ignition JAGUAR XJ 1994 2.G AJ16 Engine Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1994, Model line: XJ, Model: JAGUAR XJ 1994 2.GPages: 73, PDF Size: 2.06 MB

Page 14 of 73

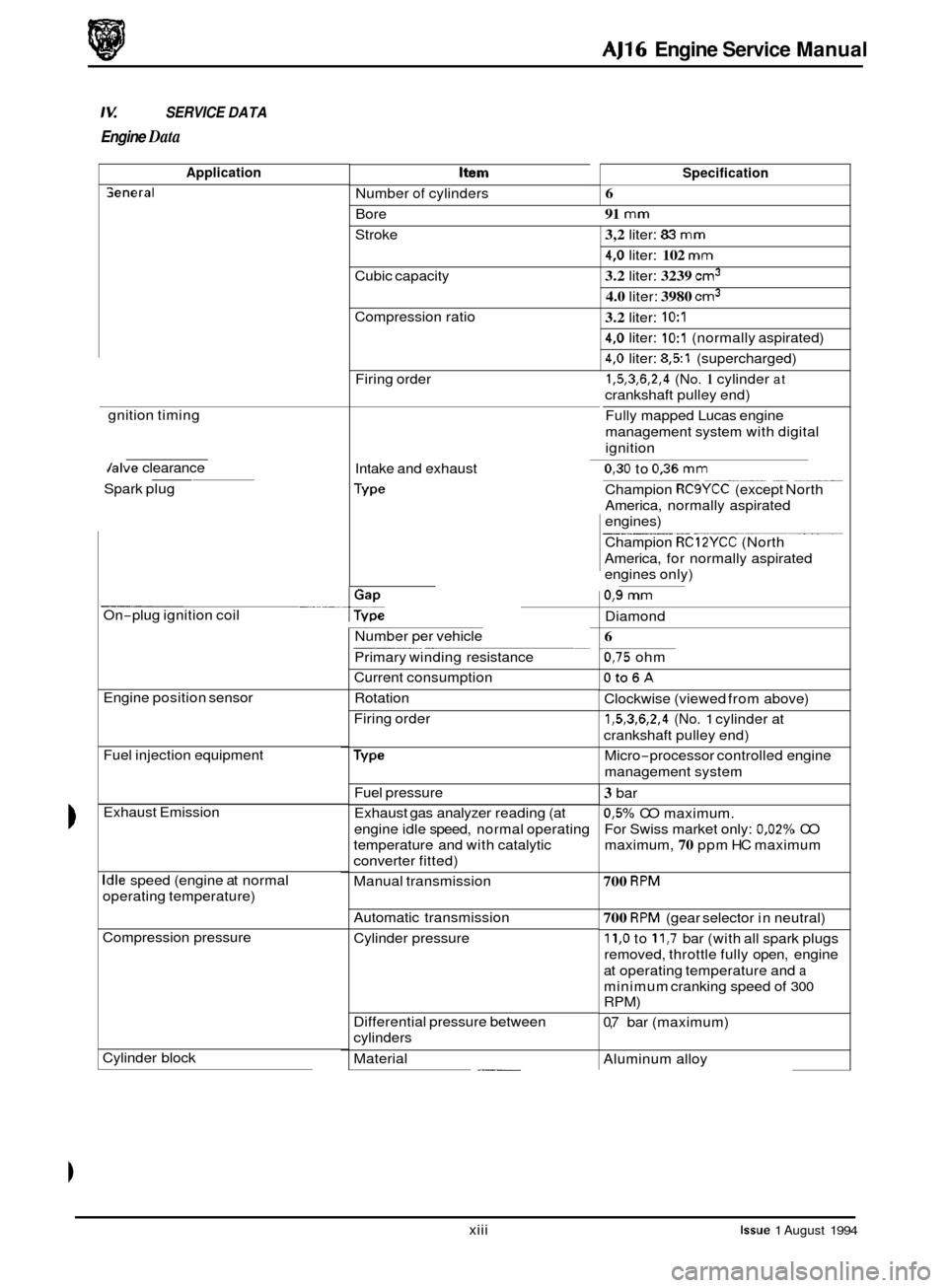

AJ16 Engine Service Manual

SERVICE DATA

Engine Data

Application Item

Number of cylinders

Bore

Specification

Seneral 6

91

mm

Stroke 3,2 liter: 83 mm

4,O liter: 102 mm

3.2 liter: 3239 cm3

4.0 liter: 3980 cm3

Cubic capacity

Compression ratio

3.2 liter: 1O:l

4,O liter: 1O:l (normally aspirated)

