washer reservoir JAGUAR XFR 2010 1.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 28 of 3039

Instrument Panel Console

Instrument Panel Lower Trim Panel

Overhead Console501-14: Handles, Locks, Latches and Entry SystemsSpecificationDescription and OperationComponent Location

Overview

System Operation and Component DescriptionDiagnosis and TestingLocks, Latches and Entry SystemsRemoval and InstallationDoor Lock Cylinder Cover

Exterior Front Door Handle

Exterior Luggage Compartment Lid Release Switch

Exterior Rear Door Handle

Front Door Latch

Front Door Lock Cylinder

Interior Front Door Handle

Luggage Compartment Lid Latch Actuator

Luggage Compartment Lid Lock Cylinder

Rear Door Latch501-16: Wipers and WashersSpecificationDescription and OperationComponent Location

Overview

System Operation and Component DescriptionDiagnosis and TestingWipers and WashersRemoval and InstallationHeadlamp Washer Jet

Headlamp Washer Pump

Rain Sensor

Windshield Washer Reservoir

Windshield Wiper Motor

Windshield Wiper Pivot Arm

Windshield Washer Pump501-17: Roof Opening PanelSpecificationDescription and OperationComponent Location

Page 750 of 3039

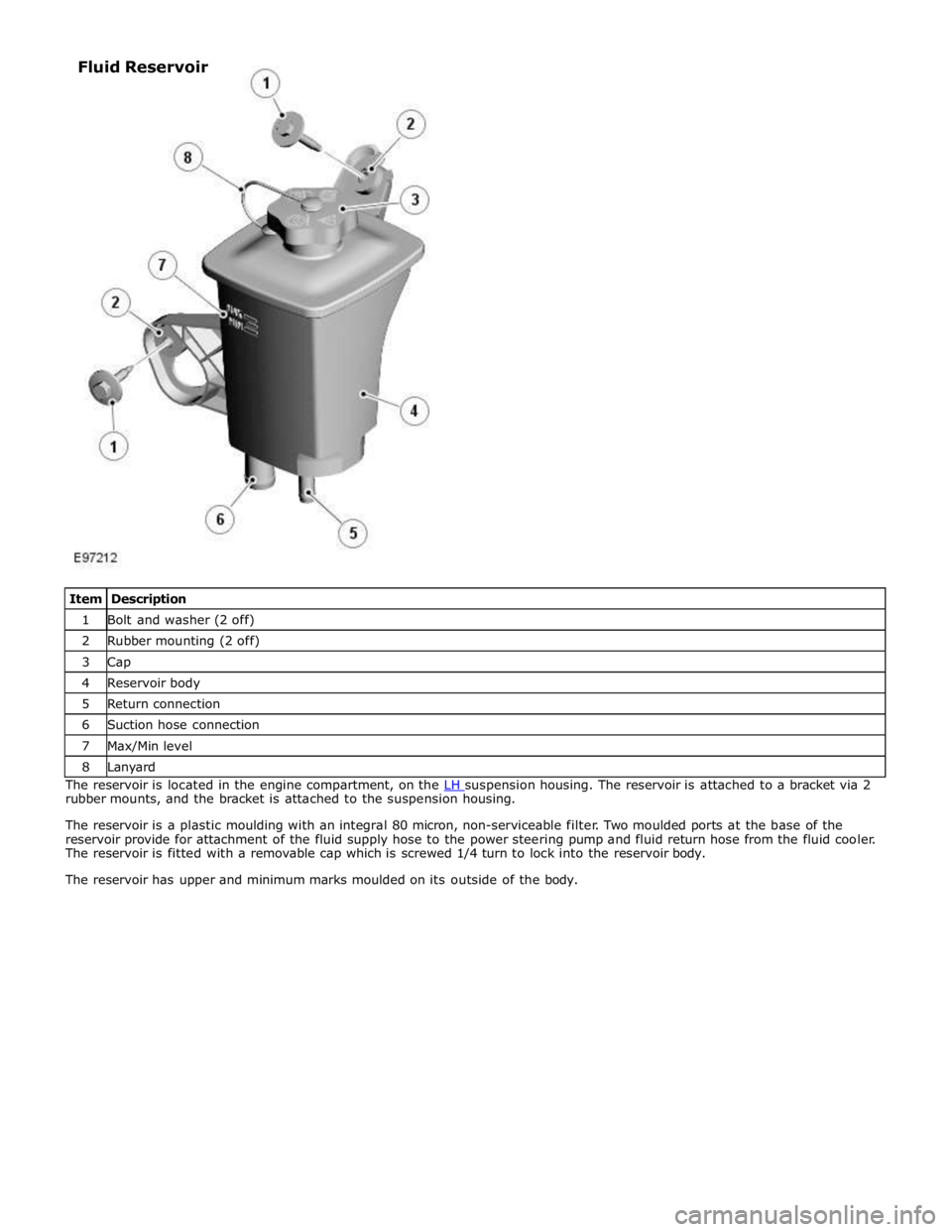

1 Bolt and washer (2 off) 2 Rubber mounting (2 off) 3 Cap 4 Reservoir body 5 Return connection 6 Suction hose connection 7 Max/Min level 8 Lanyard The reservoir is located in the engine compartment, on the LH suspension housing. The reservoir is attached to a bracket via 2 rubber mounts, and the bracket is attached to the suspension housing.

The reservoir is a plastic moulding with an integral 80 micron, non-serviceable filter. Two moulded ports at the base of the

reservoir provide for attachment of the fluid supply hose to the power steering pump and fluid return hose from the fluid cooler.

The reservoir is fitted with a removable cap which is screwed 1/4 turn to lock into the reservoir body.

The reservoir has upper and minimum marks moulded on its outside of the body. Fluid Reservoir

