remove seats JEEP CHEROKEE 1988 Service Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1988, Model line: CHEROKEE, Model: JEEP CHEROKEE 1988Pages: 1378, PDF Size: 19.9 MB

Page 331 of 1378

Remove axle shaft oil seal from axle housing tube.

3) Place axle shaft in a vise. Drill a 1/4" (6.35 mm) hole

3/4 of the way through bearing retaining ring. Chisel off bearing

retaining ring. Do not use a torch. Press bearing off axle. Remove

seal and retainer plate.

Installation

Lubricate bearing and seal lip. Install retainer plate and

seal over axle. Press axle shaft bearing and retaining ring on shaft

simultaneously. Ensure bearing and ring are seated against axle shaft

shoulder. To complete installation, reverse removal procedure to

complete installation.

WHEEL CYLINDER

Removal

Remove wheel assemblies, brake drums and brake shoes.

Disconnect brake line at wheel cylinder. Do not bend brake line away

from cylinder. Remove cylinder-to-support plate bolts. Remove

cylinder.

Installation

To install, reverse removal procedure. Start brake line

fitting into cylinder before installing cylinder to support plate.

OVERHAUL

DISC BRAKE CALIPER

Disassembly

1) Clean caliper exterior with brake cleaning solvent. Drain

residual fluid from caliper and place caliper on a clean working

surface.

2) Remove piston from caliper by applying compressed air to

inlet port. Use just enough pressure to ease piston out of bore.

Protect piston from damage with folded shop towels. Do not try to

catch piston by hand.

3) Pry dust boot out of bore with screwdriver. Do not scratch

bore. Using a small plastic or wooden stick, pry piston seal from

bore. See Fig. 11. Remove bleeder screw, sleeves, and bushings.

Cleaning & Inspection

Clean all parts with brake cleaning solvent. Blow dry parts.

Check for damaged or worn parts. Stains on piston bore can be polished

with crocus cloth. Do not use emery cloth or any other abrasive.

Reassembly

1) Lubricate bore and new seal with brake fluid. Install seal

in groove using fingers. Lubricate piston with brake fluid. Slide

metal retainer portion of dust boot over open end of piston. Pull boot

rearward until boot lip seats in piston groove.

2) Push retainer portion of dust boot forward until boot is

flush with rim at open end of piston and boot fold snaps into place.

Insert piston in bore being careful not to unseat piston seal.

3) Push piston to bottom of bore using hammer handle.

Position dust boot retainer in counterbore at top of piston bore. Seat

dust boot retainer with Dust Boot Installer (J-22904 or J-33028).

Reverse removal procedure to complete installation.

Page 334 of 1378

MASTER CYLINDER - GRAND WAGONEER

NOTE: Do not hone master cylinder bore. Bore has a highly polished

"bearingized" surface. Honing will cause premature failure

of rubber parts.

Disassembly

1) Clean outside of cylinder thoroughly and remove cover.

Drain fluid. Pump piston to remove any remaining fluid. On

Delco/Moraine models with composite fluid reservoir, install metal

flange in vise and pry reservoir off with a pry bar. Bendix composite

reservoir is held on by 4 bolts on bottom of reservoir. On manual

brake models, remove boot from cylinder to uncover push rod retainer.

2) Pry up retainer tab to release retainer. Remove snap ring

from groove in cylinder bore. Remove both piston assemblies. Remove

remaining internal parts from bore. Note direction of piston seals.

Remove and discard all rubber parts from piston assemblies.

