engine coolant JAGUAR XJ 1994 2.G AJ16 Engine Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1994, Model line: XJ, Model: JAGUAR XJ 1994 2.GPages: 73, PDF Size: 2.06 MB

Page 21 of 73

AJ16 Engine Service Manual

1.5 Coohg System

The engine is liquid cooled by a mixture of water and anti-freeze circulating around the coolant passages. The coolant

pump is mounted on the left hand side of the cylinder block and is driven from the crankshaft nose by a three point

belt drive (which includes the generator). The pump is a fully assembled bolt

-on unit. The coolant is fed into the cylin- der block at two places via an external delivery pipe. The coolant is drawn from the cylinder head via a self-contained

thermostat housing back to the radiator or recirculated according to the thermostat position.

7.6 Supercharger

The supercharger optionally available on the 4,O liter engine is a Roots blower type which gives better engine efficiency

at part throttle conditions and responsive off

-boost performance. The principal changes to the engine for the super- charged version are to the piston, valve timing, intake manifold and the additional drive to the supercharger. A lower

compression ratio

of 8.5:l is used which provides the optimum balance between high speed performance and fuel

economy.

The engine heat exchanger of the intercooler system is incorporated into the intake manifold. The blower incorporates

an air by

-pass system which improves efficiency under part throttle conditions. The by-pass valve is controlled by a vacuum actuator referenced to the intake manifold pressure.

2. SERVICE PROCEDURES

2.1 SPS )oint Control System

Afeature of the engine is the use of the SPS joint control system on the cylinder head bolts, crankshaft main bearing

bolts and connecting rod bearing nuts and bolts. This system ensures that the joints receive maximum clamp loading

for a given fixing size and type of material by tightening the fixing to its particular yield point. This greatly helps to

prevent premature cylinder head gasket failures.

0

CAUTION: All SPS fixings must be used only once. Discard

fixings on removal and replace with new bolts/

nuts every time a 'strip down' has been carried

out.

