engine JAGUAR S TYPE 1999 1.G Powertrain Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1999, Model line: S TYPE, Model: JAGUAR S TYPE 1999 1.GPages: 75, PDF Size: 3.4 MB

Page 66 of 75

Automatic TransmissionAJ-V6/AJ28

61

Introduction

The 5R55N type 5-speed automatic transmission is fitted to both the V6 and V8 engines. The

transmission is controlled electronically by the powertrain control module (PCM) without the use of a

dedicated control module. Normal P, R, N, D drive functions plus manual selection of 4th, 3th and 2nd

gears are provided by a Jaguar style ÔJÕ gate (not the same as XJ and XK Series - see ÔS-TYPE IntroductionÕ

Techical Guide). Sports mode and traction assistance are selected at the ÔJÕ gate.

Specification

Transmission weight with fluid: 90 kg (198 lbs)

Oil type: Mercon V semi-synthetic (not compatible with other fluids)

Oil capacity: 9 Litres (9.5 quarts) - new

5 Litres (5.3 quarts) - after draining

Oil Fill/change: Filled for life, no top up required (no dipstick)

Gear ratios: 1st 2nd 3rd 4th 5th Rev

3.24 : 1 2.44 : 1 1.55 : 1 1 : 1 0.75 : 1 3.07 : 1

D.307.313

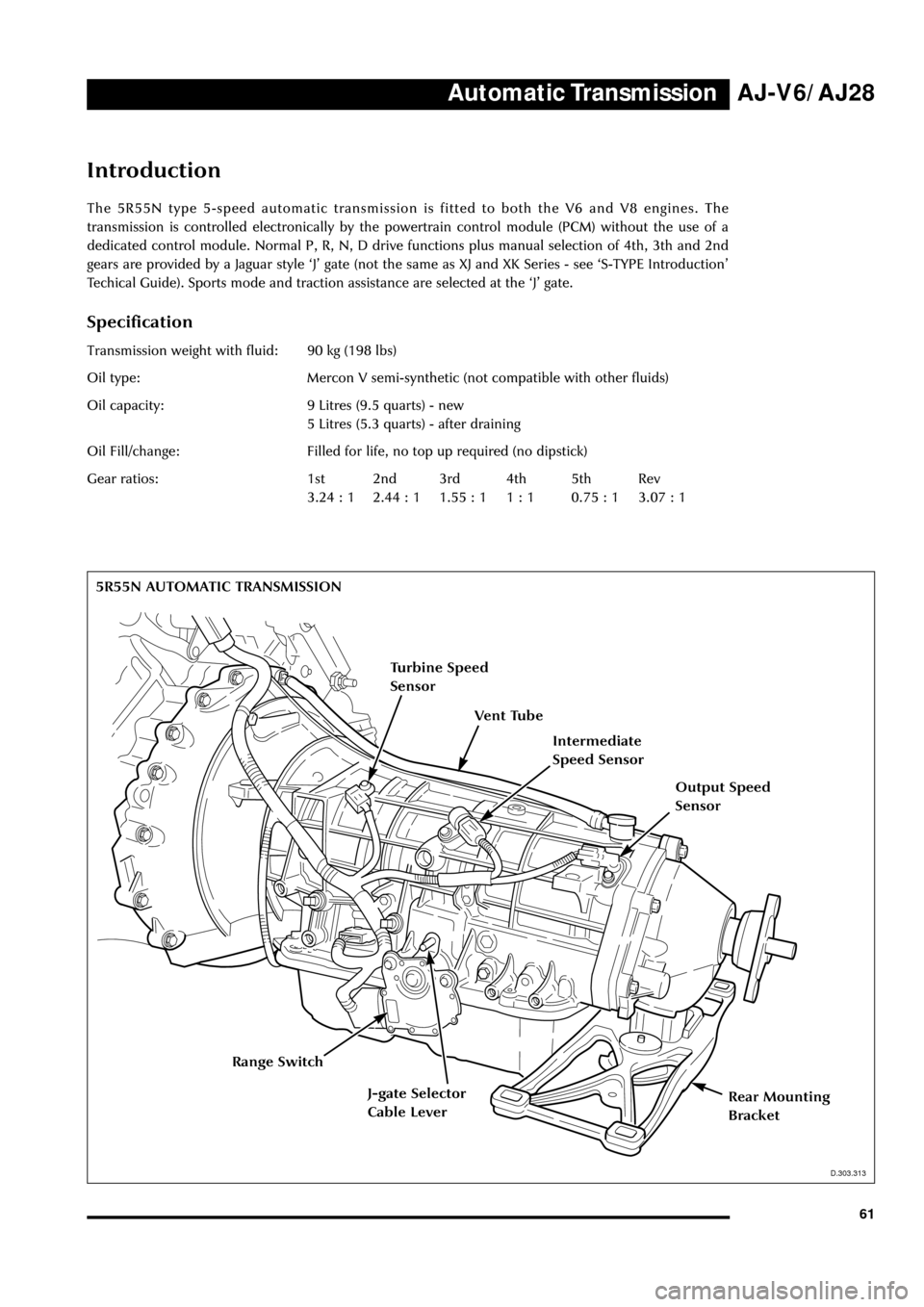

5R55N AUTOMATIC TRANSMISSION

D.303.313

Vent Tube

Turbine Speed

Sensor

Intermediate

Speed Sensor

Output Speed

Sensor

Range Switch

Rear Mounting

BracketJ-gate Selector

Cable Lever

Page 67 of 75

Automatic Transmission AJ-V6/AJ28

62

D.307.321

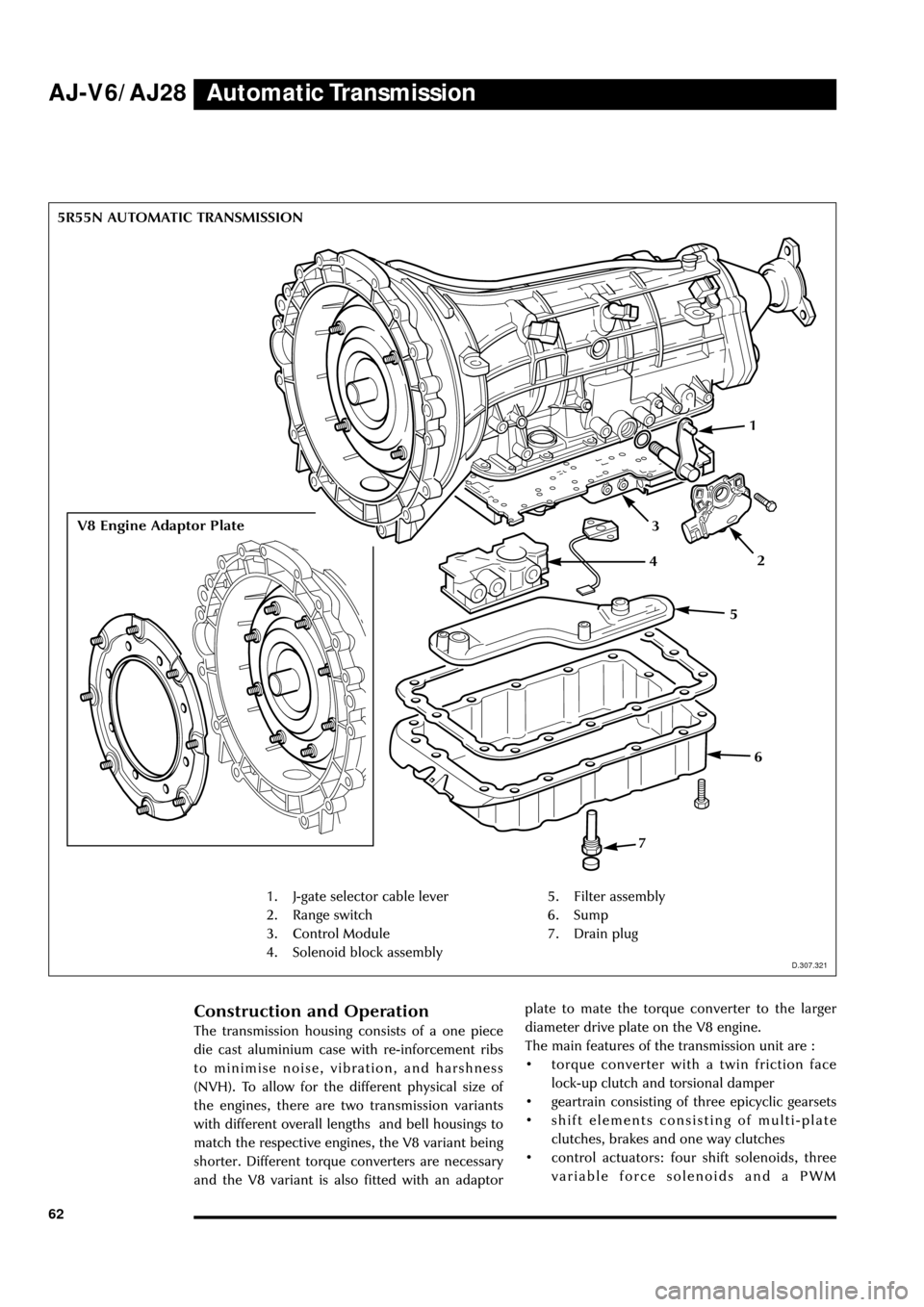

V8 Engine Adaptor Plate

