TPMS JAGUAR XFR 2010 1.G Owner's Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 466 of 3039

1 Check for additional DTCs: C1A5631, C1A5831, C1A6031 or C1A6231 Is a C1A5631, C1A5831, C1A6031 or C1A6231 DTC also logged?

Yes

Refer to the DTC Index and remedial actions.

No

GO to G3. G3: CHECK INITIATOR INSTALLATION 1 Check for correct installation of Initiator. REFER to: (204-04 Wheels and Tires) Tire Pressure Monitoring System (TPMS) Front Antenna (Removal and Installation), Tire Pressure Monitoring System (TPMS) Rear Antenna (Removal and Installation). Is the Initiator correctly installed?

Yes

GO to G4. No

Rectify as required. REFER to: (204-04 Wheels and Tires)

Tire Pressure Monitoring System (TPMS) Front Antenna (Removal and Installation), Tire Pressure Monitoring System (TPMS) Rear Antenna (Removal and Installation). G4: CHECK FOR SHORT CIRCUIT IN INITIATOR HARNESS 1 Locate and remove module blue connector L. 2 Measure the resistance across the relevant initiator circuits within the blue connector. Is the resistance less than 1 Ohm?

Yes

A value of less than 1 Ohm indicates a short circuit, rectify the short circuit as required.

No

Install the correct tire low pressure sensor, of correct frequency, in accordance with that defined in the

manufacturer approved diagnostic system new tire low pressure sensor application, to the position

identified by the logged DTC.

REFER to: Tire Low Pressure Sensor (204-04 Wheels and Tires, Removal and Installation).

PINPOINT TEST H : SPARE TIRE LOW PRESSURE SENSOR NO OPERATION TEST

CONDITIONS DETAILS/RESULTS/ACTIONS H1: ESTABLISH THE TYPE OF SPARE WHEEL AND TIRE ASSEMBLY INSTALLED 1 Establish the type of spare wheel and tire assembly Installed. Is the spare wheel a mini/space saver type? Yes

Tire low pressure sensors are not installed to mini/space-saver spare wheels. Tire low pressure sensors

are installed to full size spare wheels only. The DTC is to be ignored and no repair action is required.

No

GO to H2. H2: ESTABLISH THAT THE SPARE WHEEL HAS A TIRE LOW PRESSURE SENSOR INSTALLED 1 Establish that the spare wheel has a tire low pressure sensor installed, considering the following additional information:

a) As a visual confirmation, the tire low pressure sensor has a metal valve stem rather than a rubber

one. Is a tire low pressure sensor installed? Yes

GO to H3. No

A new spare tire low pressure sensor should be installed. Note: Refer to the note above the DTC index

about replacing components which may remain under manufacturer warranty. Refer to the relevant section

of the workshop manual. H3: CONFIRM OPERATION OF THE SPARE WHEEL PRESSURE SENSOR 1 Deflate the spare tire, in close proximity to the vehicle, until it is completely deflated. 2 Complete an ignition cycle to ignition on and verify that the instrument cluster reports a spare tire pressure warning for approximately 20 seconds. 3 Re-inflate the spare tire, in close proximity to the vehicle, to the recommended spare tire pressure. 4 Complete an ignition cycle to ignition on and verify that the instrument cluster no longer reports a spare tire pressure warning. Does the instrument cluster continue to report a spare tire pressure warning? Yes

GO to H4. No

No repair action is required. It is possible that the customer may have placed items in the vehicle's luggage compartment that prevented correct RF reception. H4: VERIFY THAT THE SPARE TIRE LOW PRESSURE SENSOR ID HAS BEEN CORRECTLY PROGRAMMED TO THE

MODULE 1 Remove tire low pressure sensor. Record the 8 character hexadecimal ID written on the casing. 2 Use the approved diagnostic system to read the spare tire sensor ID from the module. Refer to the relevant procedure in the workshop manual. 3 Compare the IDs from steps 1 & 2.

