lock JAGUAR S TYPE 2005 1.G Technical Guide Update

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2005, Model line: S TYPE, Model: JAGUAR S TYPE 2005 1.GPages: 133, PDF Size: 3.48 MB

Page 37 of 133

JAGUARS-TYPEOccupant Protection

32

Seatbelts

D.501.1777

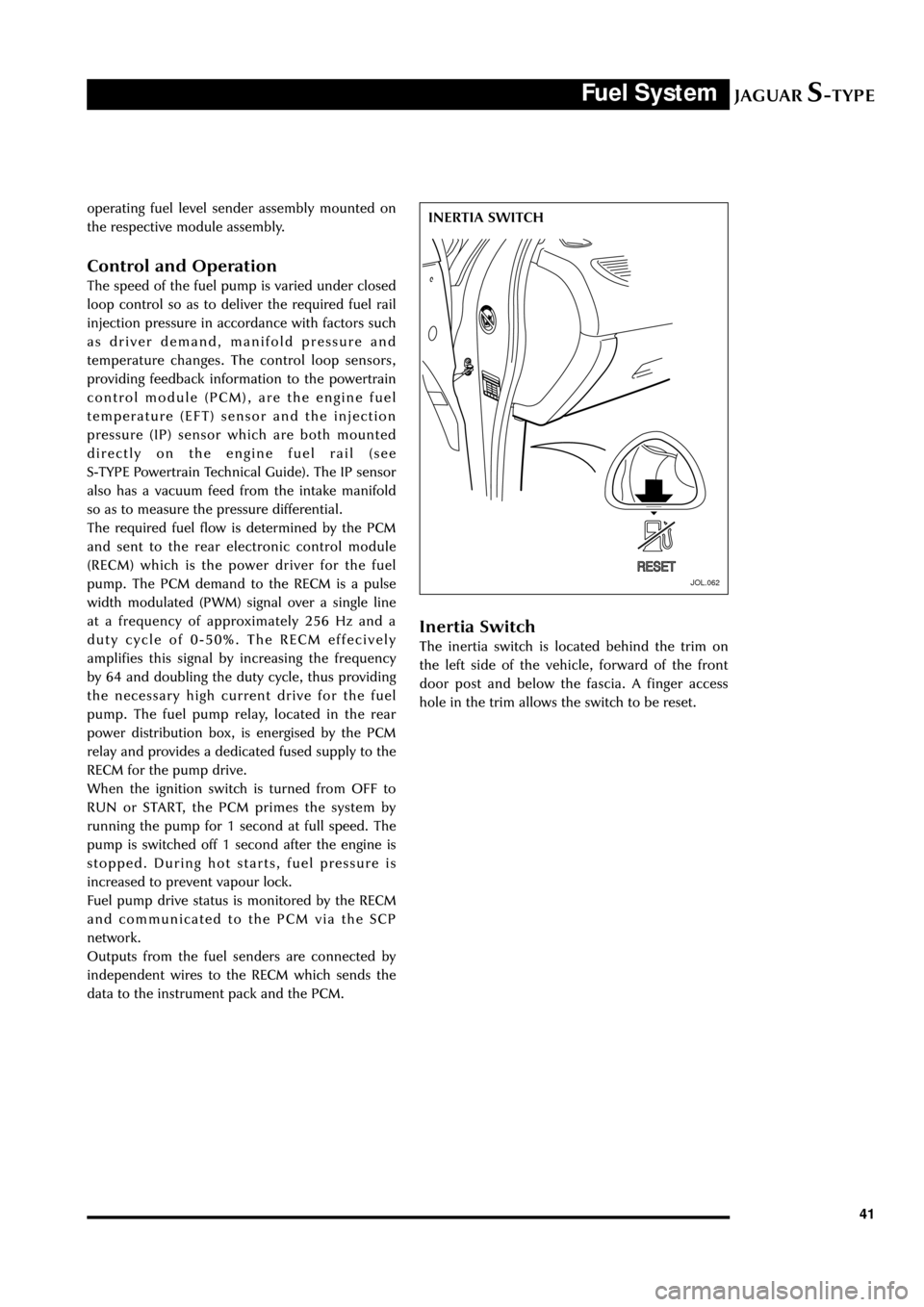

REAR SEAT BELT RETRACTOR ASSEMBLIES

D.501.1465

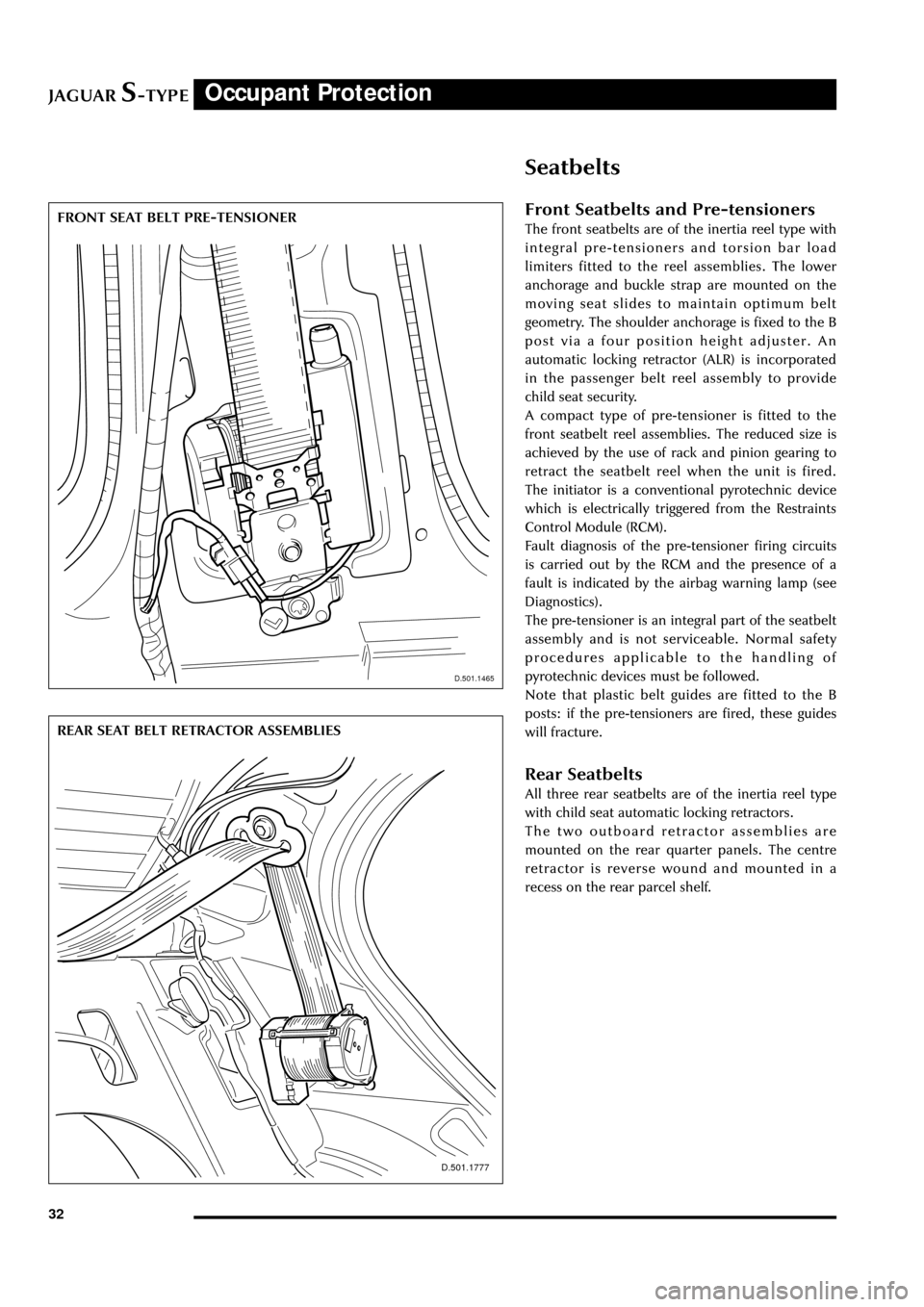

FRONT SEAT BELT PRE-TENSIONERFront Seatbelts and Pre-tensioners

The front seatbelts are of the inertia reel type with

integral pre-tensioners and torsion bar load

limiters fitted to the reel assemblies. The lower

anchorage and buckle strap are mounted on the

moving seat slides to maintain optimum belt

geometry. The shoulder anchorage is fixed to the B

post via a four position height adjuster. An

automatic locking retractor (ALR) is incorporated

in the passenger belt reel assembly to provide

child seat security.

A compact type of pre-tensioner is fitted to the

front seatbelt reel assemblies. The reduced size is

achieved by the use of rack and pinion gearing to

retract the seatbelt reel when the unit is fired.

The initiator is a conventional pyrotechnic device

which is electrically triggered from the Restraints

Control Module (RCM).

Fault diagnosis of the pre-tensioner firing circuits

is carried out by the RCM and the presence of a

fault is indicated by the airbag warning lamp (see

Diagnostics).

The pre-tensioner is an integral part of the seatbelt

assembly and is not serviceable. Normal safety

procedures applicable to the handling of

pyrotechnic devices must be followed.

Note that plastic belt guides are fitted to the B

posts: if the pre-tensioners are fired, these guides

will fracture.

Rear Seatbelts

All three rear seatbelts are of the inertia reel type

with child seat automatic locking retractors.

The two outboard retractor assemblies are

mounted on the rear quarter panels. The centre

retractor is reverse wound and mounted in a

recess on the rear parcel shelf.