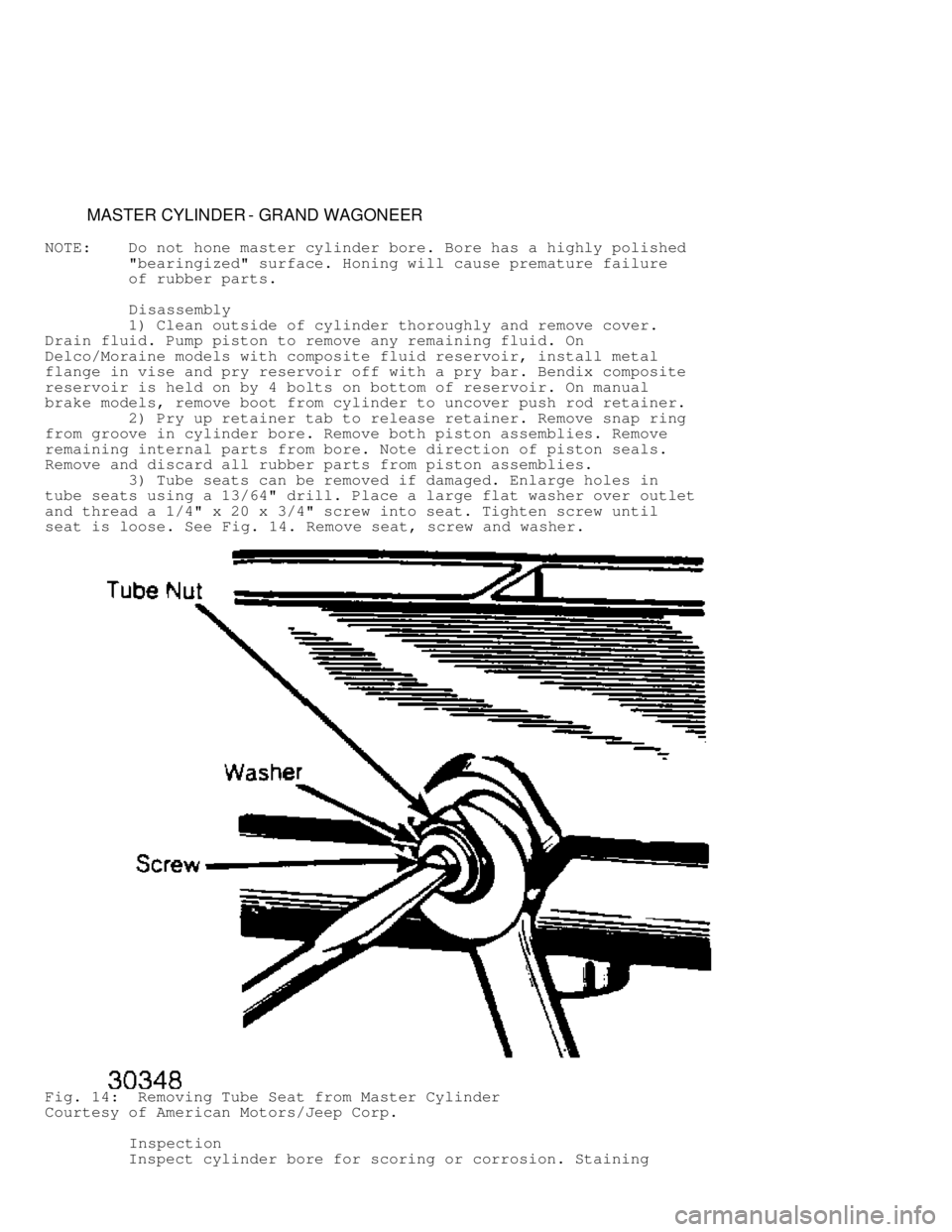

3) Tube seats can be removed if damaged. Enlarge holes in

tube seats using a 13/64" drill. Place a large flat washer over outlet

and thread a 1/4" x 20 x 3/4" screw into seat. Tighten screw until

seat is loose. See Fig. 14. Remove seat, screw and washer.

Fig. 14: Removing Tube Seat from Master Cylinder

Courtesy of American Motors/Jeep Corp.

Inspection

Inspect cylinder bore for scoring or corrosion. Staining

Page 335 of 1378

which has not pitted or roughened surface of cylinder can be removed

with crocus cloth. If cylinder bore is scored, pitted or corroded,

replace master cylinder.

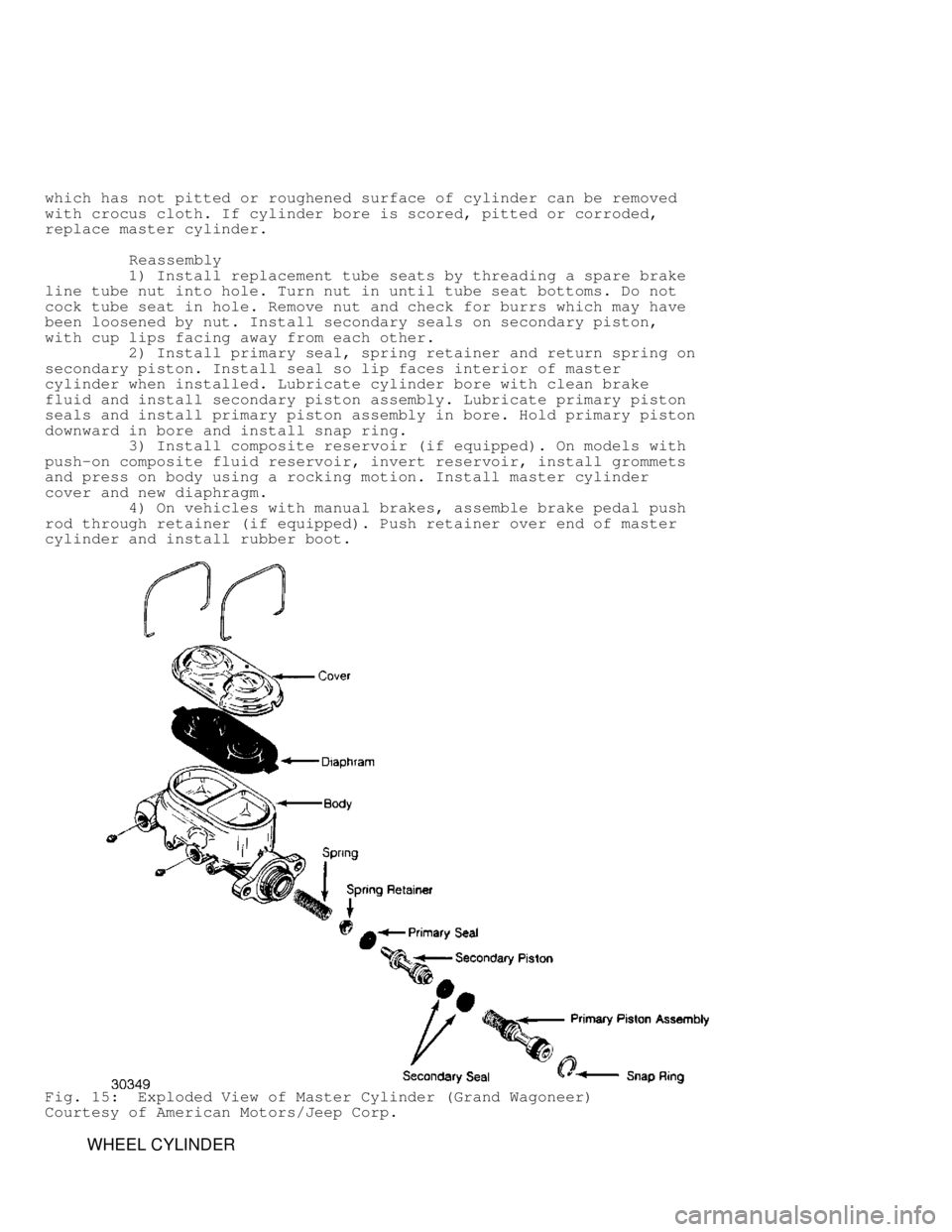

Reassembly

1) Install replacement tube seats by threading a spare brake

line tube nut into hole. Turn nut in until tube seat bottoms. Do not

cock tube seat in hole. Remove nut and check for burrs which may have

been loosened by nut. Install secondary seals on secondary piston,

with cup lips facing away from each other.

2) Install primary seal, spring retainer and return spring on

secondary piston. Install seal so lip faces interior of master

cylinder when installed. Lubricate cylinder bore with clean brake

fluid and install secondary piston assembly. Lubricate primary piston

seals and install primary piston assembly in bore. Hold primary piston

downward in bore and install snap ring.

