lights JEEP CHEROKEE 1994 Service User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 1994, Model line: CHEROKEE, Model: JEEP CHEROKEE 1994Pages: 1784, PDF Size: 77.09 MB

Page 349 of 1784

other side. When coolant temperature is too high the

switch closes providing a path to ground, and the indi-

cator bulb lights.

TACHOMETER

The tachometer displays the engine speed (RPM).

With the engine running, the tachometer receives an

engine speed signal from the Powertrain Control

Module pin 43 (values shown in Specifications chart).

SPEEDOMETER/ODOMETER SYSTEM

The speedometer/odometer system consists of an elec-

tric speedometer and pushbutton reset odometer

mounted in the cluster. The system also includes the

wire harness from the cluster to the vehicle speed sen-

sor at the transmission, and the adapter and pinion in

the transmission. A signal is sent from a transmission

mounted vehicle speed sensor to the speedometer/odom-

eter circuitry through the wiring harness. Refer to

Group 21 - Transmission for selecting the proper pinion,

and selecting and indexing the proper adapter.

FUEL GAUGE

The fuel gauge pointer position is controlled by a

magnetic field created by electrical current flow through

the coils within the gauge. A change in current flow will

change the magnetic field which changes the pointer po-

sition. The fuel level sender is a variable resistor that

changes electrical resistance with a change of the level

of fuel in the tank (values shown in Specifications

chart).

LOW FUEL WARNING LAMP

The low fuel warning lamp will light when the fuel

level falls below approximately 4 gallons. A low fuel

warning module controls when the lamp will light.

When the module senses 66.5 ohms or less from the

fuel level sender for 10 continuous seconds, the lamp

will light. The lamp will remain on until the module

senses 63.5 ohms or more from the fuel level sender

for 20 continuous seconds.

UPSHIFT INDICATOR LAMP

Vehicles equipped with manual transmissions have an

optional upshift indicator lamp. The lamp is controlled

by the Powertrain Control Module. The lamp lights to

indicate when the driver should shift to the next high-

est gear for best fuel economy. The Powertrain Control

Module will turn the lamp off after 3 to 5 seconds if the

upshift is not performed. The lamp will remain off until

the vehicle stops accelerating and is brought back to the

range of lamp operation or shifted into another gear.

The indicator lamp is normally illuminated when

the ignition switch is turned ON and is turned off

when the engine is started. The lamp will be lighted

during engine operation according to engine speed

and load.

BRAKE INDICATOR LAMP

The brake indicator lamp warns the driver that the

parking brake is applied or that hydraulic pressure in

the split brake system is unequal.

Voltage is supplied through the brake indicator

bulb to 3 switches. A path to ground for the current

is available if:

²The brake warning switch is closed (with unequal

brake system hydraulic pressures), or

²

The ignition switch is in the START position (to test

the bulb), or

²The park brake switch is closed (with the parking

brake applied).

ANTI-LOCK BRAKE SYSTEM (ABS) INDICATOR

LAMP

The anti-lock brake system (ABS) lamp lights to in-

dicate a system self-check is in process at vehicle

start-up. If light remains on after start-up or comes

on and stays on while driving, it may indicate that

the ABS system has detected a malfunction or has

become inoperative.

4WD INDICATOR LAMP

COMMAND-TRAC 4WD

The PART TIME lamp lights when the vehicle is en-

gaged in four-wheel drive mode. Voltage is supplied to

one side of the indicator bulb. A switch in the transfer

case area is connected to the other side of the indicator

bulb. When the switch is closed, a path to ground is pro-

vided and the indicator bulb lights.

SELECT-TRAC 4WD

The four-wheel drive icon or FULL TIME lamp

lights when the vehicle is engaged in full time four-

wheel drive mode. The PART TIME lamp lights when

the vehicle is in part time four-wheel drive mode.

Voltage is supplied to one side of the indicators.

Switches in the transfer case area are connected to

the other side of the indicator bulbs. When a switch

is closed, a path to ground is provided and the indi-

cator bulb lights.

MALFUNCTION INDICATOR LAMP (CHECK ENGINE)

The Malfunction Indicator Lamp (Check Engine)

lights each time the ignition switch is turned ON and

stays on for 3 seconds as a bulb test.

If the PCM receives an incorrect signal or no signal

from certain sensors or emission related systems the

lamp is turned on (pin 32 of PCM). This is a warning

that the PCM has recorded a system or sensor mal-

function. In some cases when a diagnostic trouble

code is declared the PCM will go into a limp-in mode

in an attempt to keep the system operating. It sig-

nals an immediate need for service.

The lamp also can be used to display diagnostic

trouble codes (DTC). Cycle the ignition switch ON,

OFF, ON, OFF, ON within 5 seconds. This will allow

any trouble codes stored in the PCM memory to be

displayed in a series of flashes representing digits.

8E - 2 XJ INSTRUMENT PANEL AND GAUGESJ

Page 353 of 1784

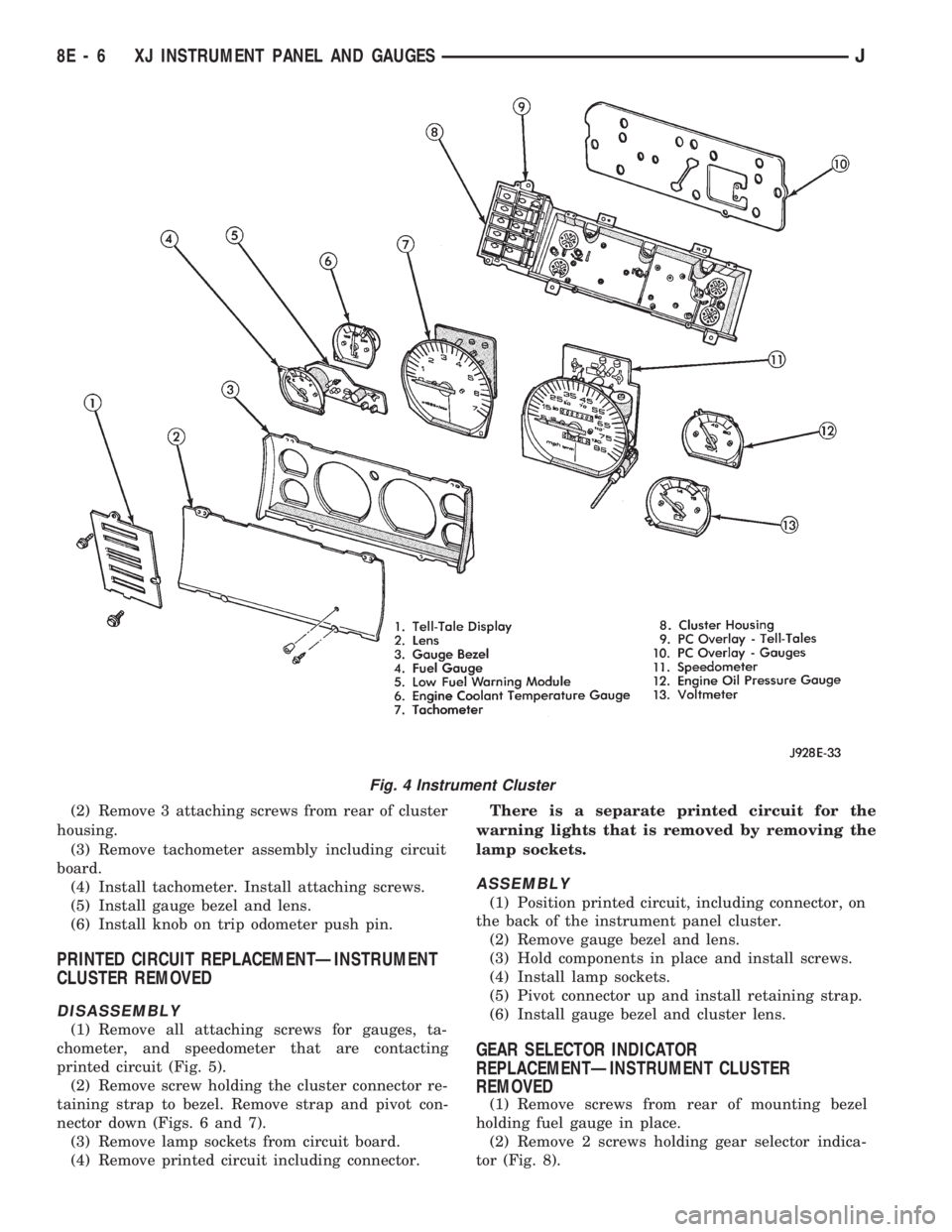

(2) Remove 3 attaching screws from rear of cluster

housing.

(3) Remove tachometer assembly including circuit

board.

(4) Install tachometer. Install attaching screws.

(5) Install gauge bezel and lens.

(6) Install knob on trip odometer push pin.

PRINTED CIRCUIT REPLACEMENTÐINSTRUMENT

CLUSTER REMOVED

DISASSEMBLY

(1) Remove all attaching screws for gauges, ta-

chometer, and speedometer that are contacting

printed circuit (Fig. 5).

(2) Remove screw holding the cluster connector re-

taining strap to bezel. Remove strap and pivot con-

nector down (Figs. 6 and 7).

(3) Remove lamp sockets from circuit board.

(4) Remove printed circuit including connector.There is a separate printed circuit for the

warning lights that is removed by removing the

lamp sockets.

ASSEMBLY

(1) Position printed circuit, including connector, on

the back of the instrument panel cluster.

(2) Remove gauge bezel and lens.

(3) Hold components in place and install screws.

(4) Install lamp sockets.

(5) Pivot connector up and install retaining strap.

(6) Install gauge bezel and cluster lens.

GEAR SELECTOR INDICATOR

REPLACEMENTÐINSTRUMENT CLUSTER

REMOVED

(1) Remove screws from rear of mounting bezel

holding fuel gauge in place.

