JEEP CHEROKEE 1994 Service Repair Manual

Manufacturer: JEEP, Model Year: 1994, Model line: CHEROKEE, Model: JEEP CHEROKEE 1994Pages: 1784, PDF Size: 77.09 MB

Page 1051 of 1784

STEERING LINKAGEÐXJ

INDEX

page page

Drag Link.............................. 14

Pitman Arm............................. 15

Service Information....................... 14Steering Dampener....................... 15

Tie Rod ................................ 14

SERVICE INFORMATION

The steering linkage consists of a pitman arm, drag

link, tie rod, and steering dampener. Adjustment

sleeves are used on the tie rod and drag link for toe

and steering wheel alignment.

Refer to Group 2, Front Suspension and Axle for

additional information.

The tie-rod end ball stud seals should be inspected

during all oil changes.

A damaged ball stud seal requires removal of the

seal. Inspect the tie-rod end ball stud at the throat

opening. Check for lubricant loss, contamination, ball

stud wear or corrosion. If these conditions exist, re-

place the tie-rod. A replacement seal can be installed

if lubricant is in good condition. Otherwise, a com-

plete replacement ball stud end should be installed.

Lubricate the tie-rod end with MOPARtMulti-Mile-

age Lubricant, or equivalent product.

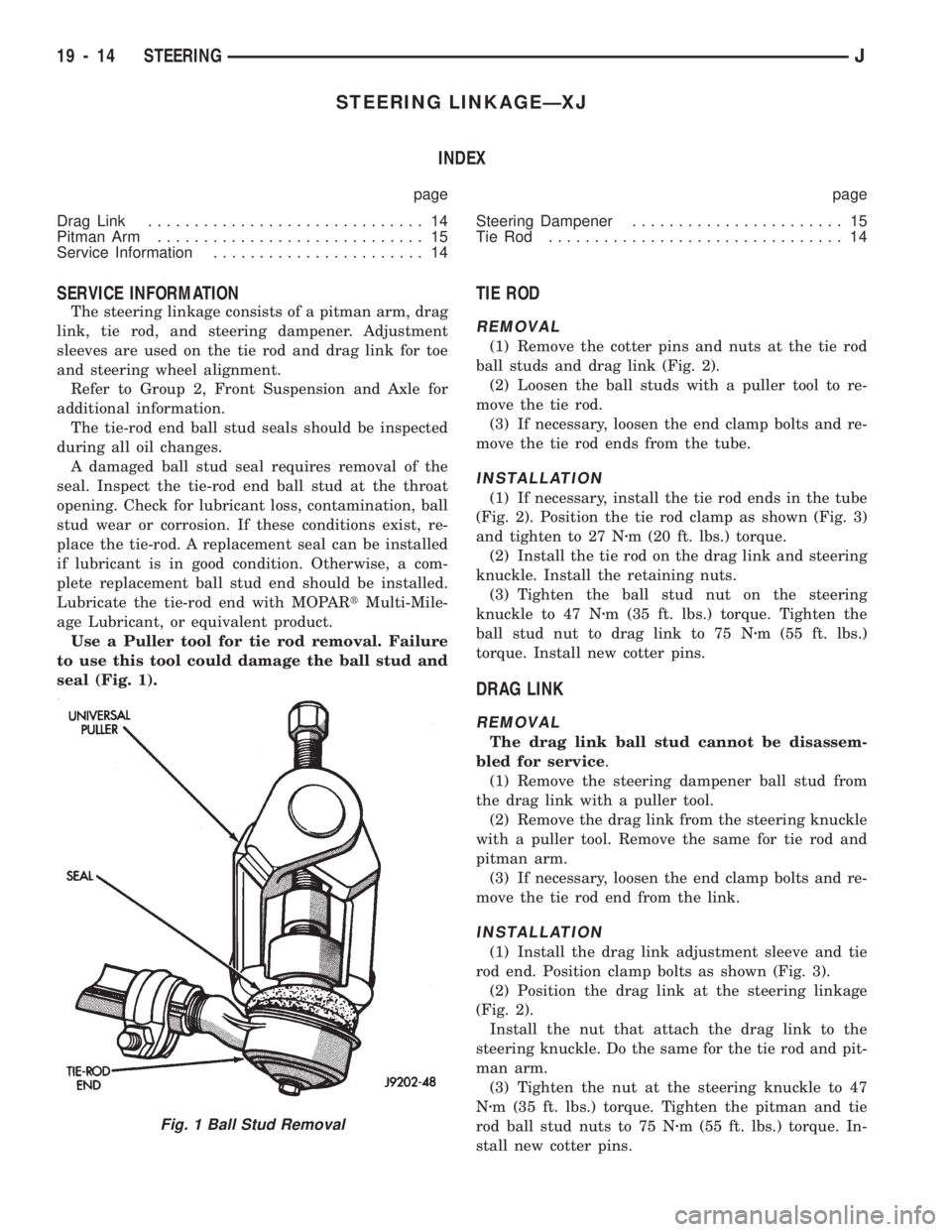

Use a Puller tool for tie rod removal. Failure

to use this tool could damage the ball stud and

seal (Fig. 1).

