Tow JEEP CHEROKEE 1994 Service User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 1994, Model line: CHEROKEE, Model: JEEP CHEROKEE 1994Pages: 1784, PDF Size: 77.09 MB

Page 27 of 1784

If the transfer case ATF is warm, it is accept-

able for the fluid to drip out of the fill hole. If

the fluid gushes out of the fill hole, the level is

too high.

(3) If the level is low, raise it to the bottom edge of

the fill hole with MOPAR ATF PLUS type 7176 or

an equivalent MerconŸ/Dexron IIŸ ATF.

(4) Install the fill-hole plug. Tighten the plug with

47 NIm (35 ft. lbs.) torque.

(5) Remove the support and lower the vehicle.

FLUID CHANGE

When it becomes necessary to change the ATF in a

Jeepttransfer case, use the following procedure.

(1) Raise and support the vehicle.

(2) Remove the fill-hole plug from the transfer

case.

(3) Place an appropriate container under the trans-

fer case drain-hole plug.

(4) Remove the drain-hole plug and drain the ATF

from the transfer case into the container.

Care should be exercised when disposing used

ATF after it has been drained from a transfer

case.

CAUTION: Do not over-tighten the drain and fill-hole

plugs. Over-tightening can strip the hole threads

and/or crack the aluminum housing.

(5) Install the drain-hole plug in the transfer case.

Tighten the plug with 47 NIm (35 ft. lbs.) torque.

(6) Fill the transfer case to the bottom edge of the

fill hole with MOPAR ATF PLUS type 7176 (or an

equivalent MerconŸ/Dexron IIŸ ATF).

(7) Install the fill-hole plug in the transfer case.

Tighten the plug with 47 NIm (35 ft. lbs.) torque.

(8) Remove the support and lower the vehicle.

FRONT AND REAR AXLES

RECOMMENDED MAINTENANCE

The lubricant level in axle differential housings

should be determined at the same time as the engine

oil is changed and the oil filter is replaced. Add lu-

bricant as necessary.

In addition, with normal driving conditions, the

axle lubricant should be changed after each 48

000-km (30,000-miles). With severe driving condi-

tions, after each 29 000-km (12,000-miles).

LUBRICANT SPECIFICATIONS

For normal vehicle operation, use SAE 75W-90,

API Quality Grade GL-5 gear lubricant in all Jeept

front (4WD only) and rear axles. Vehicles equipped

with a Trac-Loc rear axle also require a friction mod-

ifier additive with the gear lubricant.

When involved in trailer towing applications

use SAE 80W-140, API Quality Grade GL-5 gearlubricant in the rear axle. XJ Vehicles equipped

with a class III trailer hitch require SAE

75W-140 synthetic gear lubricant in the rear

axle.

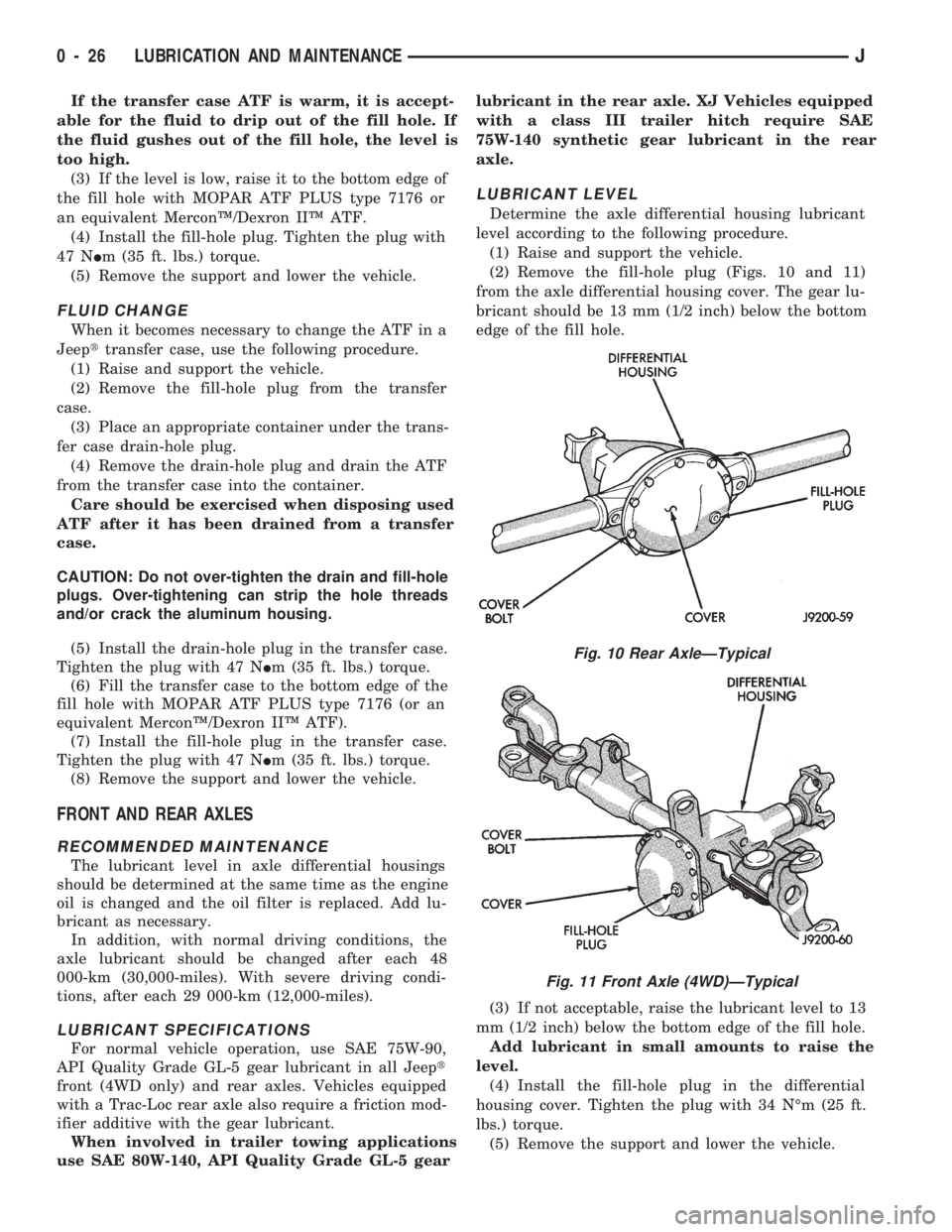

LUBRICANT LEVEL

Determine the axle differential housing lubricant

level according to the following procedure.

(1) Raise and support the vehicle.

(2) Remove the fill-hole plug (Figs. 10 and 11)

from the axle differential housing cover. The gear lu-

bricant should be 13 mm (1/2 inch) below the bottom

edge of the fill hole.

(3) If not acceptable, raise the lubricant level to 13

mm (1/2 inch) below the bottom edge of the fill hole.

Add lubricant in small amounts to raise the

level.

(4) Install the fill-hole plug in the differential

housing cover. Tighten the plug with 34 NÉm (25 ft.

lbs.) torque.

(5) Remove the support and lower the vehicle.

Fig. 10 Rear AxleÐTypical

Fig. 11 Front Axle (4WD)ÐTypical

0 - 26 LUBRICATION AND MAINTENANCEJ

Page 43 of 1784

not change except when a spindle or ball stud is

damaged or bent. The angle is not adjustable and the

damaged component(s) must be replaced to correct

mis-alignment.

