sensor JAGUAR XJ 1994 2.G ZF Automatic Transmission Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1994, Model line: XJ, Model: JAGUAR XJ 1994 2.GPages: 74, PDF Size: 2.66 MB

Page 5 of 74

ZF Automatic Transmissions Service Manual

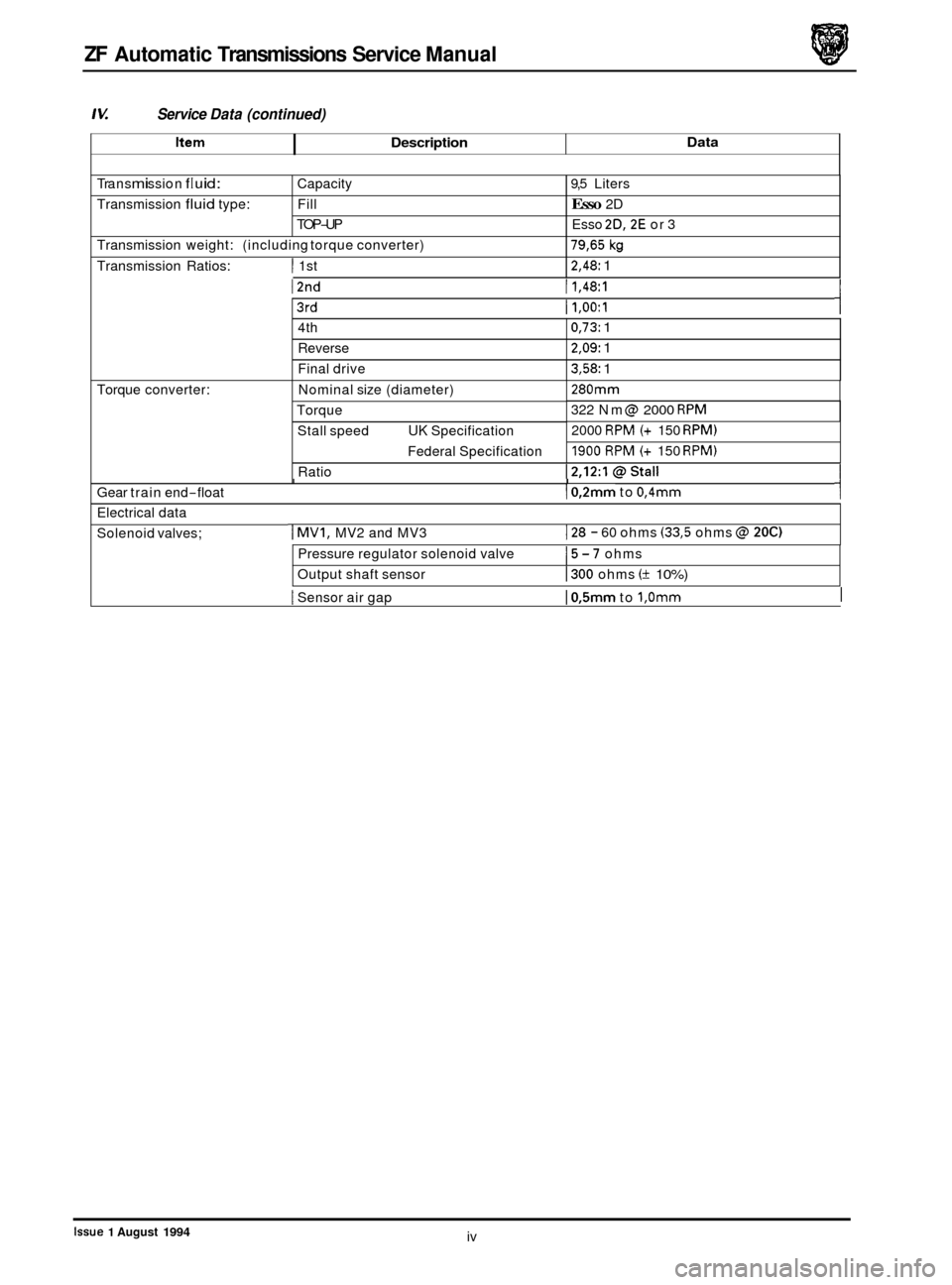

Item Description I

IC! Service Data (continued)

Data

Tra ns m i ssi on f I u i d :

Transmission fluid type: Capacity

9,5 Liters

Fill Esso 2D

TOP

-UP Esso 2D,2E or 3

Torque converter:

Transmission

weight: (including torque converter)

Transmission Ratios:

I 1st

I2nd

79,65 kg

2,48: 1

I1,48:1

4th

Reverse

Final drive

I3rd

0,73: 1

2,09: 1

3,58: 1

I1,OO:l

Nominal size (diameter)

