atf JEEP CHEROKEE 1994 Service User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 1994, Model line: CHEROKEE, Model: JEEP CHEROKEE 1994Pages: 1784, PDF Size: 77.09 MB

Page 1221 of 1784

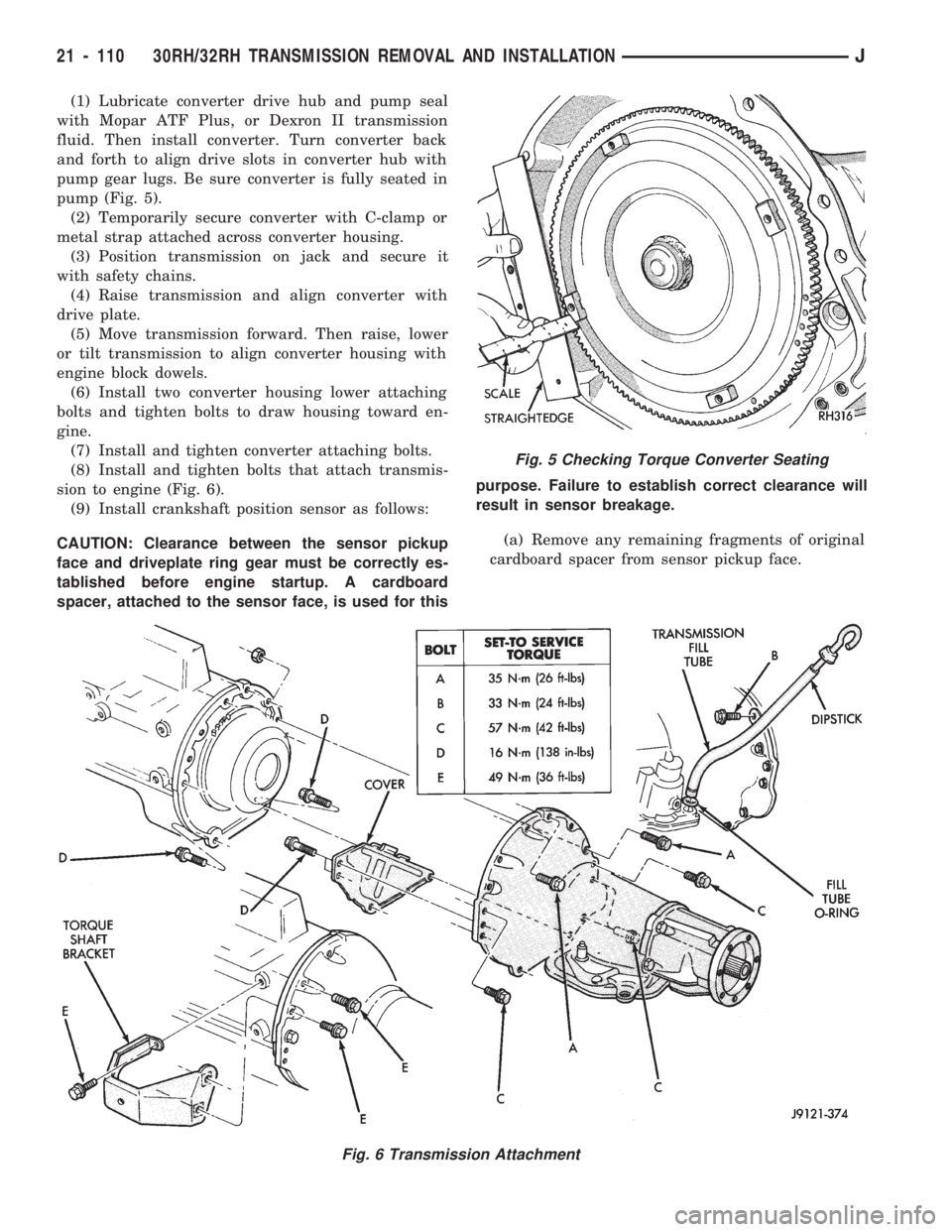

(1) Lubricate converter drive hub and pump seal

with Mopar ATF Plus, or Dexron II transmission

fluid. Then install converter. Turn converter back

and forth to align drive slots in converter hub with

pump gear lugs. Be sure converter is fully seated in

pump (Fig. 5).

(2) Temporarily secure converter with C-clamp or

metal strap attached across converter housing.

(3) Position transmission on jack and secure it

with safety chains.

(4) Raise transmission and align converter with

drive plate.

(5) Move transmission forward. Then raise, lower

or tilt transmission to align converter housing with

engine block dowels.

(6) Install two converter housing lower attaching

bolts and tighten bolts to draw housing toward en-

gine.

(7) Install and tighten converter attaching bolts.

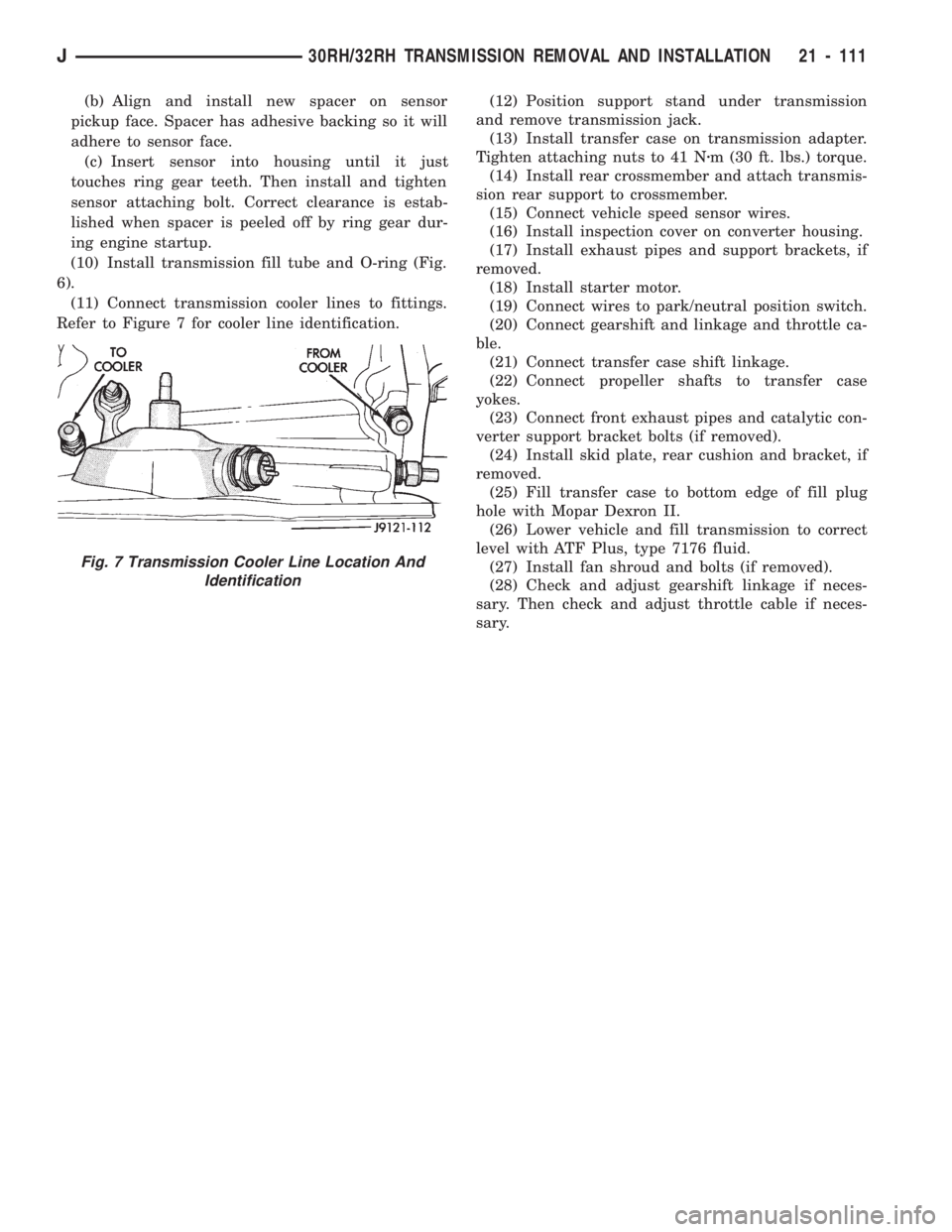

(8) Install and tighten bolts that attach transmis-

sion to engine (Fig. 6).