CAUTION:Do not attempt to modify any suspension

or steering component by heating and bending.

PRE-ALIGNMENT INSPECTION

Before starting a front wheel alignment, the follow-

ing inspection and necessary corrections must be

completed.

(1) Tires with the same recommended air pressure,

size, and thread wear. Refer to Group 22, Tires And

Wheels for diagnosis information.

(2) Front wheel bearings for wear.

(3) Ball studs, steering linkage pivot points and

steering gear for looseness, roughness, binding or

wear. Refer to Group 19, Steering for additional in-

formation.

(4) Front wheels for excessive radial or lateral

runout and unbalance. Refer to Group 22, Tires And

Wheels for diagnosis information.

(5) Suspension components for wear and noise.

Check components for correct torque. Refer to Groups

2 and 3, Suspension and Axle for additional informa-

tion.

ALIGNMENT MEASUREMENTS AND ADJUSTMENTS

Before each alignment reading, the vehicle should

be jounced (rear first, then front). Grasp each bumper

at the center and jounce the vehicle up and down

several times. Always release the bumper in the

down position.Set the front end alignment to

specifications with the vehicle at its NOR-

MALLY RIDE HEIGHT.

CAMBER

The wheel camber angle (Fig. 1) is preset at ZERO

DEGREES (0É). The angle is not adjustable and can-

not be altered.

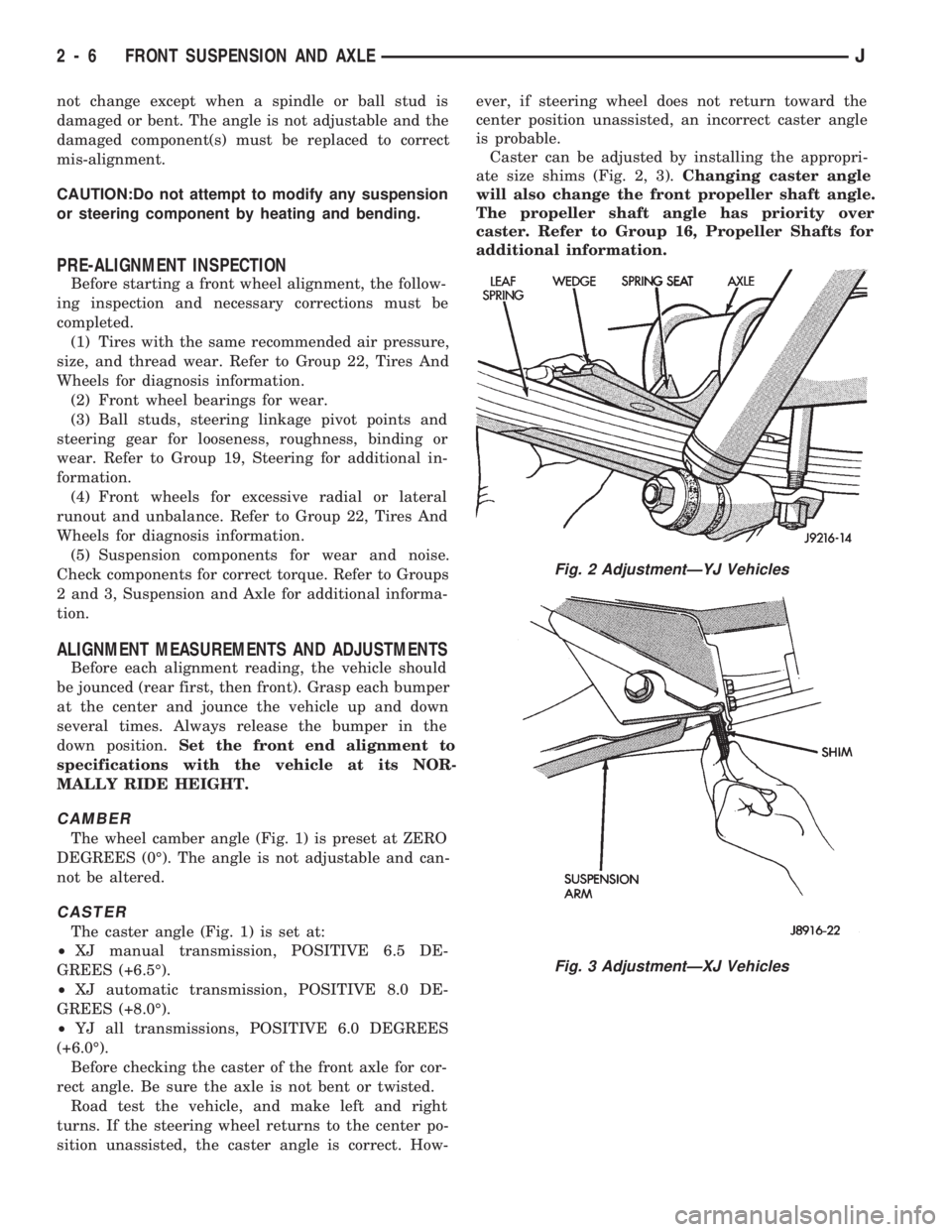

CASTER

The caster angle (Fig. 1) is set at:

²XJ manual transmission, POSITIVE 6.5 DE-

GREES (+6.5É).

²XJ automatic transmission, POSITIVE 8.0 DE-

GREES (+8.0É).

²YJ all transmissions, POSITIVE 6.0 DEGREES

(+6.0É).

Before checking the caster of the front axle for cor-

rect angle. Be sure the axle is not bent or twisted.

Road test the vehicle, and make left and right

turns. If the steering wheel returns to the center po-

sition unassisted, the caster angle is correct. How-ever, if steering wheel does not return toward the

center position unassisted, an incorrect caster angle

is probable.

Caster can be adjusted by installing the appropri-

ate size shims (Fig. 2, 3).Changing caster angle

will also change the front propeller shaft angle.

The propeller shaft angle has priority over

caster. Refer to Group 16, Propeller Shafts for

additional information.

Fig. 2 AdjustmentÐYJ Vehicles

Fig. 3 AdjustmentÐXJ Vehicles

2 - 6 FRONT SUSPENSION AND AXLEJ

Page 49 of 1784

(2) Install the bolts and finger tighten the nuts

(Fig. 3).

(3) Remove support and lower the vehicle.

(4) Tighten the front and rear nuts to 115 Nzm (85

ft. lbs.) torque.

SPRING AND SHOCK DIAGNOSIS

A squeak noise from the shock absorber can be pro-

duced if movement between the rubber bushings and

the metal occurs. This noise can usually be stopped

by tightening the attaching nuts. If the squeak noisepersists, inspect for damaged and worn bushings, and

attaching components. Repair as necessary.

The shock absorber bushings do not require any

type of lubrication. Do not lubricate the bushings to

reduce bushing noise. Grease or mineral oil-base lu-

bricants will deteriorate the bushing rubber.

The shock absorbers are not refillable or adjust-

able. If a malfunction occurs, the shock absorber

must be replaced. To test a shock absorber, hold it in

an upright position and force the piston into and out

of the cylinder four or five times. The action through-

out each stroke should be smooth and even.

