differential JEEP CHEROKEE 1994 Service User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 1994, Model line: CHEROKEE, Model: JEEP CHEROKEE 1994Pages: 1784, PDF Size: 77.09 MB

Page 59 of 1784

(9) Disconnect the tie rod from the steering

knuckle. Disconnect the steering dampener from the

axle bracket.

(10) Support the axle with a hydraulic jack under

the differential. Raise the axle just enough to relieve

the axle weight from the springs.

(11) Remove the spring U-bolts from the plate

brackets.

(12) Loosen BUT DO NOT REMOVE the bolts that

attach the spring rear pivot at the frame rail brack-

ets. This will allow the springs to pivot without bind-

ing on the bushings.

(13) Disconnect shackle from the springs and lower

the springs to the surface.

(14) Lower the jack enough to remove the axle.

INSTALLATION

CAUTION: All suspension components that use rub-

ber bushings should be tightened with the vehicle

at the normal height. It is important to have the

springs supporting the weight of the vehicle when

the fasteners are torqued. If the springs are not at

their normal ride position, vehicle ride comfort

could be affected along with premature rubber

bushing wear. Rubber bushings must never be lu-

bricated.

(1) Support the axle on a hydraulic jack under the

differential. Position the axle under the vehicle.

(2) Raise the springs and install the spring shackle

bolts.Do not tighten at this time.

(3) Lower the axle and align the spring center

bolts with the locating holes in the axle pads and

plate brackets.

(4) Install the spring U-bolts through the plate

brackets and tighten to 122 Nzm (90 ft. lbs.) torque.

(5) Connect the track bar to the axle bracket and

install the bolt.Do not tighten at this time.

It is important that the springs support the

weight of the vehicle when the track bar is con-

nected. If the springs are not at their usual po-

sition, the vehicle ride comfort could be affected.

(6) Install the shock absorber and tighten the nut

to 61 Nzm (45 ft. lbs.) torque.

(7) Install the stabilizer bar link to the axle

bracket. Tighten the nut to 61 Nzm (45 ft. lbs.)

torque.

(8) Install the tie rod to the steering knuckles and

tighten the nuts to 47 Nzm (35 ft. lbs.) torque. Install

the steering dampener to the axle bracket and

tighten the bolt to 75 Nzm (55 ft. lbs.) torque.

(9) Install the brake components and ABS brake

sensor (if equipped). Refer to Group 5ÐBrakes.

(10) Connect the vent hose to the tube fitting and

axle shift motor vacuum harness.(11) Align the reference marks and connect the

drive shaft to the axle yoke. Tighten the U-joint

clamp bolts to 19 Nzm (14 ft. lbs.) torque.

(12) Check differential lubricant and add if neces-

sary.

(13) Install the wheel and tire assemblies.

(14) Remove the supports and lower the vehicle.

(15) Tighten the spring rear pivot bolt/nut to 142

Nzm (105 ft. lbs.) torque. Tighten the spring shackle

bolt/nut to 135 Nzm (100 ft. lbs.) torque.

(16) Tighten the track bar nut at the axle bracket

to 100 Nzm (74 ft. lbs.) torque.

(17) Check the front wheel alignment.

LUBRICANT CHANGE

The gear lubricant will drain quicker if the vehicle

has been recently driven.

(1) Raise and support the vehicle.

(2) Remove the lubricant fill hole plug from the

differential housing cover.

(3) Remove the differential housing cover and

drain the lubricant from the housing.

(4) Clean the housing cavity with a flushing oil,

light engine oil or lint free cloth.Do not use water,

steam, kerosene or gasoline for cleaning.

(5) Remove the sealant from the housing and cover

surfaces. Use solvent to clean the mating surfaces.

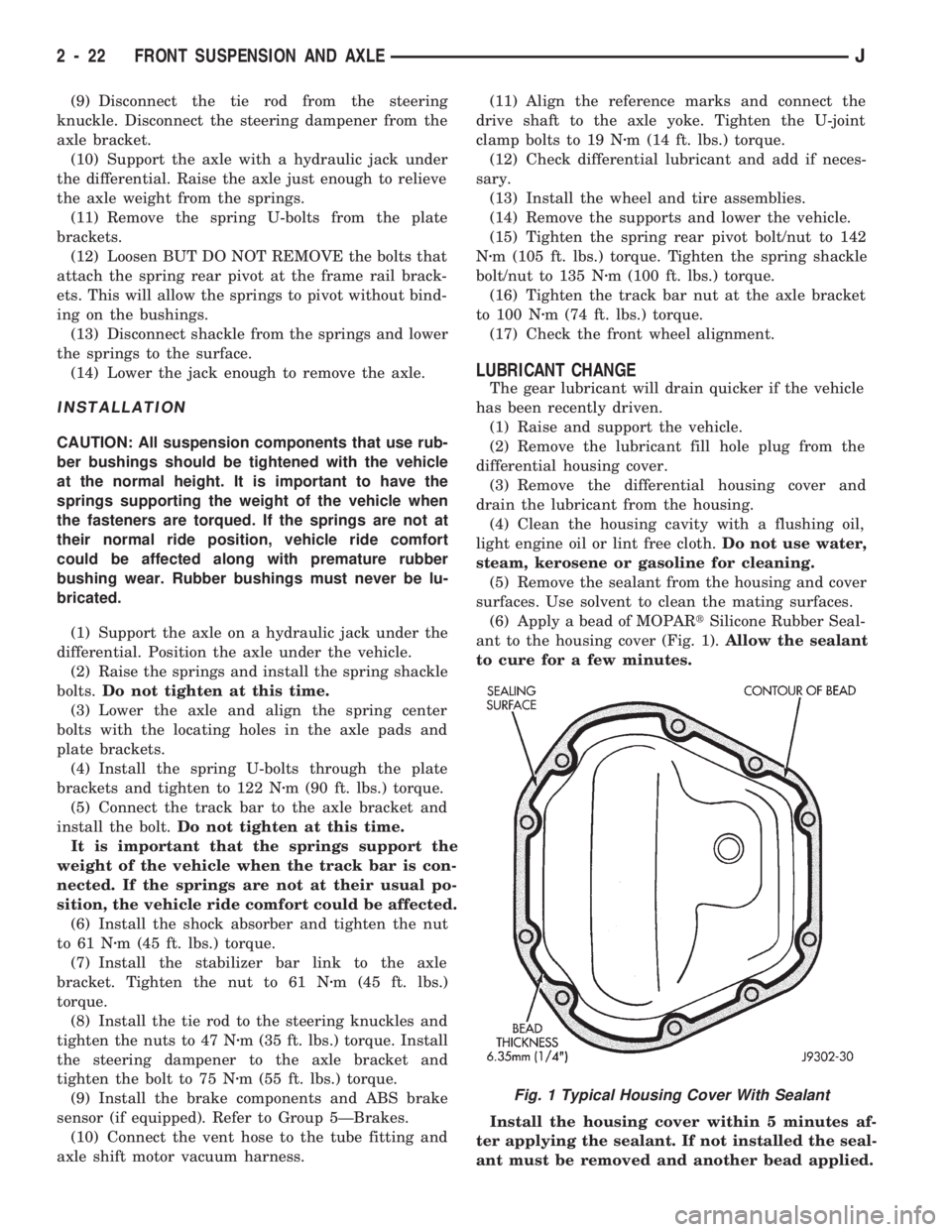

(6) Apply a bead of MOPARtSilicone Rubber Seal-

ant to the housing cover (Fig. 1).Allow the sealant

to cure for a few minutes.