(2) Remove 2 screws holding gear selector indica-

tor (Fig. 8).

Fig. 4 Instrument Cluster

8E - 6 XJ INSTRUMENT PANEL AND GAUGESJ

Page 363 of 1784

DIAGNOSINGÐALL LAMPS OUT

(1) Inspect fuse #9. Replace as required.

(2) Measure voltage at instrument cluster connec-

tor terminal 20. Meter should read zero ohms. If not,

repair open to ground.

UPSHIFT INDICATOR LAMP

Vehicles equipped with manual transmissions have

an optional upshift indicator lamp. The lamp is con-

trolled by the PCM. The lamp lights to indicate when

the driver should shift to the next highest gear for best

fuel economy. The PCM will turn the lamp off after 3 to

5 seconds if the upshift is not performed. The lamp will

remain off until the vehicle stops accelerating and is

brought back to the range of lamp operation or shifted

into another gear.

The indicator lamp is normally illuminated when

the ignition switch is turned ON and it is turned off

when the engine is started. The lamp will be lighted

during engine operation according to engine speed

and load.

(1) Turn ignition switch to ON.

(2) Ground pin 2 of cluster connector. Lamp should

light. If not, replace bulb. If OK, continue with step 3.

(3) Turn ignition switch to OFF. Check for conti-

nuity between cluster connector pin 2 and pin 54 of

the PCM. If not, repair open. If OK, refer to DRB

scan tool actuator test of upshift indicator.

BRAKE INDICATOR LAMP

The brake indicator is a dual function lamp. It will in-

dicate an unequal pressure condition in the split brake

hydraulic system and it also will indicate when the park-

ing brake is engaged. Separate switches are used for each

indicator lamp function. A switch mounted on the brake

pedal assembly will close a ground circuit whenever the

parking brakes are applied. A second switch is installed

in the brake hydraulic lines near the master cylinder. If

the switch is balanced by equal pressure on both ends of

the switch valve, the valve remains centered and the

lamp remains off. If the valve is shifted by unequal pres-

sure between the front or rear brake hydraulic systems,

the lamp circuit is connected to ground. To make sure

the brake lamp is functional before the vehicle is driven,

it is illuminated through a ground circuit when the igni-

tion switch is turned to the START position.

(1) Turn ignition switch to ON.

(2) Ground pin 1 of the cluster connector. Lamp

should light. If not, replace bulb. If OK, continue

with step 3.

(3) Turn ignition switch to OFF. Check for continuity to

park brake switch and brake warning switch.

MALFUNCTION INDICATOR LAMP (CHECK ENGINE)

The Malfunction Indicator Lamp (Check Engine) il-

luminates each time the ignition switch is turned

ON and stays on for 3 seconds as a bulb test.If the PCM receives an incorrect signal or no signal

from certain sensors or emission related systems the

lamp is turned on (pin 32 of PCM). This is a warning

that the PCM has recorded a system or sensor mal-

function. In some cases when a diagnostic fault is de-

clared the PCM will go into a limp-in mode in an

attempt to keep the system operating. It signals an

immediate need for service.

The lamp also can be used to display diagnostic

trouble codes (DTC). Cycle the ignition switch ON,

OFF, ON, OFF, ON within 5 seconds. This will allow

any DTC's stored in the PCM memory to be dis-

played in a series of flashes representing digits.

(1) Turn ignition switch to ON.

(2) Ground pin 4 of cluster connector. Lamp should

light. If not, replace bulb. If OK, continue with step 3.

(3) Turn ignition switch to OFF. Check for conti-

nuity between cluster connector pin 4 and PCM cav-

ity 32. If OK, replace PCM. If not, repair open.

SEAT BELT REMINDER LAMP

Apply 12 volts to terminal 16 of cluster connector.

Lamp should light. If not, replace bulb. If OK, check

wiring for an open to buzzer module. Refer to Group

8U - Chime/Buzzer Warning Systems.

INSTRUMENT PANEL ILLUMINATION LAMPS

The instrument panel illumination lamps share

two common connections. There is a splice after fuse

#10 that connects the lamps to battery feed. There is

also a splice that connects all lamps to ground. Be-

cause they share these common connection points in

a parallel circuit, the illumination lamps will all

come on at the same time. It also means one or more

lamps can be out without affecting the operation of

the other lamps.

On the battery side of the circuit, the headlamp

switch illumination rheostat/switch and panel lamps

fuse receive battery feed in series from the park/tail

fuse. In the park lamp position, the headlamp switch

completes the circuit from the park/tail fuse to the il-

lumination rheostat/switch and panel lamps fuse.

The illumination rheostat contains a variable resis-

tor that allows the driver to vary illumination inten-

sity from off to full brightness.

DIAGNOSIS

(1) Turn parking lamps ON.

(2) Check fuse #10. Replace as required.

(3) Measure voltage at battery side of fuse #10

with rheostat turned counterclockwise to clockwise

(LO to HI). Meter should read zero volts to battery

voltage. If not, replace headlamp switch.

(4) Measure resistance at ground side of fuse #10

with parking lamps OFF. Meter should read almost

zero ohms (except bulb filament). If not, repair open

to ground. If zero ohms, 12 volt supply wire from fuse

is shorted to ground, repair short.

8E - 16 YJ INSTRUMENT PANEL AND GAUGESJ

Page 428 of 1784

LAMPS

CONTENTS

page page

EXTERIOR LAMPS....................... 1

INTERIOR LAMPS...................... 19SPECIFICATIONS....................... 23

EXTERIOR LAMPS

INDEX

page page

Back-up/Rear Turn Signal/Tail Lamp Bulb

Replacement........................... 9

Center High Mounted Stop Lamp (CHMSL)ÐXJ . 10

Center High Mounted Stop Lamp (CHMSL)ÐYJ . 11

Daytime Running Lights (Canada Only)........ 16

DRL Module Replacement.................. 16

Fog Lamp Beam Adjustment................ 12

Fog Lamp Bulb/Element Replacement......... 13

Fog Lamp Replacement................... 15

Fog Lamp Service Information............... 12

Fog Lamp Switch Replacement.............. 14

Fog Lamp Trouble Diagnosis................ 12

Front Park/Turn Signal Lamp Bulb Replacement . . 8

Headlamp Beam Adjustment................. 3

Headlamp Bulb Replacement................ 3

Headlamp Delay Function Trouble DiagnosisÐXJ

Vehicles.............................. 16Headlamp Delay Module ReplacementÐXJ

Vehicles.............................. 16

Headlamp Dimmer Switch Replacement........ 6

Headlamp Switch Replacement............... 4

Headlamp Trouble DiagnosisÐXJ Vehicles...... 1

Headlamp Trouble DiagnosisÐYJ Vehicles...... 2

License Plate Lamp....................... 10

Sentinel Headlamp Delay ModuleÐXJ Vehicles . . 15

Service Information........................ 1

Side Marker Lamp Bulb Replacement.......... 7

Switch Tests............................. 2

Underhood Lamp Bulb Replacement.......... 18

Underhood Lamp Replacement.............. 18

Underhood Lamp Service Information......... 17

SERVICE INFORMATION

Exterior lamp circuits are comprised of the head-

lamp circuit, fog lamp circuit, and tail/side marker/

park lamp circuit. Battery voltage is controlled by

both the headlamp ON/OFF switch and headlamp

dimmer switch.

The dimmer switch functions as a fog lamp switch.

Voltage is applied to the fog lamp switch only when

the dimmer switch is in the low beam position.

HEADLAMP TROUBLE DIAGNOSISÐXJ VEHICLES

LOW AND HIGH BEAM INOPERATIVE BOTH

HEADLAMPS

(1) Place the headlamp switch in the ON position.

(2) Test the 40 amp fuse for continuity. If bad, re-

place fuse.

(3) Insert the test probe into terminal 5 of the

front lamp wire harness connector. Measure the re-

sistance from terminal 5 to body ground. The ohm-

meter should indicate zero ohms. If not OK, repair

the open circuit in the harness to body ground.(4) Disconnect the front lamp wire connector. Mea-

sure resistance between connector terminals 5 and 2.

Next measure between terminal 5 and 7. The ohm-

meter should indicate zero ohms for both measure-

ments. If not OK, replace the headlamp bulbs.

(5) Measure the voltage between the dimmer

switch wire connector terminal 2 and body ground.

The voltmeter should indicate battery voltage. If not

OK, continue with the next step.

The dimmer switch is integral with the turn

signal and is located on the steering column.

The dimmer switch switches the headlamp beam

when the turn signal lever is pulled rearward.

(6) Disconnect the dimmer switch wire connector

and place the headlamp switch in the OFF position.

Measure the resistance from terminal 2 to vehicle

body ground. The ohmmeter should indicate infinite

resistance. If OK, replace the headlamp switch and

continue with the next step. If not OK, repair the

short circuit in the wire harness that leads to termi-

nal 2.

JLAMPS 8L - 1

Page 443 of 1784

switch is turned OFF. The driver engages the module

by turning the ignition switch OFF, then turning the

headlamps OFF.

The headlamp delay module is located behind the

I/P next to the headlamp switch.

HEADLAMP DELAY MODULE REPLACEMENTÐXJ

VEHICLES

The headlamp delay module is attached to the in-

side of the instrument panel to the right of the head-

lamp switch.

REMOVAL

(1) Remove the lower instrument panel.

(2) Remove the screw that attaches the module to

the inside of the instrument panel.

(3) Disconnect the wire harness connector and re-

move the module from the instrument panel.

INSTALLATION

(1) Position the module inside the I/P and connect

the wire harness connector to the module.

(2) Install the screw that attaches the module to

the inside of the instrument panel.(3) Remove the lower instrument panel.

HEADLAMP DELAY FUNCTION TROUBLE

DIAGNOSISÐXJ VEHICLES

DELAY FUNCTION INOPERATIVE

(1) Remove, inspect and test the HD LP DLY fuse.