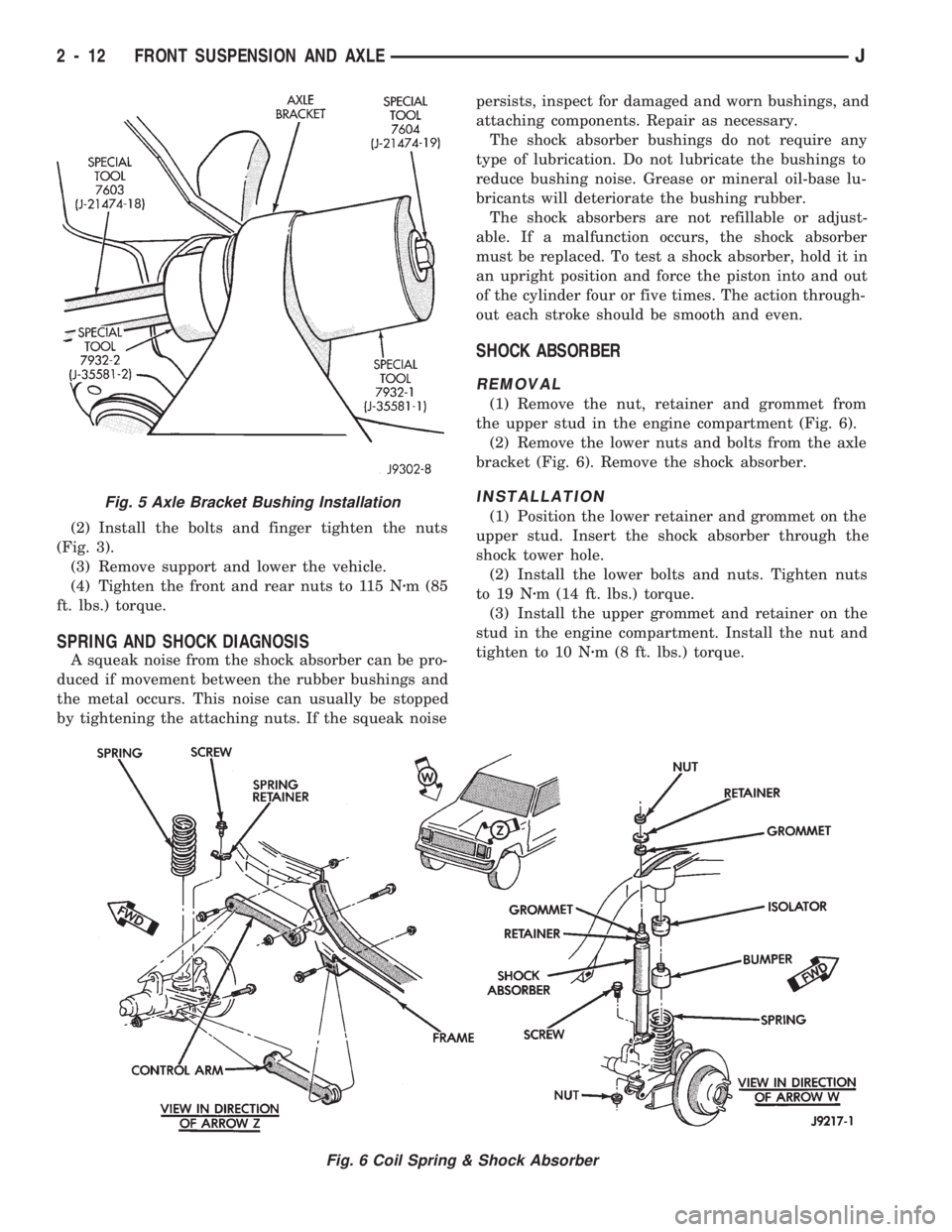

SHOCK ABSORBER

REMOVAL

(1) Remove the nut, retainer and grommet from

the upper stud in the engine compartment (Fig. 6).

(2) Remove the lower nuts and bolts from the axle

bracket (Fig. 6). Remove the shock absorber.

INSTALLATION

(1) Position the lower retainer and grommet on the

upper stud. Insert the shock absorber through the

shock tower hole.

(2) Install the lower bolts and nuts. Tighten nuts

to 19 Nzm (14 ft. lbs.) torque.

(3) Install the upper grommet and retainer on the

stud in the engine compartment. Install the nut and

tighten to 10 Nzm (8 ft. lbs.) torque.

Fig. 6 Coil Spring & Shock Absorber

Fig. 5 Axle Bracket Bushing Installation

2 - 12 FRONT SUSPENSION AND AXLEJ

Page 51 of 1784

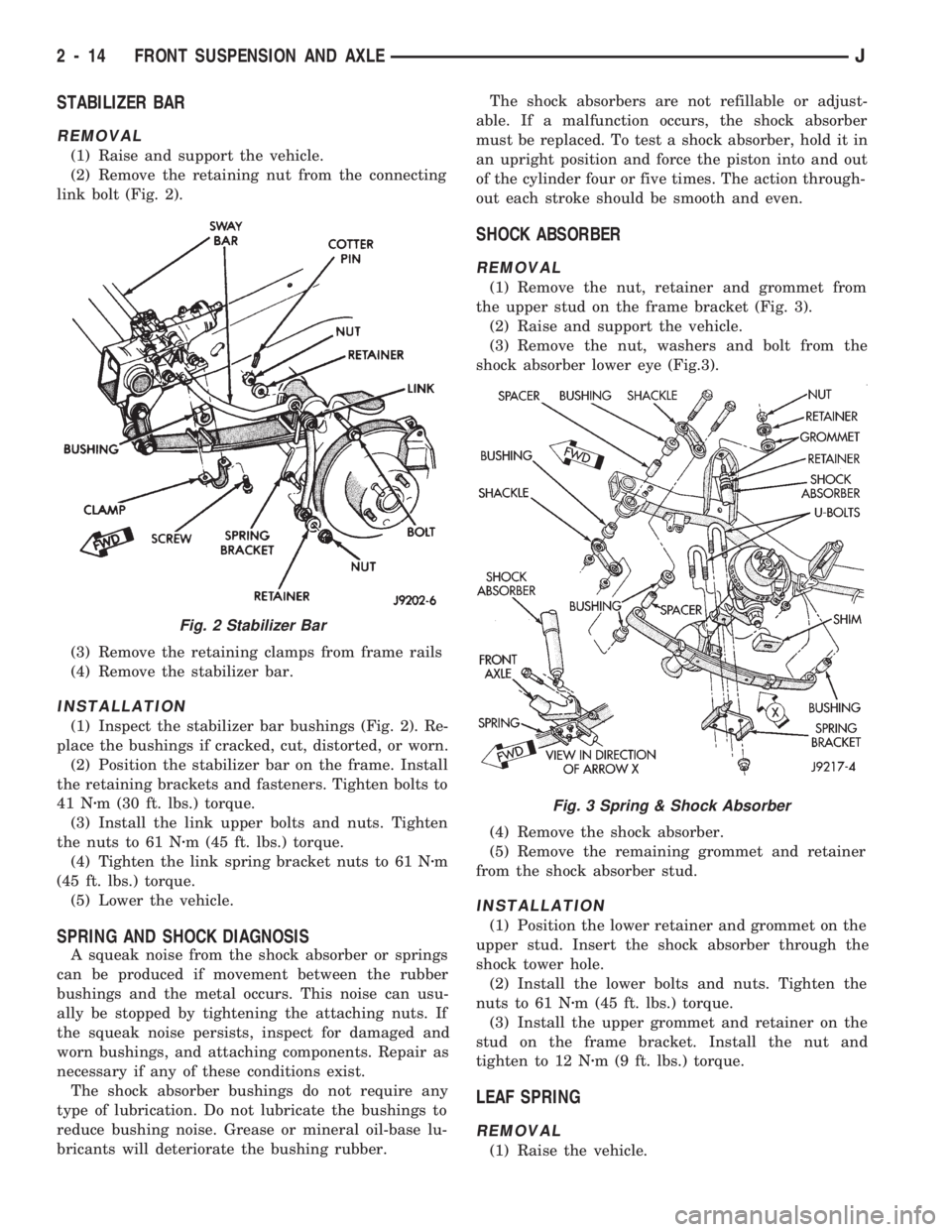

STABILIZER BAR

REMOVAL

(1) Raise and support the vehicle.