Install the housing cover within 5 minutes af-

ter applying the sealant. If not installed the seal-

ant must be removed and another bead applied.

Fig. 1 Typical Housing Cover With Sealant

2 - 22 FRONT SUSPENSION AND AXLEJ

Page 60 of 1784

(7) Install the cover and any identification tag.

Tighten the cover bolts in a criss-cross pattern to 41

Nzm (30 ft. lbs.) torque.

(8) Refill the differential with MOPARtHypoid

Gear Lubricant within 13 mm (1/2 in.) below the fill

plug hole.

(9) Install the fill hole plug and lower the vehicle.

PINION SEAL REPLACEMENT

CAUTION: The following procedures must be used

so the correct pinion bearing preload torque is re-

tained. If this procedure is not followed, the result

can be premature failure of the rear axle.

REMOVAL

(1) Raise and support the vehicle.

(2) Remove wheel and tire assemblies.

(3) Mark the propeller shaft yoke and pinion yoke

for installation alignment reference.

(4) Remove the propeller shaft from the yoke.

(5) Rotate the pinion gear three or four times.

Make sure brakes are not dragging during this

procedure.

(6) Measure the amount of torque (in Newton-

meters or inch-pounds) necessary to rotate the pinion

gear with a torque wrench. Note the torque for in-

stallation reference.It must be known to properly

adjust the pinion gear bearing preload torque

after seal installation.

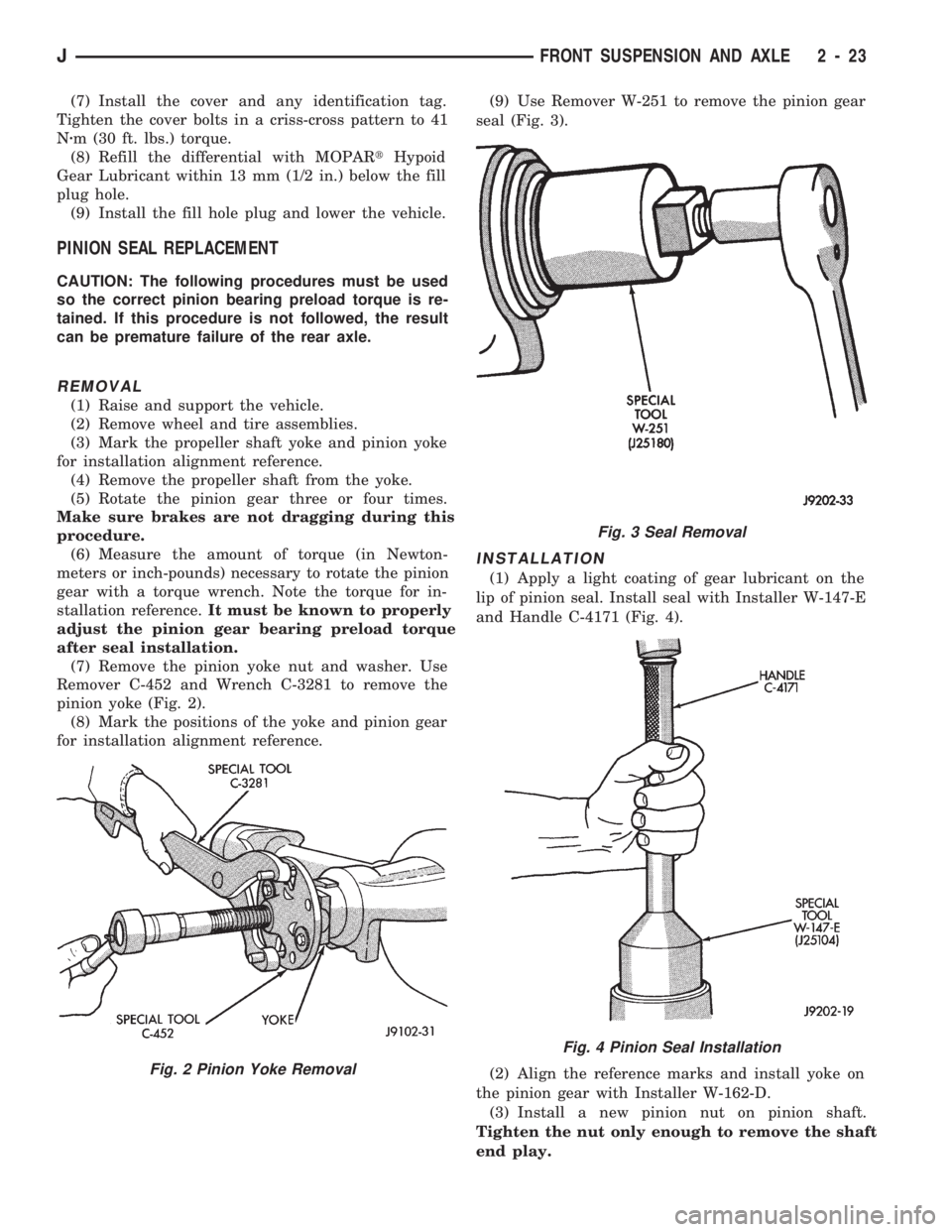

(7) Remove the pinion yoke nut and washer. Use

Remover C-452 and Wrench C-3281 to remove the

pinion yoke (Fig. 2).

(8) Mark the positions of the yoke and pinion gear

for installation alignment reference.(9) Use Remover W-251 to remove the pinion gear

seal (Fig. 3).

INSTALLATION

(1) Apply a light coating of gear lubricant on the

lip of pinion seal. Install seal with Installer W-147-E

and Handle C-4171 (Fig. 4).

(2) Align the reference marks and install yoke on

the pinion gear with Installer W-162-D.

(3) Install a new pinion nut on pinion shaft.

Tighten the nut only enough to remove the shaft

end play.

Fig. 2 Pinion Yoke Removal

Fig. 3 Seal Removal

Fig. 4 Pinion Seal Installation

JFRONT SUSPENSION AND AXLE 2 - 23

Page 61 of 1784

CAUTION: Never loosen the pinion gear nut to de-

crease the pinion gear bearing preload torque. If the

specified preload torque is exceeded, a new col-

lapsible spacer must be installed. The torque se-

quence will have to be repeated.