Torque Stall speed

UK Specification

Federal Specification

280mm

322 Nm @ 2000 RPM

2000 RPM (+ 150 RPM)

1900 RPM (+ 150 RPM)

Ratio I I Gear train end-float I0,2mm to 0,4mm

Electrical data

Solenoid valves;

I MV1, MV2 and MV3 I28 - 60 ohms (33,5 ohms @ 200

Pressure regulator solenoid valve

Output shaft sensor 15-7 ohms

I300 ohms (+ 10%)

I Sensor air gap I0,5mm to 1,Omm I

iv Issue 1 August 1994

Page 45 of 74

ZF Automatic Transmissions Service Manual

The torque converter acts in all four forward gears and in reverse. The converter lock-up clutch closes in 4th gear at

a point depending on road speed and accelerator position; engine power is then transmitted

by purely mechanical

means.

A low

-loss oil pump in the front of the transmission housing supplies the converter, the automatic gear shift and the

lubrication circuit; oil is drawn from a sump in the bottom of the gear train housing through a filter. The pump drive

gear is keyed to the converter impeller hub and therefore turns when the engine is running, thereby pressurizing the

oil.

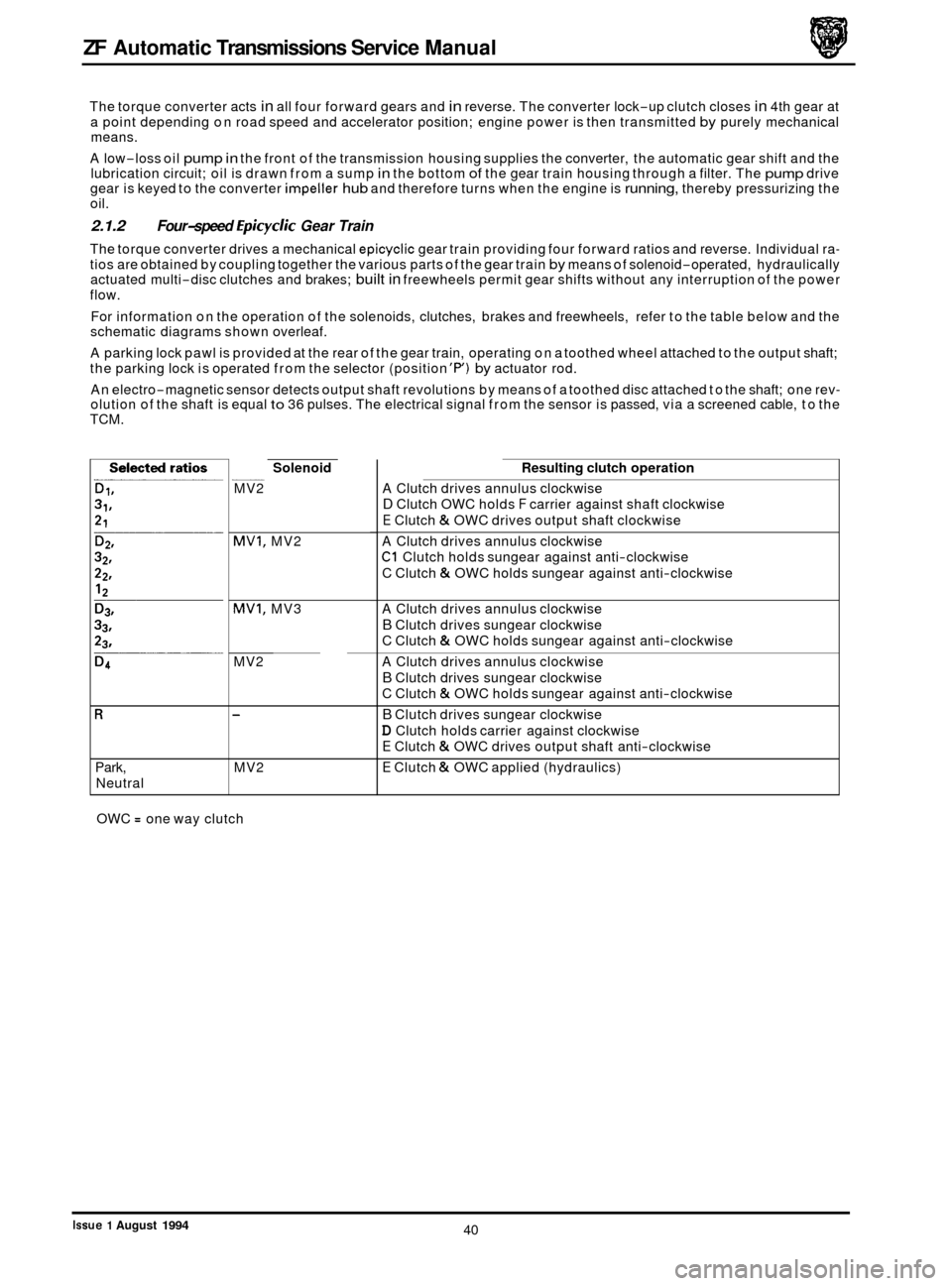

2.1.2 Four-speed Epicyclic Gear Train

The torque converter drives a mechanical epicyclic gear train providing four forward ratios and reverse. Individual ra-

tios are obtained by coupling together the various parts of the gear train by means of solenoid-operated, hydraulically

actuated multi-disc clutches and brakes; built in freewheels permit gear shifts without any interruption of the power

flow.

