height JEEP CHEROKEE 1994 Service User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 1994, Model line: CHEROKEE, Model: JEEP CHEROKEE 1994Pages: 1784, PDF Size: 77.09 MB

Page 192 of 1784

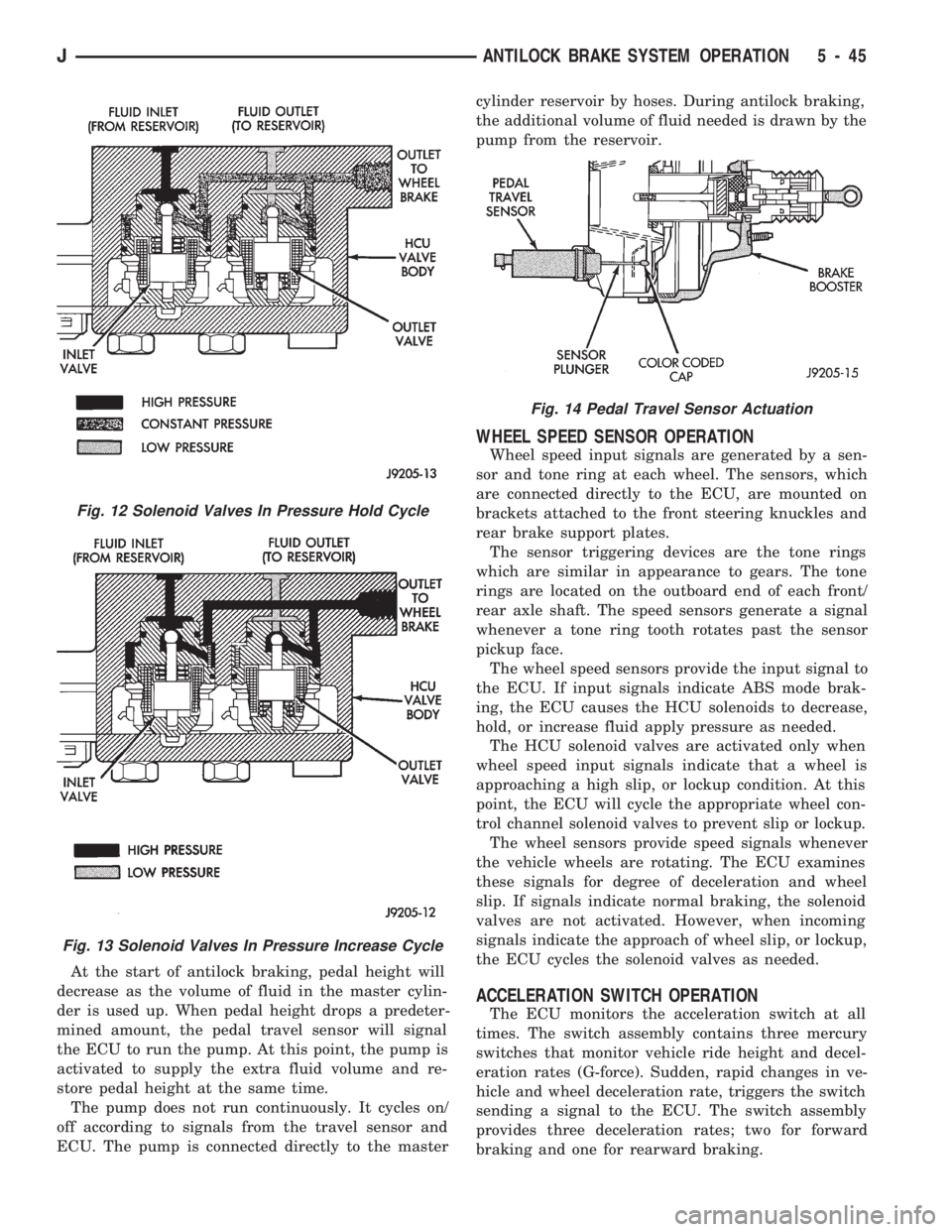

At the start of antilock braking, pedal height will

decrease as the volume of fluid in the master cylin-

der is used up. When pedal height drops a predeter-

mined amount, the pedal travel sensor will signal

the ECU to run the pump. At this point, the pump is

activated to supply the extra fluid volume and re-

store pedal height at the same time.

The pump does not run continuously. It cycles on/

off according to signals from the travel sensor and

ECU. The pump is connected directly to the mastercylinder reservoir by hoses. During antilock braking,

the additional volume of fluid needed is drawn by the

pump from the reservoir.

WHEEL SPEED SENSOR OPERATION

Wheel speed input signals are generated by a sen-

sor and tone ring at each wheel. The sensors, which

are connected directly to the ECU, are mounted on

brackets attached to the front steering knuckles and

rear brake support plates.

The sensor triggering devices are the tone rings

which are similar in appearance to gears. The tone

rings are located on the outboard end of each front/

rear axle shaft. The speed sensors generate a signal

whenever a tone ring tooth rotates past the sensor

pickup face.

The wheel speed sensors provide the input signal to

the ECU. If input signals indicate ABS mode brak-

ing, the ECU causes the HCU solenoids to decrease,

hold, or increase fluid apply pressure as needed.

The HCU solenoid valves are activated only when

wheel speed input signals indicate that a wheel is

approaching a high slip, or lockup condition. At this

point, the ECU will cycle the appropriate wheel con-

trol channel solenoid valves to prevent slip or lockup.

The wheel sensors provide speed signals whenever

the vehicle wheels are rotating. The ECU examines

these signals for degree of deceleration and wheel

slip. If signals indicate normal braking, the solenoid

valves are not activated. However, when incoming

signals indicate the approach of wheel slip, or lockup,

the ECU cycles the solenoid valves as needed.

ACCELERATION SWITCH OPERATION

The ECU monitors the acceleration switch at all

times. The switch assembly contains three mercury

switches that monitor vehicle ride height and decel-

eration rates (G-force). Sudden, rapid changes in ve-

hicle and wheel deceleration rate, triggers the switch

sending a signal to the ECU. The switch assembly

provides three deceleration rates; two for forward

braking and one for rearward braking.