Page 1827 of 3039

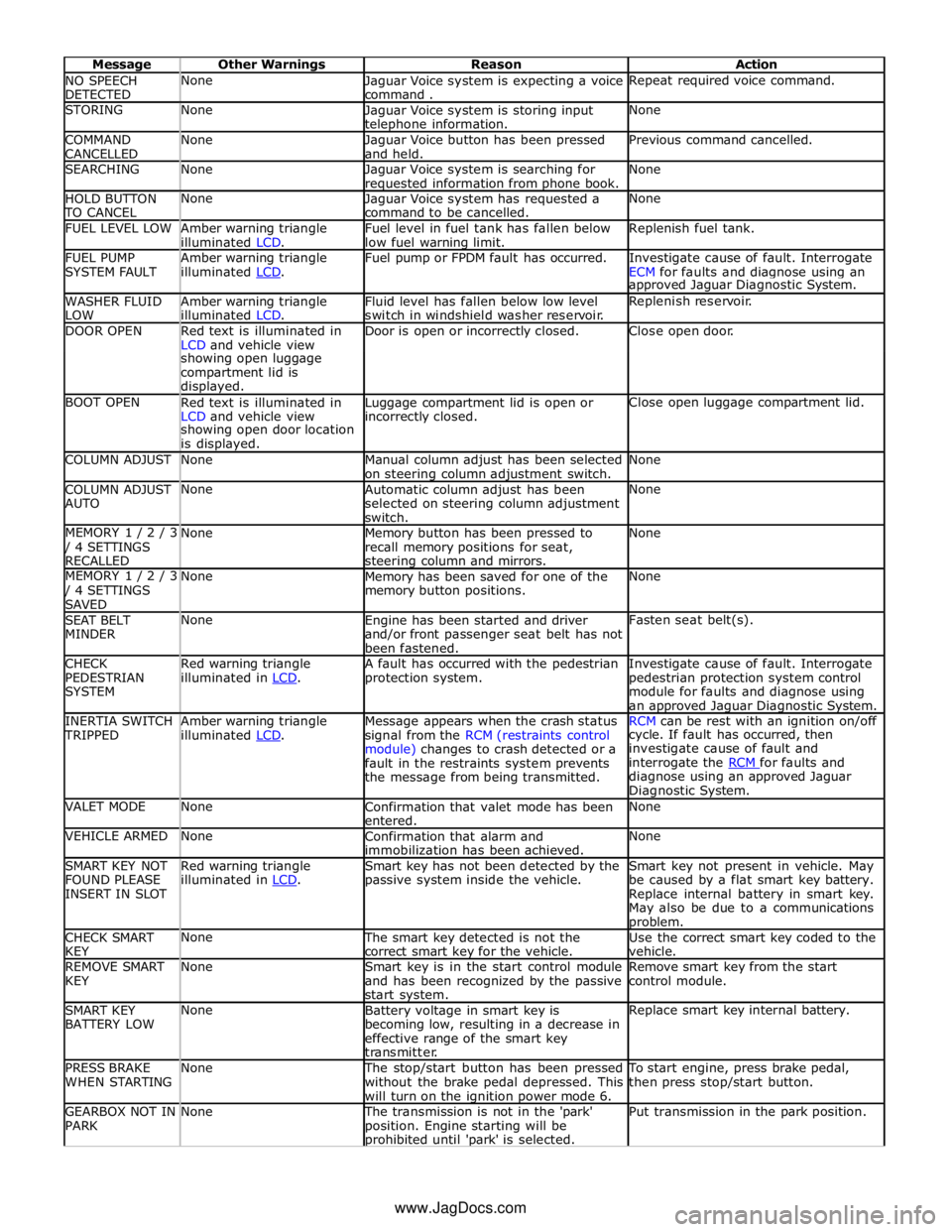

NO SPEECH

DETECTED None

Jaguar Voice system is expecting a voice

command . Repeat required voice command. STORING None

Jaguar Voice system is storing input telephone information. None COMMAND

CANCELLED None

Jaguar Voice button has been pressed

and held. Previous command cancelled. SEARCHING None

Jaguar Voice system is searching for requested information from phone book. None HOLD BUTTON TO CANCEL None

Jaguar Voice system has requested a

command to be cancelled. None FUEL LEVEL LOW

Amber warning triangle

illuminated LCD. Fuel level in fuel tank has fallen below

low fuel warning limit. Replenish fuel tank. FUEL PUMP

SYSTEM FAULT Amber warning triangle

illuminated LCD. Fuel pump or FPDM fault has occurred.

Investigate cause of fault. Interrogate

ECM for faults and diagnose using an approved Jaguar Diagnostic System. WASHER FLUID

LOW Amber warning triangle

illuminated LCD. Fluid level has fallen below low level

switch in windshield washer reservoir. Replenish reservoir. DOOR OPEN

Red text is illuminated in

LCD and vehicle view Door is open or incorrectly closed. Close open door. showing open luggage

compartment lid is

displayed. BOOT OPEN

Red text is illuminated in

LCD and vehicle view Luggage compartment lid is open or incorrectly closed. Close open luggage compartment lid. showing open door location

is displayed. COLUMN ADJUST None

Manual column adjust has been selected

on steering column adjustment switch. None COLUMN ADJUST

AUTO None

Automatic column adjust has been

selected on steering column adjustment

switch. None MEMORY 1 / 2 / 3 / 4 SETTINGS

RECALLED None

Memory button has been pressed to

recall memory positions for seat, steering column and mirrors. None MEMORY 1 / 2 / 3 / 4 SETTINGS

SAVED None

Memory has been saved for one of the

memory button positions. None SEAT BELT

MINDER None

Engine has been started and driver

and/or front passenger seat belt has not

been fastened. Fasten seat belt(s). CHECK

PEDESTRIAN

SYSTEM Red warning triangle

illuminated in LCD. A fault has occurred with the pedestrian

protection system. Investigate cause of fault. Interrogate

pedestrian protection system control

module for faults and diagnose using

an approved Jaguar Diagnostic System. INERTIA SWITCH TRIPPED Amber warning triangle

illuminated LCD. Message appears when the crash status

signal from the RCM (restraints control

module) changes to crash detected or a

fault in the restraints system prevents

the message from being transmitted. RCM can be rest with an ignition on/off cycle. If fault has occurred, then

investigate cause of fault and

interrogate the RCM for faults and diagnose using an approved Jaguar

Diagnostic System. VALET MODE None

Confirmation that valet mode has been

entered. None VEHICLE ARMED None

Confirmation that alarm and

immobilization has been achieved. None SMART KEY NOT

FOUND PLEASE

INSERT IN SLOT Red warning triangle

illuminated in LCD. Smart key has not been detected by the

passive system inside the vehicle. Smart key not present in vehicle. May

be caused by a flat smart key battery.

Replace internal battery in smart key.

May also be due to a communications problem. CHECK SMART

KEY None The smart key detected is not the

correct smart key for the vehicle. Use the correct smart key coded to the

vehicle. REMOVE SMART

KEY None

Smart key is in the start control module

and has been recognized by the passive

start system. Remove smart key from the start

control module. SMART KEY

BATTERY LOW None

Battery voltage in smart key is

becoming low, resulting in a decrease in

effective range of the smart key

transmitter. Replace smart key internal battery. PRESS BRAKE

WHEN STARTING None The stop/start button has been pressed

without the brake pedal depressed. This

will turn on the ignition power mode 6. To start engine, press brake pedal,

then press stop/start button. GEARBOX NOT IN

PARK None The transmission is not in the 'park'

position. Engine starting will be prohibited until 'park' is selected. Put transmission in the park position. www.JagDocs.com