For information on the operation of the solenoids, clutches, brakes and freewheels, refer to the table below and the

schematic diagrams shown overleaf.

A parking lock pawl is provided at the rear of the gear train, operating on a toothed wheel attached to the output shaft;

the parking lock is operated from the selector (position

'P) by actuator rod.

An electro

-magnetic sensor detects output shaft revolutions by means of a toothed disc attached to the shaft; one rev- olution of the shaft is equal to 36 pulses. The electrical signal from the sensor is passed, via a screened cable, to the

TCM.

R

Park,

Neutral

Solenoid ~

MV2

MVI, MV2

MVI, MV3

MV2

-

MV2

OWC

= one way clutch

Resulting clutch operation

A Clutch drives annulus clockwise

D Clutch OWC holds F carrier against shaft clockwise

E Clutch & OWC drives output shaft clockwise

A Clutch drives annulus clockwise

C1 Clutch holds sungear against anti-clockwise

C Clutch

& OWC holds sungear against anti-clockwise

A Clutch drives annulus clockwise

B Clutch drives sungear clockwise

C Clutch

& OWC holds sungear against anti-clockwise

A Clutch drives annulus clockwise

B Clutch drives sungear clockwise

C Clutch

& OWC holds sungear against anti-clockwise

B Clutch drives sungear clockwise

D Clutch holds carrier against clockwise

E Clutch & OWC drives output shaft anti-clockwise

E Clutch & OWC applied (hydraulics)

40

Issue 1 August 1994

Page 52 of 74

4

AFLR M- -1

4 13 9

14

15 7

J44-718

1.

Selector 2. Mode switch 3. Rotary switch

4. Transmission control unit 5. Output shaft speed sensor 6. Kick-down switch 7. Battery

8. Transmission relay

9.

10.

11.

12.

13.

14.

15.

16.

Transmission control module (TCM)

Reverse lamps

Start inhibiter

Engine speed

Ignition retard

Engine load

Engine control module

(ECM) Engine speed sensor

Fig.

1 Control Layout Schematic

2.1.5 Transmission Control Module (TCM)

The Transmission Control Module (TCM) is an electronic control unit located in the front passenger footwell behind

the underscuttle pad. It is electrically connected to the transmission and other components through a cable harness

and multiple pin plug.

The TCM continuously monitors the gear selected (via the rotary transmission switch), the speed of the output shaft

(by speed sensor on the output shaft) and throttle position ('kick

-down' switch). This information plus input from the

Engine Control Module (ECM) of throttle angle and engine speed and load in conjunction with a pre-programmed con- trol map, enables the most suitable gear to be selected.

The TCM, by operating solenoid valves

MVI, MV2 and MV3, controls the gear shift speed and in conjunction with the

solenoid operated pressure control valve, controls the gear shift quality. Gear shift quality on upshifts is improved by

the TCM momentarily retarding the ignition to reduce the torque input as the gear change takes place. Information

is fed to the TCM from sensors and

if any electronic component fails, the basic shift changes will be performed by the

hydro-mechanical system, ie Park, Reverse, Neutral, D3 or D4.

