ignition JAGUAR S TYPE 2005 1.G Technical Guide Update

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2005, Model line: S TYPE, Model: JAGUAR S TYPE 2005 1.GPages: 133, PDF Size: 3.48 MB

Page 30 of 133

JAGUARS-TYPEBody

25

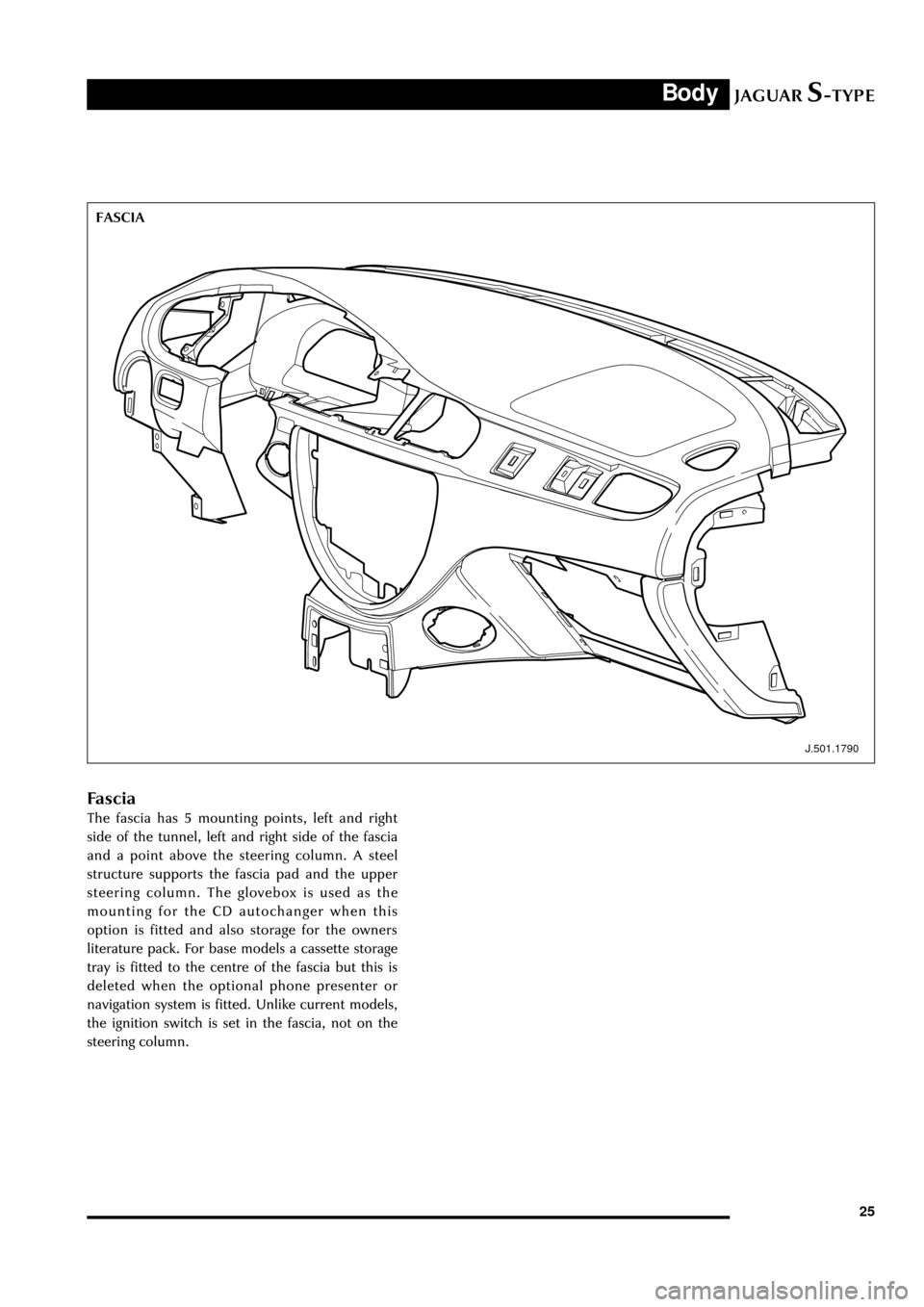

Fascia

The fascia has 5 mounting points, left and right

side of the tunnel, left and right side of the fascia

and a point above the steering column. A steel

structure supports the fascia pad and the upper

steering column. The glovebox is used as the

mounting for the CD autochanger when this

option is fitted and also storage for the owners

literature pack. For base models a cassette storage

tray is fitted to the centre of the fascia but this is

deleted when the optional phone presenter or

navigation system is fitted. Unlike current models,

the ignition switch is set in the fascia, not on the

steering column.

J.501.1790

FASCIA

Page 33 of 133

JAGUARS-TYPEBody

28bracket for the airbag. The recline motor is located

in the lower left side of the frame and drives both

sides of the squab. The position potentiometer is

mounted on the long drive shaft on the RH side.

Lumbar support comprises a flexible steel lumbar

plate, motor, drive cable and return spring. The

top of the plate has vertical slots, fitted to a cross

bar, which allows the plate to be pulled down and

deformed by the drive cable to provide increased

lumbar support. If powered lumbar support is not

fitted, the lumbar plate is used without the drive

system.

When seat heaters are fitted each front seat has a

driver or passenger seat heater control module

fitted (DSHCM/PSHCM).

Seat Covers

The cushion and squab cover are made of dual

density foam and have optional heater pad inserts.

The cushion and cushion pan have an anti-

submarining profile for increased safety.

