run flat JAGUAR XJ 1994 2.G AJ16 Engine Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1994, Model line: XJ, Model: JAGUAR XJ 1994 2.GPages: 73, PDF Size: 2.06 MB

Page 40 of 73

AJ16 Engine Service Manual

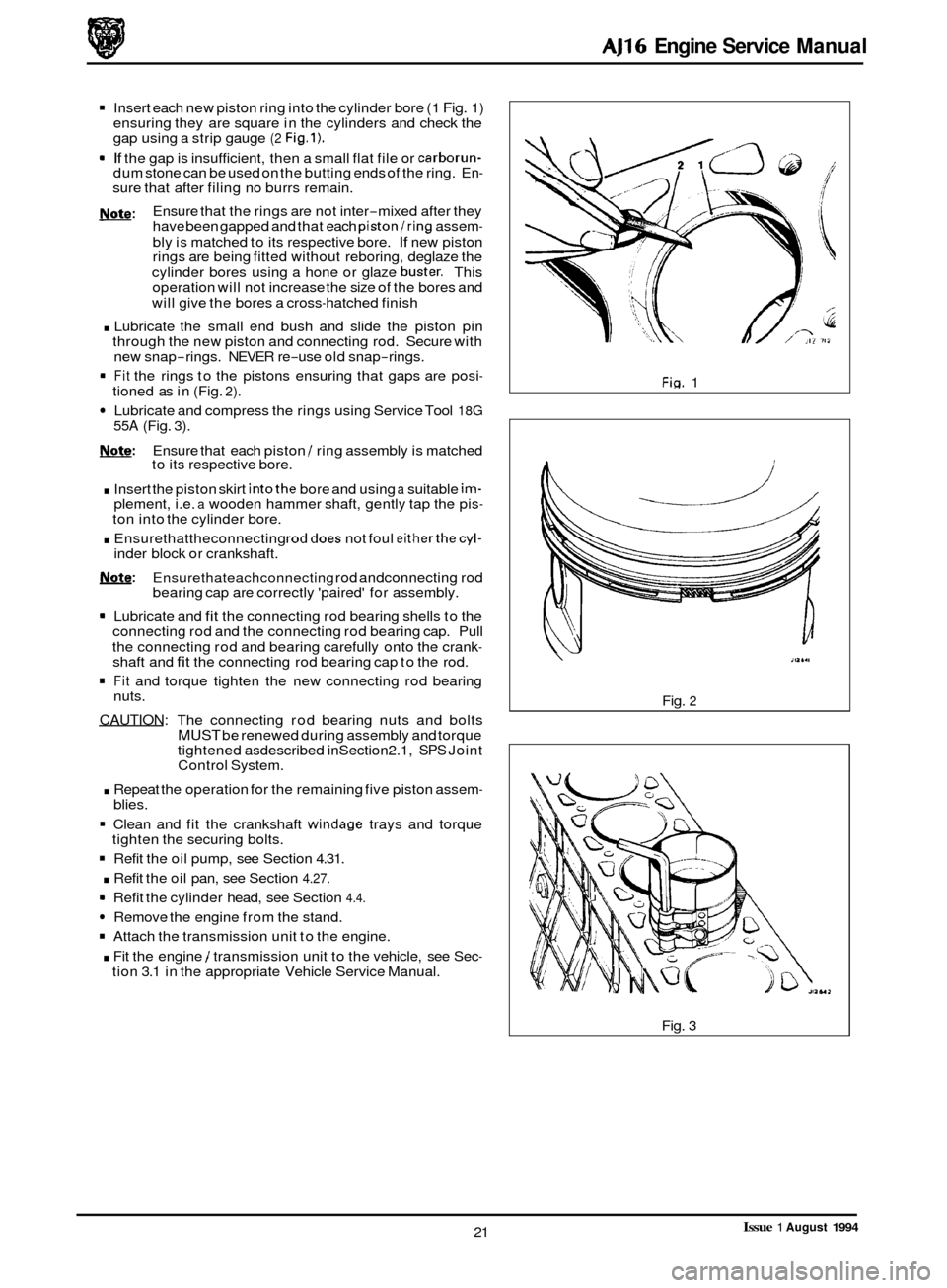

Insert each new piston ring into the cylinder bore (1 Fig. 1)

ensuring they are square in the cylinders and check the

gap using a strip gauge

(2 Fig.1).

