heating JAGUAR XFR 2010 1.G Owner's Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 1698 of 3039

Published: 11-May-2011

Climate Control - Air Conditioning - System Operation and Component Description

Description and Operation

General System Operation

To accomplish the transfer of heat, refrigerant is circulated around a sealed system, where it passes through two

pressure/temperature regimes. In each of the regimes the refrigerant changes state, during which process maximum heat

absorption or dissipation occurs.

The low pressure/temperature regime is from the thermostatic expansion valve, through the evaporator to the compressor. The

refrigerant decreases in pressure and temperature at the thermostatic expansion valve, then changes state from a liquid to a

vapor in the evaporator to absorb heat.

The high pressure/temperature regime is from the compressor, through the condenser and receiver drier assembly to the

thermostatic expansion valve. The refrigerant increases in pressure and temperature as it passes through the compressor, then

releases heat and changes state from a vapor to a liquid in the condenser.

Operation of the A/C (air conditioning) system is controlled by the ATC (automatic temperature control) module.

Refer to: Control Components (412-01 Climate Control, Description and Operation). The A/C system works in conjunction with: The air distribution and filtering system.

Refer to: Air Distribution and Filtering (412-01 Climate Control, Description and Operation). The heating and ventilation system.

Refer to: Heating and Ventilation (412-01 Climate Control, Description and Operation).

Page 1706 of 3039

Climate Control - Control Components - Overview

Description and Operation

Overview Published: 11-May-2011

The climate control system is controlled by the ATC (automatic temperature control) module. It controls the heating and

ventilation system and the A/C (air conditioning) system to regulate the temperature, volume and distribution of air into the

passenger compartment. The system is a fully automatic dual zone system capable of maintaining individual temperature

levels selected for the LH (left-hand) and RH (right-hand) sides of the passenger compartment, up to a maximum differential

of approximately 3 ºC (5.4 ºF). Manual overrides for the system include inlet air source, blower speed and air distribution.

These selections can be made using either the soft switches on the home and climate control screens of the touch screen

display (TSD), or the switches on the integrated control panel.

The ATC module also controls: The rear window heater.

The windshield heater (where fitted).

The exterior mirror heaters.

The seat heaters (where fitted).

The steering wheel heater.

TSD Home Screen

TSD Climate Control Screen

Page 1709 of 3039

6 TSD (touch screen display) 7 Integrated control panel 8 Evaporator temperature sensor 9 Humidity and temperature sensor 10 Sunload sensor 11 Refrigerant pressure sensor 12 Pollution sensor Comments:

where fitted 13 Air inlet servo motor 14 A/C (air conditioning) compressor solenoid valve 15 RH (right-hand) outer face level register 16 RH inner face level register 17 LH (left-hand) inner face level register 18 LH outer face level register 19 RH temperature blend stepper motor 20 Face/Feet distribution stepper motor 21 ATC (automatic temperature control) module 22 LH temperature blend stepper motor 23 Windshield (Defrost) stepper motor 24 Blower control module 25 RJB (rear junction box) 26 Blower

Air Inlet Control System Operation

The source of inlet air is automatically controlled unless overridden by pressing the air recirculation switch on the integrated

control panel. During automatic control, the ATC module determines the required position of the recirculation door from its 'comfort' algorithm and, if fitted, the pollution sensor.

The ATC module provides analogue signals to the air inlet servo motor along a hardwired connection. A potentiometer in the motor supplies the ATC module with a position feedback signal for closed loop control.

Air Temperature Control

Cooled air from the evaporator enters the heater assembly, where temperature blend doors direct a proportion of the air

through the heater core to produce the required output air temperature.

The two temperature blend doors operate independently to enable individual temperature settings for the left and right sides

of the passenger compartment. The temperature blend doors are operated by stepper motors, which are controlled by the ATC module using LIN bus messages.

The ATC module calculates the temperature blend stepper motor positions required to achieve the selected temperature and compares it against the current position. If there is any difference, the ATC module signals the stepper motors to adopt the new position.

Air temperature is controlled automatically unless maximum heating (HI) or maximum cooling (LO) is selected. When maximum

heating or cooling is selected, a 'comfort' algorithm in the ATC module adopts an appropriate strategy for air distribution, blower speed, and air source.

Temperature control in one side of the passenger compartment can be compromised by the other side of the passenger

compartment being set to a high level of heating or cooling. True maximum heating or cooling (displayed as 'HI' or 'LO' on the

TSD) can only be selected for the driver's side of the passenger compartment. If 'HI' or 'LO' is selected for the driver's side, the

temperature for the front passenger's side is automatically set to match the driver's side.

If A/C is selected off in the automatic mode, no cooling of the inlet air will take place. The minimum output air temperature from the system will be ambient air temperature plus any heat pick up in the air inlet path.

If the Temp. sync. soft button on the TSD is pressed, the ATC module synchronizes the temperature of the passenger side of the passenger compartment with the driver's side.

