dimensions JAGUAR XJ 1994 2.G AJ16 Engine Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1994, Model line: XJ, Model: JAGUAR XJ 1994 2.GPages: 73, PDF Size: 2.06 MB

Page 21 of 73

AJ16 Engine Service Manual

1.5 Coohg System

The engine is liquid cooled by a mixture of water and anti-freeze circulating around the coolant passages. The coolant

pump is mounted on the left hand side of the cylinder block and is driven from the crankshaft nose by a three point

belt drive (which includes the generator). The pump is a fully assembled bolt

-on unit. The coolant is fed into the cylin- der block at two places via an external delivery pipe. The coolant is drawn from the cylinder head via a self-contained

thermostat housing back to the radiator or recirculated according to the thermostat position.

7.6 Supercharger

The supercharger optionally available on the 4,O liter engine is a Roots blower type which gives better engine efficiency

at part throttle conditions and responsive off

-boost performance. The principal changes to the engine for the super- charged version are to the piston, valve timing, intake manifold and the additional drive to the supercharger. A lower

compression ratio

of 8.5:l is used which provides the optimum balance between high speed performance and fuel

economy.

The engine heat exchanger of the intercooler system is incorporated into the intake manifold. The blower incorporates

an air by

-pass system which improves efficiency under part throttle conditions. The by-pass valve is controlled by a vacuum actuator referenced to the intake manifold pressure.

2. SERVICE PROCEDURES

2.1 SPS )oint Control System

Afeature of the engine is the use of the SPS joint control system on the cylinder head bolts, crankshaft main bearing

bolts and connecting rod bearing nuts and bolts. This system ensures that the joints receive maximum clamp loading

for a given fixing size and type of material by tightening the fixing to its particular yield point. This greatly helps to

prevent premature cylinder head gasket failures.

0

CAUTION: All SPS fixings must be used only once. Discard

fixings on removal and replace with new bolts/

nuts every time a 'strip down' has been carried

out.

