tires: Tires having unequal contact and grip on the

road will cause unequal braking. Tires must be

equally inflated, identical in size, and the tread

pattern of right and left tires must be

approximately equal.

2. Vehicle loading: A heavily loaded vehicle requires

more braking effort.

3. Wheel Alignment: Misalignment of the wheels,

particularly in regard to excessive camber and

caster, will cause the brakes to pull to one side.

BRAKE FLUID LEAKS

With engine running at idle and the transmission in

“Neutral”, depress the brake pedal and hold a

constant foot pressure on the pedal. If pedal gradually

falls away with the constant pressure, the hydraulic

system may be leaking.

Check the master cylinder fluid level. While a slight

drop in reservoir level will result from normal lining

wear, an abnormally low level in resevoir indicates a

leak in the system. The hydraulic system may be

leaking internally as well as externally. Refer to

“Master Cylinder Inspection”. Also, the system may

appear to pass this test but still have slight leakage. If

fluid level is normal, check the vacuum booster push

Page 1055 of 3573

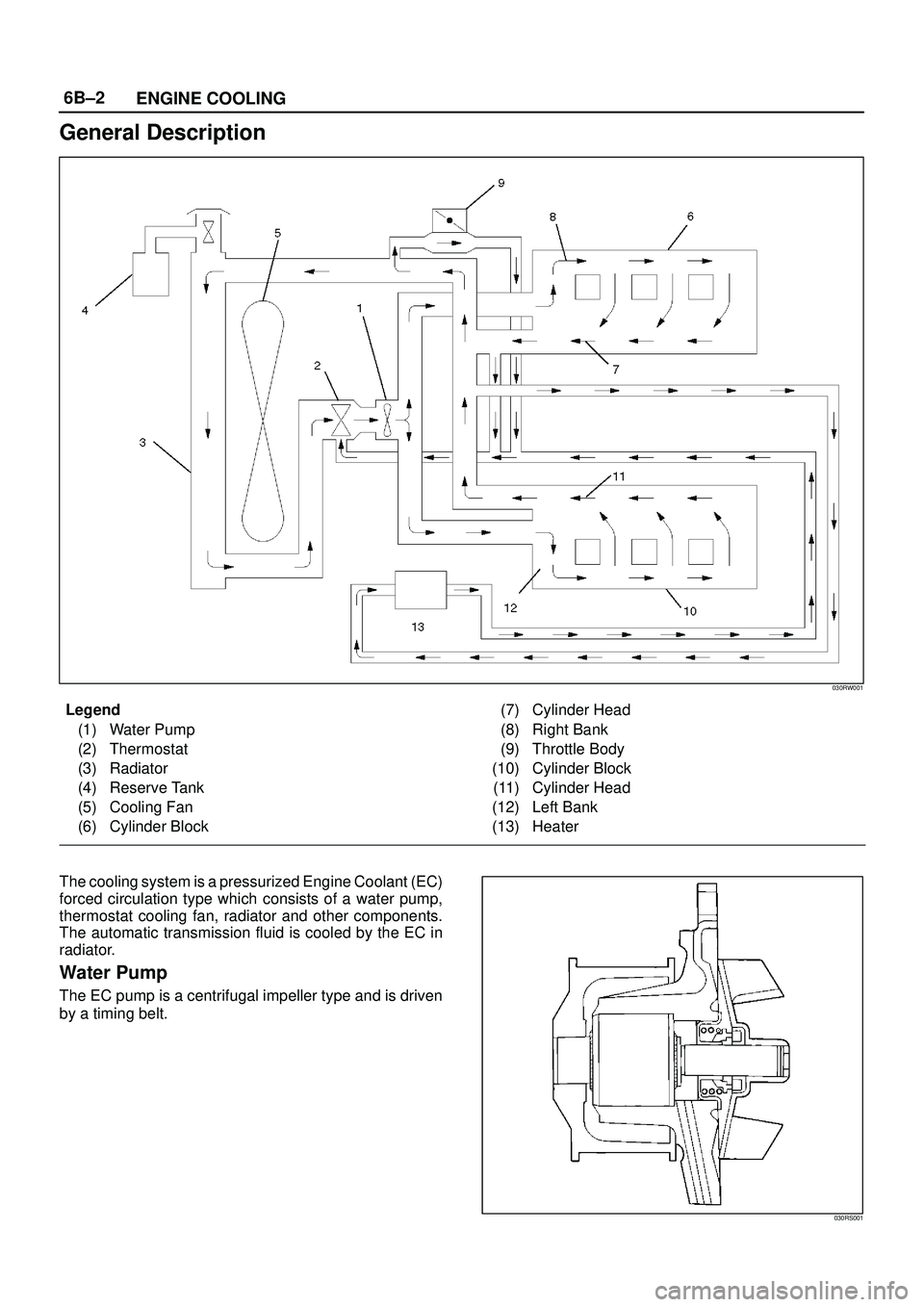

6B±2

ENGINE COOLING

General Description

030RW001

Legend

(1) Water Pump

(2) Thermostat

(3) Radiator

(4) Reserve Tank

(5) Cooling Fan

(6) Cylinder Block(7) Cylinder Head

(8) Right Bank

(9) Throttle Body

(10) Cylinder Block

(11) Cylinder Head

(12) Left Bank

(13) Heater

The cooling system is a pressurized Engine Coolant (EC)

forced circulation type which consists of a water pump,

thermostat cooling fan, radiator and other components.

The automatic transmission fluid is cooled by the EC in

radiator.

Water Pump

The EC pump is a centrifugal impeller type and is driven

by a timing belt.

