engine JAGUAR XJ 1994 2.G AJ16 Engine Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1994, Model line: XJ, Model: JAGUAR XJ 1994 2.GPages: 73, PDF Size: 2.06 MB

Page 22 of 73

AJ16 Engine Service Manual

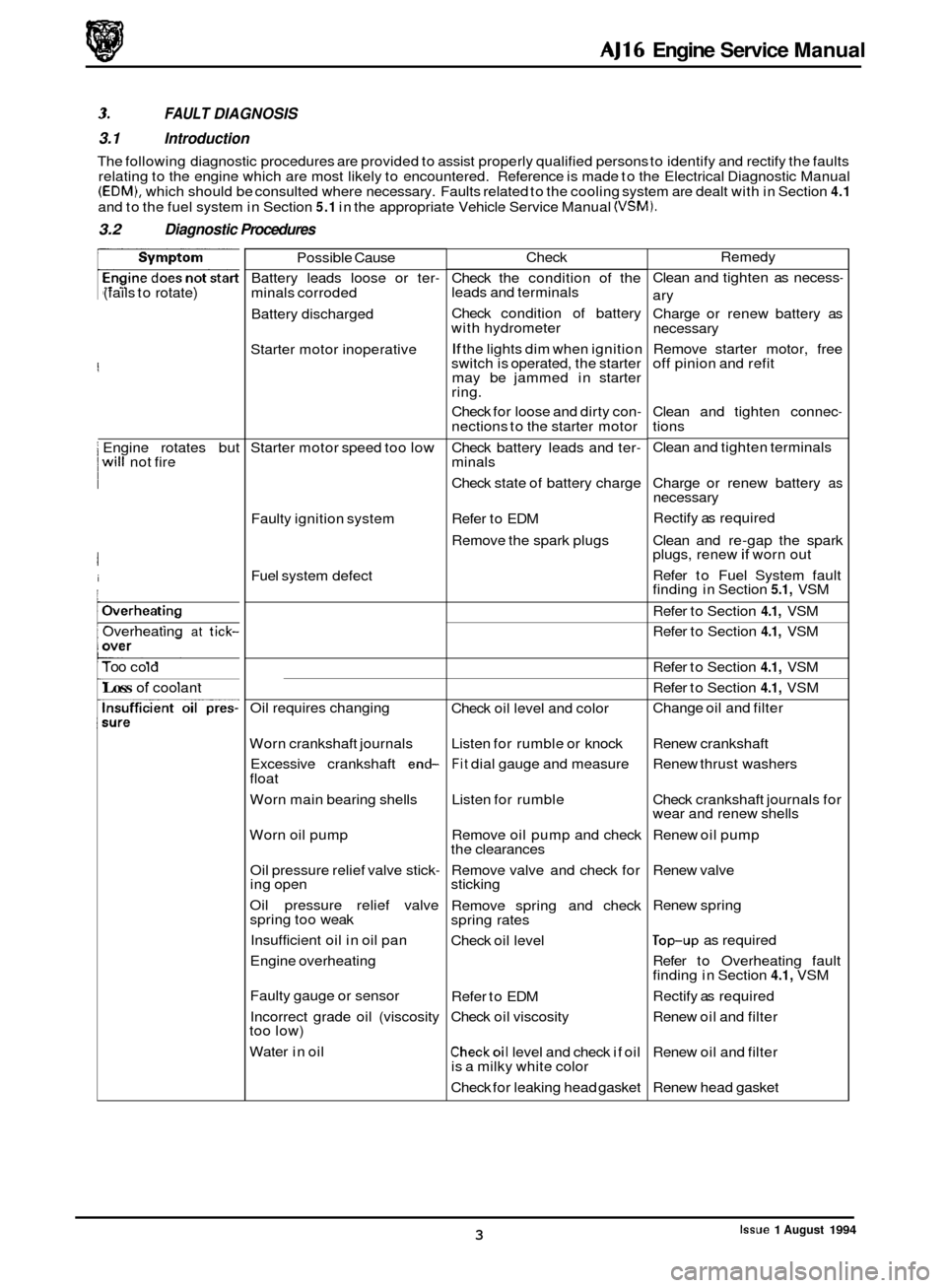

FAULT DIAGNOSIS

3.1 Introduction

The following diagnostic procedures are provided to assist properly qualified persons to identify and rectify the faults

relating to the engine which are most likely to encountered. Reference is made to the Electrical Diagnostic Manual

(EDM), which should be consulted where necessary. Faults related to the cooling system are dealt with in Section 4.1

and to the fuel system in Section 5.1 in the appropriate Vehicle Service Manual (VSM).

3.2 Diagnostic Procedures

(fails to rotate)

I Engine rotates but 0 I will not fire

I

i

/Overheating

Overheating at tick-

Too cold

Loss of coolant Possible

Cause

Battery leads loose or ter

- minals corroded

Battery discharged

Starter motor inoperative

Starter motor speed too

low

Faulty ignition system

Fuel system defect

Oil requires changing

Worn crankshaft journals

Excessive crankshaft

end- float

Worn main bearing shells

Worn oil pump Oil pressure relief valve stick

- ing open

Oil pressure relief valve

spring too weak

Insufficient oil in oil pan

Engine overheating

Faulty gauge or sensor

Incorrect grade oil (viscosity

too low)

Water in oil Check

Check the condition of the

leads and terminals

Check condition of battery

with hydrometer

If the lights dim when ignition

switch is operated, the starter

may be jammed in starter

ring.