Fig. 12 Solenoid Valves In Pressure Hold Cycle

Fig. 13 Solenoid Valves In Pressure Increase Cycle

Fig. 14 Pedal Travel Sensor Actuation

JANTILOCK BRAKE SYSTEM OPERATION 5 - 45

Page 468 of 1784

POWER SEATS

CONTENTS

page page

DIAGNOSIS............................. 1

GENERAL.............................. 1POWER SEAT MOTOR REPLACEMENT....... 2

SWITCH TESTING....................... 2

GENERAL

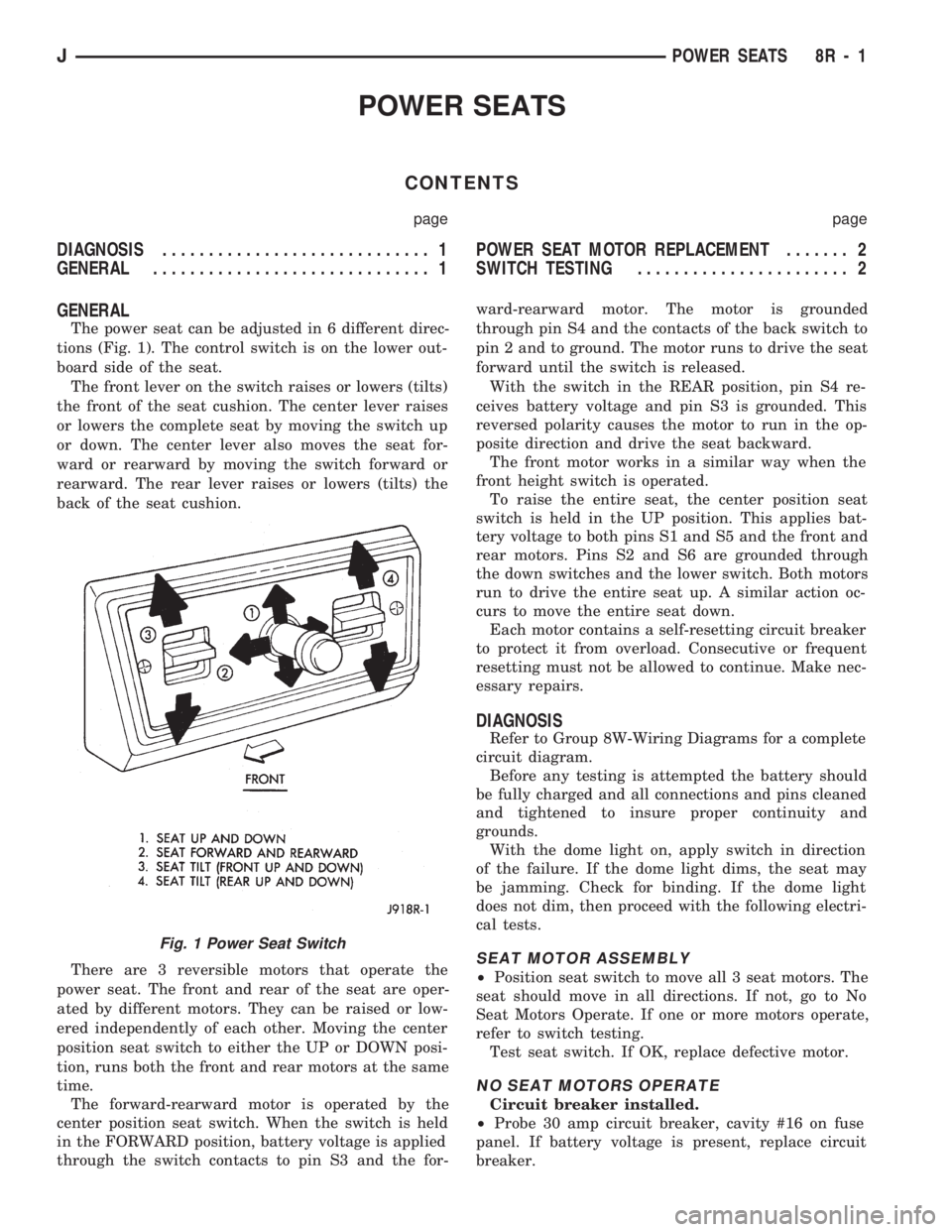

The power seat can be adjusted in 6 different direc-

tions (Fig. 1). The control switch is on the lower out-

board side of the seat.

The front lever on the switch raises or lowers (tilts)

the front of the seat cushion. The center lever raises

or lowers the complete seat by moving the switch up

or down. The center lever also moves the seat for-

ward or rearward by moving the switch forward or

rearward. The rear lever raises or lowers (tilts) the

back of the seat cushion.

There are 3 reversible motors that operate the

power seat. The front and rear of the seat are oper-

ated by different motors. They can be raised or low-

ered independently of each other. Moving the center

position seat switch to either the UP or DOWN posi-

tion, runs both the front and rear motors at the same

time.

The forward-rearward motor is operated by the

center position seat switch. When the switch is held

in the FORWARD position, battery voltage is applied

through the switch contacts to pin S3 and the for-ward-rearward motor. The motor is grounded

through pin S4 and the contacts of the back switch to

pin 2 and to ground. The motor runs to drive the seat

forward until the switch is released.

With the switch in the REAR position, pin S4 re-

ceives battery voltage and pin S3 is grounded. This

reversed polarity causes the motor to run in the op-

posite direction and drive the seat backward.

The front motor works in a similar way when the

front height switch is operated.

To raise the entire seat, the center position seat

switch is held in the UP position. This applies bat-

tery voltage to both pins S1 and S5 and the front and

rear motors. Pins S2 and S6 are grounded through

the down switches and the lower switch. Both motors

run to drive the entire seat up. A similar action oc-

curs to move the entire seat down.

Each motor contains a self-resetting circuit breaker

to protect it from overload. Consecutive or frequent

resetting must not be allowed to continue. Make nec-

essary repairs.

DIAGNOSIS

Refer to Group 8W-Wiring Diagrams for a complete

circuit diagram.

Before any testing is attempted the battery should

be fully charged and all connections and pins cleaned

and tightened to insure proper continuity and

grounds.

With the dome light on, apply switch in direction

of the failure. If the dome light dims, the seat may

be jamming. Check for binding. If the dome light

does not dim, then proceed with the following electri-

cal tests.

SEAT MOTOR ASSEMBLY

²Position seat switch to move all 3 seat motors. The

seat should move in all directions. If not, go to No

Seat Motors Operate. If one or more motors operate,

refer to switch testing.

Test seat switch. If OK, replace defective motor.

NO SEAT MOTORS OPERATE

Circuit breaker installed.

²Probe 30 amp circuit breaker, cavity #16 on fuse

panel. If battery voltage is present, replace circuit

breaker.

Fig. 1 Power Seat Switch

JPOWER SEATS 8R - 1

Page 859 of 1784

(14) Install the remaining flywheel housing bolts.

Tighten the bolts to 38 Nzm (28 ft. lbs.) torque.

(15) Install the starter motor and connect the ca-

ble. Tighten the bolts to 45 Nzm (33 ft. lbs.) torque.

(16) Install the oil filter.

(17) Lower the vehicle.

(18) Connect the coolant hoses and tighten the

clamps.

(19) If equipped with power steering:

(a) Remove the protective caps

(b) Connect the hoses to the fittings at the steer-

ing gear. Tighten the nut to 52 Nzm (38 ft. lbs.)

torque.

(c) Fill the pump reservoir with fluid.

(20) Remove the pulley-to-water pump flange

alignment capscrew and install the fan and spacer or

Tempatrol fan assembly.

(21) Tighten the serpentine drive belt according to

the specifications listed in Group 7, Cooling System.

(22) Install the fan shroud and radiator.

(23) Connect the radiator hoses.

(24) Connect the heater hoses.

(25) Connect the throttle valve rod and retainer.

(26) Connect the throttle cable and install the rod.

(27) Install the throttle valve rod spring.

(28) Connect the speed control cable, if equipped.

(29) Connect the oxygen sensor wire connector.

(30) Install the vacuum hose and check valve on

the brake booster.