46

Issue 1 August 1994

Page 53 of 74

ZF Automatic Transmissions Service Manual

Vehicle speed sensor plus input

Engine speed input

Program switch input

Solenoid valve

MVI output

Pressure control valve PCV output

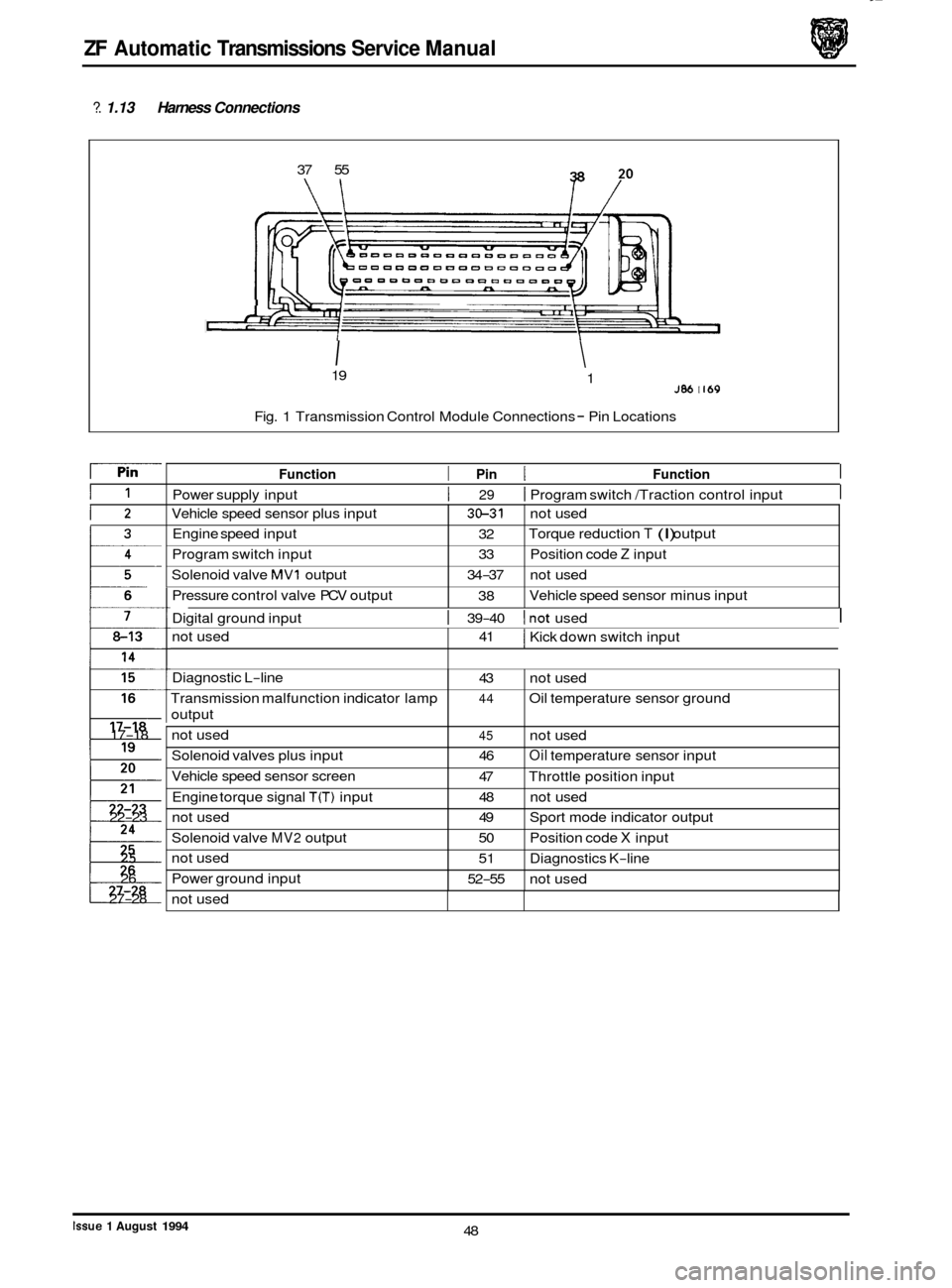

?. 1.13 Harness Connections

3&31 not used

32

33 Position code

Z input

38 Torque

reduction

T (I) output

34

-37 not used

Vehicle speed sensor minus input

37

55

not used

\I

41 I Kick down switch input

J" i"

Diagnostic L-line

Transmission malfunction indicator lamp

output

not used

Solenoid valves plus input

Vehicle speed sensor screen

Engine torque signal

T(T) input

I IU,MW II

43 not used

44 Oil temperature sensor ground

45 not used

46

Oil temperature sensor input

47 Throttle position input

48 not used

I

not used

Solenoid valve

MV2 output

not used

Power ground input 19

49 Sport mode indicator output

50 Position code X input

51 Diagnostics K

-line

52

-55 not used

J86 I I69 1

Fig.

1 Transmission Control Module Connections - Pin Locations

I1

12

13

: I

17-18

22

-23

t 27-28

25

26

Function I Pin I Function I

Power supply input I 29 I Program switch /Traction control input I

Digital ground input I 39-40 lnot used I

not used

-~

48 Issue 1 August 1994

Page 54 of 74

ZF Automatic Transmissions Service Manual

N

B

W

K

G

R

2.1.14 Rotary Switch Harness

Brown Y Yellow

Black

0 Orange

White

S Slate

Pink

L Light

Green

P Purple

Red

U Blue

Fig.