Replace if defective.

(2) Remove the delay module from the I/P. Do not

disconnect the wire harness connector. Turn the igni-

tion switch to the RUN position. Place the headlamp

switch in headlamps ON position. Turn the ignition

to the OFF position for a resistance test.

(3) Measure the resistance from the delay module

terminal 4 to vehicle body ground. The ohmmeter

should indicate zero ohms. If not, repair the open cir-

cuit in the wire harness to vehicle body ground.

(4) Measure the voltage between the delay module

terminal 8 and vehicle body ground. The voltmeter

should indicate battery voltage. If not, repair the

open circuit in the wire harness to the instrument

cluster indicator connector terminal 14.

(5) Measure the voltage between the delay module

terminal 6 and vehicle body ground. The voltmeter

should indicate battery voltage. If not, repair the

open circuit in the wire harness to the headlamp

switch.

(6) Measure the voltage between the delay module

terminal 2 and vehicle body ground. The voltmeter

should indicate battery voltage. If not, repair the

open circuit in the wire harness to the fuse.

DAYTIME RUNNING LIGHTS (CANADA ONLY)

SERVICE INFORMATION

The Daytime Running Lights (Headlamps) System

is installed on vehicles manufactured for sale in Can-

ada only. The headlamps are illuminated when the

ignition switch is turned to the ON position. The

DRL module receives a vehicle-moving signal from

the vehicle speed sensor. This provides a constant

headlamps-oncondition as long as the vehicle is

moving. The lamps are illuminated at less than 50

percent of normal intensity.

DRL MODULE REPLACEMENT

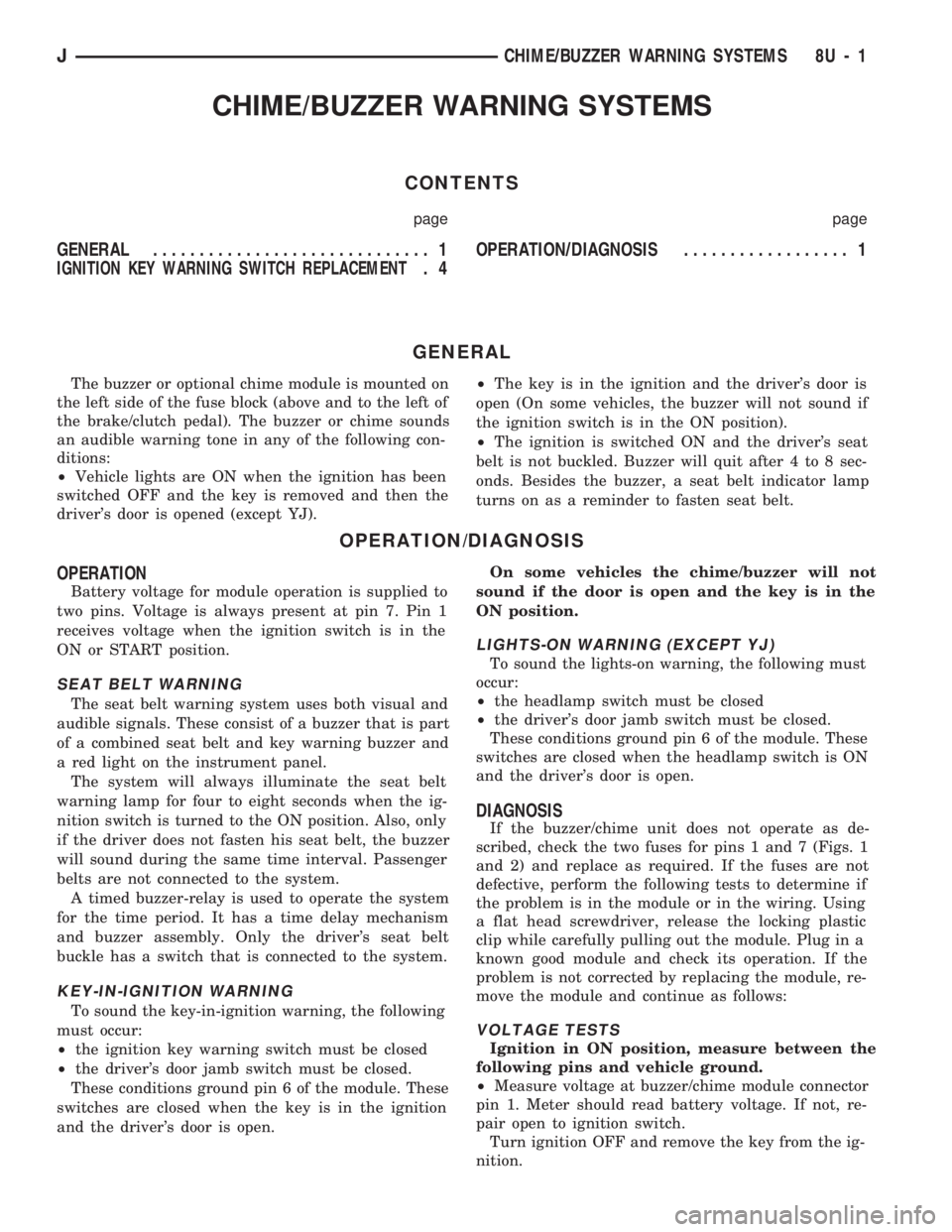

REMOVALÐXJ VEHICLES

The Daytime Running Lights (DRL) module is lo-

cated on the right fender inner panel adjacent to the

dash panel (Fig. 45).

(1) Disconnect the wire harness connector from the

module.

(2) Remove the screws that attach the module to

the fender inner panel.

(3) Remove the module from the fender inner

panel.

