diagram JAGUAR S TYPE 1999 1.G Powertrain Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1999, Model line: S TYPE, Model: JAGUAR S TYPE 1999 1.GPages: 75, PDF Size: 3.4 MB

Page 24 of 75

V6 EngineAJ-V6/AJ28

19

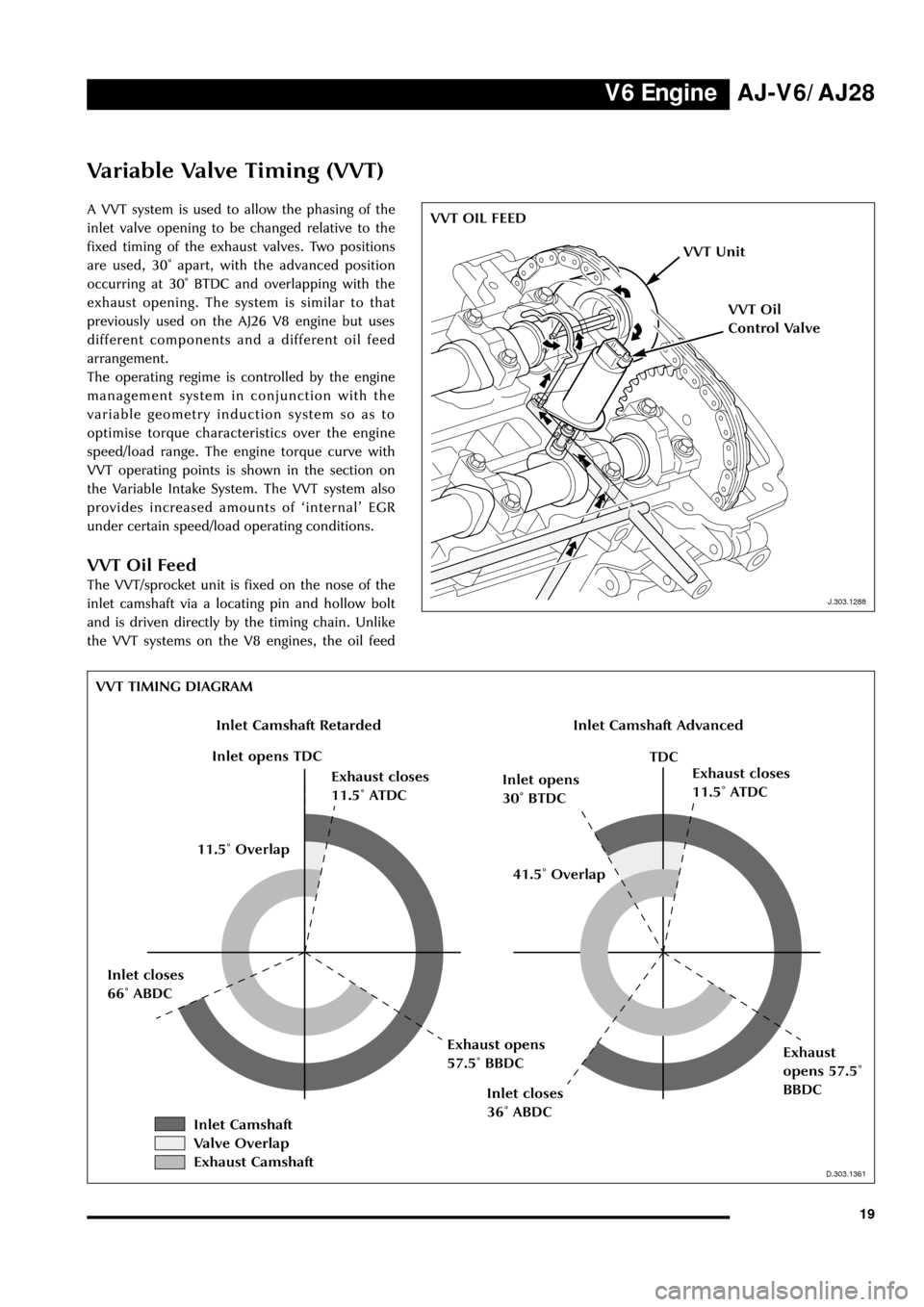

Variable Valve Timing (VVT)

A VVT system is used to allow the phasing of the

inlet valve opening to be changed relative to the

fixed timing of the exhaust valves. Two positions

are used, 30û apart, with the advanced position

occurring at 30û BTDC and overlapping with the

exhaust opening. The system is similar to that

previously used on the AJ26 V8 engine but uses

different components and a different oil feed

arrangement.