Check for loose and dirty con

- nections to the starter motor

Check battery leads and ter

- minals

Check state of battery charge

Refer to EDM

Remove the spark plugs

Check oil level and color

Listen for rumble or knock

Fit dial gauge and measure

Listen for rumble

Remove oil pump and check

the clearances

Remove valve and check for

sticking

Remove spring and check

spring rates

Check oil level

Refer to EDM

Check oil viscosity

Checkoil level and check if oil

is a milky white color

Check for leaking head gasket Remedy

Clean and tighten as necess

-

ary

Charge or renew battery as

necessary

Remove starter motor, free

off pinion and refit

Clean and tighten connec

- tions

Clean and tighten terminals

Charge or renew battery

as necessary

Rectify as required

Clean and re

-gap the spark

plugs, renew if worn out

Refer to Fuel System fault

finding in Section

5.1, VSM

Refer to Section

4.1, VSM

Refer to Section

4.1, VSM

Refer to Section

4.1, VSM

Refer to Section

4.1, VSM

Change oil and filter

Renew crankshaft

Renew thrust washers

Check crankshaft journals for

wear and renew shells

Renew oil pump

Renew valve

Renew spring

lop-up as required

Refer to Overheating fault

finding in Section

4.1, VSM

Rectify as required

Renew oil and filter

Renew oil and filter

Renew head gasket

Issue 1 August 1994 3

Page 23 of 73

AJ16 Engine Service Manual

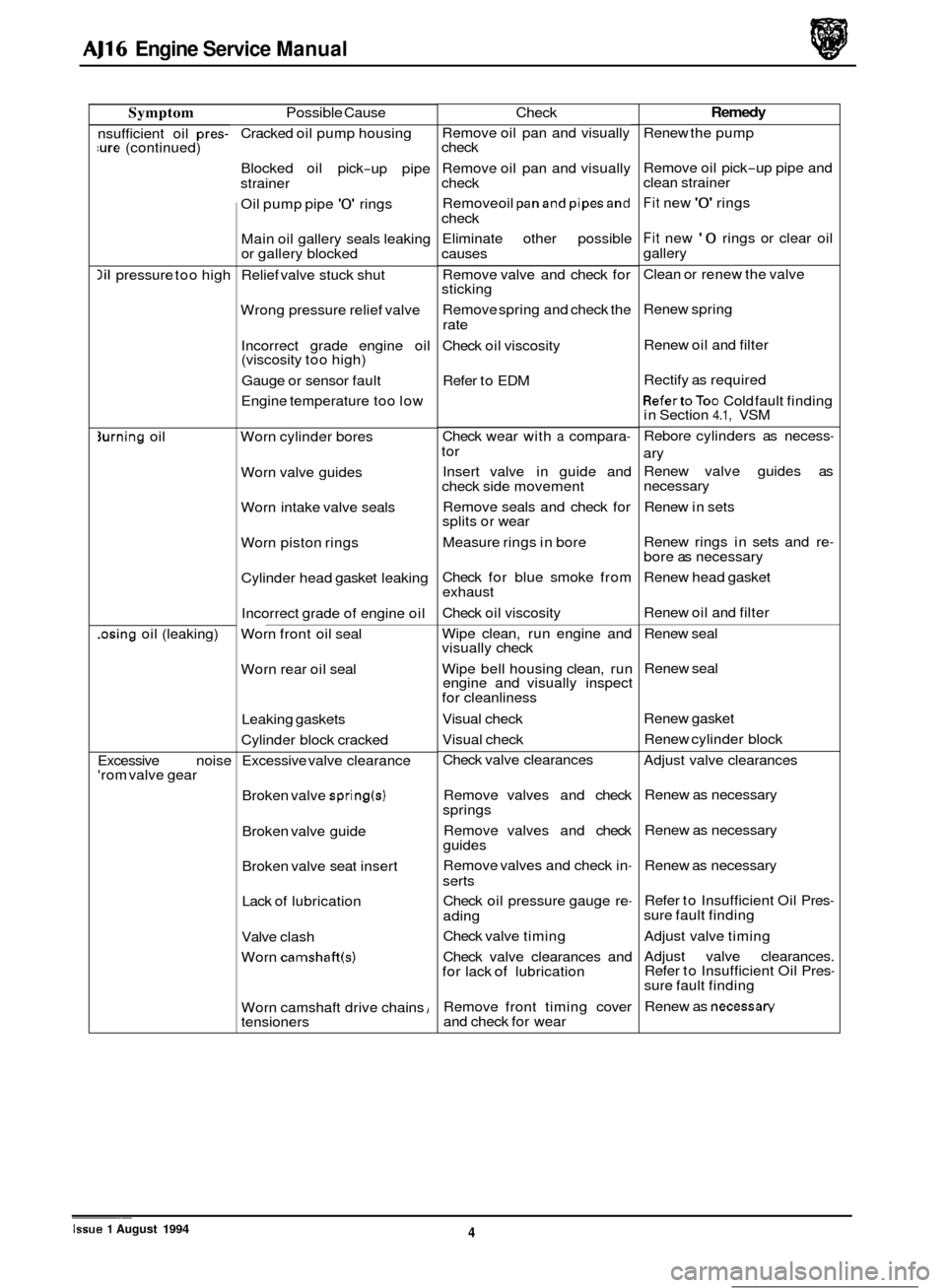

Symptom Possible Cause ~~

nsufficient

oil pres- ure (continued)

lil pressure too high

3urning oil

.osing oil (leaking)

Excessive noise

'rom valve gear Cracked

oil pump housing

Blocked oil pick

-up pipe

strainer

Oil pump pipe

'0' rings

Main oil gallery seals leaking

or gallery blocked

Relief valve stuck shut

Wrong pressure relief valve

Incorrect grade engine oil

(viscosity too high)

Gauge or sensor fault

Engine temperature too low

Worn cylinder bores

Worn valve guides

Worn intake valve seals

Worn piston rings

Cylinder head gasket leaking

Incorrect grade of engine oil

Worn front oil seal

Worn rear oil seal

Leaking gaskets

Cylinder block cracked

Excessive valve clearance

Broken valve

spring(s)

Broken valve guide

Broken valve seat insert

Lack of lubrication

Valve clash

Worn

camshaft(s)