D.501.1465

Page 46 of 133

JAGUARS-TYPEFuel System

41

JOL.062

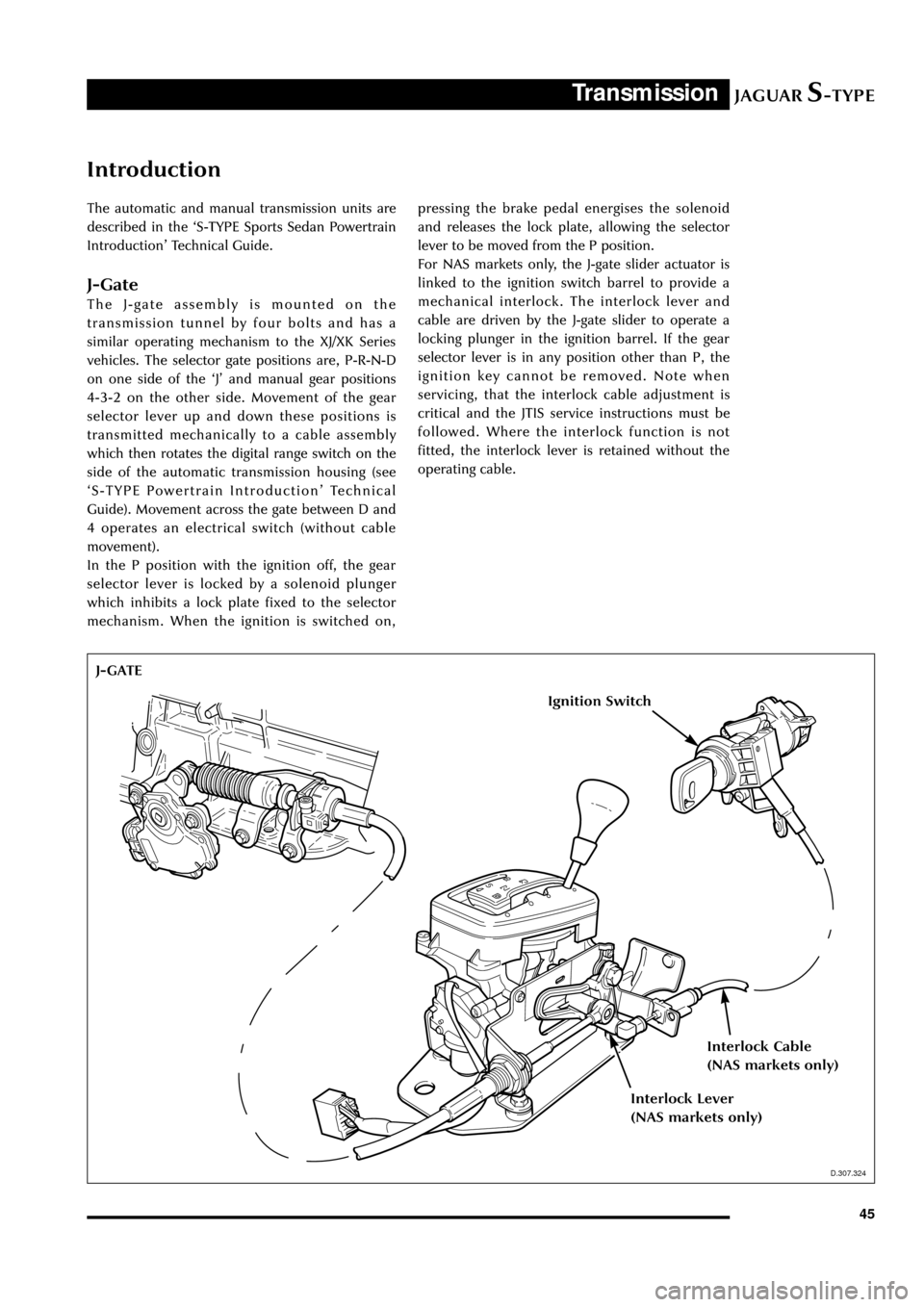

INERTIA SWITCH operating fuel level sender assembly mounted on

the respective module assembly.

Control and Operation

The speed of the fuel pump is varied under closed

loop control so as to deliver the required fuel rail

injection pressure in accordance with factors such

as driver demand, manifold pressure and

temperature changes. The control loop sensors,

providing feedback information to the powertrain

control module (PCM), are the engine fuel

temperature (EFT) sensor and the injection

pressure (IP) sensor which are both mounted

directly on the engine fuel rail (see

S-TYPE Powertrain Technical Guide). The IP sensor

also has a vacuum feed from the intake manifold

so as to measure the pressure differential.

The required fuel flow is determined by the PCM

and sent to the rear electronic control module

(RECM) which is the power driver for the fuel

pump. The PCM demand to the RECM is a pulse

width modulated (PWM) signal over a single line

at a frequency of approximately 256 Hz and a

duty cycle of 0-50%. The RECM effecively

amplifies this signal by increasing the frequency

by 64 and doubling the duty cycle, thus providing

the necessary high current drive for the fuel

pump. The fuel pump relay, located in the rear

power distribution box, is energised by the PCM

relay and provides a dedicated fused supply to the

RECM for the pump drive.

When the ignition switch is turned from OFF to

RUN or START, the PCM primes the system by

running the pump for 1 second at full speed. The

pump is switched off 1 second after the engine is

stopped. During hot starts, fuel pressure is

increased to prevent vapour lock.

Fuel pump drive status is monitored by the RECM

and communicated to the PCM via the SCP

network.

Outputs from the fuel senders are connected by

independent wires to the RECM which sends the

data to the instrument pack and the PCM.

Inertia Switch

The inertia switch is located behind the trim on

the left side of the vehicle, forward of the front

door post and below the fascia. A finger access

hole in the trim allows the switch to be reset.

Page 50 of 133

JAGUARS-TYPETransmission

45

Introduction

The automatic and manual transmission units are

described in the ÔS-TYPE Sports Sedan Powertrain

IntroductionÕ Technical Guide.