3) Install composite reservoir (if equipped). On models with\

push-on composite fluid reservoir, invert reservoir, install grommets

and press on body using a rocking motion. Install master cylinder

cover and new diaphragm.

4) On vehicles with manual brakes, assemble brake pedal push

rod through retainer (if equipped). Push retainer over end of master

cylinder and install rubber boot.

Fig. 15: Exploded View of Master Cylinder (Grand Wagoneer)

Courtesy of American Motors/Jeep Corp.

WHEEL CYLINDER

Page 378 of 1378

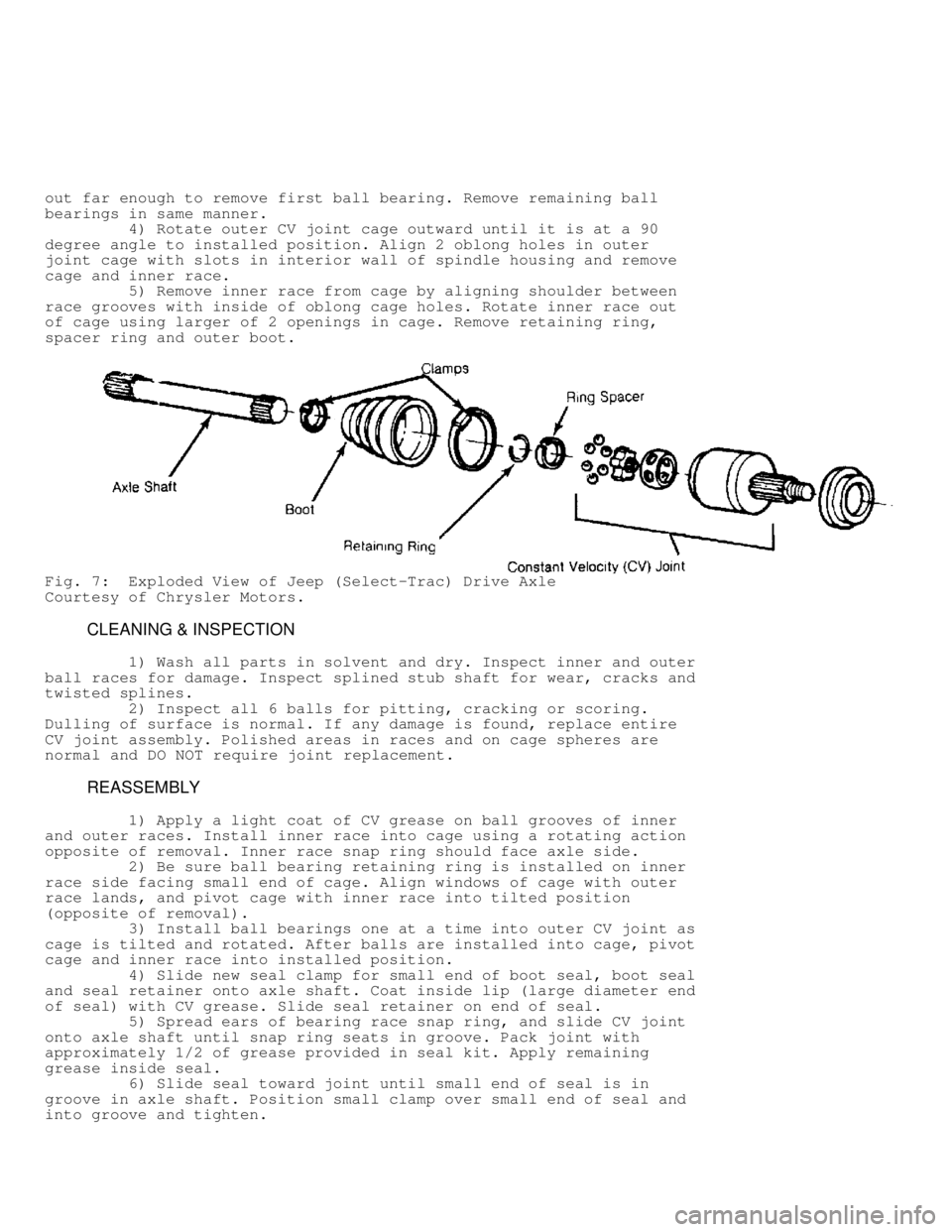

out far enough to remove first ball bearing. Remove remaining ball

bearings in same manner.

4) Rotate outer CV joint cage outward until it is at a 90

degree angle to installed position. Align 2 oblong holes in outer

joint cage with slots in interior wall of spindle housing and remove

cage and inner race.

5) Remove inner race from cage by aligning shoulder between

race grooves with inside of oblong cage holes. Rotate inner race out

of cage using larger of 2 openings in cage. Remove retaining ring,

spacer ring and outer boot.

Fig. 7: Exploded View of Jeep (Select-Trac) Drive Axle

Courtesy of Chrysler Motors.

CLEANING & INSPECTION

1) Wash all parts in solvent and dry. Inspect inner and outer

ball races for damage. Inspect splined stub shaft for wear, cracks and

twisted splines.

2) Inspect all 6 balls for pitting, cracking or scoring.

Dulling of surface is normal. If any damage is found, replace entire

CV joint assembly. Polished areas in races and on cage spheres are

normal and DO NOT require joint replacement.

REASSEMBLY

1) Apply a light coat of CV grease on ball grooves of inner

and outer races. Install inner race into cage using a rotating action

opposite of removal. Inner race snap ring should face axle side.

2) Be sure ball bearing retaining ring is installed on inner

race side facing small end of cage. Align windows of cage with outer

race lands, and pivot cage with inner race into tilted position

(opposite of removal).

3) Install ball bearings one at a time into outer CV joint as

cage is tilted and rotated. After balls are installed into cage, pivot

cage and inner race into installed position.

4) Slide new seal clamp for small end of boot seal, boot seal

and seal retainer onto axle shaft. Coat inside lip (large diameter end

of seal) with CV grease. Slide seal retainer on end of seal.

5) Spread ears of bearing race snap ring, and slide CV joint

onto axle shaft until snap ring seats in groove. Pack joint with

approximately 1/2 of grease provided in seal kit. Apply remaining

grease inside seal.