Worn camshaft drive chains i tensioners

Check

Remove oil pan and visually

check

Remove oil pan and visually

check

Removeoil

panand pipesand check Eliminate other possible

causes

Remove valve and check for

sticking

Remove spring and check the

rate

Check oil viscosity

Refer to EDM

Check wear with

a compara- tor

Insert valve in guide and

check side movement

Remove seals and check for

splits or wear

Measure rings in bore

Check for blue smoke from

exhaust

Check oil viscosity

Wipe clean, run engine and

visually check

Wipe bell housing clean, run

engine and visually inspect

for cleanliness

Visual check

Visual check

Check valve clearances

Remove valves and check

springs

Remove valves and check

guides

Remove valves and check in

- serts

Check oil pressure gauge re

- ading

Check valve timing

Check valve clearances and

for lack

of lubrication

Remove front timing cover

and check for wear

Remedy

Renew the pump

Remove oil pick

-up pipe and

clean strainer

Fit new '0' rings

Fit new '0 rings or clear oil

gallery

Clean or renew the valve

Renew spring

Renew oil and filter

Rectify as required

RefertoToo Cold fault finding

in Section 4.1, VSM

Rebore cylinders as necess

-

ary

Renew valve guides as

necessary

Renew in sets

Renew rings in sets and re

- bore as necessary

Renew head gasket

Renew oil and filter

Renew seal

Renew seal

Renew gasket Renew cylinder block

Adjust valve clearances

Renew as necessary

Renew as necessary

Renew as necessary

Refer to Insufficient Oil Pres

- sure fault finding

Adjust valve timing

Adjust valve clearances.

Refer to Insufficient Oil Pres

- sure fault finding

Renew as

necessaw

0

0

0 ~~~

Issue 1 August 1994 4

Page 24 of 73

AJ16 Engine Service Manual

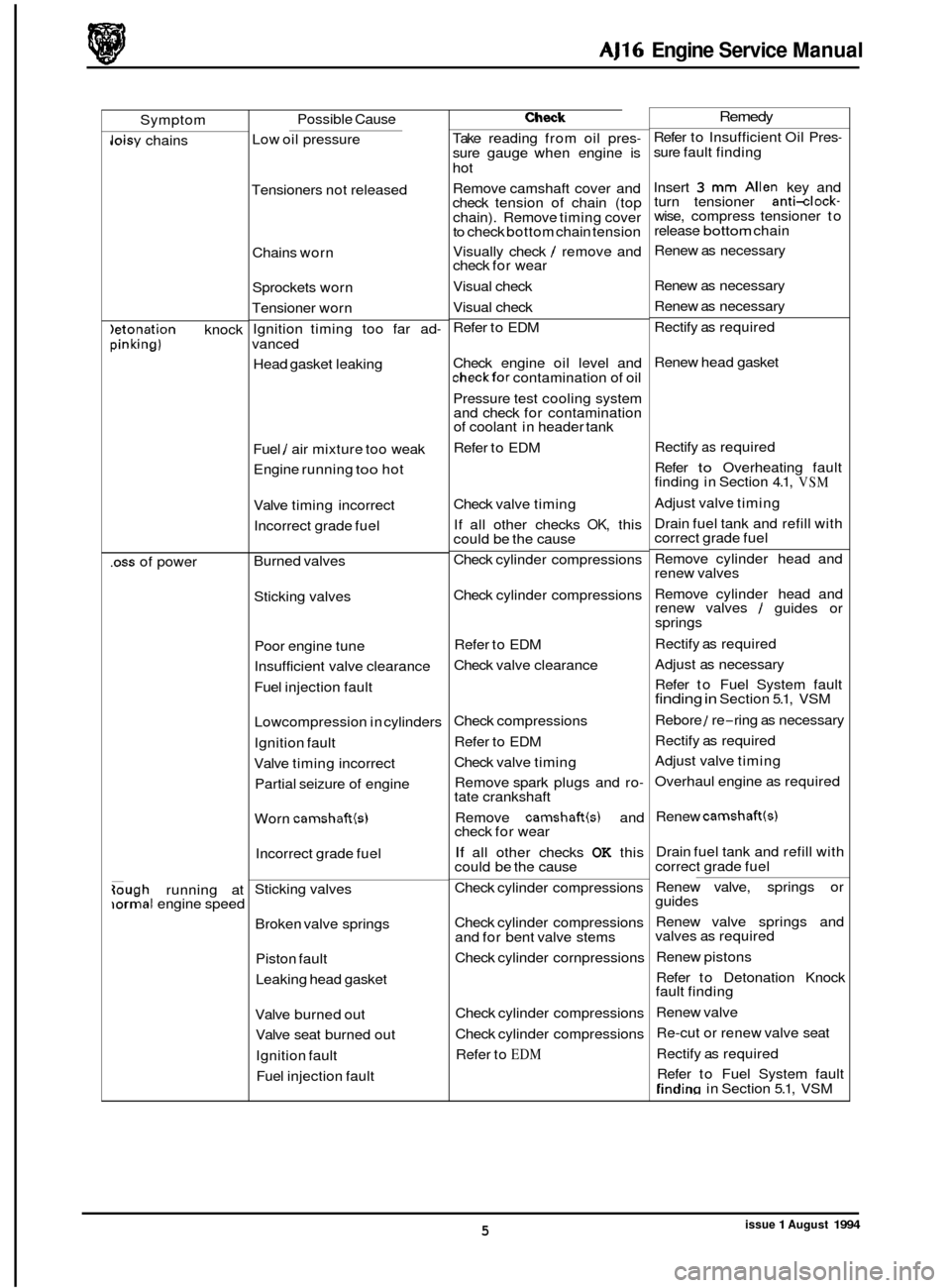

Symptom

Joisy chains

)etonation knock pinking)

.oss of power

Gugh running at iormal engine speed Possible

Cause

Low oil pressure

Tensioners not released

Chains worn

Sprockets worn

Tensioner worn

Ignition timing too far ad

- vanced

Head gasket leaking

Fuel

/ air mixture too weak

Engine running

too hot

Valve timing incorrect

Incorrect grade fuel

Burned valves Sticking valves

Poor engine tune

Insufficient valve clearance

Fuel injection fault

Lowcompression in cylinders

Ignition fault

Valve timing incorrect

Partial seizure of engine

Worn

camshaftb)