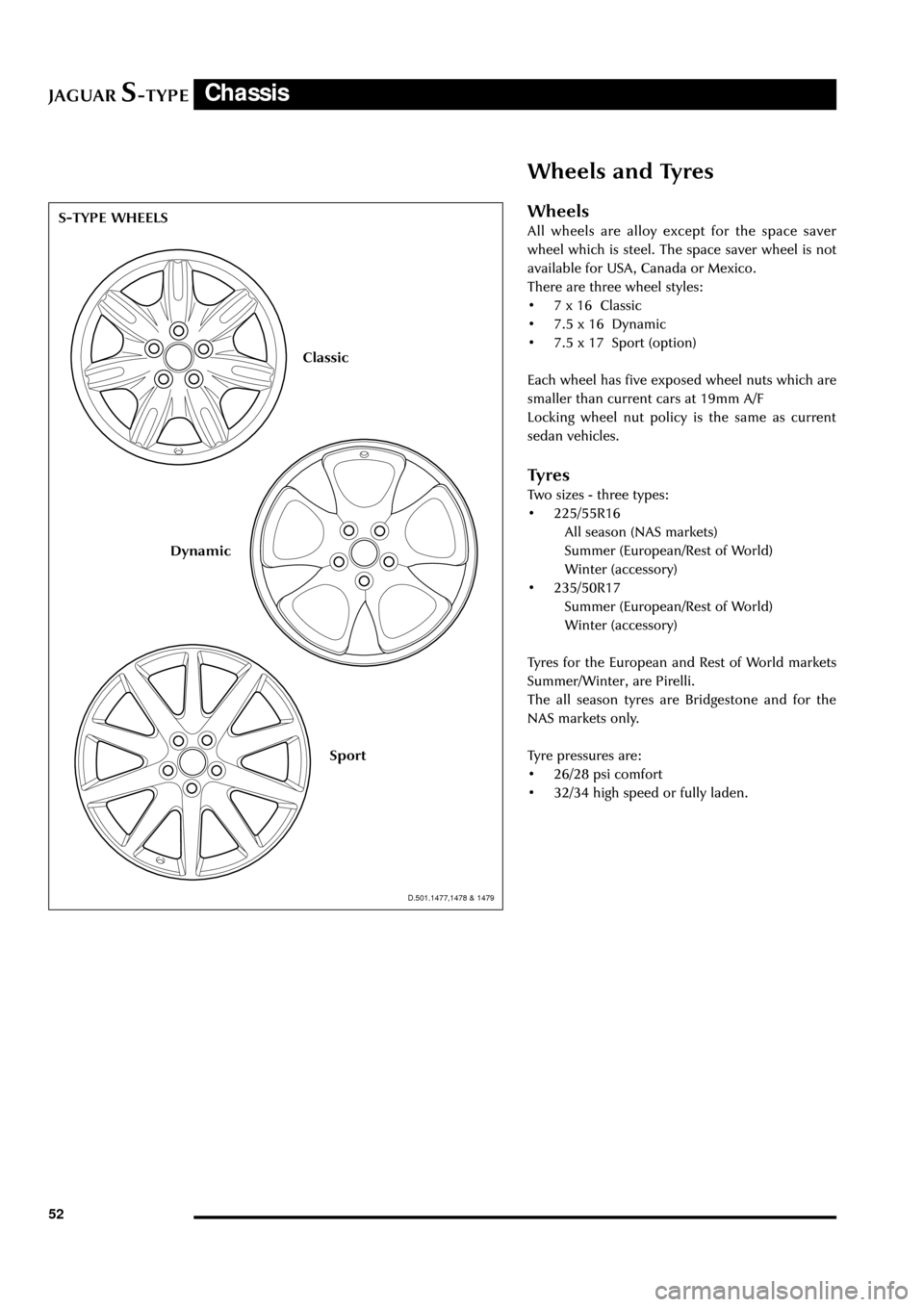

J-Gate

The J-gate assembly is mounted on the

transmission tunnel by four bolts and has a

similar operating mechanism to the XJ/XK Series

vehicles. The selector gate positions are, P-R-N-D

on one side of the ÔJÕ and manual gear positions

4-3-2 on the other side. Movement of the gear

selector lever up and down these positions is

transmitted mechanically to a cable assembly

which then rotates the digital range switch on the

side of the automatic transmission housing (see

ÔS-TYPE Powertrain IntroductionÕ Technical

Guide). Movement across the gate between D and

4 operates an electrical switch (without cable

movement).

In the P position with the ignition off, the gear

selector lever is locked by a solenoid plunger

which inhibits a lock plate fixed to the selector

mechanism. When the ignition is switched on,pressing the brake pedal energises the solenoid

and releases the lock plate, allowing the selector

lever to be moved from the P position.

For NAS markets only, the J-gate slider actuator is

linked to the ignition switch barrel to provide a

mechanical interlock. The interlock lever and

cable are driven by the J-gate slider to operate a

locking plunger in the ignition barrel. If the gear

selector lever is in any position other than P, the

ignition key cannot be removed. Note when

servicing, that the interlock cable adjustment is

critical and the JTIS service instructions must be

followed. Where the interlock function is not

fitted, the interlock lever is retained without the

operating cable.

D.307.324

J-GATE

Ignition Switch

Interlock Cable

(NAS markets only)

Interlock Lever

(NAS markets only)

D.307.324

Page 57 of 133

JAGUARS-TYPE

Wheels and Tyres

Chassis

52

Wheels

All wheels are alloy except for the space saver

wheel which is steel. The space saver wheel is not

available for USA, Canada or Mexico.

There are three wheel styles:

¥ 7 x 16 Classic

¥ 7.5 x 16 Dynamic

¥ 7.5 x 17 Sport (option)

Each wheel has five exposed wheel nuts which are

smaller than current cars at 19mm A/F

Locking wheel nut policy is the same as current

sedan vehicles.

Ty r e s

Two sizes - three types:

¥ 225/55R16

All season (NAS markets)

Summer (European/Rest of World)

Winter (accessory)

¥ 235/50R17

Summer (European/Rest of World)

Winter (accessory)

Tyres for the European and Rest of World markets

Summer/Winter, are Pirelli.

The all season tyres are Bridgestone and for the

NAS markets only.

Tyre pressures are:

¥ 26/28 psi comfort

¥ 32/34 high speed or fully laden.