Blower Control

When the system is in the automatic mode, the ATC module determines the blower speed required from a comfort algorithm. When the system is in the manual mode, the ATC module operates the blower at the speed selected using either the rotary

Page 1711 of 3039

rear window heater switch is pressed or the engine stops.

Automatic operation during a journey is initiated when low ambient air temperatures are experienced and the vehicle has been

travelling for a set period of time above a threshold speed. In this instance, no feedback is given to the driver to inform him

the rear window heater is operational (the switch LED is not illuminated). The duration of heater operation is variable depending on the ambient air temperature, vehicle speed and the amount of time the vehicle has been travelling.

Windshield Heater (Where Fitted)

Windshield heater operation is only enabled when the engine is running. The ATC module controls operation of the windshield heater using two relays in the EJB (engine junction box). When windshield heater operation is required, the ATC module broadcasts a message to the CJB on the medium speed CAN bus. On receipt of the message, the CJB energizes the relays by providing a ground path for both relay coils. This allows a battery feed to flow across the relays to power the windshield left

and right heater elements.

There are two modes of windshield heater operation; manual and automatic.

Manual operation is activated by pressing the windshield heater switch on the integrated control panel. When the switch is

pressed, the status LED in the switch illuminates and the windshield heater elements are energized. Manual operation is discontinued when the windshield heater switch is pressed a second time, 5 minutes have elapsed (the heating phase), or the

engine stops. If manual operation is discontinued by the engine stopping, the previous heating phase is resumed if the engine

is re-started within 30 seconds.

There are two variants of automatic operation; automatic operation at the start of a journey and automatic operation during a

journey.

Automatic operation at the start of a journey is initiated if the ambient air temperature is below 5 °C (41 °F). In this instance,

the switch LED is illuminated and the heater elements are energized for 6.5 minutes. Automatic operation is discontinued if the windshield heater switch is pressed or the engine stops.

Automatic operation during a journey is initiated when low ambient air temperatures are experienced and the vehicle has been

travelling for a set period of time above a threshold speed. In this instance, no feedback is given to the driver to inform him

the windshield heater is operational (the switch LED is not illuminated) and the duration of operation is variable depending upon the ambient air temperature, vehicle speed and the amount of time the vehicle has been travelling.

Exterior Mirror Heaters

Operation of the exterior mirror heaters is fully automatic and not controllable by the driver. Exterior mirror heater operation is

determined by ambient air temperature and windshield wiper status. When ambient air temperature reaches a pre-determined

level, the ATC module broadcasts an exterior mirror heating request to the door modules over the medium speed CAN bus. On receipt of this message, the door modules provide feed and ground connections to both exterior mirror heater elements.

The amount of time the exterior mirror heaters are operational increases if the windshield wipers are switched on. This ensures

the mirrors remain mist free in damp and wet conditions, where there is an increased risk of misting.

Seat Heaters (Where Fitted)

There are four seat heater settings available; off, 1, 2 and 3, which can be selected on the home and climate control screens

of the TSD. The heat setting is relayed to the vehicle occupants through a graduated display on the TSD.

Operation of the heated seats is controlled by the ATC module. When the ATC module receives a heating request from the TSD, it broadcasts a message to the CJB over the medium speed CAN bus. The CJB then provides a hardwired 12 V supply to the three heater elements in the related front seat. The heater elements, two in the seat cushion and one in the seat squab,

are wired in series. The ATC module monitors seat temperature using a temperature sensor located in each seat cushion. The CJB provides the temperature sensors with a 5 V supply. The level of the returned voltage back to the CJB is proportional to the seat temperature. The value of the return signal is broadcast to the ATC module, over the medium speed CAN bus, which allows it to control the seat temperature to the required level. The ATC module will suspend or disable operation of the seat heaters if any of the following occur:

Battery voltage exceeds 16.5 ± 0.3 V for more than 5 seconds. Seat heating is re-enabled when battery voltage

decreases to 16.2 ± 0.3 V.

If a short or open circuit is detected.

If the seat heat temperature rises significantly above the target temperature setting.

The graduated display on the TSD remains illuminated until the seat heaters are turned off or the engine stops. If the engine

is restarted within 30 seconds the seat heater resumes the previous heating level.

Page 1712 of 3039

bus. Temperature control for the heater element is provided by the steering wheel heater control module which receives a

temperature feedback signal from a NTC (negative temperature coefficient) thermistor located within the steering wheel.

ATC Module Component Description

The ATC module is mounted on the outboard end of the air inlet duct, behind the front passenger side of the instrument panel. The ATC module processes inputs from the TSD, the switches on the integrated control panel and the system sensors. In response to these inputs, the ATC module outputs control signals to the A/C system and the heating and ventilation system.

Two electrical connectors provide the interface between the ATC module and the vehicle wiring. The ATC module uses hardwired inputs from the system sensors, the LIN bus to communicate with the stepper motors and the medium speed CAN bus to communicate with other control modules on the vehicle.