6) Slide seal toward joint until small end of seal is in

groove in axle shaft. Position small clamp over small end of seal and

into groove and tighten.

Page 386 of 1378

PINION DEPTH

1) Depth Gauge Set (D-271) is used to determine pinion depth\

.

Place Master Pinion Block (D-139 on Model 44; D-120 on Model 60 and

61; D-137 on Model 70; T80T-4020-F42 on Model 80) in pinion bore of

carrier. Put Arbor Discs (D-115-4-44 on Model 44; D-116-2 on Models

60,61 and 70; (T88T-4020-A) on Arbor (D-115-3). Install arbor in

carrier with discs riding in bearing bore.

2) Put Pinion Height Block (D-115-1-44 on Model 44; D-116-1

on Models 60, 61, 70 and 80) on top of master pinion block with side

against arbor. Place Scooter Block (115-2) with Dial Indicator (D-106\

-

5) on small step of pinion height block. Zero dial indicator with

scooter block flat on pinion height block.

3) Move scooter block so dial indicator tip touches arbor.

Move block back and forth (perpendicular to arbor) to get highest

reading. This reading, plus or minus value etched on pinion head, is

thickness of shim pack necessary for pinion bearing.

4) On Model 80, Use Gauge Tube (D81T-4020-F51) and Gauge

Block (D81T-4020-F56) to determine required thickness of shim pack.

5) On all models, measure shims separately with micrometer.

If baffle is used, its thickness must be included in shim pack. This

is also true if slinger is used between inner bearing and head of

pinion shaft. Place pinion height shim pack in carrier bore for inner

bearing race. Drive bearing race into carrier, making sure cup is

fully seated.

PINION BEARING PRELOAD

1) Drive outer pinion bearing into carrier housing. Press

inner pinion bearing onto pinion shaft using Press Tube (C-3095-A).

Ensure bearing seats fully. Insert pinion shaft into carrier. Install

outer bearing, slinger (if equipped), flange, washer and nut.

NOTE: Pinion preload shims and oil seal should NOT be installed at

this time.

2) Using an INCH lb. torque wrench, tighten pinion nut until

10 INCH lbs. (1.13 N.m) rotational torque is required to move pinion

shaft. Recheck pinion depth with arbor and discs at this time. Place

pinion height block on face of pinion shaft.

3) Place dial indicator on small step of height block for

Model 44, 60 and 61 axles. Place dial indicator on high step of block

for Models 70 and 80 axles. Zero dial indicator and move it across

arbor to get highest reading. If reading is within .002" (.05 mm) of

etching on pinion face, pinion depth is correct.

NOTE: If pinion depth is not with .002" (.05 mm) of etched number

on face of pinion, shim pack under inner bearing race must

be changed before proceeding with differential settings.

4) Remove pinion nut, washer, flange, slinger and outer

bearing. Place preload shims (removed during disassembly) on pinion.

Install bearing and slinger. After lightly coating lips with gear oil,

install pinion seal in carrier housing. Install flange, washer and NEW

pinion nut. Tighten nut to specification. See TORQUE SPECIFICATIONS

table at end of this article.

5) Using an INCH lb. torque wrench, measure preload

(rotational torque) of pinion shaft. Rotational torque required to

keep pinion shaft turning freely and smoothly should be 20-40 INCH

lbs. (2.3-4.5 N.m). If preload needs to be increased, remove a few

shims and recheck. To decrease preload, add a few shims and recheck.

See Fig. 14 .

