torque JAGUAR XJ 1994 2.G ZF Automatic Transmission Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1994, Model line: XJ, Model: JAGUAR XJ 1994 2.GPages: 74, PDF Size: 2.66 MB

Page 42 of 74

ZF Automatic Transmissions Service Manual

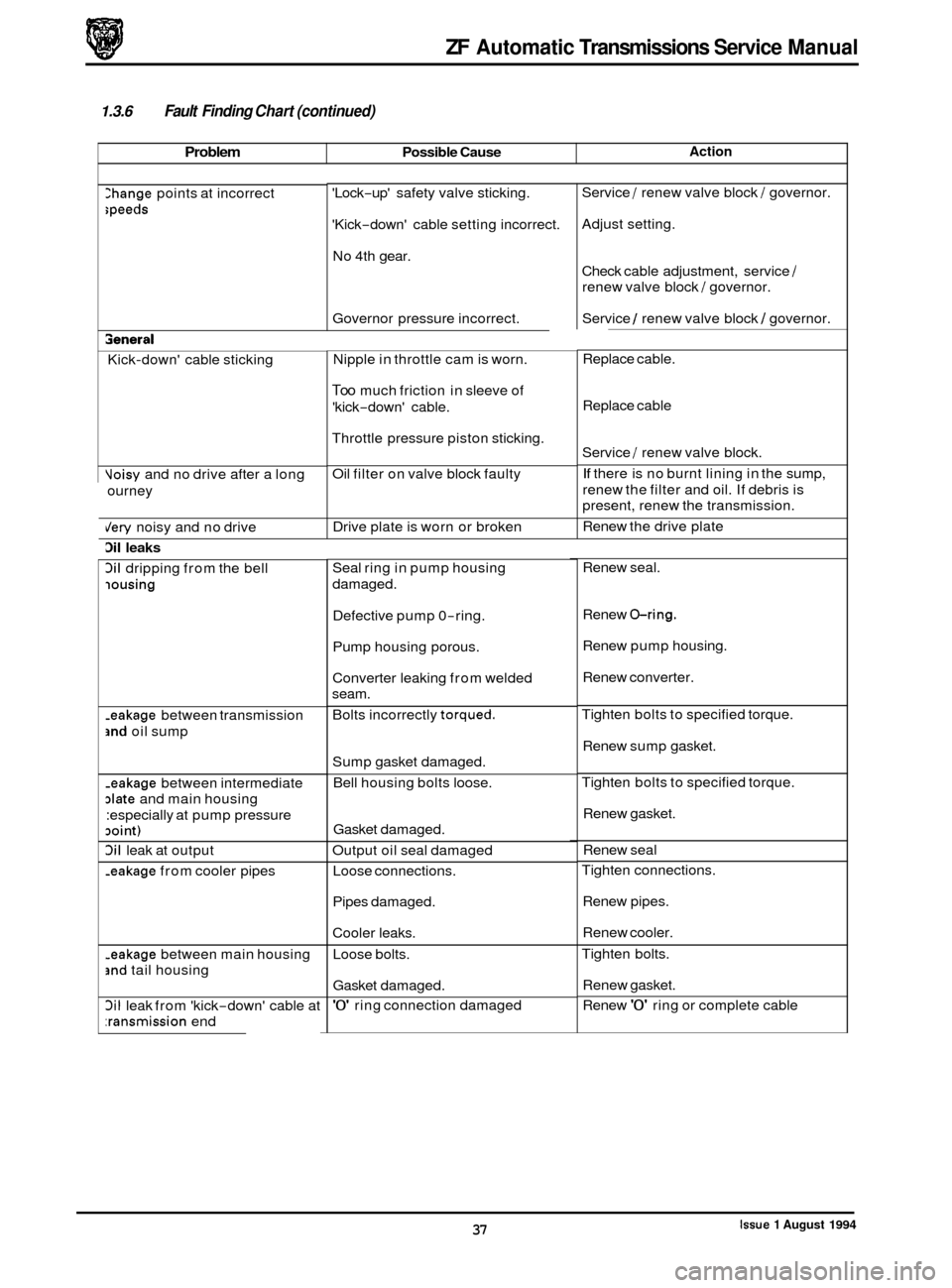

Problem Possible Cause

1.3.6 Fault Finding Chart (continued)

Action

>hange points at incorrect

;peeds

3eneral

Kick-down' cable sticking

Voisy and no drive after a long

ourney

dery noisy and no drive

3il leaks

3il dripping from the bell

iousing

-eakage between transmission

and oil sump

-eakage between intermediate

date and main housing

:especially at pump pressure

Doint)

3il leak at output

-eakage from cooler pipes

-eakage between main housing

jnd tail housing

3il leak from 'kick-down' cable at

:ransmission end 'Lock

-up'

safety valve sticking.

'Kick

-down' cable setting incorrect.

No 4th gear.

Governor pressure incorrect.

Nipple in throttle cam is worn.

Too much friction in sleeve of

'kick

-down' cable.

Throttle pressure piston sticking.

Oil filter on valve block faulty

Drive plate is worn or broken

Seal ring in pump housing

damaged.

Defective pump 0

-ring.

Pump housing porous.

Converter leaking from welded

seam.

Bolts incorrectly

torqued.

Sump gasket damaged.

Bell housing bolts loose.

Gasket damaged.

Output oil seal damaged

Loose connections.

Pipes damaged.

Cooler leaks.

Loose bolts.

Gasket damaged.

'0' ring connection damaged Service

/ renew valve

block / governor.

Adjust setting.

Check cable adjustment, service

/

renew valve block / governor.

Service

1 renew valve block I governor.

Replace cable.

Replace cable

Service

/ renew valve block.

If there is no burnt lining in the sump,

renew the filter and oil. If debris is

present, renew the transmission.

Renew the drive plate

Renew seal.

Renew

@ring.