A/C Compressor Solenoid Valve

The A/C compressor solenoid valve is integral with the A/C compressor. Operation of the solenoid valve is controlled by the ATC module using a hardwired drive current of differing values. By controlling the flow of refrigerant through the compressor, the

solenoid valve can control the A/C system pressure and the evaporator operating temperature.

Refrigerant Pressure Sensor

The refrigerant pressure sensor provides the ATC module with a pressure input from the high pressure side of the refrigerant system. The refrigerant pressure sensor is located in the refrigerant line between the condenser and the thermostatic

expansion valve.

The ATC module supplies a 5 V reference voltage to the refrigerant pressure sensor and receives a return signal voltage, between 0 V and 5 V, related to system pressure.

The ATC module uses the signal from the pressure sensor to protect the refrigerant system from extremes of pressure. The ATC module transmits the A/C pressure, along with the compressor drive current value, to the instrument cluster on the medium speed CAN bus. These signals are broadcast to the ECM on the high speed CAN bus to allow it to calculate the torque being applied to the engine by the compressor. www.JagDocs.com

Page 1715 of 3039

1 LH door mirror 2 Ambient air temperature sensor The ambient air temperature sensor is a NTC thermistor that provides the ATC module with an input of external air temperature. The sensor is hard wired to the ECM and its signal is transmitted to the instrument cluster on the high speed CAN bus. The instrument cluster acts as a gateway and transmits the ambient air temperature signal to the ATC module on the medium speed CAN bus. The sensor is installed in the LH door mirror, and is accessed by removing the mirror glass, cap and actuator.

Sunload Sensor

The sunload sensor consists of two photoelectric cells that provide the ATC module with inputs of light intensity; one as sensed coming from the left of the vehicle and one as sensed coming from the right. The inputs are a measure of the solar

heating effect on vehicle occupants, and are used by the ATC module to adjust blower speed, temperature and distribution to improve comfort.

The sensor is installed in the speaker grill on the upper surface of the instrument panel. Power for the sensor is provided by a

5 V feed from the instrument cluster.

The sensor also contains the active anti-theft alarm indicator.

Refer to: Anti-Theft - Active (419-01 Anti-Theft - Active, Description and Operation). Ambient Air Temperature Sensor

