open hood JAGUAR XFR 2010 1.G User Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 2039 of 3039

Exterior Lighting - Headlamp Adjustment

General Procedures Published: 16-Apr-2014

NOTE: Some variation in the illustrations may occur, but the essential information is always correct.

1. Make sure to check and adjust the tyre pressures to the correct

level.

Park the vehicle on a horizontally level surface.

2. Align the headlamp beam setting equipment to one headlamp.

Headlamp beam setter

3. NOTE: The headlamp setting is 1 % below horizontal and parallel.

Check the headlamp beam alignment.

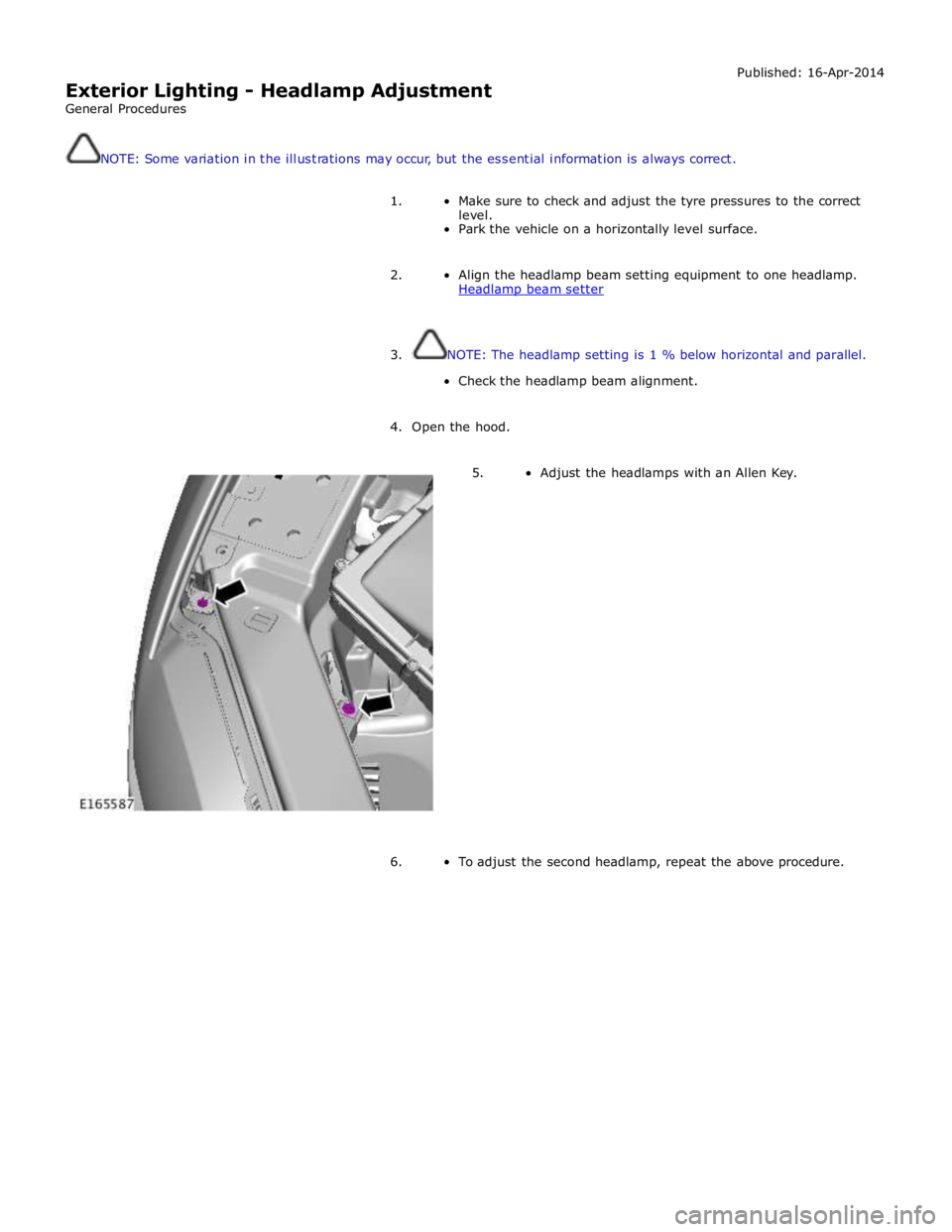

4. Open the hood.

5. Adjust the headlamps with an Allen Key.

6. To adjust the second headlamp, repeat the above procedure.

Page 2091 of 3039

DTC Description Possible Cause Action B1D2711

Heater Coolant

Pump

Heater coolant pump control

circuit - short to ground Carry out any pinpoint tests associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check heater