Renew pump housing.

Renew converter.

Tighten bolts to specified torque.

Renew sump gasket.

Tighten bolts to specified torque.

Renew gasket.

Renew seal

Tighten connections.

Renew pipes.

Renew cooler.

Tighten bolts.

Renew gasket.

Renew

'0' ring or complete cable

issue 1 August 1994 37

Page 43 of 74

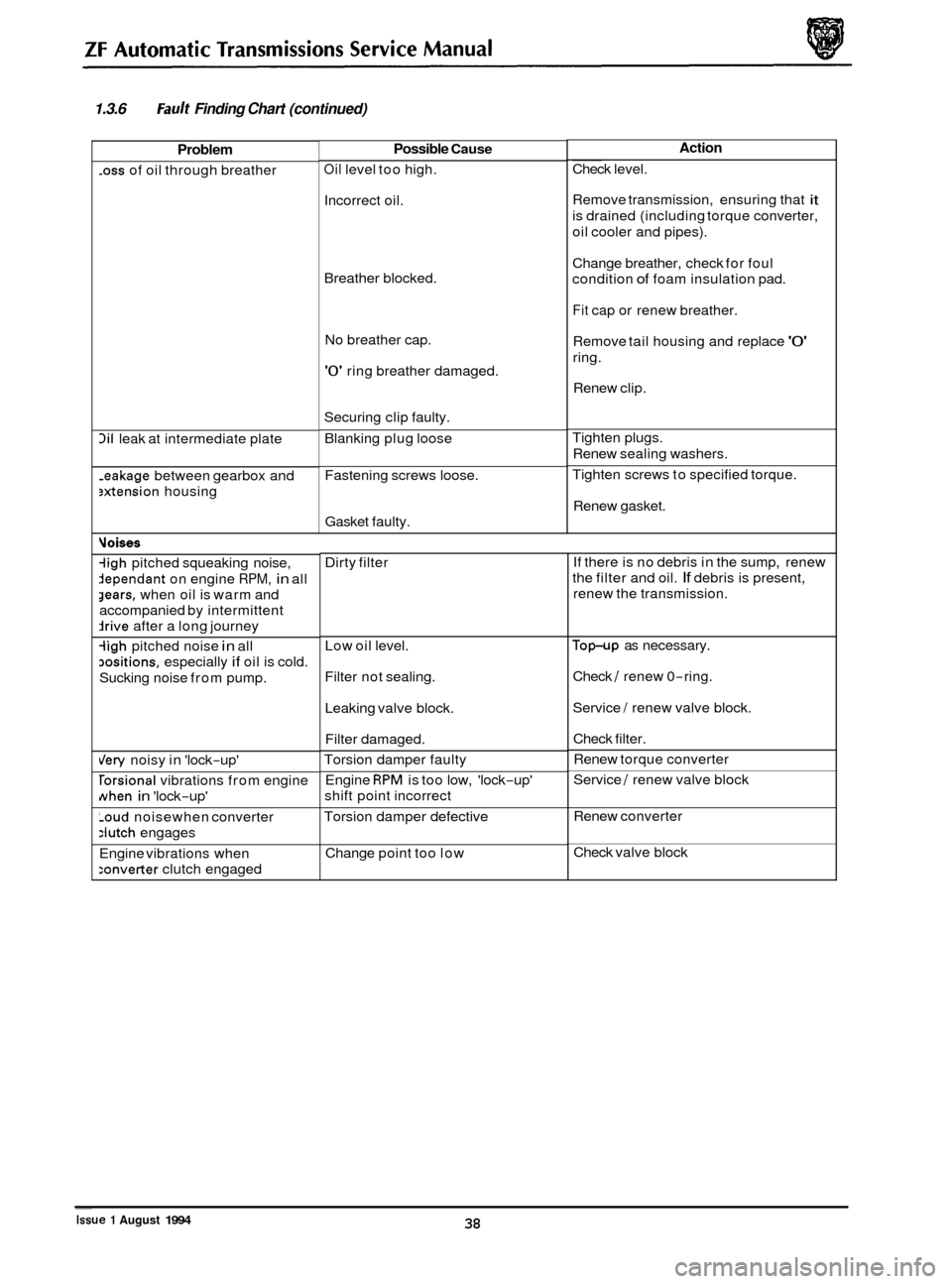

1.3.6 Fault Finding Chart (continued)

Problem

.oss of oil through breather

3il leak at intermediate plate

-eakage between gearbox and

2xtension housing

Uoises

iigh pitched squeaking noise,

jependant on engine RPM, in all

jears, when oil is warm and

accompanied by intermittent

hive after a long journey

iigh pitched noise in all

Dositions, especially if oil is cold.

Sucking noise from pump.

dery noisy in 'lock-up'

rorsional vibrations from engine

Nhen in 'lock-up'

-oud noisewhen converter

:lutch engages

Engine vibrations when

:onverter clutch engaged

Possible Cause

Oil level too high.

Incorrect oil.

Breather blocked.

No breather cap.

'0' ring breather damaged.

Securing clip faulty.

Blanking plug loose

Fastening screws loose.

Gasket faulty.

Dirty filter

Low oil level.

Filter not sealing.

Leaking valve block.

Filter damaged.

Torsion damper faulty

Engine

RPM is too low, 'lock-up'

shift point incorrect

Torsion damper defective

Change point too low

Action ___ Check level.

Remove transmission, ensuring that

it

is drained (including torque converter,

oil cooler and pipes).

Change breather, check for foul

condition

of foam insulation pad.

Fit cap or renew breather.

Remove tail housing and replace

'0'

ring.

Renew clip.

Tighten plugs. Renew sealing washers.

Tighten screws to specified torque.

Renew gasket.

If there is no debris in the sump, renew

the filter and oil.

If debris is present,

renew the transmission.

Top-up as necessary.