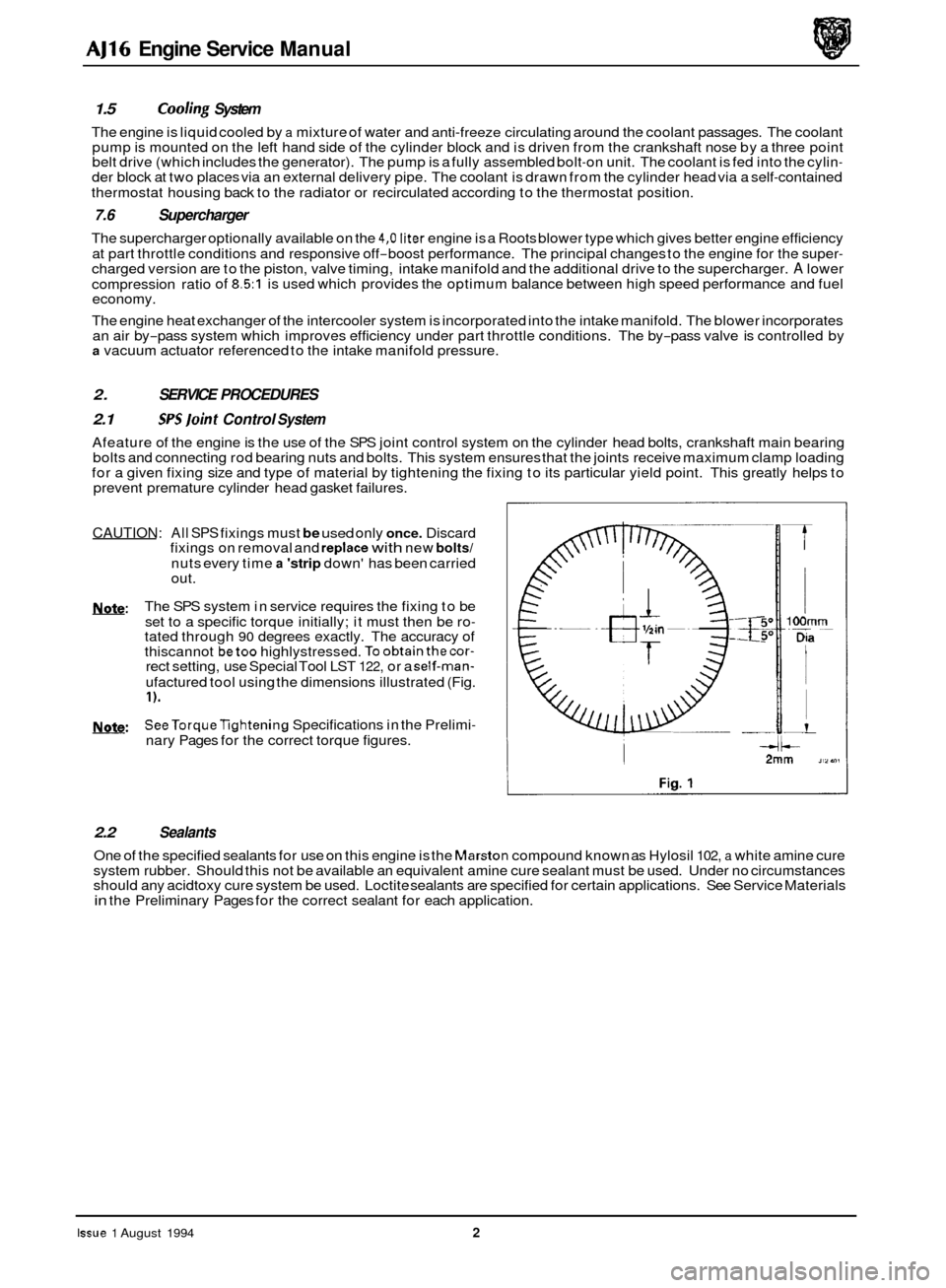

The SPS system in service requires the fixing to be

set to a specific torque initially; it must then be ro

- tated through 90 degrees exactly. The accuracy of

thiscannot betoo highlystressed. Toobtainthecor- rect setting, use Special Tool LST 122, or a self-man-

ufactured tool using the dimensions illustrated (Fig.

I).

SeeTorqueTightening Specifications in the Prelimi-

nary Pages for the correct torque figures.

b:

w:

2.2 Sealants

One of the specified sealants for use on this engine is the Marston compound known as Hylosil 102, a white amine cure

system rubber. Should this not be available an equivalent amine cure sealant must be used. Under no circumstances

should any acidtoxy cure system be used. Loctite sealants are specified for certain applications. See Service Materials

in the Preliminary Pages for the correct sealant for each application.

Issue 1 August 1994 2

Page 22 of 73

AJ16 Engine Service Manual

FAULT DIAGNOSIS

3.1 Introduction

The following diagnostic procedures are provided to assist properly qualified persons to identify and rectify the faults

relating to the engine which are most likely to encountered. Reference is made to the Electrical Diagnostic Manual

(EDM), which should be consulted where necessary. Faults related to the cooling system are dealt with in Section 4.1

and to the fuel system in Section 5.1 in the appropriate Vehicle Service Manual (VSM).

3.2 Diagnostic Procedures

(fails to rotate)

I Engine rotates but 0 I will not fire

I

i

/Overheating

Overheating at tick-

Too cold

Loss of coolant Possible

Cause

Battery leads loose or ter

- minals corroded

Battery discharged

Starter motor inoperative

Starter motor speed too

low

Faulty ignition system

Fuel system defect

Oil requires changing

Worn crankshaft journals

Excessive crankshaft

end- float

Worn main bearing shells

Worn oil pump Oil pressure relief valve stick

- ing open

Oil pressure relief valve

spring too weak

Insufficient oil in oil pan

Engine overheating

Faulty gauge or sensor

Incorrect grade oil (viscosity

too low)

Water in oil Check

Check the condition of the

leads and terminals

Check condition of battery

with hydrometer

If the lights dim when ignition

switch is operated, the starter

may be jammed in starter

ring.

Check for loose and dirty con

- nections to the starter motor

Check battery leads and ter

- minals

Check state of battery charge

Refer to EDM

Remove the spark plugs

Check oil level and color

Listen for rumble or knock

Fit dial gauge and measure

Listen for rumble

Remove oil pump and check

the clearances

Remove valve and check for

sticking

Remove spring and check

spring rates

Check oil level

Refer to EDM

Check oil viscosity

Checkoil level and check if oil

is a milky white color

Check for leaking head gasket Remedy

Clean and tighten as necess

-

ary

Charge or renew battery as

necessary

Remove starter motor, free

off pinion and refit

Clean and tighten connec

- tions

Clean and tighten terminals

Charge or renew battery

as necessary

Rectify as required

Clean and re

-gap the spark

plugs, renew if worn out

Refer to Fuel System fault

finding in Section

5.1, VSM

Refer to Section

4.1, VSM

Refer to Section

4.1, VSM

Refer to Section

4.1, VSM

Refer to Section

4.1, VSM

Change oil and filter

Renew crankshaft

Renew thrust washers

Check crankshaft journals for

wear and renew shells

Renew oil pump

Renew valve

Renew spring

lop-up as required

Refer to Overheating fault

finding in Section

4.1, VSM

Rectify as required

Renew oil and filter

Renew oil and filter

Renew head gasket

Issue 1 August 1994 3

Page 24 of 73

AJ16 Engine Service Manual

Symptom

Joisy chains

)etonation knock pinking)