coolant pump control circuit for short to ground B1D2713

Heater Coolant

Pump

Heater coolant pump control

circuit - open circuit Carry out any pinpoint tests associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check heater

coolant pump control circuit for open circuit B1D9796 Tilt Sensor

Component internal failure Suspect the battery backed sounder, check and install a

new battery backed sounder as required P057112

Brake Switch A

Circuit

Footbrake switch circuit - short

to power Refer to the electrical circuit diagrams and check

footbrake switch circuit for short to power P080111

Reverse Inhibit

Control Circuit

Electrochromic rear view mirror,

reverse inhibit circuit - short to

ground Carry out any pinpoint tests associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check

electrochromic rear view mirror, reverse inhibit circuit for

short to ground P080112

Reverse Inhibit

Control Circuit

Electrochromic rear view mirror,

reverse inhibit circuit - short to

power Refer to the electrical circuit diagrams and check

electrochromic rear view mirror, reverse inhibit circuit for

short to power P080113

Reverse Inhibit

Control Circuit

Electrochromic rear view mirror,

reverse inhibit circuit - open

circuit Refer to the electrical circuit diagrams and check

electrochromic rear view mirror, reverse inhibit circuit for

open circuit P085013

Park/Neutral Switch

Input Circuit

Park/Neutral signal circuit -

open circuit Refer to the electrical circuit diagrams and check

Park/Neutral signal circuit for open circuit P162413 Anti-theft System

RJB anti-theft signal circuit -

open circuit Refer to the electrical circuit diagrams and check RJB

anti-theft signal circuit for open circuit P254F13

Engine Hood Switch

Circuit/Open

Hood ajar switch signal circuit -

open circuit Refer to the electrical circuit diagrams and check hood

ajar switch signal circuit for open circuit U001988

Low Speed CAN

Communication Bus

Bus OFF Carry out any pinpoint tests associated with this DTC

using the manufacturer approved diagnostic system. U014200

Lost

Communication

With Body Control

Module "B"

No sub type information Carry out any pinpoint tests associated with this DTC

using the manufacturer approved diagnostic system. U015500

Lost

Communication

With Instrument

Panel Cluster (IPC)

Control Module

No sub type information Carry out any pinpoint tests associated with this DTC

using the manufacturer approved diagnostic system. U015600

Lost

Communication

With Information

Center "A"

No sub type information Carry out any pinpoint tests associated with this DTC

using the manufacturer approved diagnostic system. U016400

Lost

Communication

With HVAC Control

Module

No sub type information Carry out any pinpoint tests associated with this DTC

using the manufacturer approved diagnostic system. U016800

Lost

Communication

With Vehicle

Security Control

Module

No sub type information Check power and ground supplies to vehicle security

module U019900

Lost

Communication

With "Door Control

Module A"

No sub type information Carry out any pinpoint tests associated with this DTC

using the manufacturer approved diagnostic system. U020000

Lost

Communication

With "Door Control

Module B"

No sub type information Carry out any pinpoint tests associated with this DTC

using the manufacturer approved diagnostic system.

Page 2134 of 3039

DTC Description Possible Causes Action P254F-13

Engine Hood Switch

Circuit/Open - Circuit

open

Hood ajar switch signal circuit -

open circuit

Refer to the electrical circuit diagrams and

check hood ajar switch signal circuit for open

circuit U0010-00

Medium Speed CAN

Communication Bus - No

sub type information

Medium speed CAN

communication Bus

Carry out network integrity test using

manufacturer approved diagnostic system.

Refer to electrical circuit diagrams and test

Medium speed CAN network for open, short

circuit and high resistance U0140-00

Lost Communication

With CJB - No sub type

information

Logged when subscribed CAN

message missing from CJB

Refer to the electrical circuit diagrams and

test power and ground supplies to Central

Junction Box. Check CAN network between

Driver Door Module and Central Junction

Box. Carry out network integrity test using

manufacturer approved diagnostic system U0208-00

Lost Communication

With Driver Seat Module

(DSM) - No sub type

information

Missing message

Refer to the electrical circuit diagrams and

test power and ground supplies to Driver

Seat Module. Check CAN network between

Driver Door Module and Driver Seat Module.