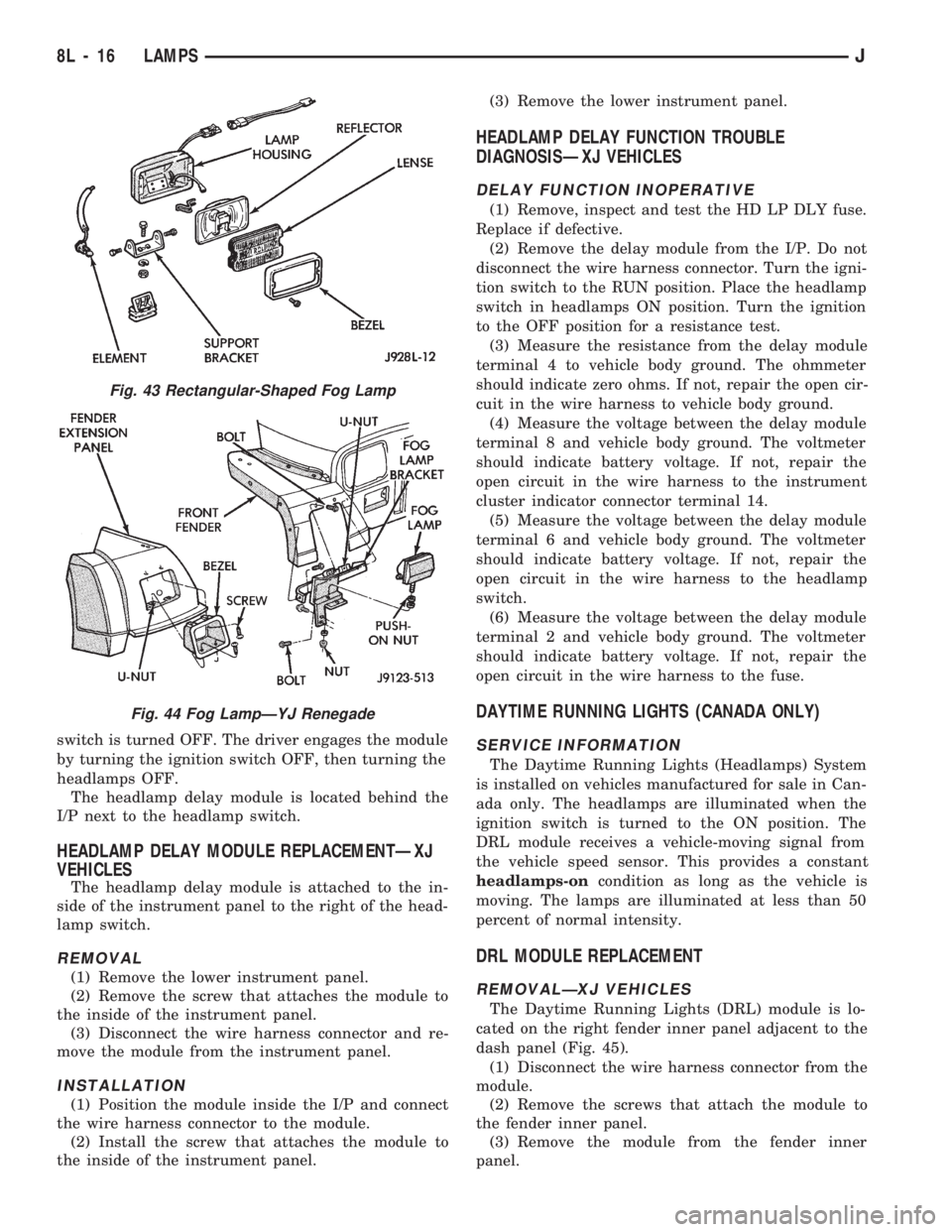

Fig. 43 Rectangular-Shaped Fog Lamp

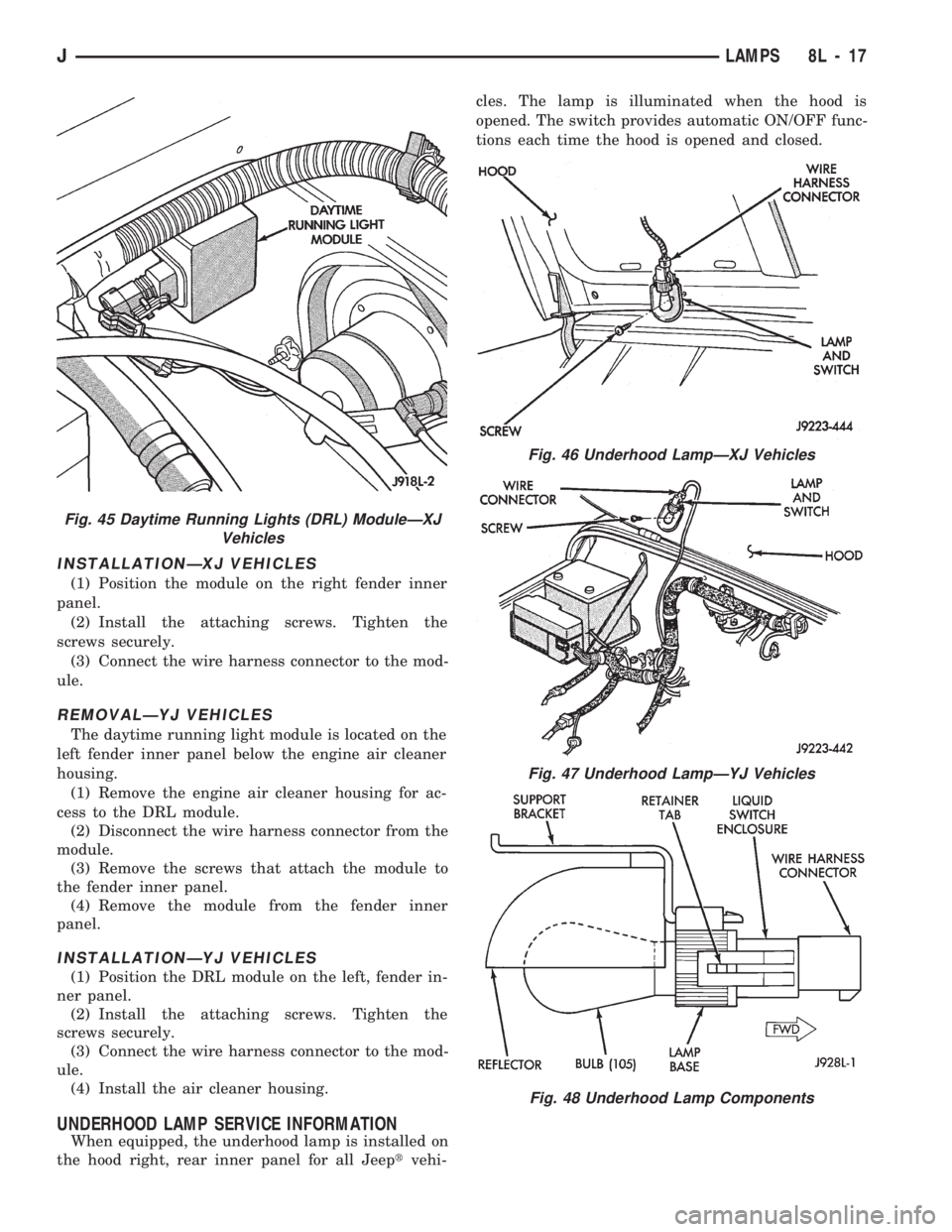

Fig. 44 Fog LampÐYJ Renegade

8L - 16 LAMPSJ

Page 444 of 1784

INSTALLATIONÐXJ VEHICLES

(1) Position the module on the right fender inner

panel.

(2) Install the attaching screws. Tighten the

screws securely.

(3) Connect the wire harness connector to the mod-

ule.

REMOVALÐYJ VEHICLES

The daytime running light module is located on the

left fender inner panel below the engine air cleaner

housing.

(1) Remove the engine air cleaner housing for ac-

cess to the DRL module.

(2) Disconnect the wire harness connector from the

module.

(3) Remove the screws that attach the module to

the fender inner panel.

(4) Remove the module from the fender inner

panel.

INSTALLATIONÐYJ VEHICLES

(1) Position the DRL module on the left, fender in-

ner panel.

(2) Install the attaching screws. Tighten the

screws securely.

(3) Connect the wire harness connector to the mod-

ule.

(4) Install the air cleaner housing.

UNDERHOOD LAMP SERVICE INFORMATION

When equipped, the underhood lamp is installed on

the hood right, rear inner panel for all Jeeptvehi-cles. The lamp is illuminated when the hood is

opened. The switch provides automatic ON/OFF func-

tions each time the hood is opened and closed.

Fig. 45 Daytime Running Lights (DRL) ModuleÐXJ

Vehicles

Fig. 46 Underhood LampÐXJ Vehicles

Fig. 47 Underhood LampÐYJ Vehicles

Fig. 48 Underhood Lamp Components

JLAMPS 8L - 17

Page 488 of 1784

CHIME/BUZZER WARNING SYSTEMS

CONTENTS

page page

GENERAL.............................. 1

IGNITION KEY WARNING SWITCH REPLACEMENT.4OPERATION/DIAGNOSIS.................. 1

GENERAL

The buzzer or optional chime module is mounted on

the left side of the fuse block (above and to the left of

the brake/clutch pedal). The buzzer or chime sounds

an audible warning tone in any of the following con-

ditions:

²Vehicle lights are ON when the ignition has been

switched OFF and the key is removed and then the

driver's door is opened (except YJ).²The key is in the ignition and the driver's door is

open (On some vehicles, the buzzer will not sound if

the ignition switch is in the ON position).

²The ignition is switched ON and the driver's seat

belt is not buckled. Buzzer will quit after 4 to 8 sec-

onds. Besides the buzzer, a seat belt indicator lamp

turns on as a reminder to fasten seat belt.

OPERATION/DIAGNOSIS

OPERATION

Battery voltage for module operation is supplied to

two pins. Voltage is always present at pin 7. Pin 1

receives voltage when the ignition switch is in the

ON or START position.

SEAT BELT WARNING

The seat belt warning system uses both visual and

audible signals. These consist of a buzzer that is part

of a combined seat belt and key warning buzzer and

a red light on the instrument panel.

The system will always illuminate the seat belt

warning lamp for four to eight seconds when the ig-

nition switch is turned to the ON position. Also, only

if the driver does not fasten his seat belt, the buzzer

will sound during the same time interval. Passenger

belts are not connected to the system.

A timed buzzer-relay is used to operate the system

for the time period. It has a time delay mechanism

and buzzer assembly. Only the driver's seat belt

buckle has a switch that is connected to the system.

KEY-IN-IGNITION WARNING

To sound the key-in-ignition warning, the following

must occur:

²the ignition key warning switch must be closed

²the driver's door jamb switch must be closed.

These conditions ground pin 6 of the module. These

switches are closed when the key is in the ignition

and the driver's door is open.On some vehicles the chime/buzzer will not

sound if the door is open and the key is in the

ON position.

LIGHTS-ON WARNING (EXCEPT YJ)

To sound the lights-on warning, the following must

occur:

²the headlamp switch must be closed

²the driver's door jamb switch must be closed.

These conditions ground pin 6 of the module. These

switches are closed when the headlamp switch is ON

and the driver's door is open.

DIAGNOSIS

If the buzzer/chime unit does not operate as de-

scribed, check the two fuses for pins 1 and 7 (Figs. 1

and 2) and replace as required. If the fuses are not

defective, perform the following tests to determine if

the problem is in the module or in the wiring. Using

a flat head screwdriver, release the locking plastic

clip while carefully pulling out the module. Plug in a

known good module and check its operation. If the

problem is not corrected by replacing the module, re-

move the module and continue as follows:

VOLTAGE TESTS

Ignition in ON position, measure between the

following pins and vehicle ground.

²Measure voltage at buzzer/chime module connector

pin 1. Meter should read battery voltage. If not, re-

pair open to ignition switch.

Turn ignition OFF and remove the key from the ig-

nition.