Page 1770 of 3039

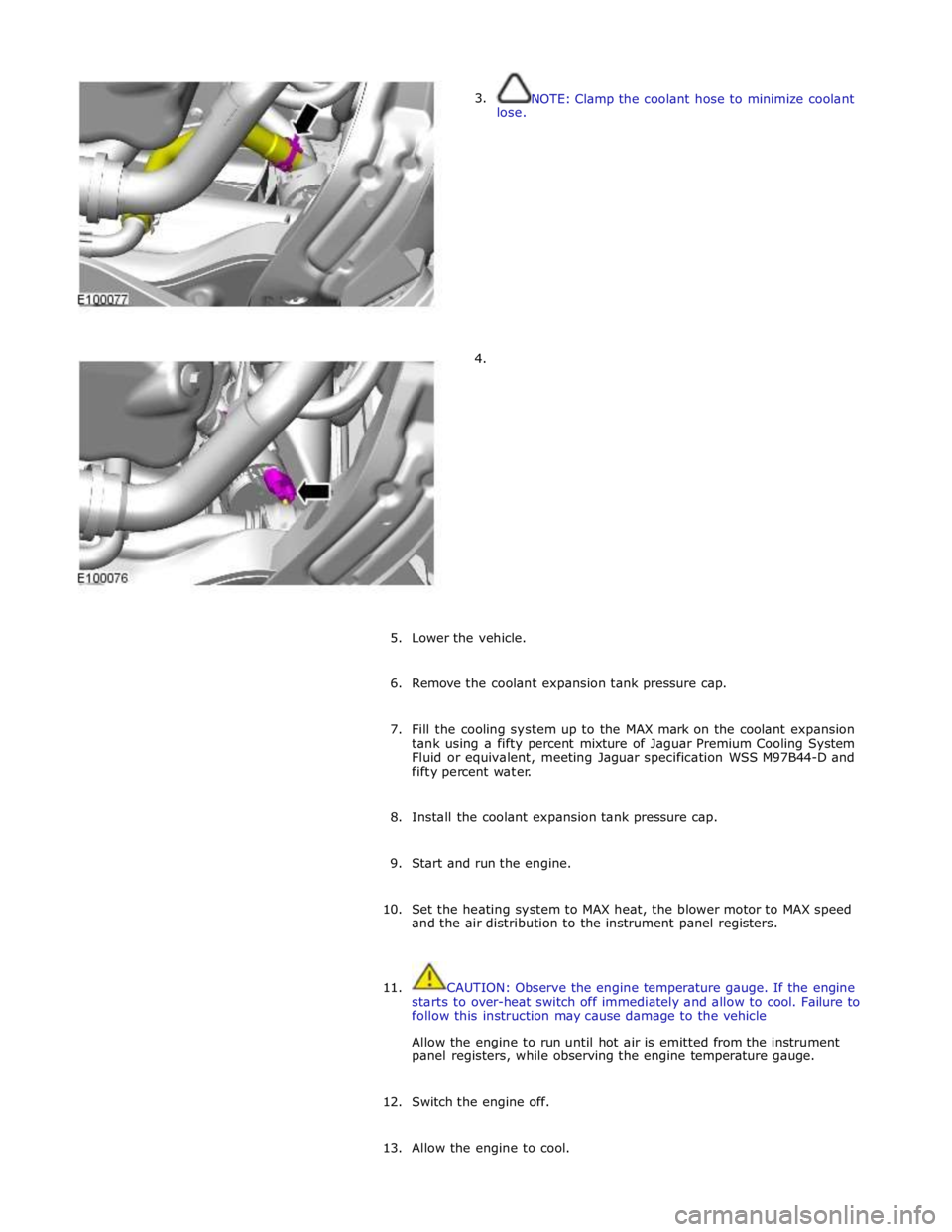

3.

lose.

4. NOTE: Clamp the coolant hose to minimize coolant

5. Lower the vehicle.

6. Remove the coolant expansion tank pressure cap.

7. Fill the cooling system up to the MAX mark on the coolant expansion

tank using a fifty percent mixture of Jaguar Premium Cooling System

Fluid or equivalent, meeting Jaguar specification WSS M97B44-D and

fifty percent water.

8. Install the coolant expansion tank pressure cap.

9. Start and run the engine.

10. Set the heating system to MAX heat, the blower motor to MAX speed

and the air distribution to the instrument panel registers.

11. CAUTION: Observe the engine temperature gauge. If the engine

starts to over-heat switch off immediately and allow to cool. Failure to

follow this instruction may cause damage to the vehicle

Allow the engine to run until hot air is emitted from the instrument

panel registers, while observing the engine temperature gauge.