Page 471 of 3039

Published: 11-May-2011

Wheels and Tires - Tire Pressure Monitoring System (TPMS) Front Antenna

Removal and Installation

Removal

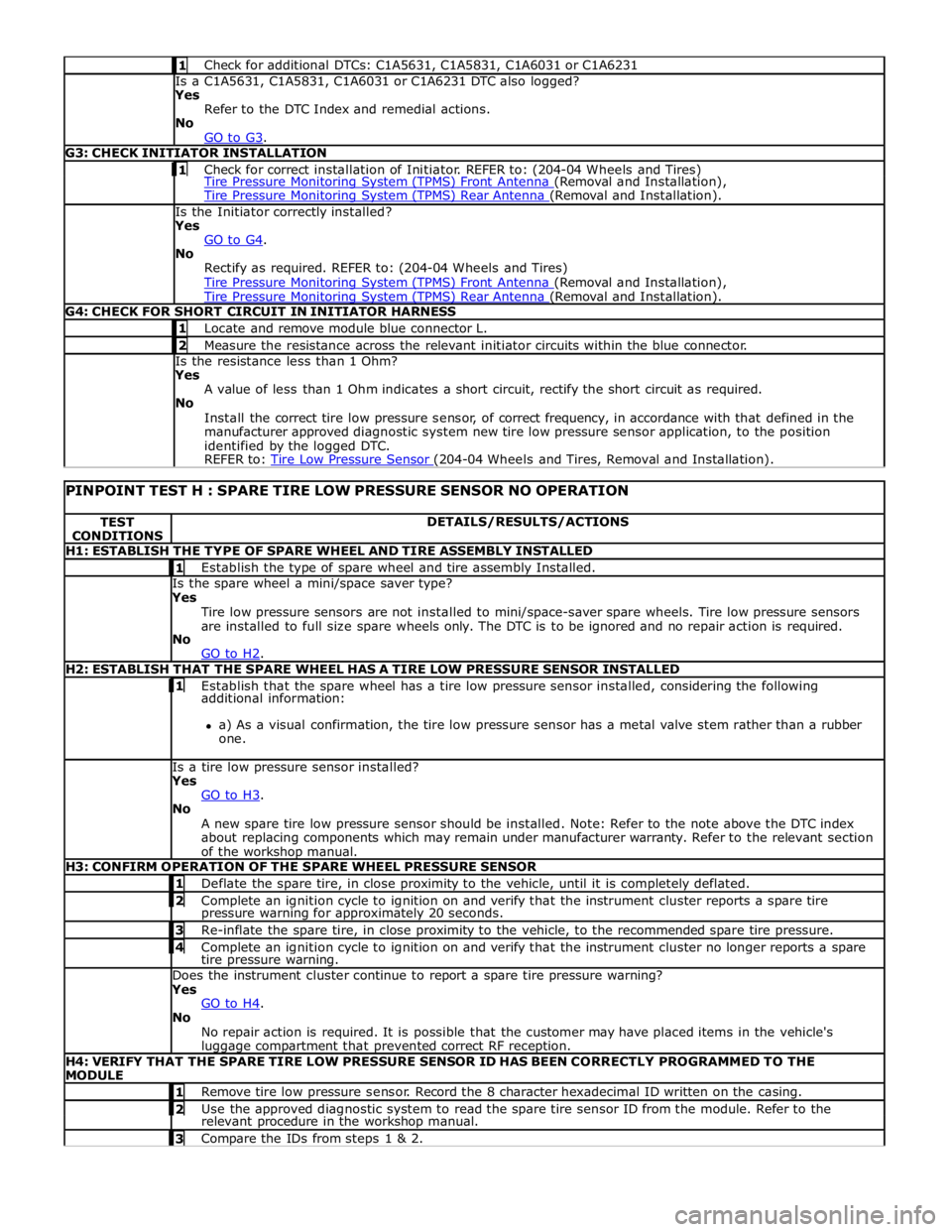

NOTE: Removal steps in this procedure may contain installation details.

1. WARNING: Make sure to support the vehicle with axle stands.

Raise and support the vehicle.

2. NOTES:

This step requires the aid of another technician.

Lower the radiator splash shield enough to access the tire pressure

monitoring system front antenna.

Note the position of the component before removal.

Installation

1. CAUTION: Make sure that the component is secured in the retainer.

NOTE: Make sure that the component is installed to the noted

removal position.

To install, reverse the removal procedure.