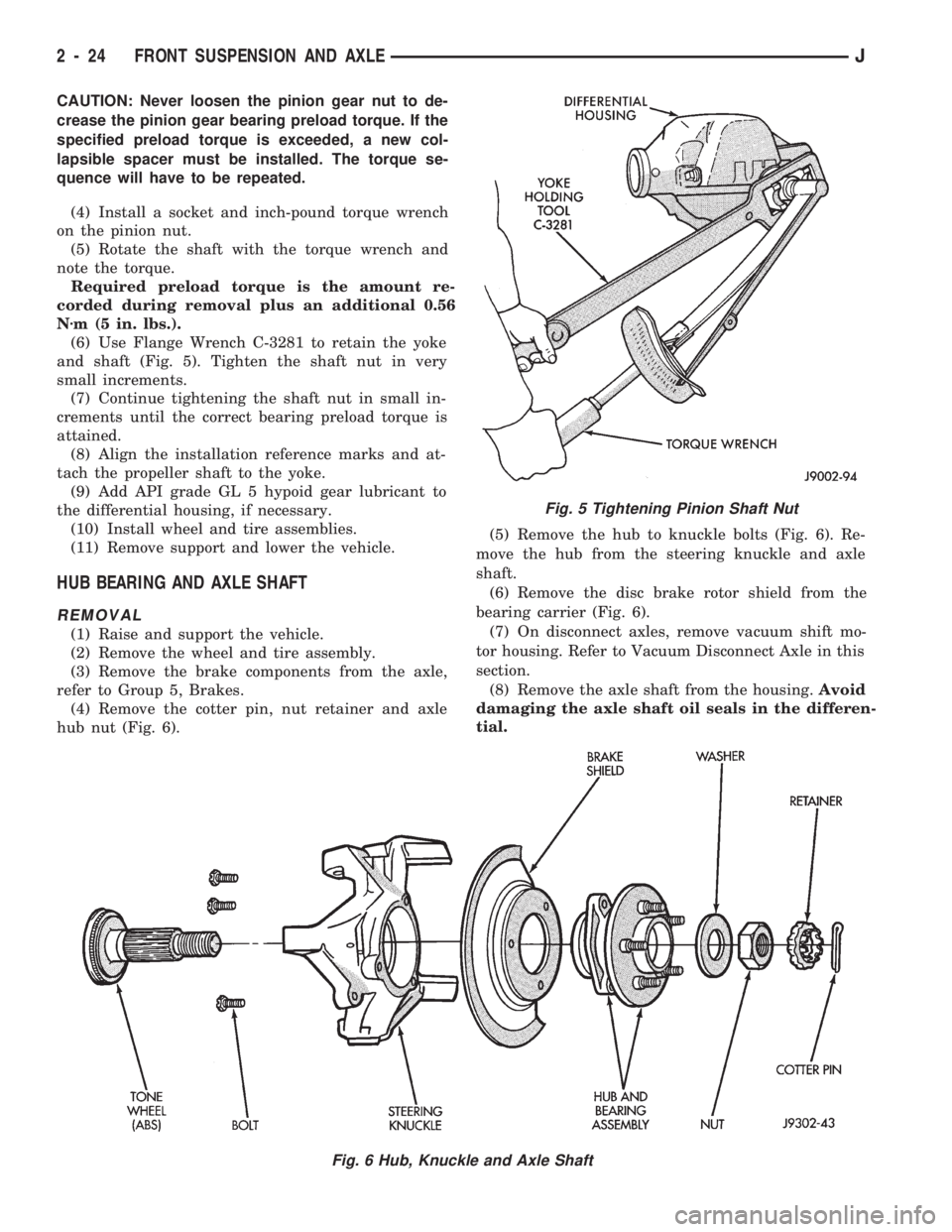

(4) Install a socket and inch-pound torque wrench

on the pinion nut.

(5) Rotate the shaft with the torque wrench and

note the torque.

Required preload torque is the amount re-

corded during removal plus an additional 0.56

Nzm (5 in. lbs.).

(6) Use Flange Wrench C-3281 to retain the yoke

and shaft (Fig. 5). Tighten the shaft nut in very

small increments.

(7) Continue tightening the shaft nut in small in-

crements until the correct bearing preload torque is

attained.

(8) Align the installation reference marks and at-

tach the propeller shaft to the yoke.

(9) Add API grade GL 5 hypoid gear lubricant to

the differential housing, if necessary.

(10) Install wheel and tire assemblies.

(11) Remove support and lower the vehicle.

HUB BEARING AND AXLE SHAFT

REMOVAL

(1) Raise and support the vehicle.

(2) Remove the wheel and tire assembly.

(3) Remove the brake components from the axle,

refer to Group 5, Brakes.

(4) Remove the cotter pin, nut retainer and axle

hub nut (Fig. 6).(5) Remove the hub to knuckle bolts (Fig. 6). Re-

move the hub from the steering knuckle and axle

shaft.

(6) Remove the disc brake rotor shield from the

bearing carrier (Fig. 6).

(7) On disconnect axles, remove vacuum shift mo-

tor housing. Refer to Vacuum Disconnect Axle in this

section.

(8) Remove the axle shaft from the housing.Avoid

damaging the axle shaft oil seals in the differen-

tial.

Fig. 5 Tightening Pinion Shaft Nut

Fig. 6 Hub, Knuckle and Axle Shaft

2 - 24 FRONT SUSPENSION AND AXLEJ

Page 62 of 1784

INSTALLATION

(1) Thoroughly clean the axle shaft (Fig. 6) and ap-

ply a thin film of Mopar Wheel Bearing Grease to

the shaft splines, seal contact surface, hub bore.

(2) Install the axle shaft into the housing and dif-

ferential side gears. Avoid damaging the axle shaft

oil seals in the differential.

(3) Install the hub bearing and brake dust shield

to the knuckle.

(4) Install the hub to knuckle bolts and tighten to

102 Nzm (75 ft. lbs.) torque.

(5) Install the hub washer and nut. Tighten the

hub nut to 237 Nzm (175 ft. lbs.) torque. Install the

nut retainer and a new cotter pin (Fig. 6).

(6) Install the brake components, refer to Group 5,

Brakes.

(7) Install the wheel and tire assembly.

(8) Remove support and lower the vehicle.