J.501.1786

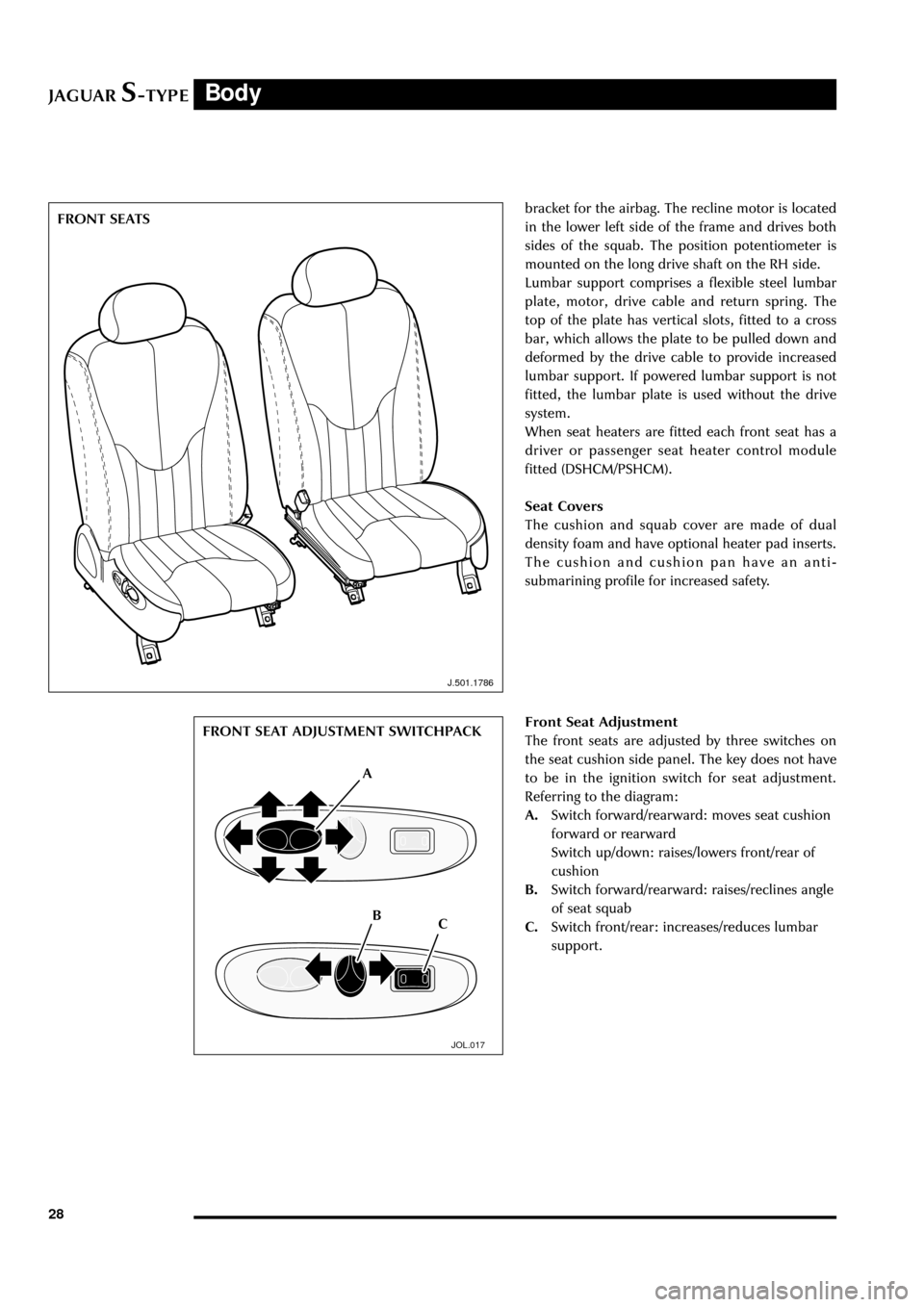

Front Seat Adjustment

The front seats are adjusted by three switches on

the seat cushion side panel. The key does not have

to be in the ignition switch for seat adjustment.

Referring to the diagram:

A.Switch forward/rearward: moves seat cushion

forward or rearward

Switch up/down: raises/lowers front/rear of

cushion

B.Switch forward/rearward: raises/reclines angle

of seat squab

C.Switch front/rear: increases/reduces lumbar

support.

JOL.017

FRONT SEAT ADJUSTMENT SWITCHPACK

A

B FRONT SEATS

C

Page 42 of 133

JAGUARS-TYPEOccupant Protection

37

D.418.445

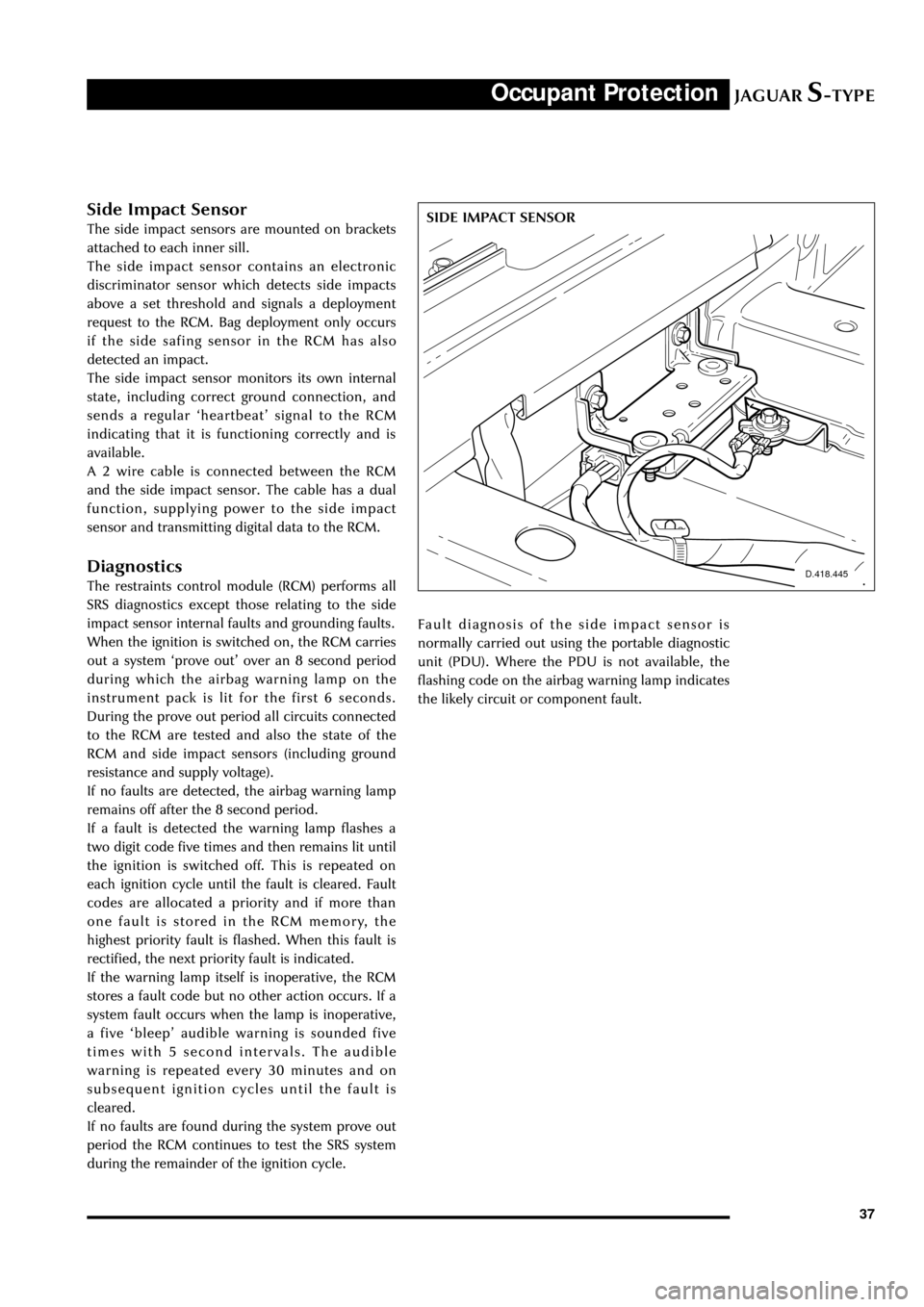

SIDE IMPACT SENSORSide Impact Sensor

The side impact sensors are mounted on brackets

attached to each inner sill.

