reset JEEP CHEROKEE 1994 Service User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 1994, Model line: CHEROKEE, Model: JEEP CHEROKEE 1994Pages: 1784, PDF Size: 77.09 MB

Page 497 of 1784

FUSIBLE LINK REPLACEMENT

CAUTION: Do not replace blown fusible links with a

standard wire. Only use fusible type wire with hypa-

lon insulation or damage to the electrical system

could occur. Also make sure correct gauge of wir-

ing is used. Refer to the wiring diagrams for proper

gauge and color.

When a fusible link blows it is important to find

out what the problem is. They are placed in the elec-

trical system for protection against shorts to ground.

This can be caused by a component failure or various

wiring failures.Do not just replace the fusible

link to correct the problem.

When diagnosing a faulty fusible link it is impor-

tant to check the wire carefully. In some instances

the link may be blown and it will not show through

the insulation, the wire should be checked over its

entire length for internal breaks.

(1) Disconnect battery negative cable.

(2) Cut out the blown portion of the fusible link.

(3) Strip 1 inch of insulation from each end of the

existing fusible link.

(4) Place a piece of heat shrink tubing over one

side of the fusible link. Make sure the tubing will be

long enough to cover and seal the entire repair area.

(5) Cut a replacement piece of fusible link approx-

imately two inches longer than the piece removed.

(6) Remove one inch of insulation from each end of

the replacement fusible link.

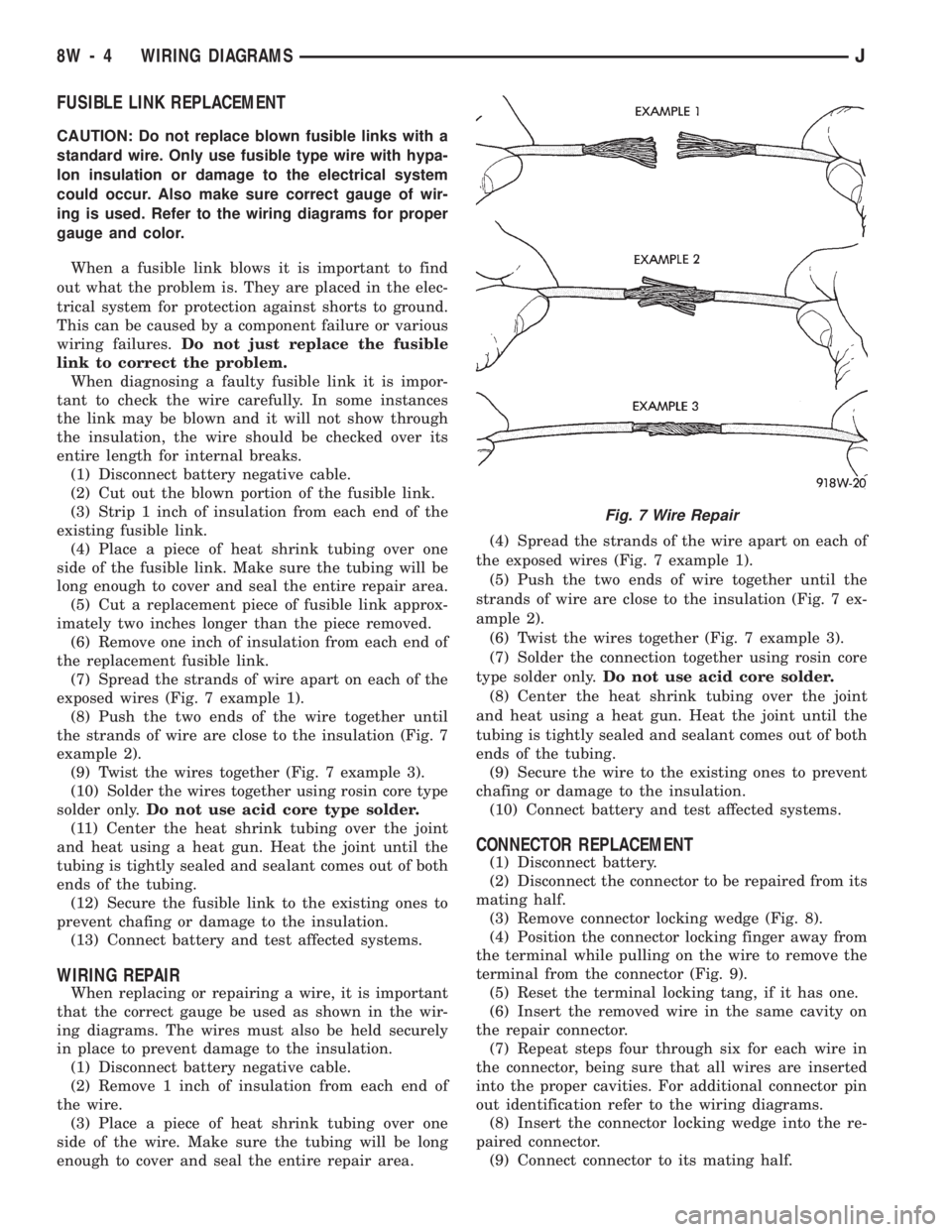

(7) Spread the strands of wire apart on each of the

exposed wires (Fig. 7 example 1).