4,O liter: 8,51 (supercharged)

1,5,3,6,2,4 (No. 1 cylinder at

crankshaft pulley end)

Fully mapped Lucas engine

management system with digital

ignition

Firing

order

gnition timing

0

0

0

Jalve clearance

Intake and exhaust 0,30 to 0,36 mm

Champion RCSYCC (except North

America, normally aspirated

engines)

Champion

RC12YCC (North

America, for normally aspirated

engines only)

__ ~ ~

--__ ~~

Spark

plug

0,9 mm

On-plug ignition coil

Diamond

Number per vehicle

Primary winding resistance

Current consumption ~ ~~

6

0,75 ohm

Oto6A

Clockwise

(viewed from above)

1,5,3,6,2,4 (No. 1 cylinder at

crankshaft pulley end)

-

Engine position sensor

Fuel injection equipment

Exhaust Emission Rotation

Firing order

Micro

-processor controlled engine

management system

Fuel pressure

Exhaust gas analyzer reading (at

engine idle speed, normal operating

temperature and with catalytic

converter fitted)

3 bar

0,5% CO maximum.

For Swiss market only:

0,02% CO

maximum,

70 ppm HC maximum

Idle speed (engine at normal

operating temperature) Manual transmission 700 RPM

Automatic

transmission 700 RPM (gear selector in neutral)

11,O to 11,7 bar (with all spark plugs

removed, throttle fully open, engine

at operating temperature and

a

minimum cranking speed of 300

RPM)

0,7 bar (maximum)