(9) Install crankshaft position sensor as follows:

CAUTION: Clearance between the sensor pickup

face and driveplate ring gear must be correctly es-

tablished before engine startup. A cardboard

spacer, attached to the sensor face, is used for thispurpose. Failure to establish correct clearance will

result in sensor breakage.

(a) Remove any remaining fragments of original

cardboard spacer from sensor pickup face.

Fig. 5 Checking Torque Converter Seating

Fig. 6 Transmission Attachment

21 - 110 30RH/32RH TRANSMISSION REMOVAL AND INSTALLATIONJ

Page 1222 of 1784

(b) Align and install new spacer on sensor

pickup face. Spacer has adhesive backing so it will

adhere to sensor face.

(c) Insert sensor into housing until it just

touches ring gear teeth. Then install and tighten

sensor attaching bolt. Correct clearance is estab-

lished when spacer is peeled off by ring gear dur-

ing engine startup.

(10) Install transmission fill tube and O-ring (Fig.

6).

(11) Connect transmission cooler lines to fittings.

Refer to Figure 7 for cooler line identification.(12) Position support stand under transmission

and remove transmission jack.

(13) Install transfer case on transmission adapter.

Tighten attaching nuts to 41 Nzm (30 ft. lbs.) torque.

(14) Install rear crossmember and attach transmis-

sion rear support to crossmember.

(15) Connect vehicle speed sensor wires.

(16) Install inspection cover on converter housing.

(17) Install exhaust pipes and support brackets, if

removed.

(18) Install starter motor.

(19) Connect wires to park/neutral position switch.

(20) Connect gearshift and linkage and throttle ca-

ble.

(21) Connect transfer case shift linkage.

(22) Connect propeller shafts to transfer case

yokes.

(23) Connect front exhaust pipes and catalytic con-

verter support bracket bolts (if removed).

(24) Install skid plate, rear cushion and bracket, if

removed.

(25) Fill transfer case to bottom edge of fill plug

hole with Mopar Dexron II.

(26) Lower vehicle and fill transmission to correct

level with ATF Plus, type 7176 fluid.

(27) Install fan shroud and bolts (if removed).

(28) Check and adjust gearshift linkage if neces-

sary. Then check and adjust throttle cable if neces-

sary.

Fig. 7 Transmission Cooler Line Location And

Identification

J30RH/32RH TRANSMISSION REMOVAL AND INSTALLATION 21 - 111

Page 1229 of 1784

OVERHAUL SERVICE INFORMATION

Inspect the transmission bushings during overhaul.

Bushing condition is important as severely worn, or

scored bushings contribute to low pressures, clutch

slip and accelerated wear of other components.How-

ever, do not replace bushings as a matter of

course. Replace bushings only when they are

actually worn, or scored.

Use recommended tools to replace bushings. The

tools are sized and designed to remove, install and

seat bushings correctly. The bushing replacement

tools are included in Bushing Tool Set C-3887-B. The

tool set is manufactured by Miller Tool Co. and is

available through the dealer tool program.

Pre-sized service bushings are available for replace-

ment purposes. Only the sun gear bushings are not

serviced. Low cost of the sun gear assembly makes it

easier to simply replace the gear and bushings as an

assembly.

Heli-Coil inserts are recommended for repairing

damaged, stripped or worn threads in aluminum

parts. These inserts are available from most automo-

tive jobbers. Stainless steel inserts are preferred.

The use of crocus cloth is permissible where neces-

sary. When used on valves, use care to avoid round-

ing off sharp edges. Sharp edges are vital as they

prevent foreign matter from getting between the

valve and valve bore.

Do not reuse oil seals, gaskets, seal rings, or O-

rings during overhaul. Replace these parts as a mat-

ter of course. Also do not reuse snap rings or E-clips

that are bent or distorted. Replace these parts as

well.

Lubricate transmission parts with Mopar ATF

Plus, Type 7176 transmission fluid during overhaul

and assembly.Use petroleum jelly to hold parts like thrust wash-

ers in place during assembly. Use Ru-Glyde, Door

Eze, or similar products to lubricate piston seals and

O-rings to ease installation. Petroleum jelly can also

be used to prelubricate parts during reassembly if de-

sired.

TRANSMISSION CASE CLEANING AND

INSPECTION

Clean the case in a solvent tank. Flush the case

bores and fluid passages thoroughly with solvent.

Dry the case and all fluid passages with compressed

air. Be sure all solvent is removed from the case and

that all fluid passages are clear.

Do not use shop towels or rags to dry the case

(or any other transmission component) unless

they are made from lint-free materials. Lint will

readily adhere to case surfaces and transmission

components and will circulate throughout the

transmission after assembly. A sufficient quan-

tity of lint can block fluid passages and interfere

with valve body operation.

Inspect the case for cracks, porous spots, worn

bores, or damaged threads. Damaged threads can be

repaired with Helicoil thread inserts. However, the

case will have to be replaced if it exhibits any type of

damage or wear.

Lubricate the front band adjusting screw threads

with petroleum jelly and thread the screw part-way

into the case. Be sure the screw turns freely.

Remount the case in a repair stand after cleaning

and inspection.

OVERRUNNING CLUTCHÐLOW-REVERSE

DRUMÐREAR SUPPORT OVERHAUL

DISASSEMBLING OVERRUNNING CLUTCH/

LOW-REVERSE DRUM

If the clutch assembly came out with the low-re-

verse drum, thread two clutch cam bolts into the

cam. Then lift the cam out of the drum with the bolts

(Fig. 30). Rotate the cam back and forth to ease re-

moval if necessary. Remove the clutch roller and

spring assembly from the race afterward.

CLEANING AND INSPECTION

Clean the overrunning clutch assembly, clutch

cam, low-reverse drum and rear support in solvent.

Dry them with compressed air after cleaning.

Inspect condition of each clutch part after cleaning.

Replace the overrunning clutch roller and spring as-

sembly if any rollers or springs are worn or dam-

aged, or if the roller cage is distorted, or damaged.

Replace the cam if worn, cracked or damaged.