Page 472 of 3039

Published: 11-May-2011

Wheels and Tires - Tire Pressure Monitoring System (TPMS) Rear Antenna

Removal and Installation

Removal

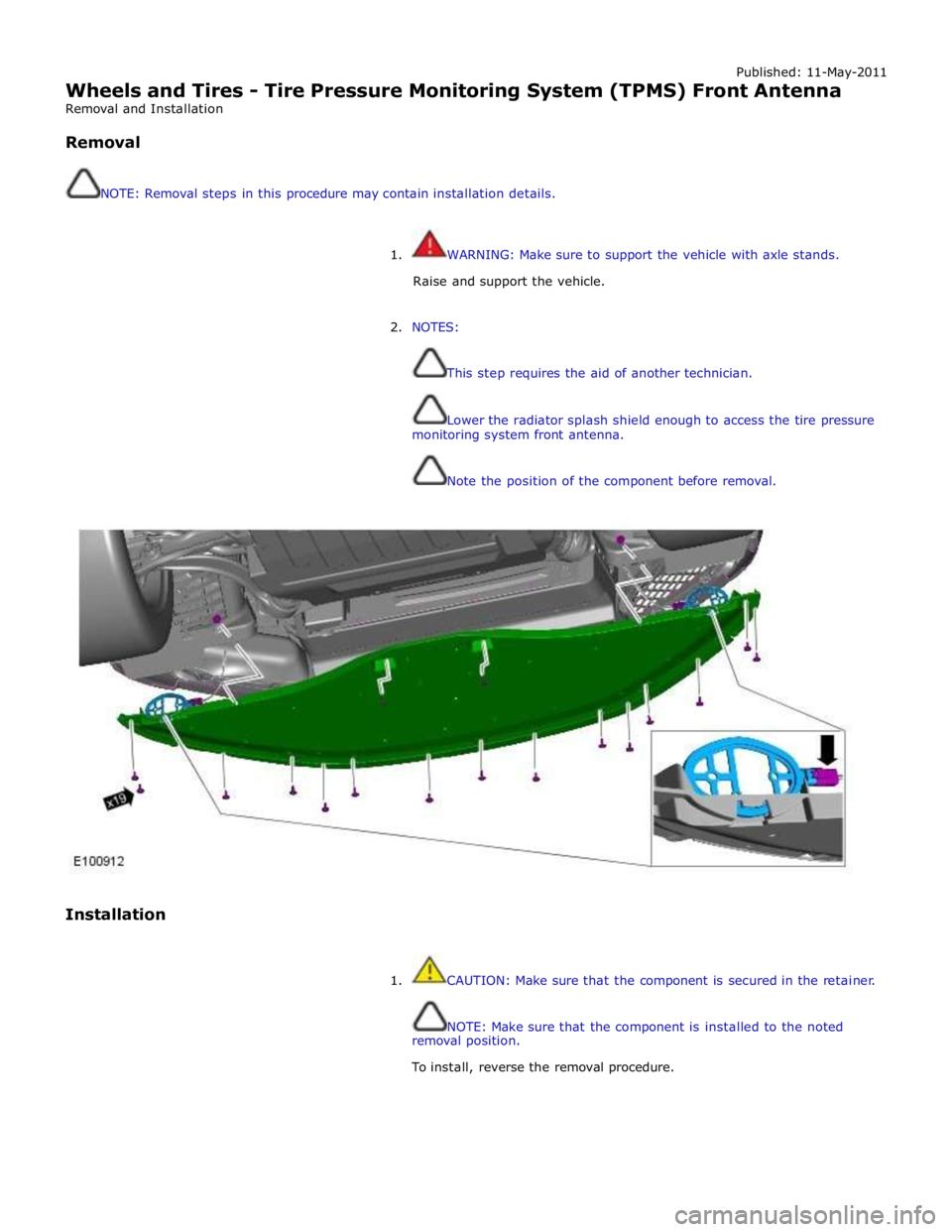

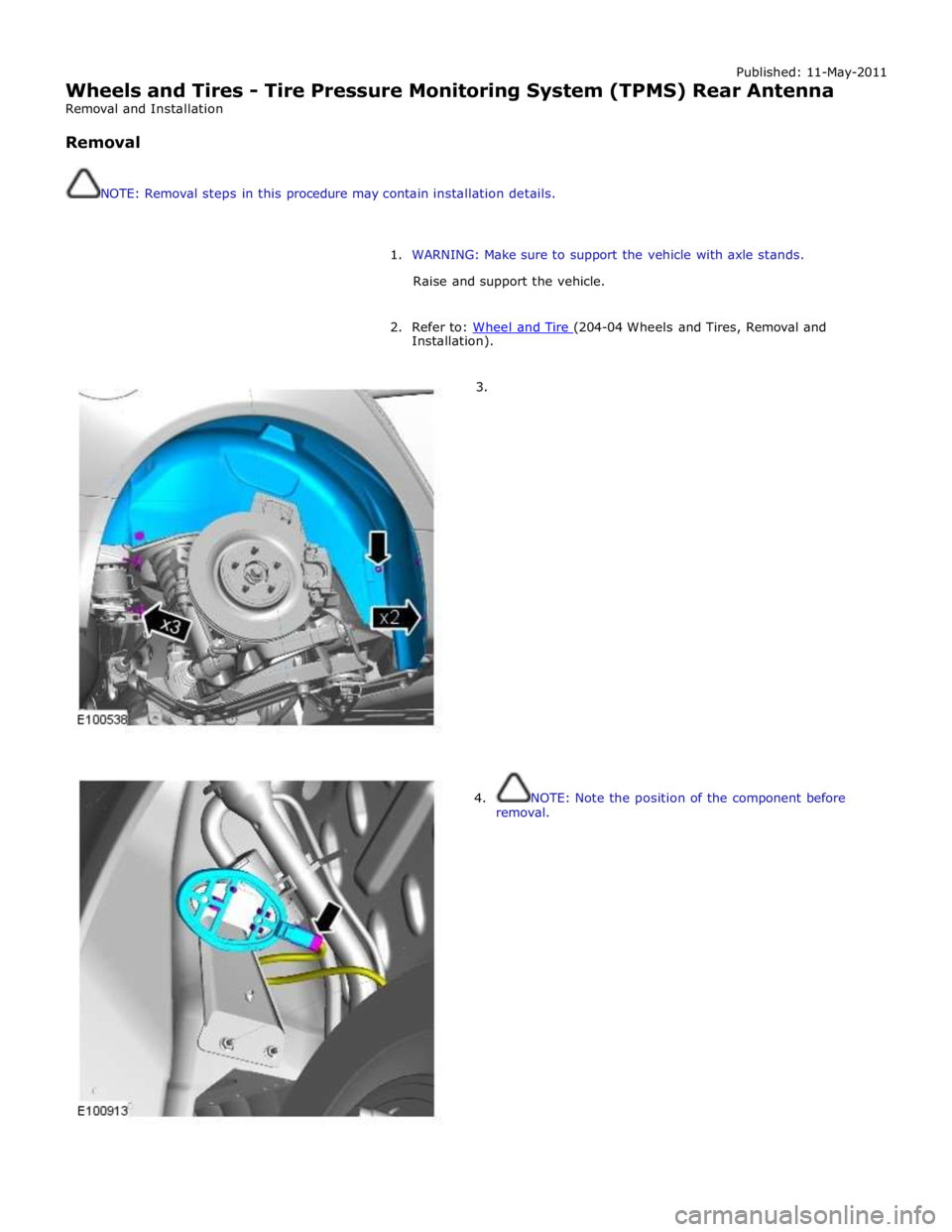

NOTE: Removal steps in this procedure may contain installation details.

1. WARNING: Make sure to support the vehicle with axle stands.

Raise and support the vehicle.

2. Refer to: Wheel and Tire (204-04 Wheels and Tires, Removal and Installation).

3.

4. NOTE: Note the position of the component before

removal.

Page 474 of 3039

Published: 11-May-2011

Wheels and Tires - Tire Pressure Monitoring System (TPMS) Module

Removal and Installation

Removal

NOTE: Removal steps in this procedure may contain installation details.

1. Switch the igntion off.

2. Remove the right-hand front seat.

Refer to: Front Seat (501-10 Seating, Removal and Installation).