Compression pressure

Cylinder pressure

Differential pressure between

cylinders

Aluminum alloy

Cylinder block

. ___ Material

xiii

Issue 1 August 1994

Page 22 of 73

AJ16 Engine Service Manual

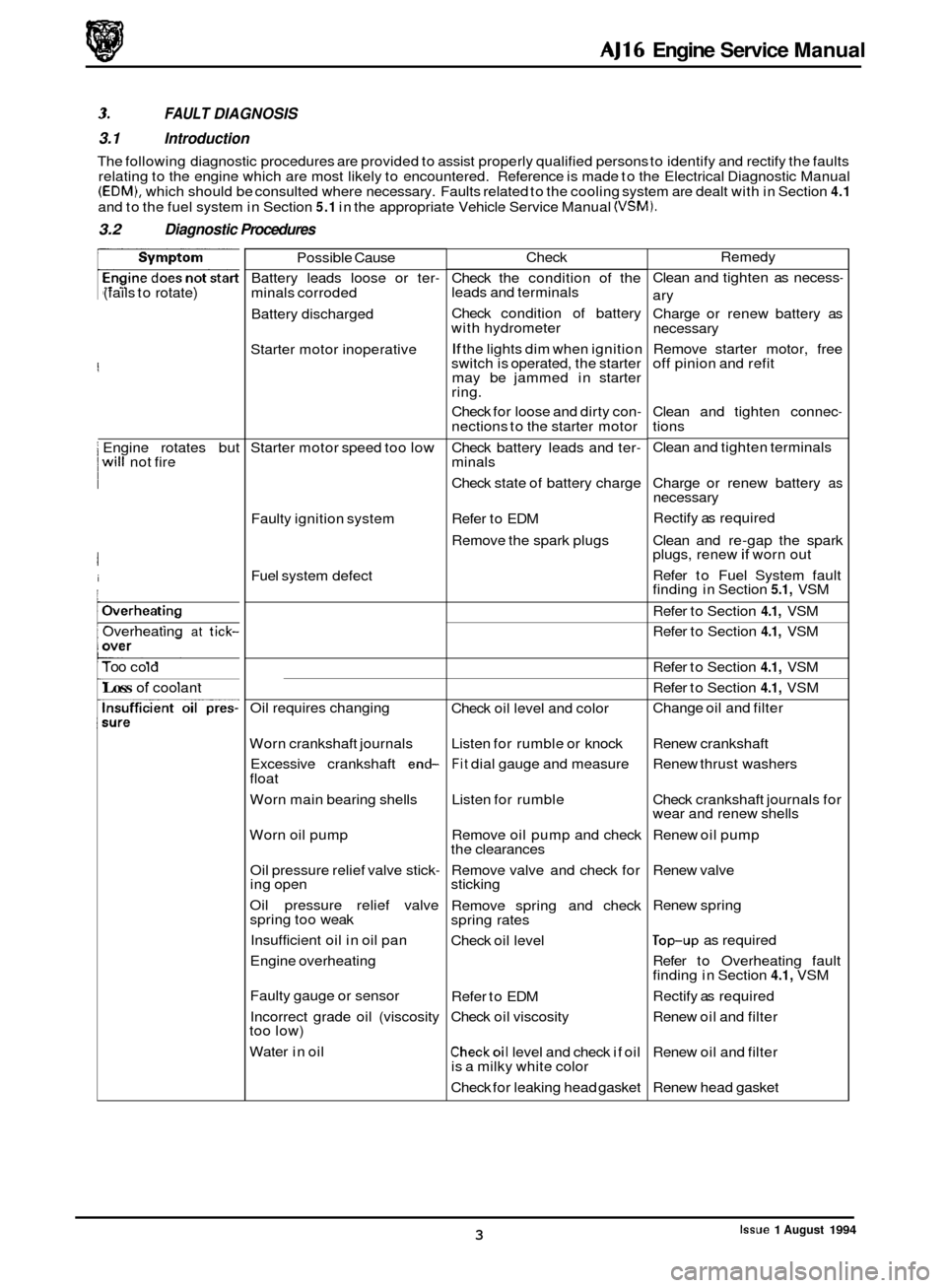

FAULT DIAGNOSIS

3.1 Introduction

The following diagnostic procedures are provided to assist properly qualified persons to identify and rectify the faults

relating to the engine which are most likely to encountered. Reference is made to the Electrical Diagnostic Manual

(EDM), which should be consulted where necessary. Faults related to the cooling system are dealt with in Section 4.1

and to the fuel system in Section 5.1 in the appropriate Vehicle Service Manual (VSM).

3.2 Diagnostic Procedures

(fails to rotate)

I Engine rotates but 0 I will not fire

I

i

/Overheating

Overheating at tick-

Too cold

Loss of coolant Possible

Cause

Battery leads loose or ter

- minals corroded

Battery discharged

Starter motor inoperative

Starter motor speed too

low

Faulty ignition system

Fuel system defect

Oil requires changing

Worn crankshaft journals

Excessive crankshaft

end- float

Worn main bearing shells

Worn oil pump Oil pressure relief valve stick

- ing open

Oil pressure relief valve

spring too weak

Insufficient oil in oil pan

Engine overheating

Faulty gauge or sensor

Incorrect grade oil (viscosity

too low)

Water in oil Check

Check the condition of the

leads and terminals

Check condition of battery

with hydrometer

If the lights dim when ignition

switch is operated, the starter

may be jammed in starter

ring.