Replace the low-reverse drum if the clutch race,

roller surface or inside diameter is scored, worn or

damaged.Do not remove the clutch race from the

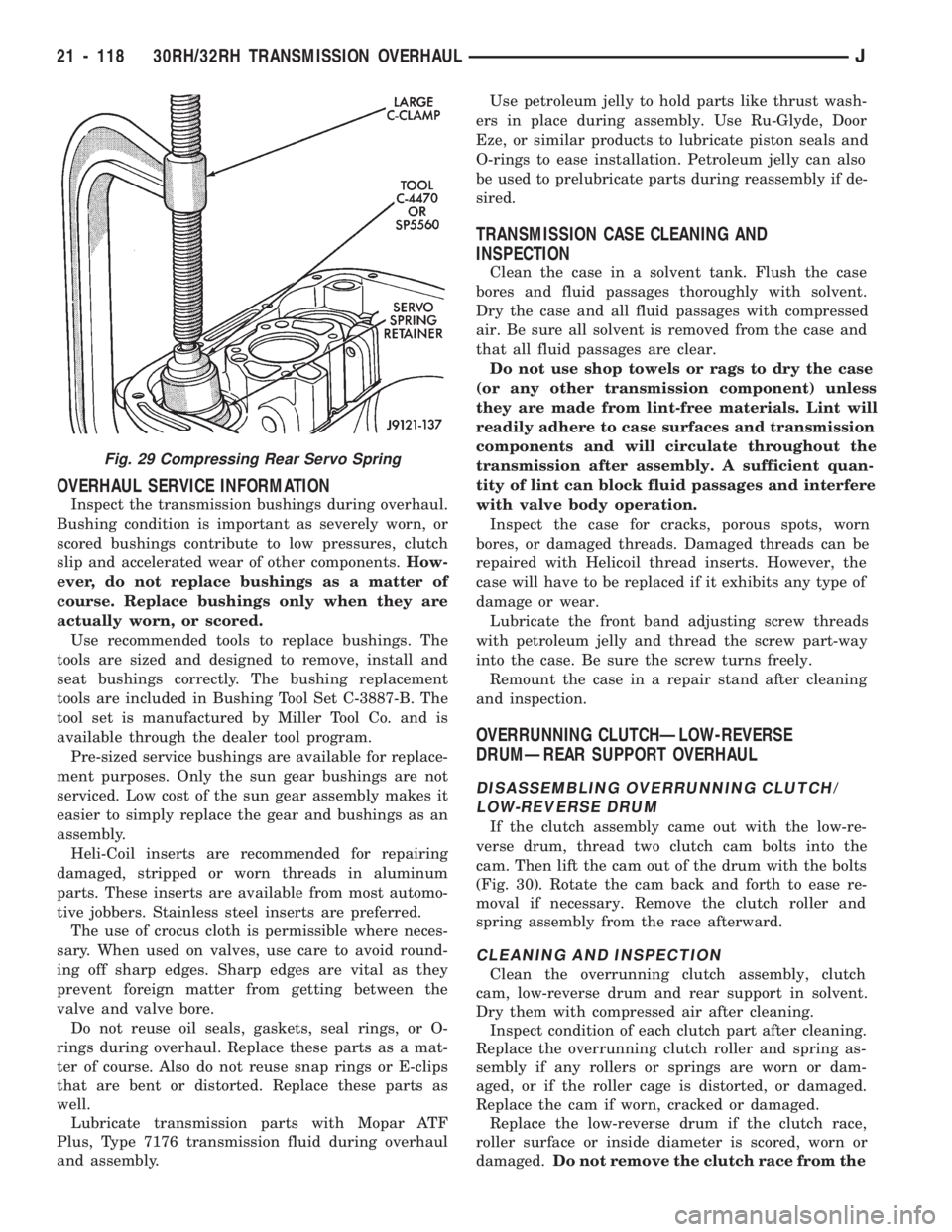

Fig. 29 Compressing Rear Servo Spring

21 - 118 30RH/32RH TRANSMISSION OVERHAULJ

Page 1255 of 1784

VALVE BODY ASSEMBLY AND ADJUSTMENT

CAUTION: Do not force valves or plugs into place

during reassembly. If the valve body bores, valves

and plugs are free of distortion or burrs, the valve

body components should all slide into place easily.

In addition, do not overtighten the transfer plate

and valve body screws during reassembly. Over-

tightening can distort the valve body resulting in

valve sticking, cross leakage and unsatisfactory op-

eration. Tighten valve body screws to recom-

mended torque only.

(1) Lubricate valve body bores, valves and plugs

with ATF Plus, or Dexron IIŸ transmission fluid.

(2) Insert rear clutch and rear servo check balls in

transfer plate (Fig. 110).

(3) Install filter screen in separator plate (Fig.

110).

(4) Align and install separator plate on transfer

plate. Verify check ball position before installing sep-

arator plate on transfer plate.

(5) Install new O-ring on converter clutch solenoid

and insert solenoid in separator plate (Fig. 115).

Then secure solenoid in position with attaching

screw. Tighten screw to 4 Nzm 35 in. lbs.) torque.