.oss of power

Gugh running at iormal engine speed Possible

Cause

Low oil pressure

Tensioners not released

Chains worn

Sprockets worn

Tensioner worn

Ignition timing too far ad

- vanced

Head gasket leaking

Fuel

/ air mixture too weak

Engine running

too hot

Valve timing incorrect

Incorrect grade fuel

Burned valves Sticking valves

Poor engine tune

Insufficient valve clearance

Fuel injection fault

Lowcompression in cylinders

Ignition fault

Valve timing incorrect

Partial seizure of engine

Worn

camshaftb)

Incorrect grade fuel

Sticking valves Broken valve springs Piston fault

Leaking head gasket

Valve burned out

Valve seat burned out

Ignition fault

Fuel injection fault

Check

Take reading from oil pres- sure gauge when engine is

hot

Remove camshaft cover and

check tension of chain (top

chain). Remove timing cover

to check bottom chain tension

Visually check

/ remove and

check for wear

Visual check

Visual check

Refer to EDM

Check engine oil level and

checkfor contamination of oil

Pressure test cooling system

and check for contamination

of coolant in header tank

Refer to EDM

Check valve timing

If all other checks

OK, this

could be the cause

Check cylinder compressions

Check cylinder compressions

Refer to EDM

Check valve clearance

Check compressions

Refer to EDM

Check valve timing

Remove spark plugs and ro

- tate crankshaft

Remove

camshaft(s) and

check for wear

If all other checks OK this

could be the cause

Check cylinder compressions

Check cylinder compressions

and for bent valve stems

Check cylinder cornpressions

Check cylinder compressions

Check cylinder compressions

Refer to

EDM

Remedy

Refer to Insufficient Oil Pres- sure fault finding

Insert

3 mm Allen key and

turn tensioner anti-clock- wise, compress tensioner to

release bottom chain

Renew as necessary

Renew as necessary

Renew as necessary

Rectify as required

Renew head gasket

Rectify

as required

Refer

to Overheating fault

finding in Section 4.1, VSM

Adjust valve timing

Drain fuel tank and refill with

correct grade fuel

Remove cylinder head and

renew valves

Remove cylinder head and

renew valves

/ guides or

springs

Rectify as required

Adjust as necessary

Refer to Fuel System fault

finding in Section 5.1, VSM

Rebore

1 re-ring as necessary

Rectify as required

Adjust valve timing

Overhaul engine as required

Renew

camshaft(s)

Drain fuel tank and refill with

correct grade fuel

Renew valve, springs or

guides

Renew valve springs and

valves as required

Renew pistons

Refer to Detonation Knock

fault finding

Renew valve

Re

-cut or renew valve seat

Rectify as required

Refer to Fuel System fault

Tindim in Section 5.1, VSM

issue 1 August 1994 5

Page 52 of 73

AJ16 Engine Service Manual

4.18 &;ne Assembly, Overhaul

SRO 12.41.05

. Remove the engine and transmission unit, see Section 3.1

. Remove the transmission unit from the engine.

. Fit the engine to a stand.

. Place a drain tray belowthe cylinder block drain plug and

Overhaul the cylinder head, see Section 4.5.

1 Remove the oil pan, see Section 4.27.

. Remove the oil pump, see Section 4.31.

. Remove the windage trays.

. Clean all components, check for damage and wear and

. Remove the rear oil seal housing, see Section 4.1 4.

. Remove the timing cover assembly.