TIE ROD

REMOVAL

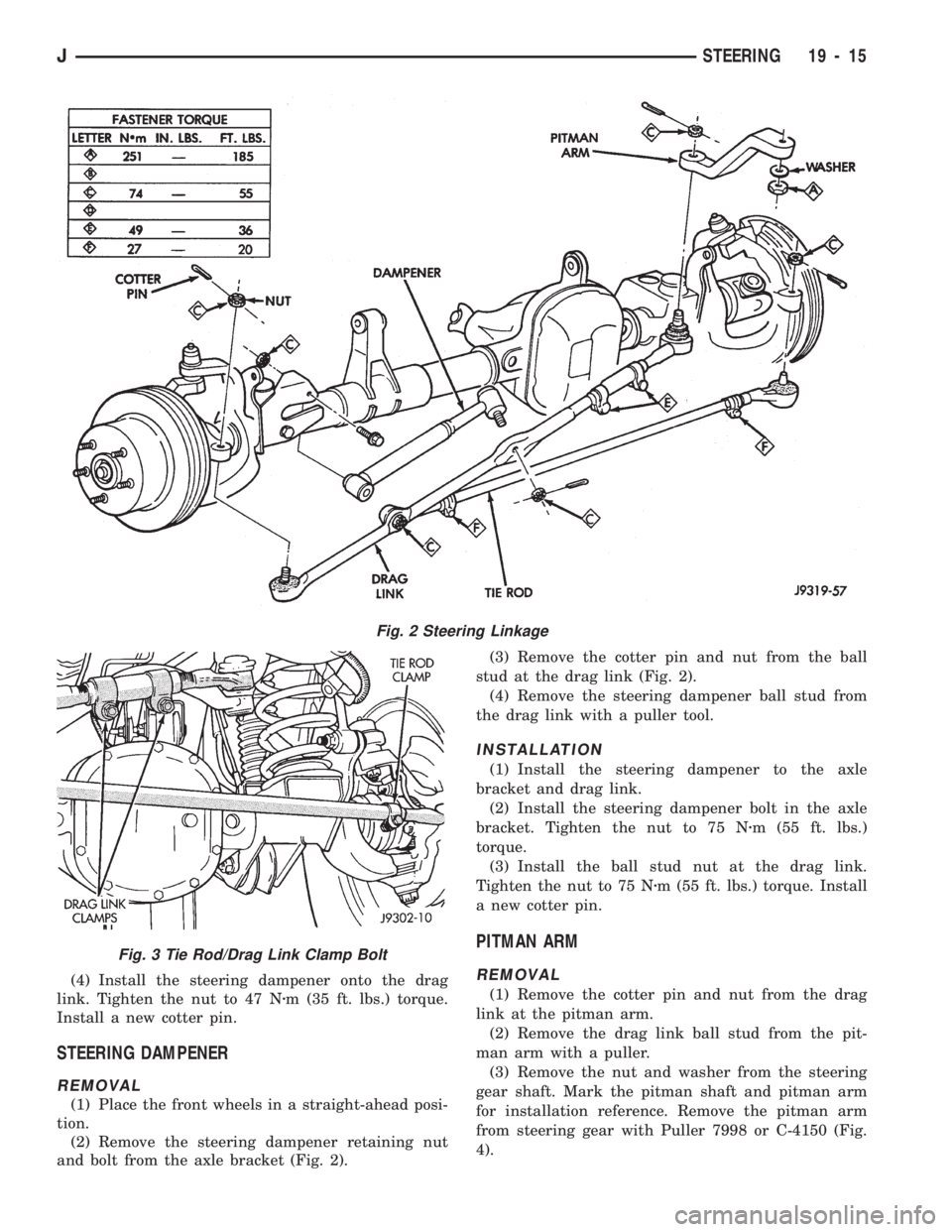

(1) Remove the cotter pins and nuts at the tie rod

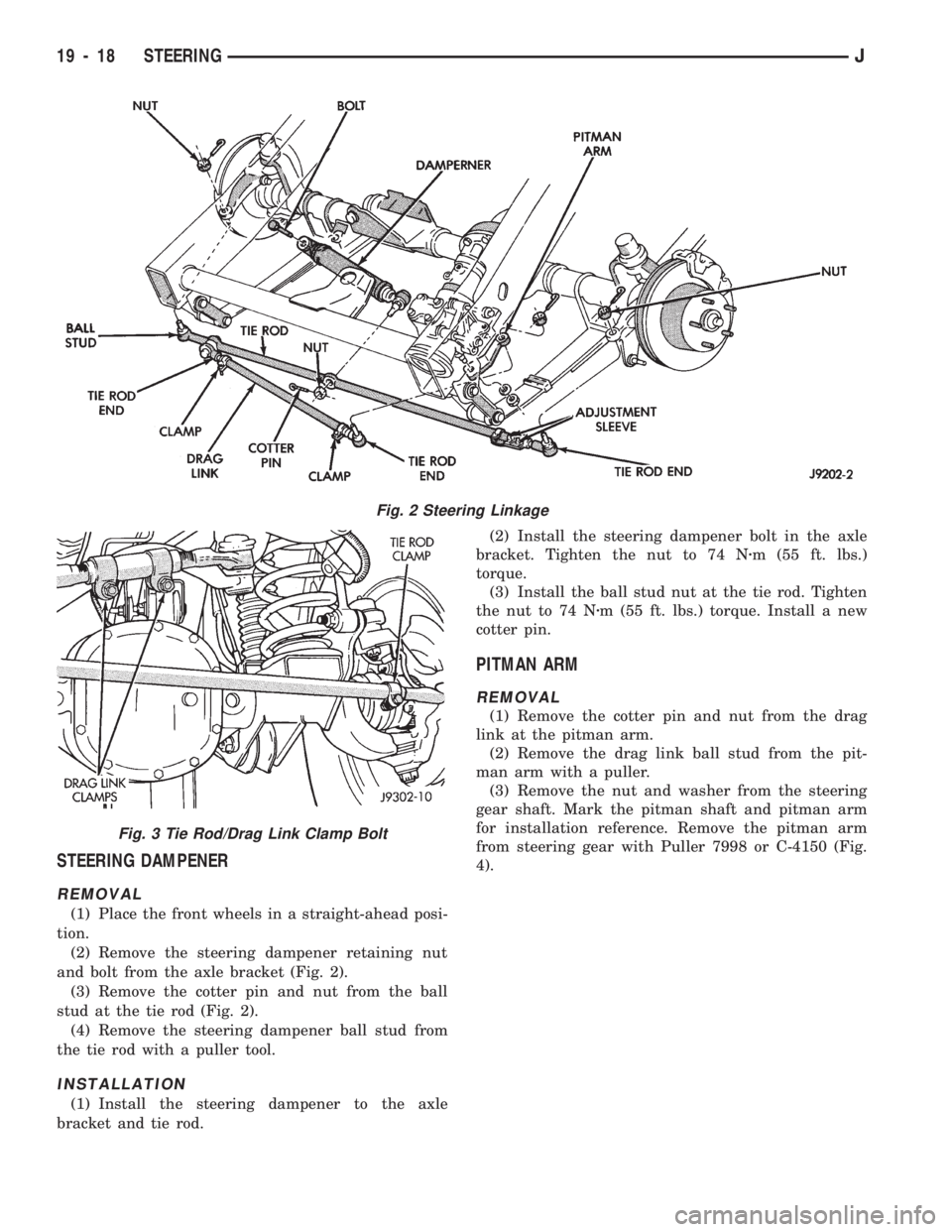

ball studs and drag link (Fig. 2).

(2) Loosen the ball studs with a puller tool to re-

move the tie rod.

(3) If necessary, loosen the end clamp bolts and re-

move the tie rod ends from the tube.