Check

I renew 0-ring.

Service

/ renew valve block.

Check filter.

Renew torque converter

Service

I renew valve block

Renew converter

Check valve block ~~

Issue 1 August 1994 38

Page 44 of 74

ZF Automatic Transmissions Service Manual

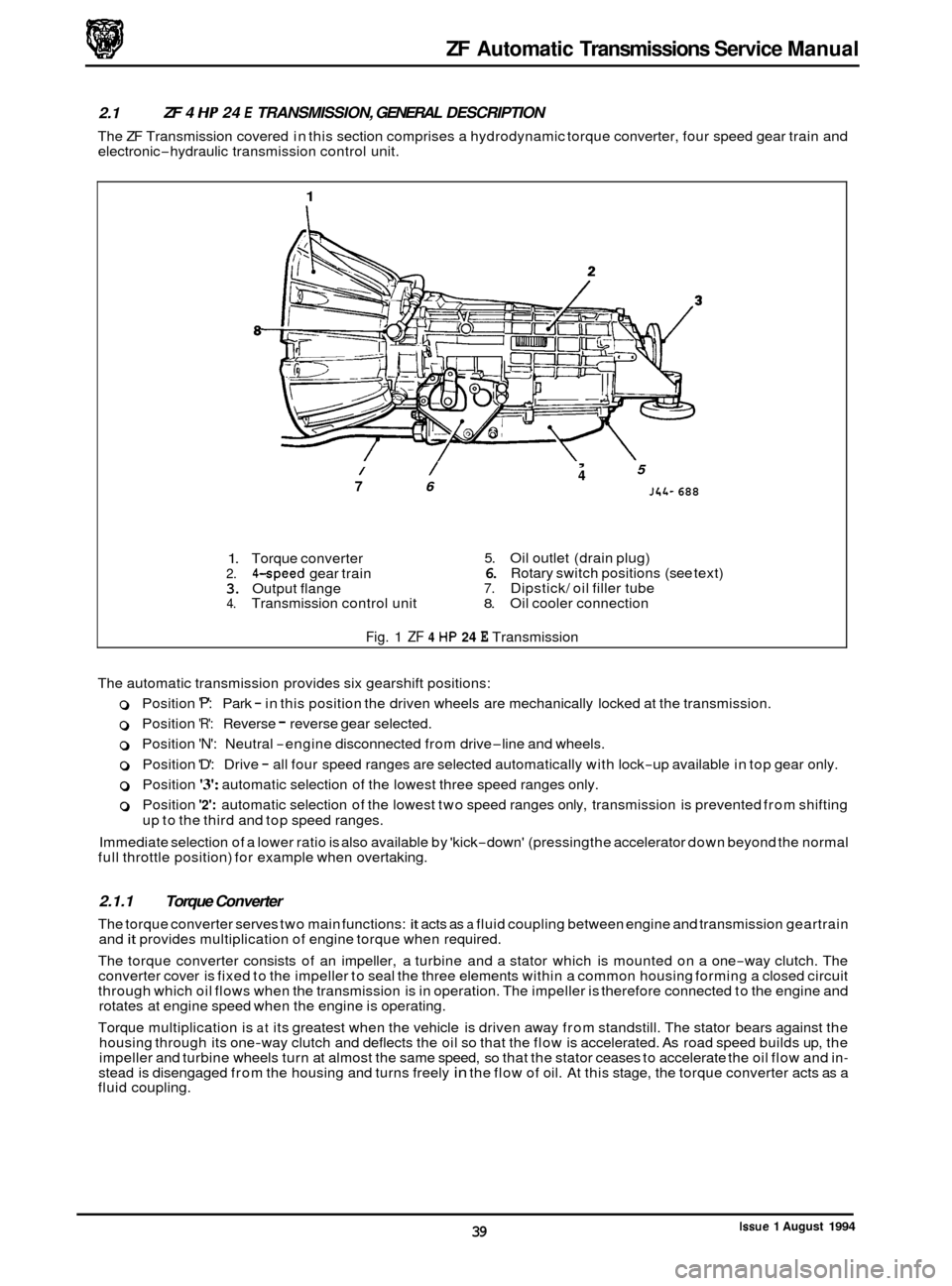

2.1

electronic-hydraulic transmission control unit.

ZF 4 HP 24 E TRANSMISSION, GENERAL DESCRIPTION

The ZF Transmission covered in this section comprises a hydrodynamic torque converter, four speed gear train and

1

/ /

7 6

, 5 4

J4L- 688

1. Torque converter 5. Oil outlet (drain plug)

2. 4-speed gear train 6. Rotary switch positions (see text)

3. Output flange 7. Dipstick/ oil filler tube 4. Transmission control unit 8. Oil cooler connection

Fig. 1 ZF 4 HP 24 E Transmission

The automatic transmission provides six gearshift positions:

0 Position 'P': Park - in this position the driven wheels are mechanically locked at the transmission.

0 Position 'R': Reverse - reverse gear selected.

0 Position 'N': Neutral -engine disconnected from drive-line and wheels.

0 Position 'D': Drive - all four speed ranges are selected automatically with lock-up available in top gear only.

0 Position '3': automatic selection of the lowest three speed ranges only.

0 Position '2': automatic selection of the lowest two speed ranges only, transmission is prevented from shifting

up to the third and top speed ranges.

Immediate selection of a lower ratio is also available by 'kick

-down' (pressing the accelerator down beyond the normal

full throttle position) for example when overtaking.

2.1.1 Torque Converter

The torque converter serves two main functions: it acts as a fluid coupling between engine and transmission geartrain

and it provides multiplication of engine torque when required.

The torque converter consists of an impeller, a turbine and a stator which is mounted on a one

-way clutch. The

converter cover is fixed to the impeller to seal the three elements within a common housing forming a closed circuit

through which oil flows when the transmission is in operation. The impeller is therefore connected to the engine and

rotates at engine speed when the engine is operating.