1 Remove the pedestal bolts and tab washer.

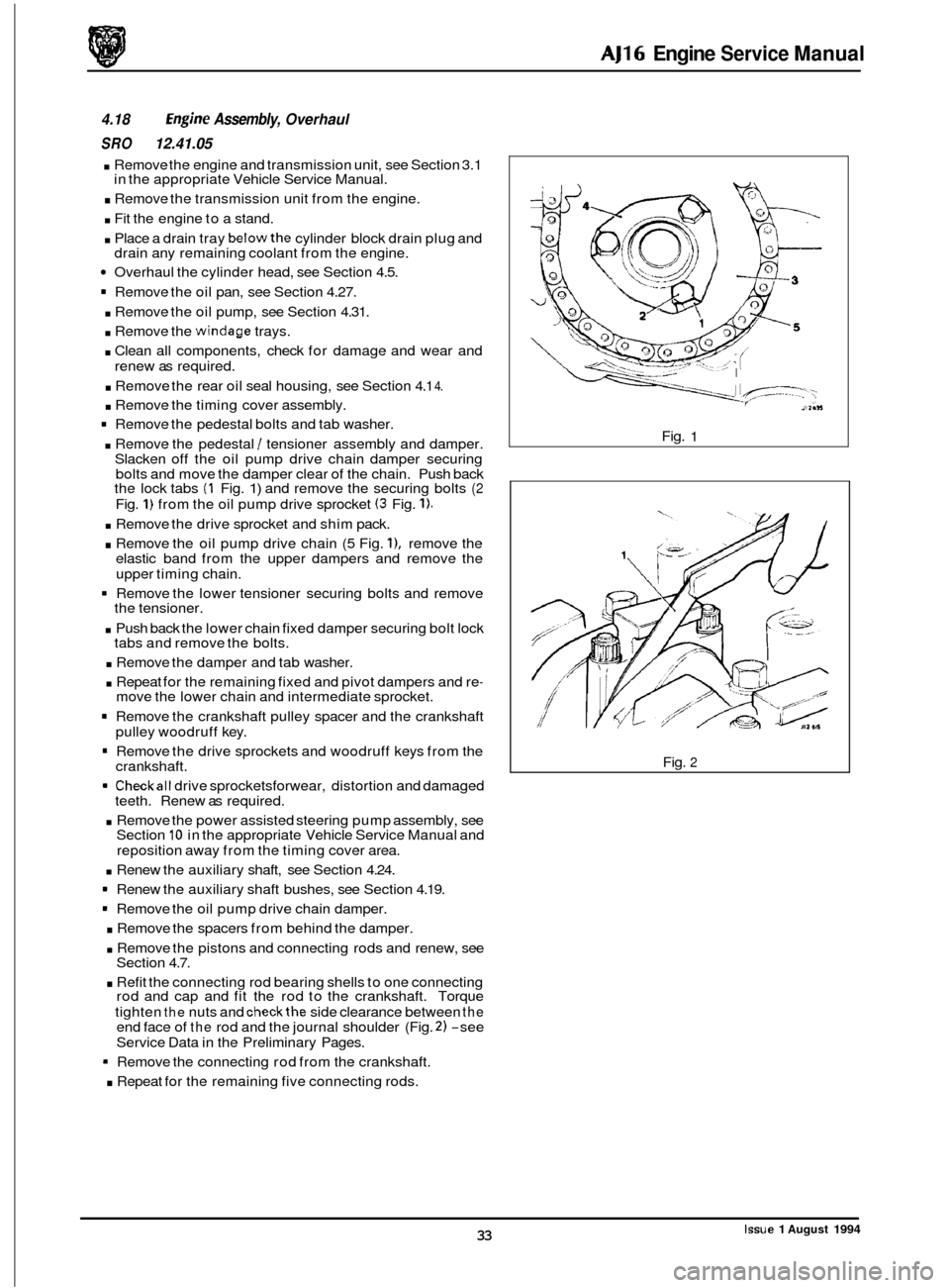

. Remove the pedestal / tensioner assembly and damper.

Slacken off the oil pump drive chain damper securing

bolts and move the damper clear of the chain. Push back

the lock tabs

(1 Fig. 1) and remove the securing bolts (2

Fig. 1) from the oil pump drive sprocket (3 Fig. 1).

in the appropriate Vehicle Service Manual.

drain any remaining coolant from the engine.

renew as required.

. Remove the drive sprocket and shim pack.

. Remove the oil pump drive chain (5 Fig. l), remove the

elastic band from the upper dampers and remove the

upper timing chain.

1 Remove the lower tensioner securing bolts and remove

the tensioner.

. Push back the lower chain fixed damper securing bolt lock

tabs and remove the bolts.

. Remove the damper and tab washer.

. Repeat for the remaining fixed and pivot dampers and re- move the lower chain and intermediate sprocket.

Remove the crankshaft pulley spacer and the crankshaft

pulley woodruff key.

= Remove the drive sprockets and woodruff keys from the

crankshaft.

1 Checkall drive sprocketsforwear, distortion and damaged

teeth. Renew as required.

. Remove the power assisted steering pump assembly, see

Section 10 in the appropriate Vehicle Service Manual and

reposition away from the timing cover area.

. Renew the auxiliary shaft, see Section 4.24.

1 Renew the auxiliary shaft bushes, see Section 4.19.

1 Remove the oil pump drive chain damper.

. Remove the spacers from behind the damper.

. Remove the pistons and connecting rods and renew, see

Section 4.7.

. Refit the connecting rod bearing shells to one connecting

rod and cap and fit the rod to the crankshaft. Torque

tighten

the nuts and checkthe side clearance between the end face of the rod and the journal shoulder (Fig. 2) -see

Service Data in the Preliminary Pages.

Remove the connecting rod from the crankshaft.

. Repeat for the remaining five connecting rods. Fig.

1

Fig. 2

Issue 1 August 1994 33