sensor JAGUAR S TYPE 1999 1.G Powertrain Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1999, Model line: S TYPE, Model: JAGUAR S TYPE 1999 1.GPages: 75, PDF Size: 3.4 MB

Page 32 of 75

V6 EngineAJ-V6/AJ28

27

D.418.428

APP Sensor

303-050

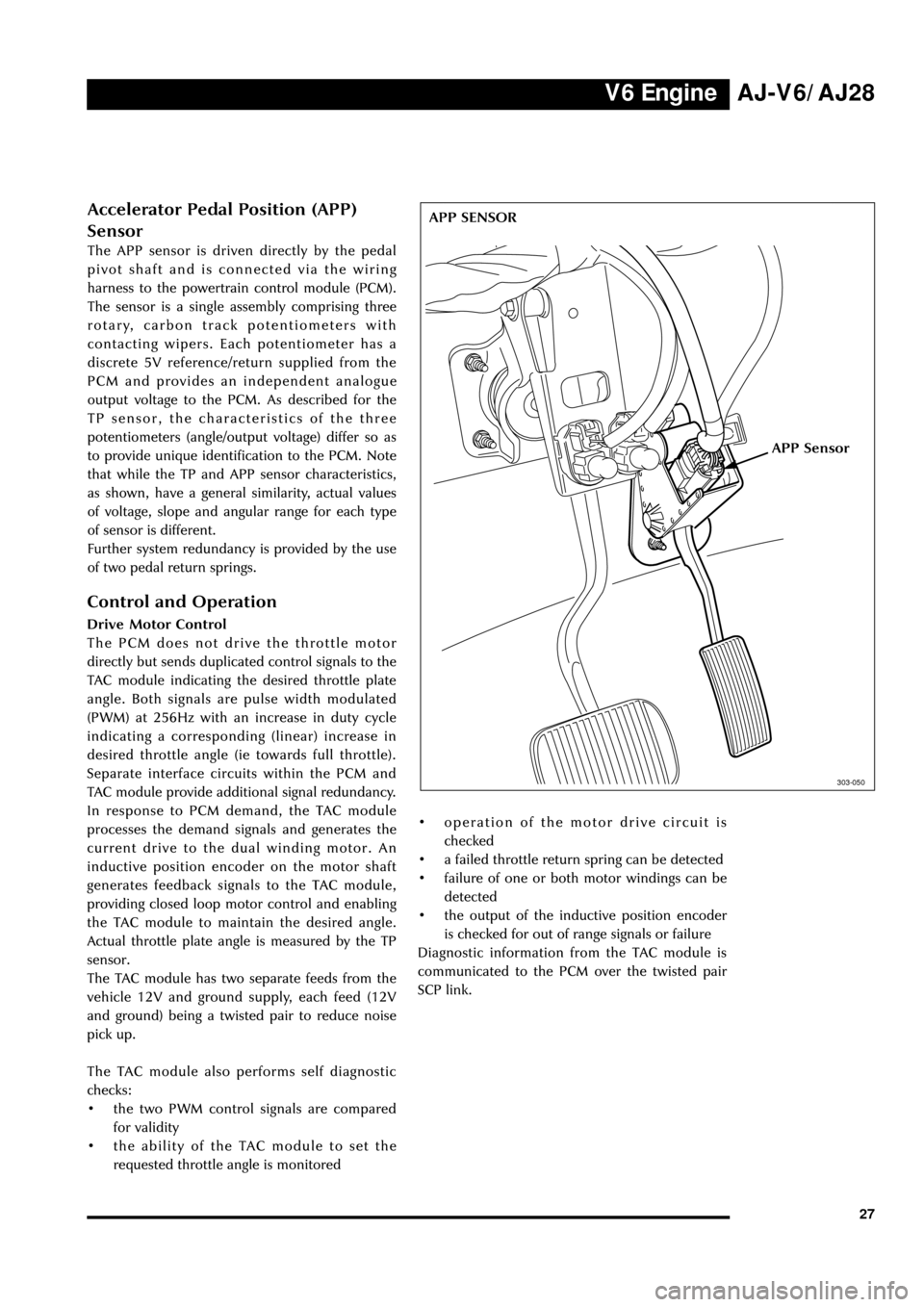

APP SENSORAccelerator Pedal Position (APP)

Sensor

The APP sensor is driven directly by the pedal

pivot shaft and is connected via the wiring

harness to the powertrain control module (PCM).

The sensor is a single assembly comprising three

rotary, carbon track potentiometers with

contacting wipers. Each potentiometer has a

discrete 5V reference/return supplied from the

PCM and provides an independent analogue

output voltage to the PCM. As described for the

TP sensor, the characteristics of the three

potentiometers (angle/output voltage) differ so as

to provide unique identification to the PCM. Note

that while the TP and APP sensor characteristics,

as shown, have a general similarity, actual values

of voltage, slope and angular range for each type

of sensor is different.

Further system redundancy is provided by the use

of two pedal return springs.