Carry out network integrity test using

manufacturer approved diagnostic system U0300-00

Internal Control Module

Software Incompatibility

- No sub type

information

Car configuration file mismatch

with vehicle specification

NOTE: After updating the car configuration

file, set the ignition to on and wait 30 seconds

before clearing the DTCs

Using the manufacturer approved diagnostic

system, check and up-date the car

configuration file as necessary U2002-24

Switch - Signal stuck

high

Signal stuck high

Clear DTC and re-test. If DTC remains,

install a new passenger side window switch U2004-24

Auxiliary Switch Pack -

Signal stuck high

Signal stuck high

Left or right rear door local

switch pressed for longer than

20 seconds

Switch circuit short to ground or

power

Refer to the electrical circuit diagrams and

check the left and right door switch circuits U2010-11

Switch Illumination -

Circuit short to ground

Switch illumination circuit short

to ground

Refer to electrical circuit diagrams and check

the switch illumination circuit U2012-08

Car Configuration

Parameter(s) - Bus

signal/message failures

Bus signal/message failures

Cycle the ignition status and re-test. If DTC

remains, re-configure the RJB using the

manufacturer approved diagnostic system U2013-24

Switch Pack - Signal

stuck high

Signal stuck high

Clear DTC and re-test. If DTC remains,

install a new driver side window switch pack U2014-44

Control Module

Hardware - Data

memory failure

Data Memory Failure

Install a new DDM/PDM, Refer to the

warranty policy and procedures manual if a

module is suspect U2100-00

Initial Configuration Not

Complete - No sub type

information

Driver/passenger door module is

not configured correctly

Re-configure the DDM/PDM using the

manufacturer approved diagnostic system U2101-00

Control Module

Configuration

Incompatible - No sub

type information

Car configuration file mismatch

with vehicle specification

Re-configure the module using the

manufacturer approved diagnostic system.

Check the configuration of the Car

Configuration File (CCF)

Page 2495 of 3039

Published: 18-Mar-2014

Handles, Locks, Latches and Entry Systems - Locks, Latches and Entry Systems

Diagnosis and Testing

Principle of Operation

For a detailed description of the locks, latches and entry systems and operation, refer to the relevant Description and

Operation section of the workshop manual. REFER to: Handles, Locks, Latches and Entry Systems (501-14, Description and

Operation).

Inspection and Verification

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault and may also cause additional faults in the vehicle being checked and/or the donor vehicle