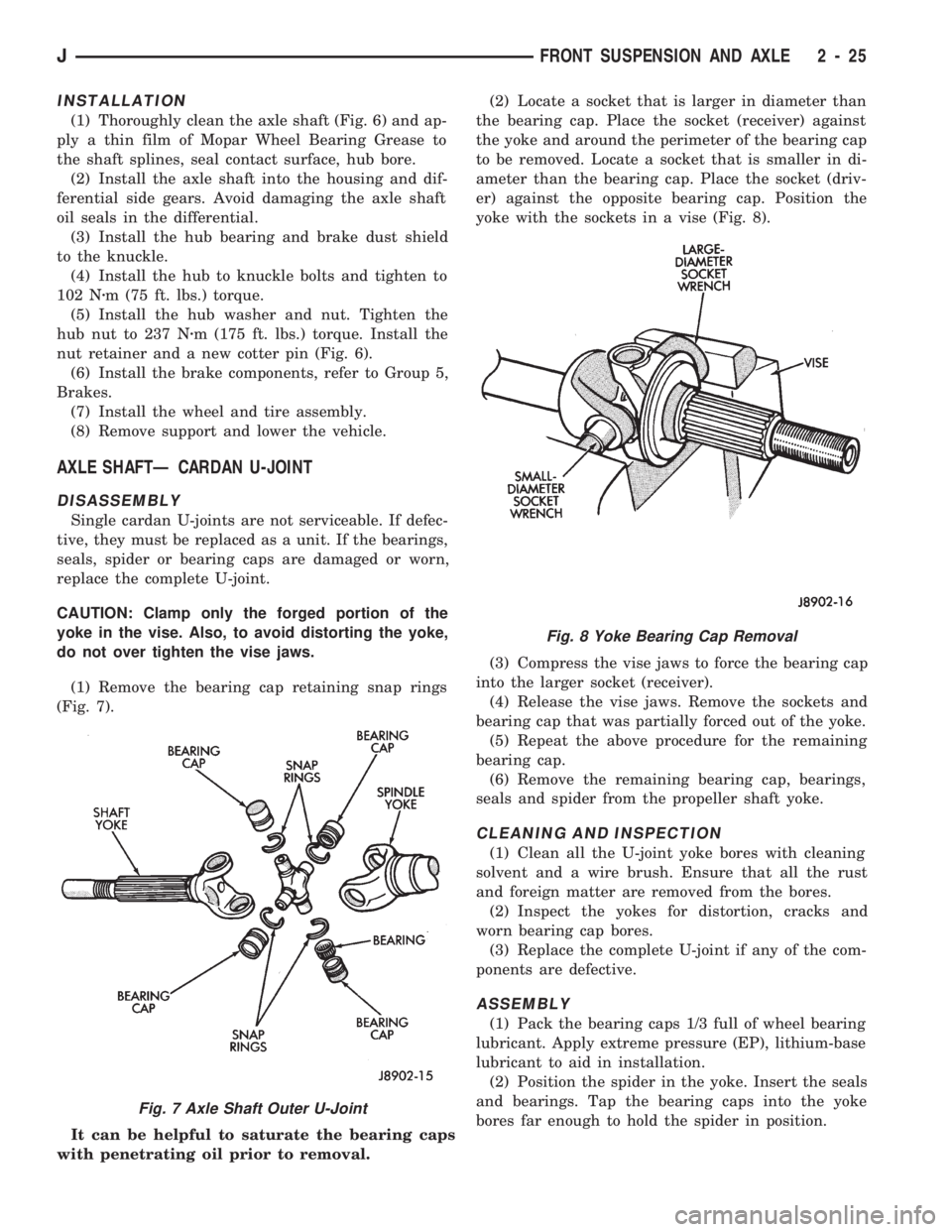

AXLE SHAFTÐ CARDAN U-JOINT

DISASSEMBLY

Single cardan U-joints are not serviceable. If defec-

tive, they must be replaced as a unit. If the bearings,

seals, spider or bearing caps are damaged or worn,

replace the complete U-joint.

CAUTION: Clamp only the forged portion of the

yoke in the vise. Also, to avoid distorting the yoke,

do not over tighten the vise jaws.

(1) Remove the bearing cap retaining snap rings

(Fig. 7).

It can be helpful to saturate the bearing caps

with penetrating oil prior to removal.(2) Locate a socket that is larger in diameter than

the bearing cap. Place the socket (receiver) against

the yoke and around the perimeter of the bearing cap

to be removed. Locate a socket that is smaller in di-

ameter than the bearing cap. Place the socket (driv-

er) against the opposite bearing cap. Position the

yoke with the sockets in a vise (Fig. 8).

(3) Compress the vise jaws to force the bearing cap

into the larger socket (receiver).

(4) Release the vise jaws. Remove the sockets and

bearing cap that was partially forced out of the yoke.

(5) Repeat the above procedure for the remaining

bearing cap.

(6) Remove the remaining bearing cap, bearings,

seals and spider from the propeller shaft yoke.

CLEANING AND INSPECTION

(1) Clean all the U-joint yoke bores with cleaning

solvent and a wire brush. Ensure that all the rust

and foreign matter are removed from the bores.

(2) Inspect the yokes for distortion, cracks and

worn bearing cap bores.

(3) Replace the complete U-joint if any of the com-

ponents are defective.

ASSEMBLY

(1) Pack the bearing caps 1/3 full of wheel bearing

lubricant. Apply extreme pressure (EP), lithium-base

lubricant to aid in installation.

(2) Position the spider in the yoke. Insert the seals

and bearings. Tap the bearing caps into the yoke

bores far enough to hold the spider in position.

Fig. 7 Axle Shaft Outer U-Joint

Fig. 8 Yoke Bearing Cap Removal

JFRONT SUSPENSION AND AXLE 2 - 25

Page 66 of 1784

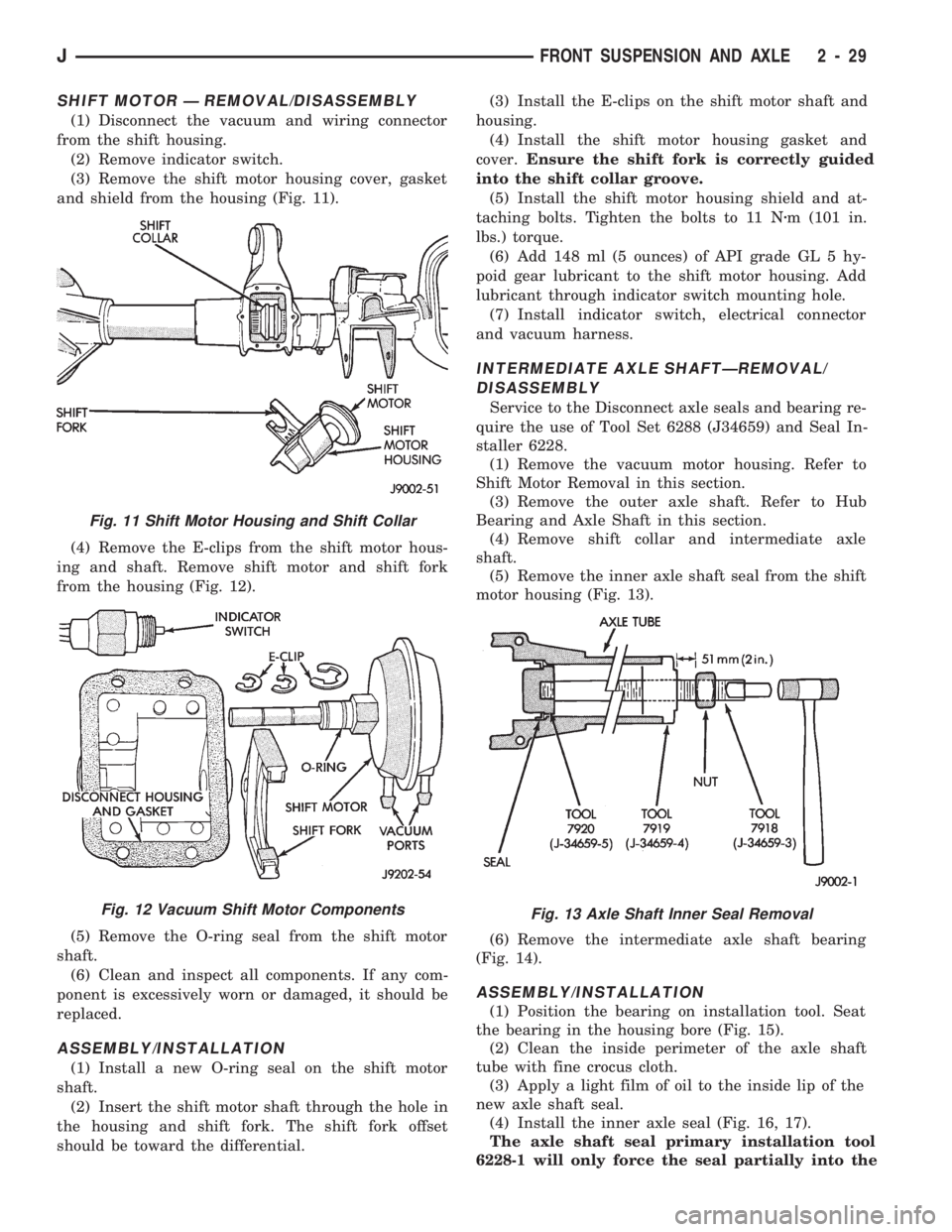

SHIFT MOTOR Ð REMOVAL/DISASSEMBLY

(1) Disconnect the vacuum and wiring connector

from the shift housing.