Incorrect grade fuel

Sticking valves Broken valve springs Piston fault

Leaking head gasket

Valve burned out

Valve seat burned out

Ignition fault

Fuel injection fault

Check

Take reading from oil pres- sure gauge when engine is

hot

Remove camshaft cover and

check tension of chain (top

chain). Remove timing cover

to check bottom chain tension

Visually check

/ remove and

check for wear

Visual check

Visual check

Refer to EDM

Check engine oil level and

checkfor contamination of oil

Pressure test cooling system

and check for contamination

of coolant in header tank

Refer to EDM

Check valve timing

If all other checks

OK, this

could be the cause

Check cylinder compressions

Check cylinder compressions

Refer to EDM

Check valve clearance

Check compressions

Refer to EDM

Check valve timing

Remove spark plugs and ro

- tate crankshaft

Remove

camshaft(s) and

check for wear

If all other checks OK this

could be the cause

Check cylinder compressions

Check cylinder compressions

and for bent valve stems

Check cylinder cornpressions

Check cylinder compressions

Check cylinder compressions

Refer to

EDM

Remedy

Refer to Insufficient Oil Pres- sure fault finding

Insert

3 mm Allen key and

turn tensioner anti-clock- wise, compress tensioner to

release bottom chain

Renew as necessary

Renew as necessary

Renew as necessary

Rectify as required

Renew head gasket

Rectify

as required

Refer

to Overheating fault

finding in Section 4.1, VSM

Adjust valve timing

Drain fuel tank and refill with

correct grade fuel

Remove cylinder head and

renew valves

Remove cylinder head and

renew valves

/ guides or

springs

Rectify as required

Adjust as necessary

Refer to Fuel System fault

finding in Section 5.1, VSM

Rebore

1 re-ring as necessary

Rectify as required

Adjust valve timing

Overhaul engine as required

Renew

camshaft(s)

Drain fuel tank and refill with

correct grade fuel

Renew valve, springs or

guides

Renew valve springs and

valves as required

Renew pistons

Refer to Detonation Knock

fault finding

Renew valve

Re

-cut or renew valve seat

Rectify as required

Refer to Fuel System fault

Tindim in Section 5.1, VSM

issue 1 August 1994 5

Page 25 of 73

AJ16 Engine Service Manual

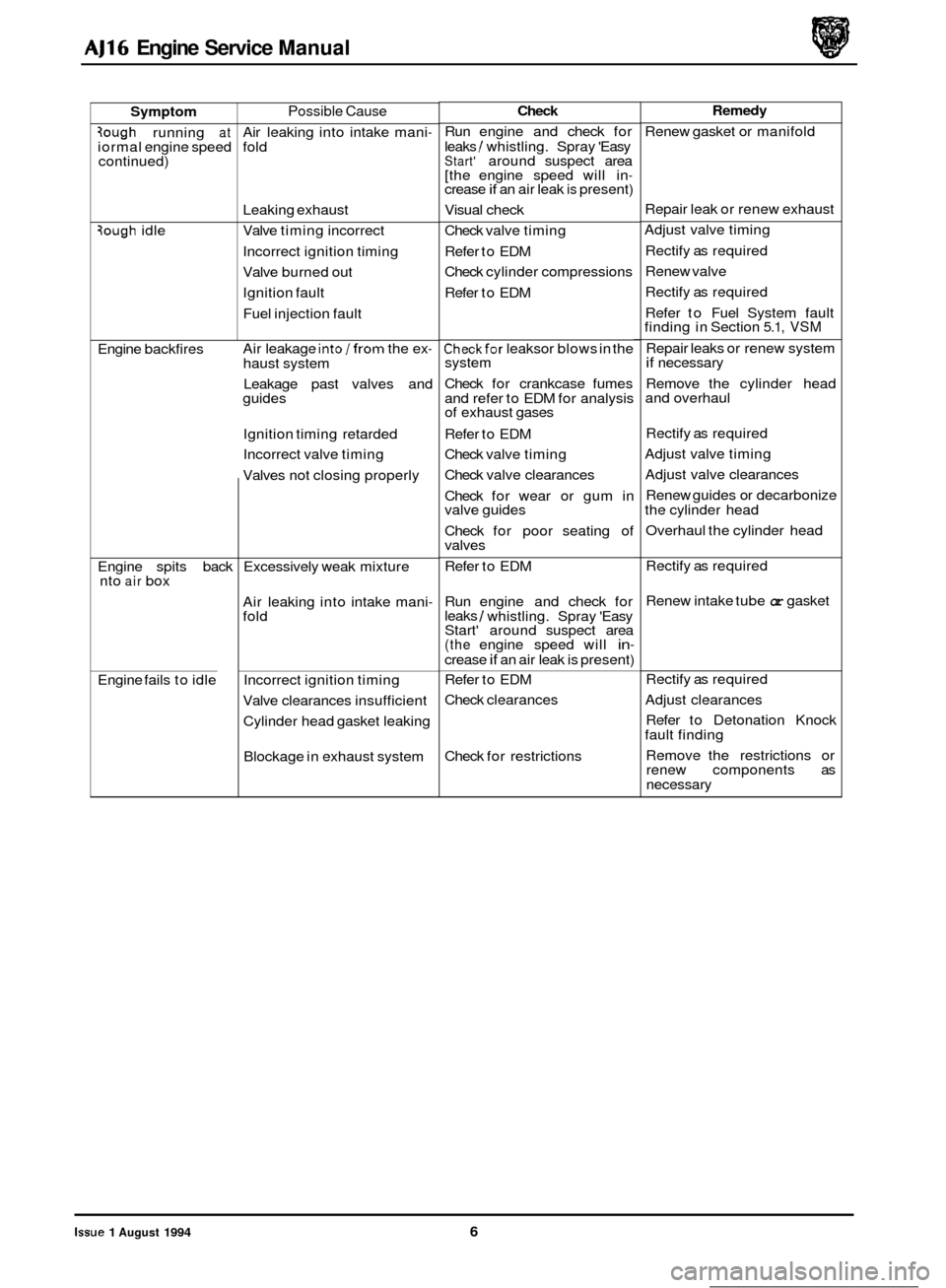

Symptom

3ough running at iormal engine speed

continued)