D.307.321

1. J-gate selector cable lever

2. Range switch

3. Control Module

4. Solenoid block assembly5. Filter assembly

6. Sump

7. Drain plug

Construction and Operation

The transmission housing consists of a one piece

die cast aluminium case with re-inforcement ribs

to minimise noise, vibration, and harshness

(NVH). To allow for the different physical size of

the engines, there are two transmission variants

with different overall lengths and bell housings to

match the respective engines, the V8 variant being

shorter. Different torque converters are necessary

and the V8 variant is also fitted with an adaptorplate to mate the torque converter to the larger

diameter drive plate on the V8 engine.

The main features of the transmission unit are :

¥ torque converter with a twin friction face

lock-up clutch and torsional damper

¥ geartrain consisting of three epicyclic gearsets

¥ shift elements consisting of multi-plate

clutches, brakes and one way clutches

¥ control actuators: four shift solenoids, three

variable force solenoids and a PWM 5R55N AUTOMATIC TRANSMISSION

1

3

7

6

5

24

Page 68 of 75

Automatic TransmissionAJ-V6/AJ28

63 controlled solenoid are mounted on an

integral, replaceable, control module

¥ three speed sensors mounted on the external

casing: turbine speed sensor, intermediate

speed sensor and output speed sensor

¥ an oil temperature sensor is fitted inside the

transmission.

The gear select lever is connected via a Bowden

cable to an operating lever on the left side of the

transmission casing. A digital rotary switch, the

transmission range switch, fits over the shaft of

the operating lever and is fixed by two bolts to

the transmission casing. Selection of a particular

drive function generates a 4 bit binary coded

signal which is transmitted directly to the PCM

over a four wire parallel interface. As on the XK

and XJ Series, lateral movement of the gear select

lever across the gate, D to 4 or 4 to D, operates a

switch which indicates the selected function to

the PCM (the Bowden cable is not actuated

laterally).

The PCM directly controls the transmission

actuators as a response to driver demand, engine

requirements and according to the selected shift

mode. Gear selection is controlled by commands

to the four shift solenoids. If, during gear

selection, the relative speeds monitored by the

speed sensors are not as expected, the PCM

varies the analogue signal to the variable force

solenoids to increase/decrease the clutch pressure

(closed loop control). Increased engagement times

due to ageing are also controlled by adaptive shiftpressure.

Apart from the sports mode and traction mode

selected by the driver, there are pre-programmed

modes selected by the PCM in response to sensed

driving conditions :

¥ increased load such as gradients and trailer

towing

¥ cruise control

¥ hot mode: strategies including clutch lock up

are applied to reduce heat.