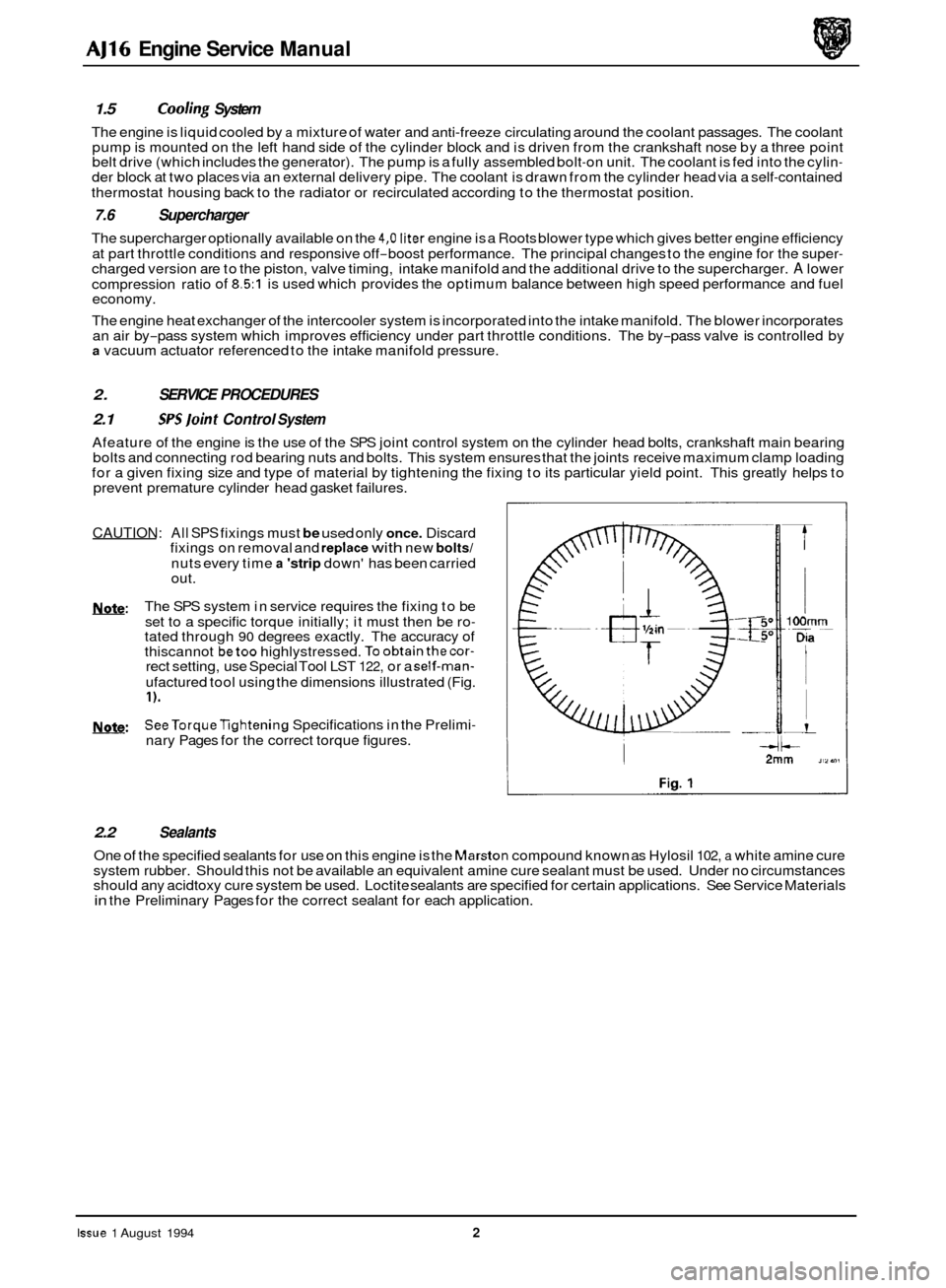

The SPS system in service requires the fixing to be

set to a specific torque initially; it must then be ro

- tated through 90 degrees exactly. The accuracy of

thiscannot betoo highlystressed. Toobtainthecor- rect setting, use Special Tool LST 122, or a self-man-

ufactured tool using the dimensions illustrated (Fig.

I).

SeeTorqueTightening Specifications in the Prelimi-

nary Pages for the correct torque figures.

b:

w:

2.2 Sealants

One of the specified sealants for use on this engine is the Marston compound known as Hylosil 102, a white amine cure

system rubber. Should this not be available an equivalent amine cure sealant must be used. Under no circumstances

should any acidtoxy cure system be used. Loctite sealants are specified for certain applications. See Service Materials

in the Preliminary Pages for the correct sealant for each application.

Issue 1 August 1994 2

Page 53 of 73

AJ16 Engine Service Manual

CAUTION: The connecting rod bearing nuts, bolts and

main bearing securing bolts MUST be renewed during assembly and torque tightened as de- scribed in Section 2.1, SPS Joint Control Sys- tem.

. Ensuring that the main bearing caps are marked relative

to the cylinder block, remove the main bearing cap bolts

and remove the caps. Carefully

lift out the crankshaft.

Place the crankshaft

on suitable blocks on a bench. Re- move and discard the bearing shells and the thrust

washers. Clean the cylinder block, crankshaft and bearing

caps.

. Check the crankshaft journals for wear and ovality, for tol- erances - see Service Data in the Preliminary Pages.

. If any ofthe dimensions are outside the stated tolerances,

then the Crankshaft must be renewed.

Fit suitable bolts to the oil gallery plugs and pull to remove

(Fig.

1 ). Check all cylinder block oil galleries for cracks and

blockages. Fit new '0' rings to the oil gallew plugs, lubri- cate the '0' rings and fit the plugs to the cylinder block oil

galleries.

Check all bearing housings for cracks, distortion and any

signs of bearing movement, i.e. scoring or overheating,

renew as necessary.

Checkthecylinder block/cylinder head mating surface for

warping, bowing and cracks.