(8) Push the two ends of the wire together until

the strands of wire are close to the insulation (Fig. 7

example 2).

(9) Twist the wires together (Fig. 7 example 3).

(10) Solder the wires together using rosin core type

solder only.Do not use acid core type solder.

(11) Center the heat shrink tubing over the joint

and heat using a heat gun. Heat the joint until the

tubing is tightly sealed and sealant comes out of both

ends of the tubing.

(12) Secure the fusible link to the existing ones to

prevent chafing or damage to the insulation.

(13) Connect battery and test affected systems.

WIRING REPAIR

When replacing or repairing a wire, it is important

that the correct gauge be used as shown in the wir-

ing diagrams. The wires must also be held securely

in place to prevent damage to the insulation.

(1) Disconnect battery negative cable.

(2) Remove 1 inch of insulation from each end of

the wire.

(3) Place a piece of heat shrink tubing over one

side of the wire. Make sure the tubing will be long

enough to cover and seal the entire repair area.(4) Spread the strands of the wire apart on each of

the exposed wires (Fig. 7 example 1).

(5) Push the two ends of wire together until the

strands of wire are close to the insulation (Fig. 7 ex-

ample 2).

(6) Twist the wires together (Fig. 7 example 3).

(7) Solder the connection together using rosin core

type solder only.Do not use acid core solder.

(8) Center the heat shrink tubing over the joint

and heat using a heat gun. Heat the joint until the

tubing is tightly sealed and sealant comes out of both

ends of the tubing.

(9) Secure the wire to the existing ones to prevent

chafing or damage to the insulation.

(10) Connect battery and test affected systems.

CONNECTOR REPLACEMENT

(1) Disconnect battery.

(2) Disconnect the connector to be repaired from its

mating half.

(3) Remove connector locking wedge (Fig. 8).

(4) Position the connector locking finger away from

the terminal while pulling on the wire to remove the

terminal from the connector (Fig. 9).

(5) Reset the terminal locking tang, if it has one.

(6) Insert the removed wire in the same cavity on

the repair connector.

(7) Repeat steps four through six for each wire in

the connector, being sure that all wires are inserted

into the proper cavities. For additional connector pin

out identification refer to the wiring diagrams.

(8) Insert the connector locking wedge into the re-

paired connector.

(9) Connect connector to its mating half.

Fig. 7 Wire Repair

8W - 4 WIRING DIAGRAMSJ

Page 988 of 1784

SPEED CONTROLÐPCM OUTPUT

Speed control operation is regulated by the power-

train control module (PCM). The PCM controls the

vacuum to the throttle actuator through the speed

control vacuum and vent solenoids. Refer to Group

8H for speed control information.

TACHOMETERÐPCM OUTPUT

The powertrain control module (PCM) supplies en-

gine rpm values to the instrument cluster tachome-

ter (if equipped). Refer to Group 8E for tachometer

information.

TORQUE CONVERTER CLUTCH RELAYÐPCM

OUTPUT

ALL 2.5L 4 CYL. WITH 3-SPEED AUTO. TRANS

4.0L 6 CYL. YJ MODELS WITH 3-SPEED AUTO.