1 Transmission Connector (%way)

temperature

sensor

Color Code

I I /Indigo II I

Issue 1 August 1994 49

Page 68 of 74

ZF Automatic Transmissions Service Manual

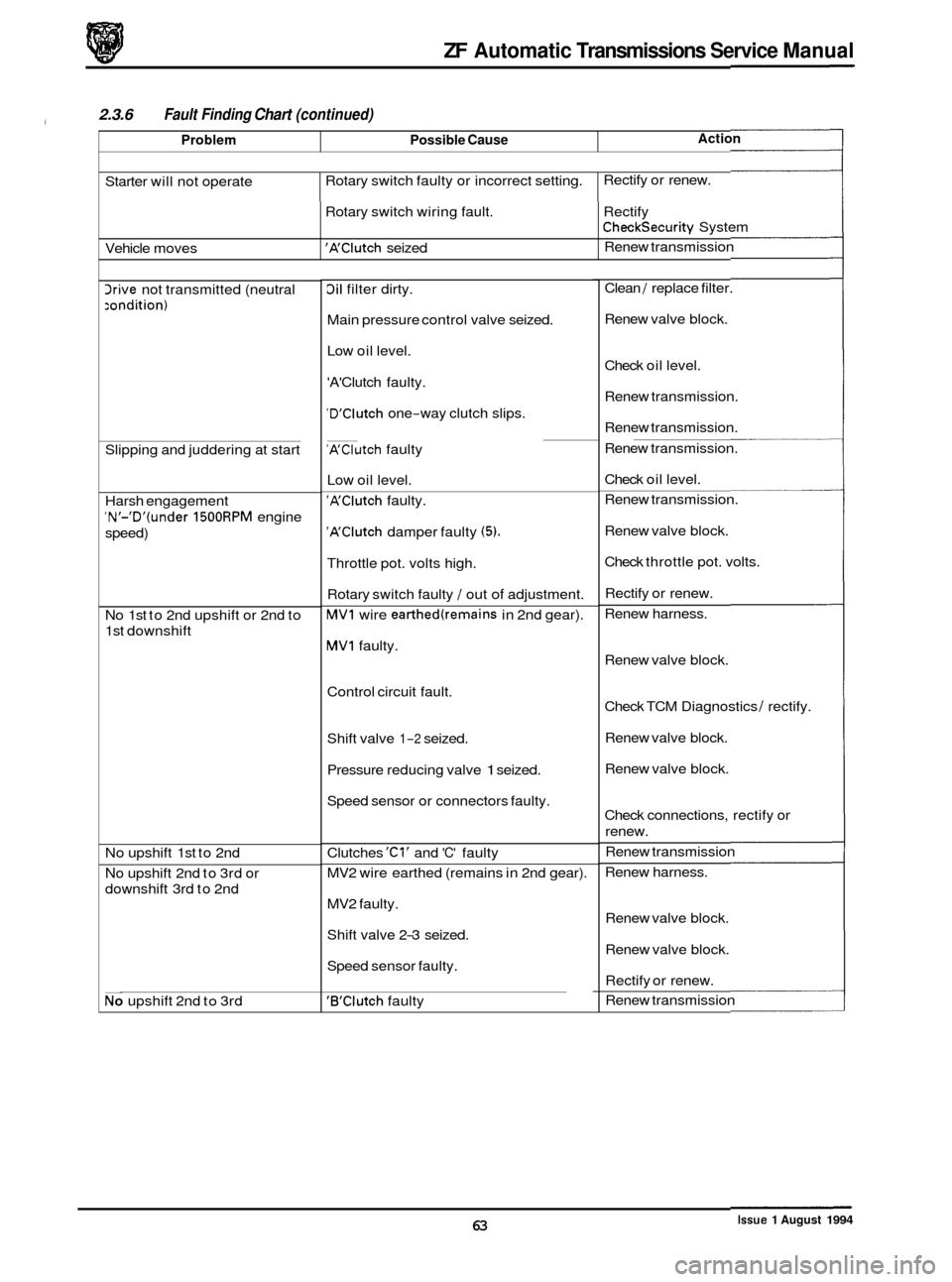

Problem Possible Cause

2.3.6 Fault Finding Chart (continued)

e Action

Starter will not operate Rotary

switch faulty or incorrect setting. Rectify

or renew.

3rive not transmitted (neutral

:ondition)

Vehicle moves

Slipping and juddering at start Rotary

switch wiring fault. Rectify 'A'Clutch seized Renew

transmission

Checksecurity System

Harsh engagement

'N'-'D'(under 1500RPM engine

speed)

No 1st to 2nd upshift or 2nd to

1st downshift

No upshift 1st to 2nd

No upshift 2nd to 3rd or

downshift 3rd to 2nd

No upshift 2nd to 3rd

3il filter dirty.

Main pressure control valve seized.

Low oil level.

'A'Clutch faulty.

'D'Clutch one-way clutch slips. ~

'A'Clutch faulty

Low oil level.

'A'Clutch faulty.

'A'Clutch damper faulty (5).

Throttle pot. volts high.

Rotary switch faulty

/ out of adjustment.

MVI wire earthed(remains in 2nd gear).

MVI faulty.

Control circuit fault.

Shift valve

1-2 seized.

Pressure reducing valve

1 seized.

Speed sensor or connectors faulty.

Clutches

'Cl' and 'C' faulty

MV2 wire earthed (remains in 2nd gear).