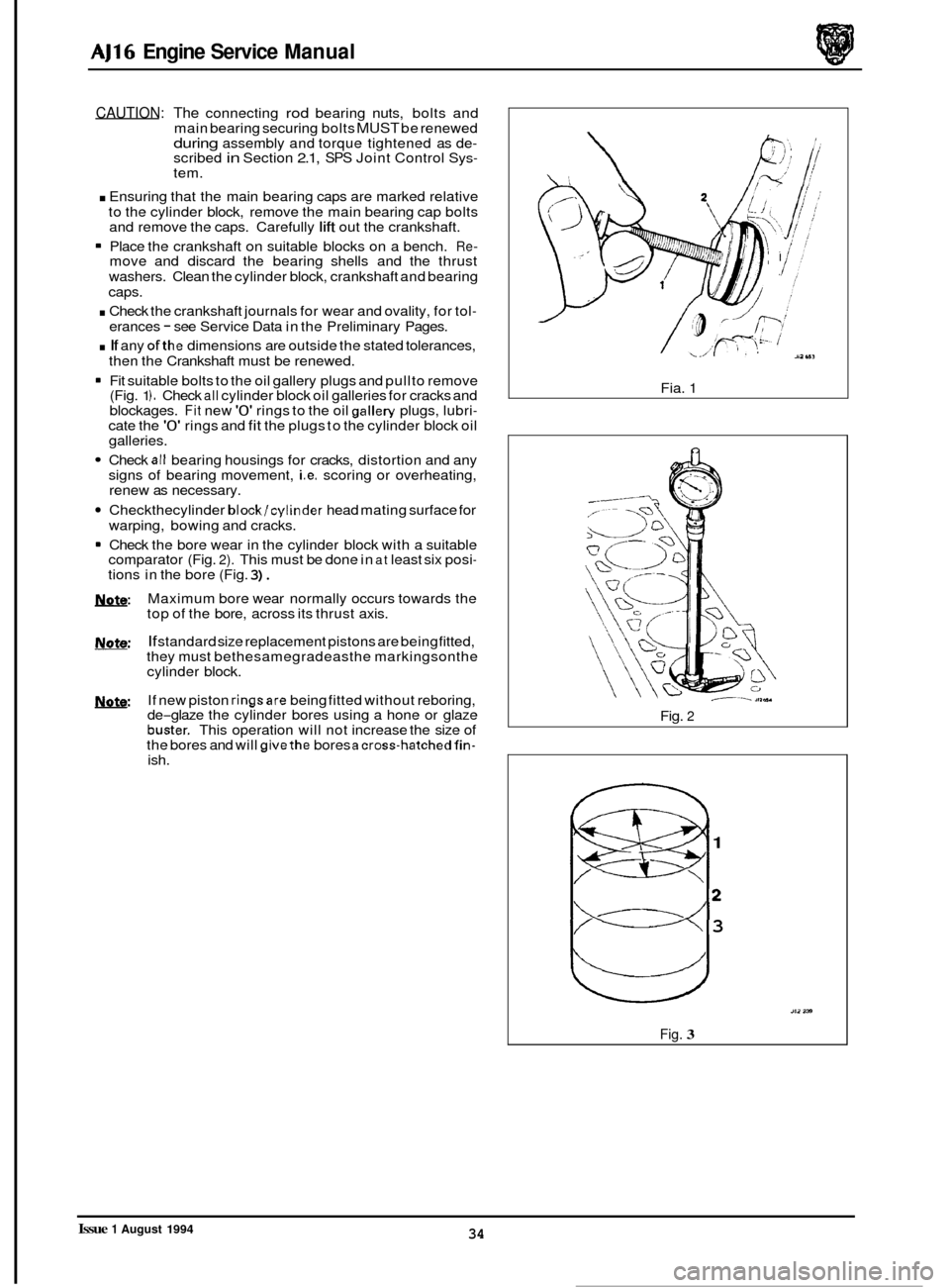

Check the bore wear in the cylinder block with a suitable

comparator (Fig.

2). This must be done in at least six posi- tions in the bore (Fig. 3).

Maximum bore wear normally occurs towards the

top of the bore, across its thrust axis.

If standard size replacement pistons are being fitted,

they must bethesamegradeasthe markingsonthe

cylinder block.

If new piston

ringsare being fitted without reboring,

de-glaze the cylinder bores using a hone or glaze buster. This operation will not increase the size of

the bores and will givethe bores across-hatchedfin- ish.

&&:

m:

b:

Fia. 1

Fig. 2

1

m2 3

,!I 25s

Fig. 3

34 Issue 1 August 1994