(2) Remove the retaining nut from the connecting

link bolt (Fig. 2).

(3) Remove the retaining clamps from frame rails

(4) Remove the stabilizer bar.

INSTALLATION

(1) Inspect the stabilizer bar bushings (Fig. 2). Re-

place the bushings if cracked, cut, distorted, or worn.

(2) Position the stabilizer bar on the frame. Install

the retaining brackets and fasteners. Tighten bolts to

41 Nzm (30 ft. lbs.) torque.

(3) Install the link upper bolts and nuts. Tighten

the nuts to 61 Nzm (45 ft. lbs.) torque.

(4) Tighten the link spring bracket nuts to 61 Nzm

(45 ft. lbs.) torque.

(5) Lower the vehicle.

SPRING AND SHOCK DIAGNOSIS

A squeak noise from the shock absorber or springs

can be produced if movement between the rubber

bushings and the metal occurs. This noise can usu-

ally be stopped by tightening the attaching nuts. If

the squeak noise persists, inspect for damaged and

worn bushings, and attaching components. Repair as

necessary if any of these conditions exist.

The shock absorber bushings do not require any

type of lubrication. Do not lubricate the bushings to

reduce bushing noise. Grease or mineral oil-base lu-

bricants will deteriorate the bushing rubber.The shock absorbers are not refillable or adjust-

able. If a malfunction occurs, the shock absorber

must be replaced. To test a shock absorber, hold it in

an upright position and force the piston into and out

of the cylinder four or five times. The action through-

out each stroke should be smooth and even.

SHOCK ABSORBER

REMOVAL

(1) Remove the nut, retainer and grommet from

the upper stud on the frame bracket (Fig. 3).

(2) Raise and support the vehicle.

(3) Remove the nut, washers and bolt from the

shock absorber lower eye (Fig.3).

(4) Remove the shock absorber.

(5) Remove the remaining grommet and retainer

from the shock absorber stud.

INSTALLATION

(1) Position the lower retainer and grommet on the

upper stud. Insert the shock absorber through the

shock tower hole.

(2) Install the lower bolts and nuts. Tighten the

nuts to 61 Nzm (45 ft. lbs.) torque.

(3) Install the upper grommet and retainer on the

stud on the frame bracket. Install the nut and

tighten to 12 Nzm (9 ft. lbs.) torque.

LEAF SPRING

REMOVAL

(1) Raise the vehicle.

Fig. 2 Stabilizer Bar

Fig. 3 Spring & Shock Absorber

2 - 14 FRONT SUSPENSION AND AXLEJ

Page 53 of 1784

AXLE NOISE/VIBRATION DIAGNOSIS

INDEX

page page

Driveline Snap........................... 17

Gear and Bearing Noise................... 16

General Information....................... 16Low Speed Knock........................ 17

Vibration............................... 17

GENERAL INFORMATION

Axle bearing problem conditions are usually caused

by:

²Insufficient or incorrect lubricant

²Foreign matter/water contamination

²Incorrect bearing preload torque adjustment

²Incorrect backlash (to tight)

When serviced, the bearings must be cleaned thor-

oughly. They should be dried with lint-free shop tow-

els.Never dry bearings with compressed air.

This will overheat them and brinell the bearing

surfaces. This will result in noisy operation after

repair.

Axle gear problem conditions are usually the result

of:

²Insufficient lubrication

²Incorrect or contaminated lubricant

²Overloading (excessive engine torque) or exceeding

vehicle weight capacity

²Incorrect clearance or backlash adjustment

Insufficient lubrication is usually the result of a

housing cover leak. It can also be from worn axle

shaft or pinion gear seals. Check for cracks or porous

areas in the housing or tubes.

Using the wrong lubricant will cause overheating

and gear failure. Gear tooth cracking and bearing

spalling are indicators of this.

Axle component breakage is most often the result

of:

²Severe overloading

²Insufficient lubricant

²Incorrect lubricant

²Improperly tightened components

Overloading occurs when towing heavier than rec-

ommended loads. Component breakage can occur

when the wheels are spun excessively. Incorrect lu-

bricant quantity contributes to breakage. Loose dif-

ferential components can also cause breakage.

Incorrect bearing preload or gear backlash will not

result in component breakage. Mis-adjustment will

produce enough noise to cause service repair before a

failure occurs. If a mis-adjustment condition is not

corrected, component failure can result.

Excessive bearing preload may not be noisy. This

condition will cause high temperature which can re-

sult in bearing failure.

GEAR AND BEARING NOISE

GEAR NOISE

Axle gear noise can be caused by insufficient lubri-

cant. Incorrect backlash, tooth contact, or worn/dam-

aged gears can cause noise.

Gear noise usually happens at a specific speed

range. The range is 30 to 40 mph, or above 50 mph.

The noise can also occur during a specific type of

driving condition. These conditions are acceleration,

deceleration, coast, or constant load.

When road testing, accelerate the vehicle to the

speed range where the noise is the greatest. Shift

out-of-gear and coast through the peak-noise range.

If the noise stops or changes greatly, check for insuf-

ficient lubricant. Incorrect ring gear backlash, or

gear damage can cause noise changes.

Differential side and pinion gears can be checked

by turning the vehicle. They usually do not cause

noise in straight-ahead driving. These gears are

loaded during vehicle turns. If noise does occur dur-

ing vehicle turns, the side or pinion gears could be

worn or damaged. A worn pinion gear mate shaft can

also cause a snapping or a knocking noise.

BEARING NOISE

The axle shaft, differential and pinion gear bear-

ings can all produce noise when worn or damaged.

Bearing noise can be either a whining, or a growling

sound.

Pinion gear bearings have a constant-pitch noise.

This noise changes only with vehicle speed. Pinion

bearing noise will be higher because it rotates at a

faster rate. Drive the vehicle and load the differen-

tial. If bearing noise occurs the pinion rear bearing is

the source of the noise. If the bearing noise is heard

during a coast, front bearing is the source.

Worn, damaged differential bearings usually pro-

duce a low pitch noise. Differential bearing noise is

similar to pinion bearing. The pitch of differential

bearing noise is also constant and varies only with

vehicle speed.

Axle shaft bearings produce noise and vibration

when worn or damaged. The noise generally changes

when the bearings are loaded. Road test the vehicle.

Turn the vehicle sharply to the left and to the right.