JCHIME/BUZZER WARNING SYSTEMS 8U - 1

Page 1747 of 1784

BODY SOLENOIDS, TRANSMISSION

VALVE ............................21-175

BODY STRIPES/DECALS...........23-25,23-153

BODY, THROTTLE.................14-29,14-59

BODY UNDERCOAT....................23-203

BOOSTER CHECK VALVE TEST, POWER......5-11

BOOSTER INSTALLATION, POWER

BRAKE..........................5-23,5-51

BOOSTER OPERATION, POWER BRAKE......5-22

BOOSTER, POWER BRAKE............5-22,5-40

BOOSTER REMOVAL, POWER BRAKE . . . 5-22,5-51

BOOSTER TEST, MASTER CYLINDER/

POWER.............................5-11

BOOSTER VACUUM TEST, POWER..........5-12

BORES, HONING CYLINDER................9-2

BOX, GLOVE.........................23-194

BRACKET, FUEL FILTER.................23-86

BRACKET, FUEL FILTER SHIELD...........13-17

BRACKET, I/P TWEETER SPEAKER/

COURTESY LAMP SUPPORT............23-95

BRACKET, MUFFLER/TAILPIPE HANGER.....13-16

BRACKET, REARVIEW MIRROR

RETAINING........................23-183

BRACKET REPLACEMENT, INTERIOR

REARVIEW MIRROR SUPPORT..........23-75

BRACKETS, CATALYTIC CONVERTER/

MUFFLER/TAILPIPE SUPPORT...........23-85

BRACKETSÐXJ VEHICLES, SPARE TIRE/

WHEEL HOLDDOWN AND FLOOR.......23-128

BRAKE ADJUSTMENT, DRUM..............5-35

BRAKE ADJUSTMENT PARKING............5-63

BRAKE BLEEDINGÐBRAKE FLUID AND

LEVELÐBRAKELINES AND HOSES........5-13

BRAKE BLEEDINGÐWITH ABS BRAKES.....5-14

BRAKE BLEEDINGÐWITH STANDARD

BRAKES.............................5-13

BRAKE BOOSTER INSTALLATION,

POWER.........................5-23,5-51

BRAKE BOOSTER OPERATION, POWER......5-22

BRAKE BOOSTER, POWER............5-22,5-40

BRAKE BOOSTER REMOVAL, POWER . . . 5-22,5-51

BRAKE CABLE TENSIONER REPLACEMENT

(XJ), PARKING........................5-61

BRAKE CHECK, PRELIMINARY..............5-7

BRAKE COMPONENTS, WHEEL.............5-1

BRAKE DIAGNOSIS, ABS..................5-3

BRAKE DIAGNOSIS, SERVICE..............5-7

BRAKE DRUM REFINISHING..............5-37

BRAKE FLUID CONTAMINATION............5-13

BRAKE FLUID, IMPORTANCE OF CLEAN.....5-48

BRAKE FLUID LEVEL....................5-13

BRAKE FLUID, RECOMMENDED........5-13,5-48

BRAKE FLUID TUBE RETAINER CLIP,

FUEL AND; BODY COMPONENTSÐXJ

VEHICLES..........................23-86

BRAKE FLUID TUBE RETAINER CLIP,

FUEL AND; FRAME AND BUMPERS......13-16

BRAKE FLUID/LUBRICANTS/CLEANING

SOLVENTS............................5-1

BRAKE FRONT CABLE REPLACEMENT

(YJ), PARKING........................5-62

BRAKE INDICATOR INOPERATIVE..........8E-4

BRAKE INDICATOR LAMP; INSTRUMENT

PANEL AND GAUGESÐXJ...............8E-2

BRAKE INDICATOR LAMP; INSTRUMENT

PANEL AND GAUGESÐYJ

..............8E-16

BRAKE LEVER INSTALLATION (XJ WITH

FULLCONSOLE), PARKING

..............5-60

BRAKE LEVER INSTALLATION (XJ WITH

MINICONSOLE), PARKING

...............5-58

BRAKE LEVER INSTALLATION (XJ

WITHOUT CONSOLE), PARKING

..........5-60

BRAKE LEVER REMOVAL (XJ WITH FULL

CONSOLE), PARKING

..................5-59

BRAKE LEVER REMOVAL (XJ WITH MINI

CONSOLE), PARKING

..................5-58

BRAKE LEVER REMOVAL (XJ WITHOUT

CONSOLE), PARKING

..................5-60

BRAKE OPERATION, PARKING

.............5-56

BRAKE OVERHAUL, SECOND

............21-232

BRAKE PACK REQUIREMENTS, AW-4

CLUTCH

...........................21-328

BRAKE PEDAL AND BRAKELIGHT

SWITCH

.............................5-65

BRAKE PEDAL INSTALLATION

.............5-66BRAKE PEDAL INSTALLATION (YJ),

PARKING............................5-61

BRAKE PEDAL REMOVAL.................5-65

BRAKE PEDAL REMOVAL (YJ), PARKING....5-61

BRAKE PEDAL SERVICE..................5-65

BRAKE PISTON AND TRANSMISSION

CASE OVERHAUL, FIRST-REVERSE......21-237

BRAKE PROBLEMS, DIAGNOSING

PARKING............................5-10

BRAKE PROBLEMS, DIAGNOSING

SERVICE.............................5-8

BRAKE REAR CABLE REPLACEMENT

(XJ), PARKING........................5-62

BRAKE REAR CABLE REPLACEMENT (YJ),

PARKING............................5-63

BRAKE ROTOR REFINISHING, DISC.........5-32

BRAKE ROTOR RUNOUT, DISC............5-31

BRAKE ROTOR THICKNESS, DISC..........5-31

BRAKE ROTOR THICKNESS VARIATION,

DISC...............................5-31

BRAKE SAFETY PRECAUTIONS.............5-2

BRAKE SERVO, SECOND COAST.........21-181

BRAKE SWITCH.......................14-54

BRAKE SWITCHÐPCM INPUT............14-20

BRAKE SYSTEM (ABS), ANTILOCK..........5-1

BRAKE SYSTEM (ABS) INDICATOR

LAMP, ANTI-LOCK.....................8E-2

BRAKE SYSTEM OPERATION, ANTILOCK.....5-43

BRAKE SYSTEM, POWER.................0-32

BRAKE TORQUE SPECIFICATIONS..........5-67

BRAKE WARNING LIGHT DISPLAY...........5-4

BRAKE WARNING LIGHTS.................5-1

BRAKELIGHT SWITCH ADJUSTMENT........5-66

BRAKELIGHT SWITCH, BRAKE PEDAL.......5-65

BRAKELIGHT SWITCH INSTALLATION.......5-66

BRAKELIGHT SWITCH REMOVAL...........5-66

BRAKELINE CHARTS....................5-15

BRAKELINES AND HOSES................5-15

BRAKELINING MATERIAL..................5-1

BRAKES, BRAKE BLEEDINGÐWITH ABS.....5-14

BRAKES, BRAKE BLEEDINGÐWITH

STANDARD..........................5-13

BRAKES, DISC.........................5-24

BRAKES, DRUM........................5-34

BRAKES, PARKING......................5-56

BRAKES, POWER........................5-1

BRAKESHOE INSTALLATION, DISC..........5-26

BRAKESHOE INSTALLATION, DRUM........5-34

BRAKESHOE REMOVAL, DISC.............5-25

BRAKESHOE REMOVAL, DRUM............5-34

BRAKING MODE, ABS OPERATION IN

ANTILOCK...........................5-43

BRAKING MODE, ABS OPERATION

IN NORMAL..........................5-43

BREAK-IN, ENGINE......................0-13

BRUSH GUARD........................23-3

BUCKET SEAT COMPONENTS, POWER....23-106

BUCKET SEAT CUSHION AND COVER......23-98

BUCKET SEAT PLATFORM AND TRACKS . . . 23-105

BUCKET SEATBACK COVER AND FRAME . . . 23-100

BUCKET SEATBACK RECONDITIONING.....23-102

BUCKET SEATS, FRONT.................23-97

BUFFING AND POLISHING..............23-203

BULB REPLACEMENT, BACK-UP/REAR

TURN SIGNAL/TAIL LAMP...............8L-9

BULB REPLACEMENT, FRONT PARK/

TURN SIGNAL LAMP

...................8L-8

BULB REPLACEMENT, HEADLAMP

..........8L-3

BULB REPLACEMENT, INSTRUMENT

CLUSTER

...........................8E-19

BULB REPLACEMENT, SIDE MARKER

LAMP

...............................8L-7

BULB REPLACEMENT, UNDERHOOD

LAMP

..............................8L-18

BULB REPLACEMENTÐYJ VEHICLES,

HARDTOP DOME/CARGO LAMP

.........8L-20

BULB/ELEMENT REPLACEMENT, FOG

LAMP

..............................8L-13

BUMPER, FRONT

..................13-3,13-14

BUMPER, LIFTGATE LICENSE PLATE

SCREW ANCHOR

.....................23-72

BUMPER, REAR

...................13-6,13-18

BUMPER, REAR JOUNCE

................13-18

BUMPERÐXJ VEHICLES, REAR

SEATBACK LATCH STRIKER

...........23-111BUMPERS AND FRAME ATTACHED

COMPONENTS, YJ....................13-14

BUMPERS, FUEL FILLER DOOR...........23-31

BUMPERS, XJ.........................13-3

BUSHING AND PISTON CLEARANCE, AW-

4 ................................21-326

BUSHING REPLACEMENT, AXLE.......2-11,2-32

BUSHING REPLACEMENT, LEAF SPRING

EYE; FRONT SUSPENSION AND AXLE.....2-15

BUSHING REPLACEMENT, LEAF SPRING

EYE; REAR SUSPENSION AND AXLES . . . 3-4,3-6

BUZZER SYSTEM, CHIME/WARNING........8A-1

CABLE, ACCELERATOR PEDAL AND

THROTTLE.....................14-16,14-54

CABLE ADJUSTMENT, PARK INTERLOCK . . . 21-186

CABLE ADJUSTMENT, SHIFT............21-186

CABLE ADJUSTMENT, TRANSMISSION

THROTTLE....................21-98,21-185

CABLE ADJUSTMENT, TRANSMISSION

THROTTLE VALVE....................21-70

CABLE ADJUSTMENT (XJ), PARK

INTERLOCK.........................21-97

CABLE ADJUSTMENT (XJ), SHIFT.........21-97

CABLE REPLACEMENT, HEATER

CONTROL..........................24-30

CABLE REPLACEMENT, LATCH

RELEASE...........................23-10

CABLE REPLACEMENT, SERVO............8H-9

CABLE REPLACEMENT, TRANSMISSION

THROTTLE.........................21-184

CABLE REPLACEMENT (XJ),

PARKING BRAKE REAR.................5-62

CABLE REPLACEMENT (YJ), PARKING

BRAKE FRONT........................5-62

CABLE REPLACEMENT (YJ), PARKING

BRAKE REAR.........................5-63

CABLE RESISTANCE, SPARK PLUG........8D-18

CABLE TENSIONER REPLACEMENT (XJ),

PARKING BRAKE......................5-61

CABLE, THROTTLE.....................14-16

CABLEÐCONSOLE SHIFT AUTOMATIC,

PARK-LOCK.........................19-45

CABLES, DISTRIBUTOR CAP AND ROTOR,

IGNITION............................0-18

CABLES, SPARK PLUG SECONDARY . . 8D-17,8D-29

CABLES, VENT DOOR CONTROL..........24-39

CALIBRATION VALUES, GAUGE...........8E-22

CALIPER ASSEMBLY....................5-29

CALIPER CLEANING AND INSPECTION......5-28

CALIPER DISASSEMBLY..................5-27

CALIPER INSTALLATION..................5-30

CALIPER OPERATION AND WEAR

COMPENSATION......................5-24

CALIPER REMOVAL.....................5-27

CAMSHAFT........................9-29,9-69

CAMSHAFT PIN REPLACEMENT........9-31,9-71

CAMSHAFT POSITION SENSOR; FUEL

SYSTEM............................14-54

CAMSHAFT POSITION SENSOR;