Page 619 of 1378

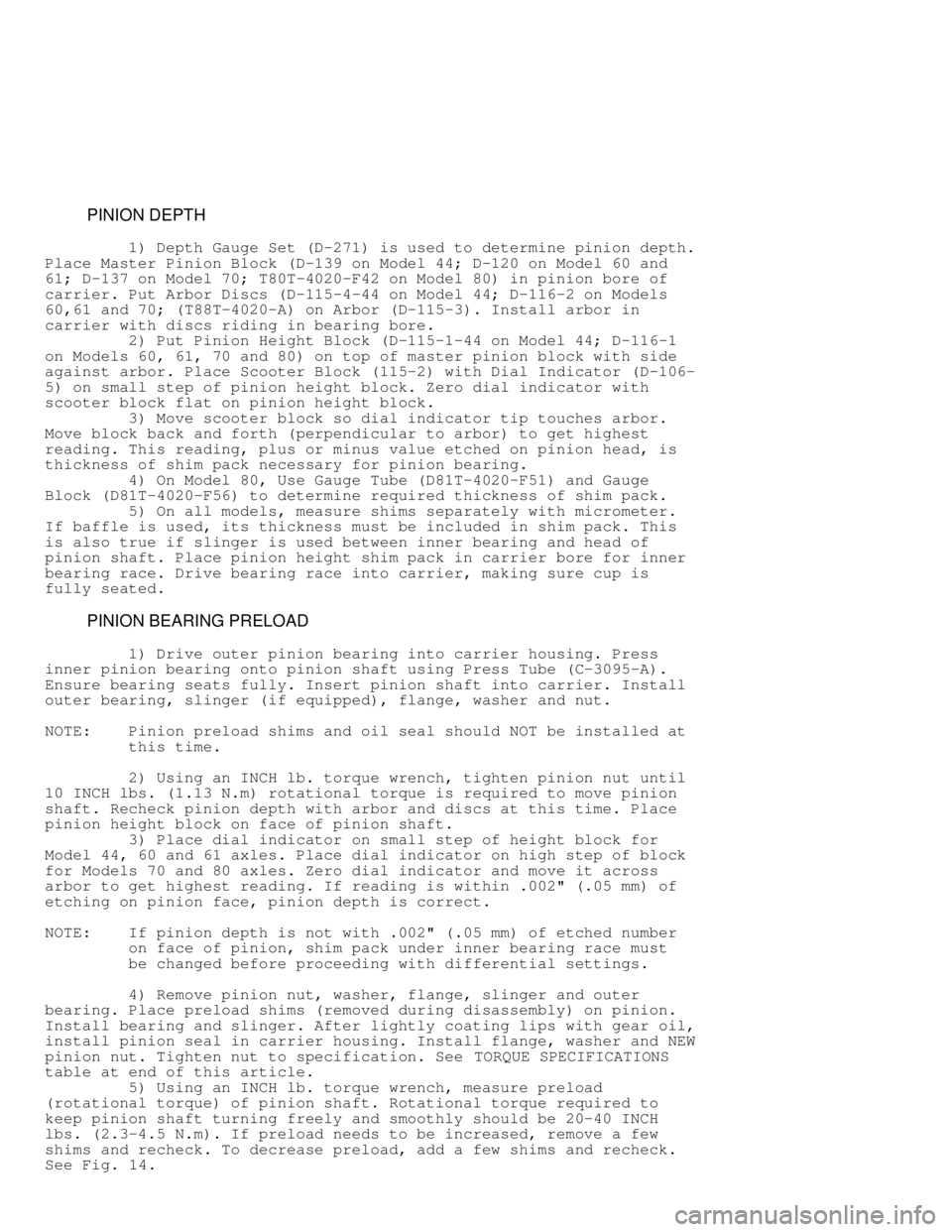

cylinder head design and type of metal used.

Remove valve guide from cylinder head by pressing or tapping

on a stepped drift. See Fig. 8. Once valve guide is installed,

distance from cylinder head to top of valve guide must be checked.

This distance must be within specification.

Aluminum heads are often heated before installing valve

guide. Guide is sometimes chilled in dry ice before installation.

Combination of a heated head and chilled guide insures a tight guide

fit upon assembly. The new guide must be reamed to specification.

Fig. 8: Typical Valve Guide Remover & Installer

This Graphic For General Information Only

VALVES & VALVE SEATS

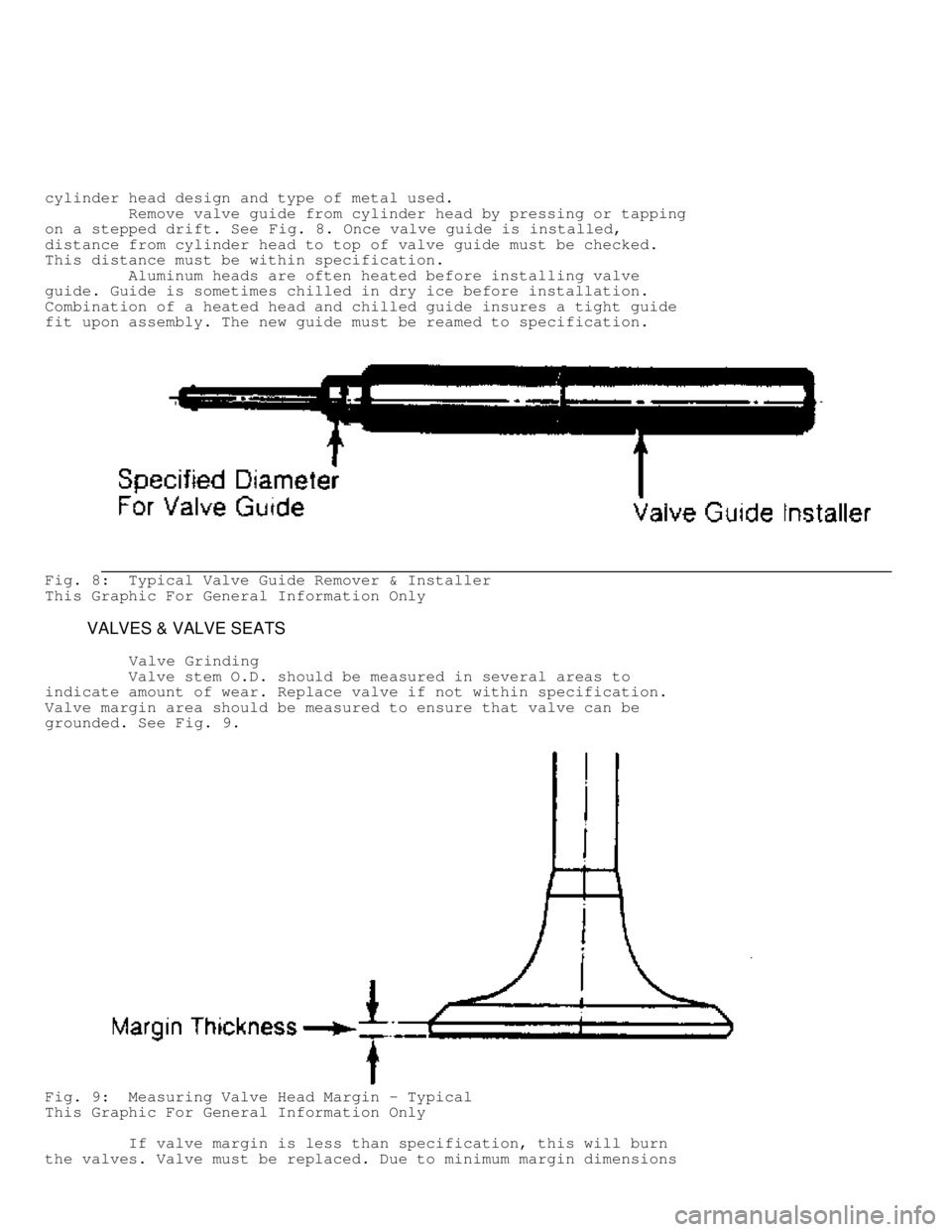

Valve Grinding

Valve stem O.D. should be measured in several areas to

indicate amount of wear. Replace valve if not within specification.

Valve margin area should be measured to ensure that valve can be

grounded. See Fig. 9.

Fig. 9: Measuring Valve Head Margin - Typical

This Graphic For General Information Only

If valve margin is less than specification, this will burn

the valves. Valve must be replaced. Due to minimum margin dimensions

Page 620 of 1378

during manufacture, some new type valves cannot be reground.

Resurface valve on proper angle specification using valve

grinding machine. Follow manufacturer's instructions for valve

grinding machine. Specifications may indicate a different valve face

angle than seat angle.