Check for loose and dirty con

- nections to the starter motor

Check battery leads and ter

- minals

Check state of battery charge

Refer to EDM

Remove the spark plugs

Check oil level and color

Listen for rumble or knock

Fit dial gauge and measure

Listen for rumble

Remove oil pump and check

the clearances

Remove valve and check for

sticking

Remove spring and check

spring rates

Check oil level

Refer to EDM

Check oil viscosity

Checkoil level and check if oil

is a milky white color

Check for leaking head gasket Remedy

Clean and tighten as necess

-

ary

Charge or renew battery as

necessary

Remove starter motor, free

off pinion and refit

Clean and tighten connec

- tions

Clean and tighten terminals

Charge or renew battery

as necessary

Rectify as required

Clean and re

-gap the spark

plugs, renew if worn out

Refer to Fuel System fault

finding in Section

5.1, VSM

Refer to Section

4.1, VSM

Refer to Section

4.1, VSM

Refer to Section

4.1, VSM

Refer to Section

4.1, VSM

Change oil and filter

Renew crankshaft

Renew thrust washers

Check crankshaft journals for

wear and renew shells

Renew oil pump

Renew valve

Renew spring

lop-up as required

Refer to Overheating fault

finding in Section

4.1, VSM

Rectify as required

Renew oil and filter

Renew oil and filter

Renew head gasket

Issue 1 August 1994 3

Page 24 of 73

AJ16 Engine Service Manual

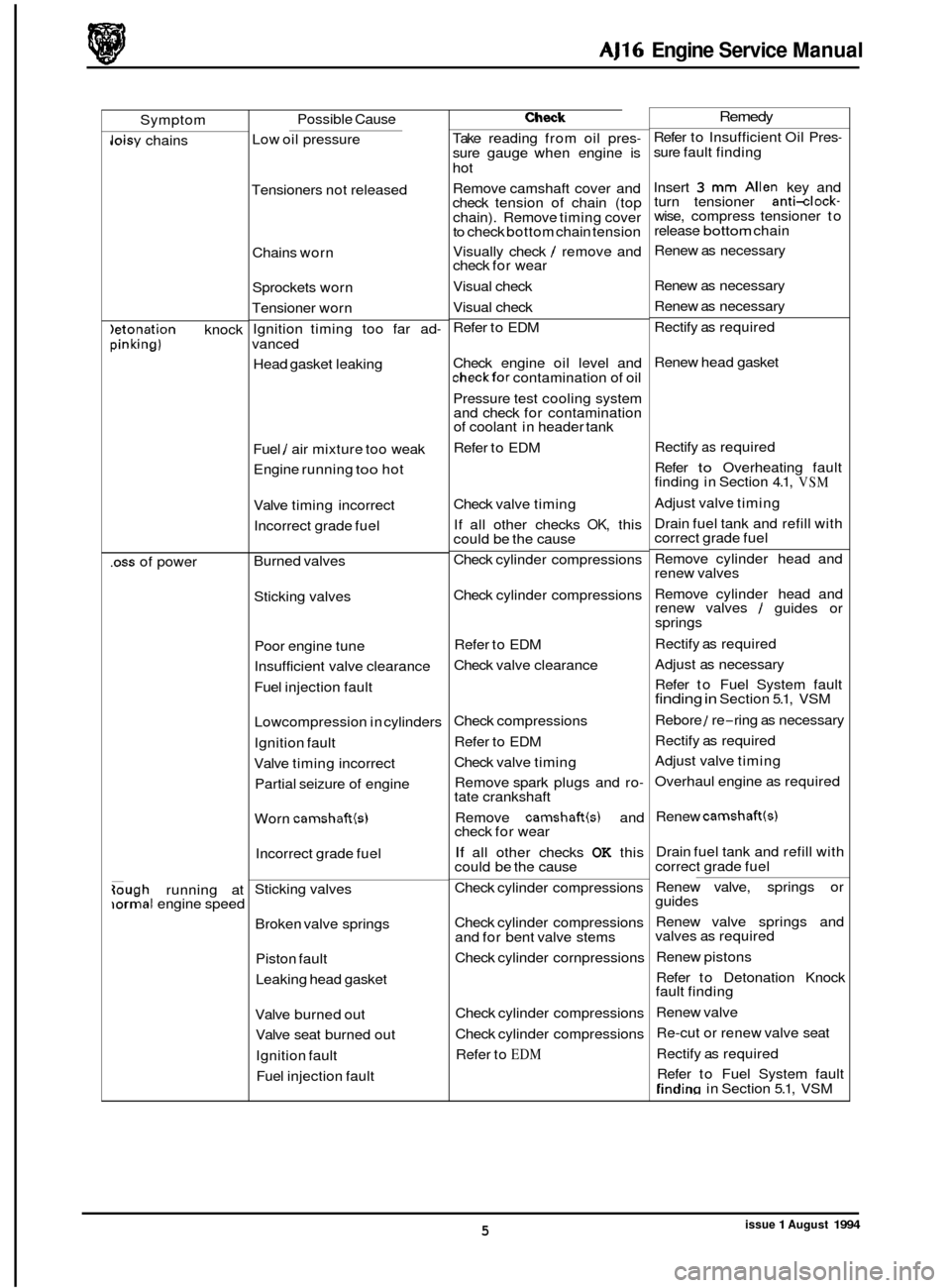

Symptom

Joisy chains

)etonation knock pinking)