IGNITION SYSTEMS..............8D-1,8D-20

CAMSHAFT POSITION SENSORÐPCM

INPUT.............................14-20

CAMSHAFT POSITION SENSOR TEST;

FUEL SYSTEM.......................14-43

CAMSHAFT POSITION SENSOR TEST;

IGNITION SYSTEMS...................8D-8

CANADA ONLY, DAYTIME RUNNING

LIGHTS............................8L-16

CANISTER, EVAP...................25-4,25-9

CAP AND ROTOR, IGNITION CABLES,

DISTRIBUTOR........................0-18

CAP, DISTRIBUTOR.....................8D-9

CAP, FUEL TANK FILLER TUBE; EMISSION

CONTROL SYSTEMS...............25-4,25-9

CAP, FUEL TANK FILLER TUBE; FUEL

SYSTEM............................14-12

CAP, RADIATOR PRESSURE...............7-20

CAPACITIES, COOLING SYSTEM...........7-38

CAPACITIES, FLUID......................0-4

CAPACITIES, FUEL TANK...........14-12,14-62

CAPACITY TEST, FUEL PUMP..............14-7

CAR REPLACEMENT, PITMAN SHAFT

SEALSÐIN

.........................19-21

CARDAN (CV), DOUBLE

.................16-10

CARDAN, SINGLE

.......................16-9

CARDAN U-JOINT, AXLE SHAFT

............2-25

JINDEX3

Description Group-Page Description Group-Page Description Group-Page

Page 1750 of 1784

CRANKSHAFT POSITION SENSORÐPCM

INPUT.............................14-20

CRANKSHAFT POSITION SENSOR TEST;

FUEL SYSTEM.......................14-44

CRANKSHAFT POSITION SENSOR TEST;

IGNITION SYSTEMS...................8D-9

CROSSMEMBER COVER, FRAME..........13-14

CROSSMEMBER, RADIATOR SUPPORT......23-5

CUSHION AND COVER, BUCKET SEAT......23-98

CUSHION COVERÐXJ VEHICLES, REAR

SEAT .............................23-107

CUSHION, ENGINE FRONT SUPPORT.......13-15

CUSHION RECONDITIONINGÐXJ

VEHICLES, REAR SEAT...............23-108

CUSHIONÐXJ VEHICLES, REAR SEAT.....23-107

CYLINDER BLOCK..................9-45,9-85

CYLINDER BORES, HONING................9-2

CYLINDER COMBUSTION PRESSURE

LEAKAGE TEST DIAGNOSIS...........9-5,9-6

CYLINDER DISPOSAL, LIFTGATE

SUPPORT ROD......................23-70

CYLINDER, DOOR KEY LOCK.............23-54

CYLINDER ENGINE, VACUUM ROUTING

SCHEMATICÐ2.5L 4...................25-2

CYLINDER ENGINE, VACUUM ROUTING

SCHEMATICÐ4.0L 6...................25-3

CYLINDER, FULL-METAL DOOR KEY

LOCK.............................23-178

CYLINDER HEAD COVER, ENGINE......9-18,9-59

CYLINDER HEAD, ENGINE............9-19,9-60

CYLINDER HEAD GASKET FAILURE

DIAGNOSIS, ENGINE....................9-5

CYLINDER INSTALLATION, MASTER....5-20,5-50

CYLINDER INSTALLATION, WHEEL.........5-37

CYLINDER, LIFTGATE SUPPORT ROD......23-69

CYLINDER, MASTER.....................5-40

CYLINDER OVERHAUL, WHEEL............5-36

CYLINDER OVERHAUL, MASTER...........5-20

CYLINDER REMOVAL, MASTER........5-20,5-50

CYLINDER REMOVAL, WHEEL.............5-36

CYLINDER REPLACEMENT, LIFTGATE

LOCK...............................8P-7

CYLINDER, STANDARD MASTER...........5-20

CYLINDER, TAILGATE LOCK.............23-160

CYLINDER/POWER BOOSTER TEST,

MASTER............................5-11

CYLINDER/STRIKER, LIFTGATE LATCH/

KEY LOCK..........................23-68

CYLINDERS, KEY LOCK............23-2,23-132

D RANGE FIRST GEAR, HYDRAULIC

FLOW IN...........................21-87

D RANGE SECOND GEAR, HYDRAULIC

FLOW IN...........................21-88

D RANGE THIRD GEAR, HYDRAULIC

FLOW IN...........................21-89

DAMAGE TORQUE, COLLISION............13-1

DAMAGED OR WORN THREADS, REPAIR.....9-4

DAMPENER, STEERING............19-15,19-18

DAMPER, ENGINE......................9-13

DAMPER, VIBRATION................9-26,9-67

DASH PANEL INSULATION PANEL.........23-95

DASH PANEL INSULATOR PANEL.........23-11

DATA LINK CONNECTORÐPCM INPUT.....14-20

DATA LINK CONNECTORÐPCM OUTPUT....14-24

DATA, VEHICLE DIMENSION . . . INTRO.-3,INTRO.-4

DATA, VEHICLE LOAD................INTRO.-3

DATA, XJ VEHICLE LOAD.............INTRO.-5

DATA, YJ-VEHICLE LOAD.............INTRO.-6

DAYTIME RUNNING LIGHTS (CANADA

ONLY) .............................8L-16

DECODING, VEHICLE CODE...........INTRO.-3

DECODING, VEHICLE IDENTIFICATION

NUMBER (VIN)....................INTRO.-2

DEFLECTOR, COWL WEATHERSTRIP

SEAL/CROSSMEMBER AIR.............23-10

DEFOGGER GRID REPAIR, REAR

WINDOW............................8N-2

DEFOGGER GRID TEST, REAR

WINDOW............................8N-1

DEFOGGER, REAR WINDOW..............8A-1

DEFOGGER RELAY, REAR

................8N-4

DEFOGGER SWITCH REPLACEMENT,

REAR WINDOW

.......................8N-4

DEFOGGER/FOG LAMP/REAR WIPER

SWITCHES, REAR

....................8E-21

DEFROSTER DUCT REPLACEMENT

........24-29DEFROSTER NOZZLE AND DUCT..........24-40

DELAY FUNCTION TROUBLE

DIAGNOSISÐXJ VEHICLES, HEADLAMP . . . 8L-16

DELAY MODULE REPLACEMENTÐXJ

VEHICLES, HEADLAMP................8L-16

DELAY MODULEÐXJ VEHICLES,

SENTINEL HEADLAMP.................8L-15

DELIVERY SYSTEM, FUEL................14-2

DEPTH INFORMATION, PINION GEAR;

FRONT SUSPENSION AND AXLE..........2-37

DEPTH INFORMATION, PINION GEAR;

REAR SUSPENSION AND AXLES..........3-19

DEPTH VARIANCE, PINION GEAR; FRONT

SUSPENSION AND AXLE................2-38

DEPTH VARIANCE, PINION GEAR; REAR

SUSPENSION AND AXLES...........3-20,3-38

DESCRIPTION (AIR CONDITIONING).......24-41

DESCRIPTION; AUDIO SYSTEMS...........8F-1

DESCRIPTION (HEATING)................24-37

DESCRIPTION; HEATING AND AIR

CONDITIONING.................24-17,24-22

DESCRIPTION; OVERHEAD CONSOLE.......8C-1

DESCRIPTION; POWER DOOR LOCKS.......8P-1

DESCRIPTION; POWER WINDOWS.........8S-1

DESCRIPTION; TRANSMISSION AND

TRANSFER CASE....................21-156

DESCRIPTION; TURN SIGNALS AND

HAZARD WARNING FLASHER........8J-1,8J-2

DESCRIPTION/SYSTEM OPERATION,

MULTI-PORT FUEL INJECTION (MFI)Ð

COMPONENT........................14-17

DESIGNATION CODES, VEHICLE........INTRO.-1

DESIGNATIONS, LABELS/PLATES, CODES

AND DIMENSIONS.................INTRO.-1

DESIGNATIONS, VEHICLE.............INTRO.-1

DETECTION AND REPAIR, FIXED GLASS

WATER LEAK..................23-83,23-189

DIAGNOSING INTERMITTENT

WINDSHIELD WASHER................8K-12

DIAGNOSING NON-INTERMITTENT

WINDSHIELD WASHER................8K-12

DIAGNOSING PARKING BRAKE

PROBLEMS..........................5-10

DIAGNOSING POWER DOOR LOCKS....8P-1,8P-9

DIAGNOSING REAR WIPER...............8K-6

DIAGNOSING REAR WIPER WASHER.......8K-6

DIAGNOSING REAR WIPER/WASHER......8K-14

DIAGNOSING SERVICE BRAKE

PROBLEMS...........................5-8

DIAGNOSING WINDSHIELD WASHER

(INTERMITTENT)......................8K-4

DIAGNOSING WINDSHIELD WASHER

(NON-INTERMITTENT)..................8K-4

DIAGNOSING WINDSHIELD WIPERS . . . 8K-3,8K-11

DIAGNOSINGÐALL LAMPS OUT..........8E-16

DIAGNOSINGÐTURN SIGNAL

INOPERATIVE.........................8J-2

DIAGNOSIS, 2.5L STARTER MOTOR NOISE . . . 8A-13

DIAGNOSIS, 30RH/32RH TRANSMISSION . . 21-69,

21-77,21-78,21-79,21-80,21-81,21-82,21-83,21-84,

21-85

DIAGNOSIS, ABS BRAKE..................5-3

DIAGNOSIS, ABS FAULT................5-4,5-6

DIAGNOSIS, AIR CONDITIONING

SYSTEM............................24-12

DIAGNOSIS AND REPAIR............8G-1,8G-2

DIAGNOSIS; AUDIO SYSTEMS.............8F-1

DIAGNOSIS, AW-4 TRANSMISSION

.......21-167

DIAGNOSIS, AXLE NOISE/VIBRATION;