MV2 faulty.

Shift valve 2

-3 seized.

Speed sensor faulty.

'B'Clutch faulty Clean

/ replace

filter.

Renew valve block.

Check oil level.

Renew transmission.

Renew transmission.

Renew transmission.

Check oil level.

Renew transmission.

Renew valve block.

Check throttle pot. volts.

Rectify or renew.

Renew harness.

Renew valve block.

Check TCM Diagnostics

/ rectify.

Renew valve block.

Renew valve block.

Check connections, rectify or

renew.

Renew transmission

Renew harness.

Renew valve block.

Renew valve block.

Rectify or renew.

Renew transmission

Issue 1 August 1994 63

Page 69 of 74

ZF Automatic Transmissions Service Manual

0

2.3.6 Fault Finding Chart (continued)

Problem

Uo upshift 3rd to 4th or

lownshift 4th to 3rd

Vo upshift 3rd to 4th

lownshift 4th to 3rd too hard

Manual gearshift D to 3rd too

lard

Manual gearshift 3rd to 2nd too

9ard

Vo 1st gear; 2nd gear start only.

No 1st or 2nd gear; 3rd gear

start only

No 2nd gear; transmission shifts

1st to 3rd gear

Light throttle gear change

speeds incorrect

Up to 'kick

-down' detent, gear

change speeds not to

specification

Possible Cause

Shift valve 3-4 seized.

MVl wire earthed.

MV1 faulty.

Speed sensor faulty.

'F'Clutch faulty

3rain orifice 'F' partially blocked.

Damper

'E' faulty.

Damper

'E' faulty.

Drain orifice

'F' partially blocked.

Damper

'Cl' faulty

Speed sensor faulty.

MV1 faulty.

MV1 wire earthed.

Shift valve 1

-2 seized.

'1st Gear Inhibit' circuit operated or

'Performance Mode' switch faulty.

Transmission 'Limp Home' mode.

Speed sensor faulty.

MV1 or MV2 faulty.

Shift valves 1

-2 and 2-3 seized.

Speed sensor faulty.

Shift valve 2

-3 seized.

Shift valves sticking.

Speed sensor faulty.

Throttle pot. volts incorrect.

Transmission Control Module

(TCM).

'Kick-down' switch out of adjustment

3enew valve block.

3enew harness.

Renew valve block.

Rectify or renew.

Renew transmission

Renew valve block.

Renew valve block.

Renew valve block.

Renew valve block.

Renew valve block

Check or renew speed sensor.

Renew valve block.

Renew harness.

Renew valve block.

Operate 'Performance Mode' switch

to correct function or renew switch.

Check Diagnostics

1 JDS.

Renew speed sensor.

Renew valve block.

Renew valve block.

Check or

recheck Diagnostics,

renew speed sensor.

Renew valve block.

Renew valve block.

Check or renew speed sensor.

Check voltage

- JDS.

Check TCM Diagnostics.