3ough idle

Engine backfires

Engine spits back

nto

air box

Engine fails to idle

Possible Cause

Air leaking into intake mani- fold

Leaking exhaust

Valve timing incorrect

Incorrect ignition timing

Valve burned out

Ignition fault

Fuel injection fault

Air leakage

intolfrom the ex- haust system

Leakage past valves and

guides

Ignition timing retarded

Incorrect valve timing

Valves not closing properly

Excessively weak mixture

Air leaking into intake mani

- fold

Incorrect ignition timing

Valve clearances insufficient

Cylinder head gasket leaking

Blockage in exhaust system

Check

Run engine and check for

leaks / whistling. Spray 'Easy Start' around suspect area

[the engine speed will in- crease if an air leak is present)

Visual check

Check valve timing

Refer to EDM

Check cylinder compressions

Refer to EDM

Checkfor leaksor blows in the

system

Check for crankcase fumes

and refer to EDM for analysis

of exhaust gases

Refer to EDM

Check valve timing

Check valve clearances

Check for wear or gum in

valve guides

Check for poor seating of

valves

Refer to EDM

Run engine and check for

leaks

/ whistling. Spray 'Easy

Start' around suspect area

(the engine speed will in- crease if an air leak is present)

Refer to EDM

Check clearances

Check for restrictions

Remedy

Renew gasket or manifold

Repair leak or renew exhaust

Adjust valve timing

Rectify as required

Renew valve

Rectify as required

Refer to Fuel System fault

finding in Section

5.1, VSM

Repair leaks or renew system if necessary

Remove the cylinder head

and overhaul

Rectify as required

Adjust valve timing

Adjust valve clearances

Renew guides or decarbonize

the cylinder head

Overhaul the cylinder head

Rectify as required

Renew intake tube

or gasket

Rectify as required

Adjust clearances

Refer to Detonation Knock

fault finding

Remove the restrictions or

renew components as

necessary

Issue 1 August 1994 6

Page 26 of 73

AJ16 Engine Service Manual

SERVICE OPERATIONS

4.1 Camshaft, Renew

SRO 12.13.01

Remove camshaft cover, see Section 4.2.

Drain the cooling system, see Section 4.1 in the appropri

- ate Vehicle Service Manual.

1 Rotate the engine and set No. 1 cylinder at TDC using Ser- viceTool 18G 1433 (1 Fig. 1).

Push back the lock tabs (1 Fig.2) from the camshaft

sprocket securing bolts (2 Fig. 2). and slacken off the bolts.

Remove the upper chain tensioner valve clamp bolt

(3 Fig.

2), remove the clamp (4 Fig. 2) and remove the

valve (5 Fig. 2).

1 Using a 3 mm Allen key, wind backthe tensioner (6 Fig. 2) (turn clockwise) until the snail engages in the park posi- tion. Remove the tensioner housing securing bolt (7 Fig. 2) and withdraw the tensioner assembly (8, 9 Fig. 2).

1 Remove and discard the '0' ring (9 Fig. 2) and gasket (10 Fig. 2).

. Remove the camshaft sprocket securing bolts and tab

washers (1,2 Fig. 2) and remove the sprockets (11 Fig. 2) (ensure that neither the bolts nor the tab washer drop into

the timing case).

CAUTION: Do not rotate the engine while the camshaft is

disconnected.

. Remove the cylinder head bolt from No. 2 cap, left-hand

1 Remove No. 2 cap from the left-hand camshaft.

1 Fit spacer tool 18G 1435 (2 Fig. 3) to the head.

Fit and torque tighten the cylinder head bolt.

Repeat the procedure for Nos 3,4,5 and 6 caps, left-hand

camshaft (3 Fig. 3).

Remove the cylinder head bolt from

No. 7 cap, left-hand

camshaft.

Loosen in sequence the securing bolts from Nos 1 and 7 caps, until theleft-handcamshaft isfree. Liftthecamshaft

from the cylinder head and fit spacer tool 18G 1435 to No. 7 cylinder head bolt position (5 Fig. 3). Fit and torque

tighten the bolt.

Clean

all components and examine for wear and damage.

Renew all worn or damaged components.

Lubricate the new left

-hand camshaft.

Fit the camshaft at approximately TDC.

Lubricate Nos 1 and 7 caps.

Fit No. 1 cap but do not tighten the securing bolts. Remove No. 7 cap cylinder head bolt.

1 Remove the spacer tool. Fit No. 7 cap but do not tighten

the securing bolts.

1 Finally tighten Nos 1 and 7 cap securing bolts in sequence.

Remove No. 4 cap cylinder head bolt and remove the

spacer tool. Lubricate and fit No. 4 cap.

CAUTION: The cylinder head bolts MUST be renewed dur- ing assembly and torque tightened as de- scribed in Section 2.1, SPS Joint Control System.

camshaft

(1 Fig. 3).

1 Repeat

the procedure for the right-hand camshaft.

1

Fia. 1

Fia. 2

Fig. 3

Issue 1 August 1994 7

Page 27 of 73

AJ16 Engine Service Manual

. Fit and tighten No. 4 cap securing bolts.

. Fit and tighten No. 4 cap cylinder head bolt.

CAUTION: The cylinder head bolts MUST be renewed dur- ing assembly and torque tightened as de- scribed in Section 2.1, SPS Joint Control

System.

. Repeat the procedure for Nos 2,3,5 and 6 caps, left-hand

Set the left-hand camshaft to TDC.

. Repeat the procedure for the right-hand camshaft.

. Check and adjust valve clearances see Section 4.3.

Refit the camshaft cover, see Section 4.2.

camshaft. ~~

Issue 1 August 1994 8

Page 28 of 73

AJ16 Engine Service Manual

4.2 Camshaft Cover Gasket, Renew

SRO 12.29.39

1 Remove the top cover and disconnect the on-plug coils

from the spark plugs.

. Disconnect the camshaft cover breather hose.

1 Remove the camshaft cover to cylinder head securing

Screws (1 Fig. 11, and remove the camshaft cover (2 Fig. 1).

. Remove and discard the camshaft cover gasket (3 Fig. 1).