NOTE: Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests

1. Verify the customer concern, to be sure the correct issue is investigated

2. Visually inspect for obvious signs of damage and system integrity

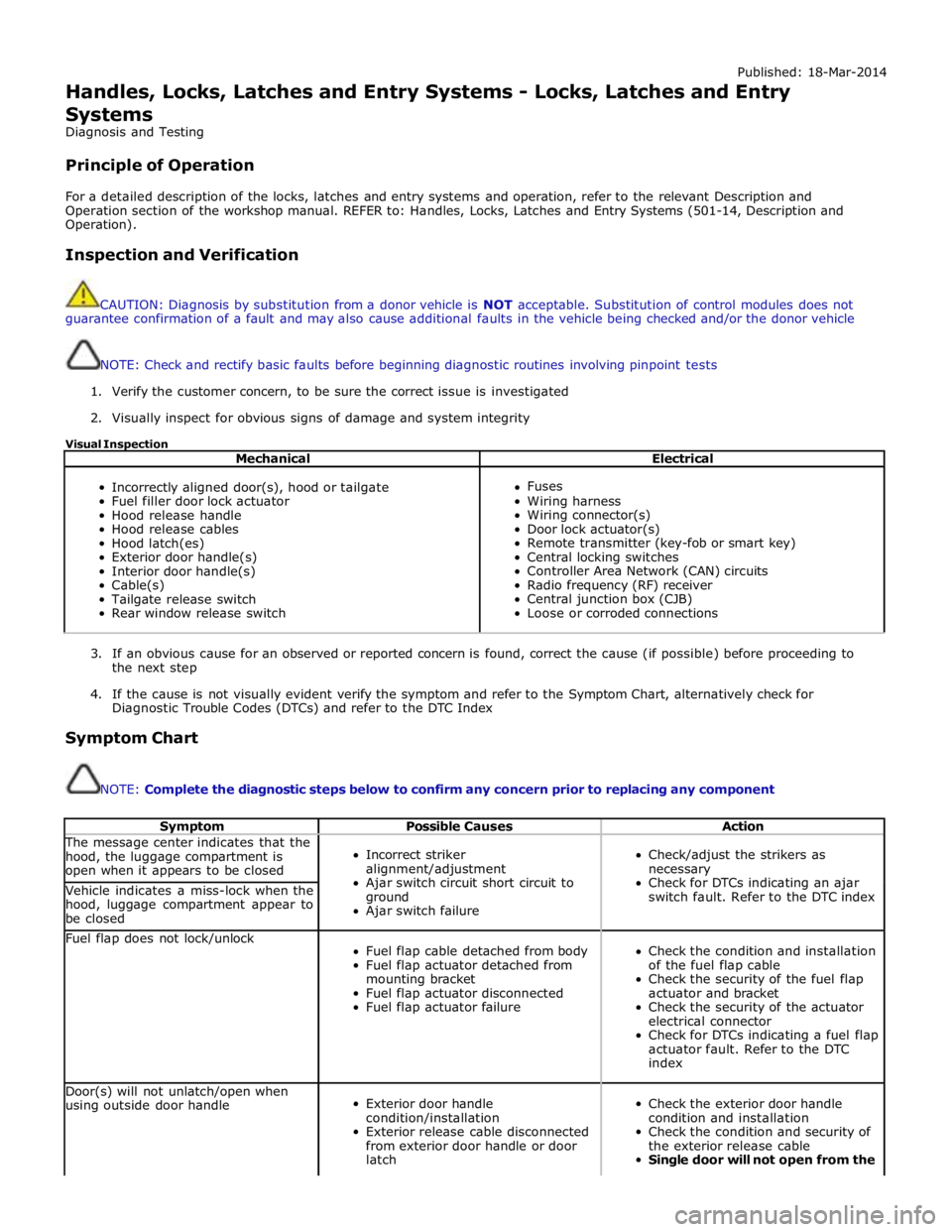

Visual Inspection

Mechanical Electrical

Incorrectly aligned door(s), hood or tailgate

Fuel filler door lock actuator

Hood release handle

Hood release cables

Hood latch(es)

Exterior door handle(s)

Interior door handle(s)

Cable(s)

Tailgate release switch

Rear window release switch

Fuses

Wiring harness

Wiring connector(s)

Door lock actuator(s)

Remote transmitter (key-fob or smart key)

Central locking switches

Controller Area Network (CAN) circuits

Radio frequency (RF) receiver

Central junction box (CJB)

Loose or corroded connections

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to

the next step

4. If the cause is not visually evident verify the symptom and refer to the Symptom Chart, alternatively check for

Diagnostic Trouble Codes (DTCs) and refer to the DTC Index

Symptom Chart

NOTE: Complete the diagnostic steps below to confirm any concern prior to replacing any component

Symptom Possible Causes Action The message center indicates that the

hood, the luggage compartment is

open when it appears to be closed

Incorrect striker

alignment/adjustment

Ajar switch circuit short circuit to

ground

Ajar switch failure

Check/adjust the strikers as

necessary

Check for DTCs indicating an ajar

switch fault. Refer to the DTC index Vehicle indicates a miss-lock when the

hood, luggage compartment appear to

be closed Fuel flap does not lock/unlock

Fuel flap cable detached from body

Fuel flap actuator detached from

mounting bracket

Fuel flap actuator disconnected

Fuel flap actuator failure

Check the condition and installation

of the fuel flap cable

Check the security of the fuel flap

actuator and bracket

Check the security of the actuator

electrical connector

Check for DTCs indicating a fuel flap

actuator fault. Refer to the DTC

index Door(s) will not unlatch/open when

using outside door handle

Exterior door handle

condition/installation

Exterior release cable disconnected

from exterior door handle or door

latch

Check the exterior door handle

condition and installation

Check the condition and security of

the exterior release cable

Single door will not open from the

Page 2686 of 3039

NOTE: A = Non-deployed hinge; B = Deployed hinge

Item Description 1 Firing pin 2 Stabilizing link 3 Engine compartment lid leaf 4 Intermediate leaf 5 Body leaf The hinge system incorporates a number of leaves. This includes a leaf attached to the body, an intermediate leaf and a leaf

attached to the hood. During normal operation the hinge opens and closes using the hood and intermediate leaves. These are

attached together by a firing pin. When the actuators are fired the firing pins fail. This allows the hood and intermediate

leaves to separate and deploy the hood upwards. When the hood deploys the hood latches act as temporary hinges.