Control and Operation

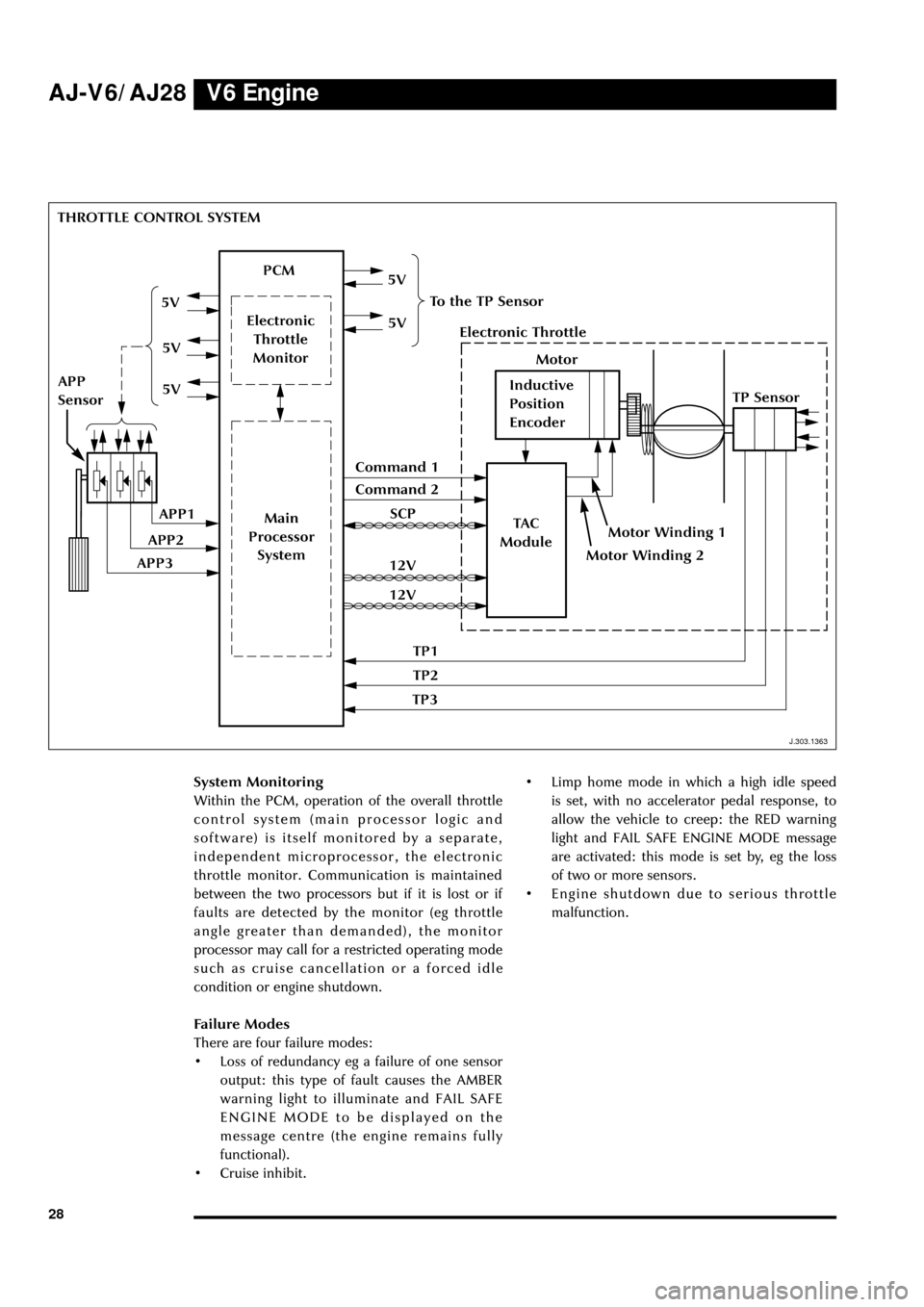

Drive Motor Control

The PCM does not drive the throttle motor

directly but sends duplicated control signals to the

TAC module indicating the desired throttle plate

angle. Both signals are pulse width modulated

(PWM) at 256Hz with an increase in duty cycle

indicating a corresponding (linear) increase in

desired throttle angle (ie towards full throttle).

Separate interface circuits within the PCM and

TAC module provide additional signal redundancy.

In response to PCM demand, the TAC module

processes the demand signals and generates the

current drive to the dual winding motor. An

inductive position encoder on the motor shaft

generates feedback signals to the TAC module,

providing closed loop motor control and enabling

the TAC module to maintain the desired angle.

Actual throttle plate angle is measured by the TP

sensor.

The TAC module has two separate feeds from the

vehicle 12V and ground supply, each feed (12V

and ground) being a twisted pair to reduce noise

pick up.

The TAC module also performs self diagnostic

checks:

¥ the two PWM control signals are compared

for validity

¥ the ability of the TAC module to set the

requested throttle angle is monitored¥ operation of the motor drive circuit is

checked

¥ a failed throttle return spring can be detected

¥ failure of one or both motor windings can be

detected

¥ the output of the inductive position encoder

is checked for out of range signals or failure

Diagnostic information from the TAC module is

communicated to the PCM over the twisted pair

SCP link.

Page 33 of 75

V6 Engine AJ-V6/AJ28

28¥ Limp home mode in which a high idle speed

is set, with no accelerator pedal response, to

allow the vehicle to creep: the RED warning

light and FAIL SAFE ENGINE MODE message

are activated: this mode is set by, eg the loss

of two or more sensors.

¥ Engine shutdown due to serious throttle

malfunction.

J.303.1363

THROTTLE CONTROL SYSTEM

System Monitoring

Within the PCM, operation of the overall throttle

control system (main processor logic and

software) is itself monitored by a separate,

independent microprocessor, the electronic

throttle monitor. Communication is maintained

between the two processors but if it is lost or if

faults are detected by the monitor (eg throttle

angle greater than demanded), the monitor

processor may call for a restricted operating mode

such as cruise cancellation or a forced idle

condition or engine shutdown.

Failure Modes

There are four failure modes:

¥ Loss of redundancy eg a failure of one sensor

output: this type of fault causes the AMBER

warning light to illuminate and FAIL SAFE

ENGINE MODE to be displayed on the

message centre (the engine remains fully

functional).

¥ Cruise inhibit.