3. Refer to: B-Pillar Lower Trim Panel (501-05 Interior Trim and Ornamentation, Removal and Installation).

4. Detach and reposition the floor covering.

5. www.JagDocs.com

Page 476 of 3039

Published: 11-May-2011

Wheels and Tires - Tire Pressure Monitoring System (TPMS) Receiver

Removal and Installation

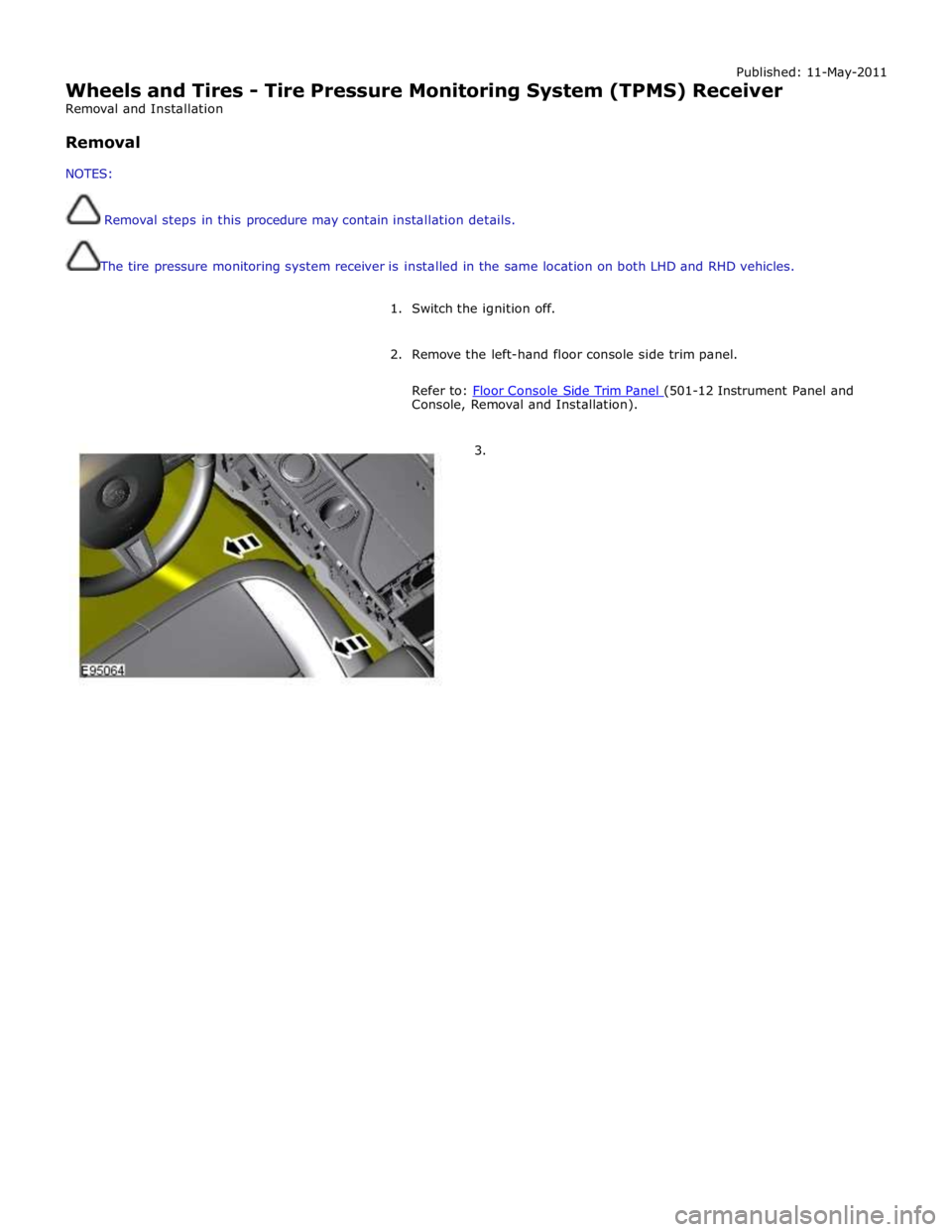

Removal

NOTES:

Removal steps in this procedure may contain installation details.

The tire pressure monitoring system receiver is installed in the same location on both LHD and RHD vehicles.

1. Switch the ignition off.

2. Remove the left-hand floor console side trim panel.

Refer to: Floor Console Side Trim Panel (501-12 Instrument Panel and Console, Removal and Installation).

3.

Page 1784 of 3039

7 Instrument cluster 8 Steering column motor 9 High speed CAN bus connection to other vehicle systems 10 Engine oil pressure switch 11 Steering column adjustment switch 12 Brake fluid level switch 13 LH (left-hand) steering column multifunction switch 14 Start control module 15 Clockspring 16 RH (right-hand) steering column multifunction switch 17 Engine coolant level sensor 18 Auxiliary lighting switch