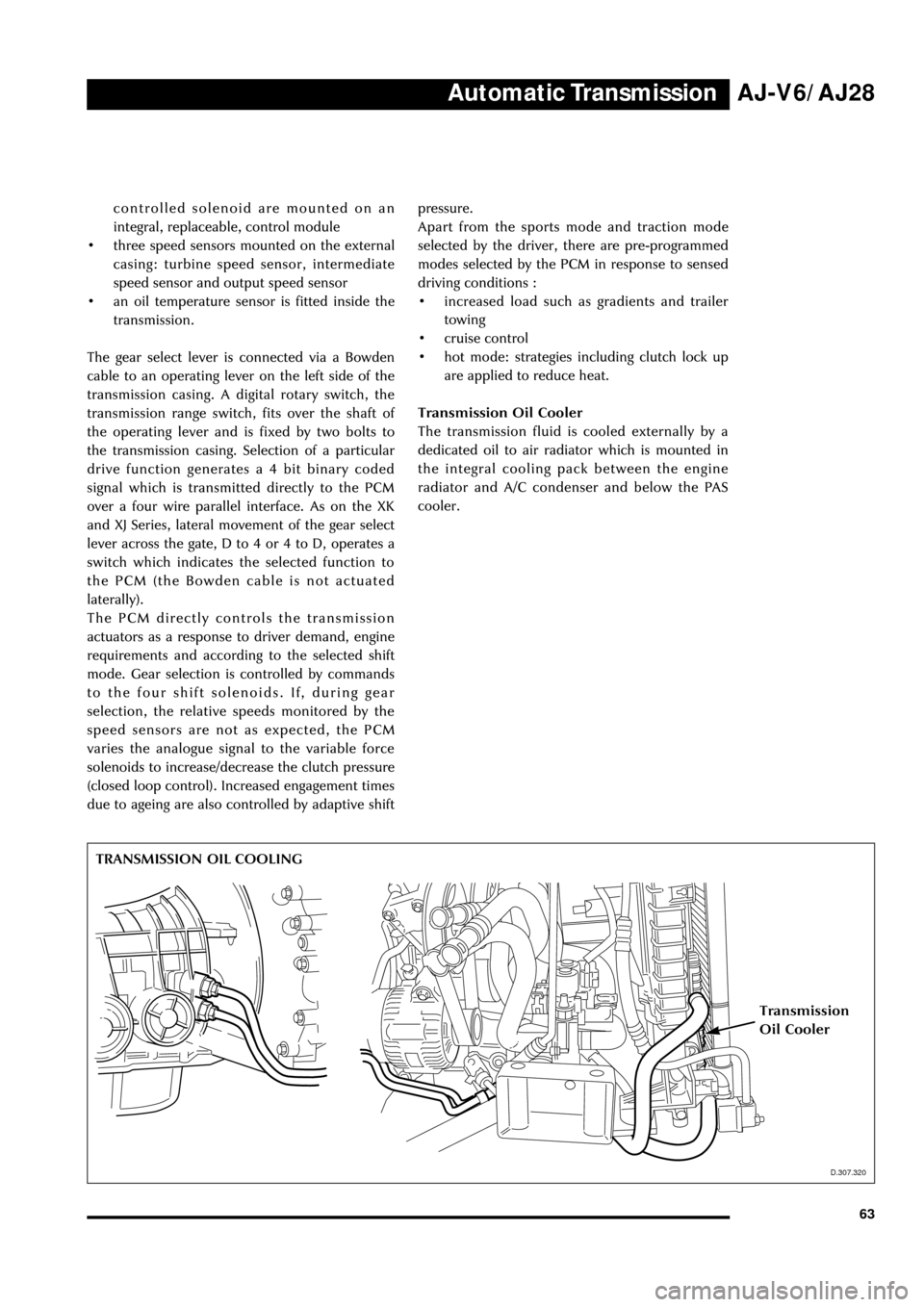

Transmission Oil Cooler

The transmission fluid is cooled externally by a

dedicated oil to air radiator which is mounted in

the integral cooling pack between the engine

radiator and A/C condenser and below the PAS

cooler.