J.303.1363

PCM

Electronic

Throttle

Monitor

Main

Processor

SystemTAC

Module

Motor

Electronic Throttle

TP Sensor

Command 1

Command 2

SCP

APP

Sensor

Motor Winding 1

Motor Winding 2

To the TP Sensor

APP1

APP2

APP3

5V

5V

5V

5V

5V

12V

12V

TP1

TP2

TP3

Inductive

Position

Encoder

Page 34 of 75

V6 EngineAJ-V6/AJ28

29

D.303.1215

FUEL RAIL AND LOWER INTAKE MANIFOLD

Fuel Supply

D.303.1215

EFT Sensor

De-pressurisation

Valve

IP Sensor

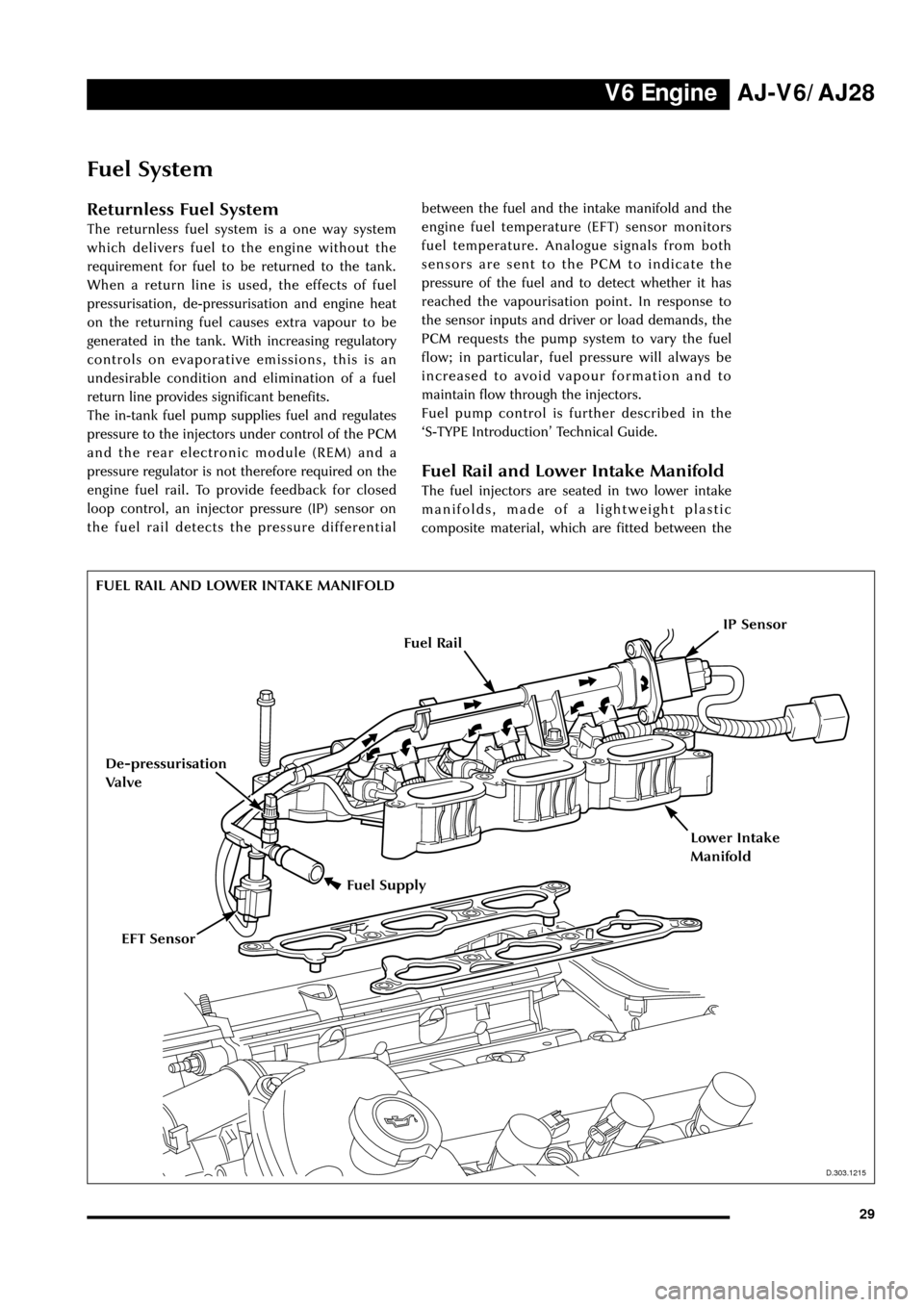

Fuel System

Returnless Fuel System

The returnless fuel system is a one way system

which delivers fuel to the engine without the

requirement for fuel to be returned to the tank.

When a return line is used, the effects of fuel

pressurisation, de-pressurisation and engine heat

on the returning fuel causes extra vapour to be

generated in the tank. With increasing regulatory

controls on evaporative emissions, this is an

undesirable condition and elimination of a fuel

return line provides significant benefits.

The in-tank fuel pump supplies fuel and regulates

pressure to the injectors under control of the PCM

and the rear electronic module (REM) and a

pressure regulator is not therefore required on the

engine fuel rail. To provide feedback for closed

loop control, an injector pressure (IP) sensor on

the fuel rail detects the pressure differentialbetween the fuel and the intake manifold and the

engine fuel temperature (EFT) sensor monitors

fuel temperature. Analogue signals from both

sensors are sent to the PCM to indicate the

pressure of the fuel and to detect whether it has

reached the vapourisation point. In response to

the sensor inputs and driver or load demands, the

PCM requests the pump system to vary the fuel

flow; in particular, fuel pressure will always be

increased to avoid vapour formation and to

maintain flow through the injectors.

Fuel pump control is further described in the

ÔS-TYPE IntroductionÕ Technical Guide.

Fuel Rail and Lower Intake Manifold

The fuel injectors are seated in two lower intake

manifolds, made of a lightweight plastic

composite material, which are fitted between the

Fuel Rail

Lower Intake

Manifold

Page 35 of 75

Ignition System

V6 Engine AJ-V6/AJ28

30cylinder heads and the upper intake manifold

assembly.

The injectors are of the top fed, split spray type

and are supplied from a common fuel rail

assembly which bolts to the lower manifold. The

integral fuel rail consists of an upper delivery pipe

and a lower pipe with six takeoff feeds for the

injectors. The IP sensor is bolted to a flange at the

junction of the two pipes and has an electrical

connection to the fuel rail harness and a vacuum

feed from the intake manifold. A steel cross-over

pipe provides the coupling to the vehicle

mounted fuel line and also carries the EFT sensor,

on a bracket, and the de-pressurisation valve. The

cross-over pipe is connected to the fuel rail via a

semi-rigid length of pipe.

All fuel injectors and sensors use a common

electrical harness with a single multi-way

connection to the main engine harness.