Torque multiplication is

at its greatest when the vehicle is driven away from standstill. The stator bears against the

housing through its one-way clutch and deflects the oil so that the flow is accelerated. As road speed builds up, the

impeller and turbine wheels turn at almost the same speed, so that the stator ceases to accelerate the oil flow and in- stead is disengaged from the housing and turns freely in the flow of oil. At this stage, the torque converter acts as a

fluid coupling.

Issue 1 August 1994 39

Page 45 of 74

ZF Automatic Transmissions Service Manual

The torque converter acts in all four forward gears and in reverse. The converter lock-up clutch closes in 4th gear at

a point depending on road speed and accelerator position; engine power is then transmitted

by purely mechanical

means.

A low

-loss oil pump in the front of the transmission housing supplies the converter, the automatic gear shift and the

lubrication circuit; oil is drawn from a sump in the bottom of the gear train housing through a filter. The pump drive

gear is keyed to the converter impeller hub and therefore turns when the engine is running, thereby pressurizing the

oil.

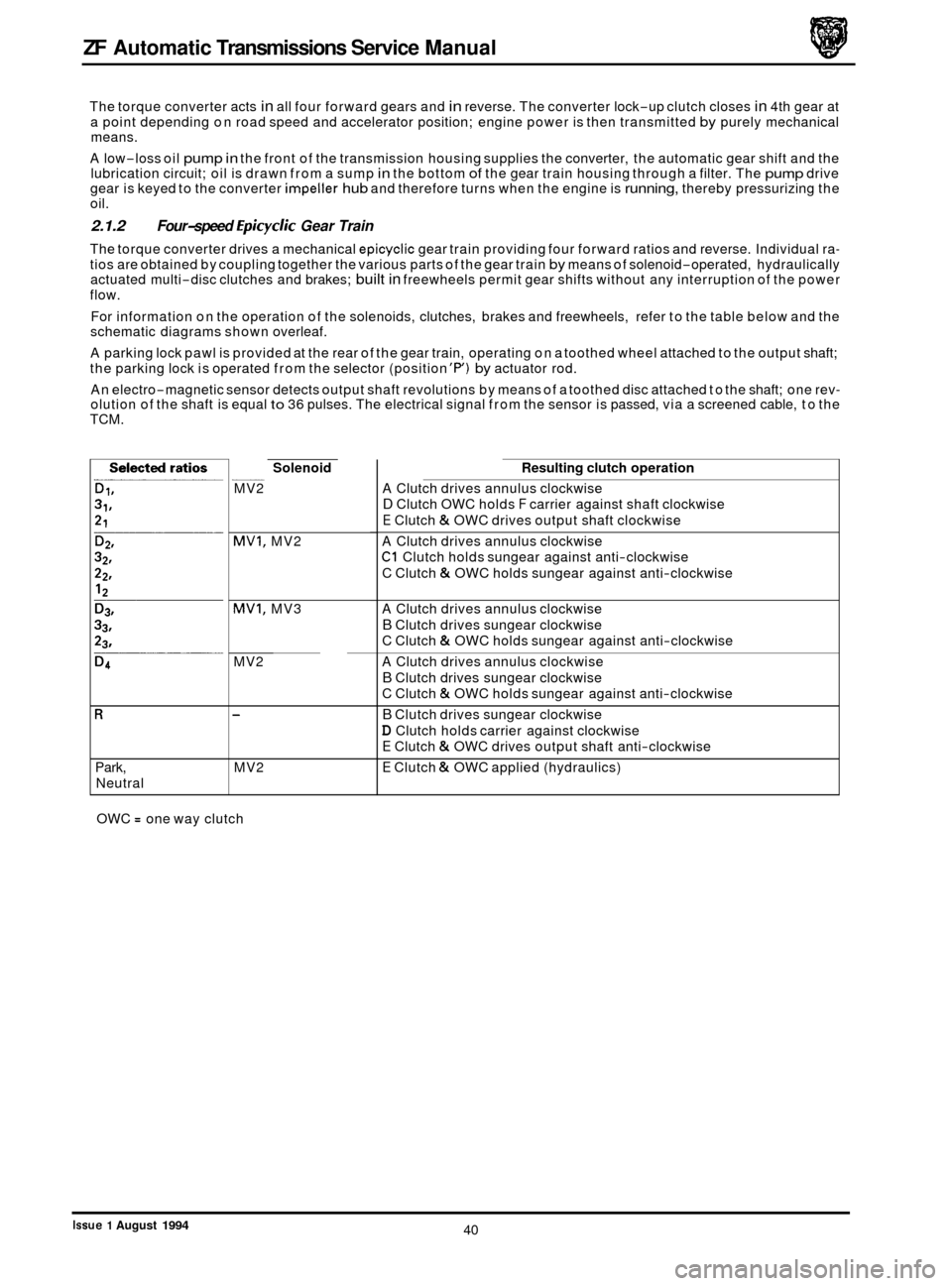

2.1.2 Four-speed Epicyclic Gear Train

The torque converter drives a mechanical epicyclic gear train providing four forward ratios and reverse. Individual ra-

tios are obtained by coupling together the various parts of the gear train by means of solenoid-operated, hydraulically

actuated multi-disc clutches and brakes; built in freewheels permit gear shifts without any interruption of the power

flow.

For information on the operation of the solenoids, clutches, brakes and freewheels, refer to the table below and the

schematic diagrams shown overleaf.

A parking lock pawl is provided at the rear of the gear train, operating on a toothed wheel attached to the output shaft;

the parking lock is operated from the selector (position

'P) by actuator rod.

An electro

-magnetic sensor detects output shaft revolutions by means of a toothed disc attached to the shaft; one rev- olution of the shaft is equal to 36 pulses. The electrical signal from the sensor is passed, via a screened cable, to the

TCM.