The operating regime is controlled by the engine

management system in conjunction with the

variable geometry induction system so as to

optimise torque characteristics over the engine

speed/load range. The engine torque curve with

VVT operating points is shown in the section on

the Variable Intake System. The VVT system also

provides increased amounts of ÔinternalÕ EGR

under certain speed/load operating conditions.

VVT Oil Feed

The VVT/sprocket unit is fixed on the nose of the

inlet camshaft via a locating pin and hollow bolt

and is driven directly by the timing chain. Unlike

the VVT systems on the V8 engines, the oil feed

J.303.1288

VVT OIL FEED

J.303.1288

VVT Unit

VVT Oil

Control Valve

D.303.1361

VVT TIMING DIAGRAM

D.303.1361

Inlet Camshaft RetardedInlet Camshaft Advanced

Inlet opens TDC

Exhaust closes

11.5û ATDCInlet opens

30û BTDCExhaust closes

11.5û ATDC

TDC

Inlet closes

36û ABDC

Exhaust

opens 57.5û

BBDC Inlet closes

66û ABDCExhaust opens

57.5û BBDC41.5û Overlap 11.5û Overlap

Inlet Camshaft

Valve Overlap

Exhaust Camshaft

Page 71 of 75

Manual Transmission AJ-V6/AJ28

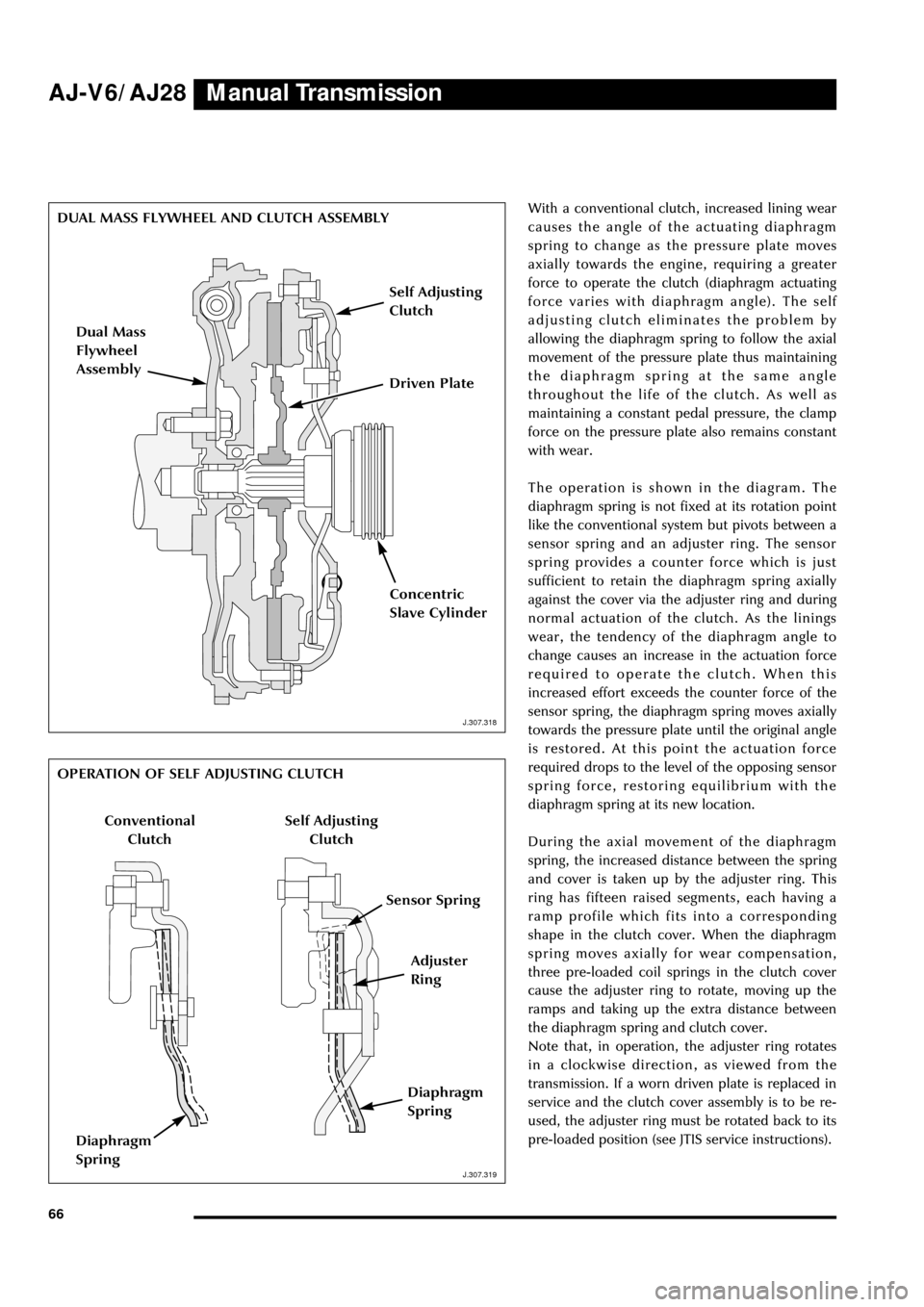

66With a conventional clutch, increased lining wear

causes the angle of the actuating diaphragm

spring to change as the pressure plate moves

axially towards the engine, requiring a greater

force to operate the clutch (diaphragm actuating

force varies with diaphragm angle). The self

adjusting clutch eliminates the problem by

allowing the diaphragm spring to follow the axial

movement of the pressure plate thus maintaining

the diaphragm spring at the same angle

throughout the life of the clutch. As well as

maintaining a constant pedal pressure, the clamp

force on the pressure plate also remains constant

with wear.

The operation is shown in the diagram. The

diaphragm spring is not fixed at its rotation point