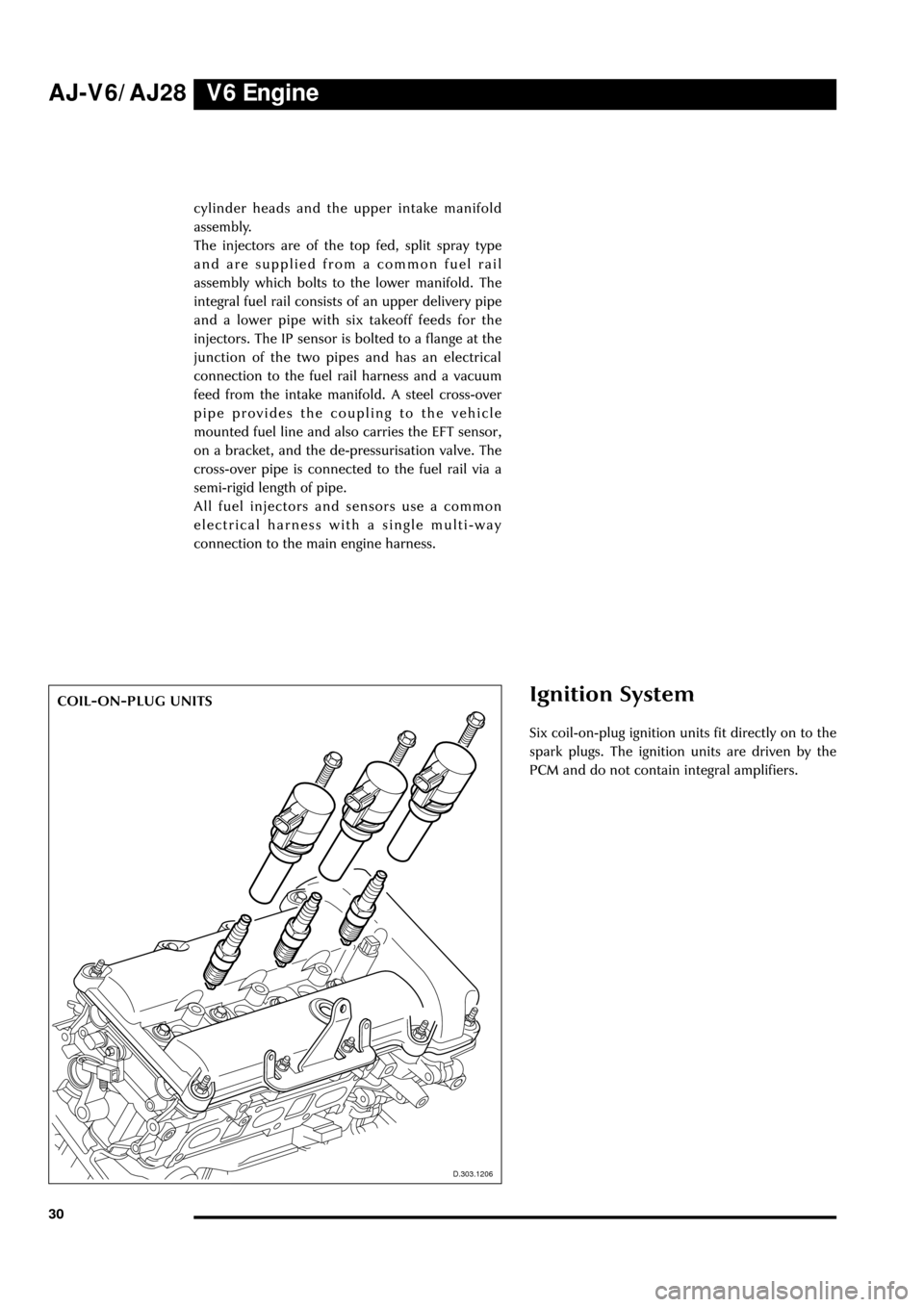

Six coil-on-plug ignition units fit directly on to the

spark plugs. The ignition units are driven by the

PCM and do not contain integral amplifiers.

D.303.1206D.303.1206

COIL-ON-PLUG UNITS

Page 40 of 75

V6 EngineAJ-V6/AJ28

35

J.303.1384

ENGINE BLOCK HEATER

D.303.1384

J.303.1377

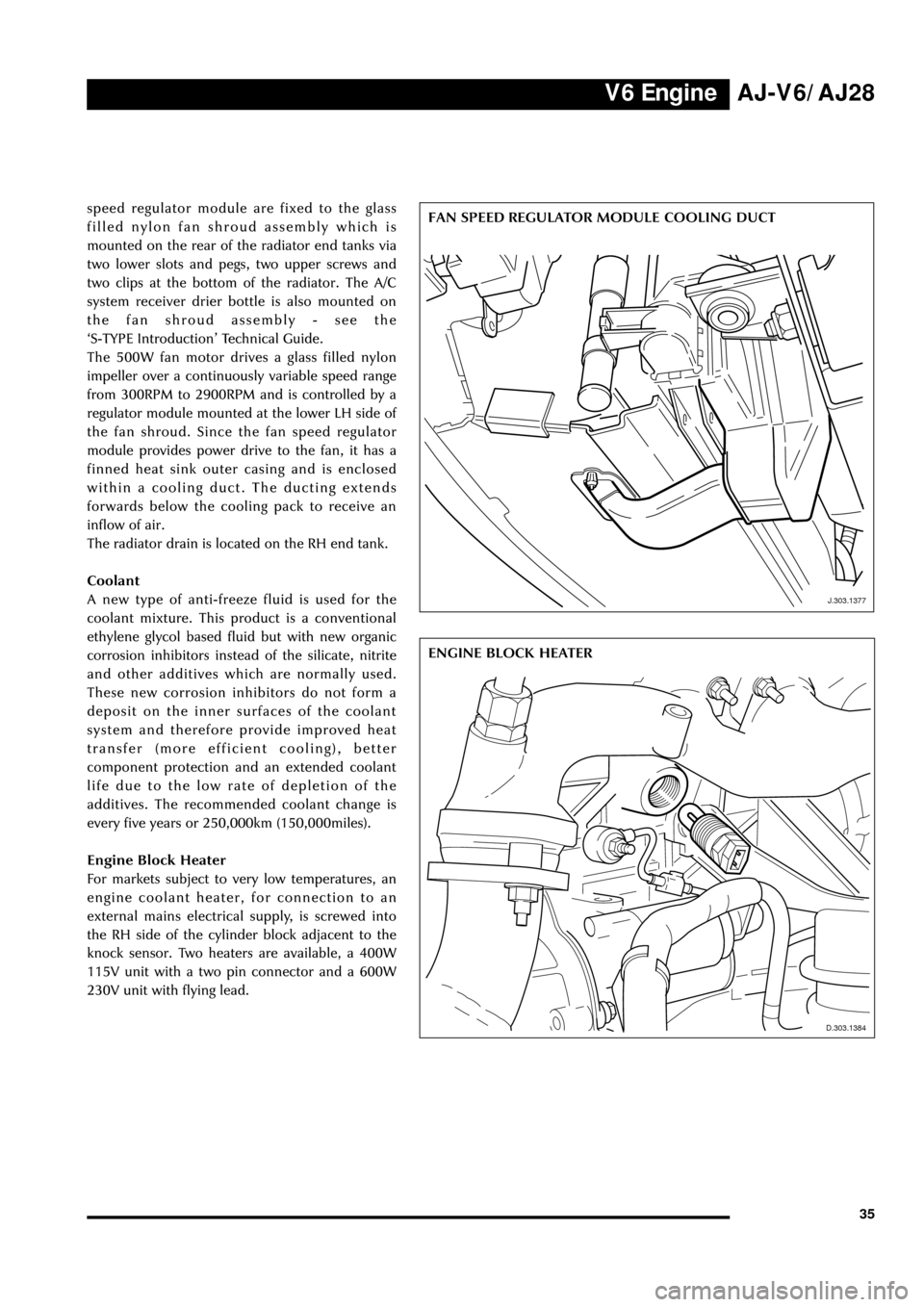

FAN SPEED REGULATOR MODULE COOLING DUCT speed regulator module are fixed to the glass

filled nylon fan shroud assembly which is

mounted on the rear of the radiator end tanks via

two lower slots and pegs, two upper screws and

two clips at the bottom of the radiator. The A/C

system receiver drier bottle is also mounted on

the fan shroud assembly - see the

ÔS-TYPE IntroductionÕ Technical Guide.

The 500W fan motor drives a glass filled nylon

impeller over a continuously variable speed range

from 300RPM to 2900RPM and is controlled by a

regulator module mounted at the lower LH side of

the fan shroud. Since the fan speed regulator

module provides power drive to the fan, it has a

finned heat sink outer casing and is enclosed

within a cooling duct. The ducting extends

forwards below the cooling pack to receive an

inflow of air.