Page 2534 of 3039

Published: 11-May-2011

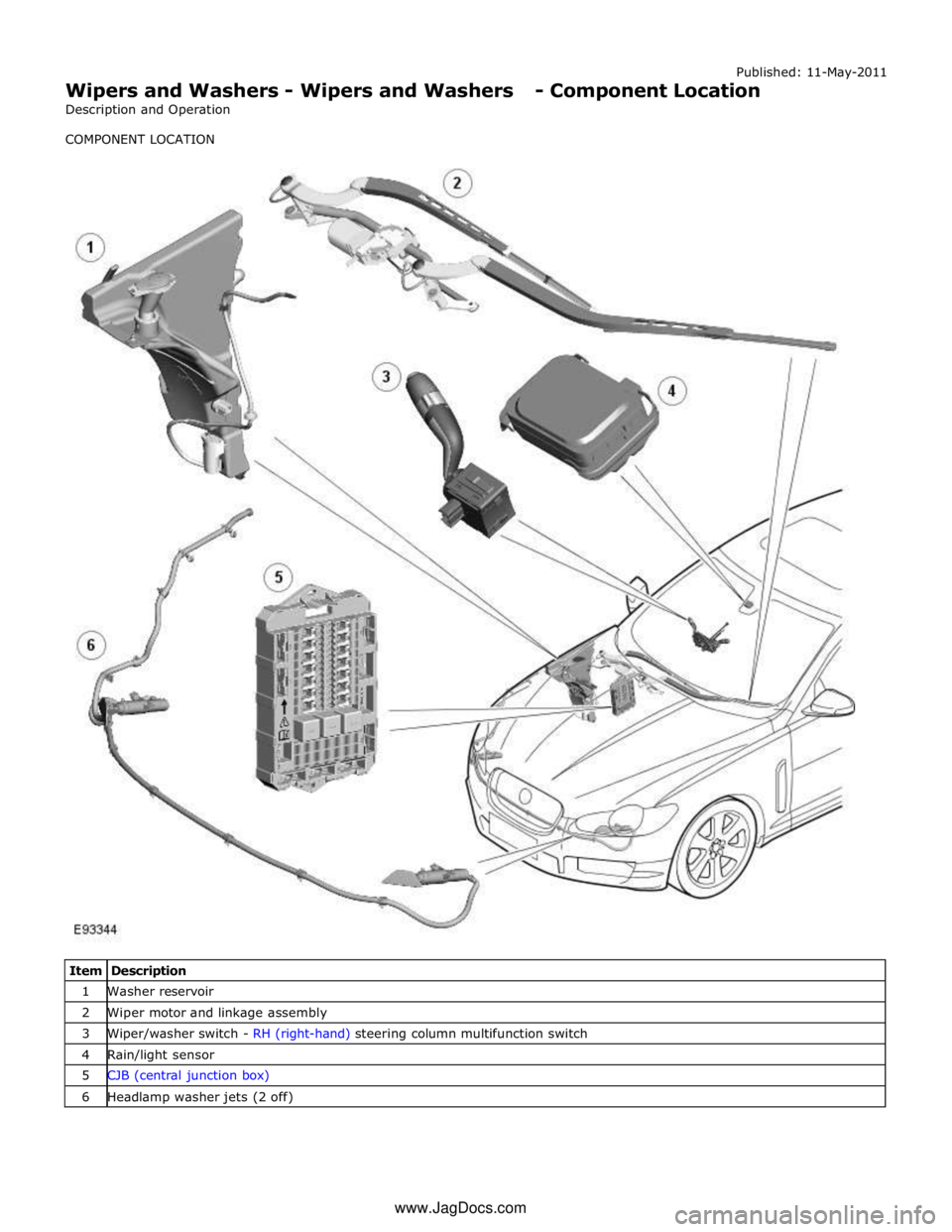

Wipers and Washers - Wipers and Washers - Component Location

Description and Operation

COMPONENT LOCATION

Item Description 1 Washer reservoir 2 Wiper motor and linkage assembly 3 Wiper/washer switch - RH (right-hand) steering column multifunction switch 4 Rain/light sensor 5 CJB (central junction box) 6 Headlamp washer jets (2 off) www.JagDocs.com

Page 2536 of 3039

Published: 11-May-2011

Wipers and Washers - Wipers and Washers - System Operation and

Component Description

Description and Operation

Control Diagram

NOTE: A = Hardwired; N = Medium speed CAN (controller area network) bus; O = LIN (local interconnect network) bus

Item Description 1 Battery 2 EJB (engine junction box) 3 Wiper motor 4 Headlamp washer pump 5 Rain/Light sensor 6 Washer reservoir fluid level switch

Page 2537 of 3039

7 Windshield washer pump 8 Wiper/Washer switch - RH (right-hand) steering column multifunction switch 9 Instrument cluster 10 CJB (central junction box) 11 BJB (battery junction box)

WINDSHIELD WIPERS System Operation

Operation of the wipers and washers is controlled by the CJB in response to driver inputs from the wiper control switch and signals from the rain/light sensor. The instrument cluster monitors the condition of the wiper/washer control switch and

transmits driver requests to the CJB over the medium speed CAN bus.