FRONT SUSPENSION AND AXLE

..........2-16

DIAGNOSIS, AXLE NOISE/VIBRATION;

REAR SUSPENSION AND AXLES

..........3-7

DIAGNOSIS, BELT

.......................7-31

DIAGNOSIS CHARTS, INSPECTION

..........6-4

DIAGNOSIS; CHIME/BUZZER WARNING

SYSTEMS

...........................8U-1

DIAGNOSIS, CLUTCH

.....................6-3

DIAGNOSIS, COMPRESSOR

..............24-13

DIAGNOSIS, CONVERTER HOUSING

LEAK

..............................21-73

DIAGNOSIS; COOLING SYSTEM

.............7-4

DIAGNOSIS, CYLINDER COMBUSTION

PRESSURE LEAKAGE TEST

...............9-6

DIAGNOSIS, DISCONNECT AXLE/SHIFT

MOTOR

.............................2-27DIAGNOSIS, DOME/COURTESY LAMP

TROUBLE...........................8L-19

DIAGNOSIS, ECU........................5-4

DIAGNOSISÐELECTRICAL, SERVICE.......24-14

DIAGNOSIS, ENGINE.....................9-5

DIAGNOSIS, ENGINE CYLINDER HEAD

GASKET FAILURE......................9-5

DIAGNOSIS, EXHAUST SYSTEM............11-2

DIAGNOSIS, FOG LAMP TROUBLE.........8L-12

DIAGNOSIS, GAUGE PACKAGE............8E-22

DIAGNOSIS, GEAR LEAKAGE..............19-8

DIAGNOSIS GUIDES AND CHARTS........21-76

DIAGNOSISÐHAZARD LAMPS

INOPERATIVE.....................8J-1,8J-2

DIAGNOSIS, HCU........................5-4

DIAGNOSIS, HEATING SYSTEM...........24-11

DIAGNOSIS, IGNITION OFF DRAW (IOD).....8A-8

DIAGNOSIS, IGNITION SECONDARY

CIRCUIT...........................8D-12

DIAGNOSIS, ILLUMINATED ENTRY

SYSTEM TROUBLE..............8L-21,8L-22

DIAGNOSIS INFORMATION, GENERAL;

CLUTCH..............................6-3

DIAGNOSIS INFORMATION, GENERAL;

TRANSMISSION AND TRANSFER

CASE.............................21-167

DIAGNOSIS, INSTRUMENT CLUSTER;

INSTRUMENT PANEL AND

GAUGESÐXJ.........................8E-3

DIAGNOSIS, INSTRUMENT CLUSTER;

INSTRUMENT PANEL AND

GAUGESÐYJ........................8E-14

DIAGNOSIS, INTAKE MANIFOLD LEAKAGE.....9-5

DIAGNOSIS, LIGHTED VANITY MIRROR

TROUBLE...........................8L-19

DIAGNOSIS, MANUAL STEERING

SYSTEM............................19-36

DIAGNOSISÐMECHANICAL, SERVICE;

ENGINES.............................9-8

DIAGNOSISÐMECHANICAL, SERVICE;

HEATING AND AIR CONDITIONING........24-8

DIAGNOSIS, MULTI-PORT FUEL

INJECTION (MFI)ÐGENERAL...........14-32

DIAGNOSIS, NOISE.....................3-45

DIAGNOSIS, NP231 SERVICE............21-274

DIAGNOSIS, NP242 SERVICE............21-295

DIAGNOSIS, PERFORMANCE.............24-10

DIAGNOSIS; POWER MIRRORS............8T-1

DIAGNOSIS; POWER SEATS..............8R-1

DIAGNOSIS, POWER STEERING SYSTEM....19-3,

19-4,19-5,19-6,19-7

DIAGNOSIS, PRELIMINARY..............21-69

DIAGNOSIS, PRESSURE..................24-9

DIAGNOSIS PROCEDURES; BRAKES......5-3,5-7

DIAGNOSIS, PUMP LEAKAGE..............19-8

DIAGNOSIS, RADIO NOISE................8F-2

DIAGNOSIS; REAR WINDOW DEFOGGER....8N-2

DIAGNOSIS, SERPENTINE DRIVE BELT......7-32

DIAGNOSIS, SERVICE BRAKE..............5-7

DIAGNOSIS, SERVICE; FRONT

SUSPENSION AND AXLE................2-18

DIAGNOSIS, SERVICE; REAR

SUSPENSION AND AXLES................3-9

DIAGNOSIS, SERVICE; TRANSMISSION

AND TRANSFER CASE . 21-2,21-33,21-171,21-172

DIAGNOSIS, SPRING AND SHOCK;

