Cooling JAGUAR XFR 2010 1.G Manual PDF

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 1387 of 3039

Published: 19-Aug-2013

Electronic Engine Controls - V8 S/C 5.0L Petrol - Engine Coolant Temperature

(ECT) Sensor

Removal and Installation

Removal

NOTES:

Some variation in the illustrations may occur, but the essential information is always correct.

Removal steps in this procedure may contain installation details.

1. WARNING: Do not work on or under a vehicle supported only by a jack.

Always support the vehicle on safety stands.

Raise and support the vehicle.

2. Refer to: Cooling System Partial Draining, Filling and Bleeding (303-03B Engine Cooling - V6 3.0L Petrol, General Procedures).

3. Refer to: Catalytic Converter RH (309-00C Exhaust System - V8 5.0L Petrol/V8 S/C 5.0L Petrol, Removal and Installation).

4. Torque: 48 Nm

Page 1431 of 3039

transmission functions. The Mechatronic valve block comprises the following components:

TCM

Pressure regulator solenoids

Shift control solenoid

Damper

Hydraulic spool valves

Selector valve

Temperature sensor

Turbine speed sensor

Output shaft speed sensor.

Sensors

Speed Sensors

The turbine speed sensor and the output shaft speed sensor are Hall effect type sensors located in the Mechatronic valve block

and are not serviceable items. The TCM monitors the signals from each sensor to determine the input (turbine) speed and the output shaft speed.

The turbine speed is monitored by the TCM to calculate the slip of the torque converter clutch and internal clutch slip. This signal allows the TCM to accurately control the slip timing during shifts and adjust clutch application or release pressure for overlap shift control.

The output shaft speed is monitored by the TCM and compared to engine speed signals received on the CAN bus from the ECM. Using a comparison of the two signals the TCM calculates the transmission slip ratio for plausibility and maintains adaptive pressure control.

Temperature Sensor

The temperature sensor is also located in the Mechatronic valve block. The TCM uses the temperature sensor signals to determine the temperature of the transmission fluid. These signals are used by the TCM to control the transmission operation to promote faster warm-up in cold conditions or to assist with fluid cooling by controlling the transmission operation when high

fluid temperatures are experienced. If the sensor fails, the TCM will use a default value and a fault code will be stored in the TCM.

Damper

There is one damper located in the valve housing. The damper is used to regulate and dampen the regulated pressure supplied

via EPRS. The damper is load dependent through modulation of the damper against return spring pressure.

The damper comprises a piston, a housing bore and a spring. The piston is subject to the pressure applied by the spring. The

bore has a connecting port to the function to which it applies. Fluid pressure applied to the applicable component (i.e. a

clutch) is also subjected to the full area of the piston, which moves against the opposing force applied by the spring. The

movement of the piston creates an action similar to a shock absorber, momentarily delaying the build up of pressure in the

circuit. This results in a more gradual application of clutches improving shift quality.

Spool Valves

The valve block spool valves control various functions of the transmission. The spool valves are of conventional design and are

operated by fluid pressure.

Each spool valve is located in its spool bore and held in a default (unpressurized) position by a spring. The spool bore has a

number of ports which allow fluid to flow to other valves and clutches to enable transmission operation. Each spool has a

piston which is waisted to allow fluid to be diverted into the applicable ports when the valve is operated.

When fluid pressure moves a spool, one or more ports in the spool bore are covered or uncovered. Fluid is prevented from

flowing or is allowed to flow around the applicable waisted area of the spool and into another uncovered port. The fluid is

either passed through galleries to actuate another spool, operate a clutch or is returned to the fluid pan.

Page 1486 of 3039

22.

23.

24.

Refer to: Catalytic Converter LH (309-00C Exhaust System - V8 5.0L Petrol/V8 S/C 5.0L Petrol, Removal and Installation).

25. Refer to: Catalytic Converter RH (309-00C Exhaust System - V8 5.0L Petrol/V8 S/C 5.0L Petrol, Removal and Installation).

26. Refer to: Battery Disconnect and Connect (414-01 Battery, Mounting and Cables, General Procedures).

27. Check and top up the cooling system as required.

28. Set the heater controls to HOT.

29. CAUTION: Observe the engine temperature warning light. If the

warning light is displayed, switch off immediately and allow to cool.

Failure to follow this instruction may cause damage to the vehicle.

Start the engine and allow to idle until hot air is emited at the face

registers.

Page 1487 of 3039

30. CAUTION: Observe the engine temperature warning light. If the

warning light is displayed, switch off immediately and allow to cool.

Failure to follow this instruction may cause damage to the vehicle.

Raise the engine speed to 2000 RPM and maintain at 2000 RPM until the

engine cooling fan operates.

31. CAUTION: Switch off the engine and allow the coolant temperature

to go cold.

Switch the engine off and allow to cool.

32. Visually check the engine and cooling system for signs of coolant

leakage.

33. WARNINGS:

When releasing the cooling system pressure, cover the coolant

expansion tank cap with a thick cloth.

Since injury such as scalding could be caused by escaping steam or

coolant, make sure the vehicle cooling system is cool prior to carrying

out this procedure.