12. Switch the engine off.

13. Allow the engine to cool.

Page 1825 of 3039

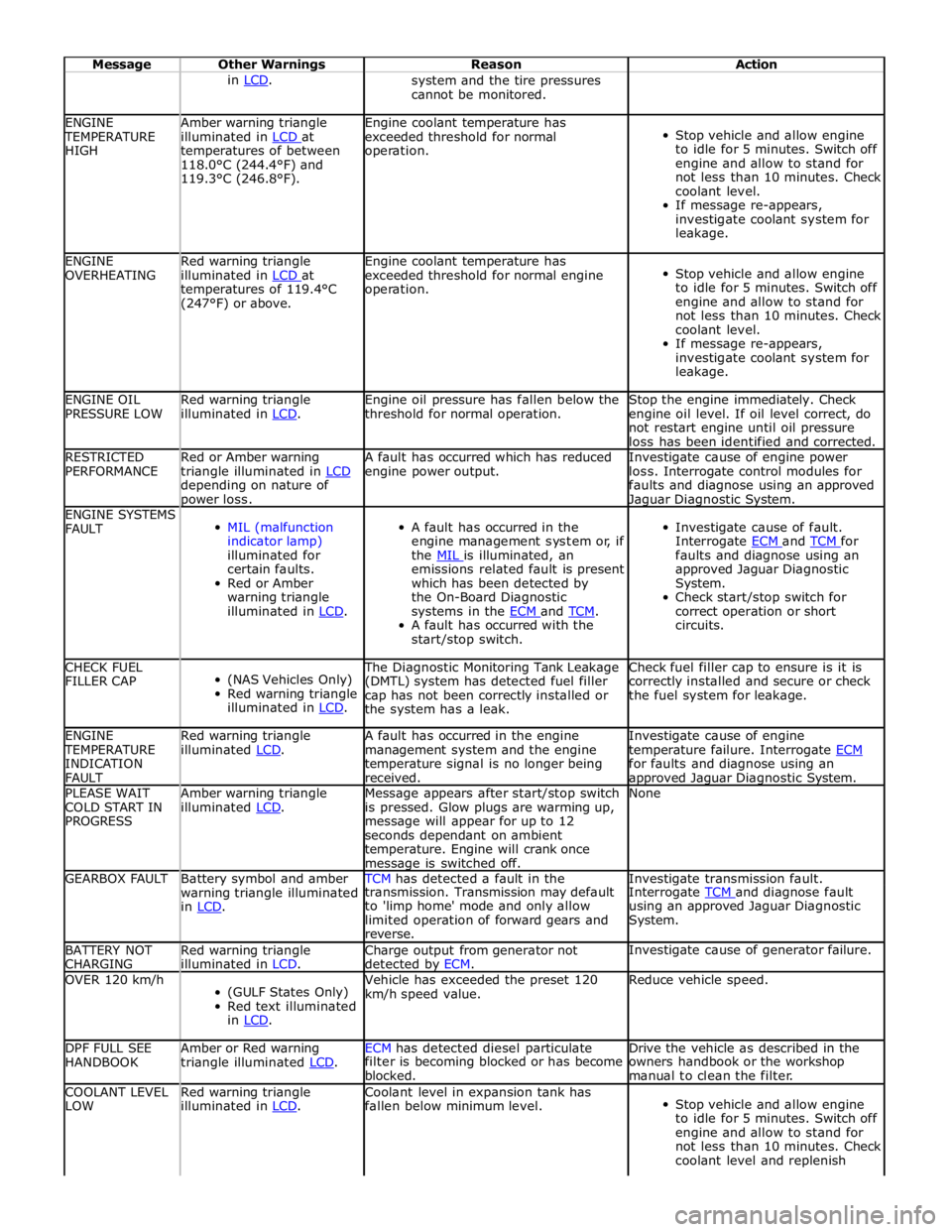

Message Other Warnings Reason Action in LCD. system and the tire pressures

cannot be monitored. ENGINE TEMPERATURE

HIGH Amber warning triangle

illuminated in LCD at temperatures of between

118.0°C (244.4°F) and

119.3°C (246.8°F). Engine coolant temperature has

exceeded threshold for normal

operation.

Stop vehicle and allow engine

to idle for 5 minutes. Switch off

engine and allow to stand for

not less than 10 minutes. Check

coolant level.

If message re-appears,

investigate coolant system for

leakage. ENGINE

OVERHEATING Red warning triangle

illuminated in LCD at temperatures of 119.4°C

(247°F) or above. Engine coolant temperature has

exceeded threshold for normal engine

operation.

Stop vehicle and allow engine

to idle for 5 minutes. Switch off

engine and allow to stand for

not less than 10 minutes. Check

coolant level.

If message re-appears,

investigate coolant system for

leakage. ENGINE OIL

PRESSURE LOW Red warning triangle

illuminated in LCD. Engine oil pressure has fallen below the

threshold for normal operation. Stop the engine immediately. Check

engine oil level. If oil level correct, do

not restart engine until oil pressure

loss has been identified and corrected. RESTRICTED

PERFORMANCE Red or Amber warning

triangle illuminated in LCD depending on nature of power loss. A fault has occurred which has reduced

engine power output. Investigate cause of engine power

loss. Interrogate control modules for

faults and diagnose using an approved Jaguar Diagnostic System. ENGINE SYSTEMS

FAULT

MIL (malfunction

indicator lamp)

illuminated for

certain faults.

Red or Amber

warning triangle

illuminated in LCD.

A fault has occurred in the

engine management system or, if

the MIL is illuminated, an emissions related fault is present

which has been detected by

the On-Board Diagnostic

systems in the ECM and TCM. A fault has occurred with the

start/stop switch.

Investigate cause of fault.

Interrogate ECM and TCM for faults and diagnose using an

approved Jaguar Diagnostic

System.

Check start/stop switch for

correct operation or short

circuits. CHECK FUEL

FILLER CAP

(NAS Vehicles Only)

Red warning triangle

illuminated in LCD. The Diagnostic Monitoring Tank Leakage

(DMTL) system has detected fuel filler

cap has not been correctly installed or

the system has a leak. Check fuel filler cap to ensure is it is

correctly installed and secure or check

the fuel system for leakage. ENGINE TEMPERATURE

INDICATION

FAULT Red warning triangle

illuminated LCD. A fault has occurred in the engine

management system and the engine

temperature signal is no longer being

received. Investigate cause of engine

temperature failure. Interrogate ECM for faults and diagnose using an approved Jaguar Diagnostic System. PLEASE WAIT

COLD START IN

PROGRESS Amber warning triangle

illuminated LCD. Message appears after start/stop switch

is pressed. Glow plugs are warming up,

message will appear for up to 12

seconds dependant on ambient

temperature. Engine will crank once message is switched off. None GEARBOX FAULT

Battery symbol and amber

warning triangle illuminated

in LCD. TCM has detected a fault in the Investigate transmission fault. transmission. Transmission may default

to 'limp home' mode and only allow

limited operation of forward gears and

reverse. Interrogate TCM and diagnose fault using an approved Jaguar Diagnostic

System. BATTERY NOT

CHARGING Red warning triangle

illuminated in LCD. Charge output from generator not

detected by ECM. Investigate cause of generator failure. OVER 120 km/h

(GULF States Only)

Red text illuminated

in LCD. Vehicle has exceeded the preset 120

km/h speed value. Reduce vehicle speed. DPF FULL SEE

HANDBOOK Amber or Red warning

triangle illuminated LCD. ECM has detected diesel particulate Drive the vehicle as described in the filter is becoming blocked or has become

blocked. owners handbook or the workshop

manual to clean the filter. COOLANT LEVEL

LOW Red warning triangle

illuminated in LCD. Coolant level in expansion tank has

fallen below minimum level.