R

Park,

Neutral

Solenoid ~

MV2

MVI, MV2

MVI, MV3

MV2

-

MV2

OWC

= one way clutch

Resulting clutch operation

A Clutch drives annulus clockwise

D Clutch OWC holds F carrier against shaft clockwise

E Clutch & OWC drives output shaft clockwise

A Clutch drives annulus clockwise

C1 Clutch holds sungear against anti-clockwise

C Clutch

& OWC holds sungear against anti-clockwise

A Clutch drives annulus clockwise

B Clutch drives sungear clockwise

C Clutch

& OWC holds sungear against anti-clockwise

A Clutch drives annulus clockwise

B Clutch drives sungear clockwise

C Clutch

& OWC holds sungear against anti-clockwise

B Clutch drives sungear clockwise

D Clutch holds carrier against clockwise

E Clutch & OWC drives output shaft anti-clockwise

E Clutch & OWC applied (hydraulics)

40

Issue 1 August 1994

Page 46 of 74

ZF Automatic Transmissions Service Manual

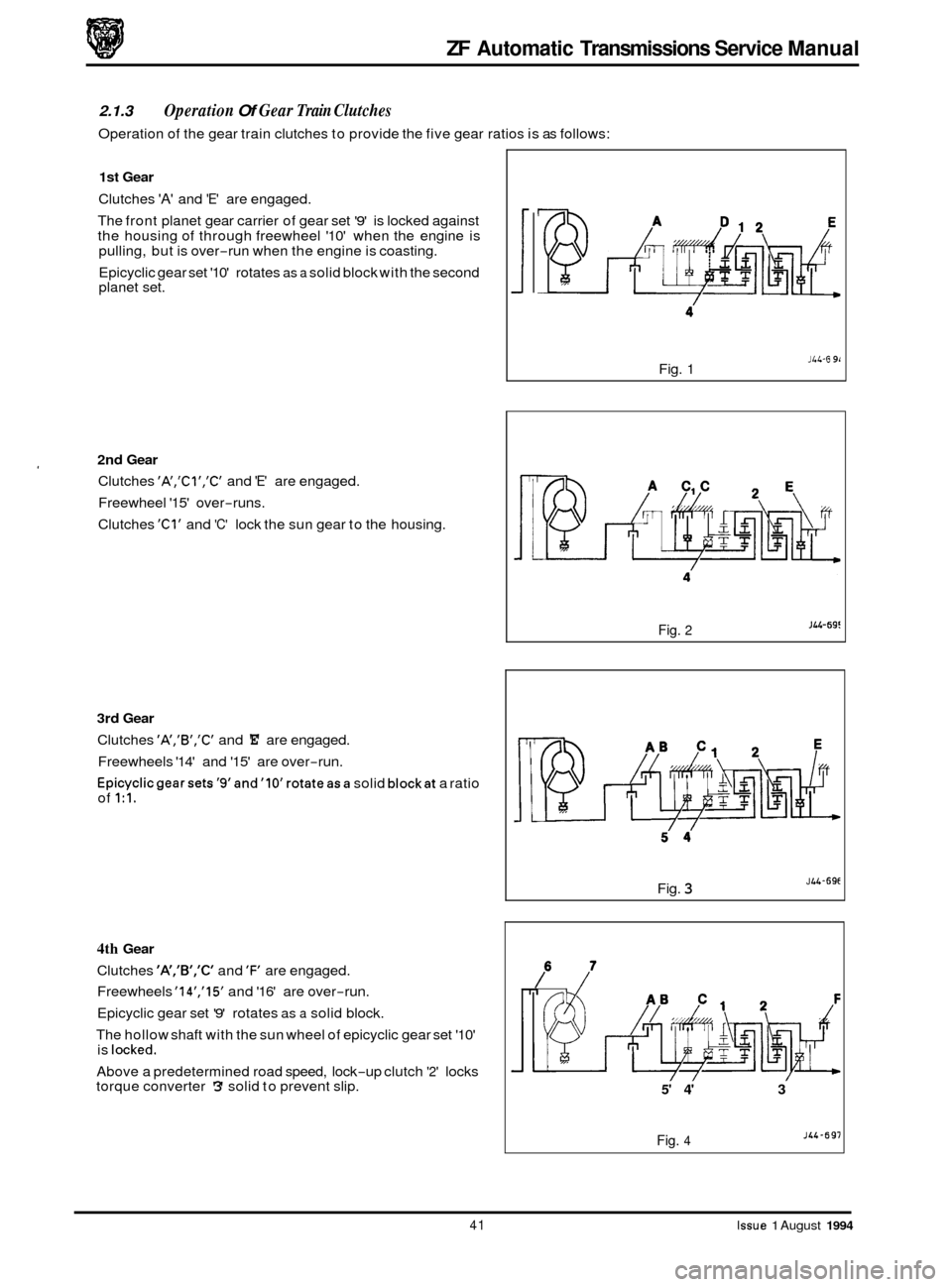

2.1.3 Operation Of Gear Train Clutches

Operation of the gear train clutches to provide the five gear ratios is as follows:

1st Gear

Clutches 'A' and 'E' are engaged.

The front planet gear carrier of gear set

'9' is locked against

the housing of through freewheel '10' when the engine is

pulling, but is over

-run when the engine is coasting.

Epicyclic gear set

'10' rotates as a solid block with the second

planet set.

2nd Gear

Freewheel '15' over-runs.

Clutches

'Cl' and 'C' lock the sun gear to the housing.

* Clutches 'A','Cl','C' and 'E' are engaged.

3rd Gear

Clutches 'A','B','C' and 'E' are engaged.

Freewheels '14' and '15' are over

-run.

Epicyclicgearsets'9'and'lO'rotateasa solid blockat a ratio

of 1:l.