The side impact sensor contains an electronic

discriminator sensor which detects side impacts

above a set threshold and signals a deployment

request to the RCM. Bag deployment only occurs

if the side safing sensor in the RCM has also

detected an impact.

The side impact sensor monitors its own internal

state, including correct ground connection, and

sends a regular ÔheartbeatÕ signal to the RCM

indicating that it is functioning correctly and is

available.

A 2 wire cable is connected between the RCM

and the side impact sensor. The cable has a dual

function, supplying power to the side impact

sensor and transmitting digital data to the RCM.

Diagnostics

The restraints control module (RCM) performs all

SRS diagnostics except those relating to the side

impact sensor internal faults and grounding faults.

When the ignition is switched on, the RCM carries

out a system Ôprove outÕ over an 8 second period

during which the airbag warning lamp on the

instrument pack is lit for the first 6 seconds.

During the prove out period all circuits connected

to the RCM are tested and also the state of the

RCM and side impact sensors (including ground

resistance and supply voltage).

If no faults are detected, the airbag warning lamp

remains off after the 8 second period.

If a fault is detected the warning lamp flashes a

two digit code five times and then remains lit until

the ignition is switched off. This is repeated on

each ignition cycle until the fault is cleared. Fault

codes are allocated a priority and if more than

one fault is stored in the RCM memory, the

highest priority fault is flashed. When this fault is

rectified, the next priority fault is indicated.

If the warning lamp itself is inoperative, the RCM

stores a fault code but no other action occurs. If a

system fault occurs when the lamp is inoperative,

a five ÔbleepÕ audible warning is sounded five

times with 5 second intervals. The audible

warning is repeated every 30 minutes and on

subsequent ignition cycles until the fault is

cleared.

If no faults are found during the system prove out

period the RCM continues to test the SRS system

during the remainder of the ignition cycle.Fault diagnosis of the side impact sensor is

normally carried out using the portable diagnostic

unit (PDU). Where the PDU is not available, the

flashing code on the airbag warning lamp indicates

the likely circuit or component fault.

Page 46 of 133

JAGUARS-TYPEFuel System

41

JOL.062

INERTIA SWITCH operating fuel level sender assembly mounted on

the respective module assembly.

Control and Operation

The speed of the fuel pump is varied under closed

loop control so as to deliver the required fuel rail

injection pressure in accordance with factors such

as driver demand, manifold pressure and

temperature changes. The control loop sensors,

providing feedback information to the powertrain

control module (PCM), are the engine fuel

temperature (EFT) sensor and the injection

pressure (IP) sensor which are both mounted

directly on the engine fuel rail (see

S-TYPE Powertrain Technical Guide). The IP sensor

also has a vacuum feed from the intake manifold

so as to measure the pressure differential.

The required fuel flow is determined by the PCM

and sent to the rear electronic control module

(RECM) which is the power driver for the fuel

pump. The PCM demand to the RECM is a pulse

width modulated (PWM) signal over a single line

at a frequency of approximately 256 Hz and a

duty cycle of 0-50%. The RECM effecively

amplifies this signal by increasing the frequency

by 64 and doubling the duty cycle, thus providing

the necessary high current drive for the fuel

pump. The fuel pump relay, located in the rear

power distribution box, is energised by the PCM

relay and provides a dedicated fused supply to the

RECM for the pump drive.

When the ignition switch is turned from OFF to

RUN or START, the PCM primes the system by

running the pump for 1 second at full speed. The

pump is switched off 1 second after the engine is

stopped. During hot starts, fuel pressure is

increased to prevent vapour lock.

Fuel pump drive status is monitored by the RECM

and communicated to the PCM via the SCP

network.

Outputs from the fuel senders are connected by

independent wires to the RECM which sends the

data to the instrument pack and the PCM.