(2) Remove indicator switch.

(3) Remove the shift motor housing cover, gasket

and shield from the housing (Fig. 11).

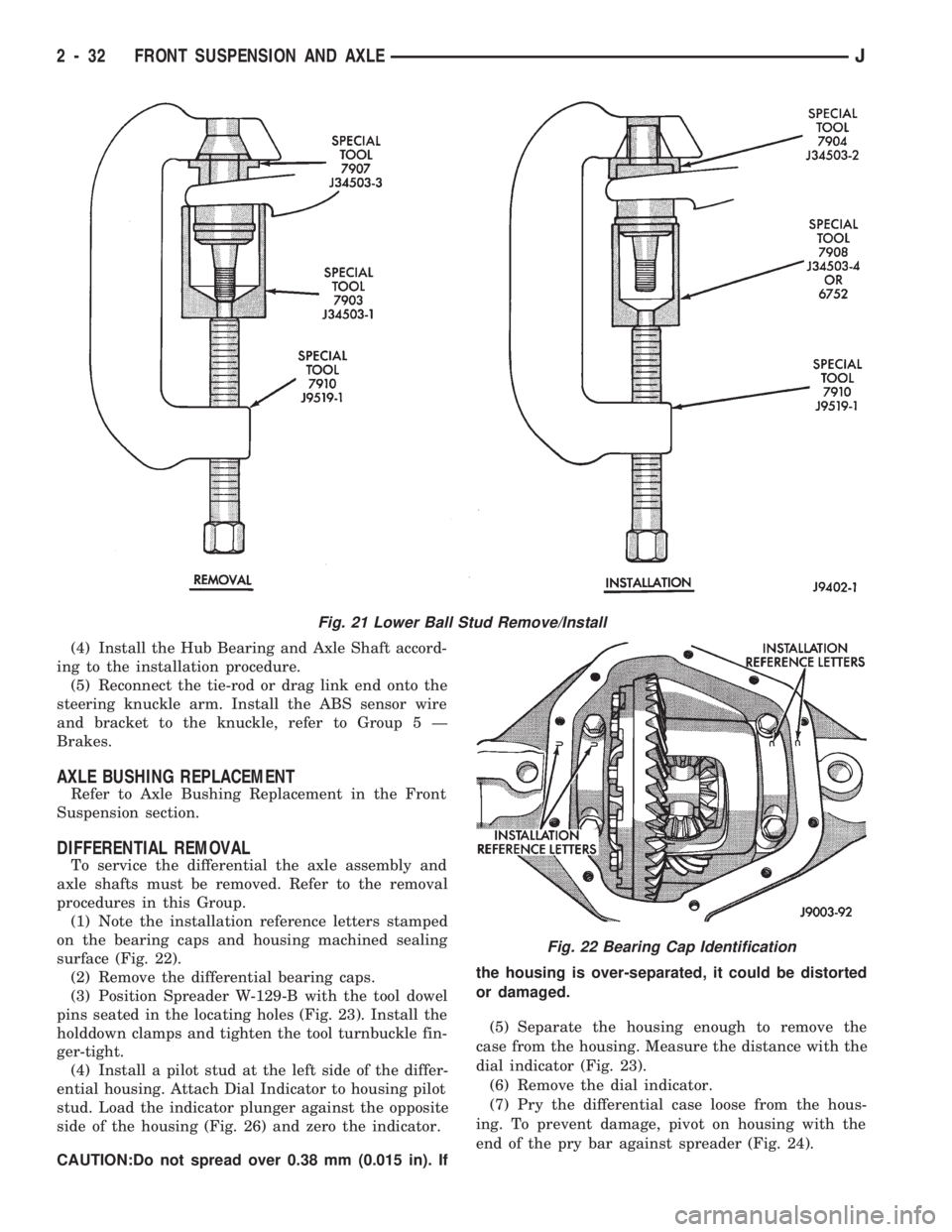

(4) Remove the E-clips from the shift motor hous-

ing and shaft. Remove shift motor and shift fork

from the housing (Fig. 12).

(5) Remove the O-ring seal from the shift motor

shaft.

(6) Clean and inspect all components. If any com-

ponent is excessively worn or damaged, it should be

replaced.

ASSEMBLY/INSTALLATION

(1) Install a new O-ring seal on the shift motor

shaft.

(2) Insert the shift motor shaft through the hole in

the housing and shift fork. The shift fork offset

should be toward the differential.(3) Install the E-clips on the shift motor shaft and

housing.

(4) Install the shift motor housing gasket and

cover.Ensure the shift fork is correctly guided

into the shift collar groove.

(5) Install the shift motor housing shield and at-

taching bolts. Tighten the bolts to 11 Nzm (101 in.

lbs.) torque.

(6) Add 148 ml (5 ounces) of API grade GL 5 hy-

poid gear lubricant to the shift motor housing. Add

lubricant through indicator switch mounting hole.

(7) Install indicator switch, electrical connector

and vacuum harness.

INTERMEDIATE AXLE SHAFTÐREMOVAL/

DISASSEMBLY

Service to the Disconnect axle seals and bearing re-

quire the use of Tool Set 6288 (J34659) and Seal In-

staller 6228.

(1) Remove the vacuum motor housing. Refer to

Shift Motor Removal in this section.

(3) Remove the outer axle shaft. Refer to Hub

Bearing and Axle Shaft in this section.

(4) Remove shift collar and intermediate axle

shaft.

(5) Remove the inner axle shaft seal from the shift

motor housing (Fig. 13).

(6) Remove the intermediate axle shaft bearing

(Fig. 14).

ASSEMBLY/INSTALLATION

(1) Position the bearing on installation tool. Seat

the bearing in the housing bore (Fig. 15).

(2) Clean the inside perimeter of the axle shaft

tube with fine crocus cloth.

(3) Apply a light film of oil to the inside lip of the

new axle shaft seal.

(4) Install the inner axle seal (Fig. 16, 17).

The axle shaft seal primary installation tool

6228-1 will only force the seal partially into the

Fig. 11 Shift Motor Housing and Shift Collar

Fig. 12 Vacuum Shift Motor ComponentsFig. 13 Axle Shaft Inner Seal Removal

JFRONT SUSPENSION AND AXLE 2 - 29

Page 69 of 1784

(4) Install the Hub Bearing and Axle Shaft accord-

ing to the installation procedure.

(5) Reconnect the tie-rod or drag link end onto the

steering knuckle arm. Install the ABS sensor wire

and bracket to the knuckle, refer to Group 5 Ð

Brakes.

AXLE BUSHING REPLACEMENT

Refer to Axle Bushing Replacement in the Front

Suspension section.