4th Gear

Clutches 'A','B','C' and 'F' are engaged.

Freewheels

'14','15' and '16' are over-run.

Epicyclic gear set

'9' rotates as a solid block.

The hollow shaft with the sun wheel of epicyclic gear set '10'

is

locked.

Above a predetermined road speed, lock-up clutch '2' locks

torque converter '3' solid to prevent slip.

I

J4L-G 9 1 Fig. 1

JLL-69: Fig. 2

J 4L-69E Fig. 3

5' 4' 3

JLL-697 Fig. 4

41 Issue 1 August 1994

Page 48 of 74

ZF Automatic Transmissions Service Manual

2.1.6 Transmission Rotary Switch

This switch is located on a square extension of the transmission selector shaft and is linked to the shift lever via the

selector cable. The switch comprises a selector bar which moves across a series of copper segments located on the

switch quadrant. The copper segments are set out in seven bands, each band providing an electrical output or com

- bination of outputs to the TCM.

The electrical outputs to the TCM are in the form of a three

-digit code which takes up three of the seven bands of the

quadrant; the remaining four bands are used for reverse, ground and start inhibit.

2.1.7 Decoder Module

The decoder module, located on the right hand side of the J-gate assembly, is used to translate the three-digit codes

from the rotary transmission switch into single-line functions to feed the illumination module and to provide the fol-

lowing information:

. Cruise control, ie when cruise control can or cannot be engaged.

. Indication when the vehicle is not in 'P' Park.

. Provide the ECM with a Park/ Neutral signal.

2.1.8 Performance Mode Switch

This switch, located on the shift lever surround, provides two alternative shift patterns:

. 'Normal Mode' -for everyday use,

. 'Sport Mode'- gear changes take place at higher road speeds in order to enhance performance.

Note: Torque converter 'lock-up' occurs in fourth gear in each mode.

2. I. 9 'Kick-down' Mechanism

'Kick-down' is activated by the final travel of the accelerator pedal which contacts a floor-mounted switch located be- hind the pedal. Operation of the switch provides a signal to the TCM that a downward change is required. The switch

is adjustable to ensure that the pedal does not overtravel and stretch the cable.

2.1.10 Reverse Safefy Inhibit

If 'R' Reverse is selected when the vehicle is travelling forwards at more than 5 mile / h, solenoid valve MV2 will be

energised to prevent engagement of reverse gear.

2.1.11 Gearshift hterlock

A brake pedal /gearshift interlock is incorporated in the gear selector mechanism. The gear selector lever may only

be moved from the P - Park position if the ignition key switch is in position II and the foot brake is applied.

The ignition key cannot be removed from the ignition switch unless the shift lever is in

the 'P - Park position. Once

the ignition key has been removed, the shift lever is locked in the park position.

2.1.12 Starter Inhibit Switch

The starter inhibit switch prevents the starter motor from being operated when the shift lever is not in position 'P' - Park or position 'N' - Neutral. The switch is located in the gear selector housing.

issue 1 August 1994 47

Page 52 of 74

4

AFLR M- -1

4 13 9

14

15 7

J44-718

1.

Selector 2. Mode switch 3. Rotary switch

4. Transmission control unit 5. Output shaft speed sensor 6. Kick-down switch 7. Battery

8. Transmission relay

9.

10.

11.

12.

13.

14.

15.

16.

Transmission control module (TCM)

Reverse lamps

Start inhibiter

Engine speed

Ignition retard

Engine load

Engine control module

(ECM) Engine speed sensor

Fig.

1 Control Layout Schematic

2.1.5 Transmission Control Module (TCM)

The Transmission Control Module (TCM) is an electronic control unit located in the front passenger footwell behind

the underscuttle pad. It is electrically connected to the transmission and other components through a cable harness

and multiple pin plug.

The TCM continuously monitors the gear selected (via the rotary transmission switch), the speed of the output shaft

(by speed sensor on the output shaft) and throttle position ('kick

-down' switch). This information plus input from the

Engine Control Module (ECM) of throttle angle and engine speed and load in conjunction with a pre-programmed con- trol map, enables the most suitable gear to be selected.

The TCM, by operating solenoid valves

MVI, MV2 and MV3, controls the gear shift speed and in conjunction with the

solenoid operated pressure control valve, controls the gear shift quality. Gear shift quality on upshifts is improved by

the TCM momentarily retarding the ignition to reduce the torque input as the gear change takes place. Information

is fed to the TCM from sensors and

if any electronic component fails, the basic shift changes will be performed by the

hydro-mechanical system, ie Park, Reverse, Neutral, D3 or D4.