INSTALLATION

(1) If necessary, install the tie rod ends in the tube

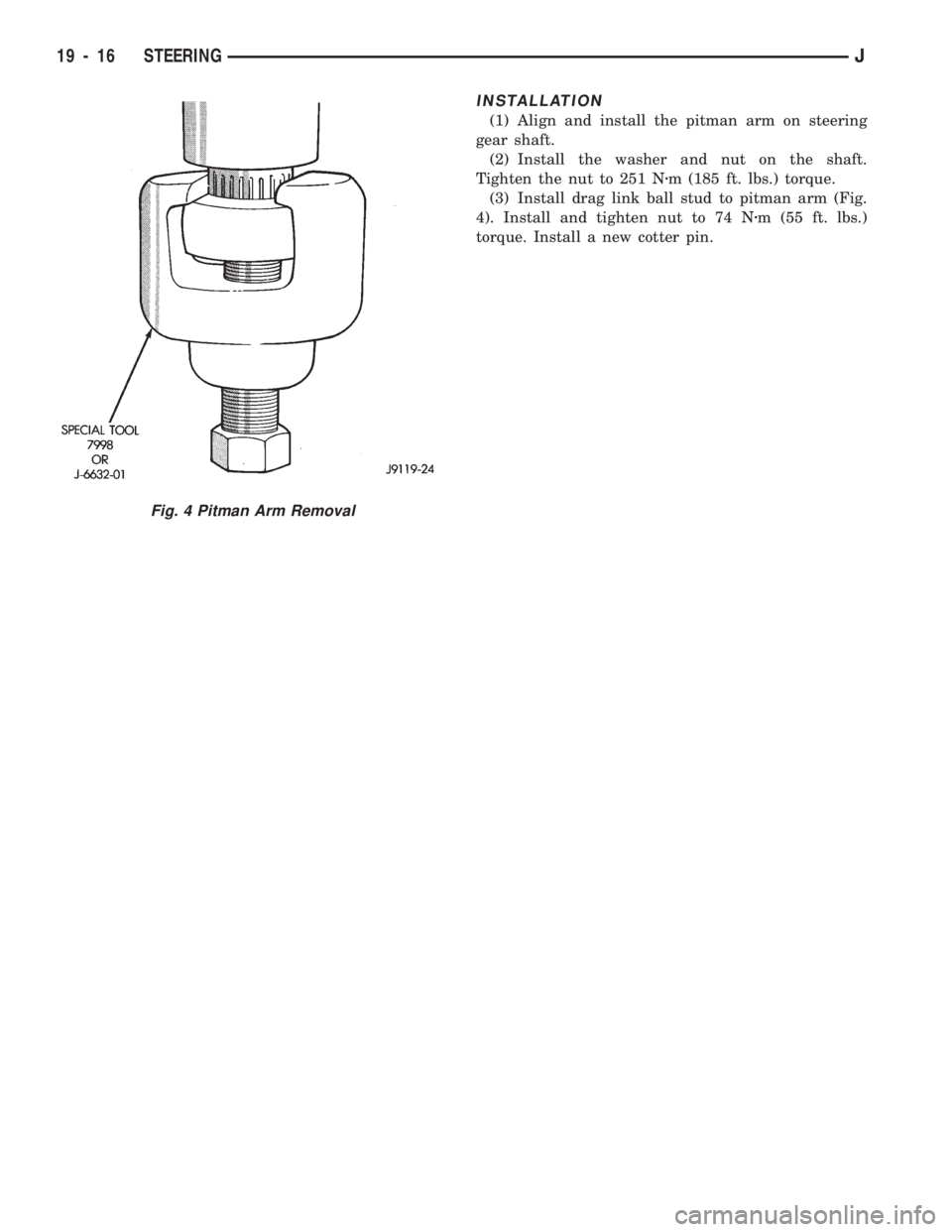

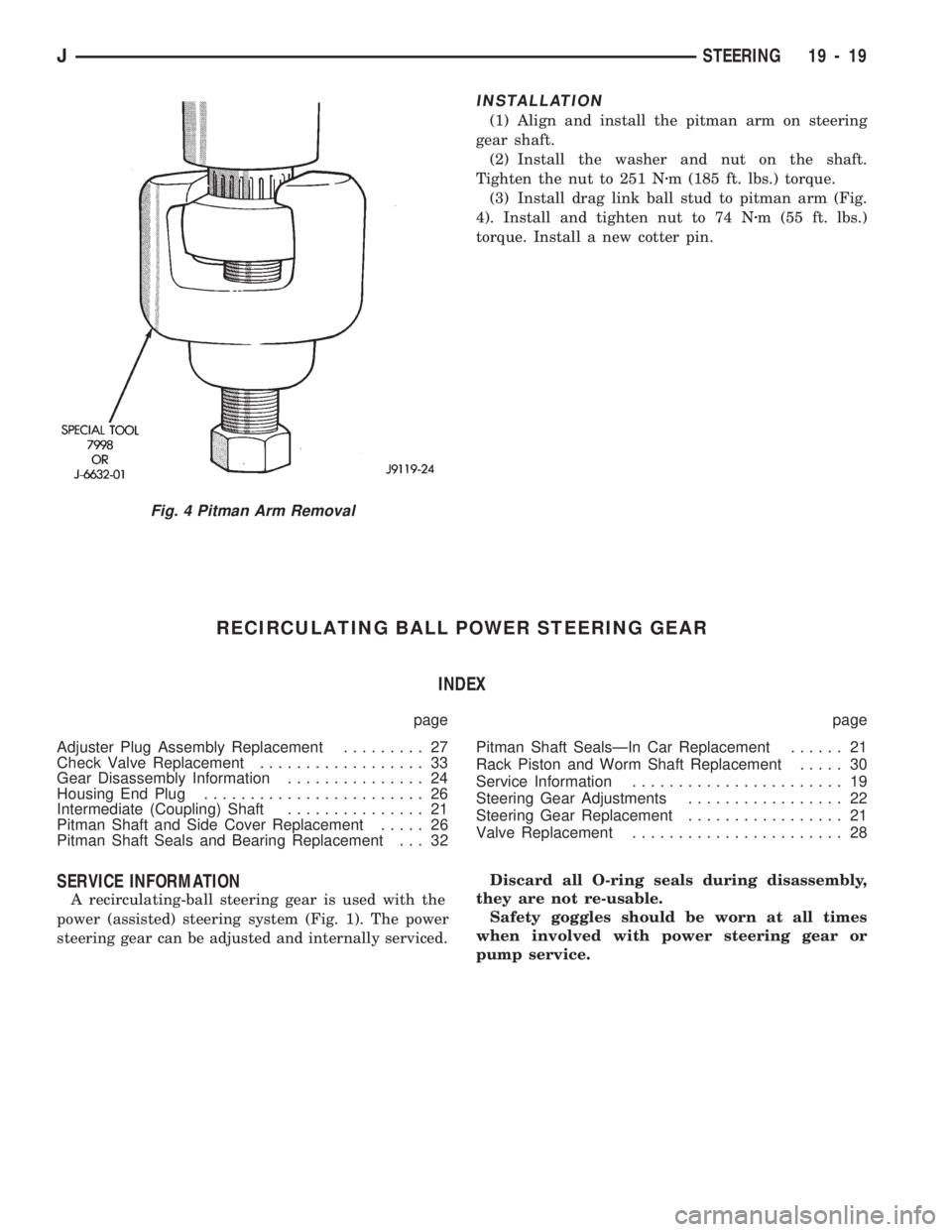

(Fig. 2). Position the tie rod clamp as shown (Fig. 3)

and tighten to 27 Nzm (20 ft. lbs.) torque.