The radiator drain is located on the RH end tank.

Coolant

A new type of anti-freeze fluid is used for the

coolant mixture. This product is a conventional

ethylene glycol based fluid but with new organic

corrosion inhibitors instead of the silicate, nitrite

and other additives which are normally used.

These new corrosion inhibitors do not form a

deposit on the inner surfaces of the coolant

system and therefore provide improved heat

transfer (more efficient cooling), better

component protection and an extended coolant

life due to the low rate of depletion of the

additives. The recommended coolant change is

every five years or 250,000km (150,000miles).

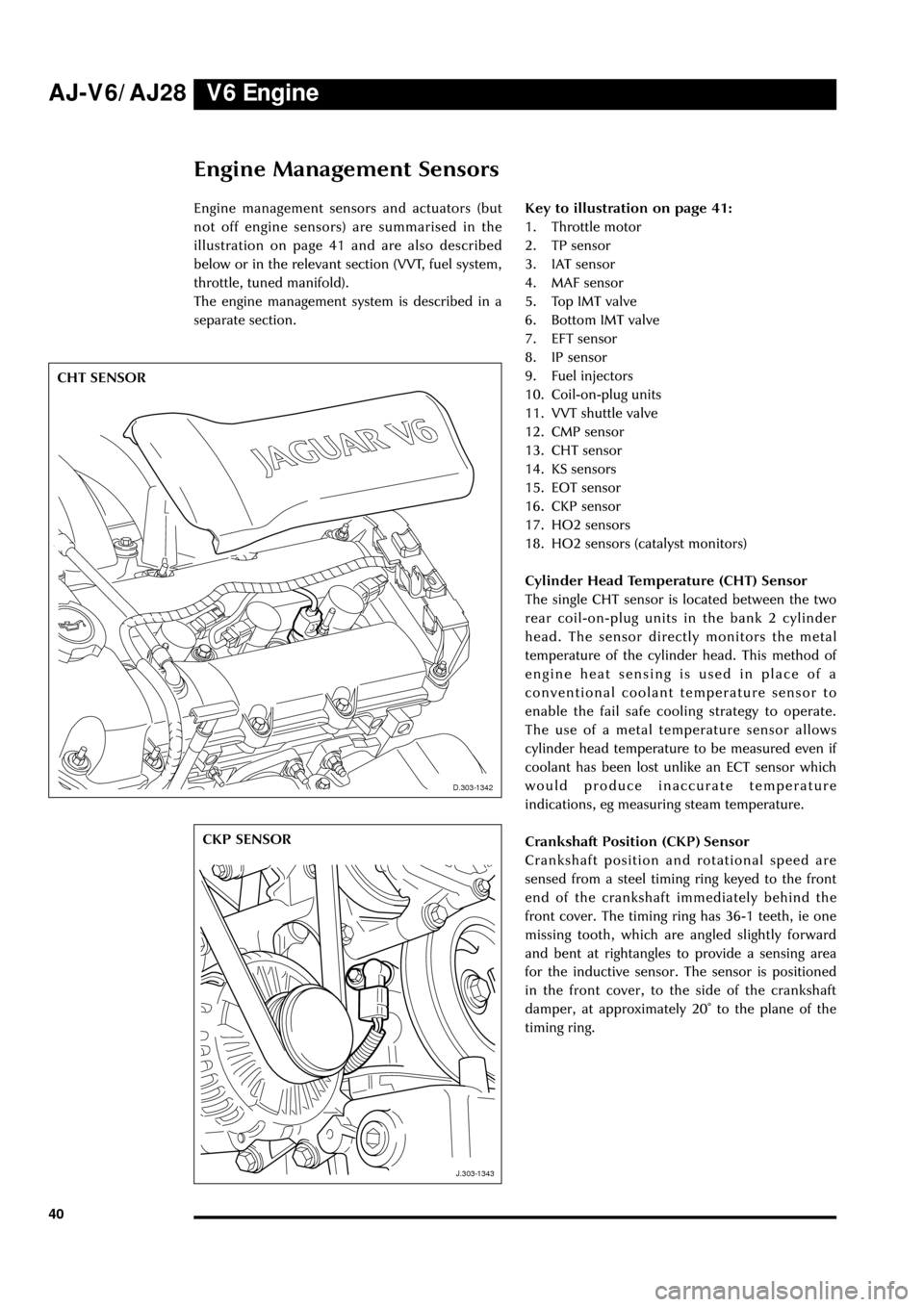

Engine Block Heater

For markets subject to very low temperatures, an

engine coolant heater, for connection to an

external mains electrical supply, is screwed into

the RH side of the cylinder block adjacent to the

knock sensor. Two heaters are available, a 400W

115V unit with a two pin connector and a 600W

230V unit with flying lead.

J.303.1377

Page 45 of 75

V6 Engine AJ-V6/AJ28

40

Engine Management Sensors

Key to illustration on page 41:

1. Throttle motor

2. TP sensor

3. IAT sensor

4. MAF sensor

5. Top IMT valve

6. Bottom IMT valve

7. EFT sensor

8. IP sensor

9. Fuel injectors

10. Coil-on-plug units

11. VVT shuttle valve

12. CMP sensor

13. CHT sensor

14. KS sensors

15. EOT sensor

16. CKP sensor

17. HO2 sensors

18. HO2 sensors (catalyst monitors)

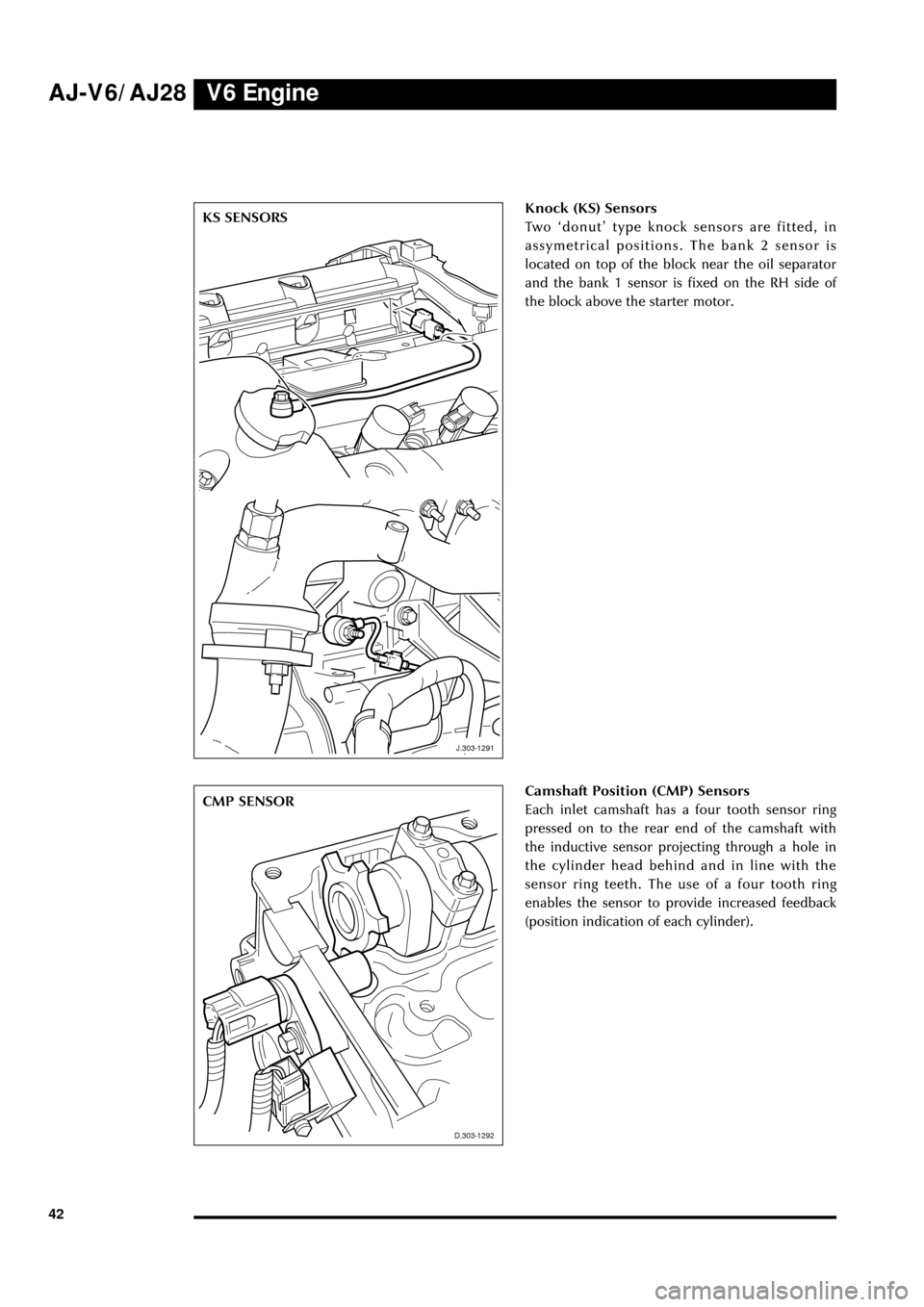

Cylinder Head Temperature (CHT) Sensor

The single CHT sensor is located between the two

rear coil-on-plug units in the bank 2 cylinder

head. The sensor directly monitors the metal

temperature of the cylinder head. This method of

engine heat sensing is used in place of a

conventional coolant temperature sensor to

enable the fail safe cooling strategy to operate.

The use of a metal temperature sensor allows

cylinder head temperature to be measured even if

coolant has been lost unlike an ECT sensor which

would produce inaccurate temperature

indications, eg measuring steam temperature.

Crankshaft Position (CKP) Sensor

Crankshaft position and rotational speed are

sensed from a steel timing ring keyed to the front

end of the crankshaft immediately behind the

front cover. The timing ring has 36-1 teeth, ie one

missing tooth, which are angled slightly forward

and bent at rightangles to provide a sensing area

for the inductive sensor. The sensor is positioned

in the front cover, to the side of the crankshaft

damper, at approximately 20û to the plane of the

timing ring.

D.303.1342

J.303.1343

CHT SENSOR

CKP SENSOR

D.303-1342

J.303-1343

Engine management sensors and actuators (but

not off engine sensors) are summarised in the

illustration on page 41 and are also described

below or in the relevant section (VVT, fuel system,

throttle, tuned manifold).

The engine management system is described in a

separate section.

Page 47 of 75

V6 Engine AJ-V6/AJ28

42

J.303.1291

KS SENSORS

J.303-1291

Knock (KS) Sensors

Two ÔdonutÕ type knock sensors are fitted, in

assymetrical positions. The bank 2 sensor is

located on top of the block near the oil separator

and the bank 1 sensor is fixed on the RH side of

the block above the starter motor.

D.303.1292

CMP SENSOR

D.303-1292

Camshaft Position (CMP) Sensors

Each inlet camshaft has a four tooth sensor ring

pressed on to the rear end of the camshaft with

the inductive sensor projecting through a hole in

the cylinder head behind and in line with the

sensor ring teeth. The use of a four tooth ring

enables the sensor to provide increased feedback

(position indication of each cylinder).