This will load the bearings and change the noise

2 - 16 FRONT SUSPENSION AND AXLEJ

Page 66 of 1784

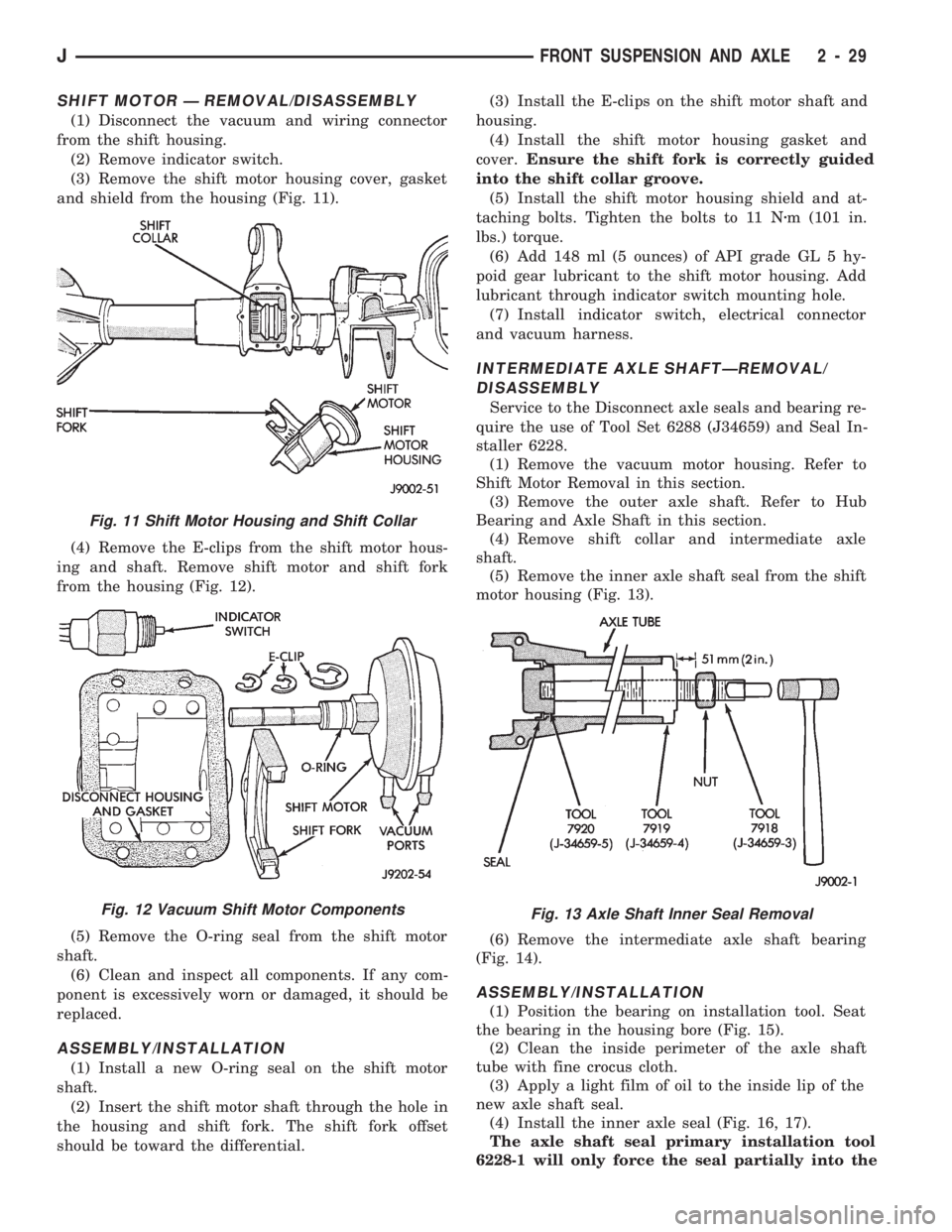

SHIFT MOTOR Ð REMOVAL/DISASSEMBLY

(1) Disconnect the vacuum and wiring connector

from the shift housing.

(2) Remove indicator switch.

(3) Remove the shift motor housing cover, gasket

and shield from the housing (Fig. 11).

(4) Remove the E-clips from the shift motor hous-

ing and shaft. Remove shift motor and shift fork

from the housing (Fig. 12).

(5) Remove the O-ring seal from the shift motor

shaft.

(6) Clean and inspect all components. If any com-

ponent is excessively worn or damaged, it should be

replaced.

ASSEMBLY/INSTALLATION

(1) Install a new O-ring seal on the shift motor

shaft.

(2) Insert the shift motor shaft through the hole in

the housing and shift fork. The shift fork offset

should be toward the differential.(3) Install the E-clips on the shift motor shaft and

housing.

(4) Install the shift motor housing gasket and

cover.Ensure the shift fork is correctly guided

into the shift collar groove.

(5) Install the shift motor housing shield and at-

taching bolts. Tighten the bolts to 11 Nzm (101 in.

lbs.) torque.

(6) Add 148 ml (5 ounces) of API grade GL 5 hy-

poid gear lubricant to the shift motor housing. Add

lubricant through indicator switch mounting hole.

(7) Install indicator switch, electrical connector

and vacuum harness.

INTERMEDIATE AXLE SHAFTÐREMOVAL/

DISASSEMBLY

Service to the Disconnect axle seals and bearing re-

quire the use of Tool Set 6288 (J34659) and Seal In-

staller 6228.

(1) Remove the vacuum motor housing. Refer to

Shift Motor Removal in this section.

(3) Remove the outer axle shaft. Refer to Hub

Bearing and Axle Shaft in this section.

(4) Remove shift collar and intermediate axle

shaft.

(5) Remove the inner axle shaft seal from the shift

motor housing (Fig. 13).

(6) Remove the intermediate axle shaft bearing

(Fig. 14).

ASSEMBLY/INSTALLATION

(1) Position the bearing on installation tool. Seat

the bearing in the housing bore (Fig. 15).

(2) Clean the inside perimeter of the axle shaft

tube with fine crocus cloth.

(3) Apply a light film of oil to the inside lip of the

new axle shaft seal.

(4) Install the inner axle seal (Fig. 16, 17).