(2) Install the tie rod on the drag link and steering

knuckle. Install the retaining nuts.

(3) Tighten the ball stud nut on the steering

knuckle to 47 Nzm (35 ft. lbs.) torque. Tighten the

ball stud nut to drag link to 75 Nzm (55 ft. lbs.)

torque. Install new cotter pins.

DRAG LINK

REMOVAL

The drag link ball stud cannot be disassem-

bled for service.

(1) Remove the steering dampener ball stud from

the drag link with a puller tool.

(2) Remove the drag link from the steering knuckle

with a puller tool. Remove the same for tie rod and

pitman arm.

(3) If necessary, loosen the end clamp bolts and re-

move the tie rod end from the link.

INSTALLATION

(1) Install the drag link adjustment sleeve and tie

rod end. Position clamp bolts as shown (Fig. 3).

(2) Position the drag link at the steering linkage

(Fig. 2).

Install the nut that attach the drag link to the

steering knuckle. Do the same for the tie rod and pit-

man arm.

(3) Tighten the nut at the steering knuckle to 47

Nzm (35 ft. lbs.) torque. Tighten the pitman and tie

rod ball stud nuts to 75 Nzm (55 ft. lbs.) torque. In-

stall new cotter pins.

Fig. 1 Ball Stud Removal

19 - 14 STEERINGJ

Page 1052 of 1784

(4) Install the steering dampener onto the drag

link. Tighten the nut to 47 Nzm (35 ft. lbs.) torque.

Install a new cotter pin.

STEERING DAMPENER

REMOVAL

(1) Place the front wheels in a straight-ahead posi-

tion.

(2) Remove the steering dampener retaining nut

and bolt from the axle bracket (Fig. 2).(3) Remove the cotter pin and nut from the ball

stud at the drag link (Fig. 2).

(4) Remove the steering dampener ball stud from

the drag link with a puller tool.

INSTALLATION

(1) Install the steering dampener to the axle

bracket and drag link.

(2) Install the steering dampener bolt in the axle

bracket. Tighten the nut to 75 Nzm (55 ft. lbs.)

torque.

(3) Install the ball stud nut at the drag link.

Tighten the nut to 75 Nzm (55 ft. lbs.) torque. Install

a new cotter pin.

PITMAN ARM

REMOVAL

(1) Remove the cotter pin and nut from the drag

link at the pitman arm.

(2) Remove the drag link ball stud from the pit-

man arm with a puller.

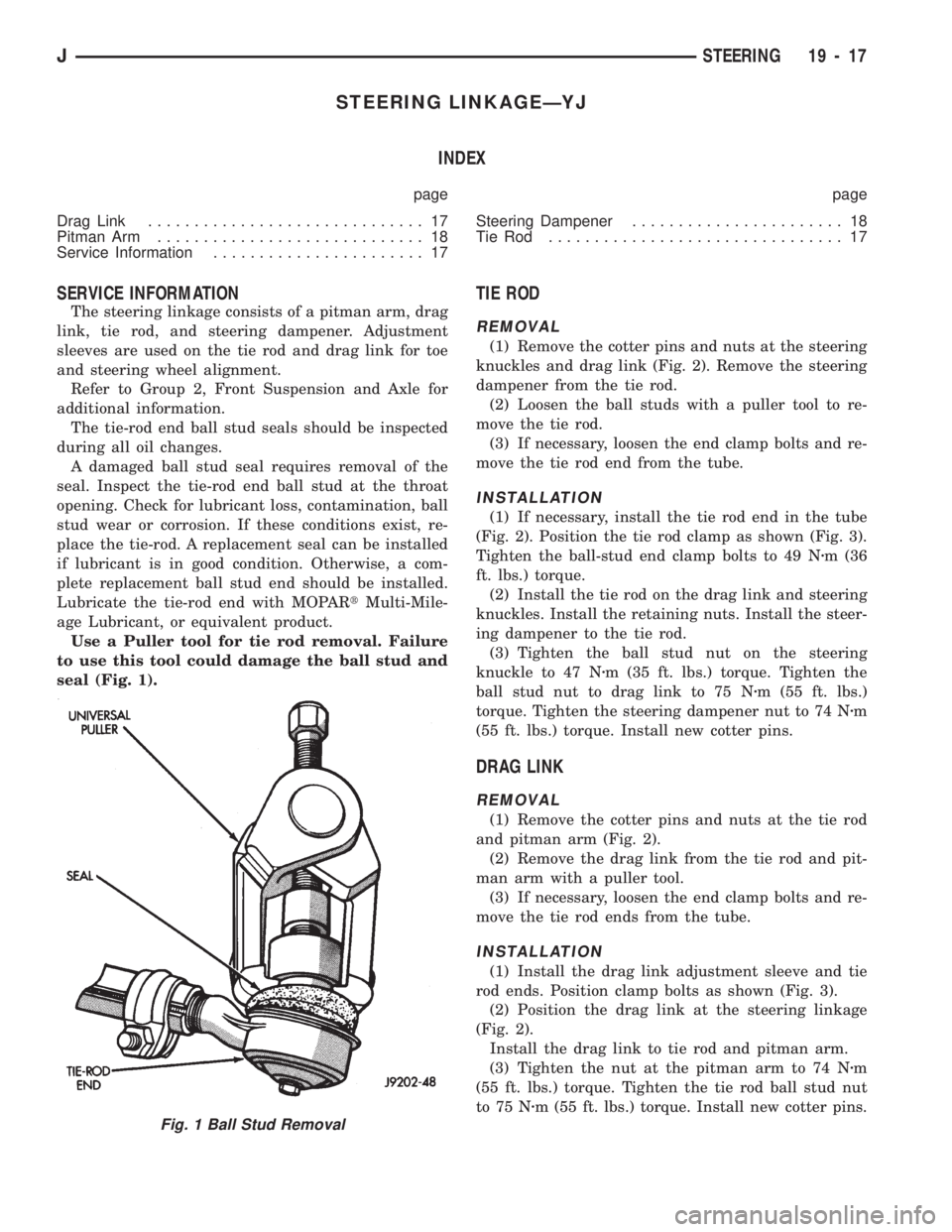

(3) Remove the nut and washer from the steering

gear shaft. Mark the pitman shaft and pitman arm

for installation reference. Remove the pitman arm

from steering gear with Puller 7998 or C-4150 (Fig.