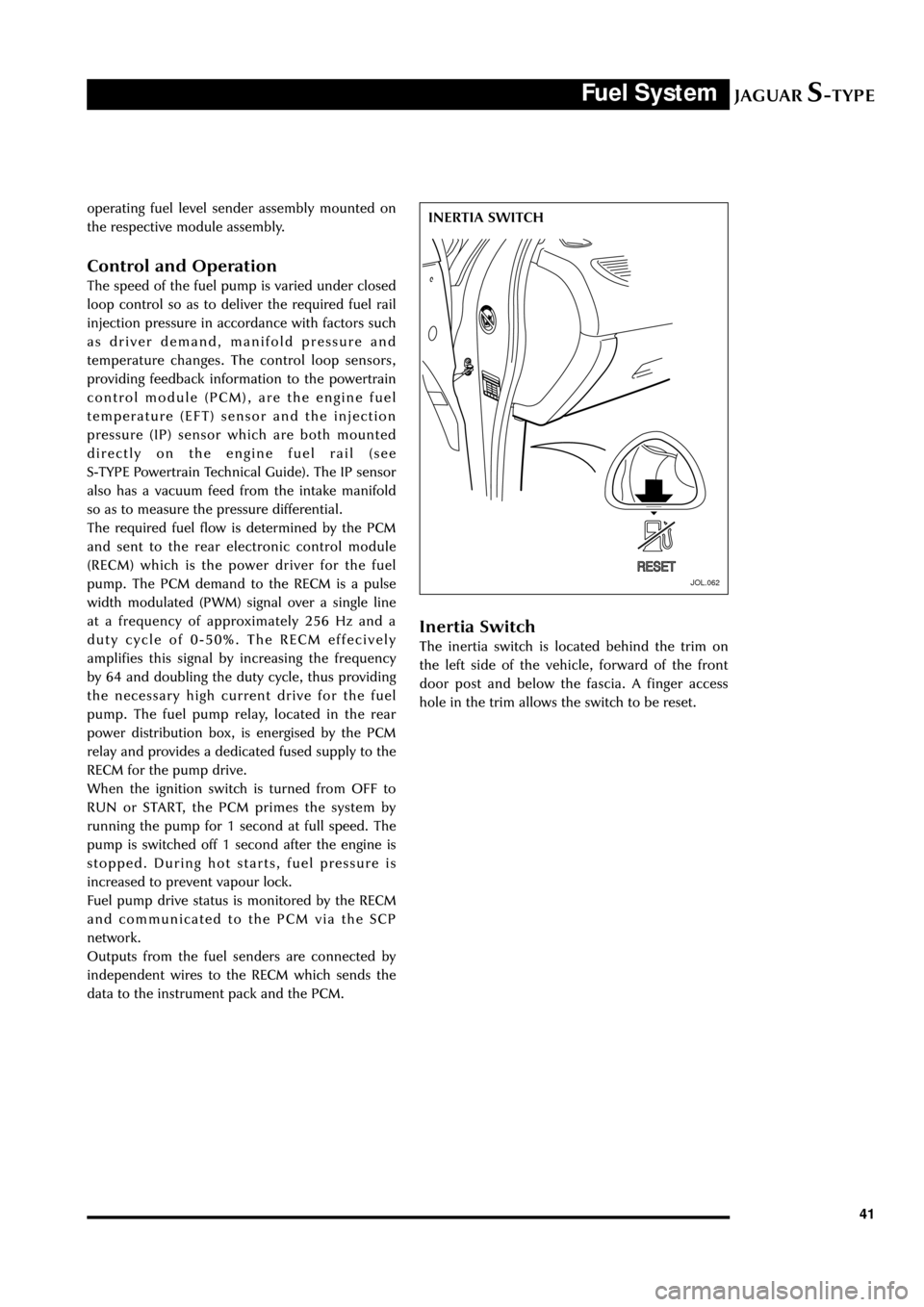

Inertia Switch

The inertia switch is located behind the trim on

the left side of the vehicle, forward of the front

door post and below the fascia. A finger access

hole in the trim allows the switch to be reset.

Page 50 of 133

JAGUARS-TYPETransmission

45

Introduction

The automatic and manual transmission units are

described in the ÔS-TYPE Sports Sedan Powertrain

IntroductionÕ Technical Guide.

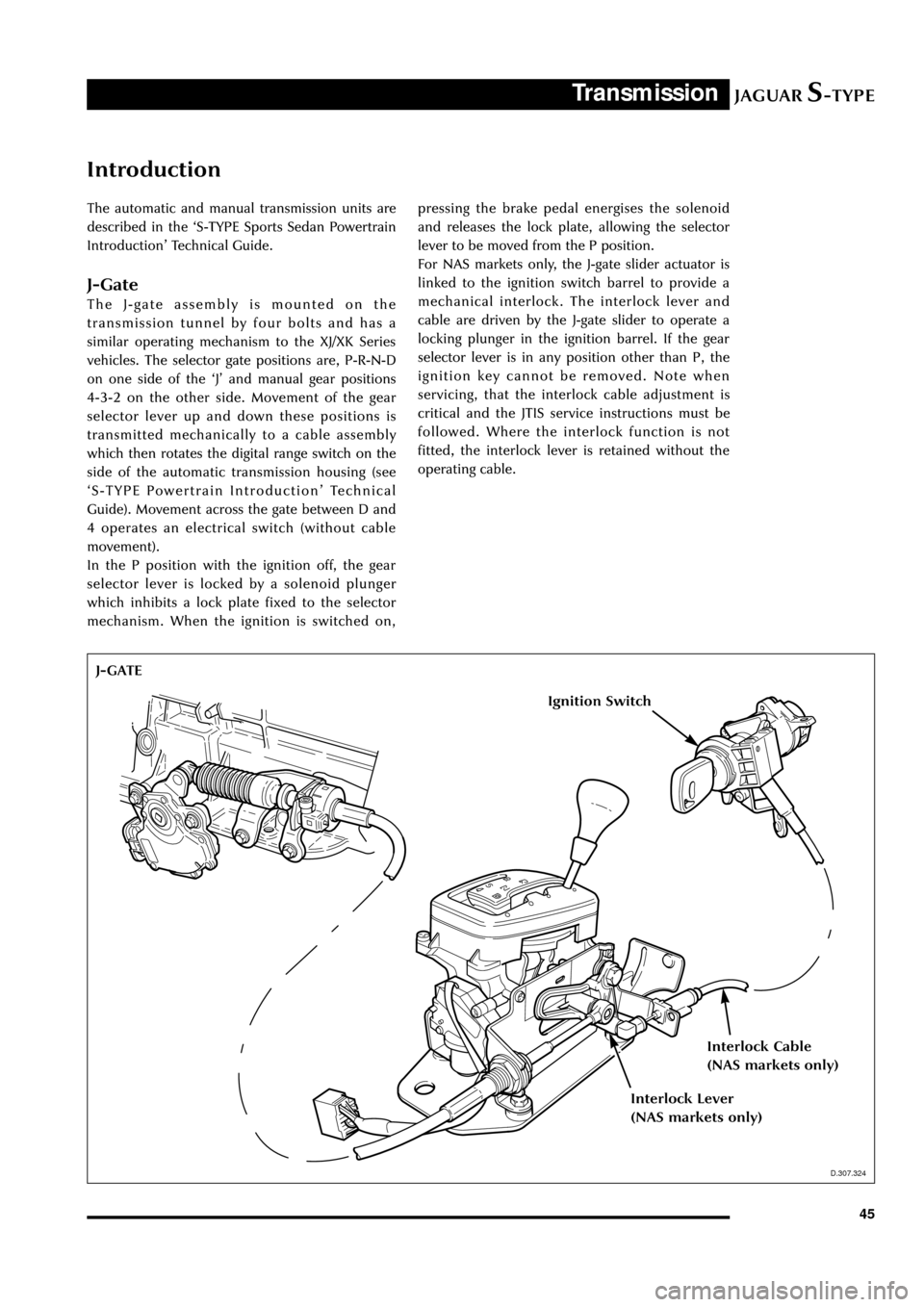

J-Gate

The J-gate assembly is mounted on the

transmission tunnel by four bolts and has a

similar operating mechanism to the XJ/XK Series

vehicles. The selector gate positions are, P-R-N-D

on one side of the ÔJÕ and manual gear positions

4-3-2 on the other side. Movement of the gear

selector lever up and down these positions is

transmitted mechanically to a cable assembly

which then rotates the digital range switch on the

side of the automatic transmission housing (see

ÔS-TYPE Powertrain IntroductionÕ Technical

Guide). Movement across the gate between D and

4 operates an electrical switch (without cable

movement).