(31) Connect the coolant temperature sensor wire

connector.

(32) Connect the idle speed actuator wire connec-

tor.

(33) Connect the fuel inlet and return hoses at the

fuel rail. Verify that the quick-connect fitting assem-

bly fits securely over the fuel lines by giving the fuel

lines a firm tug.

(34) Install the fuel line bracket to the intake

manifold.

(35) Connect all fuel injection wire connections.

(36) Install the engine ground strap.

(37) Connect the ignition coil wire connector.

(38) Remove the coolant temperature sending unit

to permit air to escape from the block. Fill the cool-

ing system with coolant. Install the coolant tempera-

ture sending unit when the system is filled.

(39) Install the battery and connect the battery ca-

bles.

(40) Install the air cleaner bonnet to the throttle

body.

(41) Install the air cleaner.

(42) Lower the hood and secure in place.

(43) Start the engine and inspect for leaks.

(44) Stop the engine and check the fluid levels.

Add fluid, as required.ENGINE CYLINDER HEAD COVER

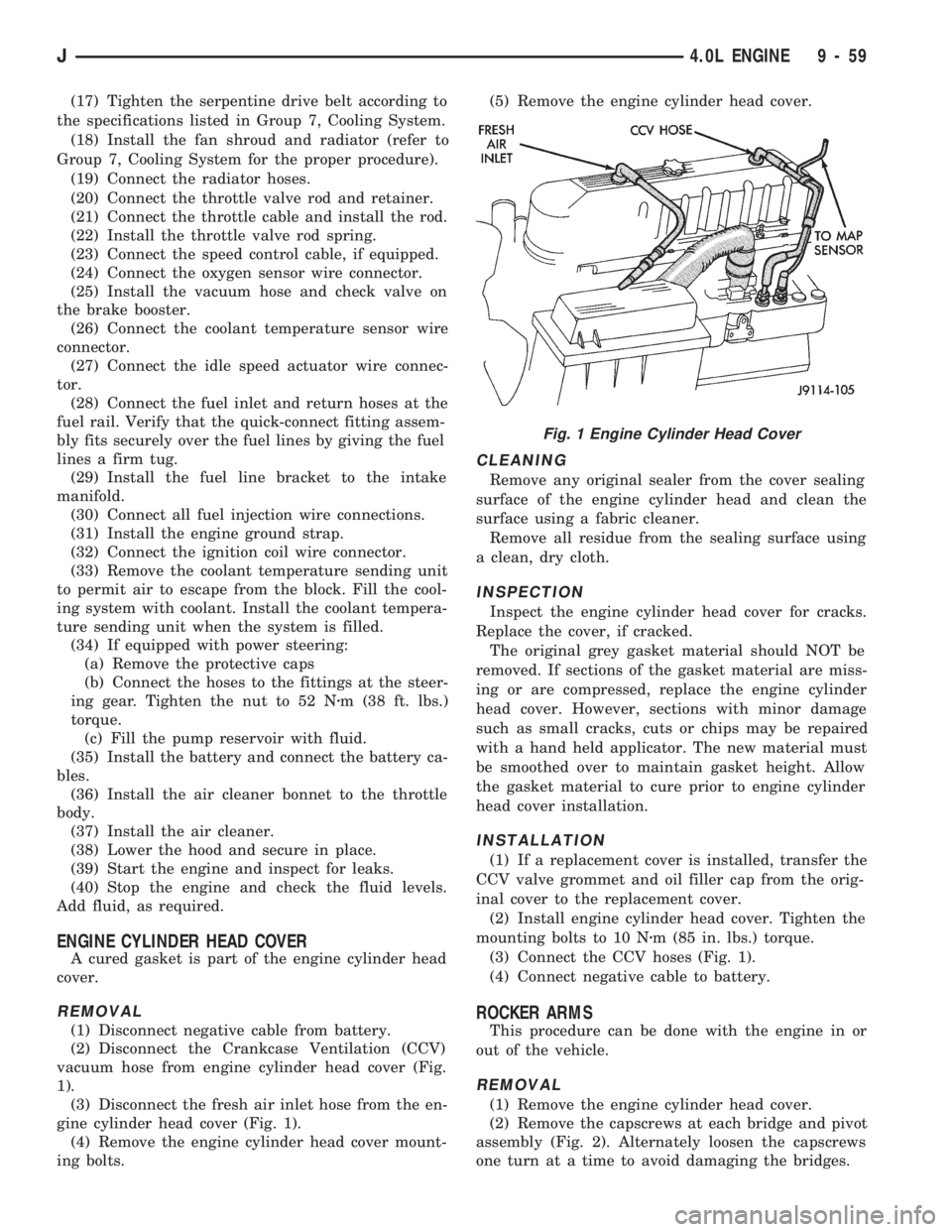

A cured gasket is part of the engine cylinder head

cover.

REMOVAL

(1) Disconnect negative cable from battery.

(2) Disconnect the Crankcase Ventilation (CCV)

vacuum hose from engine cylinder head cover (Fig.

1).

(3) Disconnect the fresh air inlet hose from the en-

gine cylinder head cover (Fig. 1).

(4) Remove the engine cylinder head cover mount-

ing bolts.

(5) Remove the engine cylinder head cover.

CLEANING

Remove any original sealer from the cover sealing

surface of the engine cylinder head and clean the

surface using a fabric cleaner.

Remove all residue from the sealing surface using

a clean, dry cloth.

INSPECTION

Inspect the engine cylinder head cover for cracks.

Replace the cover, if cracked.

The original grey gasket material should NOT be

removed. If sections of the gasket material are miss-

ing or are compressed, replace the engine cylinder

head cover. However, sections with minor damage

such as small cracks, cuts or chips may be repaired

with a hand held applicator. The new material must

be smoothed over to maintain gasket height. Allow

the gasket material to cure prior to engine cylinder

head cover installation.

INSTALLATION

(1) If a replacement cover is installed, transfer the

CCV valve grommet the oil filler cap from the origi-

nal cover to the replacement cover.

(2) Install engine cylinder head cover. Tighten the

mounting bolts to 10 Nzm (85 in. lbs.) torque.

Fig. 1 Engine Cylinder Head Cover

9 - 18 2.5L ENGINEJ

Page 900 of 1784

(17) Tighten the serpentine drive belt according to

the specifications listed in Group 7, Cooling System.

(18) Install the fan shroud and radiator (refer to

Group 7, Cooling System for the proper procedure).

(19) Connect the radiator hoses.

(20) Connect the throttle valve rod and retainer.

(21) Connect the throttle cable and install the rod.

(22) Install the throttle valve rod spring.

(23) Connect the speed control cable, if equipped.

(24) Connect the oxygen sensor wire connector.

(25) Install the vacuum hose and check valve on

the brake booster.

(26) Connect the coolant temperature sensor wire

connector.

(27) Connect the idle speed actuator wire connec-

tor.

(28) Connect the fuel inlet and return hoses at the

fuel rail. Verify that the quick-connect fitting assem-

bly fits securely over the fuel lines by giving the fuel

lines a firm tug.

(29) Install the fuel line bracket to the intake

manifold.

(30) Connect all fuel injection wire connections.