46

Issue 1 August 1994

Page 53 of 74

ZF Automatic Transmissions Service Manual

Vehicle speed sensor plus input

Engine speed input

Program switch input

Solenoid valve

MVI output

Pressure control valve PCV output

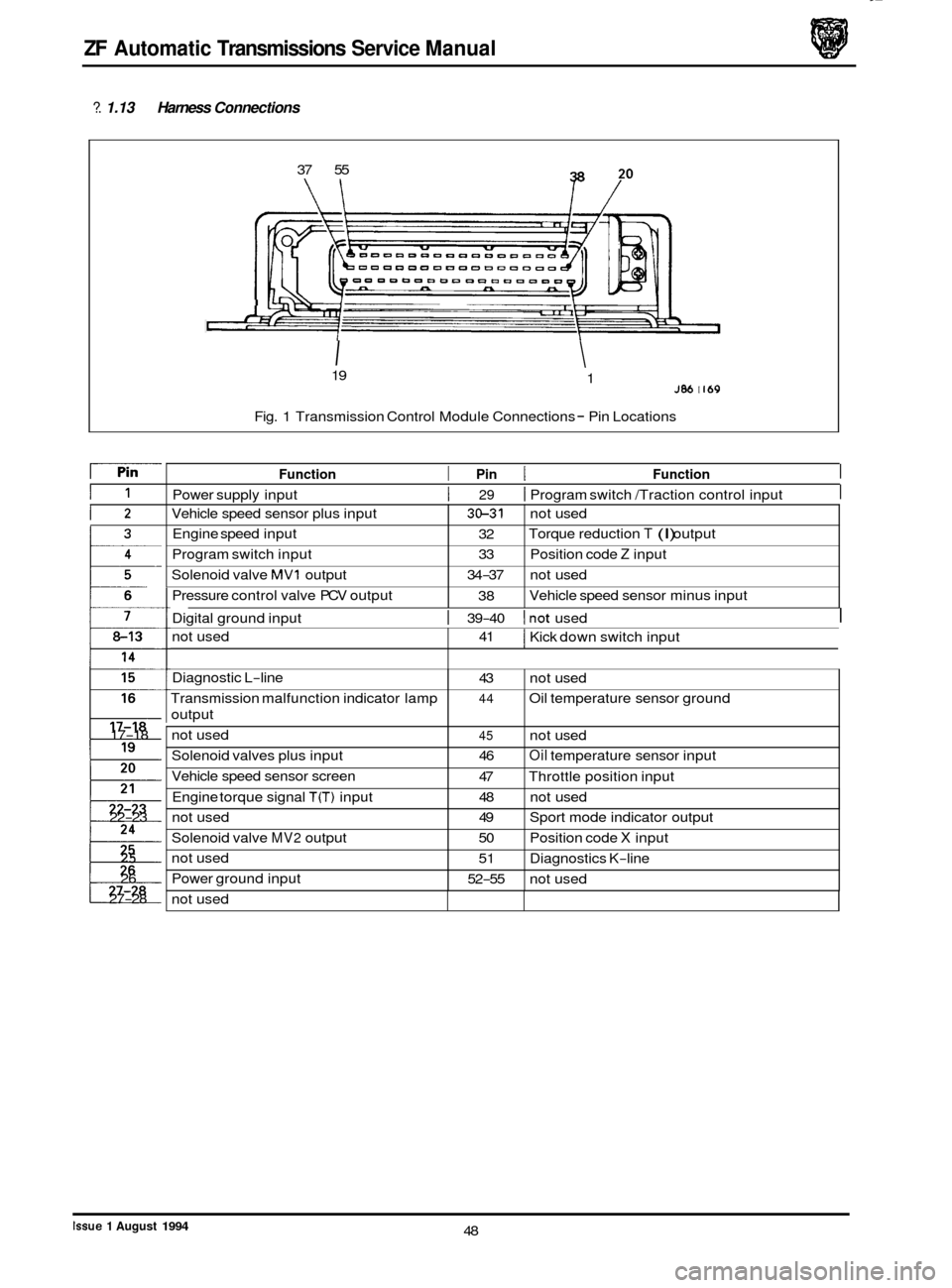

?. 1.13 Harness Connections

3&31 not used

32

33 Position code

Z input

38 Torque

reduction

T (I) output

34

-37 not used

Vehicle speed sensor minus input

37

55

not used

\I

41 I Kick down switch input

J" i"

Diagnostic L-line

Transmission malfunction indicator lamp

output

not used

Solenoid valves plus input

Vehicle speed sensor screen

Engine torque signal

T(T) input

I IU,MW II

43 not used

44 Oil temperature sensor ground

45 not used

46

Oil temperature sensor input

47 Throttle position input

48 not used

I

not used

Solenoid valve

MV2 output

not used

Power ground input 19

49 Sport mode indicator output

50 Position code X input

51 Diagnostics K

-line

52

-55 not used

J86 I I69 1

Fig.