The axle shaft seal primary installation tool

6228-1 will only force the seal partially into the

Fig. 11 Shift Motor Housing and Shift Collar

Fig. 12 Vacuum Shift Motor ComponentsFig. 13 Axle Shaft Inner Seal Removal

JFRONT SUSPENSION AND AXLE 2 - 29

Page 73 of 1784

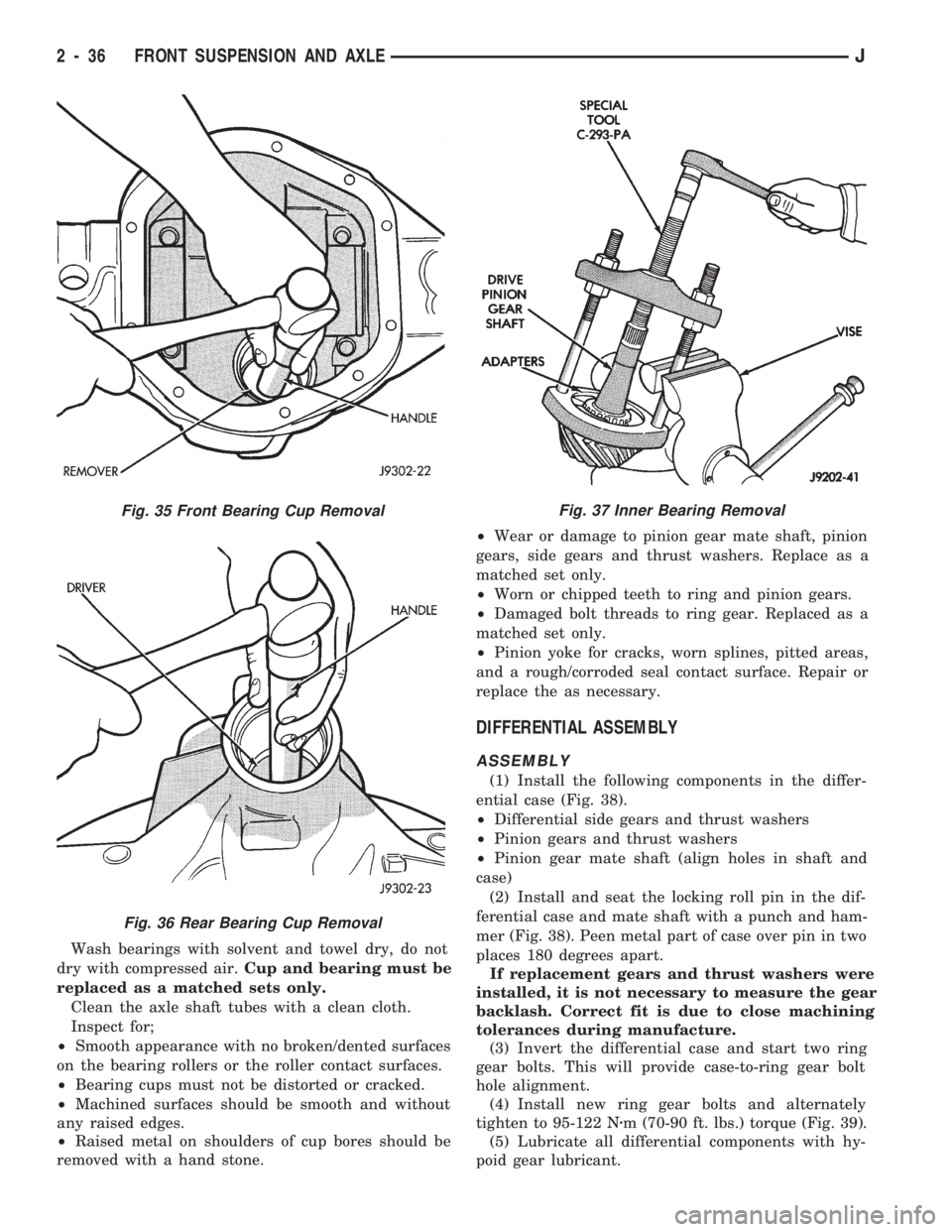

Wash bearings with solvent and towel dry, do not

dry with compressed air.Cup and bearing must be

replaced as a matched sets only.

Clean the axle shaft tubes with a clean cloth.

Inspect for;

²Smooth appearance with no broken/dented surfaces

on the bearing rollers or the roller contact surfaces.

²Bearing cups must not be distorted or cracked.

²Machined surfaces should be smooth and without

any raised edges.

²Raised metal on shoulders of cup bores should be

removed with a hand stone.²Wear or damage to pinion gear mate shaft, pinion

gears, side gears and thrust washers. Replace as a

matched set only.

²Worn or chipped teeth to ring and pinion gears.

²Damaged bolt threads to ring gear. Replaced as a

matched set only.

²Pinion yoke for cracks, worn splines, pitted areas,

and a rough/corroded seal contact surface. Repair or

replace the as necessary.

DIFFERENTIAL ASSEMBLY

ASSEMBLY

(1) Install the following components in the differ-

ential case (Fig. 38).

²Differential side gears and thrust washers

²Pinion gears and thrust washers

²Pinion gear mate shaft (align holes in shaft and

case)

(2) Install and seat the locking roll pin in the dif-

ferential case and mate shaft with a punch and ham-

mer (Fig. 38). Peen metal part of case over pin in two

places 180 degrees apart.

If replacement gears and thrust washers were

installed, it is not necessary to measure the gear

backlash. Correct fit is due to close machining

tolerances during manufacture.

(3) Invert the differential case and start two ring

gear bolts. This will provide case-to-ring gear bolt

hole alignment.

(4) Install new ring gear bolts and alternately

tighten to 95-122 Nzm (70-90 ft. lbs.) torque (Fig. 39).

(5) Lubricate all differential components with hy-

poid gear lubricant.

Fig. 35 Front Bearing Cup Removal

Fig. 36 Rear Bearing Cup Removal

Fig. 37 Inner Bearing Removal

2 - 36 FRONT SUSPENSION AND AXLEJ

Page 87 of 1784

line. You may encounter fuels containing 3 percent

or more methanol along with other alcohols called co-

solvents.

Problems that are the result of using methanol/gas-

oline blends are not the responsibility of Chrysler

Corporation. They may not be covered by the vehicle

warranty.

MTBE/ETBE

Gasoline and MTBE (Methyl Tertiary Butyl Ether)

blends are a mixture of unleaded gasoline and up to

15 percent MTBE. Gasoline and ETBE (Ethyl Ter-

tiary Butyl Ether) are blends of gasoline and up to

17 percent ETBE. Gasoline blended with MTBE or

ETBE may be used in your vehicle.CLEAN AIR GASOLINE

Many gasolines are now being blended that con-

tribute to cleaner air, especially in those areas of the

country where air pollution levels are high. These

new blends provide a cleaner burning fuel and some

are referred to asReformulated Gasoline.

In areas of the country where carbon monoxide lev-

els are high, gasolines are being treated with oxy-

genated materials such as MTBE, ETBE and

ethanol.

Chrysler Corporation supports these efforts toward

cleaner air and recommends that you use these gas-

olines as they become available.

FUEL DELIVERY SYSTEM

INDEX

page page

Fuel Filter............................... 8

Fuel Pressure Leak Down Test............... 7

Fuel Pressure Release Procedure............. 5

Fuel Pump Capacity Test................... 7

Fuel Pump Electrical Control................. 5Fuel Pump Module........................ 2

Fuel System Pressure Test.................. 5

Fuel Tubes/Lines/Hoses and Clamps........... 9

Quick-Connect Fittings..................... 9

FUEL PUMP MODULE

The fuel pump module is installed in the top of the

fuel tank. The fuel pump module contains the follow-

ing components:

²Electric fuel pump

²Fuel pump reservoir

²In-tank fuel filter

²Fuel gauge sending unit

²Fuel supply and return tube connections

The fuel pump used on all vehicles is a gear/rotor

type pump. It is driven by a permanent magnet 12

volt electric motor that is immersed in the fuel tank.

The electrical pump is integral with the fuel sender

unit. The pump/sender assembly is installed inside

the fuel tank.

The fuel pump has a check valve at the outlet end

that consists of a ball held against a seat by force ap-

plied from a spring. When the pump is operating,

fuel pressure overcomes spring pressure and forces

the ball off its seat, allowing fuel to flow. When the

pump is not operating, spring pressure forces the ball

back against the seat preventing fuel backflow

through the pump.