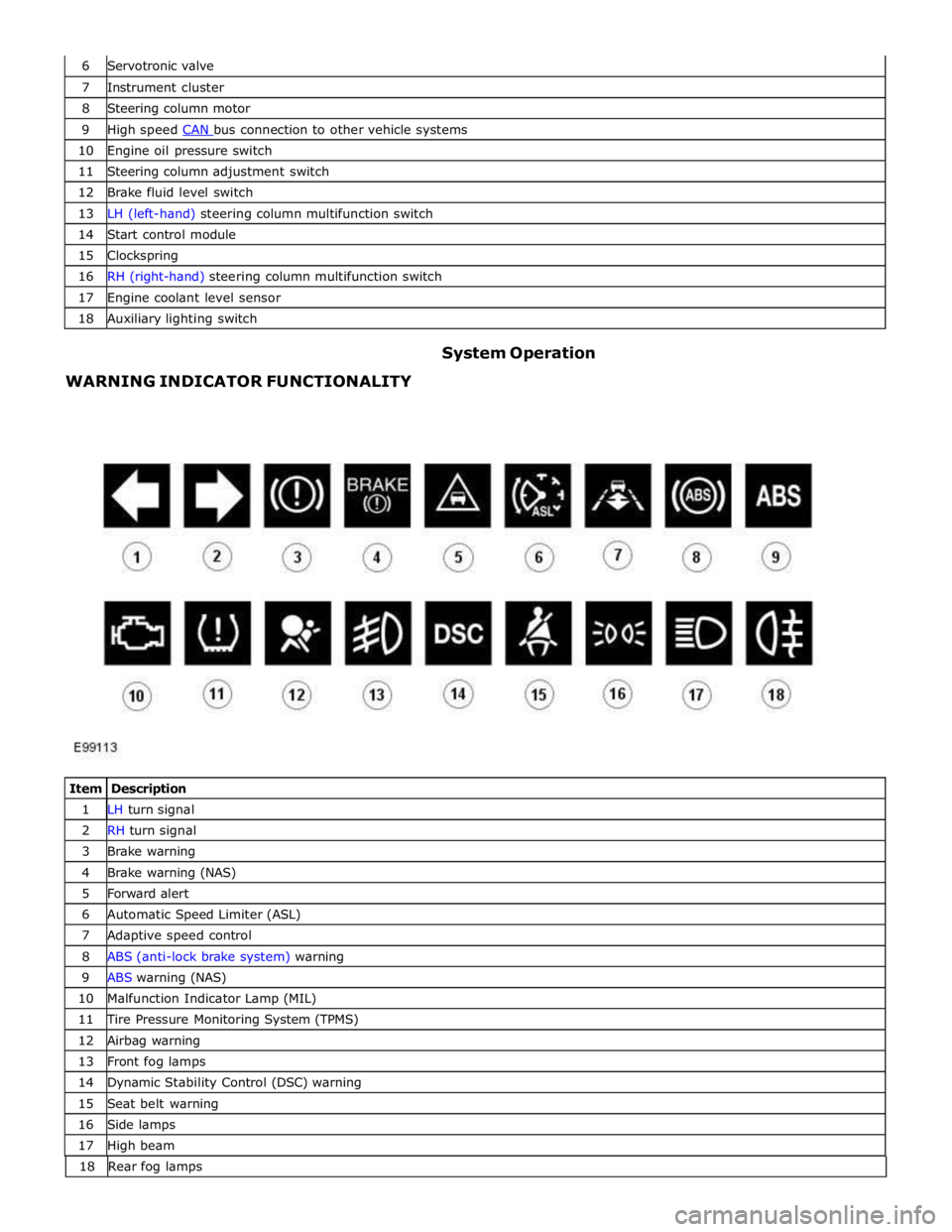

WARNING INDICATOR FUNCTIONALITY System Operation

Item Description 1 LH turn signal 2 RH turn signal 3 Brake warning 4 Brake warning (NAS) 5 Forward alert 6 Automatic Speed Limiter (ASL) 7 Adaptive speed control 8 ABS (anti-lock brake system) warning 9 ABS warning (NAS) 10 Malfunction Indicator Lamp (MIL) 11 Tire Pressure Monitoring System (TPMS) 12 Airbag warning 13 Front fog lamps 14 Dynamic Stability Control (DSC) warning 15 Seat belt warning 16 Side lamps 17 High beam 18 Rearfoglamps