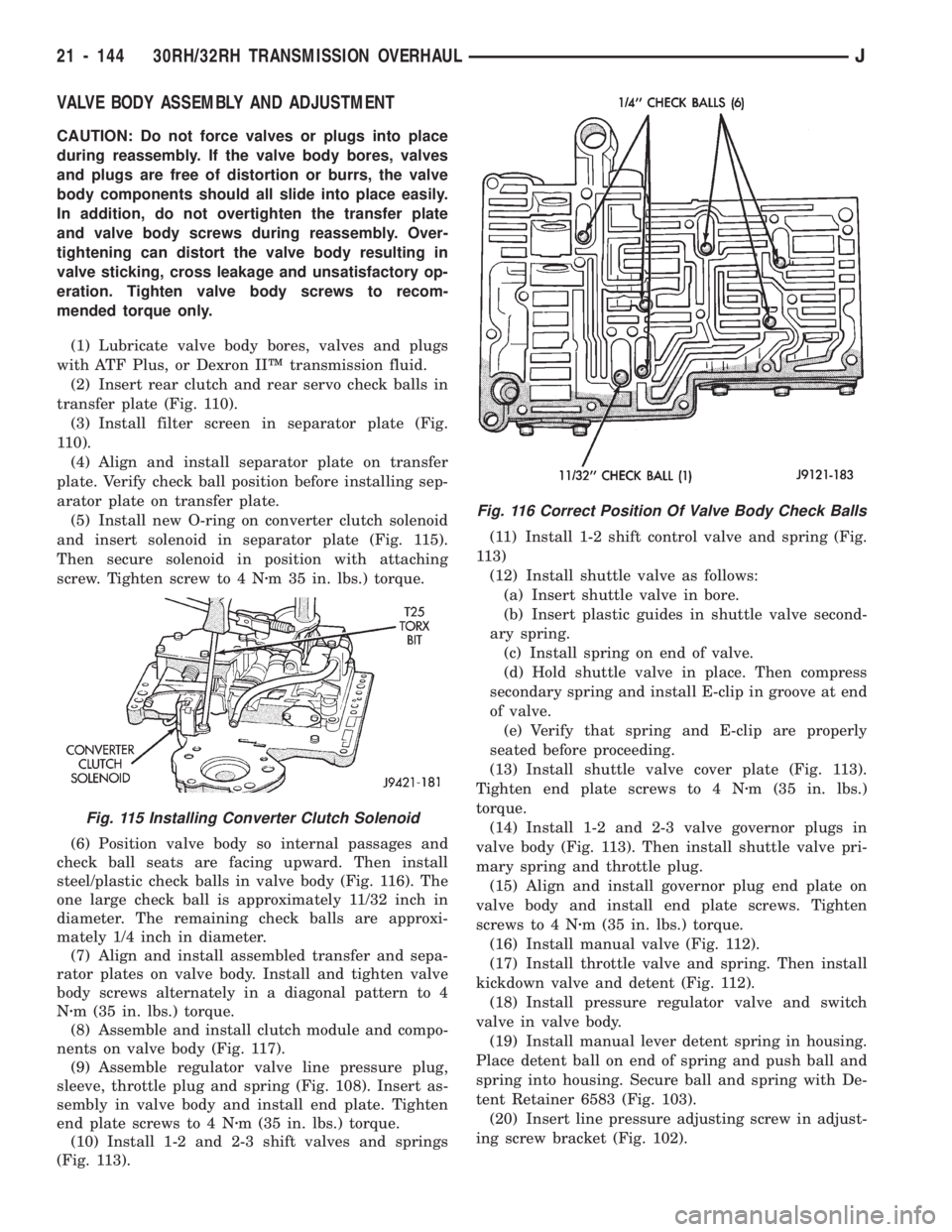

(6) Position valve body so internal passages and

check ball seats are facing upward. Then install

steel/plastic check balls in valve body (Fig. 116). The

one large check ball is approximately 11/32 inch in

diameter. The remaining check balls are approxi-

mately 1/4 inch in diameter.

(7) Align and install assembled transfer and sepa-

rator plates on valve body. Install and tighten valve

body screws alternately in a diagonal pattern to 4

Nzm (35 in. lbs.) torque.

(8) Assemble and install clutch module and compo-

nents on valve body (Fig. 117).

(9) Assemble regulator valve line pressure plug,

sleeve, throttle plug and spring (Fig. 108). Insert as-

sembly in valve body and install end plate. Tighten

end plate screws to 4 Nzm (35 in. lbs.) torque.

(10) Install 1-2 and 2-3 shift valves and springs

(Fig. 113).(11) Install 1-2 shift control valve and spring (Fig.

113)

(12) Install shuttle valve as follows:

(a) Insert shuttle valve in bore.

(b) Insert plastic guides in shuttle valve second-

ary spring.

(c) Install spring on end of valve.

(d) Hold shuttle valve in place. Then compress

secondary spring and install E-clip in groove at end

of valve.

(e) Verify that spring and E-clip are properly

seated before proceeding.

(13) Install shuttle valve cover plate (Fig. 113).

Tighten end plate screws to 4 Nzm (35 in. lbs.)

torque.

(14) Install 1-2 and 2-3 valve governor plugs in

valve body (Fig. 113). Then install shuttle valve pri-

mary spring and throttle plug.

(15) Align and install governor plug end plate on

valve body and install end plate screws. Tighten

screws to 4 Nzm (35 in. lbs.) torque.

(16) Install manual valve (Fig. 112).

(17) Install throttle valve and spring. Then install

kickdown valve and detent (Fig. 112).

(18) Install pressure regulator valve and switch

valve in valve body.

(19) Install manual lever detent spring in housing.

Place detent ball on end of spring and push ball and

spring into housing. Secure ball and spring with De-

tent Retainer 6583 (Fig. 103).

(20) Insert line pressure adjusting screw in adjust-

ing screw bracket (Fig. 102).

Fig. 116 Correct Position Of Valve Body Check Balls

Fig. 115 Installing Converter Clutch Solenoid

21 - 144 30RH/32RH TRANSMISSION OVERHAULJ

Page 1257 of 1784

rect sequence. The correct sequence is line pressure

adjustment first and throttle pressure adjustment

last.

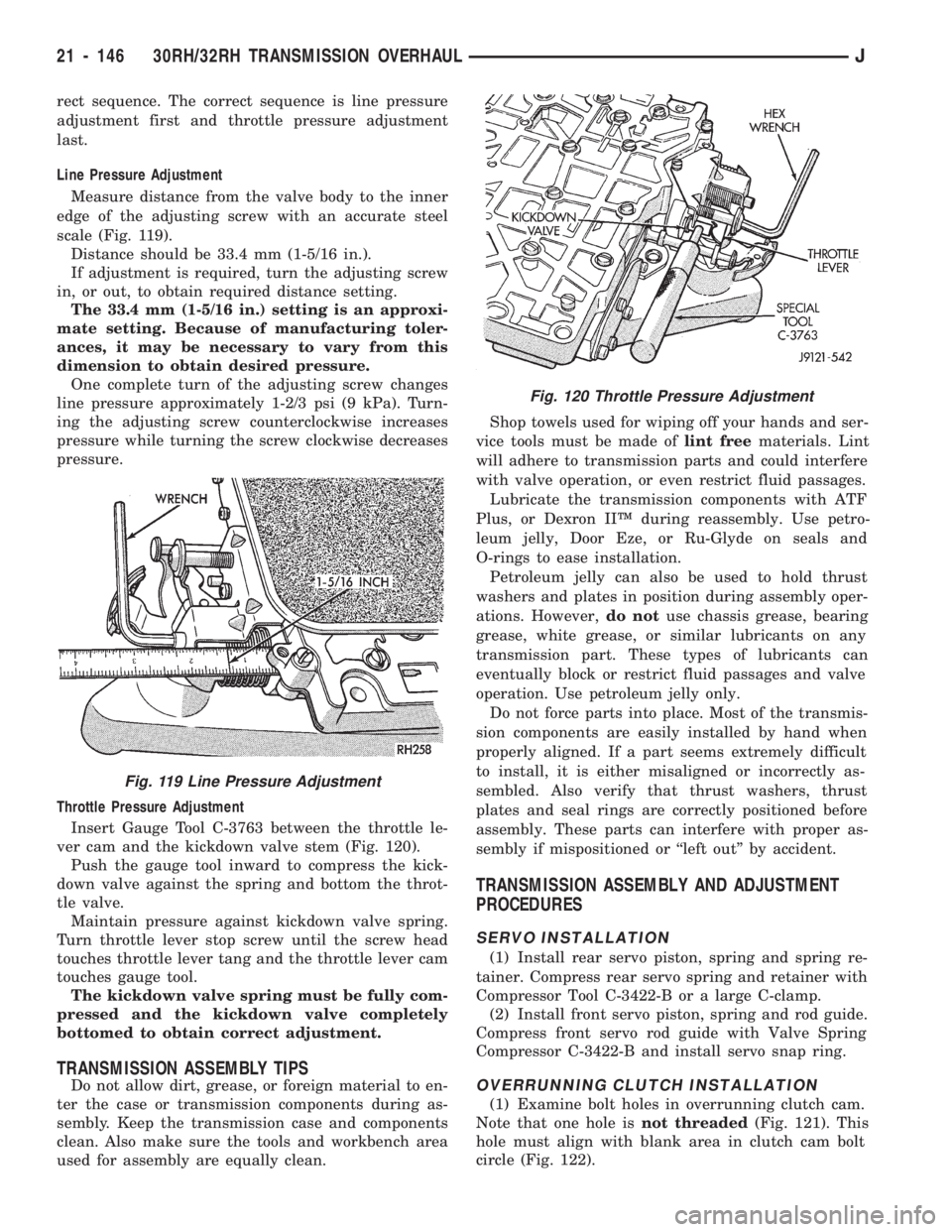

Line Pressure Adjustment

Measure distance from the valve body to the inner

edge of the adjusting screw with an accurate steel

scale (Fig. 119).

Distance should be 33.4 mm (1-5/16 in.).

If adjustment is required, turn the adjusting screw

in, or out, to obtain required distance setting.