D.307.320

TRANSMISSION OIL COOLING

Transmission

Oil Cooler

D.307.320

Page 70 of 75

Manual TransmissionAJ-V6/AJ28

65

D.307.315

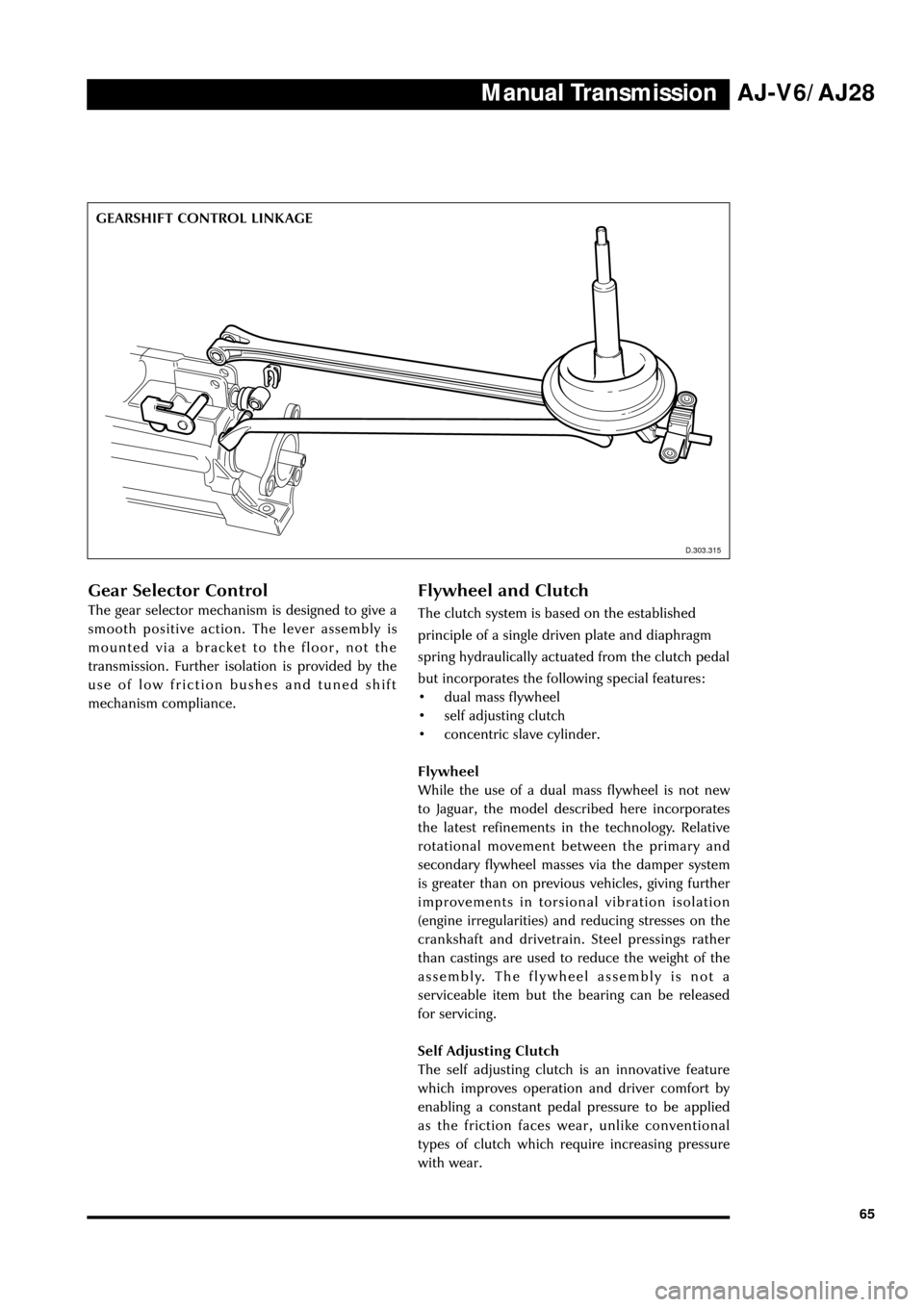

Gear Selector Control

The gear selector mechanism is designed to give a

smooth positive action. The lever assembly is

mounted via a bracket to the floor, not the

transmission. Further isolation is provided by the

use of low friction bushes and tuned shift

mechanism compliance.

Flywheel and Clutch

The clutch system is based on the established

principle of a single driven plate and diaphragm

spring hydraulically actuated from the clutch pedal

but incorporates the following special features:

¥ dual mass flywheel

¥ self adjusting clutch

¥ concentric slave cylinder.