. Clean the camshaft cover and cylinder head mating faces.

1 Fit a new gasket to the camshaft cover.

. Refit the camshaft cover.

1 Fit and tighten the camshaft cover securing screws.

. Reconnect the breather hose.

1 Reconnect the on-plug coils to the spark plugs and fit the

top cover.

I Fia. I

Issue 1 August 1994 9

Page 29 of 73

AJ16 Engine Service Manual

4.3

SRO 12.29.48

1 Remove camshaft cover, see Section 4.2.

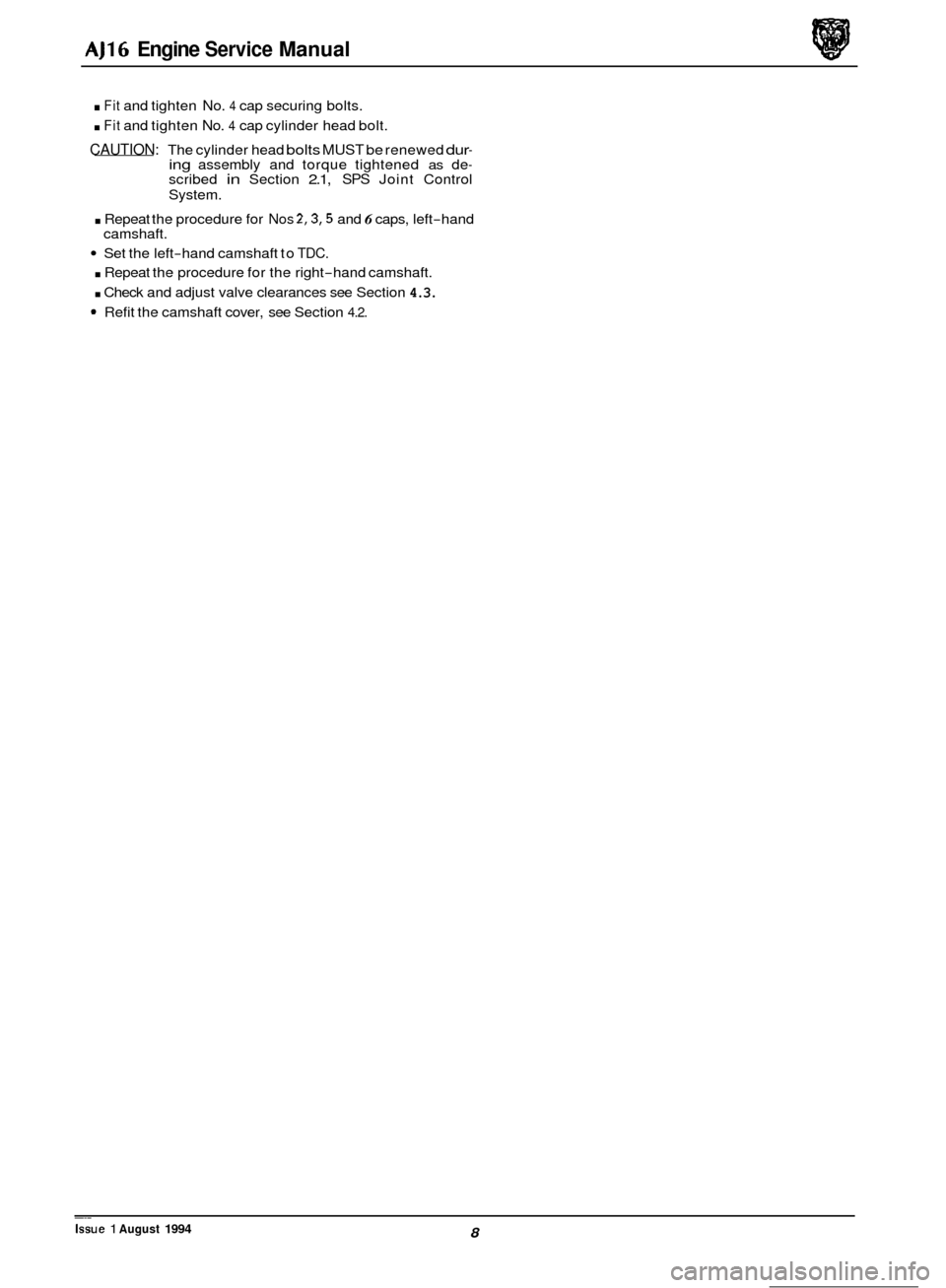

1 Rotate the engine as necessary to measurethevalve clear- ances between the heel of the cam and the cam follower

(Fig.

1). See Service Data in the Preliminary Pages for the

correct valve clearances.