D.501.1477

S-TYPE WHEELS

D.501.1477,1478 & 1479

Classic

Sport

Dynamic

D.501.1478

D.501.1479

Page 58 of 133

JAGUARS-TYPEChassis

53

Driveline

Introduction

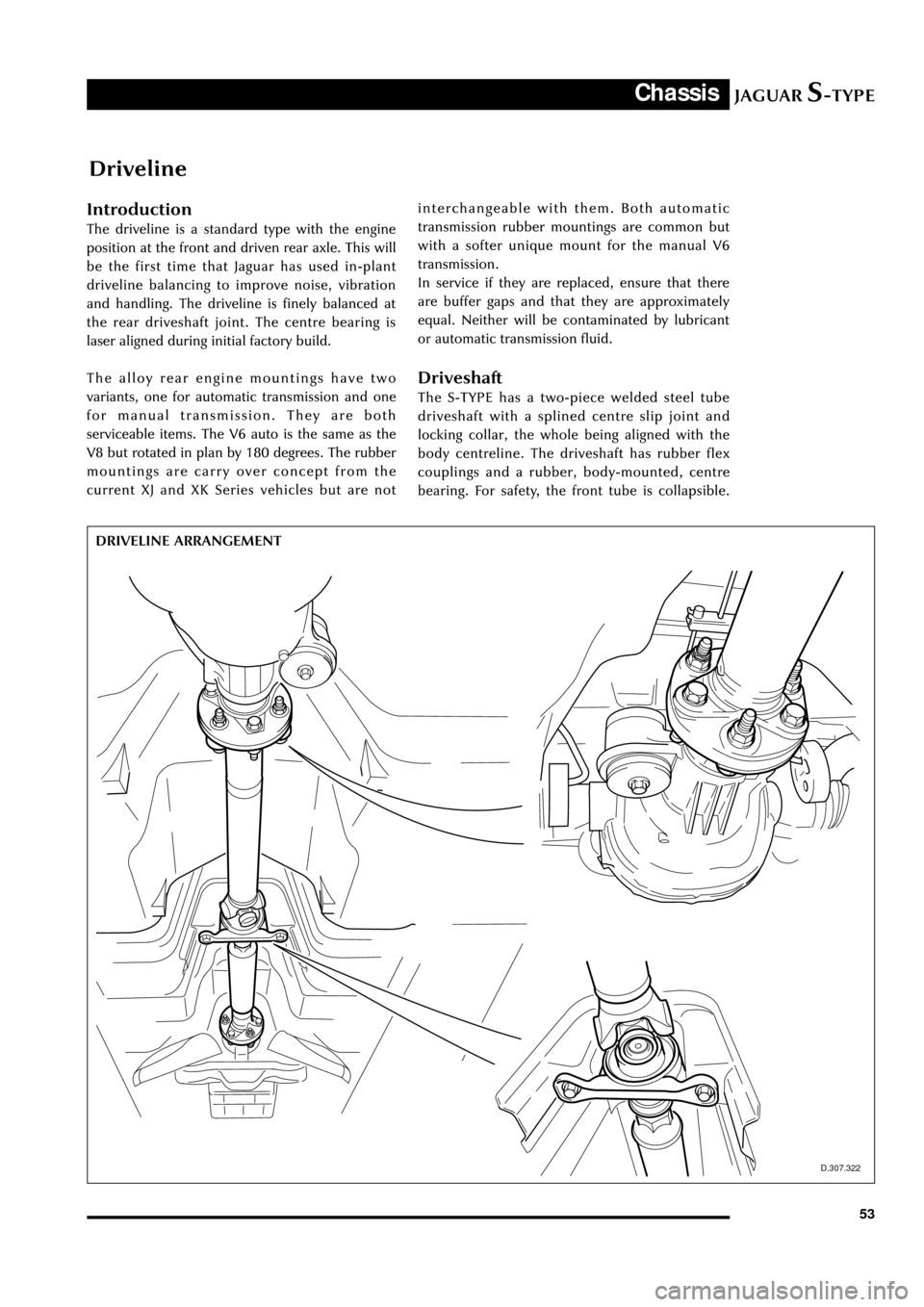

The driveline is a standard type with the engine

position at the front and driven rear axle. This will

be the first time that Jaguar has used in-plant

driveline balancing to improve noise, vibration

and handling. The driveline is finely balanced at

the rear driveshaft joint. The centre bearing is

laser aligned during initial factory build.

The alloy rear engine mountings have two

variants, one for automatic transmission and one

for manual transmission. They are both

serviceable items. The V6 auto is the same as the

V8 but rotated in plan by 180 degrees. The rubber

mountings are carry over concept from the

current XJ and XK Series vehicles but are not

D.307.322

DRIVELINE ARRANGEMENTinterchangeable with them. Both automatic

transmission rubber mountings are common but

with a softer unique mount for the manual V6

transmission.

In service if they are replaced, ensure that there

are buffer gaps and that they are approximately

equal. Neither will be contaminated by lubricant

or automatic transmission fluid.

Driveshaft

The S-TYPE has a two-piece welded steel tube

driveshaft with a splined centre slip joint and

locking collar, the whole being aligned with the

body centreline. The driveshaft has rubber flex

couplings and a rubber, body-mounted, centre

bearing. For safety, the front tube is collapsible.

Page 60 of 133

JAGUARS-TYPEChassis

55

Brakes

Brake Control Module

Brakes are controlled with a Teeves Mk 20E brake

modulator.

The anti-lock brake/traction control, control

module (ABS/TCCM) contains the integral software

for ABS and traction control, similar to current XJ

and XK Series vehicles. It is supplied as a 10 valve,

4-channel module and calibration is the same to

all powertrains. It is connected to the SCP bus for

traction control, warnings and vehicle speed.

Dynamic Stability Control

Dynamic stability control (DSC) is a new Jaguar

safety feature, which uses ABS and traction

control to control yaw movements of the vehicle.