9 If the gap is insufficient, then a small flat file or carborun- dum stone can be used on the butting ends of the ring. En- sure that after filing no burrs remain.

Ensure that the rings are not inter

-mixed after they

have been gapped and that each piston/ring assem-

bly is matched to its respective bore. If new piston

rings are being fitted without reboring, deglaze the

cylinder bores using a hone or glaze

buster. This

operation will not increase the size of the bores and

will give the bores a cross

-hatched finish

. Lubricate the small end bush and slide the piston pin

through the new piston and connecting rod. Secure with

new snap

-rings. NEVER re-use old snap-rings.

Fit the rings to the pistons ensuring that gaps are posi- tioned as in (Fig. 2).

Lubricate and compress the rings using Service Tool 18G 55A (Fig. 3).

w:

b: Ensure that each piston / ring assembly is matched

to its respective bore.

. Insert the piston skirt intothe bore and using a suitable im- 0

plement, i.e. a wooden hammer shaft, gently tap the pis- ton into the cylinder bore.

. Ensurethattheconnecting roddoes not foul eitherthecyl- inder block or crankshaft.

Note: Ensurethateachconnecting rod andconnecting rod

m Lubricate and fit the connecting rod bearing shells to the

connecting rod and the connecting rod bearing cap. Pull

the connecting rod and bearing carefully onto the crank

- shaft and fit the connecting rod bearing cap to the rod.

Fit and torque tighten the new connecting rod bearing

nuts.

CAUTION: The connecting rod bearing nuts and bolts MUST be renewed during assembly and torque

tightened asdescribed inSection2.1, SPS Joint

Control System.

. Repeat the operation for the remaining five piston assem-

bearing cap are correctly 'paired' for assembly.

blies.

Clean and fit the crankshaft

windage trays and torque

-

0 - - tighten the securing bolts.

Refit the oil pump, see Section 4.31.

. Refit the oil pan, see Section 4.27.

Refit the cylinder head, see Section 4.4.

Remove the engine from the stand.

Attach the transmission unit to the engine.

. Fit the engine / transmission unit to the vehicle, see Sec- tion 3.1 in the appropriate Vehicle Service Manual.