CAUTIONS:

Make sure the coolant level remains above the "COLD FILL RANGE"

lower level mark.

Anti-freeze concentration must be maintained at 50%.

NOTE: When the cooling system is warm, the coolant will be

approximately 10mm above the upper level mark on the expansion tank

with the cap removed.

Check and top-up the coolant if required.

34. Refer to: Transmission Fluid Level Check (307-01B Automatic Transmission/Transaxle - TDV6 3.0L Diesel /V8 5.0L Petrol/V8 S/C 5.0L

Petrol, General Procedures).

Page 1502 of 3039

20.

21.

22.

Refer to: Catalytic Converter LH (309-00C Exhaust System - V8 5.0L Petrol/V8 S/C 5.0L Petrol, Removal and Installation).

23. Refer to: Catalytic Converter RH (309-00C Exhaust System - V8 5.0L Petrol/V8 S/C 5.0L Petrol, Removal and Installation).

24. Refer to: Battery Disconnect and Connect (414-01 Battery, Mounting and Cables, General Procedures).

25. Check and top up the cooling system as required.

26. Set the heater controls to HOT.

27. CAUTION: Observe the engine temperature warning light. If the

warning light is displayed, switch off immediately and allow to cool.

Failure to follow this instruction may cause damage to the vehicle.

Start the engine and allow to idle until hot air is emited at the face

registers. www.JagDocs.com

Page 1503 of 3039

28. CAUTION: Observe the engine temperature warning light. If the

warning light is displayed, switch off immediately and allow to cool.

Failure to follow this instruction may cause damage to the vehicle.

Raise the engine speed to 2000 RPM and maintain at 2000 RPM until the

engine cooling fan operates.

29. CAUTION: Switch off the engine and allow the coolant temperature

to go cold.

Switch the engine off and allow to cool.

30. Visually check the engine and cooling system for signs of coolant

leakage.

31. WARNINGS:

When releasing the cooling system pressure, cover the coolant

expansion tank cap with a thick cloth.

Since injury such as scalding could be caused by escaping steam or

coolant, make sure the vehicle cooling system is cool prior to carrying

out this procedure.

CAUTIONS:

Make sure the coolant level remains above the "COLD FILL RANGE"

lower level mark.

Anti-freeze concentration must be maintained at 50%.

NOTE: When the cooling system is warm, the coolant will be

approximately 10mm above the upper level mark on the expansion tank

with the cap removed.

Check and top-up the coolant if required.

32. Refer to: Transmission Fluid Level Check (307-01B Automatic Transmission/Transaxle - TDV6 3.0L Diesel /V8 5.0L Petrol/V8 S/C 5.0L

Petrol, General Procedures).

Page 1519 of 3039

Published: 11-May-2011

Transmission/Transaxle Cooling - TDV6 3.0L Diesel /V8 5.0L Petrol/V8 S/C 5.0L Petrol - Transmission Cooling - Overview

Description and Operation

OVERVIEW

Transmission cooling is provided by a transmission fluid cooler, which transfers heat from the transmission to the engine

cooling system. The transmission fluid cooler is attached to a mounting bracket on the front subframe, in the front left corner

of the engine compartment.

Two hose and pipe assemblies connect the transmission fluid cooler to the automatic transmission. Two engine coolant hose

connections are incorporated into the top of the transmission fluid cooler for the supply and return of coolant from the engine

cooling system. For additional information, refer to 303-03D Engine Cooling.

Page 1520 of 3039

Published: 11-May-2011

Transmission/Transaxle Cooling - TDV6 3.0L Diesel /V8 5.0L Petrol/V8 S/C 5.0L Petrol - Transmission Cooling - System Operation and Component Description

Description and Operation

System Operation

Fluid from the pump in the automatic transmission flows through the feed hose and pipe to the transmission fluid cooler. The

fluid then flows through the transmission fluid cooler, and the return hose and pipe, to the sump of the automatic

transmission.

Page 1521 of 3039

Transmission Cooling (Description and Operation), Transmission Cooling (Description and Operation).

Inspection and Verification

1. Verify the customer concern by operating the system.

2. Visually inspect for obvious signs of damage and system integrity.

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to

the next step.

4. If the cause is not visually evident, verify the symptom and refer to the Symptom Chart, alternatively check for

Diagnostic Trouble Codes (DTCs) and refer to the DTC Index.