1 Make a note of each clearance measurement.

1 Should the clearances be incorrect, proceed as follows:

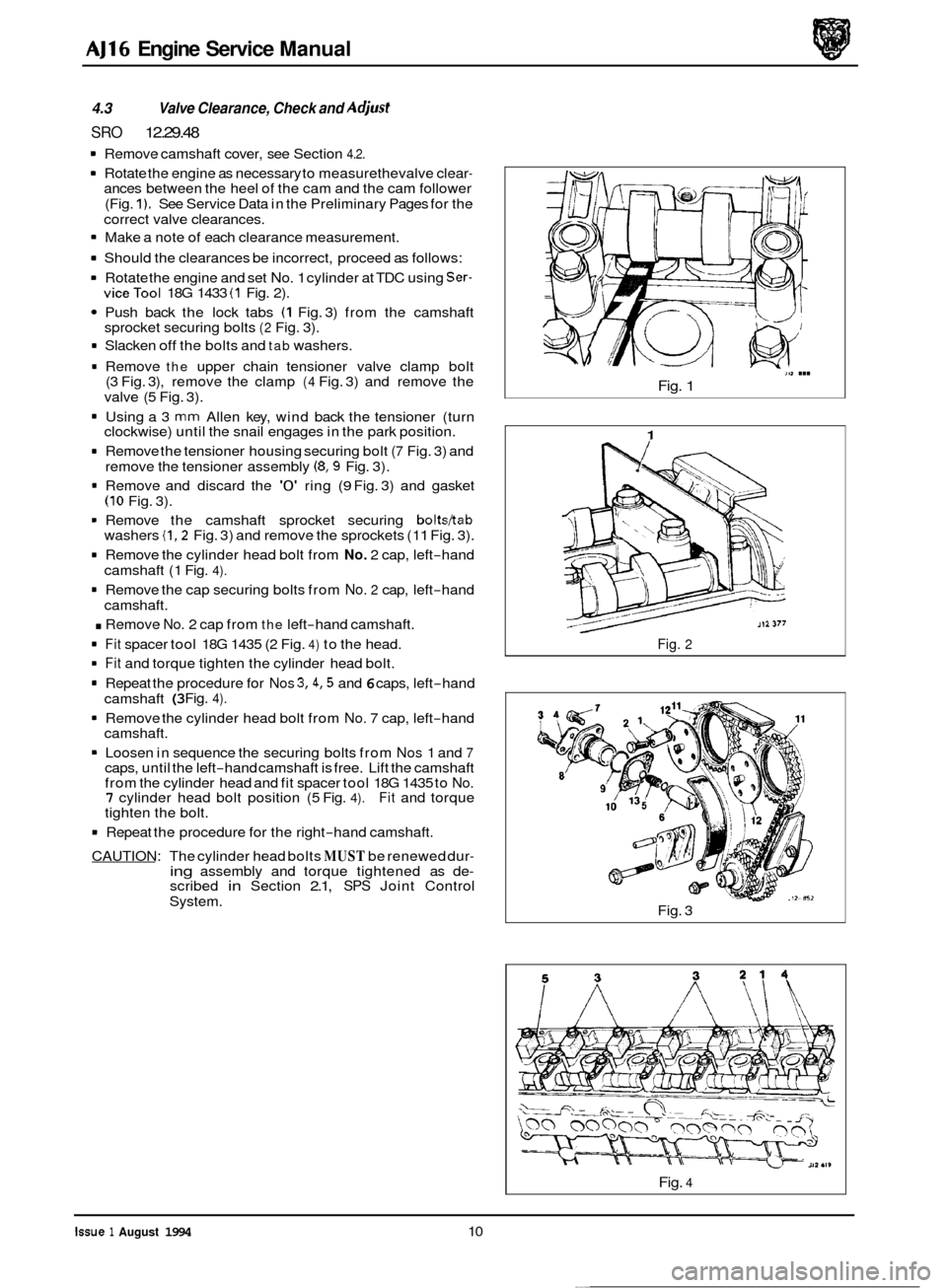

1 Rotate the engine and set No. 1 cylinder at TDC using Ser- viceTool 18G 1433 (1 Fig. 2).

Push back the lock tabs (1 Fig. 3) from the camshaft

sprocket securing bolts (2 Fig. 3).

1 Slacken off the bolts and tab washers.

1 Remove the upper chain tensioner valve clamp bolt

(3 Fig. 3), remove the clamp (4 Fig. 3) and remove the

valve (5 Fig. 3).

1 Using a 3 mm Allen key, wind back the tensioner (turn

clockwise) until the snail engages in the park position.

1 Remove the tensioner housing securing bolt (7 Fig. 3) and

remove the tensioner assembly (8,9 Fig. 3).