(31) Install the engine ground strap.

(32) Connect the ignition coil wire connector.

(33) Remove the coolant temperature sending unit

to permit air to escape from the block. Fill the cool-

ing system with coolant. Install the coolant tempera-

ture sending unit when the system is filled.

(34) If equipped with power steering:

(a) Remove the protective caps

(b) Connect the hoses to the fittings at the steer-

ing gear. Tighten the nut to 52 Nzm (38 ft. lbs.)

torque.

(c) Fill the pump reservoir with fluid.

(35) Install the battery and connect the battery ca-

bles.

(36) Install the air cleaner bonnet to the throttle

body.

(37) Install the air cleaner.

(38) Lower the hood and secure in place.

(39) Start the engine and inspect for leaks.

(40) Stop the engine and check the fluid levels.

Add fluid, as required.

ENGINE CYLINDER HEAD COVER

A cured gasket is part of the engine cylinder head

cover.

REMOVAL

(1) Disconnect negative cable from battery.

(2) Disconnect the Crankcase Ventilation (CCV)

vacuum hose from engine cylinder head cover (Fig.

1).

(3) Disconnect the fresh air inlet hose from the en-

gine cylinder head cover (Fig. 1).

(4) Remove the engine cylinder head cover mount-

ing bolts.(5) Remove the engine cylinder head cover.

CLEANING

Remove any original sealer from the cover sealing

surface of the engine cylinder head and clean the

surface using a fabric cleaner.

Remove all residue from the sealing surface using

a clean, dry cloth.

INSPECTION

Inspect the engine cylinder head cover for cracks.

Replace the cover, if cracked.

The original grey gasket material should NOT be

removed. If sections of the gasket material are miss-

ing or are compressed, replace the engine cylinder

head cover. However, sections with minor damage

such as small cracks, cuts or chips may be repaired

with a hand held applicator. The new material must

be smoothed over to maintain gasket height. Allow

the gasket material to cure prior to engine cylinder

head cover installation.

INSTALLATION

(1) If a replacement cover is installed, transfer the

CCV valve grommet and oil filler cap from the orig-

inal cover to the replacement cover.

(2) Install engine cylinder head cover. Tighten the

mounting bolts to 10 Nzm (85 in. lbs.) torque.

(3) Connect the CCV hoses (Fig. 1).

(4) Connect negative cable to battery.

ROCKER ARMS

This procedure can be done with the engine in or

out of the vehicle.

REMOVAL

(1) Remove the engine cylinder head cover.

(2) Remove the capscrews at each bridge and pivot

assembly (Fig. 2). Alternately loosen the capscrews

one turn at a time to avoid damaging the bridges.

Fig. 1 Engine Cylinder Head Cover

J4.0L ENGINE 9 - 59

Page 1020 of 1784

INSTALLATION

(1) After the PCM electrical connector has been

separated from the PCM, inspect the pins for corro-

sion, being spread apart, bent or misaligned. Also in-

spect the pin heights in the connector. If the pin

heights are different, this would indicate a pin has

separated from the connector. Repair as necessary.

(2) Install PCM. Tighten three mounting bolts to 1

Nzm (9 in. lbs.) torque.

(3) Engage 60-way connector into PCM. Tighten

connector mounting bolt to 4 Nzm (35 in. lbs.) torque.

(4) YJ Models: Install windshield washer fluid

tank.

(5) Connect negative cable to battery.

QUICK-CONNECT FITTINGS

Refer to the Fuel Delivery System section of this

group for removal/installation procedures.

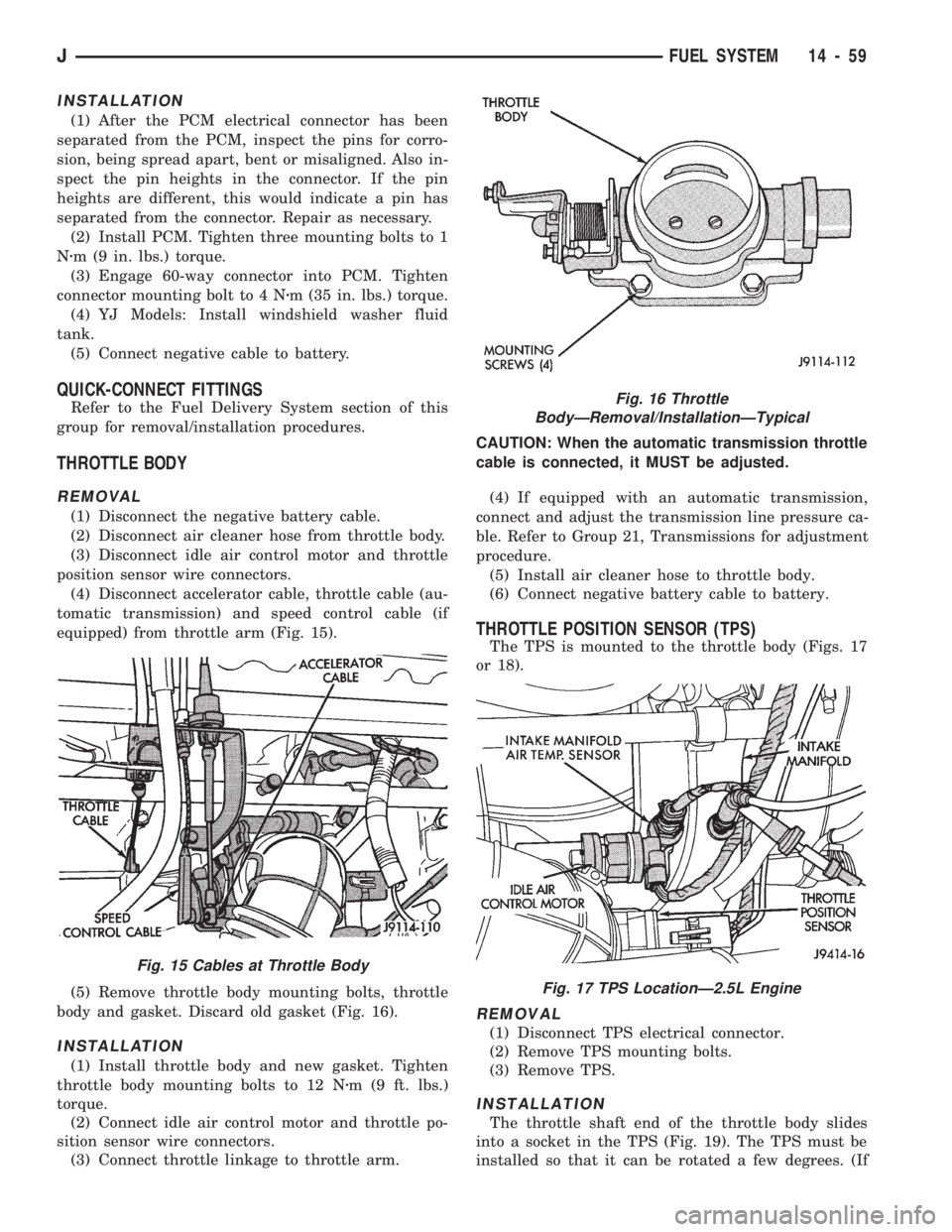

THROTTLE BODY

REMOVAL

(1) Disconnect the negative battery cable.