The wiper control switch is connected via hardwired connections to the instrument cluster. The instrument cluster outputs on 4

wires a reference voltage to the wash/wipe switch, the auto wiper switch, the wiper switch and the flick wipe switch. All the

switches are connected to the instrument cluster on a common ground. Each switch function is connected to ground via a

resistor or series of resistors and the instrument cluster monitors the ground signal and determines which function has been

selected. The instrument cluster then outputs the appropriate message on the medium speed CAN bus to the CJB which responds to the requested wiper function. The CJB then activates the appropriate function either directly or via relays in the EJB for the wipers and headlamp powerwashers. Speed Dependent Mode

When the wipers are operating, a vehicle speed signal received by the CJB on the high speed CAN bus is used to operate a speed dependent mode. If the wipers are in fast wipe and the vehicle speed decreases to below 2 km/h (1.2 mph), the wipers

will reduce to the normal wipe speed. When the vehicle speed increases to above 8 km/h (5 mph) the fast wiper speed

selection is restored. If slow speed is selected and the vehicle speed drops below 2km/h (1.2 mph), the wipers will operate in

the intermittent mode. When the vehicle speed increases to above 8 km/h (5 mph) the slow wiper speed selection is restored

– this feature is configurable by the dealer using the approved Jaguar diagnostic system.

Wiper Motor

The wiper motor is controlled by the CJB. The CJB is connected to a wiper motor normal/fast relay in the EJB on 2 wires. The CJB is also connected to a wiper run/park relay, also located in the EJB.

Driver requests are received by the CJB which energizes the wiper motor normal/fast relay in the appropriate mode (normal or fast wipe) and also energizes the run/park relay in the run mode by providing a ground for the relay coils. When wiper

operation is deselected by the driver, the CJB monitors a park switch which is integral with the wiper motor. On receipt of a signal from the park switch, the CJB de-energises the run/park relay, removing the power supply through the normal/fast relay, stopping the wipers in the park position on the windshield.

The wiper motor is a DC (direct current) motor which drives a gear wheel via a worm drive attached to the motor spindle. The

motor has 3 sets of brushes with one brush connected to ground. When the normal/fast relay is energized in the normal

position, a power feed is supplied to the brush directly opposite the ground brush and operates the motor at slow speed.

When the relay is energized in the fast position, a power feed is connected to the second motor brush, which is offset from the

ground brush and operates the motor at the fast speed. With power supplied through the offset brush, the current flows

through fewer motor coil windings. This results in a lower resistance to current flow to the ground brush and produces a higher

motor rotational speed.

WINDSHIELD WASHERS

The windshield washers are controlled by the CJB. A driver request for washer operation, via the wiper control switch, is passed to the instrument cluster on the LIN bus. The instrument cluster passes the message to the CJB on the medium speed CAN bus.

The CJB energizes the windshield washer pump during the up stroke of the first 2 wash/wipe cycles. This ensures that wiper fluid is pushed to the sides of the windshield and eliminates the trail of fluid which can occur if the fluid is pushed to the

bottom of the windshield. The wipers will continue for 3 more cycles, followed after a delay of 4 seconds, by a single dry wipe.

NOTE: The dry wipe feature is configurable using an approved Jaguar diagnostic system.

The operation of the washer pump on the wiper up stroke only is configurable using an approved Jaguar diagnostic system.

The washer button can be pressed and held and the wipers will operate continuously for up to 10 seconds. After this period

when the button is released, the wipers will continue for 3 more cycles, followed after a delay, by a single dry wipe. After this

period washing will be inhibited, the wipers will continue for 3 more cycles, followed after a delay, by a single dry wipe.

Reactivating the switch will recommence the wash/wipe cycle.

RESERVOIR LEVEL SWITCH

The level switch is connected directly to the CJB. The switch is operated by a float which closes contacts within the switch when the fluid level falls to below the switch level. When the contacts are closed a ground path is completed from the CJB through the switch. This is sensed by the CJB which issues a message to the instrument cluster which displays a low fluid level warning.

Page 2538 of 3039

HEADLAMP POWERWASHERS

The headlamp powerwash is activated when the driver requests windshield washer operation. The CJB receives the driver request via a CAN bus message from the instrument cluster. The CJB then checks for an exterior lights active signal and that a low washer fluid level signal is not present.