Symptom Chart

Condition Possible Causes Action Over heating of the

automatic

transmission Obstruction in the automatic

transmission fluid cooler Flush out the automatic transmission fluid cooler with new

automatic transmission fluid. If the flushing is unsuccessful,

install a new transmission fluid cooler. Over heating of the

automatic

transmission Obstruction in the automatic

transmission fluid tubes Flush out the automatic transmission fluid cooler tubes with new

automatic transmission fluid. If the flushing is unsuccessful install

new automatic transmission fluid cooler tubes. Loss of automatic

transmission fluid Connections to the automatic

transmission and the automatic

transmission fluid cooler Check the integrity of the tubes, connections and seals. Check the

torque of the tube fixings. Loss of automatic

transmission fluid Leak at oil cooler

Check the integrity of tubes, connections and seals. Check the torque of the tube fixings. Mechanical

Feed and return tubes

Connections to the automatic transmission and the automatic transmission fluid cooler

Automatic transmission fluid level Visual Inspection

www.JagDocs.com

Page 1522 of 3039

Published: 11-May-2011

Transmission/Transaxle Cooling - TDV6 3.0L Diesel /V8 5.0L Petrol/V8 S/C 5.0L Petrol - Transmission Fluid Cooler V8 5.0L Petrol/V8 S/C 5.0L Petrol

Removal and Installation

Removal

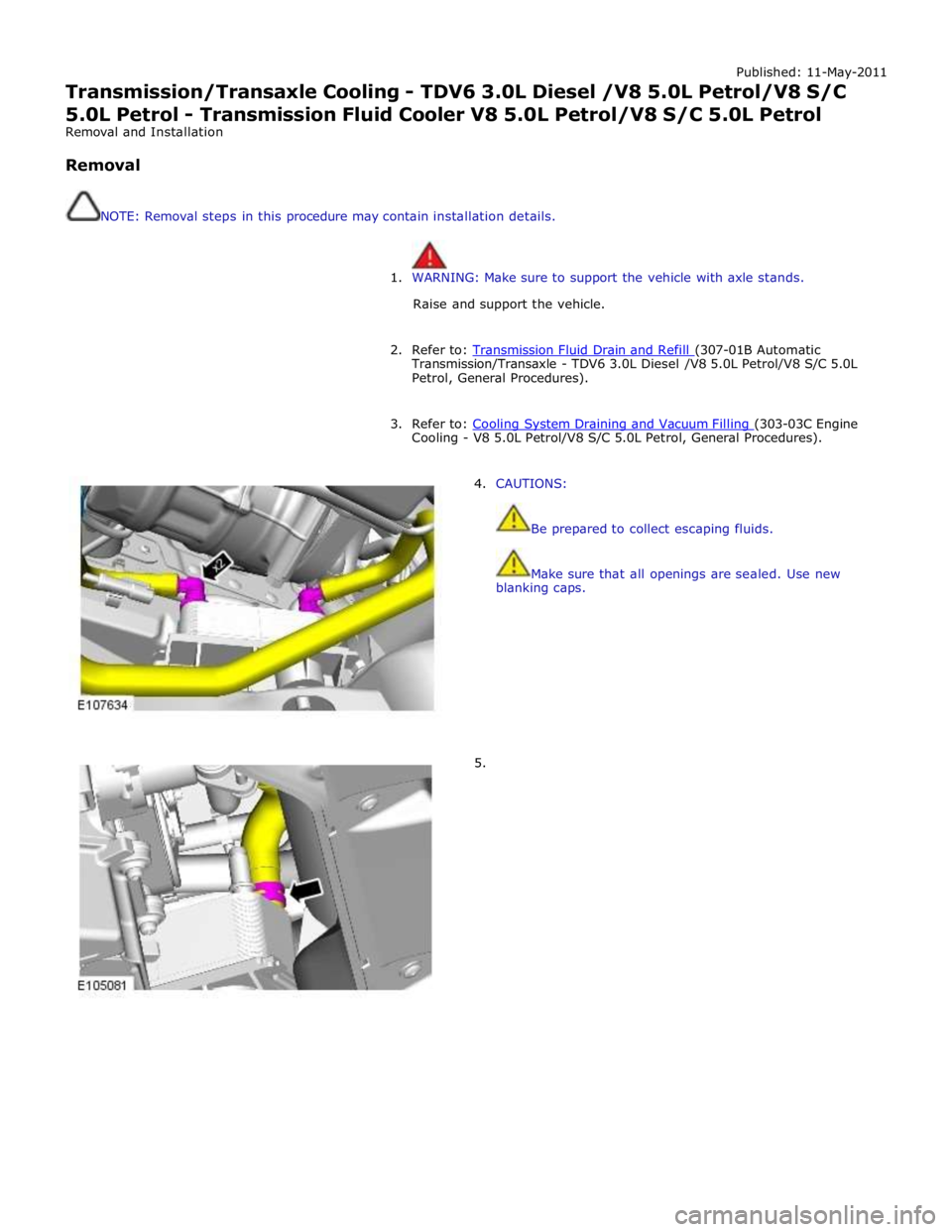

NOTE: Removal steps in this procedure may contain installation details.

1. WARNING: Make sure to support the vehicle with axle stands.

Raise and support the vehicle.

2. Refer to: Transmission Fluid Drain and Refill (307-01B Automatic Transmission/Transaxle - TDV6 3.0L Diesel /V8 5.0L Petrol/V8 S/C 5.0L

Petrol, General Procedures).

3. Refer to: Cooling System Draining and Vacuum Filling (303-03C Engine Cooling - V8 5.0L Petrol/V8 S/C 5.0L Petrol, General Procedures).

4. CAUTIONS:

Be prepared to collect escaping fluids.

Make sure that all openings are sealed. Use new

blanking caps.

5.