In the P position with the ignition off, the gear

selector lever is locked by a solenoid plunger

which inhibits a lock plate fixed to the selector

mechanism. When the ignition is switched on,pressing the brake pedal energises the solenoid

and releases the lock plate, allowing the selector

lever to be moved from the P position.

For NAS markets only, the J-gate slider actuator is

linked to the ignition switch barrel to provide a

mechanical interlock. The interlock lever and

cable are driven by the J-gate slider to operate a

locking plunger in the ignition barrel. If the gear

selector lever is in any position other than P, the

ignition key cannot be removed. Note when

servicing, that the interlock cable adjustment is

critical and the JTIS service instructions must be

followed. Where the interlock function is not

fitted, the interlock lever is retained without the

operating cable.

D.307.324

J-GATE

Ignition Switch

Interlock Cable

(NAS markets only)

Interlock Lever

(NAS markets only)

D.307.324

Page 64 of 133

JAGUARS-TYPEChassis

59

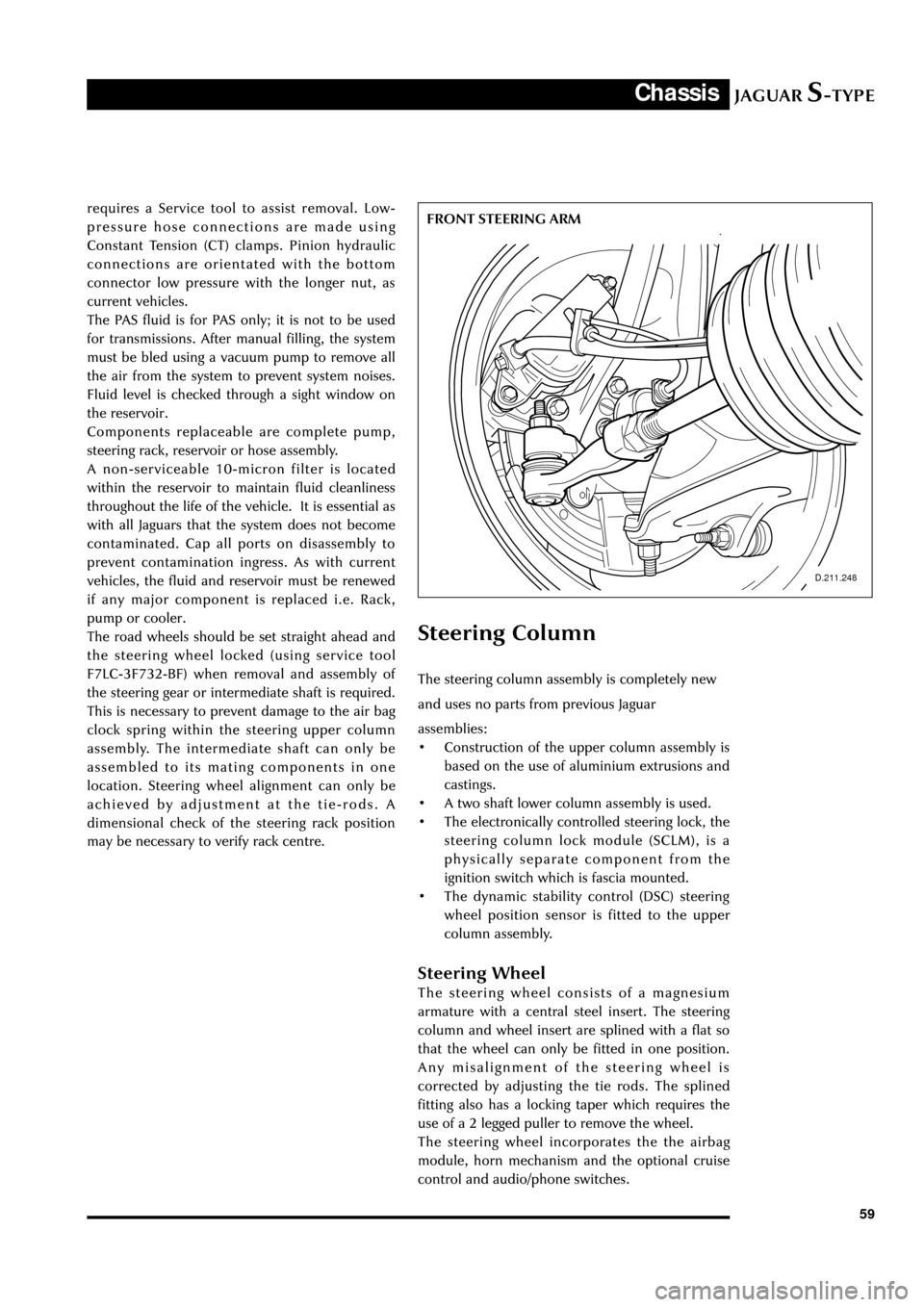

D.211.248

FRONT STEERING ARM requires a Service tool to assist removal. Low-

pressure hose connections are made using

Constant Tension (CT) clamps. Pinion hydraulic

connections are orientated with the bottom

connector low pressure with the longer nut, as

current vehicles.

The PAS fluid is for PAS only; it is not to be used

for transmissions. After manual filling, the system

must be bled using a vacuum pump to remove all

the air from the system to prevent system noises.

Fluid level is checked through a sight window on

the reservoir.

Components replaceable are complete pump,

steering rack, reservoir or hose assembly.

A non-serviceable 10-micron filter is located

within the reservoir to maintain fluid cleanliness

throughout the life of the vehicle. It is essential as

with all Jaguars that the system does not become

contaminated. Cap all ports on disassembly to

prevent contamination ingress. As with current

vehicles, the fluid and reservoir must be renewed

if any major component is replaced i.e. Rack,

pump or cooler.

The road wheels should be set straight ahead and

the steering wheel locked (using service tool

F7LC-3F732-BF) when removal and assembly of

the steering gear or intermediate shaft is required.

This is necessary to prevent damage to the air bag

clock spring within the steering upper column

assembly. The intermediate shaft can only be

assembled to its mating components in one

location. Steering wheel alignment can only be

achieved by adjustment at the tie-rods. A

dimensional check of the steering rack position

may be necessary to verify rack centre.