Stop vehicle and allow engine

to idle for 5 minutes. Switch off

engine and allow to stand for

not less than 10 minutes. Check

coolant level and replenish

Page 1869 of 3039

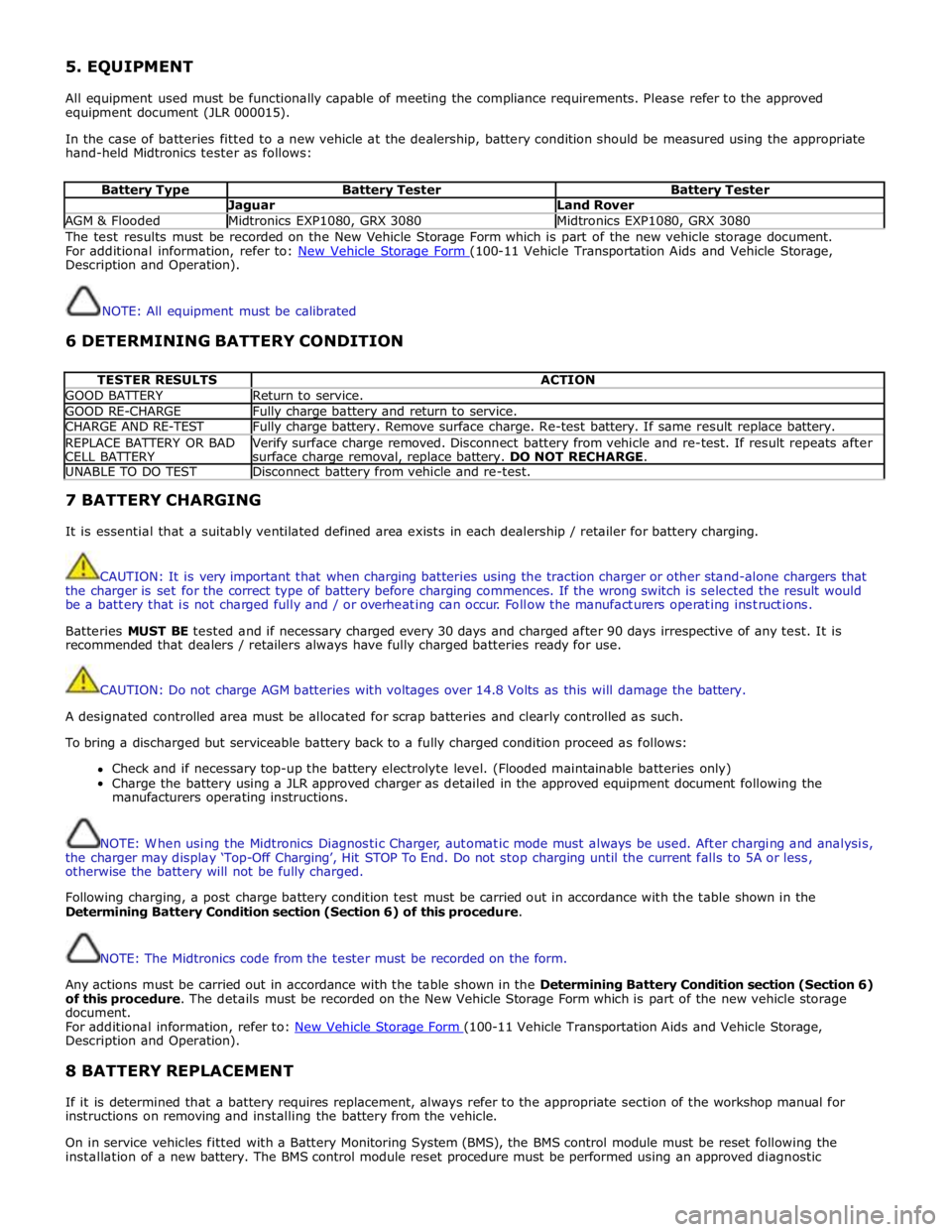

5. EQUIPMENT

All equipment used must be functionally capable of meeting the compliance requirements. Please refer to the approved

equipment document (JLR 000015).

In the case of batteries fitted to a new vehicle at the dealership, battery condition should be measured using the appropriate

hand-held Midtronics tester as follows:

Battery Type Battery Tester Battery Tester Jaguar Land Rover AGM & Flooded Midtronics EXP1080, GRX 3080 Midtronics EXP1080, GRX 3080 The test results must be recorded on the New Vehicle Storage Form which is part of the new vehicle storage document.

For additional information, refer to: New Vehicle Storage Form (100-11 Vehicle Transportation Aids and Vehicle Storage, Description and Operation).

NOTE: All equipment must be calibrated

6 DETERMINING BATTERY CONDITION

TESTER RESULTS ACTION GOOD BATTERY Return to service. GOOD RE-CHARGE Fully charge battery and return to service. CHARGE AND RE-TEST Fully charge battery. Remove surface charge. Re-test battery. If same result replace battery. REPLACE BATTERY OR BAD

CELL BATTERY Verify surface charge removed. Disconnect battery from vehicle and re-test. If result repeats after

surface charge removal, replace battery. DO NOT RECHARGE. UNABLE TO DO TEST Disconnect battery from vehicle and re-test. 7 BATTERY CHARGING

It is essential that a suitably ventilated defined area exists in each dealership / retailer for battery charging.