Flywheel

While the use of a dual mass flywheel is not new

to Jaguar, the model described here incorporates

the latest refinements in the technology. Relative

rotational movement between the primary and

secondary flywheel masses via the damper system

is greater than on previous vehicles, giving further

improvements in torsional vibration isolation

(engine irregularities) and reducing stresses on the

crankshaft and drivetrain. Steel pressings rather

than castings are used to reduce the weight of the

assembly. The flywheel assembly is not a

serviceable item but the bearing can be released

for servicing.

Self Adjusting Clutch

The self adjusting clutch is an innovative feature

which improves operation and driver comfort by

enabling a constant pedal pressure to be applied

as the friction faces wear, unlike conventional

types of clutch which require increasing pressure

with wear. GEARSHIFT CONTROL LINKAGE

D.303.315

Page 71 of 75

Manual Transmission AJ-V6/AJ28

66With a conventional clutch, increased lining wear

causes the angle of the actuating diaphragm

spring to change as the pressure plate moves

axially towards the engine, requiring a greater

force to operate the clutch (diaphragm actuating

force varies with diaphragm angle). The self

adjusting clutch eliminates the problem by

allowing the diaphragm spring to follow the axial

movement of the pressure plate thus maintaining

the diaphragm spring at the same angle

throughout the life of the clutch. As well as

maintaining a constant pedal pressure, the clamp

force on the pressure plate also remains constant

with wear.