Steering Column

The steering column assembly is completely new

and uses no parts from previous Jaguar

assemblies:

¥ Construction of the upper column assembly is

based on the use of aluminium extrusions and

castings.

¥ A two shaft lower column assembly is used.

¥ The electronically controlled steering lock, the

steering column lock module (SCLM), is a

physically separate component from the

ignition switch which is fascia mounted.

¥ The dynamic stability control (DSC) steering

wheel position sensor is fitted to the upper

column assembly.

Steering Wheel

The steering wheel consists of a magnesium

armature with a central steel insert. The steering

column and wheel insert are splined with a flat so

that the wheel can only be fitted in one position.

Any misalignment of the steering wheel is

corrected by adjusting the tie rods. The splined

fitting also has a locking taper which requires the

use of a 2 legged puller to remove the wheel.

The steering wheel incorporates the the airbag

module, horn mechanism and the optional cruise

control and audio/phone switches.

Page 67 of 133

JAGUARS-TYPEChassis

62

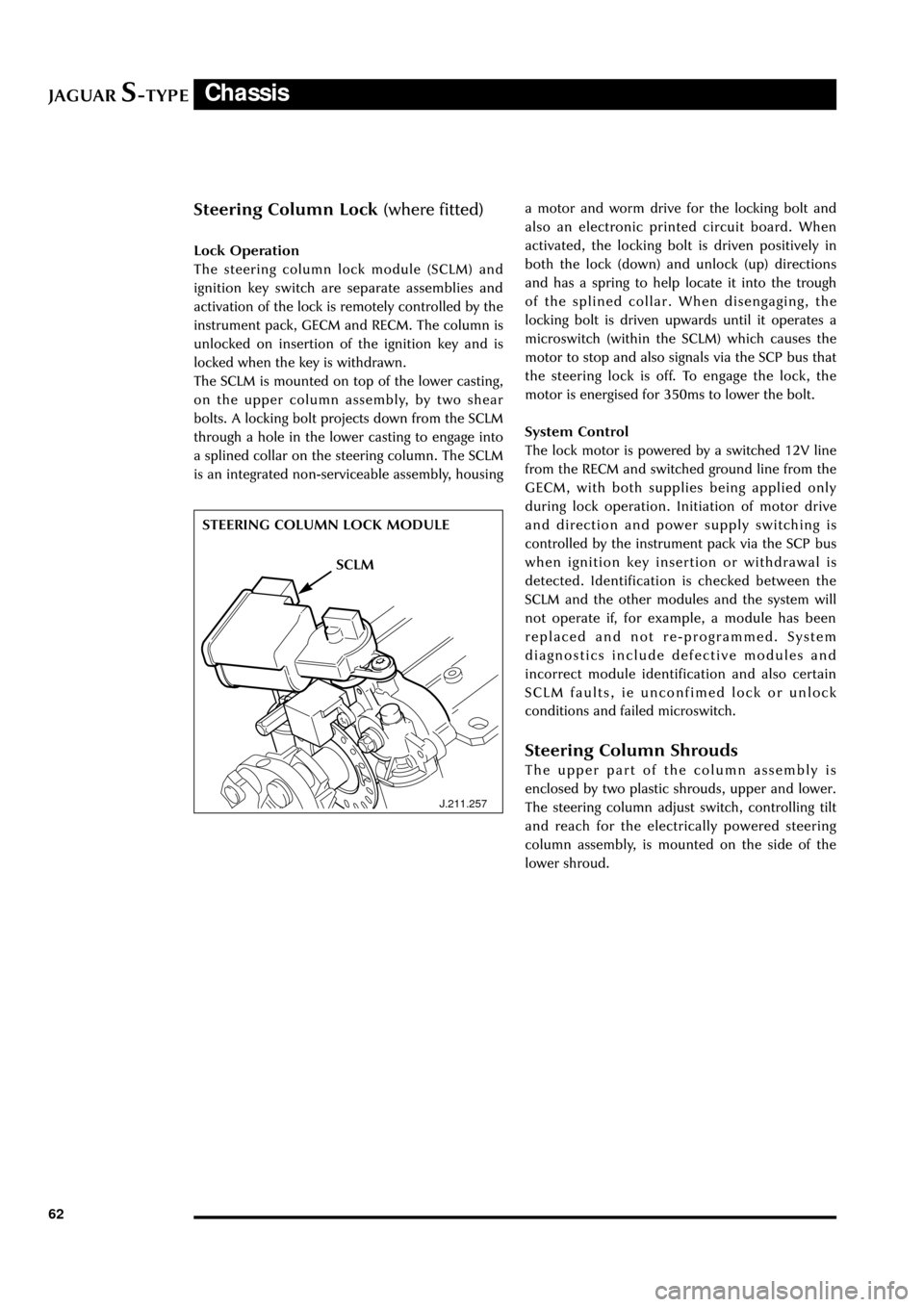

J.211.257

STEERING COLUMN LOCK MODULE

Steering Column Lock (where fitted)

Lock Operation

The steering column lock module (SCLM) and

ignition key switch are separate assemblies and

activation of the lock is remotely controlled by the

instrument pack, GECM and RECM. The column is

unlocked on insertion of the ignition key and is

locked when the key is withdrawn.

The SCLM is mounted on top of the lower casting,

on the upper column assembly, by two shear

bolts. A locking bolt projects down from the SCLM

through a hole in the lower casting to engage into

a splined collar on the steering column. The SCLM

is an integrated non-serviceable assembly, housinga motor and worm drive for the locking bolt and

also an electronic printed circuit board. When

activated, the locking bolt is driven positively in

both the lock (down) and unlock (up) directions

and has a spring to help locate it into the trough

of the splined collar. When disengaging, the

locking bolt is driven upwards until it operates a

microswitch (within the SCLM) which causes the

motor to stop and also signals via the SCP bus that

the steering lock is off. To engage the lock, the

motor is energised for 350ms to lower the bolt.

System Control

The lock motor is powered by a switched 12V line

from the RECM and switched ground line from the

GECM, with both supplies being applied only

during lock operation. Initiation of motor drive

and direction and power supply switching is

controlled by the instrument pack via the SCP bus

when ignition key insertion or withdrawal is

detected. Identification is checked between the

SCLM and the other modules and the system will

not operate if, for example, a module has been

replaced and not re-programmed. System

diagnostics include defective modules and

incorrect module identification and also certain

SCLM faults, ie unconfimed lock or unlock

conditions and failed microswitch.