The 33.4 mm (1-5/16 in.) setting is an approxi-

mate setting. Because of manufacturing toler-

ances, it may be necessary to vary from this

dimension to obtain desired pressure.

One complete turn of the adjusting screw changes

line pressure approximately 1-2/3 psi (9 kPa). Turn-

ing the adjusting screw counterclockwise increases

pressure while turning the screw clockwise decreases

pressure.

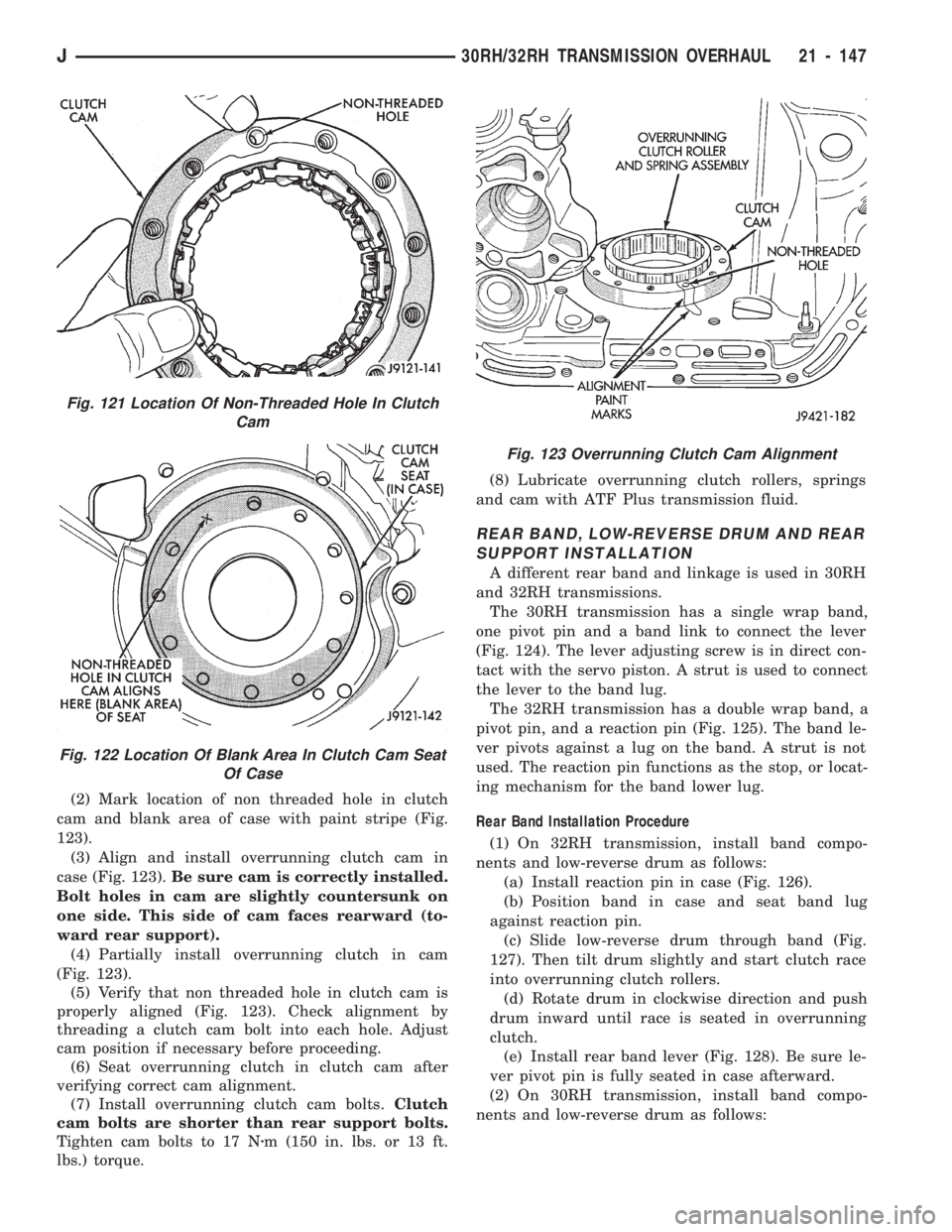

Throttle Pressure Adjustment

Insert Gauge Tool C-3763 between the throttle le-

ver cam and the kickdown valve stem (Fig. 120).

Push the gauge tool inward to compress the kick-

down valve against the spring and bottom the throt-

tle valve.

Maintain pressure against kickdown valve spring.

Turn throttle lever stop screw until the screw head

touches throttle lever tang and the throttle lever cam

touches gauge tool.

The kickdown valve spring must be fully com-

pressed and the kickdown valve completely

bottomed to obtain correct adjustment.

TRANSMISSION ASSEMBLY TIPS

Do not allow dirt, grease, or foreign material to en-

ter the case or transmission components during as-

sembly. Keep the transmission case and components

clean. Also make sure the tools and workbench area

used for assembly are equally clean.Shop towels used for wiping off your hands and ser-

vice tools must be made oflint freematerials. Lint

will adhere to transmission parts and could interfere

with valve operation, or even restrict fluid passages.

Lubricate the transmission components with ATF

Plus, or Dexron IIŸ during reassembly. Use petro-

leum jelly, Door Eze, or Ru-Glyde on seals and

O-rings to ease installation.

Petroleum jelly can also be used to hold thrust

washers and plates in position during assembly oper-

ations. However,do notuse chassis grease, bearing

grease, white grease, or similar lubricants on any

transmission part. These types of lubricants can

eventually block or restrict fluid passages and valve

operation. Use petroleum jelly only.

Do not force parts into place. Most of the transmis-

sion components are easily installed by hand when

properly aligned. If a part seems extremely difficult

to install, it is either misaligned or incorrectly as-

sembled. Also verify that thrust washers, thrust

plates and seal rings are correctly positioned before

assembly. These parts can interfere with proper as-

sembly if mispositioned or ``left out'' by accident.

TRANSMISSION ASSEMBLY AND ADJUSTMENT

PROCEDURES

SERVO INSTALLATION

(1) Install rear servo piston, spring and spring re-

tainer. Compress rear servo spring and retainer with

Compressor Tool C-3422-B or a large C-clamp.

(2) Install front servo piston, spring and rod guide.

Compress front servo rod guide with Valve Spring

Compressor C-3422-B and install servo snap ring.