Yaw is the rotary motion of the vehicle on its

vertical axis, a force that would cause oversteer or

oversteer or sideslip. The dynamic stability

control module (DSCM) contains the same

software as described but with the addition of IVD

software. The modulator is supplied as a 12 valve,

4-channel module calibrated for base suspension

only. The connectors differ between the two; the

10 valve unit has a 25-way with sliding cam, as

D.206.254

D.206.175

BRAKE CONTROL MODULE

BRAKE SYSTEM LAYOUT

Page 63 of 133

JAGUARS-TYPEChassis

58

Power Assisted Steering

Introduction

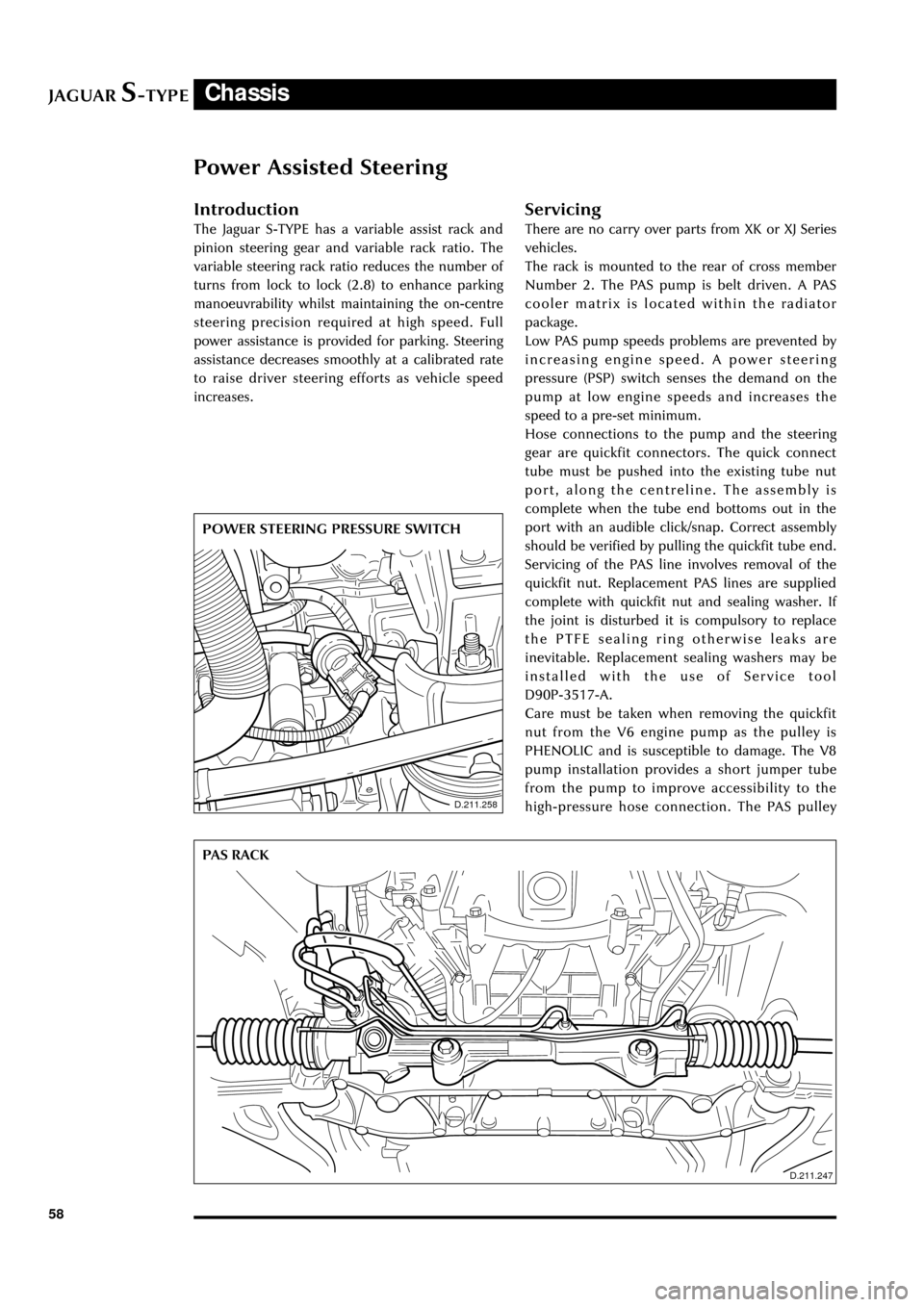

The Jaguar S-TYPE has a variable assist rack and

pinion steering gear and variable rack ratio. The

variable steering rack ratio reduces the number of

turns from lock to lock (2.8) to enhance parking

manoeuvrability whilst maintaining the on-centre

steering precision required at high speed. Full

power assistance is provided for parking. Steering

assistance decreases smoothly at a calibrated rate

to raise driver steering efforts as vehicle speed

increases.

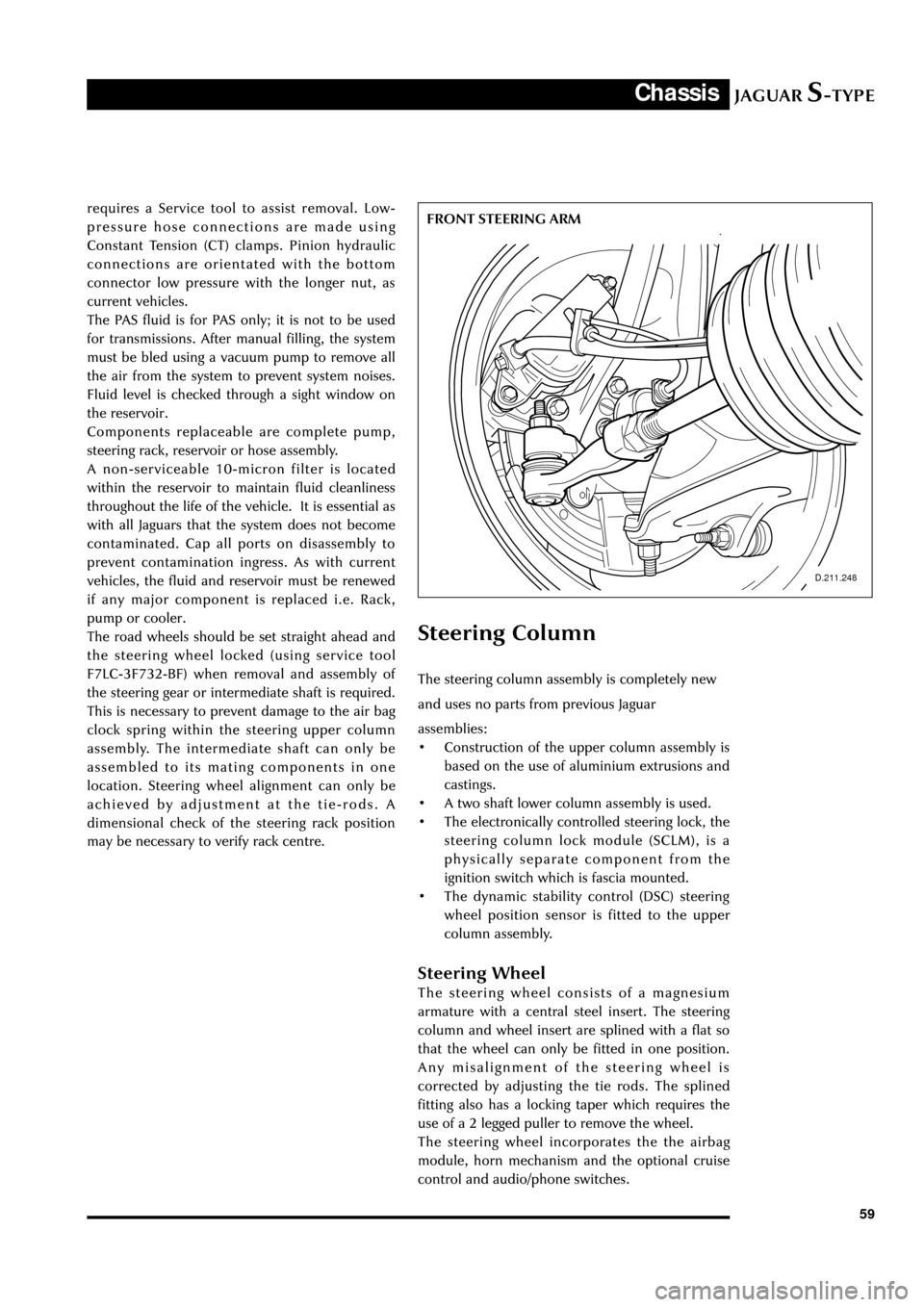

Servicing

There are no carry over parts from XK or XJ Series

vehicles.

The rack is mounted to the rear of cross member

Number 2. The PAS pump is belt driven. A PAS

cooler matrix is located within the radiator

package.

Low PAS pump speeds problems are prevented by

increasing engine speed. A power steering