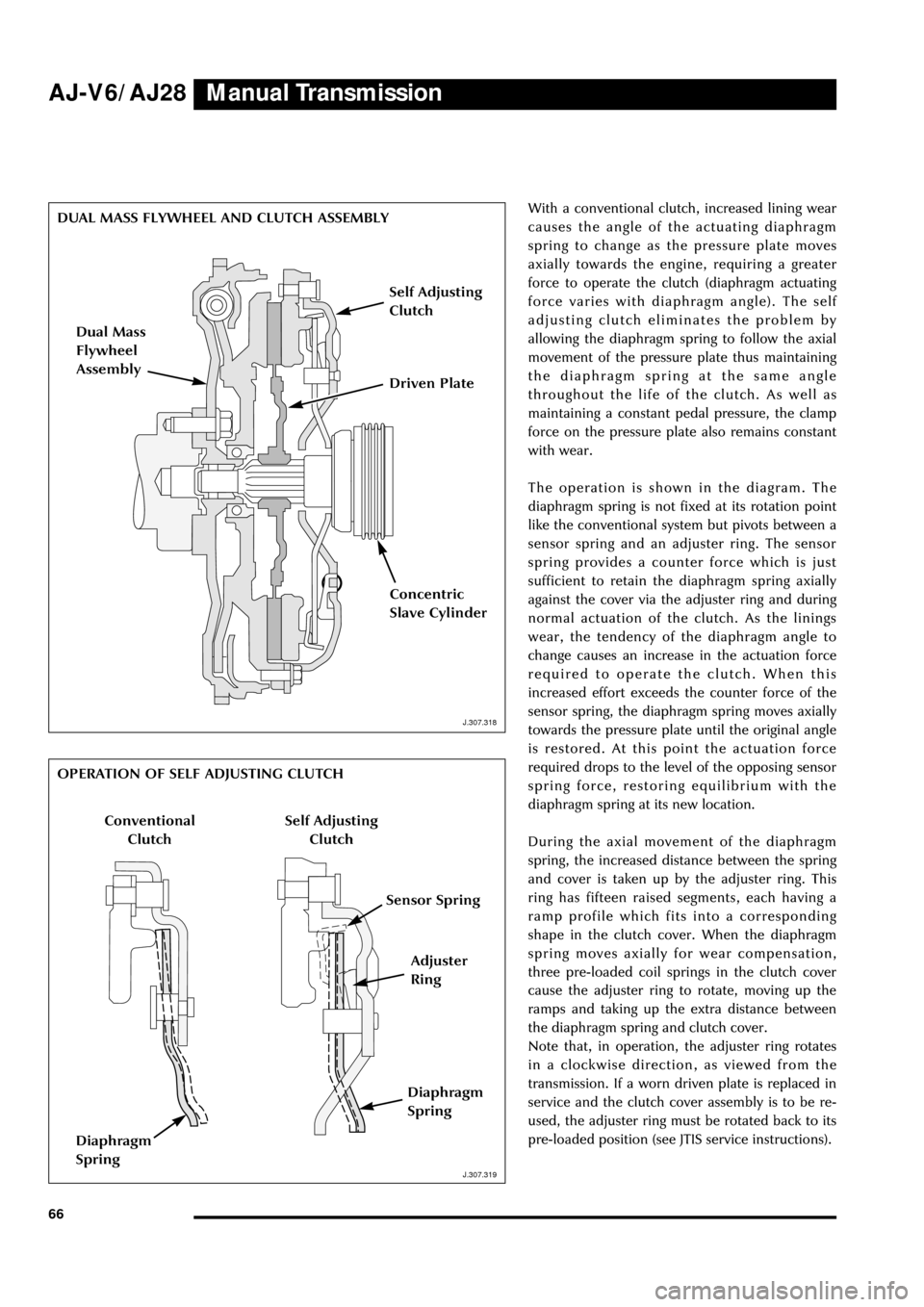

The operation is shown in the diagram. The

diaphragm spring is not fixed at its rotation point

like the conventional system but pivots between a

sensor spring and an adjuster ring. The sensor

spring provides a counter force which is just

sufficient to retain the diaphragm spring axially

against the cover via the adjuster ring and during

normal actuation of the clutch. As the linings

wear, the tendency of the diaphragm angle to

change causes an increase in the actuation force

required to operate the clutch. When this

increased effort exceeds the counter force of the

sensor spring, the diaphragm spring moves axially

towards the pressure plate until the original angle

is restored. At this point the actuation force

required drops to the level of the opposing sensor

spring force, restoring equilibrium with the

diaphragm spring at its new location.

During the axial movement of the diaphragm

spring, the increased distance between the spring

and cover is taken up by the adjuster ring. This

ring has fifteen raised segments, each having a

ramp profile which fits into a corresponding

shape in the clutch cover. When the diaphragm

spring moves axially for wear compensation,

three pre-loaded coil springs in the clutch cover

cause the adjuster ring to rotate, moving up the

ramps and taking up the extra distance between

the diaphragm spring and clutch cover.

Note that, in operation, the adjuster ring rotates

in a clockwise direction, as viewed from the

transmission. If a worn driven plate is replaced in

service and the clutch cover assembly is to be re-

used, the adjuster ring must be rotated back to its

pre-loaded position (see JTIS service instructions).

J.307.318

DUAL MASS FLYWHEEL AND CLUTCH ASSEMBLY

J.307.318

J.307.319

OPERATION OF SELF ADJUSTING CLUTCH

J.307.319

Dual Mass

Flywheel

Assembly

Self Adjusting

Clutch

Driven Plate

Concentric

Slave Cylinder

Adjuster

Ring

Conventional

Clutch

Sensor Spring

Diaphragm

Spring

Self Adjusting

Clutch

Diaphragm

Spring

Page 74 of 75

Powertrain ManagementAJ-V6/AJ28

69

Introduction

All powertrain and associated management

functions are controlled from a single unit, the

powertrain control module (PCM). These

functions are as follows:

¥ overall monitoring and control of

performance, fuel economy, emissions,

driveability and safety

¥ receives and processes direct inputs from

engine, transmission, fuel system and

ancillary systems sensors

¥ provides direct control of actuator devices

¥ communicates with other modules via the

SCP bus (eg to obtain wheel speed

information)

¥ provides system diagnostics to conform to

OBDII requirements.