Fin. 1

itl6.l

Fig. 2

Fig. 3

Issue 1 August 1994 21

Page 54 of 73

AJ16 Engine Service Manual

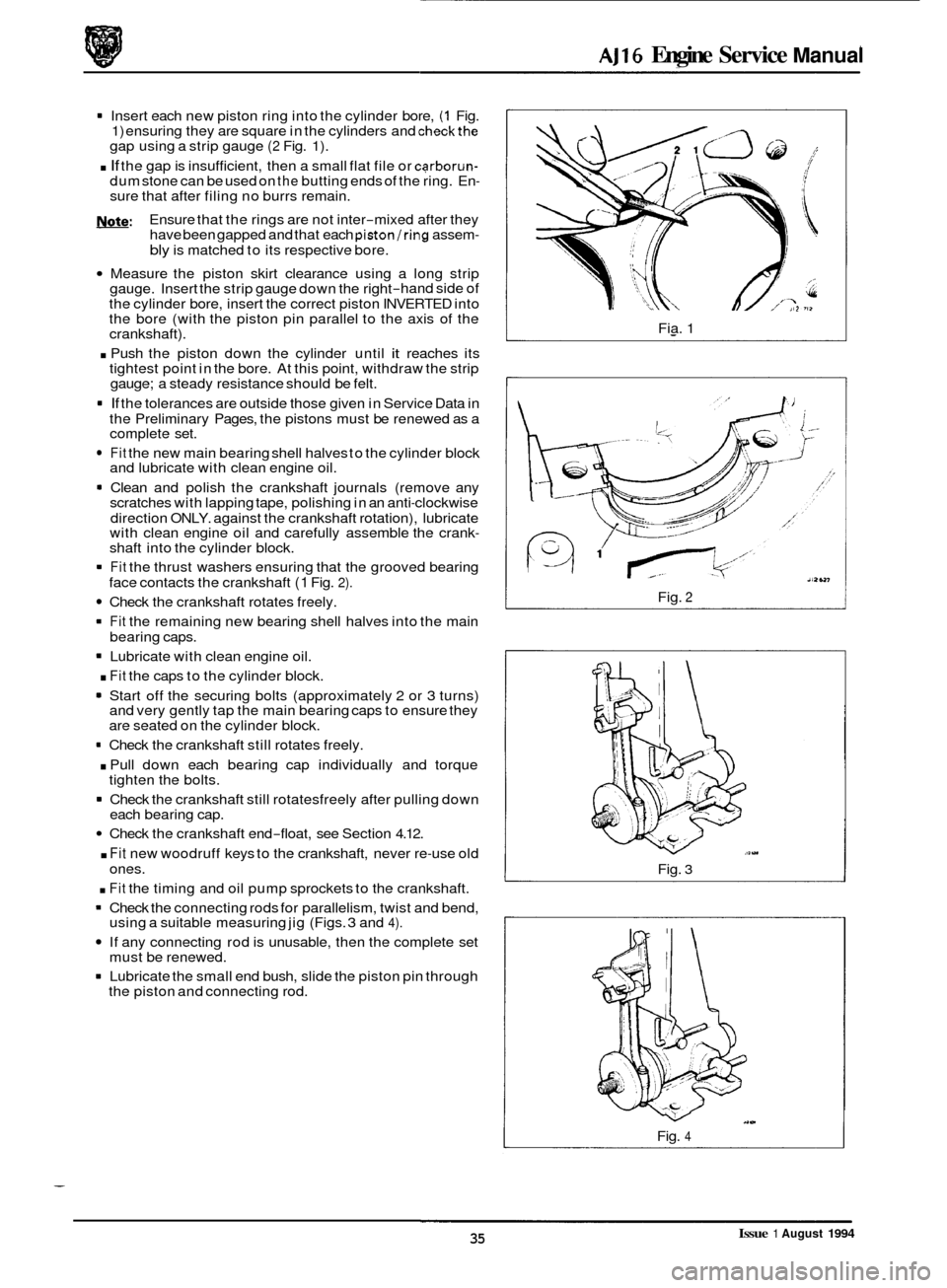

0 1 Insert each new piston ring into the cylinder bore, (1 Fig. 1) ensuring they are square in the cylinders and checkthe gap using a strip gauge (2 Fig. 1).

. If the gap is insufficient, then a small flat file or carborun- dum stone can be used on the butting ends of the ring. En- sure that after filing no burrs remain.

Ensure that the rings are not inter

-mixed after they

have been gapped and that each piston/ring assem- bly is matched to its respective bore.

Measure the piston skirt clearance using a long strip

gauge. Insert the strip gauge down the right-hand side of

the cylinder bore, insert the correct piston INVERTED into

the bore (with the piston pin parallel to the axis of the

crankshaft).

. Push the piston down the cylinder until it reaches its

tightest point in the bore. At this point, withdraw the strip

gauge; a steady resistance should be felt.

1 If the tolerances are outside those given in Service Data in

the Preliminary Pages, the pistons must be renewed as a

complete set.

Note:

0

Fit the new main bearing shell halves to the cylinder block

and lubricate with clean engine oil.

1 Clean and polish the crankshaft journals (remove any

scratches with lapping tape, polishing in an anti-clockwise

direction ONLY. against the crankshaft rotation), lubricate

with clean engine oil and carefully assemble the crank

- shaft into the cylinder block.

1 Fit the thrust washers ensuring that the grooved bearing

Check the crankshaft rotates freely.

1 Fit the remaining new bearing shell halves into the main

1 Lubricate with clean engine oil.

. Fit the caps to the cylinder block.

1 Start off the securing bolts (approximately 2 or 3 turns)

and very gently tap the main bearing caps to ensure they

are seated on the cylinder block.

face contacts

the crankshaft

(1 Fig. 2).

bearing caps.

= Check the crankshaft still rotates freely.

. Pull down each bearing cap individually and torque

1 Check the crankshaft still rotatesfreely after pulling down

tighten

the bolts.

each bearing cap.

Check the crankshaft end-float, see Section 4.12.

. Fit new woodruff keys to the crankshaft, never re-use old

. Fit the timing and oil pump sprockets to the crankshaft.

1 Check the connecting rods for parallelism, twist and bend,

If any connecting rod is unusable, then the complete set

1 Lubricate the small end bush, slide the piston pin through

ones.

using

a suitable measuring jig (Figs.

3 and 4).

must be renewed.

the piston and connecting rod. Fia.

1

Fig. 2

Fig. 3

Fig. 4

Issue 1 August 1994 35