Page 48 of 75

V6 EngineAJ-V6/AJ28

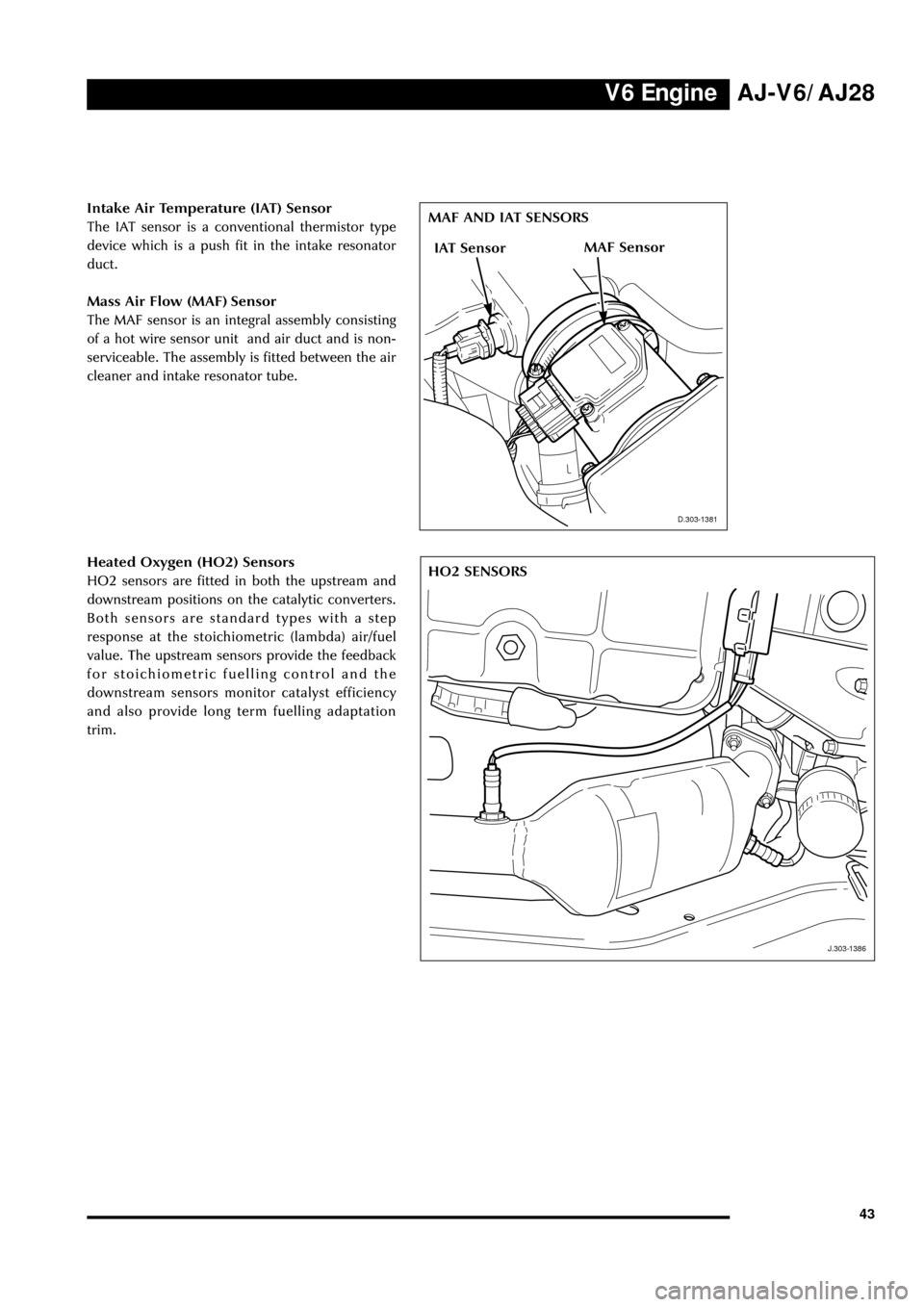

43 Intake Air Temperature (IAT) Sensor

The IAT sensor is a conventional thermistor type

device which is a push fit in the intake resonator

duct.

Mass Air Flow (MAF) Sensor

The MAF sensor is an integral assembly consisting

of a hot wire sensor unit and air duct and is non-

serviceable. The assembly is fitted between the air

cleaner and intake resonator tube.

D.303.1381

MAF AND IAT SENSORS

D.303-1381

J.303.1386

HO2 SENSORS

J.303-1386

Heated Oxygen (HO2) Sensors

HO2 sensors are fitted in both the upstream and

downstream positions on the catalytic converters.

Both sensors are standard types with a step

response at the stoichiometric (lambda) air/fuel

value. The upstream sensors provide the feedback

for stoichiometric fuelling control and the

downstream sensors monitor catalyst efficiency

and also provide long term fuelling adaptation

trim.

MAF SensorIAT Sensor

Page 50 of 75

V8 EngineAJ-V6/AJ28

45

Introduction

The AJ28 engine is a variant of the 4.0L 90û V8 units fitted to the XJ and XK range of vehicles. The AJ28

shares some of the changes incorporated in the current AJ27 engine: both engines are derived from the

original AJ26 unit. A number of features are unique to the AJ28 or are shared with the AJ-V6 engine also

described in this publication.

Features of the AJ28 engine are:

¥ Continuously variable inlet valve timing over a 48û

+

-2û crank angle: as fitted to the AJ27 engine

¥ Full authority cable-less electronic throttle control: as fitted to the AJ-V6 engine