(2) Disconnect air cleaner hose from throttle body.

(3) Disconnect idle air control motor and throttle

position sensor wire connectors.

(4) Disconnect accelerator cable, throttle cable (au-

tomatic transmission) and speed control cable (if

equipped) from throttle arm (Fig. 15).

(5) Remove throttle body mounting bolts, throttle

body and gasket. Discard old gasket (Fig. 16).

INSTALLATION

(1) Install throttle body and new gasket. Tighten

throttle body mounting bolts to 12 Nzm (9 ft. lbs.)

torque.

(2) Connect idle air control motor and throttle po-

sition sensor wire connectors.

(3) Connect throttle linkage to throttle arm.CAUTION: When the automatic transmission throttle

cable is connected, it MUST be adjusted.

(4) If equipped with an automatic transmission,

connect and adjust the transmission line pressure ca-

ble. Refer to Group 21, Transmissions for adjustment

procedure.

(5) Install air cleaner hose to throttle body.

(6) Connect negative battery cable to battery.

THROTTLE POSITION SENSOR (TPS)

The TPS is mounted to the throttle body (Figs. 17

or 18).

REMOVAL

(1) Disconnect TPS electrical connector.

(2) Remove TPS mounting bolts.

(3) Remove TPS.

INSTALLATION

The throttle shaft end of the throttle body slides

into a socket in the TPS (Fig. 19). The TPS must be

installed so that it can be rotated a few degrees. (If

Fig. 16 Throttle

BodyÐRemoval/InstallationÐTypical

Fig. 17 TPS LocationÐ2.5L Engine

Fig. 15 Cables at Throttle Body

JFUEL SYSTEM 14 - 59

Page 1333 of 1784

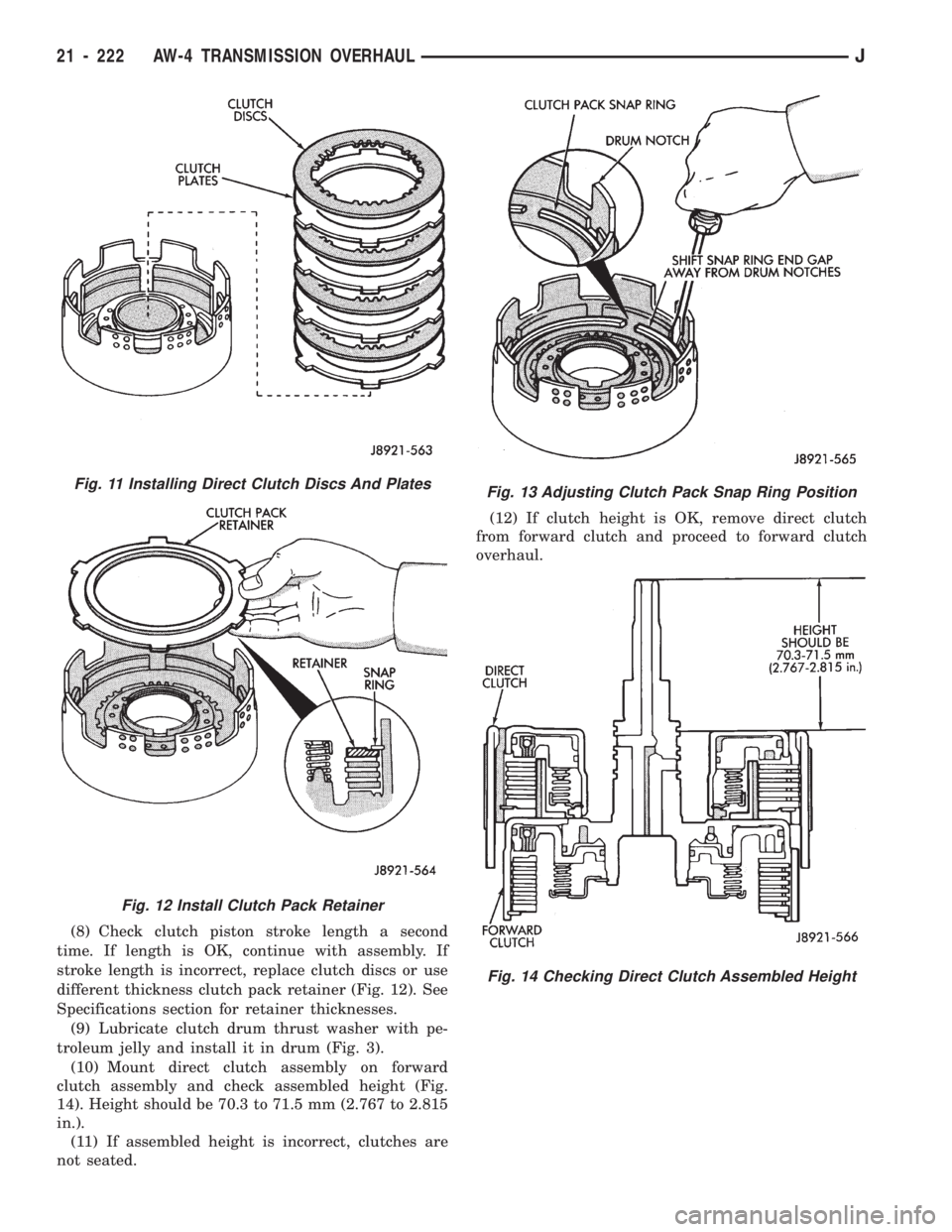

(8) Check clutch piston stroke length a second

time. If length is OK, continue with assembly. If

stroke length is incorrect, replace clutch discs or use

different thickness clutch pack retainer (Fig. 12). See

Specifications section for retainer thicknesses.

(9) Lubricate clutch drum thrust washer with pe-

troleum jelly and install it in drum (Fig. 3).

(10) Mount direct clutch assembly on forward

clutch assembly and check assembled height (Fig.

14). Height should be 70.3 to 71.5 mm (2.767 to 2.815

in.).

(11) If assembled height is incorrect, clutches are

not seated.(12) If clutch height is OK, remove direct clutch

from forward clutch and proceed to forward clutch

overhaul.