Readjust 'kick

-down' switch

Issue 1 August 1994 64

Page 70 of 74

ZF Automatic Transmissions Service Manual

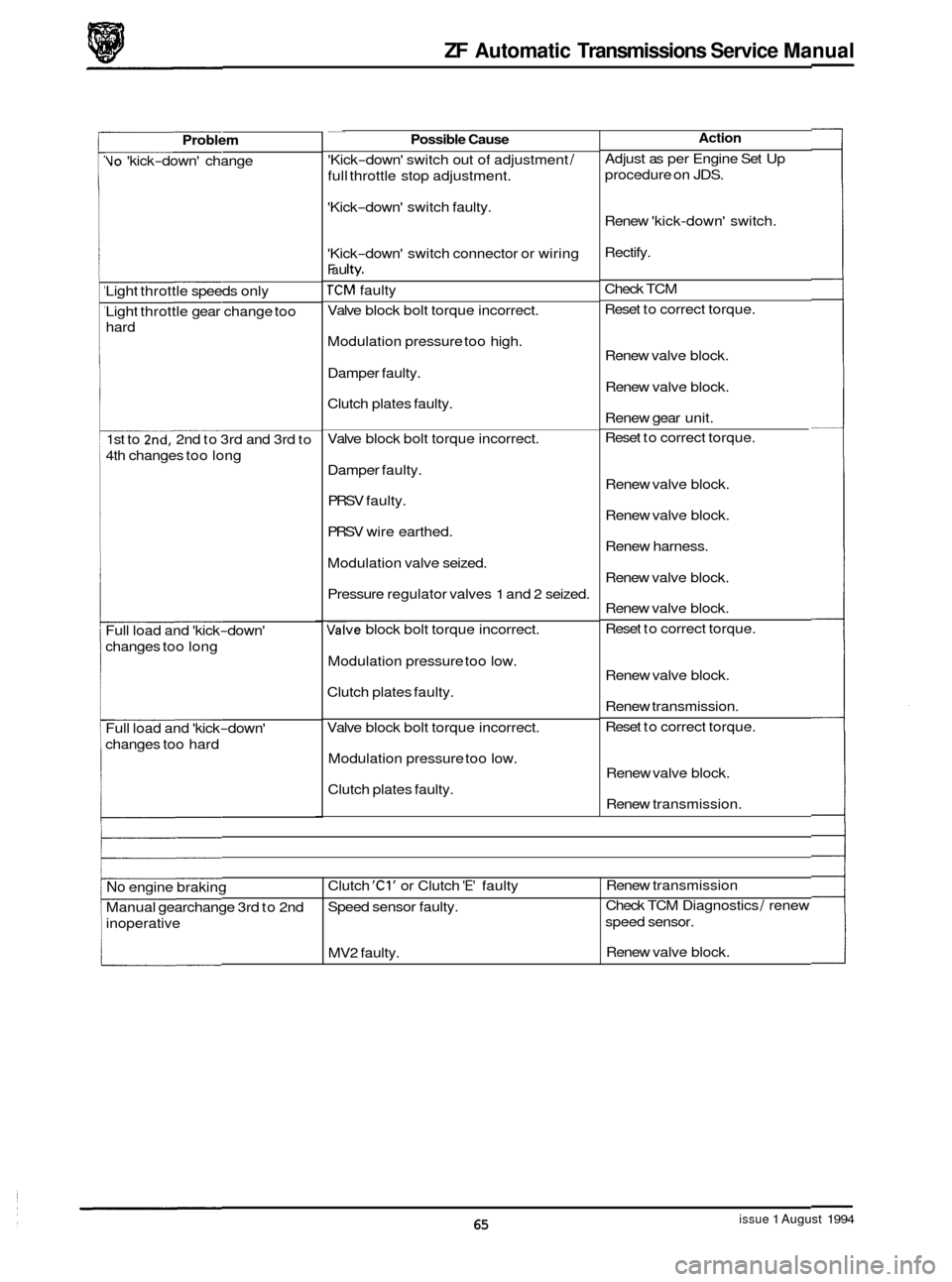

No engine braking

Manual gearchange 3rd to 2nd

inoperative Clutch 'Cl' or

Clutch 'E' faulty

Speed sensor faulty.

MV2 faulty.

a

Renew transmission

Check TCM Diagnostics

1 renew

speed sensor.

Renew valve block.

a

0

Problem

Vo 'kick-down' change

Light throttle speeds only

Light throttle gear change too

hard

1st to

2nd, 2nd to 3rd and 3rd to

4th changes too long

Full load and 'kick

-down'

changes too long

Full load and 'kick

-down'

changes too hard ~

Possible Cause

'Kick-down'

switch out of adjustment 1

full throttle stop adjustment.

'Kick

-down' switch faulty.

'Kick

-down' switch connector or wiring

Fa u Ity.

TCM faulty

Valve block bolt torque incorrect.

Modulation pressure too high.

Damper faulty.

Clutch plates faulty.

Valve block bolt torque incorrect.

Damper faulty.

PRSV faulty.

PRSV wire earthed.

Modulation valve seized.

Pressure regulator valves

1 and 2 seized.

mve block bolt torque incorrect.

Modulation pressure too low.

Clutch plates faulty.

Valve block bolt torque incorrect.

Modulation pressure too low.

Clutch plates faulty.

Action

Adjust as per Engine Set Up

procedure on JDS.

Renew 'kick

-down' switch.

Rectify.

Check TCM

Reset to correct torque.

Renew valve block.

Renew valve block.

Renew gear unit.

Reset to correct torque.

Renew valve block.

Renew valve block.

Renew harness.

Renew valve block.

Renew valve block.

Reset to correct torque.

Renew valve block.

Renew transmission.

Reset to correct torque.

Renew valve block.

Renew transmission.