Steering Column Shrouds

The upper part of the column assembly is

enclosed by two plastic shrouds, upper and lower.

The steering column adjust switch, controlling tilt

and reach for the electrically powered steering

column assembly, is mounted on the side of the

lower shroud.

SCLM

Page 73 of 133

JAGUARS-TYPEClimate Control

68Heated wiper park or (where optionally fitted)

heated front screen.

With the engine running, due to the high current

draw, press to switch on the heated wiper park to

defrost the wiper park area, or where fitted, press

to switch on the heated front screen for rapid

defrost/demist.

Heated wiper park automatically operates in cold

weather, and may stay on continuously. It is

automatically switched on when ÔDEFROSTÕ is

selected. If manually selected, the heated wiper

park will automatically switch off after 10

minutes.

Heated front screen is automatically switched on

when ÔDEFROSTÕ is selected. It will automatically

switch off after 4 minutes. The heaters will switch

off, or not operate, if low battery voltage is

detected.

Heated Rear Screen

With the engine running due to the high current

draw, press to switch on the heated rear screen

for rapid defrost/demist. The rear screen heater

will be automatically switched off after 10

minutes.

In cold conditions, the heated rear screen

operates automatically. Selecting ÔDEFROSTÕ will

also turn the heated rear screen ON. The heaters

will switch off, or not operate, if low battery

voltage is detected.

Air Distribution

Air distribution is automatically controlled when

ÔAUTOÕ is selected. Manual control can be

achieved using the air distribution buttons.

Heat at Rest Feature (V8 engine vehicles

only)

Interior heating may be continued after the

engine has been switched off by turning the

ignition to position ÔIIÕ. The climate control system

will continue to provide heat to the vehicle

interior until the engine cools down. Excessive use

will cause a low battery voltage, which may

prevent the vehicle from being started.

Voice Activated Control

Some functions of the climate control system can

be operated with the Voice Activation System

(when fitted).

A full operating description is given in the Voice

Activation Handbook included with the vehicle

literature pack.

Page 74 of 133

JAGUARS-TYPEElectrical/Electronic

69

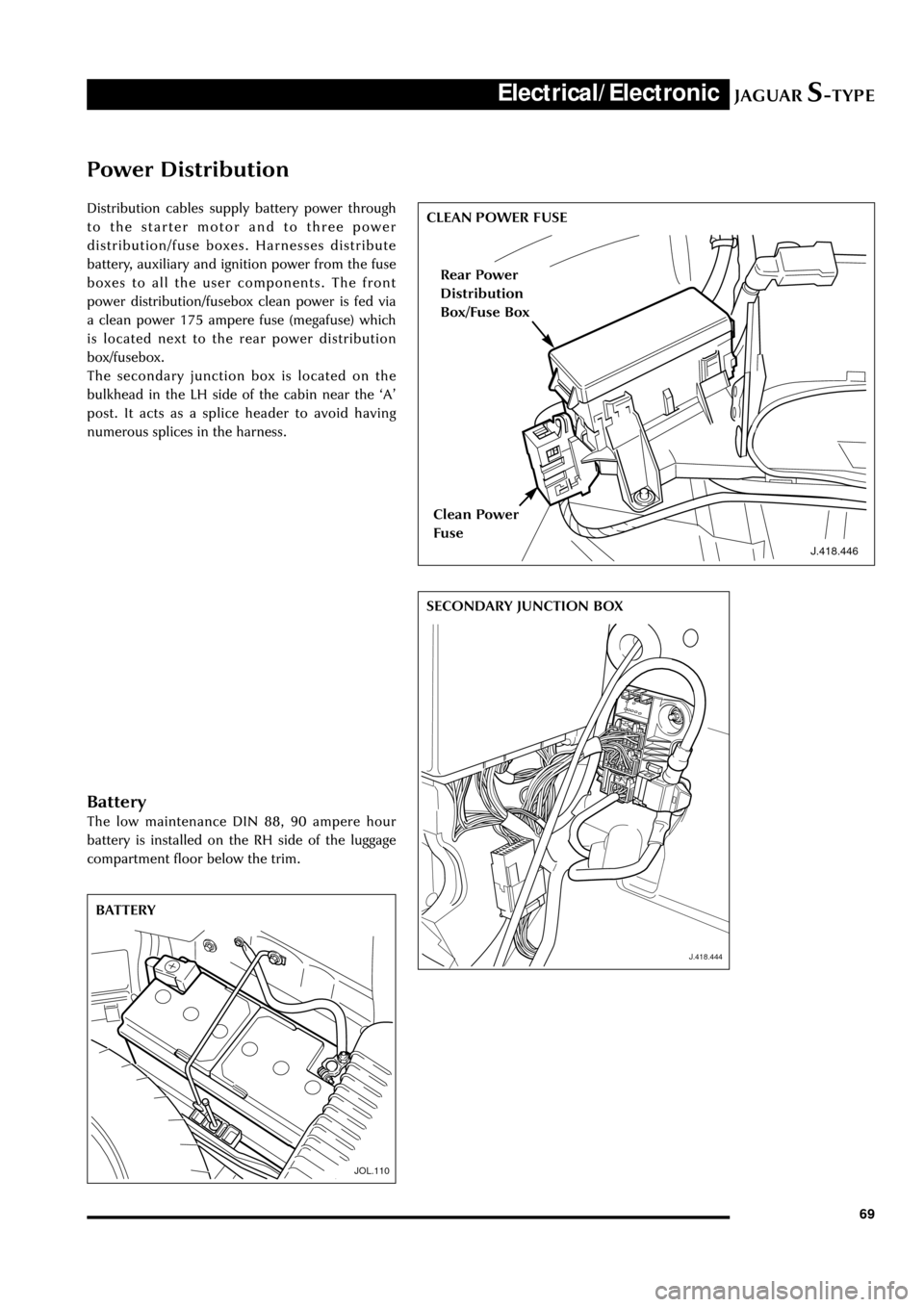

Power Distribution

Distribution cables supply battery power through

to the starter motor and to three power

distribution/fuse boxes. Harnesses distribute

battery, auxiliary and ignition power from the fuse

boxes to all the user components. The front

power distribution/fusebox clean power is fed via

a clean power 175 ampere fuse (megafuse) which

is located next to the rear power distribution

box/fusebox.

The secondary junction box is located on the

bulkhead in the LH side of the cabin near the ÔAÕ

post. It acts as a splice header to avoid having

numerous splices in the harness.