Measure valve margin after grinding. Replace valve if not

within specification. Valve stem tip can be refinished using valve

grinding machine.

Valve Lapping

During valve lapping of recent designed valves, be sure to

follow manufacturers recommendations. Surface hardening and materials

used with some valves do not permit lapping. Lapping process will

remove excessive amounts of the hardened surface.

Valve lapping is done to ensure adequate sealing between

valve face and seat. Use either a hand drill or lapping stick with

suction cup attached.

Moisten and attach suction cup to valve. Lubricate valve stem

and guide. Apply a thin coat of fine valve grinding compound between

valve and seat. Rotate lapping tool between the palms or with hand

drill.

Lift valve upward off the seat and change position often.

This is done to prevent grooving of valve seat. Lap valve until a

smooth polished seat is obtained. Thoroughly clean grinding compound

from components. Valve to valve seat concentricity should be checked.

See VALVE SEAT CONCENTRICITY.

CAUTION: Valve guides must be in good condition and free of carbon

deposits prior to valve seat grinding. Some engines contain

an induction hardened valve seat. Excessive material removal

will damage valve seats.

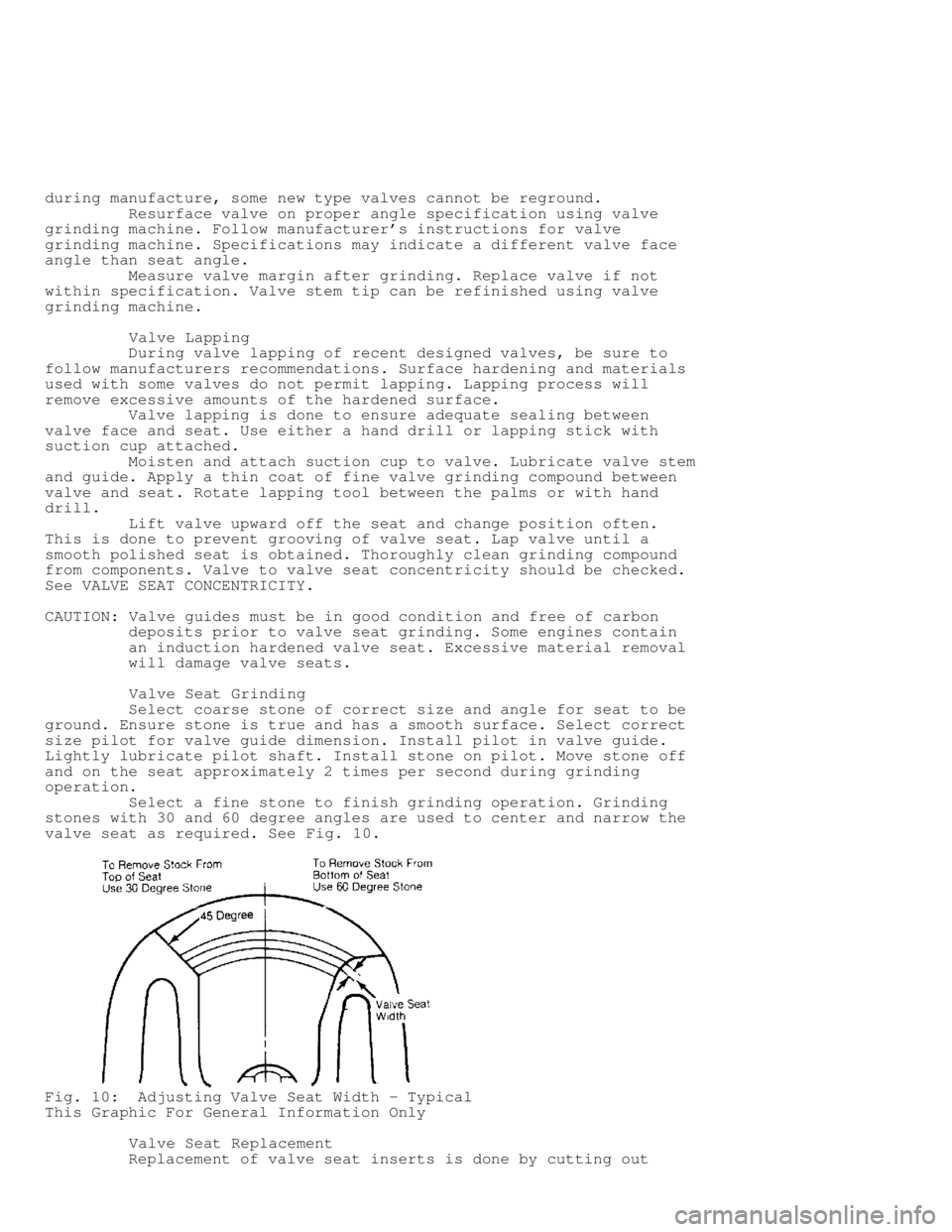

Valve Seat Grinding

Select coarse stone of correct size and angle for seat to be

ground. Ensure stone is true and has a smooth surface. Select correct

size pilot for valve guide dimension. Install pilot in valve guide.

Lightly lubricate pilot shaft. Install stone on pilot. Move stone off

and on the seat approximately 2 times per second during grinding

operation.

Select a fine stone to finish grinding operation. Grinding

stones with 30 and 60 degree angles are used to center and narrow the

valve seat as required. See Fig. 10.

Fig. 10: Adjusting Valve Seat Width - Typical

This Graphic For General Information Only

Valve Seat Replacement

Replacement of valve seat inserts is done by cutting out

Page 621 of 1378

the old insert and machining an oversize insert bore. Replacement

oversize insert is usually chilled and the cylinder head is sometimes

warmed. Valve seat is pressed into the head. This operation requires

specialized machine shop equipment.

Valve Seat Concentricity

Using dial gauge, install gauge pilot in valve guide.

Position gauge arm on the valve seat. Adjust dial indicator to zero.

Rotate arm 360 degrees and note reading. Runout should not exceed

specification.