Page 1786 of 3039

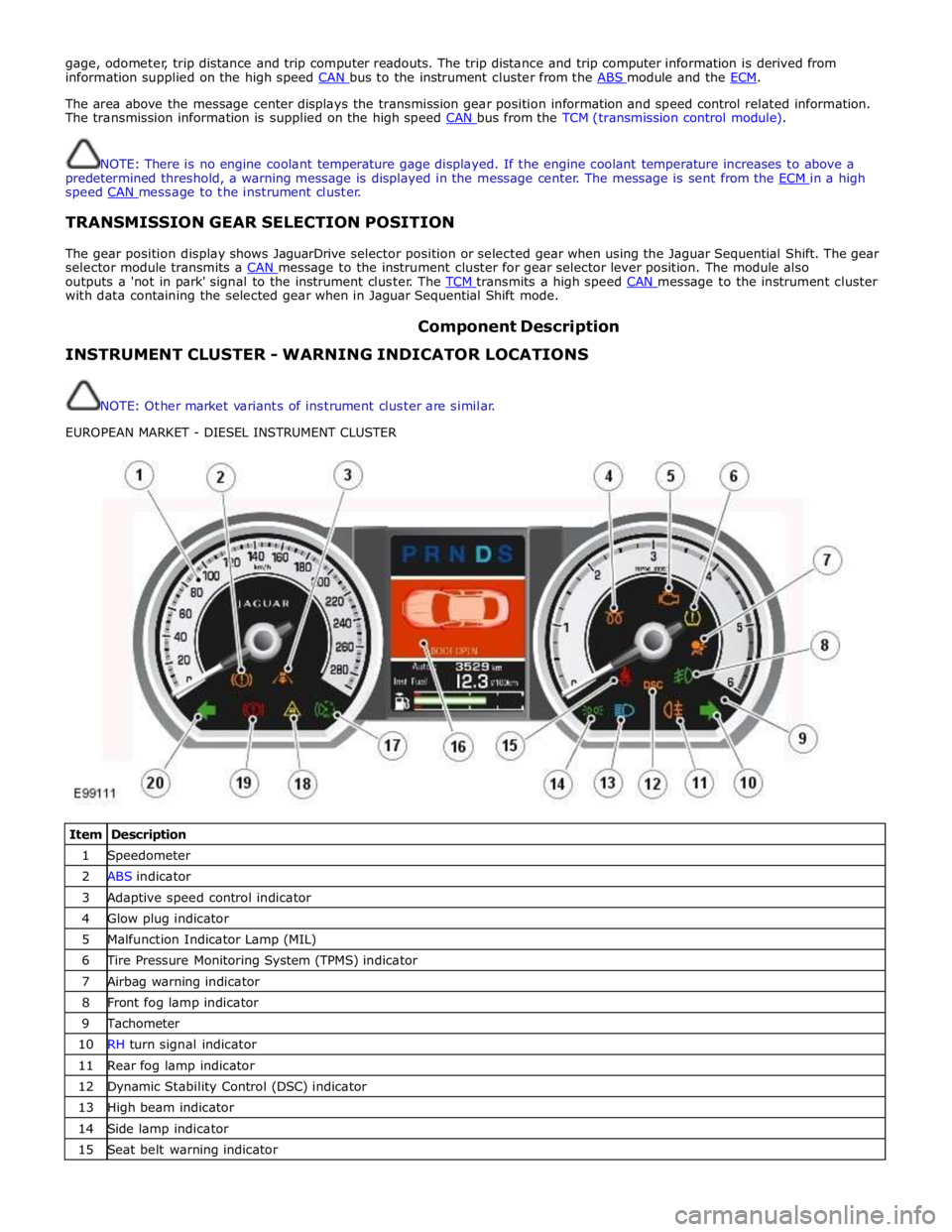

6. Adaptive Speed Control Indicator

The adaptive speed control system is controlled by the adaptive speed control module. Operation of the SET +/- switches on

the steering wheel will activate the system. Operation of the switches is detected by the adaptive speed control module. The

module issues a high speed CAN message to the instrument cluster which illuminates the adaptive speed control indicator, when the system is in 'follow mode', in an amber color and displays a 'SETSPEED XXX MPH / KM/H' message in the message

center. The indicator is illuminated in an amber color for a 3 second indicator check when the ignition is switched on.

7. Anti-lock Braking System (ABS) Warning Indicator

The ABS warning indicator is controlled by the ABS module. If a fault in the ABS system is detected by the ABS module, the module issues a high speed CAN message to the instrument cluster to illuminate the ABS warning indicator in an amber color and display the message 'ABS FAULT' in the instrument cluster. The indicator is illuminated in an amber color for a 3 second

indicator check when the ignition is switched on. If a fault is present when the ignition is on, the bulb will remain illuminated

after the 3 second indicator check period.

NOTES:

The 'ABS FAULT' message is not displayed in NAS markets).

If both the ABS warning indicator and the brake warning indicator illuminate simultaneously, a major fault in the brake system will have occurred.

On NAS vehicles, the ABS warning indicator is also used for parking brake operation. The NAS warning indicator does not have 'ABS' on the icon and will function as described previously for the parking brake operation of the brake warning indicator.

8. Engine Malfunction Indicator Lamp (MIL)

The MIL warning indicator is controlled by the ECM and illuminated by the instrument cluster on receipt of a message on the high speed CAN bus from the ECM. The indicator is illuminated in an amber color for a 3 second indicator check when the ignition is switched on.

If the MIL remains illuminated after the engine is started or illuminates when driving, a fault is present and must be

investigated at the earliest opportunity. Illumination of the MIL warning indicator alerts the driver to an OBD (on-board

diagnostic) fault which will cause excessive emissions output. This may relate to either an engine management system fault or

a transmission.

9. Tire Pressure Monitoring System (TPMS) Warning Indicator

The TPMS warning indicator is illuminated by the instrument cluster on receipt of a medium speed CAN message from the TPMS module. The indicator is illuminated in an amber color for a 3 second indicator check when the ignition is switched on.

If the indicator illuminates and is accompanied by the message 'TYRE PRESSURE SYSTEM FAULT' in the message center, then a

TPMS fault has occurred. If the indicator illuminates and accompanied by a different message, then a low tire pressure has

been detected, a spare wheel has been fitted or a TPMS sensor has failed.

10. Airbag Warning Indicator

The airbag warning indicator is controlled by the instrument cluster. The indicator is illuminated in an amber color for the 3

second indicator check when the ignition is switched on. The indicator remains illuminated after the 3 second period has

expired until the instrument cluster receives a turn off message on the high speed CAN bus from the RCM (restraints control module).

11. Front Fog Lamp Indicator

The green colored front fog lamp indicator is controlled by the CJB and illuminated by the instrument cluster on receipt of a front fog lamp on message on the medium speed CAN bus from the CJB. The indicator is illuminated for as long as the front fog lamps are active. The front fog lamp indicator is not subject to the 3 second indicator check when the ignition is switched

on.

12. Dynamic Stability Control (DSC) Indicator

The DSC warning lamp is controlled by the ABS module and illuminated by the instrument cluster in response to messages received on the high speed CAN bus. The indicator is illuminated in an amber color for the 3 second indicator check when the ignition is switched on. The DSC warning indicator, are permanently illuminated in an amber color if the instrument cluster

receives a high speed CAN message from the ABS module relating to one of the following faults:

Traction control fault

Yaw control fault

Engine drag torque control fault

Panic Brake Assist (PBA) fault

Signal missing relating to either traction control active, yaw control active or DSC switch input.