J.418.446

CLEAN POWER FUSE

J.418.444

SECONDARY JUNCTION BOX

JOL.110

BATTERY

Rear Power

Distribution

Box/Fuse Box

Clean Power

Fuse

Battery

The low maintenance DIN 88, 90 ampere hour

battery is installed on the RH side of the luggage

compartment floor below the trim.

Page 81 of 133

JAGUARS-TYPEElectrical/Electronic

76Air Conditioning Control Module (A/CCM)

The A/CCM is connected to the SCP

communication network. The A/CCM controls

automatic climate functions that maintain the

vehicle at a constant temperature setting.

Instrument Pack

The instrument pack is connected to the SCP

communication network. The instrument pack

displays information received on the SCP

including speedometer, odometer, fuel, and

message center warnings. The instrument pack

also controls the passive anti-theft system (PATS).

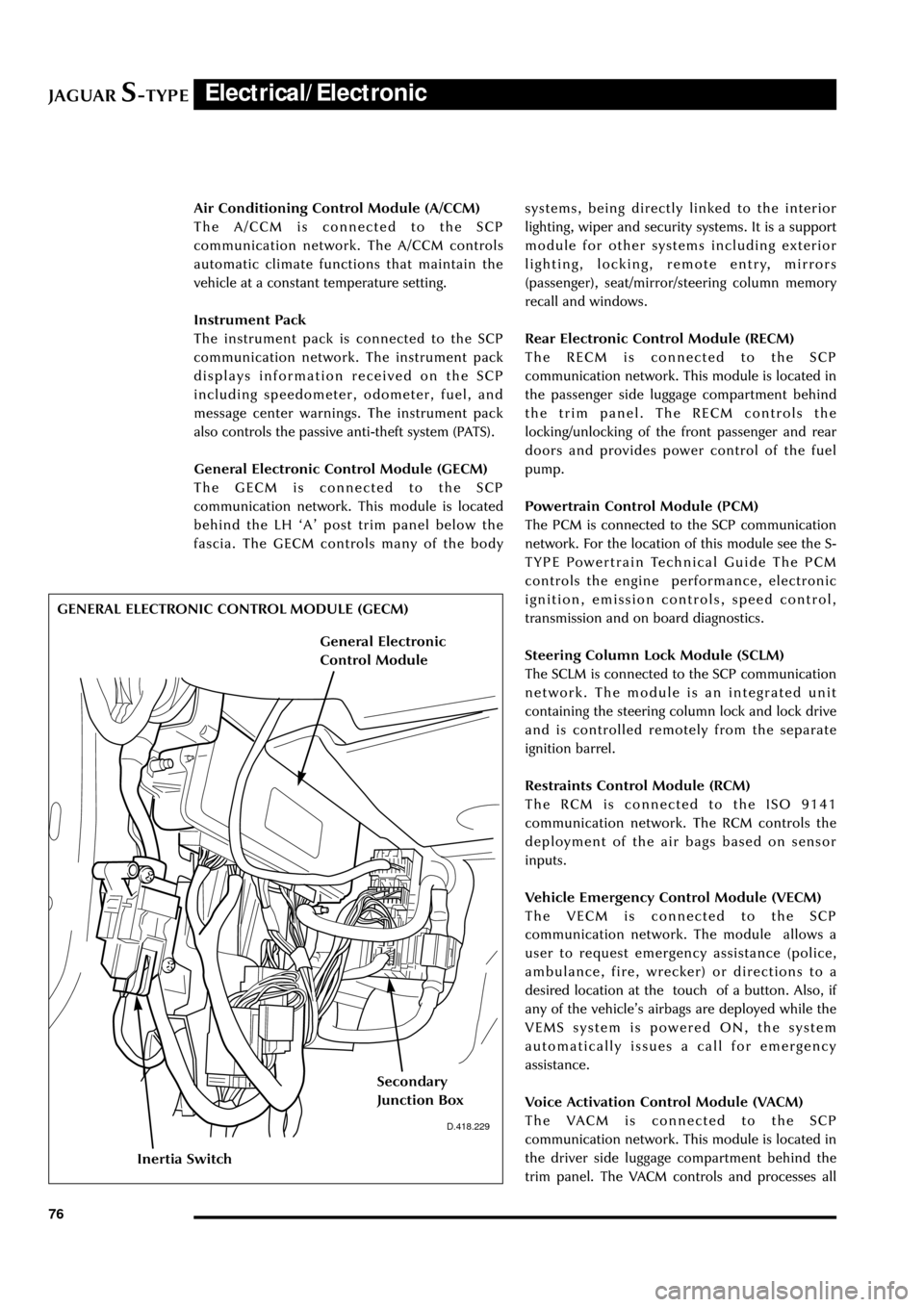

General Electronic Control Module (GECM)

The GECM is connected to the SCP

communication network. This module is located

behind the LH ÔAÕ post trim panel below the

fascia. The GECM controls many of the bodysystems, being directly linked to the interior

lighting, wiper and security systems. It is a support

module for other systems including exterior

lighting, locking, remote entry, mirrors

(passenger), seat/mirror/steering column memory

recall and windows.

Rear Electronic Control Module (RECM)

The RECM is connected to the SCP

communication network. This module is located in

the passenger side luggage compartment behind

the trim panel. The RECM controls the

locking/unlocking of the front passenger and rear

doors and provides power control of the fuel

pump.

Powertrain Control Module (PCM)

The PCM is connected to the SCP communication

network. For the location of this module see the S-

TYPE Powertrain Technical Guide The PCM

controls the engine performance, electronic

ignition, emission controls, speed control,

transmission and on board diagnostics.

Steering Column Lock Module (SCLM)

The SCLM is connected to the SCP communication

network. The module is an integrated unit

containing the steering column lock and lock drive

and is controlled remotely from the separate

ignition barrel.

Restraints Control Module (RCM)

The RCM is connected to the ISO 9141

communication network. The RCM controls the

deployment of the air bags based on sensor

inputs.

Vehicle Emergency Control Module (VECM)

The VECM is connected to the SCP

communication network. The module allows a

user to request emergency assistance (police,

ambulance, fire, wrecker) or directions to a

desired location at the touch of a button. Also, if

any of the vehicleÕs airbags are deployed while the

VEMS system is powered ON, the system

automatically issues a call for emergency

assistance.

Voice Activation Control Module (VACM)

The VACM is connected to the SCP

communication network. This module is located in

the driver side luggage compartment behind the

trim panel. The VACM controls and processes all

D.418.229

GENERAL ELECTRONIC CONTROL MODULE (GECM)

Inertia Switch

Secondary

Junction Box

General Electronic

Control Module