The CJB outputs a control voltage to a headlamp powerwash pump relay located in the EJB. The relay is energized by the CJB for a pre-determined period to allow the headlamp telescopic washers to operate.

The CJB monitors the driver washer requests and only operates the headlamp powerwash on every fourth request for windshield washer operation, provided that 10 minutes have elapsed since the last headlamp powerwash operation. The

powerwash sequence is reset when the headlamps or the ignition is switched off.

NOTE: If a low fluid reservoir level is present the CJB prohibits headlamp powerwash.

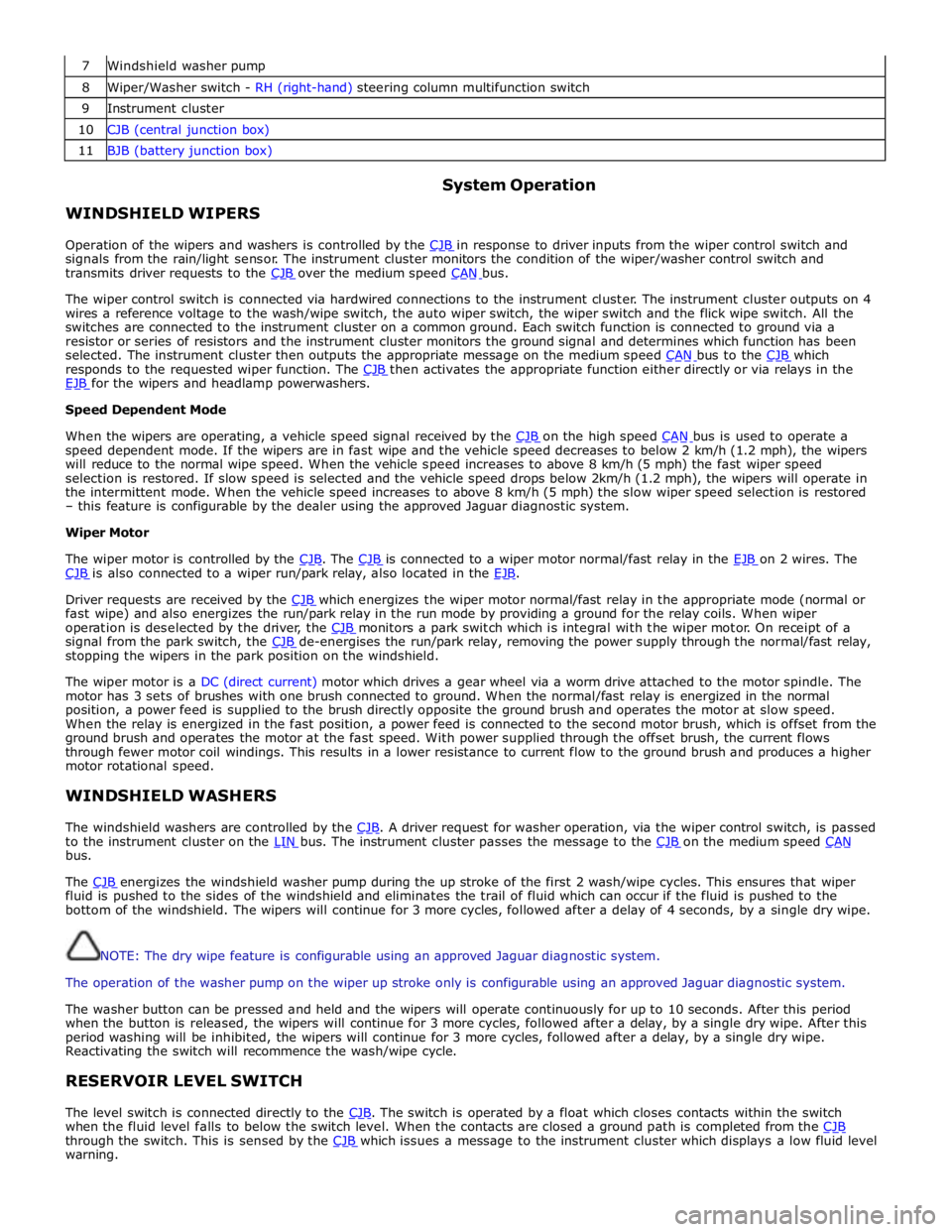

RAIN/LIGHT SENSOR

On receiving a request for automatic windshield wiper operation, the CJB interprets LIN bus messages received from the rain sensor. The rain sensor provides LIN bus messages with values ranging from 0 to 7.