The above faults will also generate an applicable DSC and ABS warning message in the message center. The DSC warning

indicator will flash at 2 Hz for if the traction control or yaw control is active when the DSC system is enabled. If the DSC

system is switched off, the warning indicator will be permanently illuminated until the DSC system is subsequently

re-activated.

13. Safety Belt Warning Indicator

The safety belt warning indicator operates for both the driver and passenger safety belts. The warning indicator is controlled by

Page 1788 of 3039

gage, odometer, trip distance and trip computer readouts. The trip distance and trip computer information is derived from

information supplied on the high speed CAN bus to the instrument cluster from the ABS module and the ECM.

The area above the message center displays the transmission gear position information and speed control related information.

The transmission information is supplied on the high speed CAN bus from the TCM (transmission control module).

NOTE: There is no engine coolant temperature gage displayed. If the engine coolant temperature increases to above a

predetermined threshold, a warning message is displayed in the message center. The message is sent from the ECM in a high speed CAN message to the instrument cluster.

TRANSMISSION GEAR SELECTION POSITION

The gear position display shows JaguarDrive selector position or selected gear when using the Jaguar Sequential Shift. The gear

selector module transmits a CAN message to the instrument cluster for gear selector lever position. The module also outputs a 'not in park' signal to the instrument cluster. The TCM transmits a high speed CAN message to the instrument cluster with data containing the selected gear when in Jaguar Sequential Shift mode.

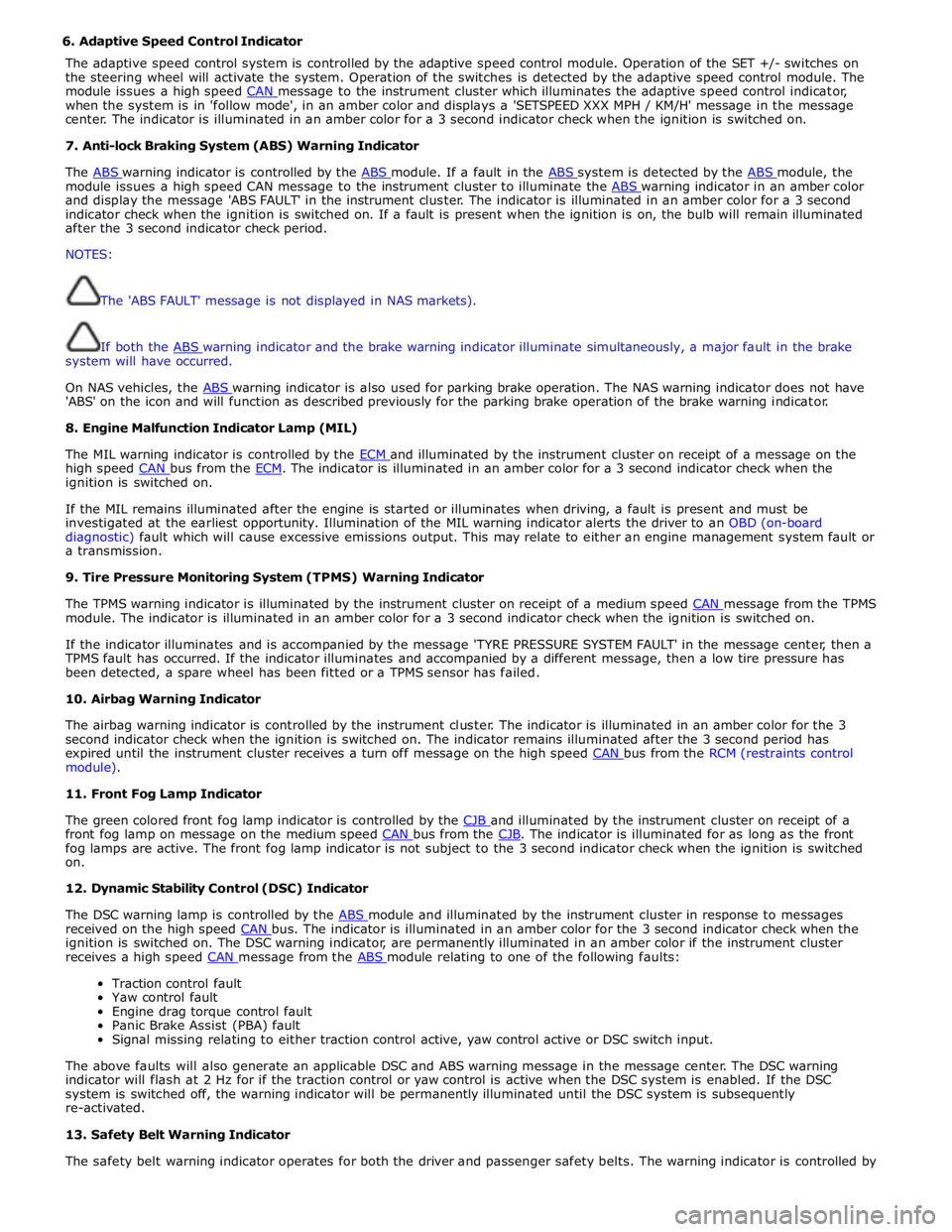

Component Description INSTRUMENT CLUSTER - WARNING INDICATOR LOCATIONS

NOTE: Other market variants of instrument cluster are similar.