NOTE: The hinges deform during the deployment process and will need to be replaced.

Page 2688 of 3039

Diagnostic Trouble Codes (DTCs) and refer to the DTC Index

5. Check DDW for open campaigns. Refer to the corresponding bulletins and SSMs which may be valid for the specific

customer complaint and carry out the recommendations as required

Symptom Chart

Symptom Message Possible Causes Action Hood

deployed CHECK

PEDESTRIAN

SYSTEM

Low speed collision

with pedestrian or

other object

WARNING: The vehicle must not be driven if the hood has been

deployed.

NOTE: Repairs due to a collision are not warrantable.

Check the vehicle for collision damage. Repair as necessary Hood not

deployed CHECK

PEDESTRIAN

SYSTEM

Pedestrian

protection system

fault

NOTE: The vehicle may be driven if a pedestrian protection

system fault is present but the hood has not been deployed.

Check the vehicle for collision damage. Repair as necessary.

Using the manufacturer approved diagnostic system, check the

pedestrian protection system control module for related DTCs

and refer to the relevant DTC index

DTC Index

For a list of Diagnostic Trouble Codes (DTCs) that could be logged on this vehicle, please refer to Section 100-00.

REFER to: Diagnostic Trouble Code (DTC) Index - DTC: Pedestrian Protection System Control Module (PPSCM) (100-00 General Information, Description and Operation).

Page 2732 of 3039

Part N-umber

Body Repairs - Water Leaks - Water Leaks

Description and Operation

General Published: 11-May-2011

If water leaks occur after bodywork repairs, the cause can be established using the checks described below. A

systematic and logical procedure is required to locate water leaks. Before beginning extensive checks, a thorough visual

inspection must be carried out.

Visual Inspection

- The following characteristics may indicate existing leaks:

- Check the clearance and accurate fit of ancillary components such as the hood, tailgate, liftgate, doors, and so

on.

- Check for correct fit and possible damage to sealing elements such as blanking plugs, rubber door seals, and so

on.

- Check water drain holes for unhindered flow.

Various tests can be used to provide further information on possible leaks:

- Water test

- Washer test

- Road test

- Chalk (powder) test

Practical execution of tests and checks

Water test

NOTE: Never aim a jet of water directly at a rubber seal.

Carry out the water test with a second person present (in the passenger compartment).

Use variable washer nozzles (concentrated water jet to fine spray mist).

Start in the lower section and spray the whole area, working upwards in stages.

Washer test

Further tests can be carried out in the washer system.

Some leaks originate here, or only occur here.

The relevant passenger compartment should be checked using a torch during the wash procedure.

Road test

If no leaks are located during the tests above, road tests should be carried out on wet roads.

Road tests under various conditions:

- At various speeds.

- On various road surfaces (asphalt to cobbles).

- With loaded or unloaded vehicle.

- Driving through puddles (splash water).

Chalk test (powder test)

In this test, the clamping load and the bearing surface of the seal are checked.

Performing the test:

- Dust the door seal with powder or coat with chalk.

- Coat the bearing surface of the seal with a thin film of Vaseline.

- Slowly close the door and open it again.

- Check the width and continuity of the imprint on the door seal.

Other test equipment

Other equipment such as stethoscopes, UV lamps, special mirrors or ultrasound measuring instruments can be used to

locate leaks.