1 Remove and discard the '0' ring (9 Fig. 3) and gasket (10 Fig. 3).

1 Remove the camshaft sprocket securing bolts/tab washers (1,2 Fig. 3) and remove the sprockets (1 1 Fig. 3).

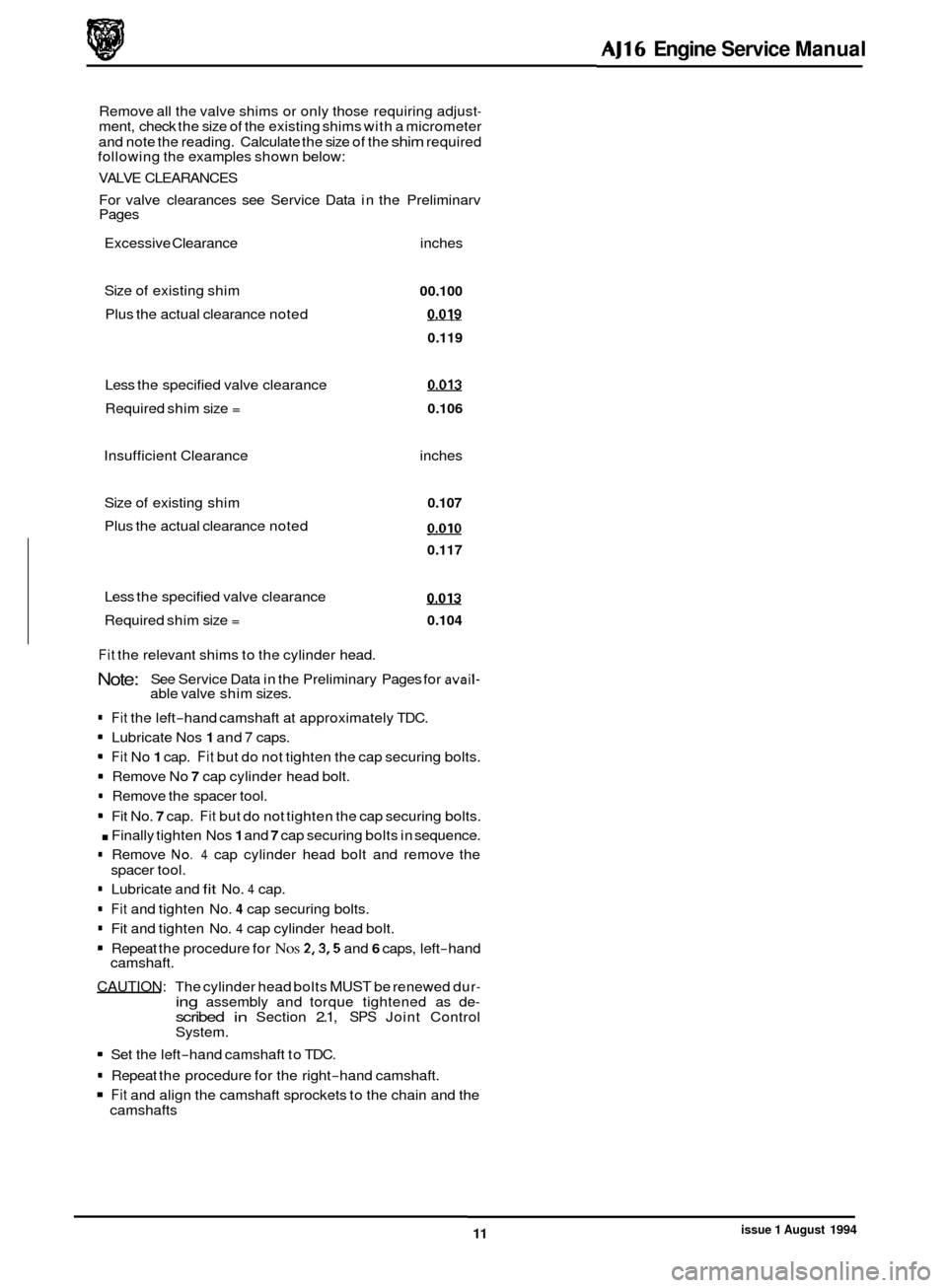

1 Remove the cylinder head bolt from No. 2 cap, left-hand

camshaft (1 Fig. 4).

1 Remove the cap securing bolts from No. 2 cap, left-hand

cams haft.

. Remove No. 2 cap from the left-hand camshaft.

1 Fit spacer tool 18G 1435 (2 Fig. 4) to the head.

1 Fit and torque tighten the cylinder head bolt.

1 Repeat the procedure for Nos 3,4,5 and 6 caps, left-hand

camshaft

(3 Fig. 4).

1 Remove the cylinder head bolt from No. 7 cap, left-hand

camshaft.

1 Loosen in sequence the securing bolts from Nos 1 and 7 caps, until the left-hand camshaft is free. Lift the camshaft

from the cylinder head and fit spacer tool 18G 1435 to No. 7 cylinder head bolt position (5 Fig. 4). Fit and torque

tighten the bolt.

Valve Clearance, Check and Aa'just

1 Repeat the procedure for the right-hand camshaft.

CAUTION: The cylinder head bolts

MUST be renewed dur- ing assembly and torque tightened as de- scribed in Section 2.1, SPS Joint Control

System.

111 ...

Fig. 1

1

Fig. 2

Fig. 3

Fig. 4

Issue 1 August 1994 10 ~~

Page 30 of 73

1.

Remove all the valve shims or only those requiring adjust- ment, check the size of the existing shims with a micrometer

and note the reading. Calculate the size of the

shim required

following the examples shown below:

VALVE CLEARANCES

For valve clearances see Service Data in the Preliminarv

I Pages

Excessive Clearance inches

Size of existing shim

Plus the actual clearance noted

Less the specified valve clearance

I

00.100

0.019

0.119

0.013

Required shim size = 0.106

Insufficient Clearance inches

Size of existing shim

0.107

Plus the actual clearance noted o.010

0.117

Less the specified valve clearance 0.013

Required shim size = 0.104

I

Fit the relevant shims to the cylinder head.

Note:

. Fit the left-hand camshaft at approximately TDC.

. Lubricate Nos 1 and 7 caps.

1 Fit No 1 cap. Fit but do not tighten the cap securing bolts.

. Remove No 7 cap cylinder head bolt.

. Remove the spacer tool.

1 Fit No. 7 cap. Fit but do not tighten the cap securing bolts.

. Finally tighten Nos 1 and 7 cap securing bolts in sequence.

. Remove No. 4 cap cylinder head bolt and remove the

. Lubricate and fit No. 4 cap.

. Fit and tighten No. 4 cap securing bolts.

. Fit and tighten No. 4 cap cylinder head bolt.

9 Repeat the procedure for Nos 2,3,5 and 6 caps, left-hand

CAUTION: The cylinder head bolts MUST be renewed dur- ing assembly and torque tightened as de- scribed in Section 2.1, SPS Joint Control

System.

See

Service Data in the Preliminary Pages for

avail- able valve shim sizes.

I

3

spacer tool.

camshaft.

1 Set the left-hand camshaft to TDC.

. Repeat the procedure for the right-hand camshaft.

Fit and align the camshaft sprockets to the chain and the

camshafts

AJ16 Engine Service Manual

11 issue 1 August 1994

Page 31 of 73

AJ16 Engine Service Manual

1 Move all the slack in the chain to the tensioner side.

1 Fit upper chain tensioner tool 18G 14361A (2 Fig. 1). Fit and

tighten the tool securing bolts (1 Fig. 1).

1 Tension the cam chain.

1 Remove the camshaft coupling (12 Fig.2) from the

sprocket (11 Fig. 2) and align the securing bolt holes. Fit

the bolts (2 Fig. 2) and tab washers (1 Fig. 2), tighten the

securing bolts and lock over the tabs.

1 Repeat the procedure for the other sprocket.

1 Slacken off the chain tensioner tool securing bolts

1 Remove the tensioner tool.

1 Clean the tensioner assembly and gasket faces.

= Fit a new housing gasket (10 Fig. 2). Fit and lubricate a

new ‘0’ ring (9 Fig. 2).

1 Fitthetensionerassembly (8,9 Fig. 2)tothecylinderhead.

Fit andtighten thetensioner assembly securing bolt (3 Fig.

2).

(1 Fig. 1).

1 Fit but do not tighten the valve clamp bolt.

1 Clean the valve assembly and fit new ‘0‘ rings (13 Fig. 2).

Lubricate the tensionervalve (5 Fig. 2). Using an Allen key,

release the tensioner, by turning the

Allen key anti-clock- wise.

1 Fit the tensioner valve (5 Fig. 2). Position the clamp (4 Fig. 2) over the valve.

1 Tighten the clamp bolt (3 Fig. 2).

1 Refit the camshaft cover, see Section 4.2. Fig.

1

I Fia. 2

Issue 1 August 1994 12