EUROPEAN MARKET - DIESEL INSTRUMENT CLUSTER

Item Description 1 Speedometer 2 ABS indicator 3 Adaptive speed control indicator 4 Glow plug indicator 5 Malfunction Indicator Lamp (MIL) 6 Tire Pressure Monitoring System (TPMS) indicator 7 Airbag warning indicator 8 Front fog lamp indicator 9 Tachometer 10 RH turn signal indicator 11 Rear fog lamp indicator 12 Dynamic Stability Control (DSC) indicator 13 High beam indicator 14 Side lamp indicator 15 Seat belt warning indicator

Page 1789 of 3039

17 Automatic Speed Limiter (ASL) indicator 18 Forward alert indicator 19 Brake warning indicator 20 LH turn signal indicator NAS MARKET - V8 NORMALLY ASPIRATED INSTRUMENT CLUSTER

Item Description 1 Speedometer 2 ABS indicator (NAS) 3 ABS indicator (ROW) 4 Adaptive speed control indicator 5 Tachometer 6 Malfunction Indicator Lamp (MIL) 7 Tire Pressure Monitoring System (TPMS) indicator 8 Airbag warning indicator 9 Front fog lamp indicator 10 RH turn signal indicator 11 Rear fog lamp indicator 12 Dynamic Stability Control (DSC) indicator 13 High beam indicator 14 Seat belt warning indicator 15 Side lamp indicator 16 Message center 17 Automatic Speed Limiter (ASL) indicator 18 Forward alert indicator 19 Brake warning indicator (NAS) 20 Brake warning indicator (ROW) 21 LH turn signal indicator The warning indicators are located in various positions in the instrument cluster. The indicators can be split into two groups;

instrument cluster controlled and externally controlled.

Instrument cluster controlled warning indicators are dependent on software logic within the instrument cluster for activation.

The cluster software controls the indicator illumination check at ignition on (power mode 6).

Externally controlled indicators are supplied with current from another vehicle system control module or illuminated by the

instrument cluster software on receipt of a bus message from another vehicle sub-system. The indicator illumination check at

ignition on (powermode 6) is also controlled by the sub-system module for these indicators.

Page 1797 of 3039

ETM Test/no. Message Center Display Gauge/Indicator/Display

Tested.

Range

Description DDC

PDC Passenger Door Control (PDC)

modules.. FAULTY.

Coms never received

Coms error . 28 - Module MODULE STATUS. Provides status of; Keyless

CONNECTED

Communication (Coms) ok status. vehicle module (KVM), Drivers KVM

seat module (DSM), WAITING Coms not received, not an DSM

Infotainment control module MISSING issue ICM

(ICM) and Integrated control FAULTY. Coms never received ICP

panel (ICP) modules.. Coms error . 29 - Module MODULE STATUS. Provides status of; Front smart

CONNECTED

Communication (Coms) ok status. junction box (FSJB), Rear smart FSJB

junction box (RSJB), Tyre WAITING Coms not received, not an RSJB

pressure monitoring system MISSING issue TPMS

(TPMS) and Adaptive front FAULTY. Coms never received AFLS

lighting system (AFLS) modules. Coms error . 30 - Module MODULE STATUS. Provides status of; Passive

CONNECTED

Communication (Coms) ok status. anti-theft system (PATS), Blind PATS

Spot Monitoring (BSM), Gear WAITING Coms not received, not an BSM

shift module (GSM) and Starter MISSING issue GSM

Control Unit (SCU) modules. FAULTY. Coms never received SCU Coms error . 31- Back to

test 2. GAUGE SWEEP. Tachometer and speedometer. N/A. Repeats display cycle from test 2.

1. If the cause is not visually evident, check for Diagnostic Trouble Codes (DTCs) and refer to the DTC Index.

DTC Index

CAUTION: When probing connectors to take measurements in the course of the pinpoint tests, use the adaptor kit, part

number 3548-1358-00

NOTES:

If the control module or a component is suspect and the vehicle remains under manufacturer warranty, refer to the

Warranty Policy and Procedures manual (section B1.2), or determine if any prior approval programme is in operation, prior to

the installation of a new module/component.

Generic scan tools may not read the codes listed, or may read only five digit codes. Match the five digits from the scan

tool to the first five digits of the seven digit code listed to identify the fault (the last two digits give extra information read by

the manufacturer-approved diagnostic system).

When performing voltage or resistance tests, always use a digital multimeter (DMM) accurate to three decimal places and

with a current calibration certificate. When testing resistance, always take the resistance of the DMM leads into account.

Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests.

If DTCs are recorded and, after performing the pinpoint tests, a fault is not present, an intermittent concern may be the

cause. Always check for loose connections and corroded terminals.

DTC Description Possible Cause Action B100811

Wiper Mode

Switch

Master wiper switch circuit -

short to ground Refer to the electrical circuit diagrams and check master

wiper switch circuit for short to ground B100815

Wiper Mode

Switch

Master wiper switch circuit -

short to power, open circuit Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Refer to the

electrical circuit diagrams and check master wiper switch

circuit for short to power, open circuit B100951

Ignition

Authorisation

Instrument cluster power and

ground supply circuits - short,

open circuit

Target SID synchronization

error following re-programming

CAN fault Carry out any pinpoint tests associated with this DTC using

the manufacturer approved diagnostic system. Refer to the

electrical circuit diagrams and check instrument cluster power

and ground supply circuits for short, open circuit. Perform the

Immobilisation application from the Set-up menu using the

manufacturer approved diagnostic system. Check CAN

communications between instrument cluster and tester www.JagDocs.com