Fig. 11 Installing Direct Clutch Discs And Plates

Fig. 12 Install Clutch Pack Retainer

Fig. 13 Adjusting Clutch Pack Snap Ring Position

Fig. 14 Checking Direct Clutch Assembled Height

21 - 222 AW-4 TRANSMISSION OVERHAULJ

Page 1338 of 1784

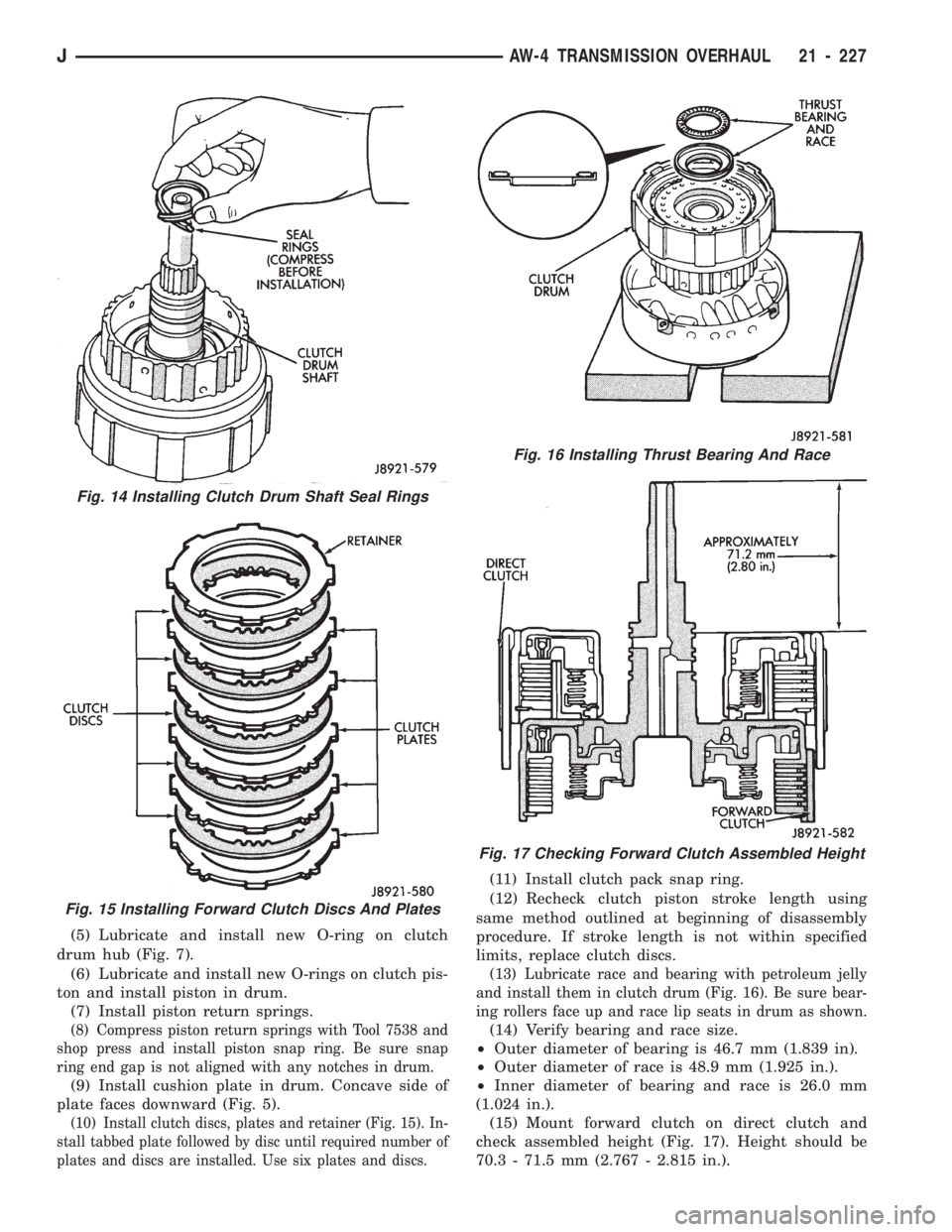

(5) Lubricate and install new O-ring on clutch

drum hub (Fig. 7).

(6) Lubricate and install new O-rings on clutch pis-

ton and install piston in drum.

(7) Install piston return springs.

(8) Compress piston return springs with Tool 7538 and

shop press and install piston snap ring. Be sure snap

ring end gap is not aligned with any notches in drum.

(9) Install cushion plate in drum. Concave side of

plate faces downward (Fig. 5).

(10) Install clutch discs, plates and retainer (Fig. 15). In-

stall tabbed plate followed by disc until required number of

plates and discs are installed. Use six plates and discs.

(11) Install clutch pack snap ring.

(12) Recheck clutch piston stroke length using

same method outlined at beginning of disassembly

procedure. If stroke length is not within specified

limits, replace clutch discs.

(13) Lubricate race and bearing with petroleum jelly

and install them in clutch drum (Fig. 16). Be sure bear-

ing rollers face up and race lip seats in drum as shown.

(14) Verify bearing and race size.

²Outer diameter of bearing is 46.7 mm (1.839 in).

²Outer diameter of race is 48.9 mm (1.925 in.).

²Inner diameter of bearing and race is 26.0 mm

(1.024 in.).

(15) Mount forward clutch on direct clutch and

check assembled height (Fig. 17). Height should be

70.3 - 71.5 mm (2.767 - 2.815 in.).