4).

Fig. 2 Steering Linkage

Fig. 3 Tie Rod/Drag Link Clamp Bolt

JSTEERING 19 - 15

Page 1053 of 1784

INSTALLATION

(1) Align and install the pitman arm on steering

gear shaft.

(2) Install the washer and nut on the shaft.

Tighten the nut to 251 Nzm (185 ft. lbs.) torque.

(3) Install drag link ball stud to pitman arm (Fig.

4). Install and tighten nut to 74 Nzm (55 ft. lbs.)

torque. Install a new cotter pin.

Fig. 4 Pitman Arm Removal

19 - 16 STEERINGJ

Page 1054 of 1784

STEERING LINKAGEÐYJ

INDEX

page page

Drag Link.............................. 17

Pitman Arm............................. 18

Service Information....................... 17Steering Dampener....................... 18

Tie Rod ................................ 17

SERVICE INFORMATION

The steering linkage consists of a pitman arm, drag

link, tie rod, and steering dampener. Adjustment

sleeves are used on the tie rod and drag link for toe

and steering wheel alignment.

Refer to Group 2, Front Suspension and Axle for

additional information.

The tie-rod end ball stud seals should be inspected

during all oil changes.

A damaged ball stud seal requires removal of the

seal. Inspect the tie-rod end ball stud at the throat

opening. Check for lubricant loss, contamination, ball

stud wear or corrosion. If these conditions exist, re-

place the tie-rod. A replacement seal can be installed

if lubricant is in good condition. Otherwise, a com-

plete replacement ball stud end should be installed.

Lubricate the tie-rod end with MOPARtMulti-Mile-

age Lubricant, or equivalent product.

Use a Puller tool for tie rod removal. Failure

to use this tool could damage the ball stud and

seal (Fig. 1).

TIE ROD

REMOVAL

(1) Remove the cotter pins and nuts at the steering

knuckles and drag link (Fig. 2). Remove the steering

dampener from the tie rod.

(2) Loosen the ball studs with a puller tool to re-

move the tie rod.

(3) If necessary, loosen the end clamp bolts and re-

move the tie rod end from the tube.

INSTALLATION

(1) If necessary, install the tie rod end in the tube

(Fig. 2). Position the tie rod clamp as shown (Fig. 3).

Tighten the ball-stud end clamp bolts to 49 Nzm (36

ft. lbs.) torque.

(2) Install the tie rod on the drag link and steering

knuckles. Install the retaining nuts. Install the steer-

ing dampener to the tie rod.

(3) Tighten the ball stud nut on the steering

knuckle to 47 Nzm (35 ft. lbs.) torque. Tighten the

ball stud nut to drag link to 75 Nzm (55 ft. lbs.)

torque. Tighten the steering dampener nut to 74 Nzm

(55 ft. lbs.) torque. Install new cotter pins.

DRAG LINK

REMOVAL

(1) Remove the cotter pins and nuts at the tie rod

and pitman arm (Fig. 2).

(2) Remove the drag link from the tie rod and pit-

man arm with a puller tool.

(3) If necessary, loosen the end clamp bolts and re-

move the tie rod ends from the tube.

INSTALLATION

(1) Install the drag link adjustment sleeve and tie

rod ends. Position clamp bolts as shown (Fig. 3).

(2) Position the drag link at the steering linkage

(Fig. 2).

Install the drag link to tie rod and pitman arm.

(3) Tighten the nut at the pitman arm to 74 Nzm

(55 ft. lbs.) torque. Tighten the tie rod ball stud nut

to 75 Nzm (55 ft. lbs.) torque. Install new cotter pins.

Fig. 1 Ball Stud Removal

JSTEERING 19 - 17

Page 1055 of 1784

STEERING DAMPENER

REMOVAL

(1) Place the front wheels in a straight-ahead posi-

tion.

(2) Remove the steering dampener retaining nut

and bolt from the axle bracket (Fig. 2).

(3) Remove the cotter pin and nut from the ball

stud at the tie rod (Fig. 2).

(4) Remove the steering dampener ball stud from

the tie rod with a puller tool.

INSTALLATION

(1) Install the steering dampener to the axle

bracket and tie rod.(2) Install the steering dampener bolt in the axle

bracket. Tighten the nut to 74 Nzm (55 ft. lbs.)

torque.

(3) Install the ball stud nut at the tie rod. Tighten

the nut to 74 Nzm (55 ft. lbs.) torque. Install a new

cotter pin.

PITMAN ARM

REMOVAL

(1) Remove the cotter pin and nut from the drag

link at the pitman arm.

(2) Remove the drag link ball stud from the pit-

man arm with a puller.

(3) Remove the nut and washer from the steering

gear shaft. Mark the pitman shaft and pitman arm

for installation reference. Remove the pitman arm

from steering gear with Puller 7998 or C-4150 (Fig.

4).

Fig. 2 Steering Linkage

Fig. 3 Tie Rod/Drag Link Clamp Bolt

19 - 18 STEERINGJ

Page 1056 of 1784

INSTALLATION

(1) Align and install the pitman arm on steering

gear shaft.

(2) Install the washer and nut on the shaft.

Tighten the nut to 251 Nzm (185 ft. lbs.) torque.

(3) Install drag link ball stud to pitman arm (Fig.

4). Install and tighten nut to 74 Nzm (55 ft. lbs.)

torque. Install a new cotter pin.

RECIRCULATING BALL POWER STEERING GEAR

INDEX

page page

Adjuster Plug Assembly Replacement......... 27

Check Valve Replacement.................. 33

Gear Disassembly Information............... 24

Housing End Plug........................ 26

Intermediate (Coupling) Shaft............... 21

Pitman Shaft and Side Cover Replacement..... 26

Pitman Shaft Seals and Bearing Replacement . . . 32Pitman Shaft SealsÐIn Car Replacement...... 21