To check valve-to-valve seat concentricity, coat valve face

lightly with Prussian Blue dye. Install valve and rotate it on valve

seat. If pattern is even and entire seat is coated at valve contact

point, valve is concentric with the seat.

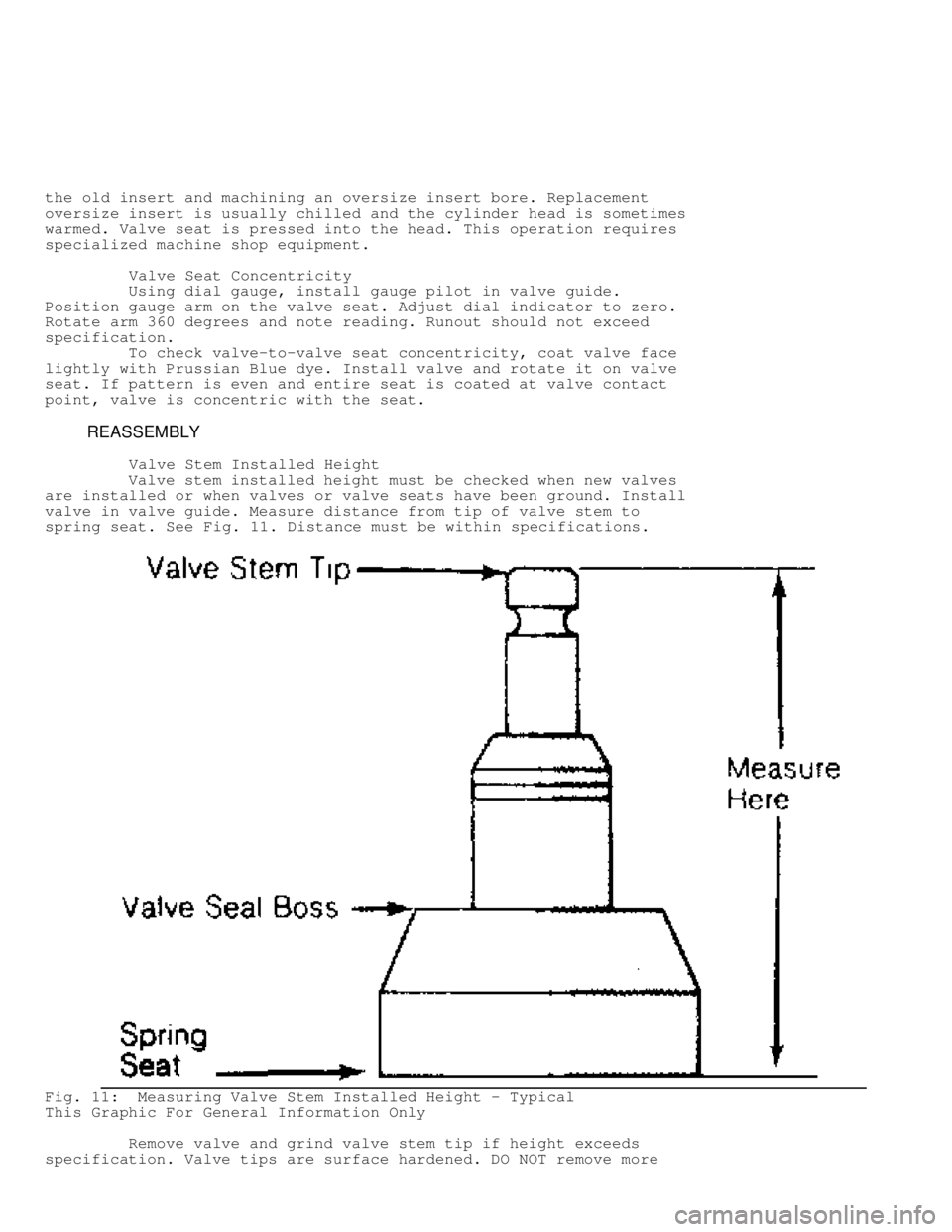

REASSEMBLY

Valve Stem Installed Height

Valve stem installed height must be checked when new valves

are installed or when valves or valve seats have been ground. Install

valve in valve guide. Measure distance from tip of valve stem to

spring seat. See Fig. 11. Distance must be within specifications.

Fig. 11: Measuring Valve Stem Installed Height - Typical

This Graphic For General Information Only

Remove valve and grind valve stem tip if height exceeds

specification. Valve tips are surface hardened. DO NOT remove more

Page 622 of 1378

than .010" (.25 mm) from tip. Chamfer sharp edge of reground valve

tip. Recheck valve stem installed height.

VALVE STEM OIL SEALS

Valve stem oil seals must be installed on valve stem. See

Fig. 2 . Seals are needed due to pressure differential at the ends of

valve guides. Atmospheric pressure above intake guide, combined with

manifold vacuum below guide, causes oil to be drawn into the cylinder.

Exhaust guides also have pressure differential created by

exhaust gas flowing past the guide, creating a low pressure area. This

low pressure area draws oil into the exhaust system.

Replacement (On Vehicle)

Mark rocker arm or overhead cam components for location.

Remove rocker arm components or overhead cam components. Components

must be installed in original location. Remove spark plugs. Valve stem

oil seals may be replaced by holding valves against seats using air

pressure.

Air pressure must be installed in cylinder using an adapter

for spark plug hole. An adapter can be constructed by welding air hose

connection to spark plug body with porcelain removed.

Install adapter in spark plug hole. Apply a minimum of 140

psi (9.8 kg/cm

�) to adapter. Air pressure should hold valve closed. If

air pressure does not hold valve closed, check for damaged or bent

valve. Cylinder head must be removed for service.

Using valve spring compressor, compress valve springs. Remove

valve locks. Carefully release spring compressor. Remove retainer or

rotator and valve spring. Remove valve stem oil seal.

If oversized valves have been installed, oversized oil seals

must be used. Coat valve stem with engine oil. Install protective

sleeve over end of valve stem. Install new oil seal over valve stem

and seat on valve guide. Remove protective sleeve. Install spring

seat, valve spring and retainer or rotator. Compress spring and

install valve locks. Remove spring compressor. Ensure valve locks

are fully seated.