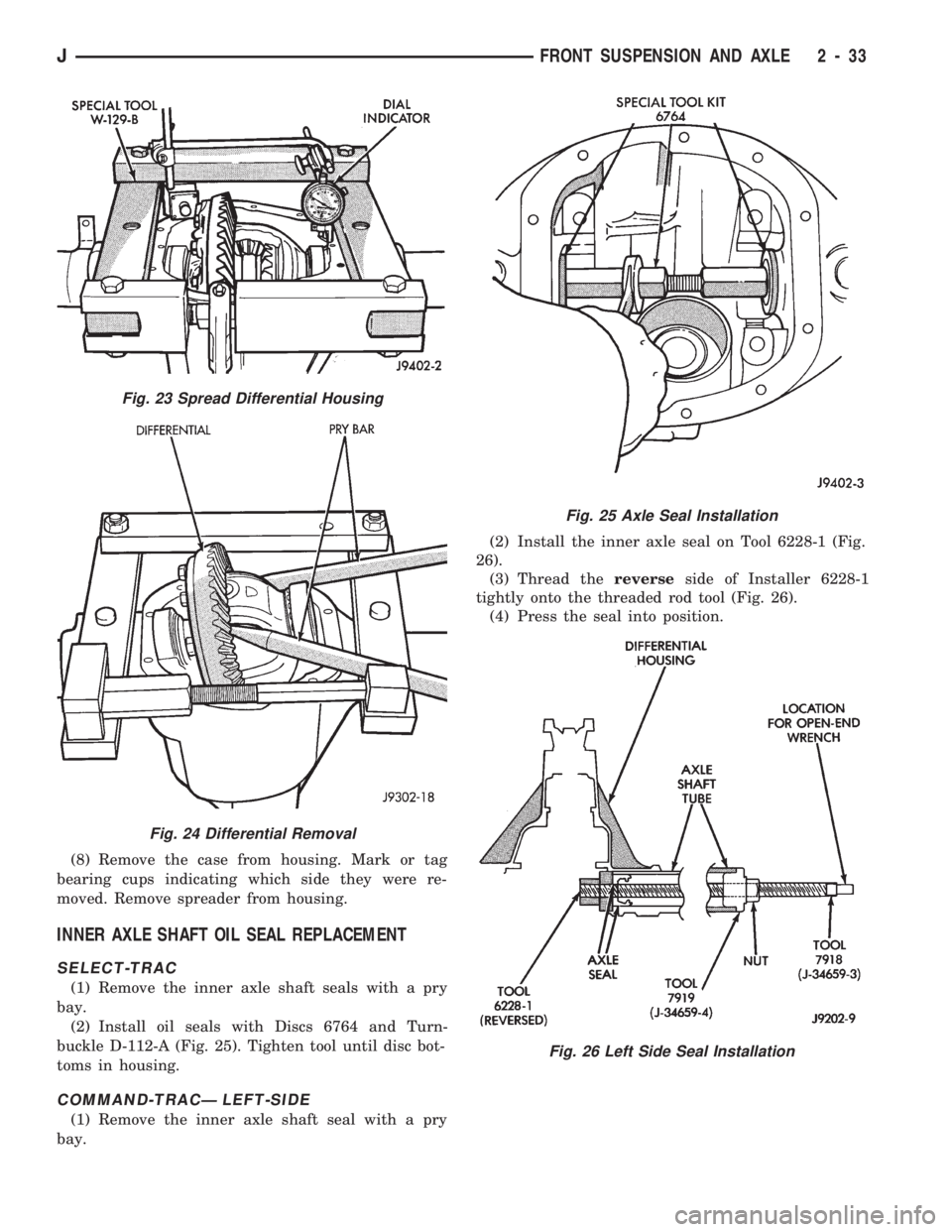

DIFFERENTIAL REMOVAL

To service the differential the axle assembly and

axle shafts must be removed. Refer to the removal

procedures in this Group.

(1) Note the installation reference letters stamped

on the bearing caps and housing machined sealing

surface (Fig. 22).

(2) Remove the differential bearing caps.

(3) Position Spreader W-129-B with the tool dowel

pins seated in the locating holes (Fig. 23). Install the

holddown clamps and tighten the tool turnbuckle fin-

ger-tight.

(4) Install a pilot stud at the left side of the differ-

ential housing. Attach Dial Indicator to housing pilot

stud. Load the indicator plunger against the opposite

side of the housing (Fig. 26) and zero the indicator.

CAUTION:Do not spread over 0.38 mm (0.015 in). Ifthe housing is over-separated, it could be distorted

or damaged.

(5) Separate the housing enough to remove the

case from the housing. Measure the distance with the

dial indicator (Fig. 23).

(6) Remove the dial indicator.

(7) Pry the differential case loose from the hous-

ing. To prevent damage, pivot on housing with the

end of the pry bar against spreader (Fig. 24).

Fig. 21 Lower Ball Stud Remove/Install

Fig. 22 Bearing Cap Identification

2 - 32 FRONT SUSPENSION AND AXLEJ

Page 70 of 1784

(8) Remove the case from housing. Mark or tag

bearing cups indicating which side they were re-

moved. Remove spreader from housing.

INNER AXLE SHAFT OIL SEAL REPLACEMENT

SELECT-TRAC

(1) Remove the inner axle shaft seals with a pry

bay.

(2) Install oil seals with Discs 6764 and Turn-

buckle D-112-A (Fig. 25). Tighten tool until disc bot-

toms in housing.

COMMAND-TRACÐ LEFT-SIDE

(1) Remove the inner axle shaft seal with a pry

bay.(2) Install the inner axle seal on Tool 6228-1 (Fig.

26).

(3) Thread thereverseside of Installer 6228-1

tightly onto the threaded rod tool (Fig. 26).

(4) Press the seal into position.