Rack Piston and Worm Shaft Replacement..... 30

Service Information....................... 19

Steering Gear Adjustments................. 22

Steering Gear Replacement................. 21

Valve Replacement....................... 28

SERVICE INFORMATION

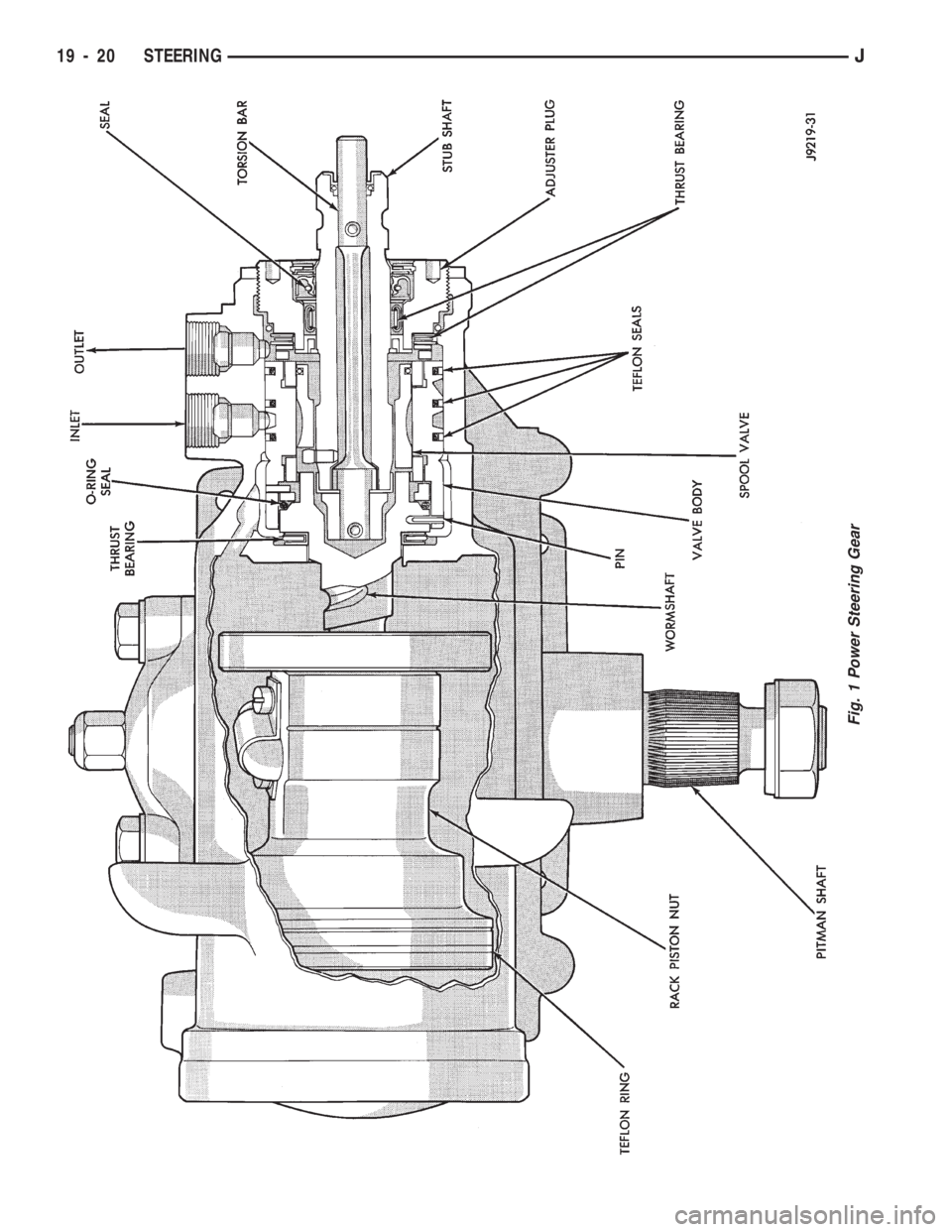

A recirculating-ball steering gear is used with the

power (assisted) steering system (Fig. 1). The power

steering gear can be adjusted and internally serviced.Discard all O-ring seals during disassembly,

they are not re-usable.

Safety goggles should be worn at all times

when involved with power steering gear or

pump service.