1 Transmission Control Module Connections - Pin Locations

I1

12

13

: I

17-18

22

-23

t 27-28

25

26

Function I Pin I Function I

Power supply input I 29 I Program switch /Traction control input I

Digital ground input I 39-40 lnot used I

not used

-~

48 Issue 1 August 1994

Page 56 of 74

ZF Automatic Transmissions Service Manual

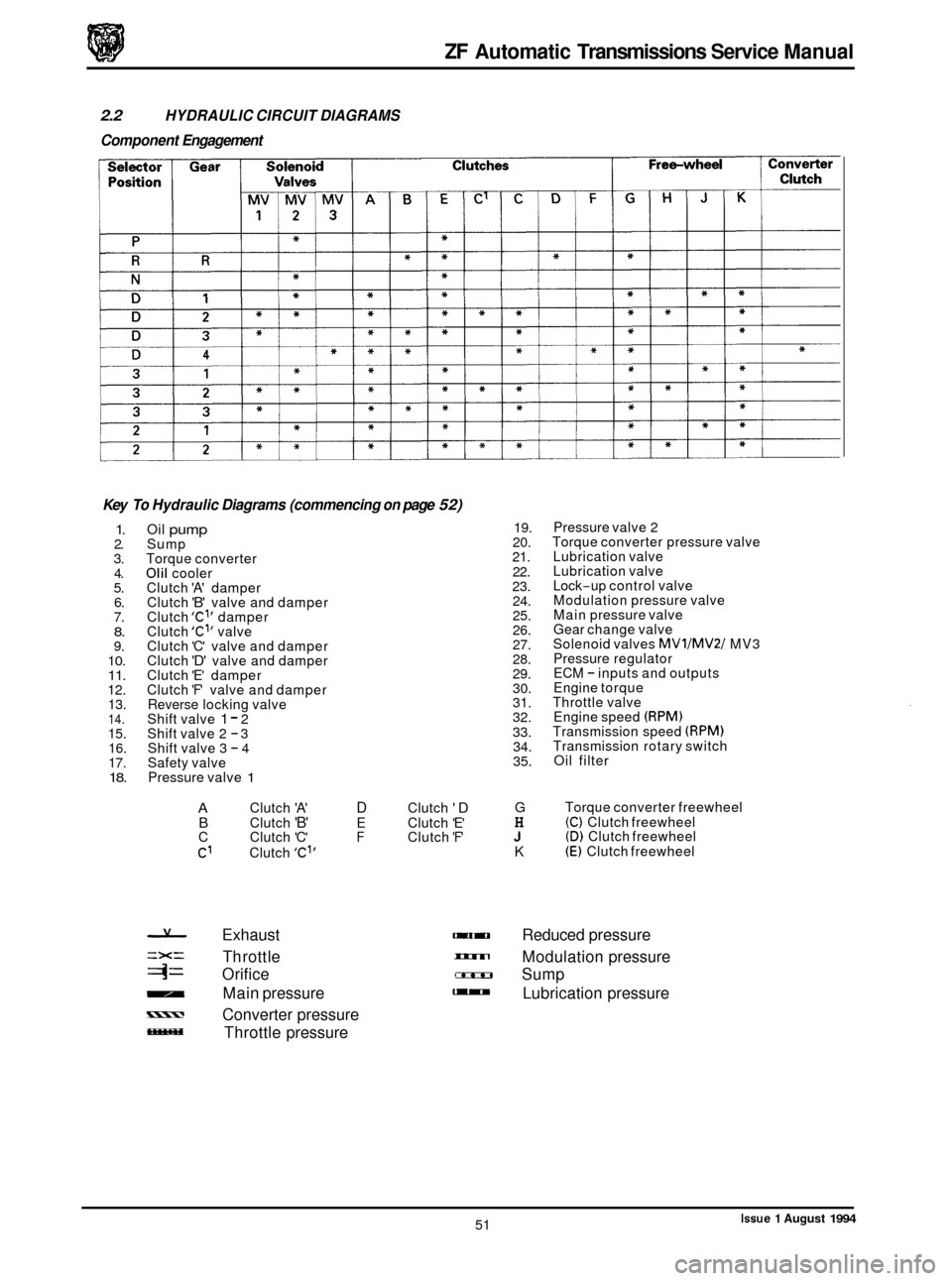

2.2 HYDRAULIC CIRCUIT DIAGRAMS

Component Engagement

Key

To Hydraulic Diagrams (commencing on page 52)

1. 2.

3. 4.

5. 6.

7.

8. 9. 10. 11. 12. 13.

14. 15. 16.

17.

18.

Oil pump Sump

Torque converter

Olil cooler

Clutch 'A' damper

Clutch 'B' valve and damper

Clutch 'Cl' damper

Clutch 'Cl' valve

Clutch 'C' valve and damper

Clutch

'D' valve and damper

Clutch 'E' damper

Clutch

'F' valve and damper

Reverse locking valve

Shift valve

1 - 2

Shift valve 2 - 3

Shift valve 3 - 4

Safety valve

Pressure valve

1

A Clutch 'A' D Clutch 'D B Clutch 'B' E Clutch 'E'

C Clutch 'C' F Clutch 'F'

C1 Clutch 'C"

19.

20.

21.

22.

23. 24.

25.

26.

27.

28.

29.

30.

31.

32.

33. 34.

35.

G

H J K

Pressure valve 2

Torque converter pressure valve

Lubrication valve

Lubrication valve

Lock

-up control valve

Modulation pressure valve

Main pressure valve

Gear change valve

Solenoid valves

MVllMV2l MV3

Pressure regulator

ECM

- inputs and outputs

Engine torque

Throttle valve Engine speed

(RPM) Transmission speed (RPM) Transmission rotary switch

Oil filter

Torque converter freewheel

(C) Clutch freewheel (D) Clutch freewheel (E) Clutch freewheel

Exhaust - Reduced pressure

=X= Th rott le - Modulation pressure

4= Orifice 2- Sump

- Main pressure - Lubrication pressure

- Converter pressure

Throttle pressure

Issue 1 August 1994 51

Page 66 of 74

ZF Automatic Transmissions Service Manual

Problem Possible Cause

2.3.4 Road Test

. Fully check all shift speeds and note. Compare the results with the specification in addition to general observations of transmission behaviour, noises, leaks etc., and consult the following Fault Finding Chart.

Action

CAUTION:

When renewing the transmission, ALWAYS flush out the oil cooler and feed and return pipes.

2.3.5 Electrical Checks

. Check 'Kick-down'.

If any electrical component fault is suspected, refer to Electrical Diagnostic Manual (EDM) to verify the failure mode

before a repair or replacement is attempted.

2.3.6 Fault Finding Chart

Stall speed too low

Stall speed too high and keeps

,ising

hceleration below specification

Top speed below specification

'osition 'P - Park

Nil1 not move out of Park

Ioes not engage Park

Ioes not hold Stator

freewheel faulty allowing stator to

revolve

Engine out of tune

Transmission slip

Engine out of tune

Torque converter freewheel faulty

allowing stator to revolve.

'Kick

-down' switch defective.

Transmission

in 'Limp Home' mode

Engine out of tune

Torque converter freewheel seized

Engine out of tune

Gearshift interlock failure

Check cable adjustment

Parking pawl mechanism sticking

Check cable adjustment

Parking pawl mechanism damaged Renew

torque converter

Check engine tune

Check oil level, check mechanical

failure, renew transmission as

necessary

Check engine tune

Renew torque converter.

Refer to EDM, rectify

I renew

'Kick

-down'switch.

Check.

Check

engine tune

Renew torque converter

Check engine tune

Refer to EDM, rectify

- renew fuse,

check circuits, renew relay and

solenoid.

Check central

'P, check Park switch,

check Brake switch.

Adjust to correct setting

Renew park pawl components:

connecting bar, pawl pin, torsion

spring, pawl, guide piece and guide

sheet.

Adjust to correct setting

Replace park pawl components

61 Issue 1 August 1994