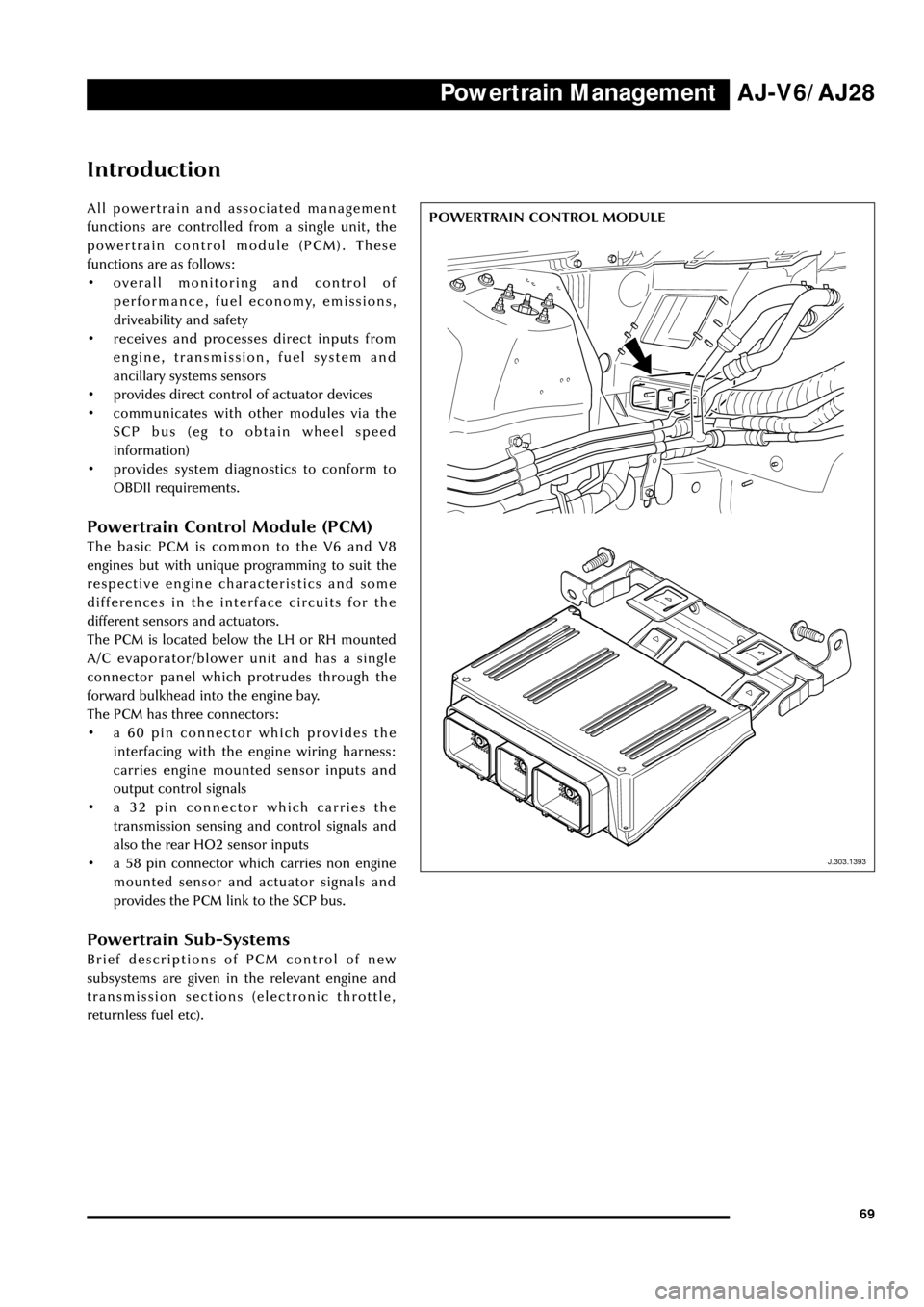

Powertrain Control Module (PCM)

The basic PCM is common to the V6 and V8

engines but with unique programming to suit the

respective engine characteristics and some

differences in the interface circuits for the

different sensors and actuators.

The PCM is located below the LH or RH mounted

A/C evaporator/blower unit and has a single

connector panel which protrudes through the

forward bulkhead into the engine bay.

The PCM has three connectors:

¥ a 60 pin connector which provides the

interfacing with the engine wiring harness:

carries engine mounted sensor inputs and

output control signals

¥ a 32 pin connector which carries the

transmission sensing and control signals and

also the rear HO2 sensor inputs

¥ a 58 pin connector which carries non engine

mounted sensor and actuator signals and

provides the PCM link to the SCP bus.

Powertrain Sub-Systems

Brief descriptions of PCM control of new

subsystems are given in the relevant engine and

transmission sections (electronic throttle,

returnless fuel etc).

J.303.1393

POWERTRAIN CONTROL MODULE

J.303.1393