pressure (PSP) switch senses the demand on the

pump at low engine speeds and increases the

speed to a pre-set minimum.

Hose connections to the pump and the steering

gear are quickfit connectors. The quick connect

tube must be pushed into the existing tube nut

port, along the centreline. The assembly is

complete when the tube end bottoms out in the

port with an audible click/snap. Correct assembly

should be verified by pulling the quickfit tube end.

Servicing of the PAS line involves removal of the

quickfit nut. Replacement PAS lines are supplied

complete with quickfit nut and sealing washer. If

the joint is disturbed it is compulsory to replace

the PTFE sealing ring otherwise leaks are

inevitable. Replacement sealing washers may be

installed with the use of Service tool

D90P-3517-A.

Care must be taken when removing the quickfit

nut from the V6 engine pump as the pulley is

PHENOLIC and is susceptible to damage. The V8

pump installation provides a short jumper tube

from the pump to improve accessibility to the

high-pressure hose connection. The PAS pulley

D.211.247

PA S R AC K

D.211.258

POWER STEERING PRESSURE SWITCH

Page 64 of 133

JAGUARS-TYPEChassis

59

D.211.248

FRONT STEERING ARM requires a Service tool to assist removal. Low-

pressure hose connections are made using

Constant Tension (CT) clamps. Pinion hydraulic

connections are orientated with the bottom

connector low pressure with the longer nut, as

current vehicles.