like the conventional system but pivots between a

sensor spring and an adjuster ring. The sensor

spring provides a counter force which is just

sufficient to retain the diaphragm spring axially

against the cover via the adjuster ring and during

normal actuation of the clutch. As the linings

wear, the tendency of the diaphragm angle to

change causes an increase in the actuation force

required to operate the clutch. When this

increased effort exceeds the counter force of the

sensor spring, the diaphragm spring moves axially

towards the pressure plate until the original angle

is restored. At this point the actuation force

required drops to the level of the opposing sensor

spring force, restoring equilibrium with the

diaphragm spring at its new location.

During the axial movement of the diaphragm

spring, the increased distance between the spring

and cover is taken up by the adjuster ring. This

ring has fifteen raised segments, each having a

ramp profile which fits into a corresponding

shape in the clutch cover. When the diaphragm

spring moves axially for wear compensation,

three pre-loaded coil springs in the clutch cover

cause the adjuster ring to rotate, moving up the

ramps and taking up the extra distance between

the diaphragm spring and clutch cover.

Note that, in operation, the adjuster ring rotates

in a clockwise direction, as viewed from the

transmission. If a worn driven plate is replaced in

service and the clutch cover assembly is to be re-

used, the adjuster ring must be rotated back to its

pre-loaded position (see JTIS service instructions).

J.307.318

DUAL MASS FLYWHEEL AND CLUTCH ASSEMBLY

J.307.318

J.307.319

OPERATION OF SELF ADJUSTING CLUTCH

J.307.319

Dual Mass

Flywheel

Assembly

Self Adjusting

Clutch

Driven Plate

Concentric

Slave Cylinder

Adjuster

Ring

Conventional

Clutch

Sensor Spring

Diaphragm

Spring

Self Adjusting

Clutch

Diaphragm

Spring