Fig. 15 Installing Forward Clutch Discs And Plates

Fig. 16 Installing Thrust Bearing And Race

Fig. 17 Checking Forward Clutch Assembled Height

Fig. 14 Installing Clutch Drum Shaft Seal Rings

JAW-4 TRANSMISSION OVERHAUL 21 - 227

Page 1464 of 1784

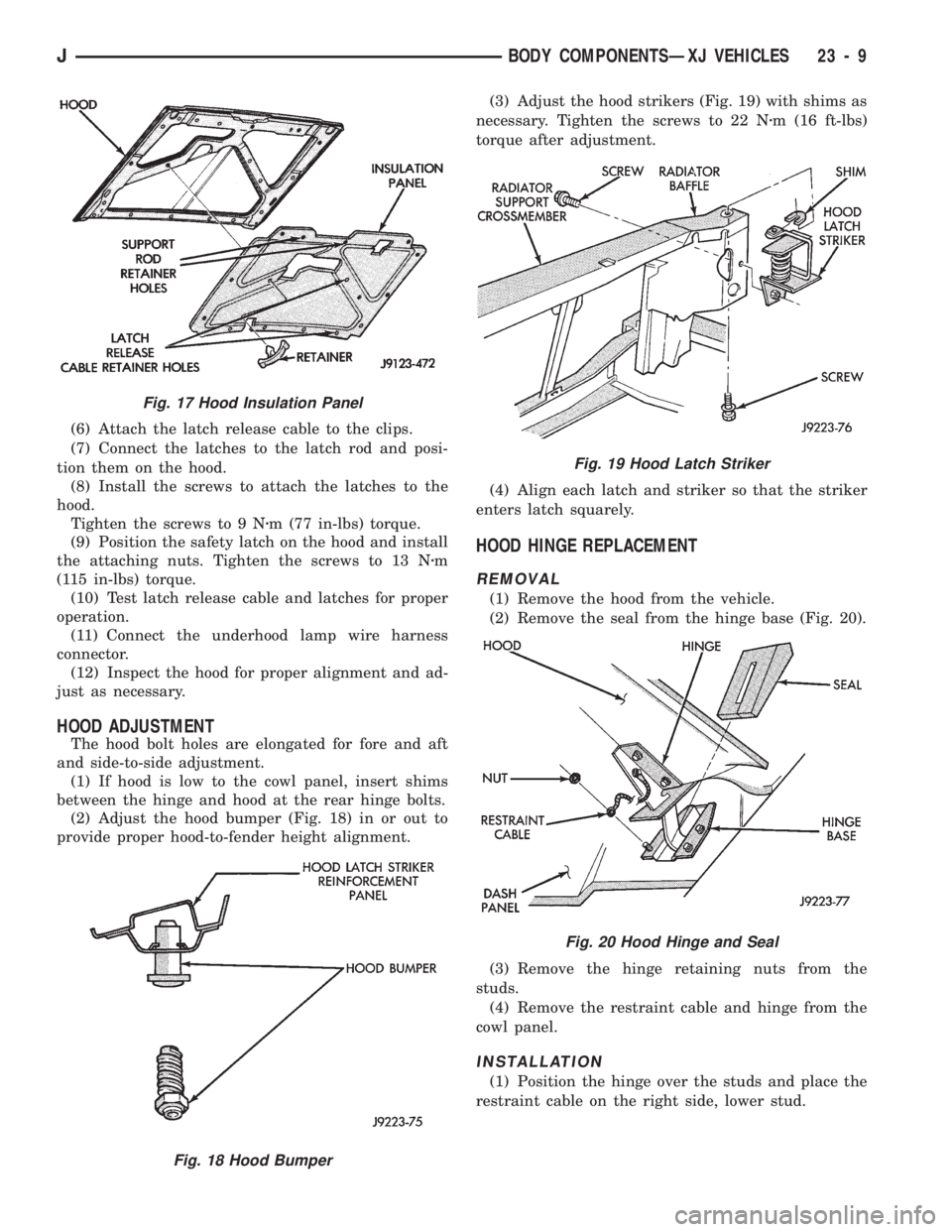

(6) Attach the latch release cable to the clips.

(7) Connect the latches to the latch rod and posi-

tion them on the hood.

(8) Install the screws to attach the latches to the

hood.

Tighten the screws to 9 Nzm (77 in-lbs) torque.

(9) Position the safety latch on the hood and install

the attaching nuts. Tighten the screws to 13 Nzm

(115 in-lbs) torque.

(10) Test latch release cable and latches for proper

operation.

(11) Connect the underhood lamp wire harness

connector.

(12) Inspect the hood for proper alignment and ad-

just as necessary.

HOOD ADJUSTMENT

The hood bolt holes are elongated for fore and aft

and side-to-side adjustment.

(1) If hood is low to the cowl panel, insert shims

between the hinge and hood at the rear hinge bolts.

(2) Adjust the hood bumper (Fig. 18) in or out to

provide proper hood-to-fender height alignment.(3) Adjust the hood strikers (Fig. 19) with shims as

necessary. Tighten the screws to 22 Nzm (16 ft-lbs)

torque after adjustment.

(4) Align each latch and striker so that the striker

enters latch squarely.

HOOD HINGE REPLACEMENT

REMOVAL

(1) Remove the hood from the vehicle.

(2) Remove the seal from the hinge base (Fig. 20).

(3) Remove the hinge retaining nuts from the

studs.

(4) Remove the restraint cable and hinge from the

cowl panel.

INSTALLATION

(1) Position the hinge over the studs and place the

restraint cable on the right side, lower stud.

Fig. 17 Hood Insulation Panel

Fig. 18 Hood Bumper

Fig. 19 Hood Latch Striker

Fig. 20 Hood Hinge and Seal

JBODY COMPONENTSÐXJ VEHICLES 23 - 9

Page 1603 of 1784

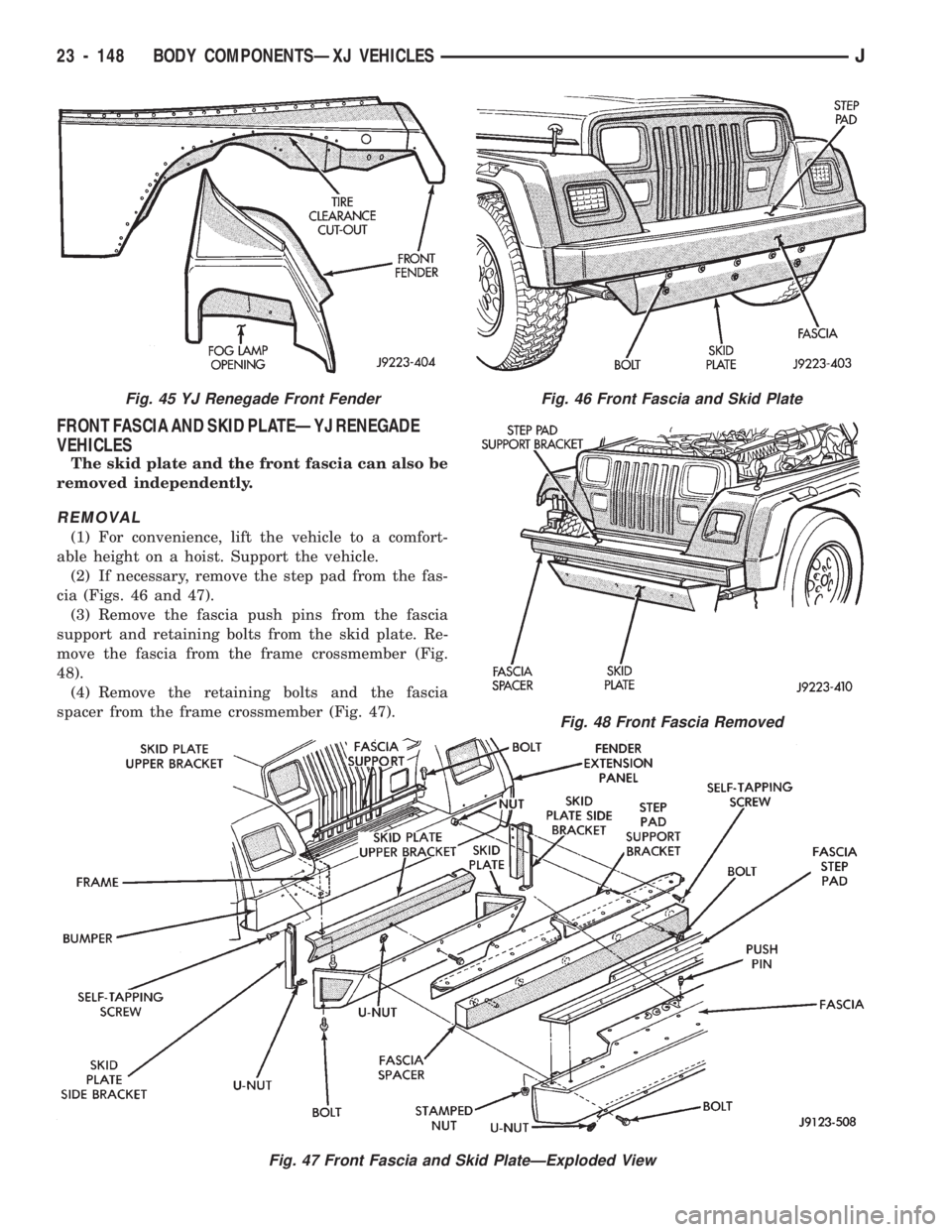

FRONT FASCIA AND SKID PLATEÐYJ RENEGADE

VEHICLES

The skid plate and the front fascia can also be

removed independently.