¥ Air assisted fuel injection: similar to system used on the AJ27 engine

¥ Unique induction manifold with centrally mounted throttle body

¥ Returnless fuel system: similar to AJ-V6 engine

¥ Twin wall exhaust manifold

¥ Engine management system as used on the AJ-V6

¥ New sensors

¥ Modified sump and oil cooler

¥ Modified front end ancillary drive and components

Engine Specification

Maximum power DIN - 209 kW (281 BHP) at 6100 RPM

EEC - 203 kW (276 PS) at 6100 RPM

Maximum torque DIN - 390 Nm (287 lbft) at 4300 RPM

EEC - 278 Nm (279 lbft) at 4300 RPM

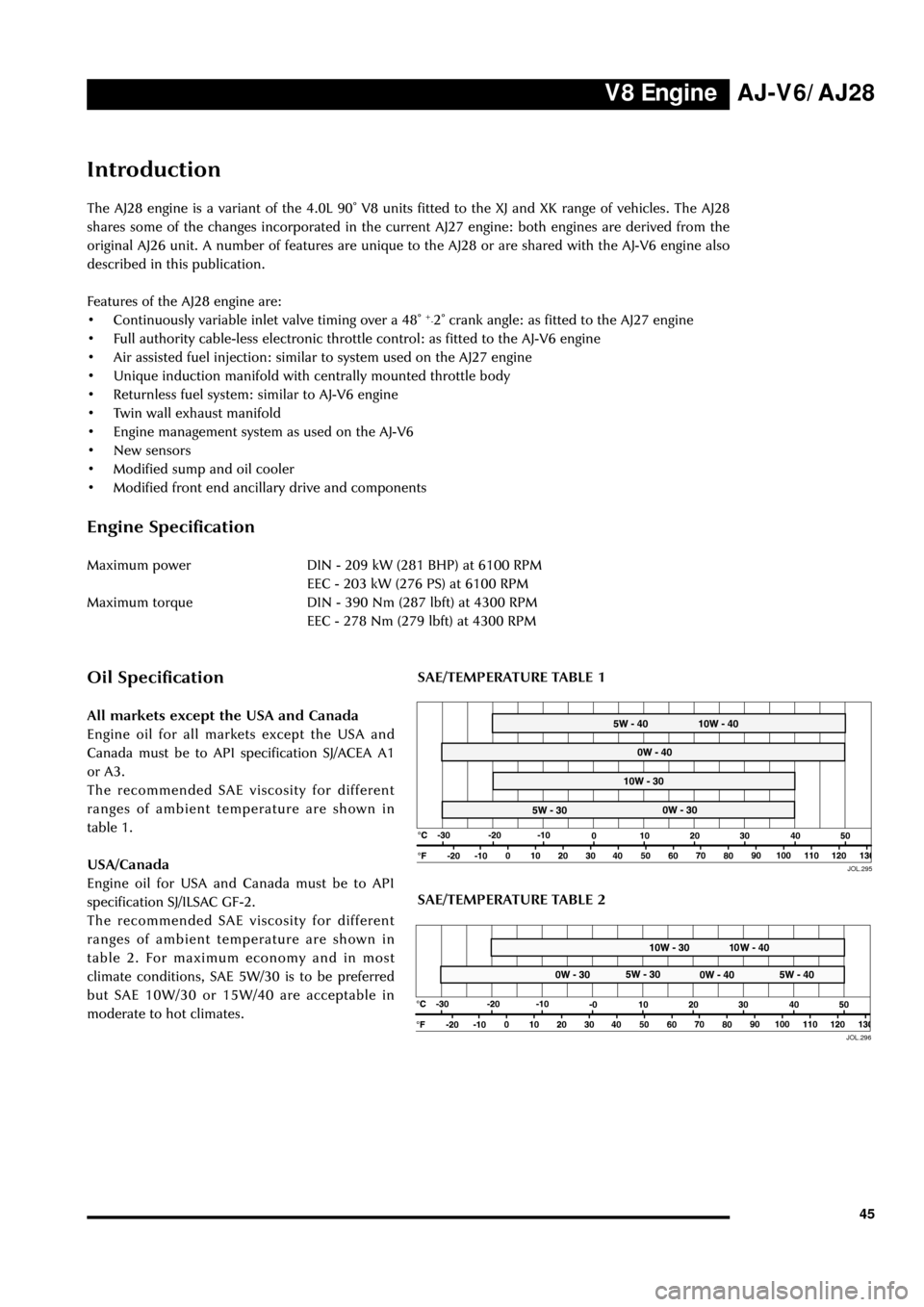

Oil Specification

All markets except the USA and Canada

Engine oil for all markets except the USA and

Canada must be to API specification SJ/ACEA A1

or A3.

The recommended SAE viscosity for different

ranges of ambient temperature are shown in

table 1.

USA/Canada

Engine oil for USA and Canada must be to API

specification SJ/ILSAC GF-2.

The recommended SAE viscosity for different

ranges of ambient temperature are shown in

table 2. For maximum economy and in most

climate conditions, SAE 5W/30 is to be preferred

but SAE 10W/30 or 15W/40 are acceptable in

moderate to hot climates.

JOL.29550

50JOL.296

SAE/TEMPERATURE TABLE 2

SAE/TEMPERATURE TABLE 1

Page 51 of 75

V8 Engine AJ-V6/AJ28

46

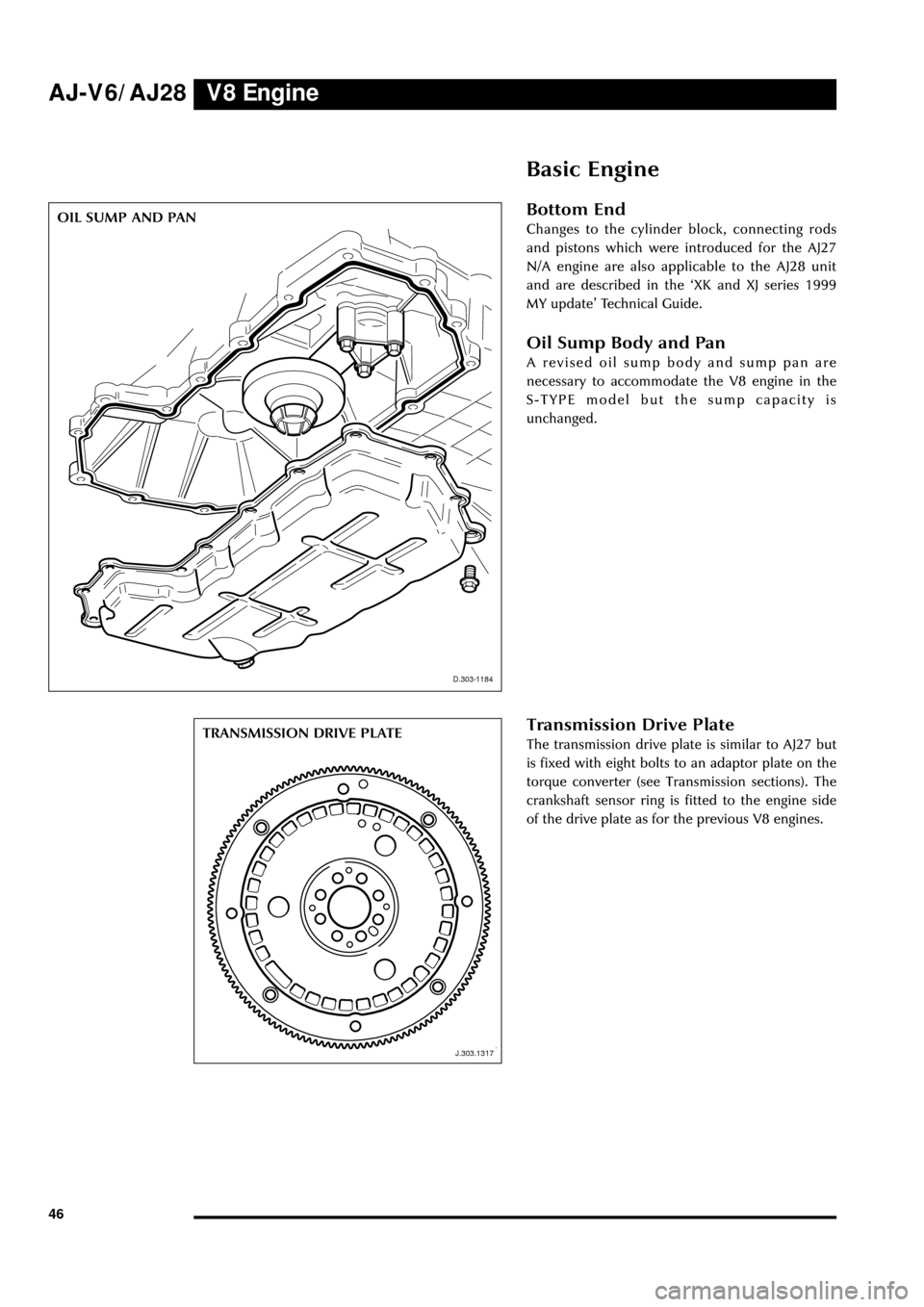

Basic Engine

Bottom End

Changes to the cylinder block, connecting rods

and pistons which were introduced for the AJ27

N/A engine are also applicable to the AJ28 unit

and are described in the ÔXK and XJ series 1999

MY updateÕ Technical Guide.

Oil Sump Body and Pan

A revised oil sump body and sump pan are

necessary to accommodate the V8 engine in the

S-TYPE model but the sump capacity is

unchanged.

D.303.1184

OIL SUMP AND PAN

D.303-1184

J.303.1317

TRANSMISSION DRIVE PLATE

J.303.1317

Transmission Drive Plate

The transmission drive plate is similar to AJ27 but

is fixed with eight bolts to an adaptor plate on the

torque converter (see Transmission sections). The

crankshaft sensor ring is fitted to the engine side

of the drive plate as for the previous V8 engines.