The PAS fluid is for PAS only; it is not to be used

for transmissions. After manual filling, the system

must be bled using a vacuum pump to remove all

the air from the system to prevent system noises.

Fluid level is checked through a sight window on

the reservoir.

Components replaceable are complete pump,

steering rack, reservoir or hose assembly.

A non-serviceable 10-micron filter is located

within the reservoir to maintain fluid cleanliness

throughout the life of the vehicle. It is essential as

with all Jaguars that the system does not become

contaminated. Cap all ports on disassembly to

prevent contamination ingress. As with current

vehicles, the fluid and reservoir must be renewed

if any major component is replaced i.e. Rack,

pump or cooler.

The road wheels should be set straight ahead and

the steering wheel locked (using service tool

F7LC-3F732-BF) when removal and assembly of

the steering gear or intermediate shaft is required.

This is necessary to prevent damage to the air bag

clock spring within the steering upper column

assembly. The intermediate shaft can only be

assembled to its mating components in one

location. Steering wheel alignment can only be

achieved by adjustment at the tie-rods. A

dimensional check of the steering rack position

may be necessary to verify rack centre.

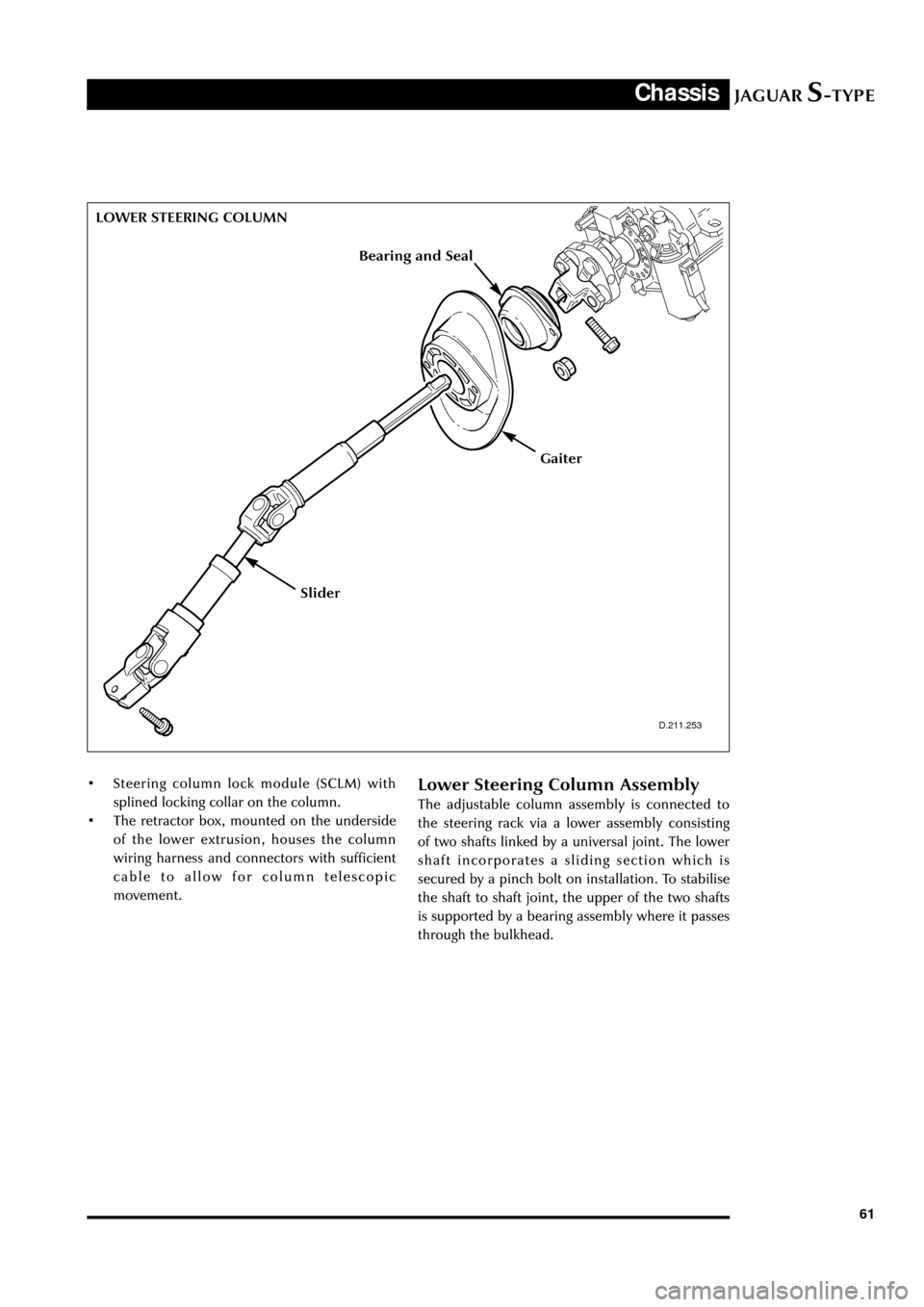

Steering Column

The steering column assembly is completely new

and uses no parts from previous Jaguar

assemblies:

¥ Construction of the upper column assembly is

based on the use of aluminium extrusions and

castings.

¥ A two shaft lower column assembly is used.

¥ The electronically controlled steering lock, the

steering column lock module (SCLM), is a

physically separate component from the

ignition switch which is fascia mounted.

¥ The dynamic stability control (DSC) steering

wheel position sensor is fitted to the upper

column assembly.

Steering Wheel

The steering wheel consists of a magnesium

armature with a central steel insert. The steering

column and wheel insert are splined with a flat so

that the wheel can only be fitted in one position.

Any misalignment of the steering wheel is

corrected by adjusting the tie rods. The splined

fitting also has a locking taper which requires the

use of a 2 legged puller to remove the wheel.

The steering wheel incorporates the the airbag

module, horn mechanism and the optional cruise

control and audio/phone switches.