.oss of power

Gugh running at iormal engine speed Possible

Cause

Low oil pressure

Tensioners not released

Chains worn

Sprockets worn

Tensioner worn

Ignition timing too far ad

- vanced

Head gasket leaking

Fuel

/ air mixture too weak

Engine running

too hot

Valve timing incorrect

Incorrect grade fuel

Burned valves Sticking valves

Poor engine tune

Insufficient valve clearance

Fuel injection fault

Lowcompression in cylinders

Ignition fault

Valve timing incorrect

Partial seizure of engine

Worn

camshaftb)

Incorrect grade fuel

Sticking valves Broken valve springs Piston fault

Leaking head gasket

Valve burned out

Valve seat burned out

Ignition fault

Fuel injection fault

Check

Take reading from oil pres- sure gauge when engine is

hot

Remove camshaft cover and

check tension of chain (top

chain). Remove timing cover

to check bottom chain tension

Visually check

/ remove and

check for wear

Visual check

Visual check

Refer to EDM

Check engine oil level and

checkfor contamination of oil

Pressure test cooling system

and check for contamination

of coolant in header tank

Refer to EDM

Check valve timing

If all other checks

OK, this

could be the cause

Check cylinder compressions

Check cylinder compressions

Refer to EDM

Check valve clearance

Check compressions

Refer to EDM

Check valve timing

Remove spark plugs and ro

- tate crankshaft

Remove

camshaft(s) and

check for wear

If all other checks OK this

could be the cause

Check cylinder compressions

Check cylinder compressions

and for bent valve stems

Check cylinder cornpressions

Check cylinder compressions

Check cylinder compressions

Refer to

EDM

Remedy

Refer to Insufficient Oil Pres- sure fault finding

Insert

3 mm Allen key and

turn tensioner anti-clock- wise, compress tensioner to

release bottom chain

Renew as necessary

Renew as necessary

Renew as necessary

Rectify as required

Renew head gasket

Rectify

as required

Refer

to Overheating fault

finding in Section 4.1, VSM

Adjust valve timing

Drain fuel tank and refill with

correct grade fuel

Remove cylinder head and

renew valves

Remove cylinder head and

renew valves

/ guides or

springs

Rectify as required

Adjust as necessary

Refer to Fuel System fault

finding in Section 5.1, VSM

Rebore

1 re-ring as necessary

Rectify as required

Adjust valve timing

Overhaul engine as required

Renew

camshaft(s)