Install rocker arms or overhead cam components. Tighten all

bolts to specification. Adjust valves if required. Remove adapter.

Install spark plugs, valve cover and gasket.

VALVE SPRING INSTALLED HEIGHT

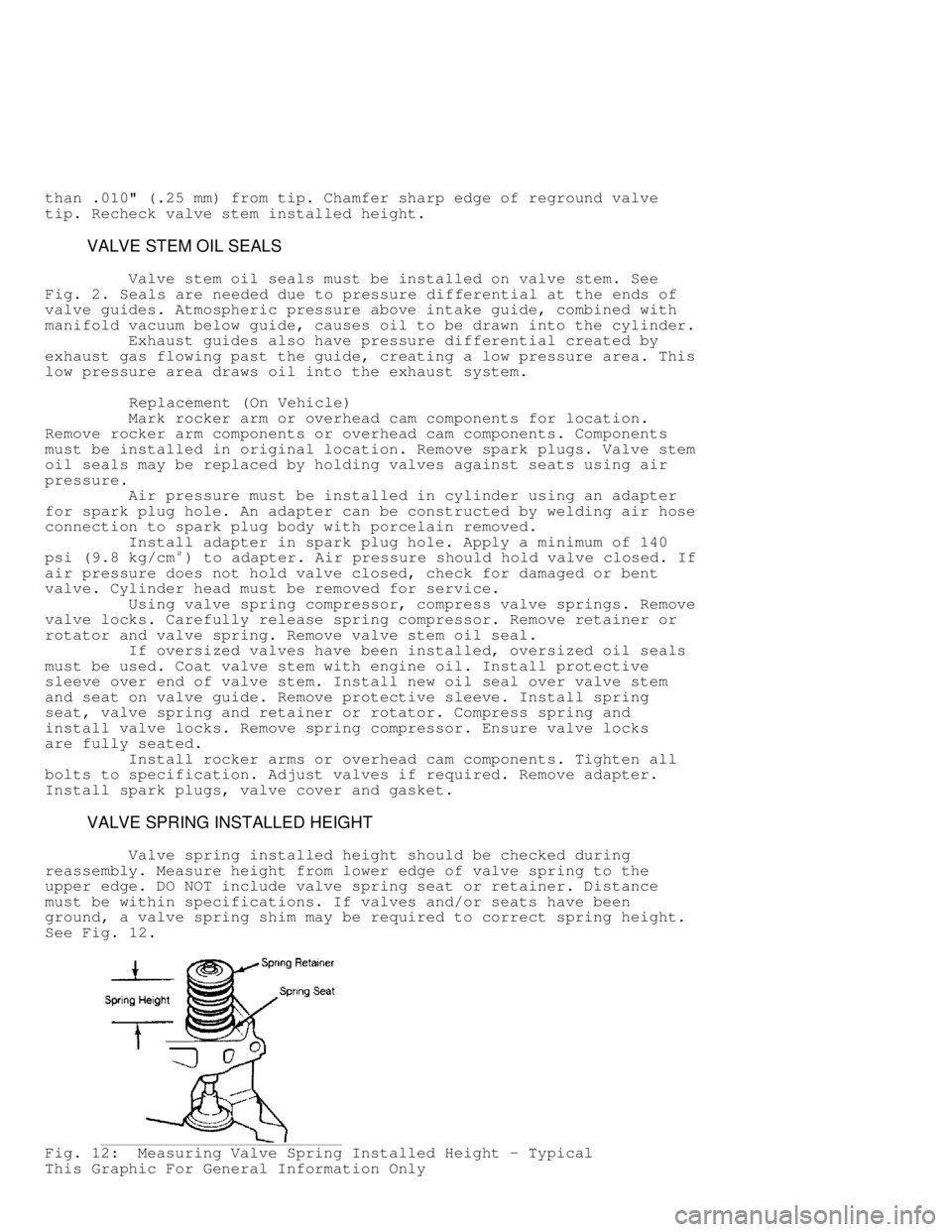

Valve spring installed height should be checked during

reassembly. Measure height from lower edge of valve spring to the

upper edge. DO NOT include valve spring seat or retainer. Distance

must be within specifications. If valves and/or seats have been

ground, a valve spring shim may be required to correct spring height.

See Fig. 12 .

Fig. 12: Measuring Valve Spring Installed Height - Typical

This Graphic For General Information Only

Page 829 of 1378

1 - 25 Amp

Rear Washer/Wiper.

2 - 15 Amp

Radio, Cigarette Lighter.

3 - 25 Amp

Blower Motor.

4 - 20 Amp

Turn Signal, Back-Up Lights, Rear Window Defogger Relay.

5 - 10 Amp

Dome Light, Courtesy Lights, Glove Box Light, Cargo Light,

Radio Memory, Power Mirrors, Teltak Connector.

6 - 15 Amp

Hazard Warning System, Stoplights.

7 - 10 Amp

Parking Lights, Headlight Warning Chime/Buzzer, Instrument

Panel Light Dimmer.

8 - 7.5 Amp

Gauges, Instrument Cluster, Seat Belt Warning, Headlight

Delay, Chime Module, Overhead Console.

9 - 5 Amp

Instrument Panel Illumination.

10 - 25 Amp

Rear Window Defogger.

11 - 30 Amp (Circuit Breaker)

Power Door Locks, Power Seats, Trailer Towing Wiring Harness.

12 - 10 Amp

ETR Radio, Power Antenna.

13 - Not Used (1984-87); 7.5 Amp (1988)

Transmission Control Unit.

14 - 25 Amp

Headlight Delay, Horns, Security Alarm.

15 - 5.5 Amp (Circuit Breaker)

Front Wiper.

16 - 30 Amp (Circuit Breaker)

Power Windows.

17 - 10 Amp

Clock, Security Alarm (Ign).

CAUTIONS & WARNINGS

REPLACING BLOWN FUSES

Before replacing a blown fuse, remove ignition key, turn off

all lights and accessories to avoid damaging the electrical system. Be

sure to use fuse with the correct indicated amperage rating. The use

of an incorrect amperage rating fuse may result in a dangerous