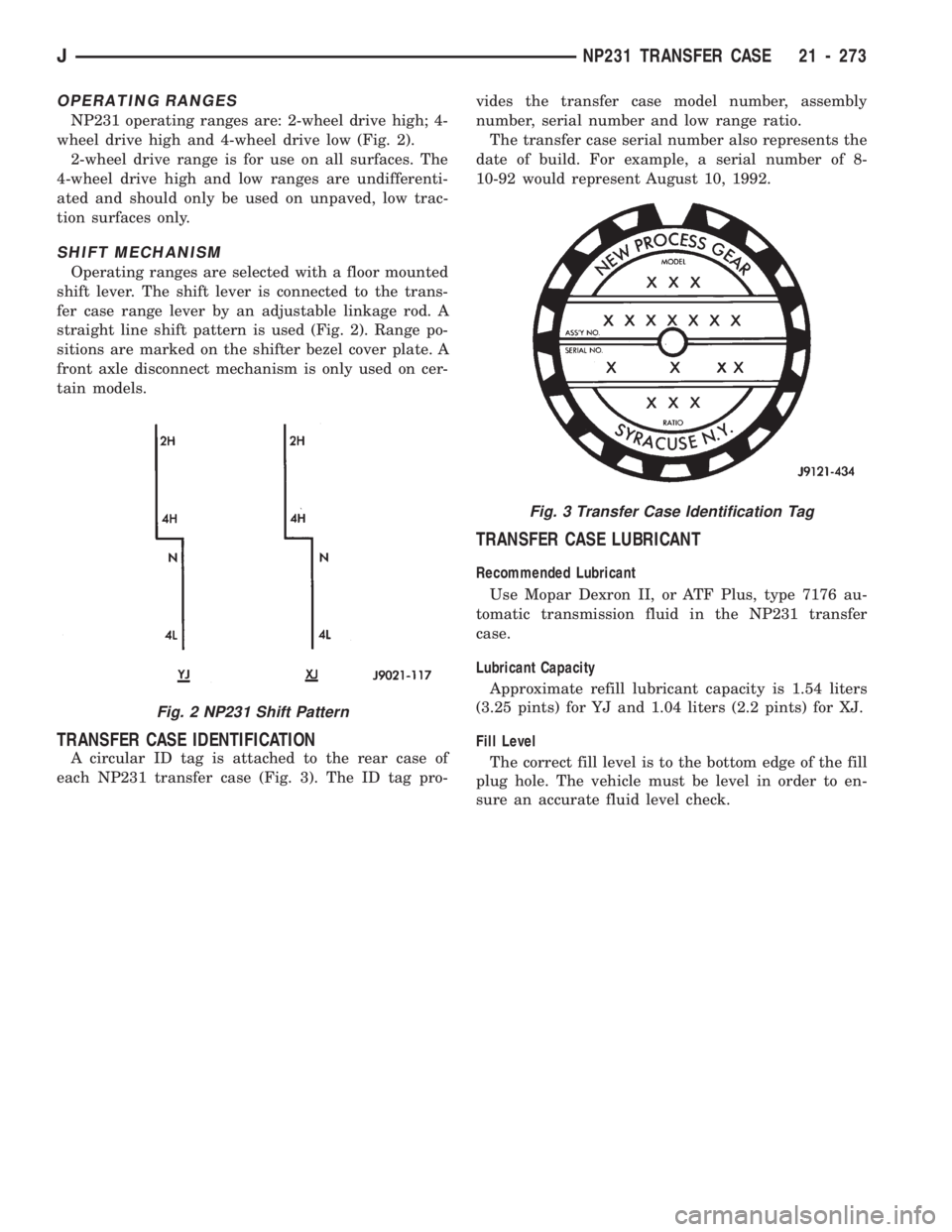

OVERRUNNING CLUTCH INSTALLATION

(1) Examine bolt holes in overrunning clutch cam.

Note that one hole isnot threaded(Fig. 121). This

hole must align with blank area in clutch cam bolt

circle (Fig. 122).

Fig. 120 Throttle Pressure Adjustment

Fig. 119 Line Pressure Adjustment

21 - 146 30RH/32RH TRANSMISSION OVERHAULJ

Page 1258 of 1784

(2) Mark location of non threaded hole in clutch

cam and blank area of case with paint stripe (Fig.

123).

(3) Align and install overrunning clutch cam in

case (Fig. 123).Be sure cam is correctly installed.

Bolt holes in cam are slightly countersunk on

one side. This side of cam faces rearward (to-

ward rear support).

(4) Partially install overrunning clutch in cam

(Fig. 123).

(5) Verify that non threaded hole in clutch cam is

properly aligned (Fig. 123). Check alignment by

threading a clutch cam bolt into each hole. Adjust

cam position if necessary before proceeding.

(6) Seat overrunning clutch in clutch cam after

verifying correct cam alignment.

(7) Install overrunning clutch cam bolts.Clutch

cam bolts are shorter than rear support bolts.

Tighten cam bolts to 17 Nzm (150 in. lbs. or 13 ft.

lbs.) torque.(8) Lubricate overrunning clutch rollers, springs

and cam with ATF Plus transmission fluid.

REAR BAND, LOW-REVERSE DRUM AND REAR

SUPPORT INSTALLATION

A different rear band and linkage is used in 30RH

and 32RH transmissions.

The 30RH transmission has a single wrap band,

one pivot pin and a band link to connect the lever

(Fig. 124). The lever adjusting screw is in direct con-

tact with the servo piston. A strut is used to connect

the lever to the band lug.

The 32RH transmission has a double wrap band, a

pivot pin, and a reaction pin (Fig. 125). The band le-

ver pivots against a lug on the band. A strut is not

used. The reaction pin functions as the stop, or locat-

ing mechanism for the band lower lug.

Rear Band Installation Procedure

(1) On 32RH transmission, install band compo-

nents and low-reverse drum as follows:

(a) Install reaction pin in case (Fig. 126).

(b) Position band in case and seat band lug

against reaction pin.

(c) Slide low-reverse drum through band (Fig.

127). Then tilt drum slightly and start clutch race

into overrunning clutch rollers.

(d) Rotate drum in clockwise direction and push

drum inward until race is seated in overrunning

clutch.

(e) Install rear band lever (Fig. 128). Be sure le-

ver pivot pin is fully seated in case afterward.

(2) On 30RH transmission, install band compo-

nents and low-reverse drum as follows:

Fig. 123 Overrunning Clutch Cam Alignment

Fig. 121 Location Of Non-Threaded Hole In Clutch

Cam

Fig. 122 Location Of Blank Area In Clutch Cam Seat

Of Case

J30RH/32RH TRANSMISSION OVERHAUL 21 - 147

Page 1384 of 1784

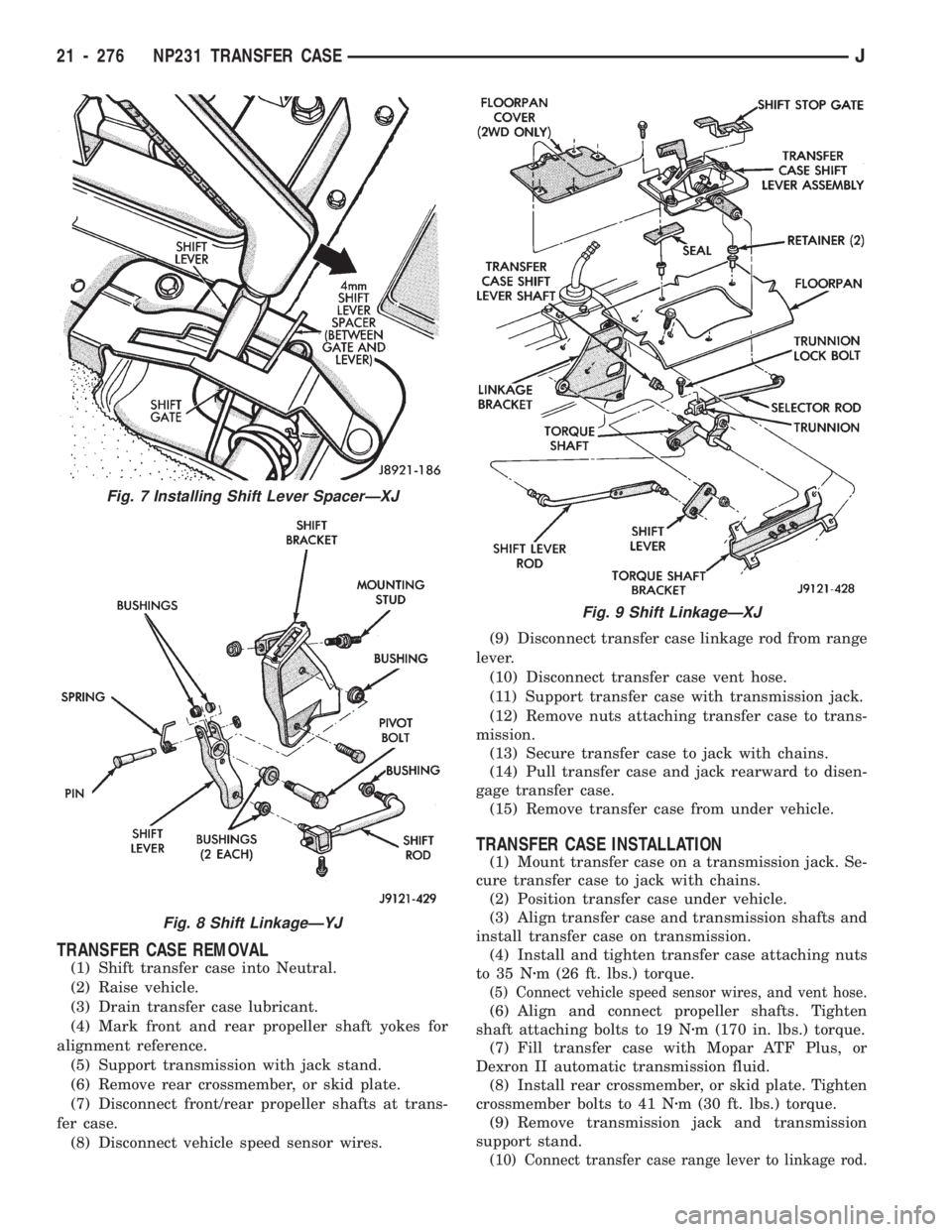

OPERATING RANGES

NP231 operating ranges are: 2-wheel drive high; 4-

wheel drive high and 4-wheel drive low (Fig. 2).

2-wheel drive range is for use on all surfaces. The

4-wheel drive high and low ranges are undifferenti-

ated and should only be used on unpaved, low trac-

tion surfaces only.

SHIFT MECHANISM

Operating ranges are selected with a floor mounted

shift lever. The shift lever is connected to the trans-

fer case range lever by an adjustable linkage rod. A

straight line shift pattern is used (Fig. 2). Range po-

sitions are marked on the shifter bezel cover plate. A

front axle disconnect mechanism is only used on cer-

tain models.

TRANSFER CASE IDENTIFICATION

A circular ID tag is attached to the rear case of

each NP231 transfer case (Fig. 3). The ID tag pro-vides the transfer case model number, assembly

number, serial number and low range ratio.

The transfer case serial number also represents the

date of build. For example, a serial number of 8-

10-92 would represent August 10, 1992.

TRANSFER CASE LUBRICANT

Recommended Lubricant

Use Mopar Dexron II, or ATF Plus, type 7176 au-

tomatic transmission fluid in the NP231 transfer

case.

Lubricant Capacity

Approximate refill lubricant capacity is 1.54 liters

(3.25 pints) for YJ and 1.04 liters (2.2 pints) for XJ.

Fill Level

The correct fill level is to the bottom edge of the fill

plug hole. The vehicle must be level in order to en-

sure an accurate fluid level check.

Fig. 2 NP231 Shift Pattern

Fig. 3 Transfer Case Identification Tag

JNP231 TRANSFER CASE 21 - 273

Page 1387 of 1784

TRANSFER CASE REMOVAL

(1) Shift transfer case into Neutral.

(2) Raise vehicle.

(3) Drain transfer case lubricant.

(4) Mark front and rear propeller shaft yokes for

alignment reference.

(5) Support transmission with jack stand.

(6) Remove rear crossmember, or skid plate.

(7) Disconnect front/rear propeller shafts at trans-

fer case.

(8) Disconnect vehicle speed sensor wires.(9) Disconnect transfer case linkage rod from range

lever.

(10) Disconnect transfer case vent hose.

(11) Support transfer case with transmission jack.

(12) Remove nuts attaching transfer case to trans-

mission.

(13) Secure transfer case to jack with chains.

(14) Pull transfer case and jack rearward to disen-

gage transfer case.

(15) Remove transfer case from under vehicle.

TRANSFER CASE INSTALLATION

(1) Mount transfer case on a transmission jack. Se-

cure transfer case to jack with chains.

(2) Position transfer case under vehicle.

(3) Align transfer case and transmission shafts and

install transfer case on transmission.

(4) Install and tighten transfer case attaching nuts

to 35 Nzm (26 ft. lbs.) torque.

(5) Connect vehicle speed sensor wires, and vent hose.

(6) Align and connect propeller shafts. Tighten

shaft attaching bolts to 19 Nzm (170 in. lbs.) torque.

(7) Fill transfer case with Mopar ATF Plus, or

Dexron II automatic transmission fluid.

(8) Install rear crossmember, or skid plate. Tighten

crossmember bolts to 41 Nzm (30 ft. lbs.) torque.

(9) Remove transmission jack and transmission

support stand.

(10) Connect transfer case range lever to linkage rod.