CAUTION: It is very important that when charging batteries using the traction charger or other stand-alone chargers that

the charger is set for the correct type of battery before charging commences. If the wrong switch is selected the result would

be a battery that is not charged fully and / or overheating can occur. Follow the manufacturers operating instructions.

Batteries MUST BE tested and if necessary charged every 30 days and charged after 90 days irrespective of any test. It is

recommended that dealers / retailers always have fully charged batteries ready for use.

CAUTION: Do not charge AGM batteries with voltages over 14.8 Volts as this will damage the battery.

A designated controlled area must be allocated for scrap batteries and clearly controlled as such.

To bring a discharged but serviceable battery back to a fully charged condition proceed as follows:

Check and if necessary top-up the battery electrolyte level. (Flooded maintainable batteries only)

Charge the battery using a JLR approved charger as detailed in the approved equipment document following the

manufacturers operating instructions.

NOTE: When using the Midtronics Diagnostic Charger, automatic mode must always be used. After charging and analysis,

the charger may display ‘Top-Off Charging’, Hit STOP To End. Do not stop charging until the current falls to 5A or less,

otherwise the battery will not be fully charged.

Following charging, a post charge battery condition test must be carried out in accordance with the table shown in the

Determining Battery Condition section (Section 6) of this procedure.

NOTE: The Midtronics code from the tester must be recorded on the form.

Any actions must be carried out in accordance with the table shown in the Determining Battery Condition section (Section 6)

of this procedure. The details must be recorded on the New Vehicle Storage Form which is part of the new vehicle storage

document.

For additional information, refer to: New Vehicle Storage Form (100-11 Vehicle Transportation Aids and Vehicle Storage, Description and Operation).

8 BATTERY REPLACEMENT

If it is determined that a battery requires replacement, always refer to the appropriate section of the workshop manual for

instructions on removing and installing the battery from the vehicle.

On in service vehicles fitted with a Battery Monitoring System (BMS), the BMS control module must be reset following the

installation of a new battery. The BMS control module reset procedure must be performed using an approved diagnostic