Fig. 23 Spread Differential Housing

Fig. 24 Differential Removal

Fig. 25 Axle Seal Installation

Fig. 26 Left Side Seal Installation

JFRONT SUSPENSION AND AXLE 2 - 33

Page 71 of 1784

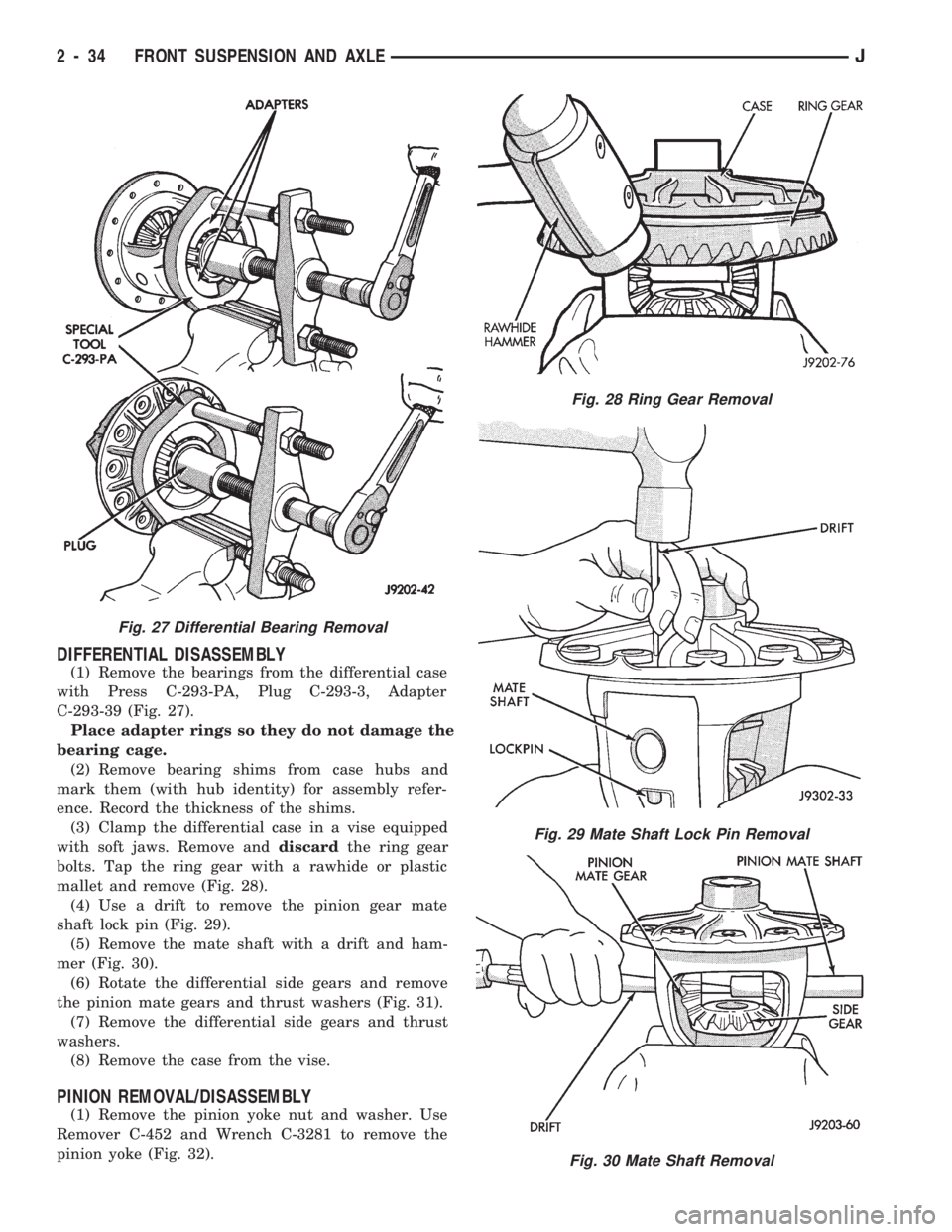

DIFFERENTIAL DISASSEMBLY

(1) Remove the bearings from the differential case

with Press C-293-PA, Plug C-293-3, Adapter

C-293-39 (Fig. 27).

Place adapter rings so they do not damage the

bearing cage.

(2) Remove bearing shims from case hubs and

mark them (with hub identity) for assembly refer-

ence. Record the thickness of the shims.

(3) Clamp the differential case in a vise equipped

with soft jaws. Remove anddiscardthe ring gear

bolts. Tap the ring gear with a rawhide or plastic

mallet and remove (Fig. 28).

(4) Use a drift to remove the pinion gear mate

shaft lock pin (Fig. 29).

(5) Remove the mate shaft with a drift and ham-

mer (Fig. 30).

(6) Rotate the differential side gears and remove

the pinion mate gears and thrust washers (Fig. 31).

(7) Remove the differential side gears and thrust

washers.

(8) Remove the case from the vise.

PINION REMOVAL/DISASSEMBLY

(1) Remove the pinion yoke nut and washer. Use

Remover C-452 and Wrench C-3281 to remove the

pinion yoke (Fig. 32).

Fig. 27 Differential Bearing Removal

Fig. 28 Ring Gear Removal

Fig. 29 Mate Shaft Lock Pin Removal

Fig. 30 Mate Shaft Removal

2 - 34 FRONT SUSPENSION AND AXLEJ

Page 72 of 1784

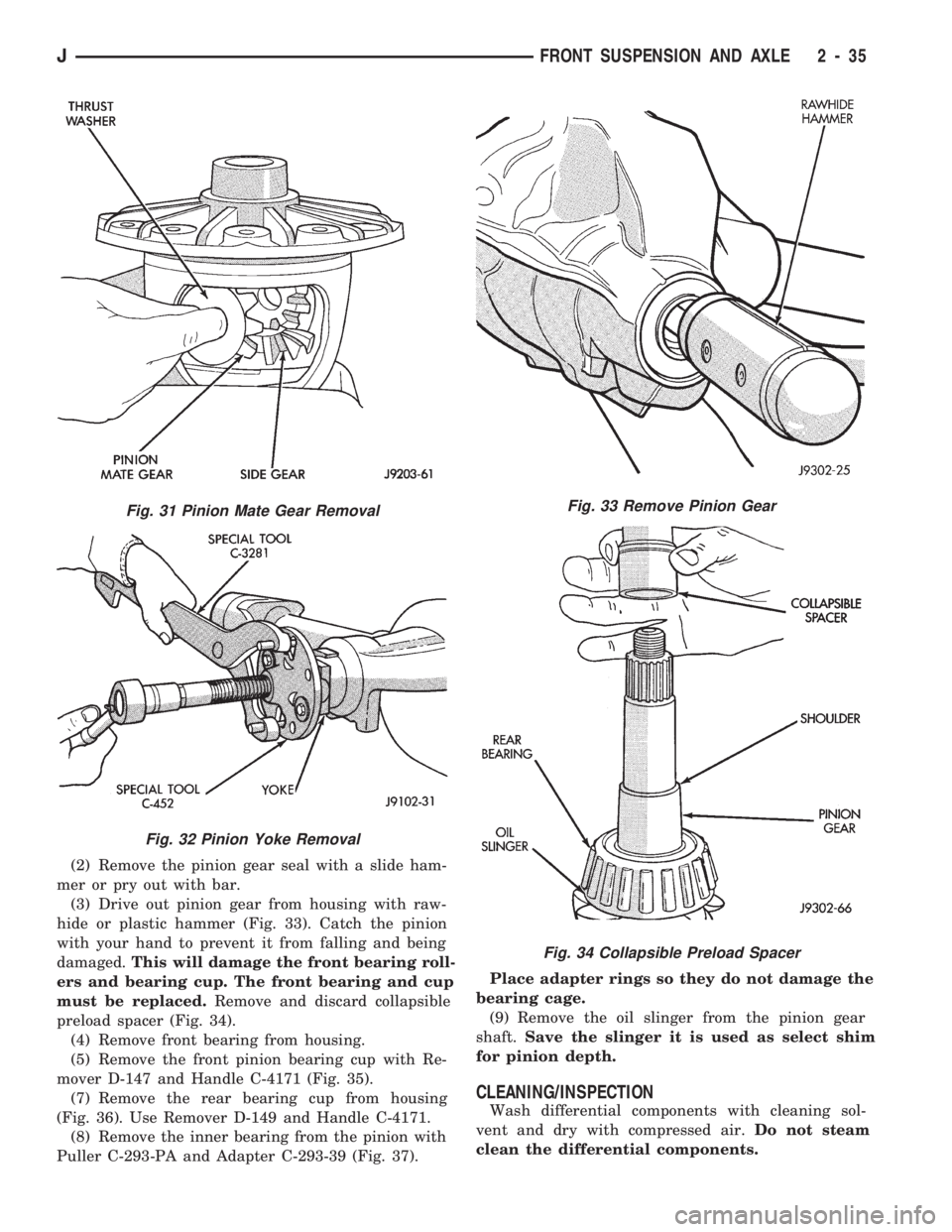

(2) Remove the pinion gear seal with a slide ham-

mer or pry out with bar.