Page 66 of 133

JAGUARS-TYPEChassis

61

D.211.253

LOWER STEERING COLUMN

Lower Steering Column Assembly

The adjustable column assembly is connected to

the steering rack via a lower assembly consisting

of two shafts linked by a universal joint. The lower

shaft incorporates a sliding section which is

secured by a pinch bolt on installation. To stabilise

the shaft to shaft joint, the upper of the two shafts

is supported by a bearing assembly where it passes

through the bulkhead.

Gaiter

Bearing and Seal

Slider

¥ Steering column lock module (SCLM) with

splined locking collar on the column.

¥ The retractor box, mounted on the underside

of the lower extrusion, houses the column

wiring harness and connectors with sufficient

cable to allow for column telescopic

movement.

Page 67 of 133

JAGUARS-TYPEChassis

62

J.211.257

STEERING COLUMN LOCK MODULE

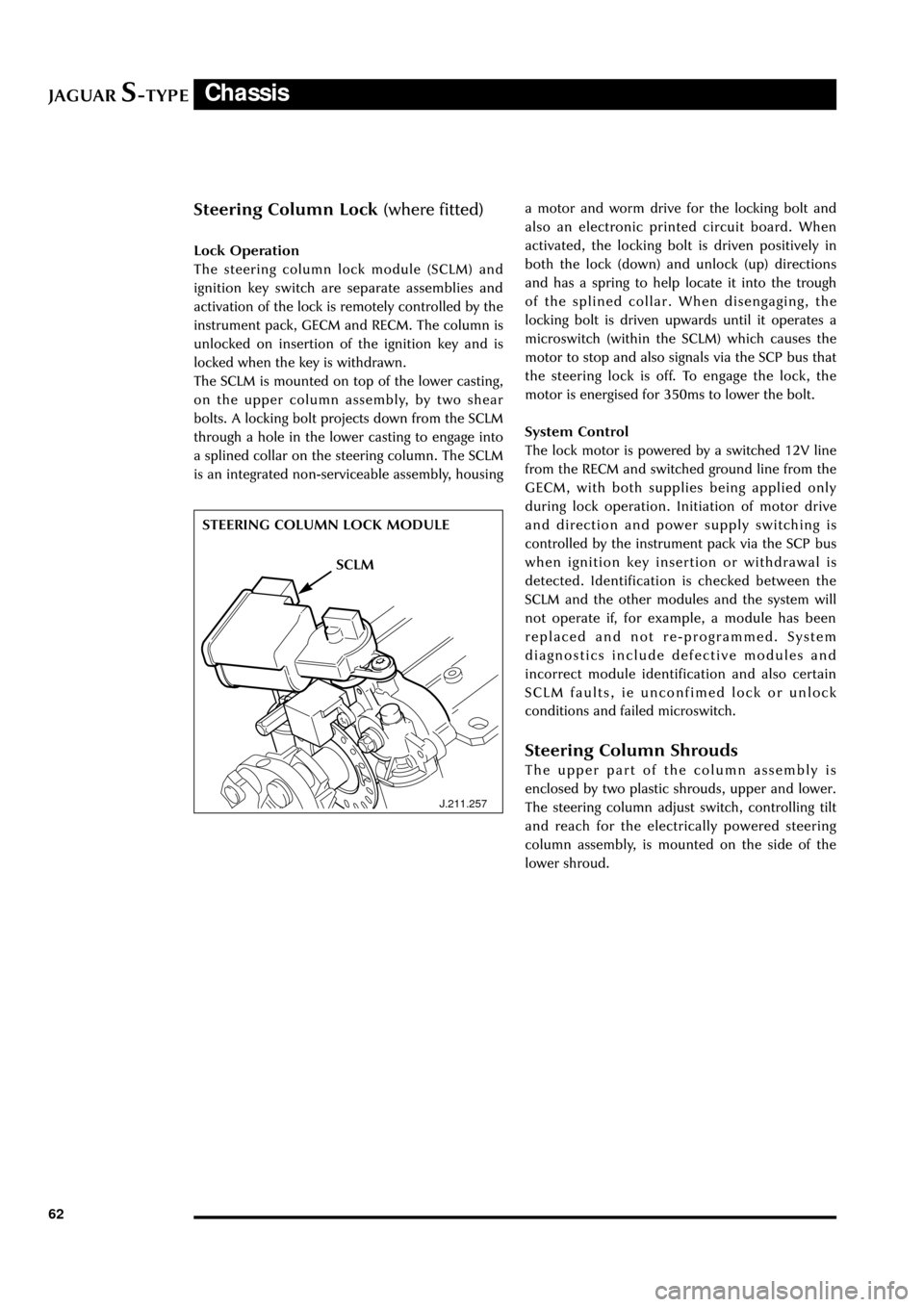

Steering Column Lock (where fitted)

Lock Operation

The steering column lock module (SCLM) and

ignition key switch are separate assemblies and

activation of the lock is remotely controlled by the

instrument pack, GECM and RECM. The column is

unlocked on insertion of the ignition key and is

locked when the key is withdrawn.

The SCLM is mounted on top of the lower casting,

on the upper column assembly, by two shear

bolts. A locking bolt projects down from the SCLM

through a hole in the lower casting to engage into

a splined collar on the steering column. The SCLM

is an integrated non-serviceable assembly, housinga motor and worm drive for the locking bolt and

also an electronic printed circuit board. When

activated, the locking bolt is driven positively in

both the lock (down) and unlock (up) directions

and has a spring to help locate it into the trough

of the splined collar. When disengaging, the

locking bolt is driven upwards until it operates a

microswitch (within the SCLM) which causes the

motor to stop and also signals via the SCP bus that

the steering lock is off. To engage the lock, the

motor is energised for 350ms to lower the bolt.

System Control

The lock motor is powered by a switched 12V line

from the RECM and switched ground line from the

GECM, with both supplies being applied only

during lock operation. Initiation of motor drive

and direction and power supply switching is

controlled by the instrument pack via the SCP bus

when ignition key insertion or withdrawal is

detected. Identification is checked between the

SCLM and the other modules and the system will

not operate if, for example, a module has been

replaced and not re-programmed. System

diagnostics include defective modules and

incorrect module identification and also certain

SCLM faults, ie unconfimed lock or unlock

conditions and failed microswitch.

Steering Column Shrouds

The upper part of the column assembly is

enclosed by two plastic shrouds, upper and lower.

The steering column adjust switch, controlling tilt

and reach for the electrically powered steering

column assembly, is mounted on the side of the

lower shroud.

SCLM