Fig. 7 Installing Shift Lever SpacerÐXJ

Fig. 8 Shift LinkageÐYJ

Fig. 9 Shift LinkageÐXJ

21 - 276 NP231 TRANSFER CASEJ

Page 1401 of 1784

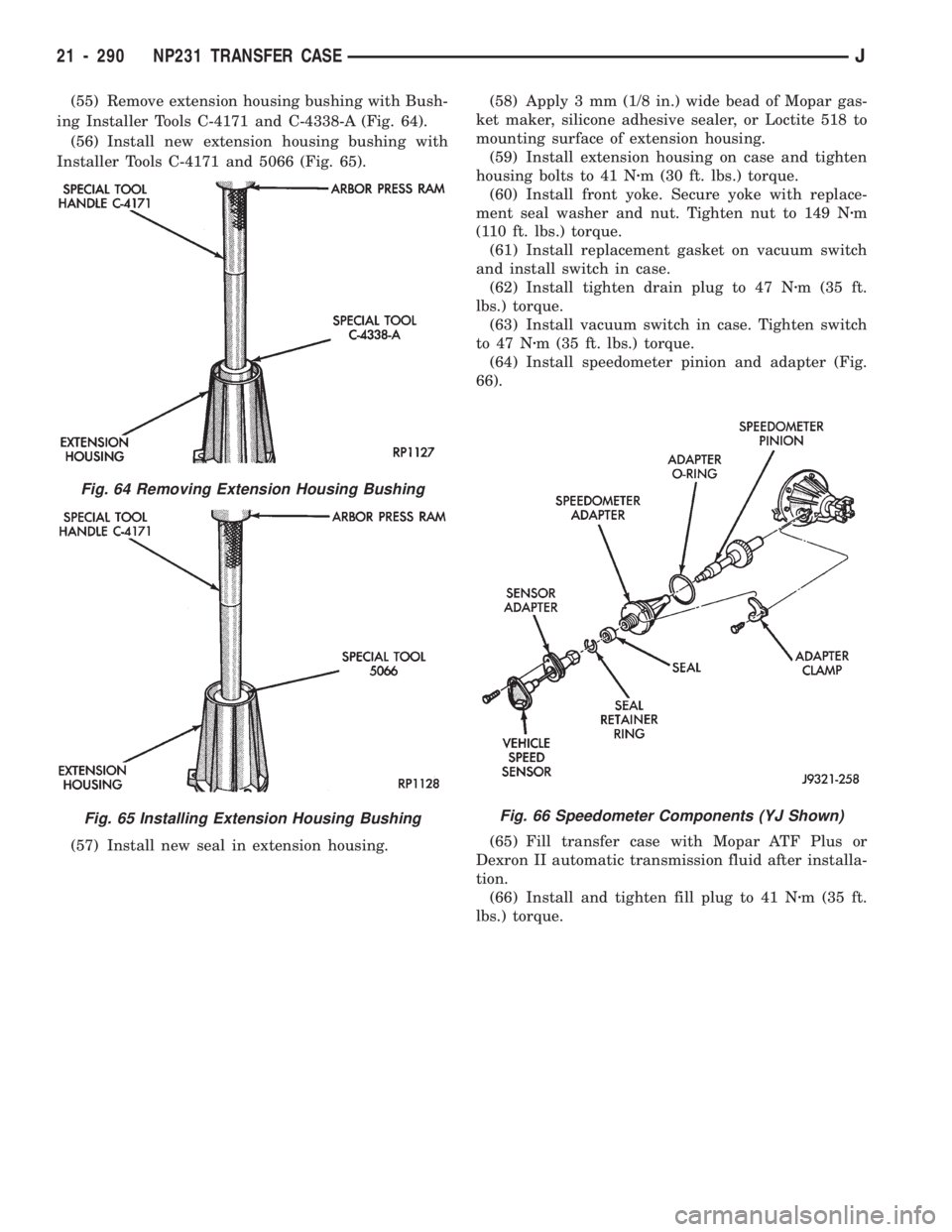

(55) Remove extension housing bushing with Bush-

ing Installer Tools C-4171 and C-4338-A (Fig. 64).

(56) Install new extension housing bushing with

Installer Tools C-4171 and 5066 (Fig. 65).

(57) Install new seal in extension housing.(58) Apply 3 mm (1/8 in.) wide bead of Mopar gas-

ket maker, silicone adhesive sealer, or Loctite 518 to

mounting surface of extension housing.

(59) Install extension housing on case and tighten

housing bolts to 41 Nzm (30 ft. lbs.) torque.

(60) Install front yoke. Secure yoke with replace-

ment seal washer and nut. Tighten nut to 149 Nzm

(110 ft. lbs.) torque.

(61) Install replacement gasket on vacuum switch

and install switch in case.

(62) Install tighten drain plug to 47 Nzm (35 ft.

lbs.) torque.

(63) Install vacuum switch in case. Tighten switch

to 47 Nzm (35 ft. lbs.) torque.

(64) Install speedometer pinion and adapter (Fig.

66).

(65) Fill transfer case with Mopar ATF Plus or

Dexron II automatic transmission fluid after installa-

tion.

(66) Install and tighten fill plug to 41 Nzm (35 ft.

lbs.) torque.

Fig. 64 Removing Extension Housing Bushing

Fig. 65 Installing Extension Housing BushingFig. 66 Speedometer Components (YJ Shown)

21 - 290 NP231 TRANSFER CASEJ

Page 1405 of 1784

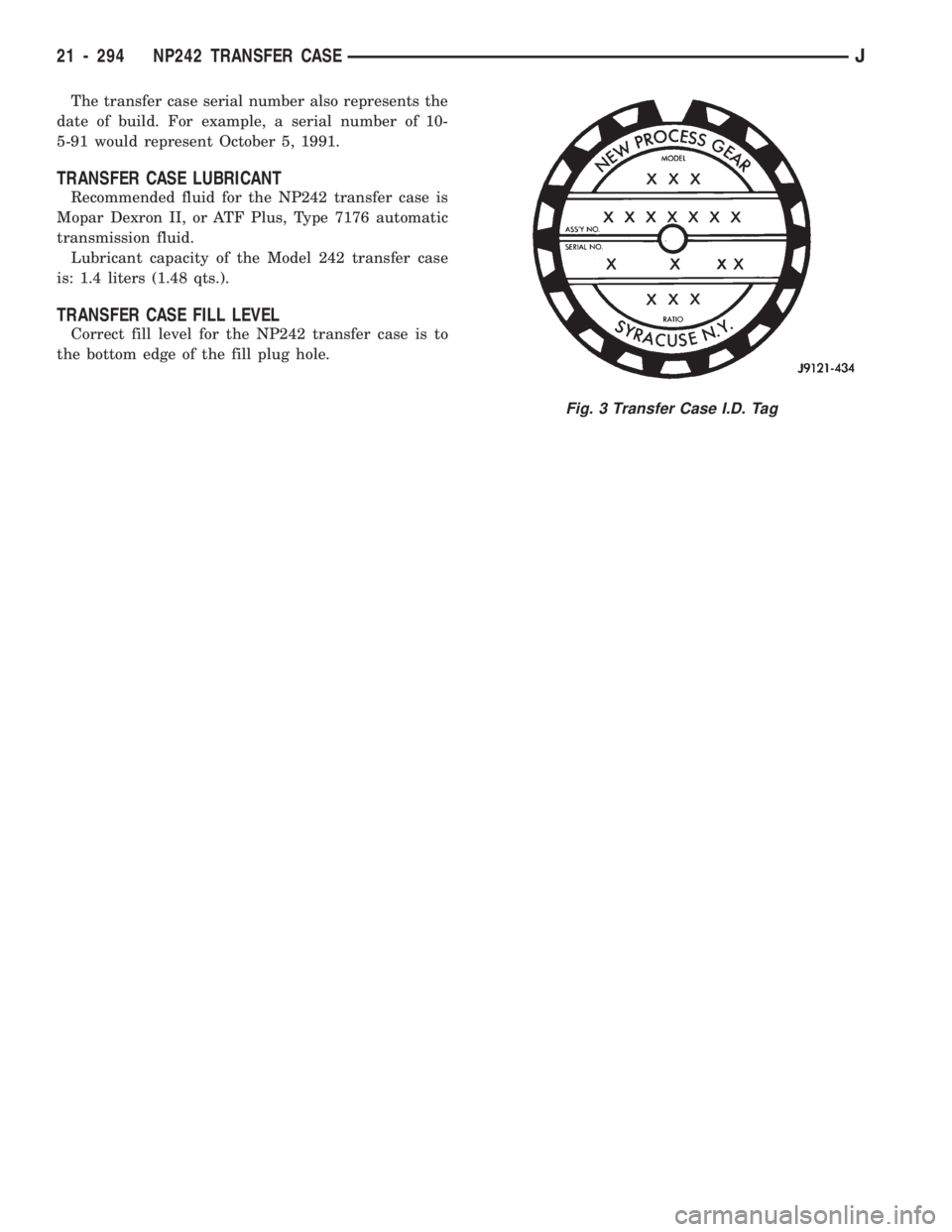

The transfer case serial number also represents the

date of build. For example, a serial number of 10-

5-91 would represent October 5, 1991.

TRANSFER CASE LUBRICANT

Recommended fluid for the NP242 transfer case is

Mopar Dexron II, or ATF Plus, Type 7176 automatic

transmission fluid.

Lubricant capacity of the Model 242 transfer case

is: 1.4 liters (1.48 qts.).

TRANSFER CASE FILL LEVEL

Correct fill level for the NP242 transfer case is to

the bottom edge of the fill plug hole.

Fig. 3 Transfer Case I.D. Tag

21 - 294 NP242 TRANSFER CASEJ