(3) Drive out pinion gear from housing with raw-

hide or plastic hammer (Fig. 33). Catch the pinion

with your hand to prevent it from falling and being

damaged.This will damage the front bearing roll-

ers and bearing cup. The front bearing and cup

must be replaced.Remove and discard collapsible

preload spacer (Fig. 34).

(4) Remove front bearing from housing.

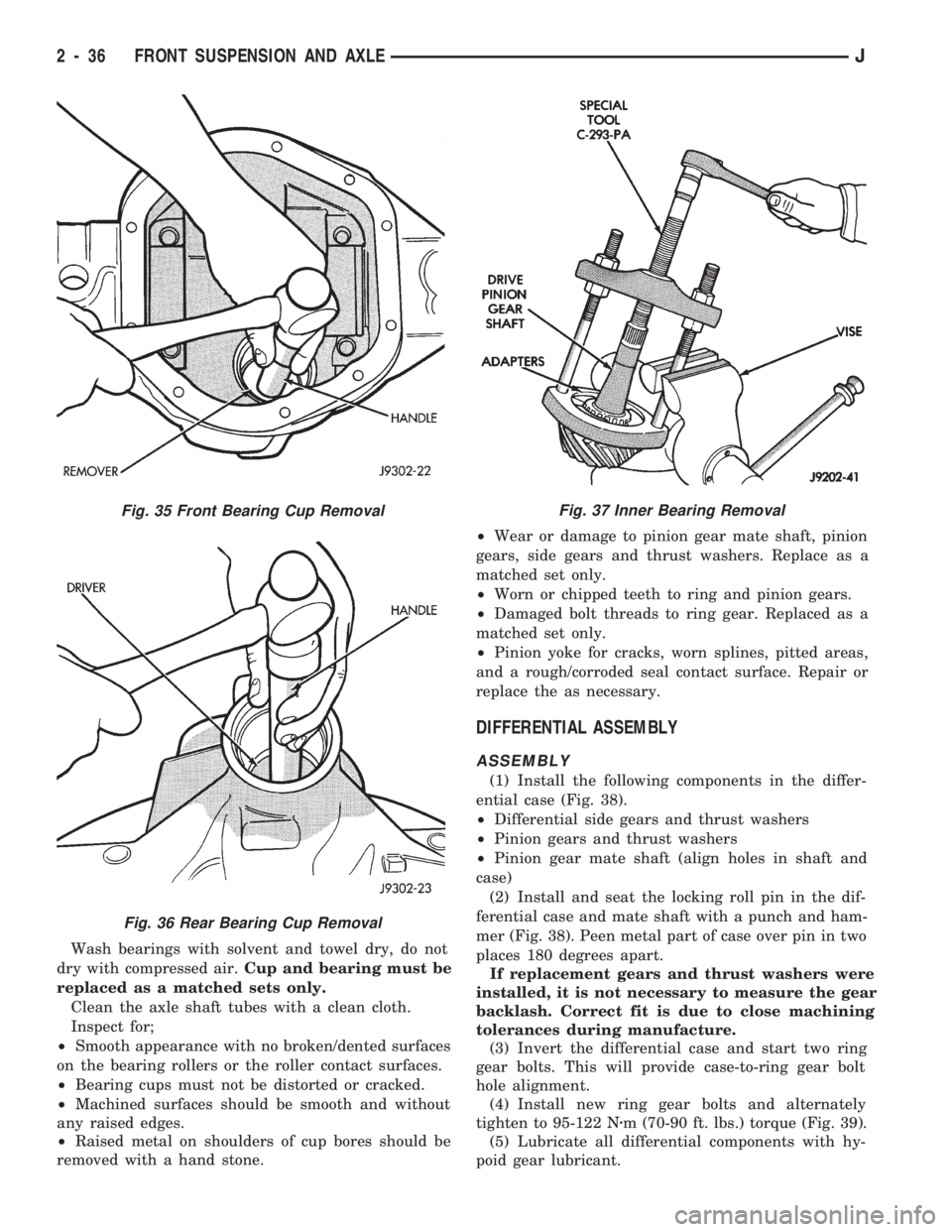

(5) Remove the front pinion bearing cup with Re-

mover D-147 and Handle C-4171 (Fig. 35).

(7) Remove the rear bearing cup from housing

(Fig. 36). Use Remover D-149 and Handle C-4171.

(8) Remove the inner bearing from the pinion with

Puller C-293-PA and Adapter C-293-39 (Fig. 37).Place adapter rings so they do not damage the

bearing cage.

(9) Remove the oil slinger from the pinion gear

shaft.Save the slinger it is used as select shim

for pinion depth.

CLEANING/INSPECTION

Wash differential components with cleaning sol-

vent and dry with compressed air.Do not steam

clean the differential components.

Fig. 31 Pinion Mate Gear Removal

Fig. 32 Pinion Yoke Removal

Fig. 33 Remove Pinion Gear

Fig. 34 Collapsible Preload Spacer

JFRONT SUSPENSION AND AXLE 2 - 35

Page 73 of 1784

Wash bearings with solvent and towel dry, do not

dry with compressed air.Cup and bearing must be

replaced as a matched sets only.

Clean the axle shaft tubes with a clean cloth.

Inspect for;

²Smooth appearance with no broken/dented surfaces

on the bearing rollers or the roller contact surfaces.

²Bearing cups must not be distorted or cracked.

²Machined surfaces should be smooth and without

any raised edges.

²Raised metal on shoulders of cup bores should be

removed with a hand stone.²Wear or damage to pinion gear mate shaft, pinion

gears, side gears and thrust washers. Replace as a

matched set only.

²Worn or chipped teeth to ring and pinion gears.

²Damaged bolt threads to ring gear. Replaced as a

matched set only.

²Pinion yoke for cracks, worn splines, pitted areas,

and a rough/corroded seal contact surface. Repair or

replace the as necessary.

DIFFERENTIAL ASSEMBLY

ASSEMBLY

(1) Install the following components in the differ-

ential case (Fig. 38).

²Differential side gears and thrust washers

²Pinion gears and thrust washers

²Pinion gear mate shaft (align holes in shaft and

case)

(2) Install and seat the locking roll pin in the dif-

ferential case and mate shaft with a punch and ham-

mer (Fig. 38). Peen metal part of case over pin in two

places 180 degrees apart.

If replacement gears and thrust washers were

installed, it is not necessary to measure the gear

backlash. Correct fit is due to close machining

tolerances during manufacture.

(3) Invert the differential case and start two ring

gear bolts. This will provide case-to-ring gear bolt

hole alignment.

(4) Install new ring gear bolts and alternately

tighten to 95-122 Nzm (70-90 ft. lbs.) torque (Fig. 39).

(5) Lubricate all differential components with hy-

poid gear lubricant.

Fig. 35 Front Bearing Cup Removal

Fig. 36 Rear Bearing Cup Removal

Fig. 37 Inner Bearing Removal

2 - 36 FRONT SUSPENSION AND AXLEJ