A signal value of 0 is interpreted by the CJB as the windshield is dry. A signal value from 1 to 5 is interpreted by the CJB as a small amount of water hitting the windshield. In this instance, the CJB initiates a slow wipe. A signal value of 7 is interpreted by the CJB as a large amount of water hitting the windshield. In this instance, the CJB initiates a fast wipe. NOTES:

The CJB will only change a fast wipe routine to a slow wipe routine if the rain sensor value is lower than 7.

A = Clean and dry windshield; B = Wet and dirty windshield

Item Description 1 Windshield outer surface 2 Optical element 3 Transmitter diodes (100% light transmitted) 4 Rain sensor

Page 2540 of 3039

and is connected at the opposite end to the LH pivot housing via a crank. The LH pivot housing crank is fitted with a second link rod which is connected directly to the crank on the RH pivot housing.

The motor crank converts rotary motion from the motor output shaft into linear movement of the link rods. The cranks

connected to each pivot housing, convert the linear motion of the link rods back to rotary motion of the pivot housings. This

rotary motion is passed to the wiper arms and blades causing the blades to wipe an arc across the windshield.

Each wiper arm is located on a taper spline on the respective pivot housing. A nut is screwed on the end of the pivot housing

shaft and positively secures the wiper arm on the taper spline.

The wiper blades are attached to the wiper arms with a quick release fittings. The blades are of the flat blade type. These

blades have an integral spring along their full length which curves the blade to match the windshield and provides even blade

to windshield contact pressure along the entire length of the blade.