Fuel system pressure is maintained at approxi-

mately 214 kPa (31 psi). This is when the pump is

operating and vacuum is supplied to the fuel pres-

sure regulator. If vacuum is not supplied to the pres-

sure regulator, fuel pressure will be approximately

55-69 kPa (8-10 psi) higher. This may be due to a

broken or clogged vacuum line. When the fuel pumpis not operating, system fuel pressure of 131-269 kPa

(19-39 psi) is maintained. This is done by the fuel

pump outlet check valve and the vacuum assisted

fuel pressure regulator.

REMOVALÐXJ MODELS

The fuel pump/gauge sender unit assembly can be

removed from the fuel tank without removing the

tank from the vehicle.

WARNING: THE FUEL SYSTEM IS UNDER A CON-

STANT PRESSURE (EVEN WITH THE ENGINE OFF).

BEFORE SERVICING THE FUEL PUMP MODULE,

THE FUEL SYSTEM PRESSURE MUST BE RE-

LEASED. REFER TO THE FUEL PRESSURE RE-

LEASE PROCEDURE IN THIS GROUP.

WARNING: EXTINGUISH ALL TOBACCO SMOKING

PRODUCTS BEFORE SERVICING THE FUEL SYS-

TEM. KEEP OPEN FLAME AWAY FROM FUEL SYS-

TEM COMPONENTS.

(1) Remove fuel filler cap. Perform the Fuel Pres-

sure Release Procedure as outlined in this group.

(2) Disconnect negative battery cable.

(3) Using an approved portable gasoline siphon/

storage tank, drain fuel tank until fuel level is below

one quarter (1/4) full.

(4) Raise and support vehicle.

14 - 2 FUEL SYSTEMJ

Page 88 of 1784

WARNING: WRAP SHOP TOWELS AROUND FUEL

HOSES TO ABSORB ANY FUEL SPILLAGE DURING

FUEL TANK REMOVAL.

(5) Disconnect fuel vent supply and return tubes

from fittings on fuel pump module.

(6) Disconnect fuel pump module electrical harness

connector from main harness.

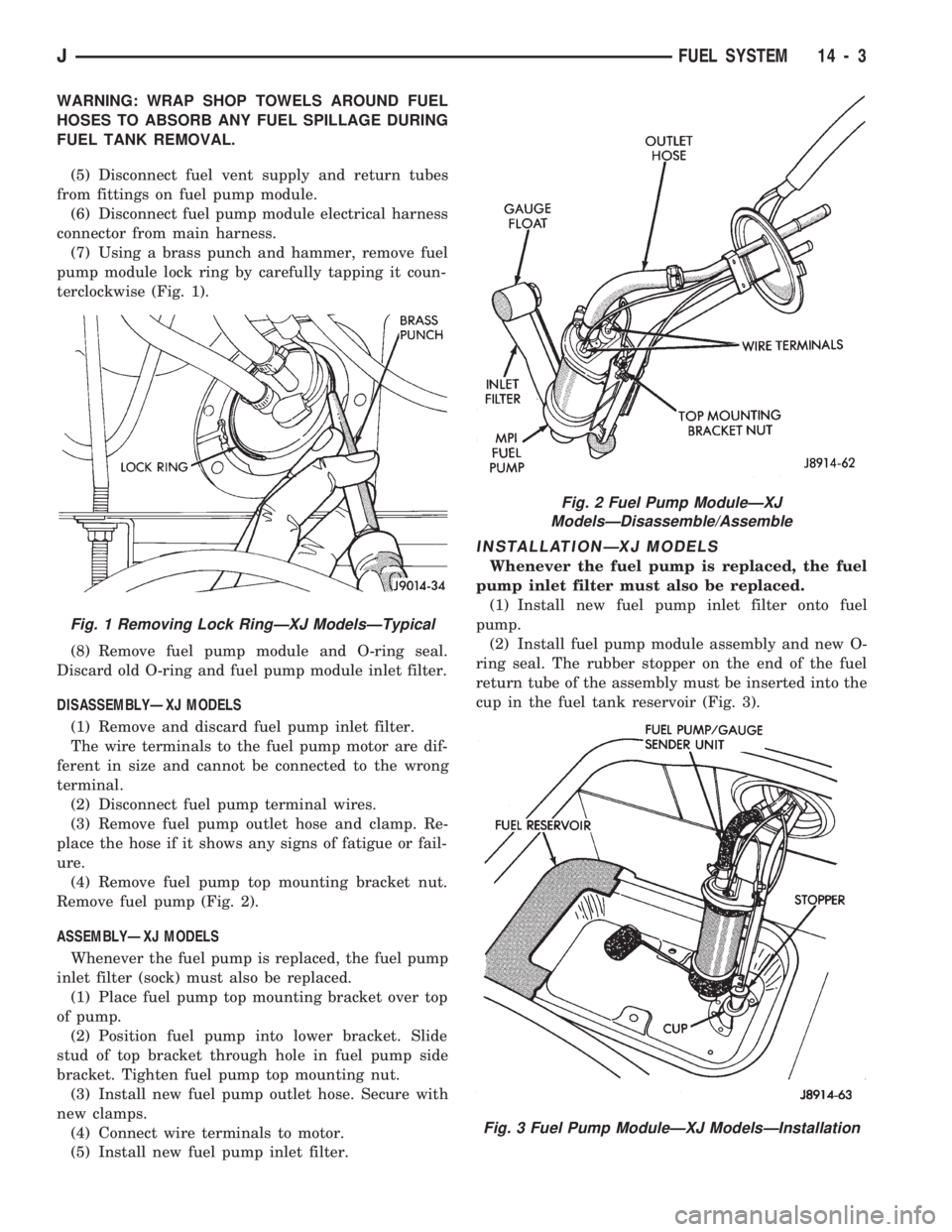

(7) Using a brass punch and hammer, remove fuel

pump module lock ring by carefully tapping it coun-

terclockwise (Fig. 1).

(8) Remove fuel pump module and O-ring seal.

Discard old O-ring and fuel pump module inlet filter.

DISASSEMBLYÐXJ MODELS

(1) Remove and discard fuel pump inlet filter.

The wire terminals to the fuel pump motor are dif-

ferent in size and cannot be connected to the wrong

terminal.

(2) Disconnect fuel pump terminal wires.

(3) Remove fuel pump outlet hose and clamp. Re-

place the hose if it shows any signs of fatigue or fail-

ure.

(4) Remove fuel pump top mounting bracket nut.

Remove fuel pump (Fig. 2).

ASSEMBLYÐXJ MODELS

Whenever the fuel pump is replaced, the fuel pump

inlet filter (sock) must also be replaced.

(1) Place fuel pump top mounting bracket over top

of pump.

(2) Position fuel pump into lower bracket. Slide

stud of top bracket through hole in fuel pump side

bracket. Tighten fuel pump top mounting nut.

(3) Install new fuel pump outlet hose. Secure with

new clamps.

(4) Connect wire terminals to motor.

(5) Install new fuel pump inlet filter.

INSTALLATIONÐXJ MODELS

Whenever the fuel pump is replaced, the fuel

pump inlet filter must also be replaced.

(1) Install new fuel pump inlet filter onto fuel

pump.

(2) Install fuel pump module assembly and new O-

ring seal. The rubber stopper on the end of the fuel

return tube of the assembly must be inserted into the

cup in the fuel tank reservoir (Fig. 3).

Fig. 1 Removing Lock RingÐXJ ModelsÐTypical

Fig. 2 Fuel Pump ModuleÐXJ

ModelsÐDisassemble/Assemble

Fig. 3 Fuel Pump ModuleÐXJ ModelsÐInstallation

JFUEL SYSTEM 14 - 3

Page 90 of 1784

(3) Install new fuel pump outlet hose. Secure with

new clamps.