FRONT SUSPENSIONAND AXLE

......2-12,2-14

DIAGNOSIS, SPRING AND SHOCK; REAR

SUSPENSIONAND AXLES

.............3-3,3-5

DIAGNOSIS, STARTING SYSTEM

..........8A-10

DIAGNOSIS; STEERING

.................19-35

DIAGNOSIS, SUSPENSION AND

STEERING SYSTEM

.....................2-7

DIAGNOSIS, SYSTEM

.....................7-7

DIAGNOSISÐTURN SIGNAL

INOPERATIVE

.........................8J-1

DIAGNOSISÐVEHICLE RUNS ROUGH

AND/OR HAS A MISS, INJECTOR

........14-49

DIAGNOSIS, VIBRATION

.............22-9,22-10

DIAGNOSISÐXJ VEHICLES, HEADLAMP

DELAY FUNCTION TROUBLE

............8L-16

DIAGNOSISÐXJ VEHICLES, HEADLAMP

TROUBLE

............................8L-1

DIAGNOSISÐYJ VEHICLES,

HEADLAMP TROUBLE

..................8L-2

6 INDEXJ

Description Group-Page Description Group-Page Description Group-Page

Page 1758 of 1784

LIFTGATE LOCK CYLINDER

REPLACEMENT.......................8P-7

LIFTGATE OPENING WEATHERSTRIP SEAL . . . 23-70

LIFTGATE PILLAR TRIM COVERSÐXJ

VEHICLES.........................23-116

LIFTGATE REMOVAL/INSTALLATION........23-65

LIFTGATE SERVICE INFORMATIONÐXJ

VEHICLES..........................23-65

LIFTGATE SUPPORT ROD BALL

STUD REPLACEMENT.................23-70

LIFTGATE SUPPORT ROD CYLINDER.......23-69

LIFTGATE SUPPORT ROD CYLINDER

DISPOSAL..........................23-70

LIFTGATE TRIM PANEL.................23-66

LIFTGATE WINDOW GLASSÐXJ

VEHICLES..........................23-81

LIFTGATE WIPER.......................8K-5

LIFTGATE WIPER SWITCH REPLACEMENT....8K-6

LIGHT DISPLAY, ABS WARNING............5-3

LIGHT DISPLAY, BRAKE WARNING..........5-4

LIGHTED VANITY MIRROR...............8L-19

LIGHTED VANITY MIRROR TROUBLE

DIAGNOSIS.........................8L-19

LIGHTS, BRAKE WARNING.................5-1

LIGHTS (CANADA ONLY), DAYTIME

RUNNING...........................8L-16

LIGHTS, SYSTEM WARNING..............5-42

LIMITED SLIP DIFFERENTIAL...............3-8

LIMITS, AW-4 OIL PUMP WEAR.........21-325

LINE CLUSTER, HIGH...................8E-12

LINE CLUSTER, LOW...................8E-11

LINE FITTINGS, TRANSMISSION COOLER . . 21-187

LINERS, REAR WHEELHOUSE FLARES.....23-18

LINERS, WHEELHOUSE SPLASH.........23-146

LINES AND FITTINGS, SERVICING

TRANSMISSION COOLER.............21-106

LINK CONNECTORÐPCM INPUT, DATA.....14-20

LINK CONNECTORÐPCM OUTPUT, DATA . . . 14-24

LINK, DRAG.....................19-14,19-17

LINK REPLACEMENT, FUSIBLE............8W-4

LINKAGE ADJUSTMENT, SHIFT....21-275,21-296

LINKAGE ADJUSTMENT (YJ), GEARSHIFT . . . 21-96

LINKAGE AND BALL STUDS, STEERING.....0-30

LINKAGE FLUID, CLUTCH..................6-1

LINKAGE, GEARSHIFT..................21-70

LINKAGE INSTALLATION, CLUTCH

HYDRAULIC..........................6-12

LINKAGE REMOVAL, CLUTCH HYDRAULIC....6-11

LINKAGEÐXJ, STEERING..........19-14,19-73

LINKAGEÐYJ, STEERING..........19-17,19-73

LINKS, FUSIBLE.......................8W-3

LOAD DATA, VEHICLE................INTRO.-3

LOAD DATA, XJ VEHICLE.............INTRO.-5

LOAD DATA, YJ-VEHICLE.............INTRO.-6

LOAD TEST, BATTERY...................8A-4

LOCATING A SYSTEM...................8W-2

LOCATIONS, SPLICE..............8W-2,8W-53

LOCATIONS, TRANSMISSION SWITCH

AND PLUG..........................21-33

LOCATIONS, XJ RHD SPLICE............8W-67

LOCATIONS, XJ SPLICE................8W-59

LOCATIONS, YJ SPLICE................8W-53

LOCK COMPONENT OVERHAUL,

ADAPTER HOUSING AND PARK........21-120

LOCK COMPONENT REPLACEMENT,

PARK .............................21-102

LOCK CYLINDER, DOOR KEY.............23-54

LOCK CYLINDER, FULL-METAL DOOR

KEY ..............................23-178

LOCK CYLINDER REPLACEMENT,

LIFTGATE............................8P-7

LOCK CYLINDER, TAILGATE.............23-160

LOCK CYLINDER/STRIKER, LIFTGATE

LATCH/KEY.........................23-68

LOCK CYLINDERS, KEY............23-2,23-132

LOCK HANDLE, FULL-METAL DOOR.......23-175

LOCK, HYDROSTATIC.....................9-4

LOCK RODS, DOOR INSIDE LATCH

RELEASE...........................23-57

LOCK SWITCH, PASSENGER DOOR

.........8P-5

LOCK SWITCHÐ2-DOOR LEFT HAND

DRIVE, DRIVERS DOOR POWER

..........8P-2

LOCK SWITCHÐ2-DOOR RIGHT HAND

DRIVE,DRIVERS DOOR POWER

..........8P-3

LOCK SWITCHÐ4-DOOR, DRIVERS

DOOR POWER

........................8P-4LOCKS, DIAGNOSING POWER DOOR . . . 8P-1,8P-9

LOCKS, POWER; ELECTRICAL.............8A-1

LOCKS, POWER; POWER DOOR LOCKS.....8P-1

LOCKS, POWER DOOR..................8P-10

LOCK/UNLOCK RELAY REPLACEMENT,

DOOR.............................8P-12

LOOP MODES OF OPERATION, OPEN

LOOP/CLOSED.......................14-27

LOOP/CLOSED LOOP MODES OF

OPERATION, OPEN...................14-27

LOSS OF SENSOR INPUT..................5-3

LOW FUEL WARNING INOPERATIVE........8E-4

LOW FUEL WARNING LAMP..............8E-2

LOW LINE CLUSTER...................8E-11

LOW SPEED KNOCK; FRONT SUSPENSION

AND AXLE...........................2-17

LOW SPEED KNOCK; REAR SUSPENSION

AND AXLES...........................3-8

LOW WASHER INDICATOR INOPERATIVE....8E-4

LOWER SUSPENSION ARM...............2-11

LUBRICANT AND REPLACEMENT PARTS,

RECOMMENDED.......................0-3

LUBRICANT CHANGE; FRONT

SUSPENSION AND AXLE................2-22

LUBRICANT CHANGE; REAR SUSPENSION

AND AXLES......................3-13,3-30

LUBRICANT, RECOMMENDED.............21-2

LUBRICANT SPECIFICATIONS, BODY........0-35

LUBRICANT SPECIFICATIONS; FRONT

SUSPENSION AND AXLE................2-20

LUBRICANT SPECIFICATIONS; REAR

SUSPENSION AND AXLES...........3-11,3-30

LUBRICANT, TRANSFER CASE.....21-273,21-294

LUBRICANT, TRANSMISSION.............21-33

LUBRICANTS, CHASSIS COMPONENT

AND WHEEL BEARING.................0-30

LUBRICANTS, CLASSIFICATION OF..........0-2

LUBRICATION, CLUTCH COMPONENT........6-1

LUBRICATION, COMPONENTS

REQUIRING NO........................0-3

LUG NUT, WHEEL......................22-11

LUGGAGE RACKÐXJ VEHICLES..........23-32

MAGNETIC CLUTCH....................24-18

MAIN BEARING FITTING CHART.......9-43,9-83

MAIN BEARINGS, CRANKSHAFT.......9-40,9-80

MAIN OIL SEALS, REAR..............9-44,9-84

MAINTENANCE, BATTERY................8B-1

MAINTENANCE, ENGINE..................0-13

MAINTENANCE SCHEDULES...............0-5

MAINTENANCE, SEVERE SERVICE...........0-5

MAJOR COMPONENT IDENTIFICATION . . . INTRO.-3

MALFUNCTION INDICATOR LAMP

(CHECK ENGINE); INSTRUMENT PANEL

AND GAUGESÐXJ................8E-2,8E-4

MALFUNCTION INDICATOR LAMP

(CHECK ENGINE); INSTRUMENT PANEL

AND GAUGESÐYJ...................8E-16

MALFUNCTION INDICATOR LAMPÐPCM

OUTPUT............................14-26

MANIFOLDÐ2.5L ENGINE, ENGINE

EXHAUST............................11-7

MANIFOLDÐ2.5L ENGINE, INTAKE.........11-8

MANIFOLDÐ4.0L ENGINE, ENGINE

EXHAUST............................11-7

MANIFOLDÐ4.0L ENGINE, INTAKE

.........11-9

MANIFOLD ABSOLUTE PRESSURE (MAP)

SENSOR; FUEL SYSTEM

...............14-57

MANIFOLD ABSOLUTE PRESSURE (MAP)

SENSOR; IGNITION SYSTEMS

......8D-5,8D-27

MANIFOLD ABSOLUTE PRESSURE (MAP)

SENSORÐPCM INPUT

................14-21

MANIFOLD ABSOLUTE PRESSURE (MAP)

SENSOR TEST; FUEL SYSTEM

..........14-44

MANIFOLD ABSOLUTE PRESSURE (MAP)

SENSOR TEST; IGNITION SYSTEMS

......8D-14

MANIFOLD AIR TEMPERATURE SENSOR,

INTAKE

........................8D-5,8D-27

MANIFOLD AIR TEMPERATURE

SENSOR TEST, INTAKE

................8D-14

MANIFOLD ASSEMBLY, PRESSURE

GAUGE

..............................24-2

MANIFOLD, INTAKE

....................14-57

MANIFOLD LEAKAGE DIAGNOSIS, INTAKE

.....9-5

MANUAL FIRST GEAR (1) POSITION,

HYDRAULIC FLOW IN

.................21-94MANUAL SECOND (2) RANGE,

HYDRAULIC FLOW IN.................21-93

MANUAL SHIFTING TEST...............21-168

MANUAL STEERING GEAR..........19-35,19-73

MANUAL STEERING GEAR

SPECIFICATIONS.....................19-44

MANUAL STEERING GEARÐYJ VEHICLES....0-32

MANUAL STEERING SYSTEM DIAGNOSIS . . . 19-36

MANUAL TRANSMISSION................0-22

MANUAL TRANSMISSION, AX 15.........21-32

MANUAL TRANSMISSION, AX 4/5..........21-1

MANUAL TRANSMISSION, SELECTIVE

SNAP RING CHARTÐAX 15...........21-321

MANUAL TRANSMISSION, TORQUE

SPECIFICATIONSÐ AX 15.............21-320

MANUAL VALVE SHAFT OVERHAUL.......21-205

MANUAL VALVE SHAFT SEAL

REPLACEMENT.....................21-178

MARKER LAMP BULB REPLACEMENT,

SIDE...............................8L-7

MASTER CYLINDER.....................5-40

MASTER CYLINDER INSTALLATION.....5-20,5-50

MASTER CYLINDER OVERHAUL...........5-20

MASTER CYLINDER REMOVAL........5-20,5-50

MASTER CYLINDER, STANDARD...........5-20

MASTER CYLINDER/POWER BOOSTER

TEST...............................5-11

MATCH MOUNTING TIRES................22-7

MATERIAL, BRAKELINING.................5-1

MATS, CARPET/FLOOR.................23-198

MATS, CARPETS AND FLOOR...........23-129

MEASUREMENT AND ADJUSTMENT,

DIFFERENTIAL SHIM PACK..............2-42

MEASUREMENT, DIFFERENTIAL AND

PINION; FRONT SUSPENSION AND AXLE....2-38

MEASUREMENT, DIFFERENTIAL AND

PINION; REAR SUSPENSION AND AXLES....3-20

MEASUREMENT, UNIVERSAL JOINT

ANGLE..............................16-4

MEASUREMENTS AND ADJUSTMENTS,

ALIGNMENT...........................2-6

MEASURING WITH PLASTIGAGE............9-3

METALS, PAINT REPAIR ON GALVANIZED . . 23-202

METRIC SYSTEM NOTATION...........INTRO.-8

METRIC, THREAD NOTATIONÐSAE.....INTRO.-9

(MFI)ÐCOMPONENT DESCRIPTION/

SYSTEM OPERATION, MULTI-

PORT FUEL INJECTION................14-17

(MFI)ÐCOMPONENT REMOVAL/

INSTALLATION, MULTI-PORT FUEL

INJECTION..........................14-54

(MFI)ÐGENERAL DIAGNOSIS,

MULTI-PORT FUEL INJECTION..........14-32

MINI-FLOOR CONSOLEÐXJ VEHICLES....23-124

MIRROR (EXTERNAL), HALF METAL

DOOR

............................23-158

MIRROR, INTERIOR REARVIEW

...........23-74

MIRROR, LIGHTED VANITY

..............8L-19

MIRROR, REARVIEW

..................23-183

MIRROR REPLACEMENT, POWER

..........8T-4

MIRROR RETAINING BRACKET,

REARVIEW

.........................23-183

MIRROR SUPPORT BRACKET

REPLACEMENT, INTERIOR REARVIEW

....23-75

MIRROR SWITCH, POWER

................8T-2

MIRROR SWITCH REPLACEMENT,

POWER

.............................8T-4

MIRROR SWITCH TESTING, POWER

........8T-2

MIRROR TROUBLE DIAGNOSIS, LIGHTED

VANITY

............................8L-19

MIRRORS, EXTERNAL

..................23-31

MIRRORS, POWER

.....................8A-1

MISS, INJECTOR DIAGNOSISÐVEHICLE

RUNS ROUGH AND/OR HAS A

..........14-49

MODE, ABS OPERATION IN ANTILOCK

BRAKING

............................5-43

MODE, ABS OPERATION IN NORMAL

BRAKING

............................5-43

MODE, VEHICLE RESPONSE IN

ANTILOCK

............................5-3

MODEL 30 AXLE AND TUBE AXLE

(2WD)

..............................2-20

MODEL 30 FRONT AXLE

.............2-46,2-47

MODEL 35, REAR AXLE

..........3-11,3-28,3-50

14 INDEXJ

Description Group-Page Description Group-Page Description Group-Page