Drain fuel tank and refill with

correct grade fuel

Renew valve, springs or

guides

Renew valve springs and

valves as required

Renew pistons

Refer to Detonation Knock

fault finding

Renew valve

Re

-cut or renew valve seat

Rectify as required

Refer to Fuel System fault

Tindim in Section 5.1, VSM

issue 1 August 1994 5

Page 25 of 73

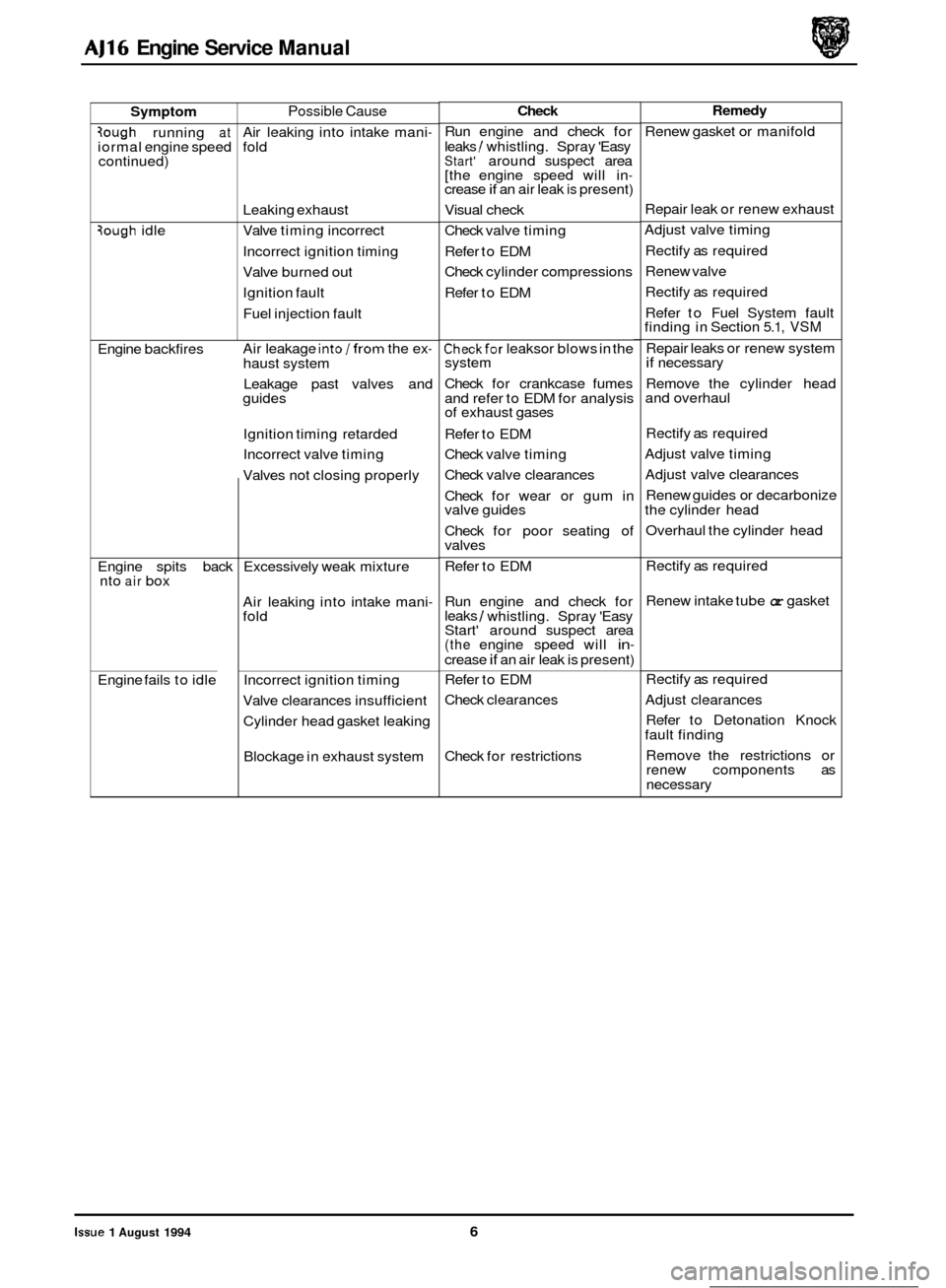

AJ16 Engine Service Manual

Symptom

3ough running at iormal engine speed

continued)

3ough idle

Engine backfires

Engine spits back

nto

air box

Engine fails to idle

Possible Cause

Air leaking into intake mani- fold

Leaking exhaust

Valve timing incorrect

Incorrect ignition timing

Valve burned out

Ignition fault

Fuel injection fault

Air leakage

intolfrom the ex- haust system

Leakage past valves and

guides

Ignition timing retarded

Incorrect valve timing

Valves not closing properly

Excessively weak mixture

Air leaking into intake mani

- fold

Incorrect ignition timing

Valve clearances insufficient

Cylinder head gasket leaking

Blockage in exhaust system

Check

Run engine and check for

leaks / whistling. Spray 'Easy Start' around suspect area

[the engine speed will in- crease if an air leak is present)

Visual check

Check valve timing

Refer to EDM

Check cylinder compressions

Refer to EDM

Checkfor leaksor blows in the

system

Check for crankcase fumes

and refer to EDM for analysis

of exhaust gases

Refer to EDM

Check valve timing

Check valve clearances

Check for wear or gum in

valve guides

Check for poor seating of

valves

Refer to EDM

Run engine and check for

leaks

/ whistling. Spray 'Easy

Start' around suspect area

(the engine speed will in- crease if an air leak is present)

Refer to EDM

Check clearances

Check for restrictions

Remedy

Renew gasket or manifold

Repair leak or renew exhaust

Adjust valve timing

Rectify as required

Renew valve

Rectify as required

Refer to Fuel System fault

finding in Section

5.1, VSM

Repair leaks or renew system if necessary

Remove the cylinder head

and overhaul

Rectify as required

Adjust valve timing

Adjust valve clearances

Renew guides or decarbonize

the cylinder head

Overhaul the cylinder head

Rectify as required

Renew intake tube

or gasket

Rectify as required

Adjust clearances

Refer to Detonation Knock

fault finding

Remove the restrictions or

renew components as

necessary

Issue 1 August 1994 6