Fig. 4 Pitman Arm Removal

JSTEERING 19 - 19

Page 1057 of 1784

Fig. 1 Power Steering Gear

19 - 20 STEERINGJ

Page 1058 of 1784

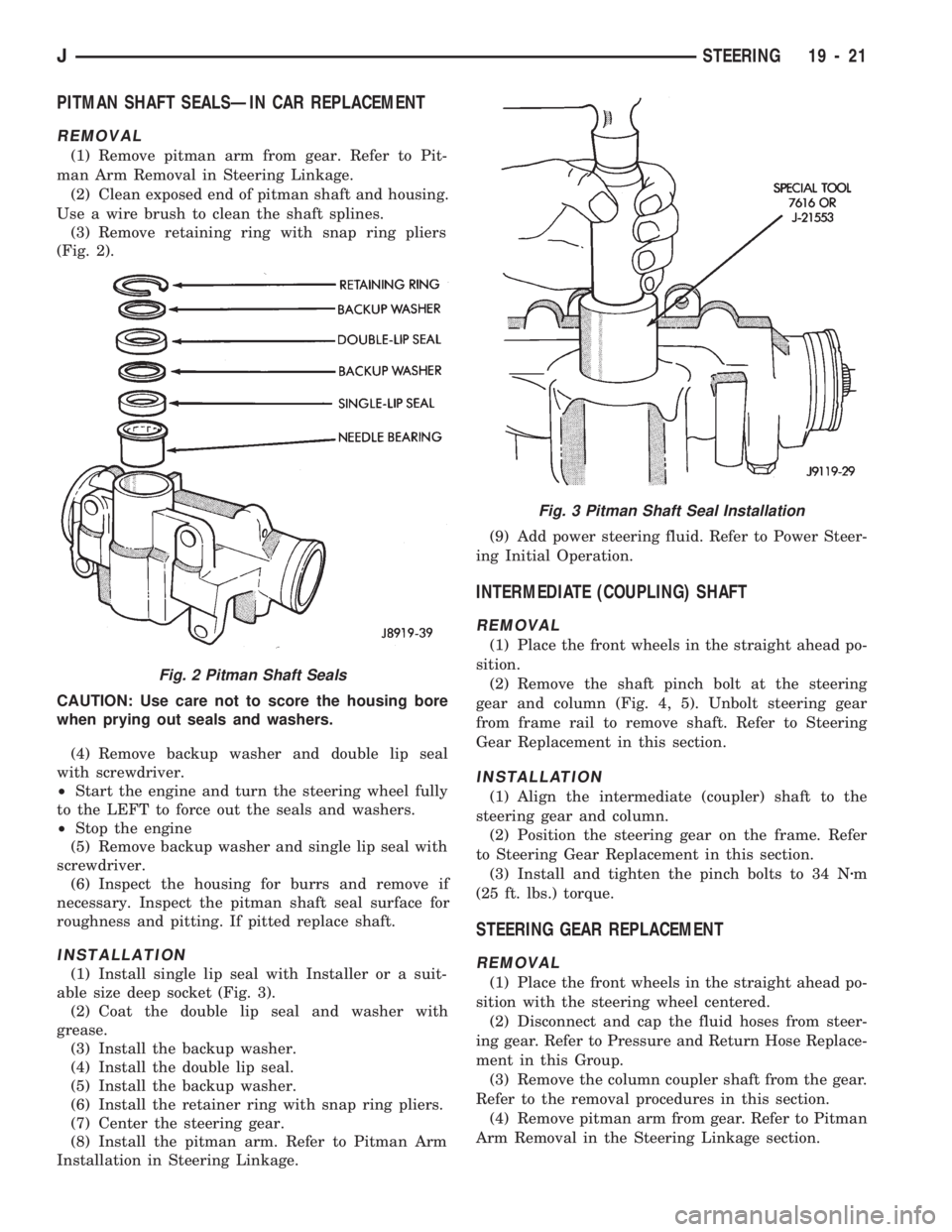

PITMAN SHAFT SEALSÐIN CAR REPLACEMENT

REMOVAL

(1) Remove pitman arm from gear. Refer to Pit-

man Arm Removal in Steering Linkage.

(2) Clean exposed end of pitman shaft and housing.

Use a wire brush to clean the shaft splines.

(3) Remove retaining ring with snap ring pliers

(Fig. 2).

CAUTION: Use care not to score the housing bore

when prying out seals and washers.

(4) Remove backup washer and double lip seal

with screwdriver.

²Start the engine and turn the steering wheel fully

to the LEFT to force out the seals and washers.

²Stop the engine

(5) Remove backup washer and single lip seal with

screwdriver.

(6) Inspect the housing for burrs and remove if

necessary. Inspect the pitman shaft seal surface for

roughness and pitting. If pitted replace shaft.

INSTALLATION

(1) Install single lip seal with Installer or a suit-

able size deep socket (Fig. 3).

(2) Coat the double lip seal and washer with

grease.

(3) Install the backup washer.

(4) Install the double lip seal.

(5) Install the backup washer.

(6) Install the retainer ring with snap ring pliers.

(7) Center the steering gear.

(8) Install the pitman arm. Refer to Pitman Arm

Installation in Steering Linkage.(9) Add power steering fluid. Refer to Power Steer-

ing Initial Operation.

INTERMEDIATE (COUPLING) SHAFT

REMOVAL

(1) Place the front wheels in the straight ahead po-

sition.

(2) Remove the shaft pinch bolt at the steering

gear and column (Fig. 4, 5). Unbolt steering gear

from frame rail to remove shaft. Refer to Steering

Gear Replacement in this section.

INSTALLATION

(1) Align the intermediate (coupler) shaft to the

steering gear and column.

(2) Position the steering gear on the frame. Refer

to Steering Gear Replacement in this section.

(3) Install and tighten the pinch bolts to 34 Nzm

(25 ft. lbs.) torque.

STEERING GEAR REPLACEMENT

REMOVAL

(1) Place the front wheels in the straight ahead po-

sition with the steering wheel centered.

(2) Disconnect and cap the fluid hoses from steer-

ing gear. Refer to Pressure and Return Hose Replace-

ment in this Group.

(3) Remove the column coupler shaft from the gear.

Refer to the removal procedures in this section.

(4) Remove pitman arm from gear. Refer to Pitman

Arm Removal in the Steering Linkage section.

Fig. 2 Pitman Shaft Seals

Fig. 3 Pitman Shaft Seal Installation

JSTEERING 19 - 21

Page 1059 of 1784

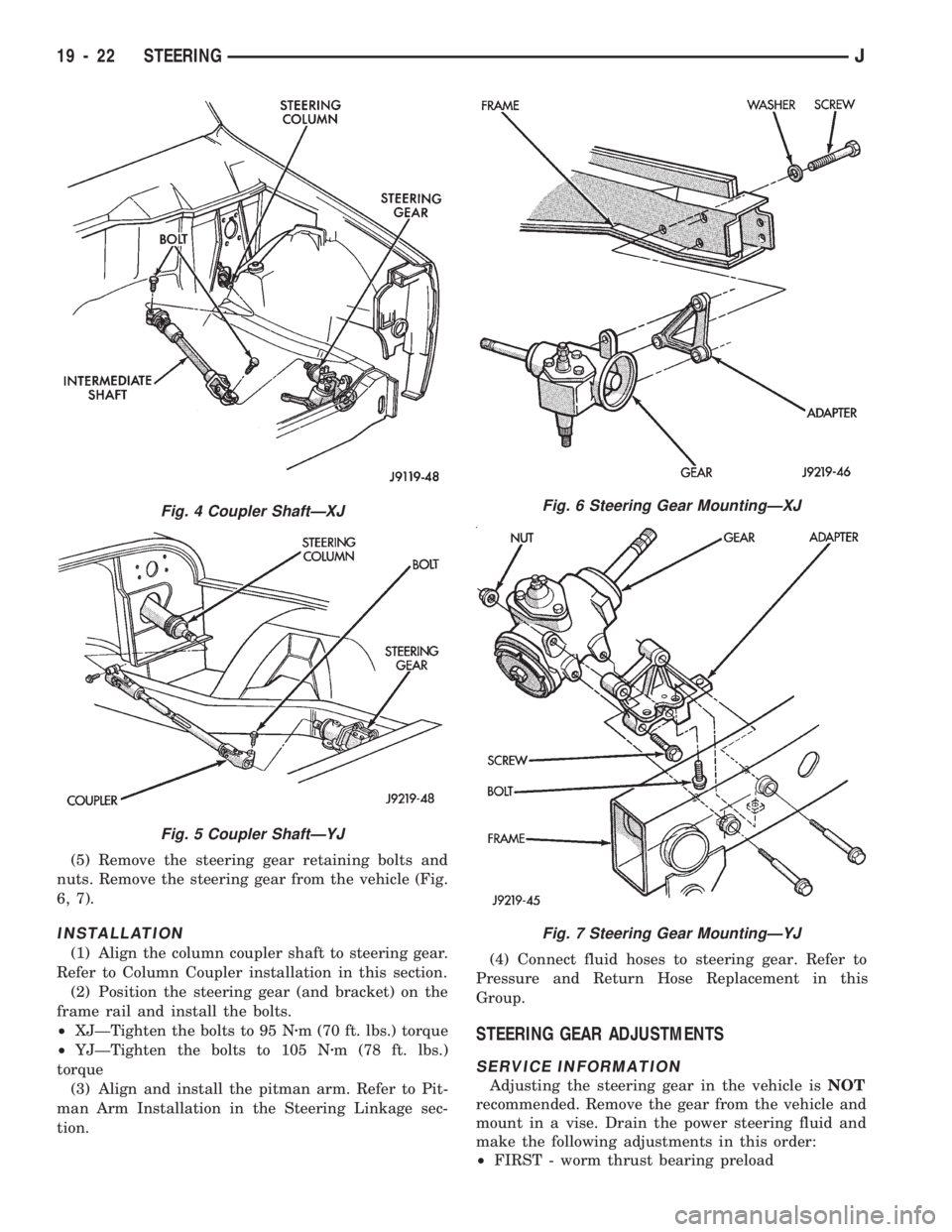

(5) Remove the steering gear retaining bolts and

nuts. Remove the steering gear from the vehicle (Fig.