030RS001

Page 1059 of 3573

6B±6

ENGINE COOLING

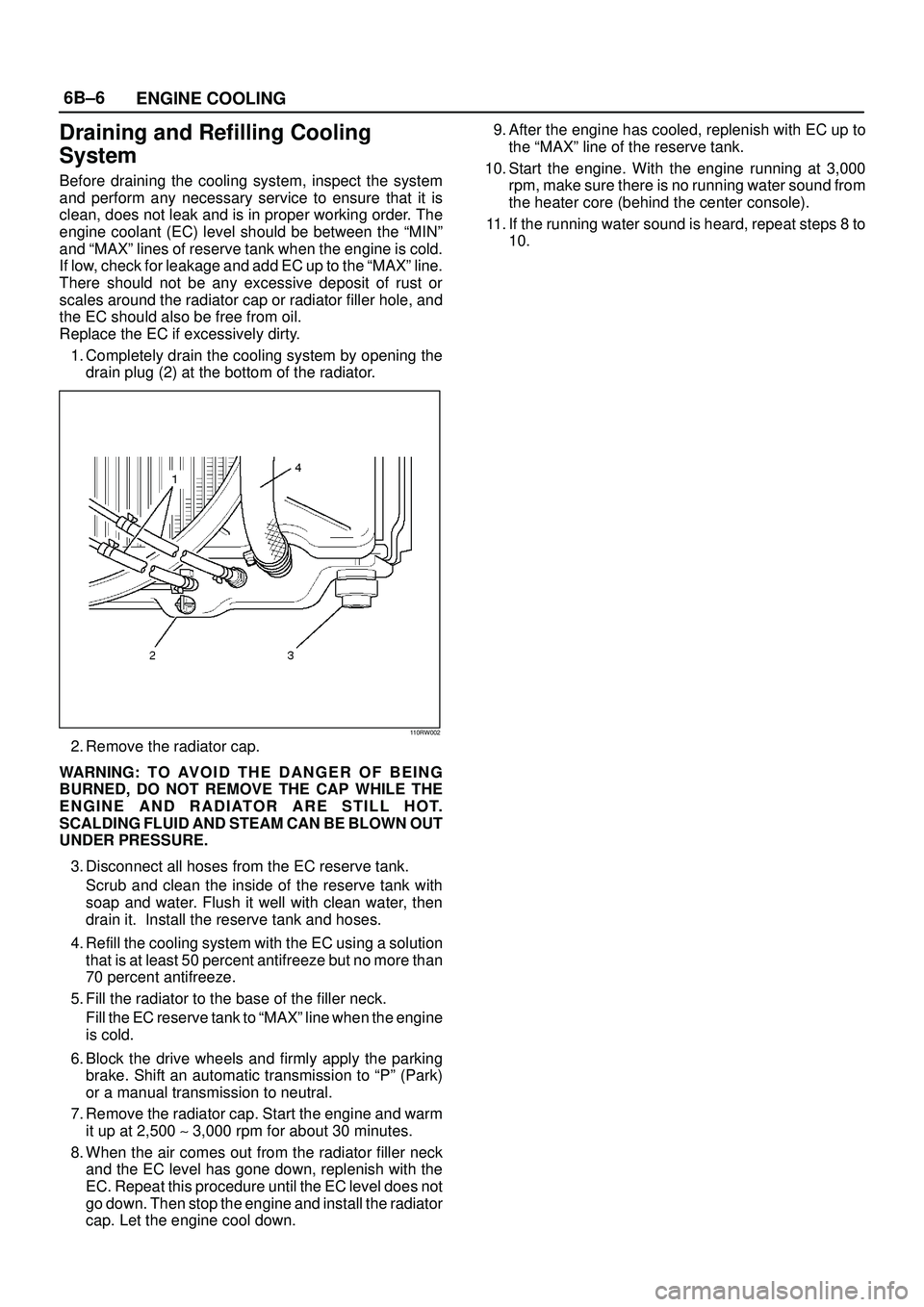

Draining and Refilling Cooling

System

Before draining the cooling system, inspect the system

and perform any necessary service to ensure that it is

clean, does not leak and is in proper working order. The

engine coolant (EC) level should be between the ªMINº

and ªMAXº lines of reserve tank when the engine is cold.

If low, check for leakage and add EC up to the ªMAXº line.

There should not be any excessive deposit of rust or

scales around the radiator cap or radiator filler hole, and

the EC should also be free from oil.

Replace the EC if excessively dirty.

1. Completely drain the cooling system by opening the

drain plug (2) at the bottom of the radiator.

110RW002

2. Remove the radiator cap.

WARNING: T O AV O I D T H E D A N G E R O F B E I N G

BURNED, DO NOT REMOVE THE CAP WHILE THE

ENGINE AND RADIATOR ARE STILL HOT.

SCALDING FLUID AND STEAM CAN BE BLOWN OUT

UNDER PRESSURE.

3. Disconnect all hoses from the EC reserve tank.

Scrub and clean the inside of the reserve tank with

soap and water. Flush it well with clean water, then

drain it. Install the reserve tank and hoses.

4. Refill the cooling system with the EC using a solution

that is at least 50 percent antifreeze but no more than

70 percent antifreeze.

5. Fill the radiator to the base of the filler neck.

Fill the EC reserve tank to ªMAXº line when the engine

is cold.

6. Block the drive wheels and firmly apply the parking

brake. Shift an automatic transmission to ªPº (Park)

or a manual transmission to neutral.

7. Remove the radiator cap. Start the engine and warm

it up at 2,500 ~ 3,000 rpm for about 30 minutes.

8. When the air comes out from the radiator filler neck

and the EC level has gone down, replenish with the

EC. Repeat this procedure until the EC level does not

go down. Then stop the engine and install the radiator

cap. Let the engine cool down.9. After the engine has cooled, replenish with EC up to

the ªMAXº line of the reserve tank.

10. Start the engine. With the engine running at 3,000

rpm, make sure there is no running water sound from

the heater core (behind the center console).

11. If the running water sound is heard, repeat steps 8 to

10.