(4) Connect wire terminals to motor.

(5) Install new fuel pump inlet filter.

INSTALLATIONÐYJ MODELS

(1) Install a new fuel pump inlet filter.

(2) Install fuel pump module assembly with a new

gasket between the assembly and tank. Tighten

mounting screws to 2 Nzm (18 in. lbs.) torque.

(3) Install fuel tank. Refer to Fuel Tank Installa-

tionÐYJ Models.

(4) Fill fuel tank. Install fuel tank cap.

(5) Install negative battery cable.

(6) Start vehicle and check for leaks.

FUEL PUMP ELECTRICAL CONTROL

For an electrical operational description of the fuel

pump, refer to the MFI SystemÐComponent Descrip-

tion/System Operation section of this group. See Au-

tomatic Shut Down (ASD) RelayÐPCM Output.

For the 1994 model year, the ballast resistor and

ballast resistor bypass relay are no longer used to

control the fuel pump circuit.

FUEL PRESSURE RELEASE PROCEDURE

WARNING: THE FUEL SYSTEM IS UNDER CON-

STANT FUEL PRESSURE (EVEN WITH THE ENGINE

OFF) OF APPROXIMATELY 131-269 KPA (19-39

PSI). THIS PRESSURE MUST BE RELEASED BE-

FORE SERVICING ANY FUEL SUPPLY OR FUEL RE-

TURN SYSTEM COMPONENT.

(1) Disconnect negative battery cable.

(2) Remove fuel tank filler neck cap to release fuel

tank pressure.

WARNING: DO NOT ALLOW FUEL TO SPILL ONTO

THE ENGINE INTAKE OR EXHAUST MANIFOLDS.

PLACE SHOP TOWELS UNDER AND AROUND THE

PRESSURE PORT TO ABSORB FUEL WHEN THE

PRESSURE IS RELEASED FROM THE FUEL RAIL.

WARNING: WEAR PROPER EYE PROTECTION

WHEN RELEASING FUEL SYSTEM PRESSURE.

(3) Remove protective cap from pressure test port

on the fuel rail (Fig. 7).

(4) Obtain the fuel pressure gauge/hose assembly

from fuel pressure gauge tool set 5069. Remove the

gauge from the hose.

(5) Place one end of hose (gauge end) into an ap-

proved gasoline container.

(6) Place a shop towel under the test port.

(7) To release fuel pressure, screw the other end of

hose onto the fuel pressure test port.(8) After fuel pressure has been released, remove

the hose from the test port.

(9) Install protective cap to fuel test port.

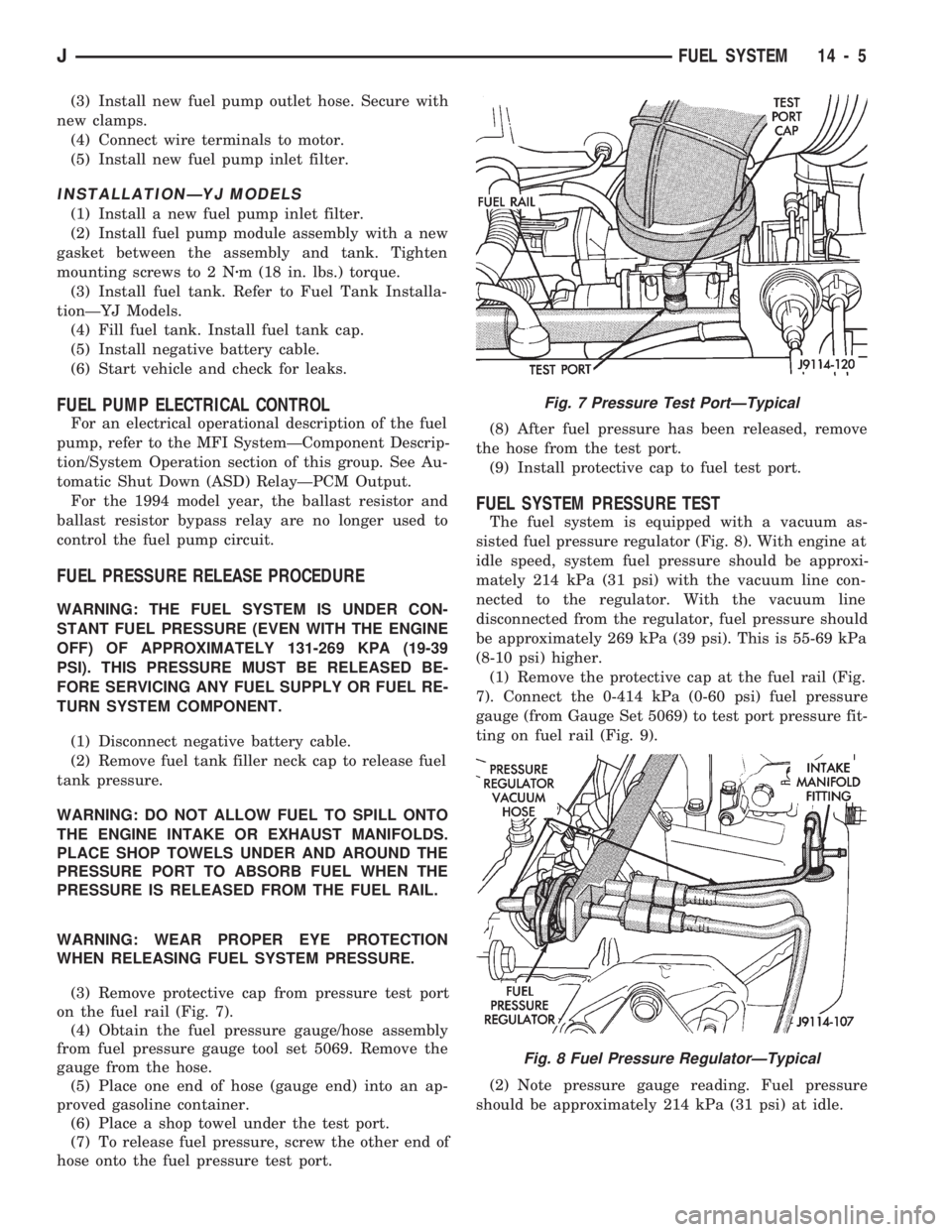

FUEL SYSTEM PRESSURE TEST

The fuel system is equipped with a vacuum as-

sisted fuel pressure regulator (Fig. 8). With engine at

idle speed, system fuel pressure should be approxi-

mately 214 kPa (31 psi) with the vacuum line con-

nected to the regulator. With the vacuum line

disconnected from the regulator, fuel pressure should

be approximately 269 kPa (39 psi). This is 55-69 kPa

(8-10 psi) higher.

(1) Remove the protective cap at the fuel rail (Fig.

7). Connect the 0-414 kPa (0-60 psi) fuel pressure

gauge (from Gauge Set 5069) to test port pressure fit-

ting on fuel rail (Fig. 9).

(2) Note pressure gauge reading. Fuel pressure

should be approximately 214 kPa (31 psi) at idle.

Fig. 7 Pressure Test PortÐTypical

Fig. 8 Fuel Pressure RegulatorÐTypical

JFUEL SYSTEM 14 - 5