issue 1 August 1994 65

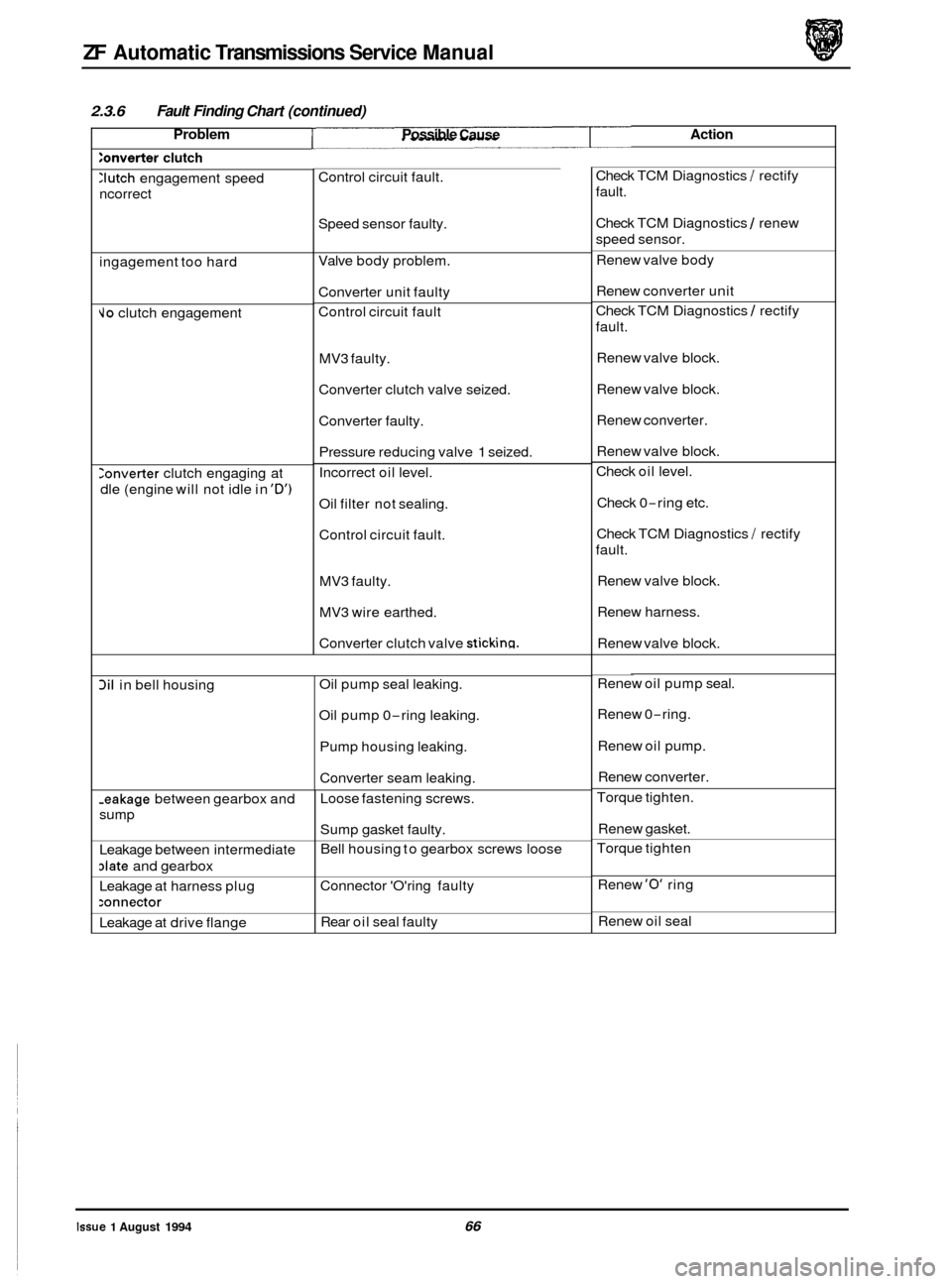

Page 71 of 74

ZF Automatic Transmissions Service Manual

0

3il in bell housing

2.3.6 Fault Finding Chart (continued)

Oil pump seal leaking.

Oil pump 0

-ring leaking.

Pump housing leaking.

Converter seam leaking.

Problem Possible Cause Action

:onverter clutch

-eakage between gearbox and

sump

Leakage between intermediate

date and gearbox

Leakage at harness plug

:onnector

Leakage at drive flange

:Iutch engagement speed

ncorrect

Loose fastening screws.

Sump gasket faulty.

Bell housing to gearbox screws loose

Connector 'O'ring faulty

Rear oil seal faulty

ingagement

too hard

Jo clutch engagement

Ionverter clutch engaging at

dle (engine will not idle in

'D')

Control circuit fault.

Speed sensor faulty.

Valve body problem.

Converter unit faulty

Control circuit fault

MV3 faulty.

Converter clutch valve seized.

Converter faulty. Pressure reducing valve

1 seized.

Incorrect oil level.

Oil filter not sealing.

Control circuit fault.

MV3 faulty.

MV3 wire earthed.

Converter clutch valve

sticking.

Check TCM Diagnostics / rectify

fault.

Check TCM Diagnostics

1 renew

speed sensor.

Renew valve body

Renew converter unit

Check TCM Diagnostics

1 rectify

fault.

Renew valve block.

Renew valve block.

Renew converter.

Renew valve block.

Check oil level.

Check 0

-ring etc.

Check TCM Diagnostics

/ rectify

fault.

Renew valve block.

Renew harness.

Renew valve block.

Renew oil pump seal.

Renew 0

-ring.

Renew oil pump.

Renew converter.

Torque tighten.

Renew gasket.

Torque tighten

Renew

'0' ring

Renew oil seal

Issue 1 August 1994 66

. _.~ -