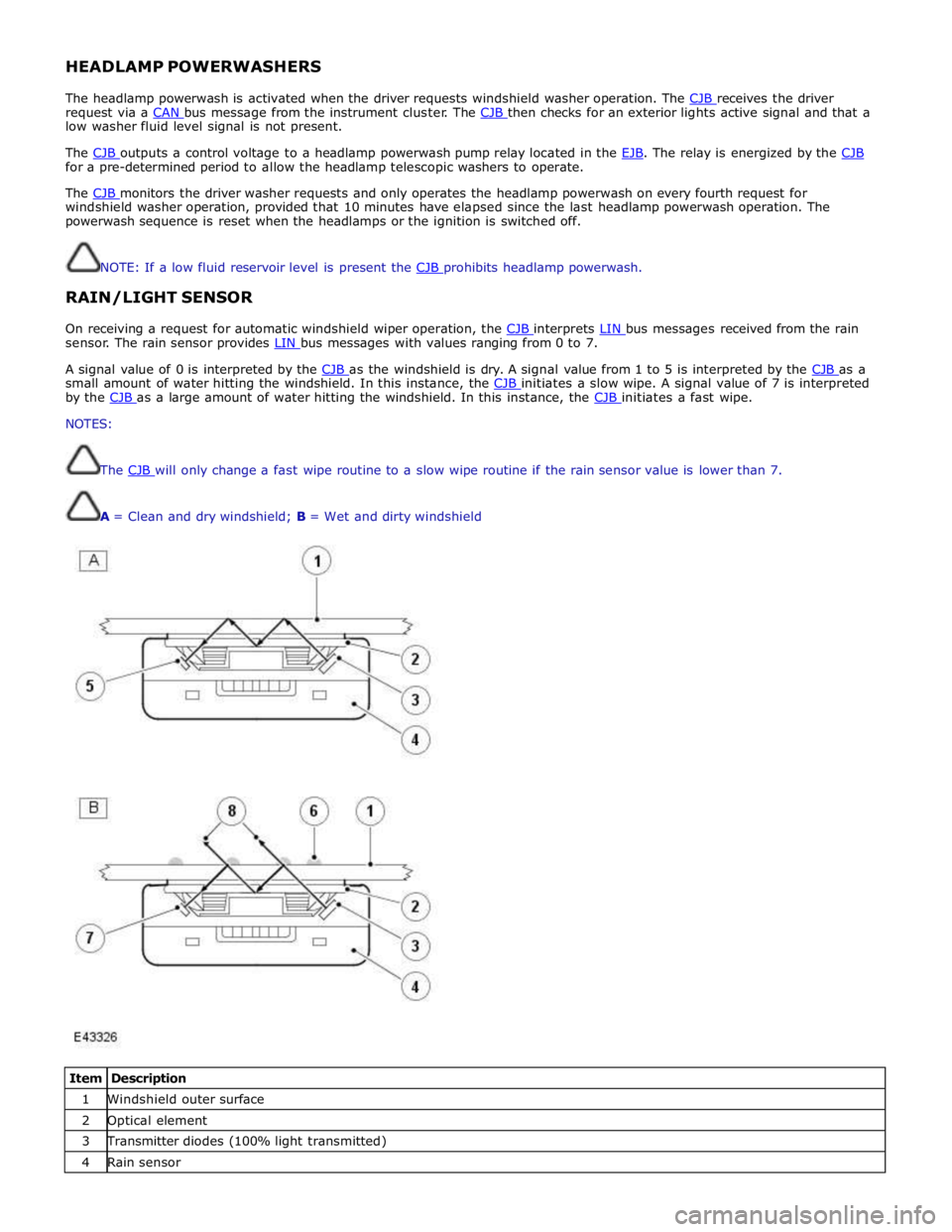

WASHER RESERVOIR

NOTE: Type 'B' washer reservoir shown

Page 2541 of 3039

1 Scrivet 2 Windshield washer feed pipe to washer jets 3 Reservoir cap 4 Reservoir filler neck 5 Captive nut (2 off) 6 Headlamp powerwash feed pipe to telescopic washer jets 7 Screw and washer (2 off) 8 Grommet 9 Washer fluid level sensor 10 Windshield washer pump 11 Headlamp washer pump 12 Location spigot The washer reservoir is located in the RH wheel arch. The reservoir is a plastic moulding and is secured in the wheel arch with 2 screws and washers and a scrivet. A level sensor is located in the reservoir and is connected to the CJB. The reservoir is fitted with a washer pump which supplies pressurized washer fluid to the windshield washer jets mounted on the wiper arms.

A vehicle fitted with optional headlamp washers is fitted with a larger reservoir and an additional pump for the headlamp

washers. The larger reservoir is identifiable by a letter 'B' moulded on the casing and has a capacity of 5.5 liters. Reservoirs

moulded with the letter 'A' are for use on vehicles with windshield washers only and have a capacity of 4.4 liters.

A filler cap is located at the top of the reservoir and is accessible from the engine compartment.

The pumps are located in rubber sealing grommets in holes in the reservoir and secured with clips. The pump fluid hoses have

quick release connectors which mate with the pumps. The fluid level sensor is a push fit into a sealing grommet in one side of

the reservoir body.

HEADLAMP POWERWASHERS (if fitted)

Item Description 1 Powerwash trim cap 2 Washer jets 3 Self-tapping screws (2 off) 4 Pressure feed from powerwash pump 5 Telescopic arm

Page 2543 of 3039

Wipers and Washers - Wipers and Washers

Diagnosis and Testing

Principle of Operation Published: 11-May-2011

For a detailed description of the wipers and washers, refer to the relevant Description and Operation sections in the workshop

manual. REFER to: (501-16 Wipers and Washers)

Wipers and Washers (Description and Operation), Wipers and Washers (Description and Operation), Wipers and Washers (Description and Operation).

Inspection and Verification