6, 7).

INSTALLATION

(1) Align the column coupler shaft to steering gear.

Refer to Column Coupler installation in this section.

(2) Position the steering gear (and bracket) on the

frame rail and install the bolts.

²XJÐTighten the bolts to 95 Nzm (70 ft. lbs.) torque

²YJÐTighten the bolts to 105 Nzm (78 ft. lbs.)

torque

(3) Align and install the pitman arm. Refer to Pit-

man Arm Installation in the Steering Linkage sec-

tion.(4) Connect fluid hoses to steering gear. Refer to

Pressure and Return Hose Replacement in this

Group.

STEERING GEAR ADJUSTMENTS

SERVICE INFORMATION

Adjusting the steering gear in the vehicle isNOT

recommended. Remove the gear from the vehicle and

mount in a vise. Drain the power steering fluid and

make the following adjustments in this order:

²FIRST - worm thrust bearing preload

Fig. 6 Steering Gear MountingÐXJ

Fig. 7 Steering Gear MountingÐYJ

Fig. 4 Coupler ShaftÐXJ

Fig. 5 Coupler ShaftÐYJ

19 - 22 STEERINGJ

Page 1060 of 1784

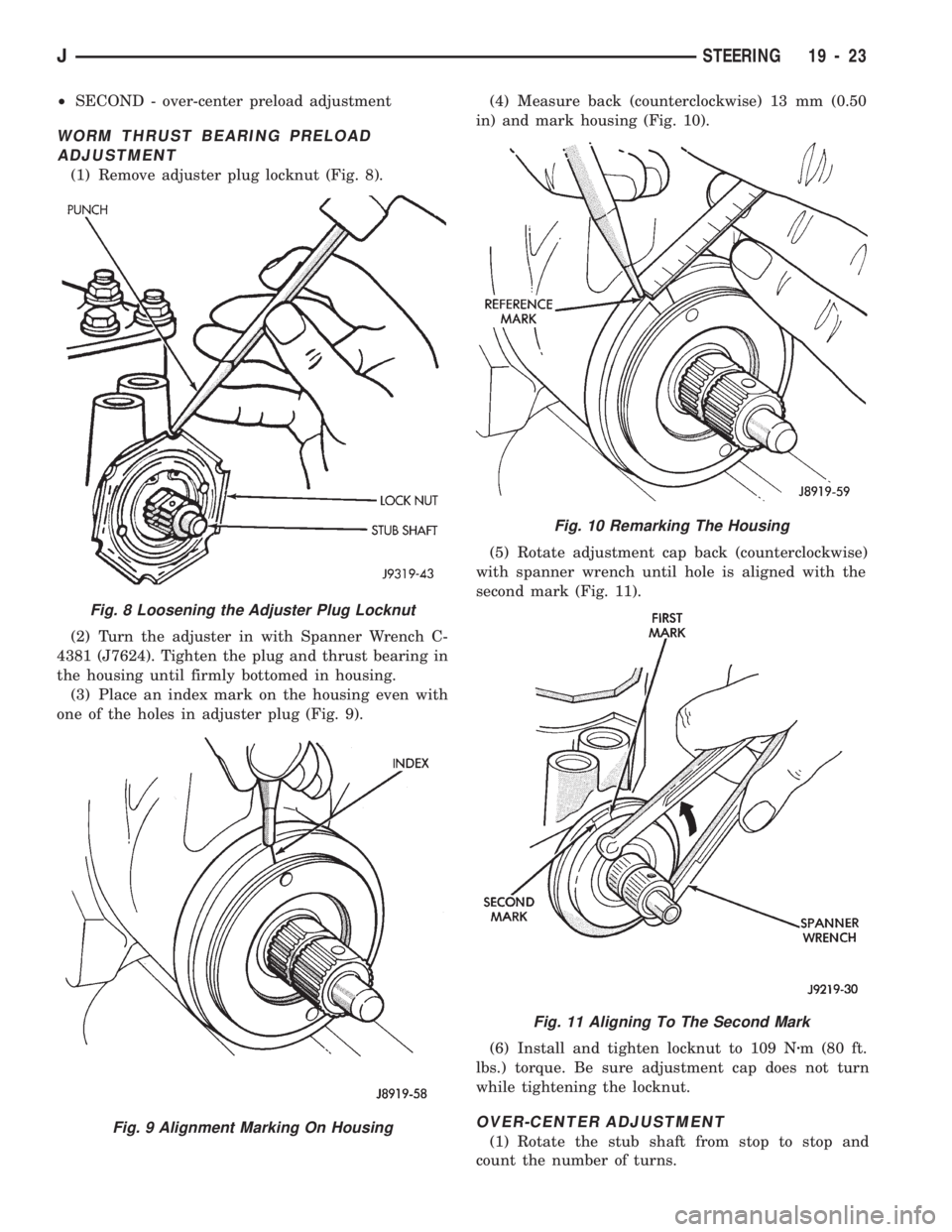

²SECOND - over-center preload adjustment

WORM THRUST BEARING PRELOAD

ADJUSTMENT

(1) Remove adjuster plug locknut (Fig. 8).

(2) Turn the adjuster in with Spanner Wrench C-

4381 (J7624). Tighten the plug and thrust bearing in

the housing until firmly bottomed in housing.

(3) Place an index mark on the housing even with

one of the holes in adjuster plug (Fig. 9).(4) Measure back (counterclockwise) 13 mm (0.50

in) and mark housing (Fig. 10).

(5) Rotate adjustment cap back (counterclockwise)

with spanner wrench until hole is aligned with the

second mark (Fig. 11).

(6) Install and tighten locknut to 109 Nzm (80 ft.

lbs.) torque. Be sure adjustment cap does not turn

while tightening the locknut.

OVER-CENTER ADJUSTMENT

(1) Rotate the stub shaft from stop to stop and

count the number of turns.

Fig. 10 Remarking The Housing

Fig. 11 Aligning To The Second Mark

Fig. 8 Loosening the Adjuster Plug Locknut

Fig. 9 Alignment Marking On Housing

JSTEERING 19 - 23