REMOVAL

(1) For convenience, lift the vehicle to a comfort-

able height on a hoist. Support the vehicle.

(2) If necessary, remove the step pad from the fas-

cia (Figs. 46 and 47).

(3) Remove the fascia push pins from the fascia

support and retaining bolts from the skid plate. Re-

move the fascia from the frame crossmember (Fig.

48).

(4) Remove the retaining bolts and the fascia

spacer from the frame crossmember (Fig. 47).

Fig. 46 Front Fascia and Skid Plate

Fig. 47 Front Fascia and Skid PlateÐExploded View

Fig. 48 Front Fascia Removed

Fig. 45 YJ Renegade Front Fender

23 - 148 BODY COMPONENTSÐXJ VEHICLESJ

Page 1604 of 1784

(5) Remove the retaining screws and the fascia

step pad support bracket from the frame crossmem-

ber (Fig. 47).

(6) Remove the retaining bolts from the skid plate.

Remove the skid plate from the brackets.

(7) Remove the retaining screws from the skid

plate brackets. Remove the brackets from the frame

rails.

(8) Remove the retaining bolts and the fascia sup-

port from the cover plate.

INSTALLATION

(1) Position the fascia support on the cover plate

and install the retaining bolts (Fig. 47). Tighten the

bolts to 5 Nzm (44 in-lbs) torque.

(2) Position the skid plate brackets at the frame

rails and install the retaining screws. Tighten the

screws to 25 Nzm (18 ft-lbs) torque.

(3) Position the skid plate at the brackets and in-

stall the retaining bolts. Tighten the bolts to 25 Nzm

(18 ft-lbs) torque.

(4) Position the fascia step pad support bracket at

the frame crossmember and install the retaining

screws. Tighten the screws to 25 Nzm (18 ft-lbs)

torque.

(5) Position the fascia spacer at the frame cross-

member and install the retaining bolts. Tighten the

nuts to 6 Nzm (53 in-lbs) torque.

(6) Position the fascia at the frame crossmember

and install the retaining bolts and push pins.

Tighten the bolts to 10 Nzm (7 ft-lbs) torque.

(7) Install the step pad on the fascia.

(8) If applicable, remove the support and lower the

vehicle.

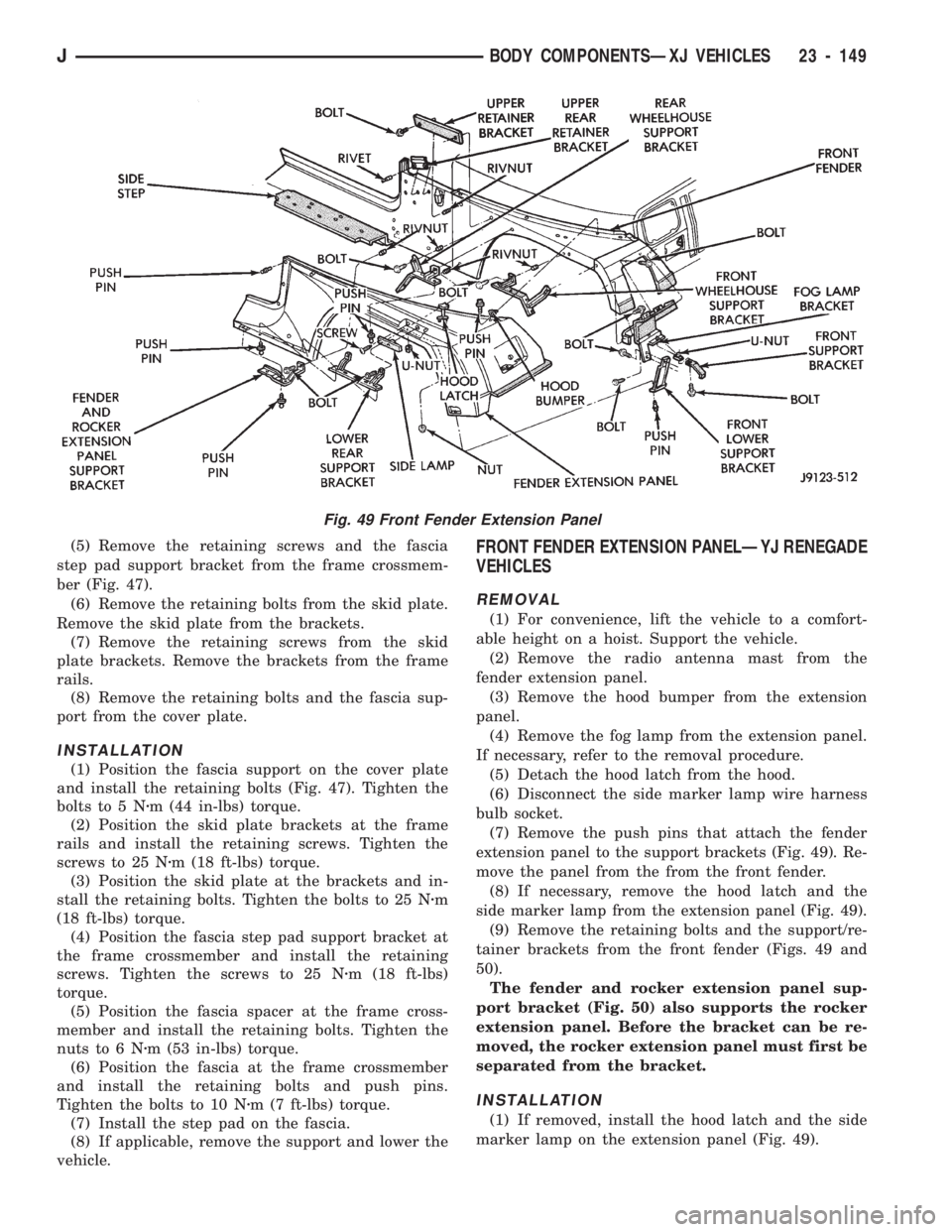

FRONT FENDER EXTENSION PANELÐYJ RENEGADE

VEHICLES

REMOVAL

(1) For convenience, lift the vehicle to a comfort-

able height on a hoist. Support the vehicle.

(2) Remove the radio antenna mast from the

fender extension panel.

(3) Remove the hood bumper from the extension

panel.

(4) Remove the fog lamp from the extension panel.

If necessary, refer to the removal procedure.

(5) Detach the hood latch from the hood.

(6) Disconnect the side marker lamp wire harness

bulb socket.

(7) Remove the push pins that attach the fender

extension panel to the support brackets (Fig. 49). Re-

move the panel from the from the front fender.

(8) If necessary, remove the hood latch and the

side marker lamp from the extension panel (Fig. 49).

(9) Remove the retaining bolts and the support/re-

tainer brackets from the front fender (Figs. 49 and

50).

The fender and rocker extension panel sup-

port bracket (Fig. 50) also supports the rocker

extension panel. Before the bracket can be re-

moved, the rocker extension panel must first be

separated from the bracket.

INSTALLATION

(1) If removed, install the hood latch and the side

marker lamp on the extension panel (Fig. 49).

Fig. 49 Front Fender Extension Panel

JBODY COMPONENTSÐXJ VEHICLES 23 - 149