Rectifying the leak using recommended tools, auxiliary equipment and materials

Tools and auxiliary equipment:

- Dry, absorbent cloths

- Variable washer nozzle

- Torch, fluorescent tube

- Mirror

- Compressed air

- Seal lip installer

- Wet/dry vacuum cleaner

- Sealing compound compressor

- Remover for interior trim

- Cutter blade or pocket knife

- Wedge (wood or plastic)

- Hot air blower

- Special mirror for concealed leaks

Page 2855 of 3039

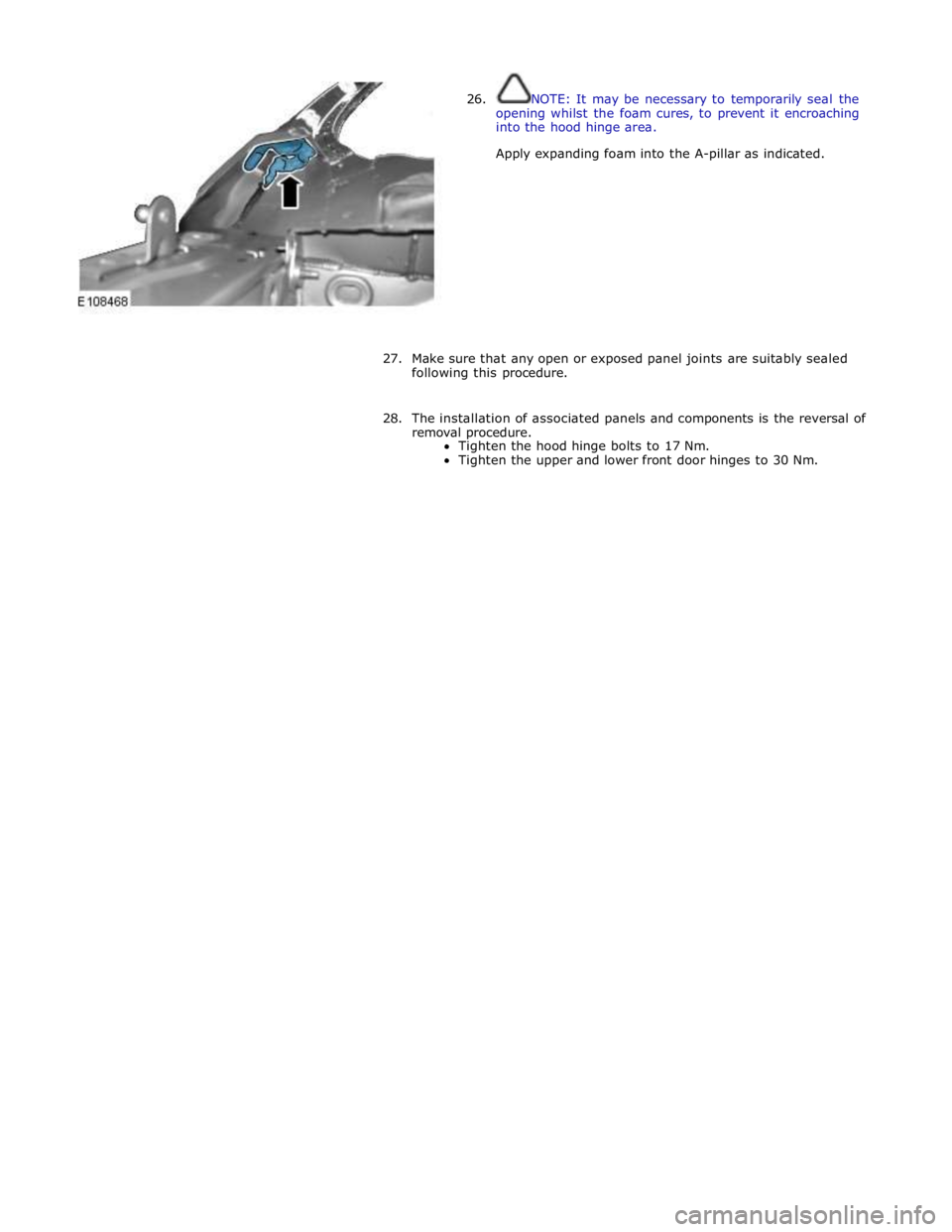

26. NOTE: It may be necessary to temporarily seal the

opening whilst the foam cures, to prevent it encroaching

into the hood hinge area.

Apply expanding foam into the A-pillar as indicated.

27. Make sure that any open or exposed panel joints are suitably sealed

following this procedure.

28. The installation of associated panels and components is the reversal of

removal procedure.

Tighten the hood hinge bolts to 17 Nm.

Tighten the upper and lower front door hinges to 30 Nm.