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault, and may also cause additional faults in the vehicle being tested and/or the donor vehicle.

1. Verify the customer concern.

2. Visually inspect for obvious signs of damage and system integrity.

Visual Inspection

Mechanical Electrical

Wiper blade(s)

Wiper pivot arm shaft

Washer reservoir

Hose(s)

Washer jet(s)

Fuse(s)

Wiring harness

Electrical connector(s)

Washer pump(s)

Wiper motor

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to

the next step.

4. If the cause is not visually evident, check for Diagnostic Trouble Codes (DTCs) and refer to the DTC Index.

DTC Index

CAUTION: When probing connectors to take measurements in the course of the pinpoint tests, use the adaptor kit, part

number 3548-1358-00.

NOTES:

If the control module or a component is suspect and the vehicle remains under manufacturer warranty, refer to the

Warranty Policy and Procedures manual (section B1.2), or determine if any prior approval programme is in operation, prior to

the installation of a new module/component.

Generic scan tools may not read the codes listed, or may read only five digit codes. Match the five digits from the scan

tool to the first five digits of the seven digit code listed to identify the fault (the last two digits give additional information

read by the manufacturer approved diagnostic system).

When performing electrical voltage or resistance tests, always use a digital multimeter (DMM) accurate to three decimal

places, and with an up-to-date calibration certificate. When testing resistance, always take the resistance of the DMM leads

into account.

Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests.

Inspect connectors for signs of water ingress, and pins for damage and/or corrosion.

If DTCs are recorded and, after performing the pinpoint tests, a fault is not present, an intermittent concern may be the

cause. Always check for loose connections and corroded terminals.

DTC Description Possible Cause Action B109512

Wiper On/Off

Relay

Wiper On/Off relay control Carry out any pinpoint tests associated with this DTC using the

manufacturer approved diagnostic system. Refer to the electrical