Page 2171 of 3039

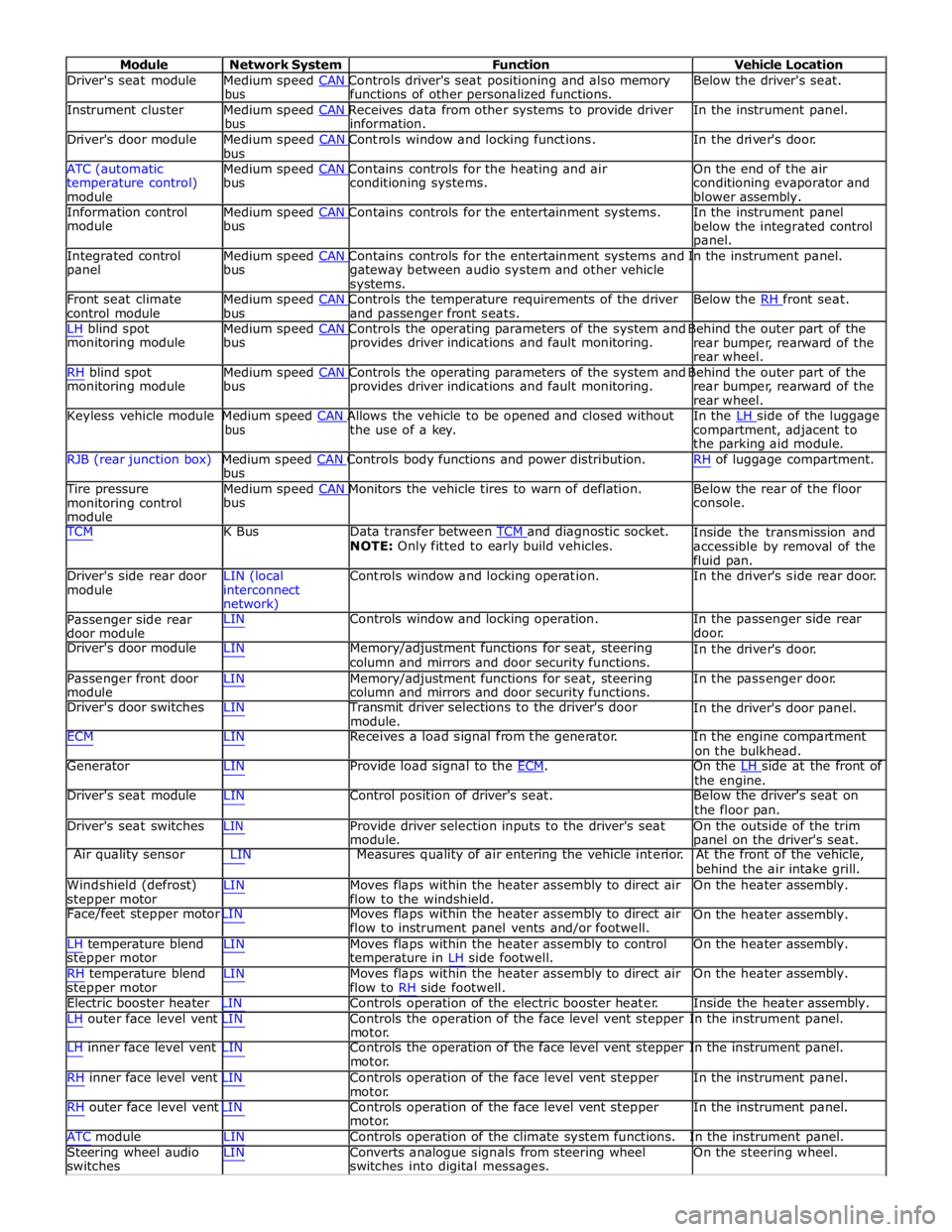

Module Network System Function Vehicle Location

Driver's seat module Medium speed CAN Controls driver's seat positioning and also memory Below the driver's seat. bus functions of other personalized functions.

Instrument cluster Medium speed CAN Receives data from other systems to provide driver In the instrument panel. bus information.

Driver's door module Medium speed CAN Controls window and locking functions. In the driver's door. bus

ATC (automatic Medium speed CAN Contains controls for the heating and air On the end of the air

temperature control)

module bus conditioning systems.

conditioning evaporator and

blower assembly.

Information control Medium speed CAN Contains controls for the entertainment systems. In the instrument panel module bus

below the integrated control

panel.

Integrated control Medium speed CAN Contains controls for the entertainment systems and In the instrument panel. panel bus

gateway between audio system and other vehicle

systems.

Front seat climate Medium speed CAN Controls the temperature requirements of the driver Below the RH front seat. control module bus and passenger front seats.

LH blind spot Medium speed CAN Controls the operating parameters of the system and Behind the outer part of the monitoring module bus provides driver indications and fault monitoring.

rear bumper, rearward of the

rear wheel.

RH blind spot Medium speed CAN Controls the operating parameters of the system and Behind the outer part of the monitoring module bus provides driver indications and fault monitoring.

rear bumper, rearward of the

rear wheel.

Keyless vehicle module Medium speed CAN Allows the vehicle to be opened and closed without In the LH side of the luggage bus the use of a key.

compartment, adjacent to

the parking aid module.

RJB (rear junction box) Medium speed CAN Controls body functions and power distribution. RH of luggage compartment. bus

Tire pressure Medium speed CAN Monitors the vehicle tires to warn of deflation. Below the rear of the floor monitoring control

module bus console.

TCM K Bus Data transfer between TCM and diagnostic socket. NOTE: Only fitted to early build vehicles. Inside the transmission and

accessible by removal of the

fluid pan.

Driver's side rear door

module LIN (local

interconnect

network) Controls window and locking operation. In the driver's side rear door.

Passenger side rear

door module LIN Controls window and locking operation. In the passenger side rear

door.

Driver's door module LIN Memory/adjustment functions for seat, steering

column and mirrors and door security functions. In the driver's door.

Passenger front door

module LIN Memory/adjustment functions for seat, steering

column and mirrors and door security functions. In the passenger door.

Driver's door switches LIN Transmit driver selections to the driver's door

module. In the driver's door panel.

ECM LIN Receives a load signal from the generator. In the engine compartment

on the bulkhead.

Generator LIN Provide load signal to the ECM. On the LH side at the front of the engine.

Driver's seat module LIN Control position of driver's seat. Below the driver's seat on

the floor pan.

Driver's seat switches LIN Provide driver selection inputs to the driver's seat

module. On the outside of the trim

panel on the driver's seat.

Air quality sensor LIN Measures quality of air entering the vehicle interior. At the front of the vehicle,

behind the air intake grill.

Windshield (defrost)

stepper motor LIN Moves flaps within the heater assembly to direct air

flow to the windshield. On the heater assembly.

Face/feet stepper motor LIN Moves flaps within the heater assembly to direct air

flow to instrument panel vents and/or footwell. On the heater assembly.

LH temperature blend

stepper motor

RH temperature blend

stepper motor LIN Moves flaps within the heater assembly to control

temperature in LH side footwell.

LIN Moves flaps within the heater assembly to direct air

flow to RH side footwell. On the heater assembly.

On the heater assembly.

Electric booster heater LIN Controls operation of the electric booster heater. Inside the heater assembly.

LH outer face level vent LIN Controls the operation of the face level vent stepper In the instrument panel.

motor.

LH inner face level vent LIN Controls the operation of the face level vent stepper In the instrument panel.

motor.

RH inner face level vent LIN Controls operation of the face level vent stepper

motor.

RH outer face level vent LIN Controls operation of the face level vent stepper

motor. In the instrument panel.

In the instrument panel.

ATC module LIN Controls operation of the climate system functions. In the instrument panel.

Steering wheel audio

switches LIN Converts analogue signals from steering wheel

switches into digital messages. On the steering wheel.