TRANS

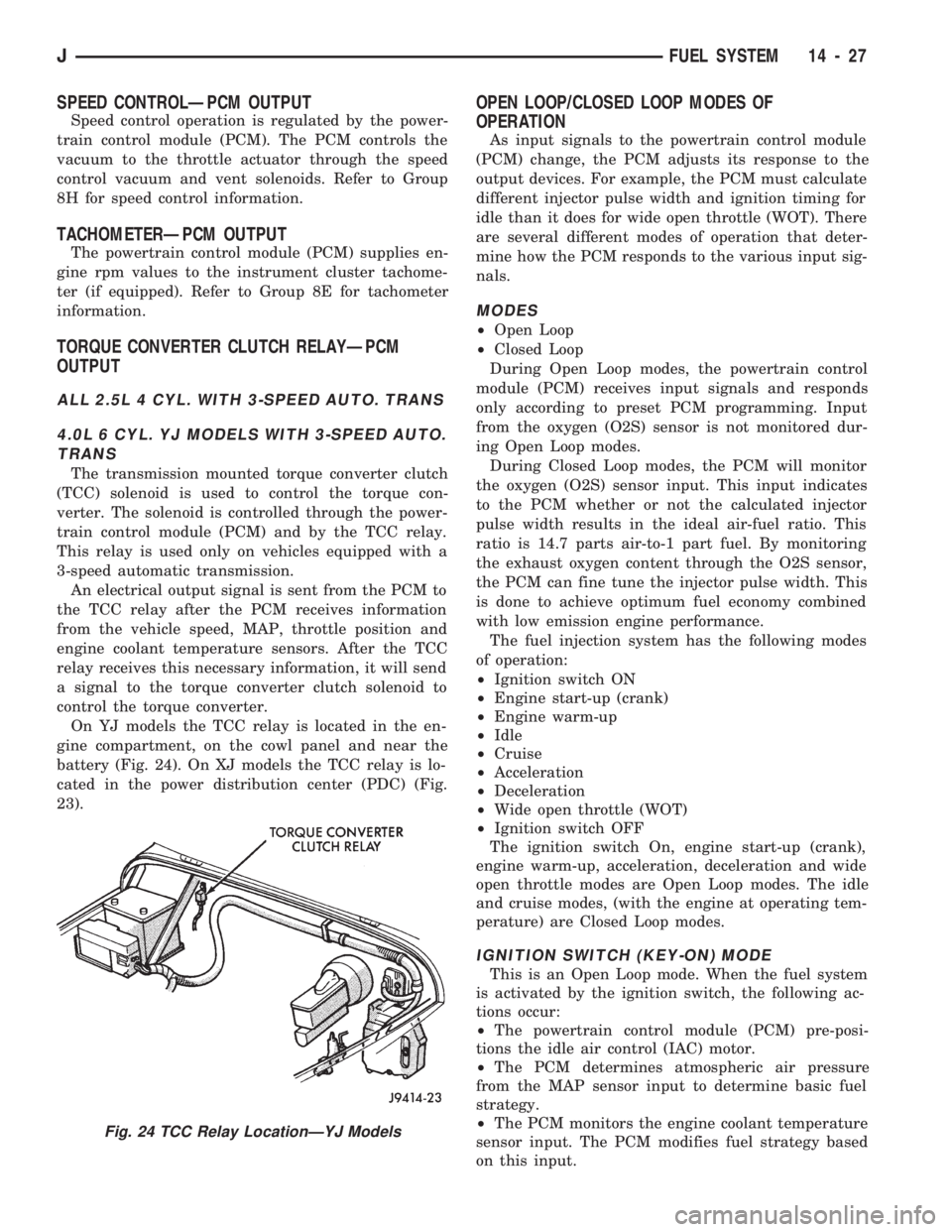

The transmission mounted torque converter clutch

(TCC) solenoid is used to control the torque con-

verter. The solenoid is controlled through the power-

train control module (PCM) and by the TCC relay.

This relay is used only on vehicles equipped with a

3-speed automatic transmission.

An electrical output signal is sent from the PCM to

the TCC relay after the PCM receives information

from the vehicle speed, MAP, throttle position and

engine coolant temperature sensors. After the TCC

relay receives this necessary information, it will send

a signal to the torque converter clutch solenoid to

control the torque converter.

On YJ models the TCC relay is located in the en-

gine compartment, on the cowl panel and near the

battery (Fig. 24). On XJ models the TCC relay is lo-

cated in the power distribution center (PDC) (Fig.

23).

OPEN LOOP/CLOSED LOOP MODES OF

OPERATION

As input signals to the powertrain control module

(PCM) change, the PCM adjusts its response to the

output devices. For example, the PCM must calculate

different injector pulse width and ignition timing for

idle than it does for wide open throttle (WOT). There

are several different modes of operation that deter-

mine how the PCM responds to the various input sig-

nals.

MODES

²Open Loop

²Closed Loop

During Open Loop modes, the powertrain control

module (PCM) receives input signals and responds

only according to preset PCM programming. Input

from the oxygen (O2S) sensor is not monitored dur-

ing Open Loop modes.

During Closed Loop modes, the PCM will monitor

the oxygen (O2S) sensor input. This input indicates

to the PCM whether or not the calculated injector

pulse width results in the ideal air-fuel ratio. This

ratio is 14.7 parts air-to-1 part fuel. By monitoring

the exhaust oxygen content through the O2S sensor,

the PCM can fine tune the injector pulse width. This

is done to achieve optimum fuel economy combined

with low emission engine performance.

The fuel injection system has the following modes

of operation:

²Ignition switch ON

²Engine start-up (crank)

²Engine warm-up

²Idle

²Cruise

²Acceleration

²Deceleration

²Wide open throttle (WOT)

²Ignition switch OFF

The ignition switch On, engine start-up (crank),

engine warm-up, acceleration, deceleration and wide

open throttle modes are Open Loop modes. The idle

and cruise modes, (with the engine at operating tem-

perature) are Closed Loop modes.

IGNITION SWITCH (KEY-ON) MODE

This is an Open Loop mode. When the fuel system

is activated by the ignition switch, the following ac-

tions occur:

²The powertrain control module (PCM) pre-posi-

tions the idle air control (IAC) motor.

²The PCM determines atmospheric air pressure

from the MAP sensor input to determine basic fuel

strategy.

²The PCM monitors the engine coolant temperature

sensor input. The PCM modifies fuel strategy based

on this input.

Fig. 24 TCC Relay LocationÐYJ Models

JFUEL SYSTEM 14 - 27

Page 1095 of 1784

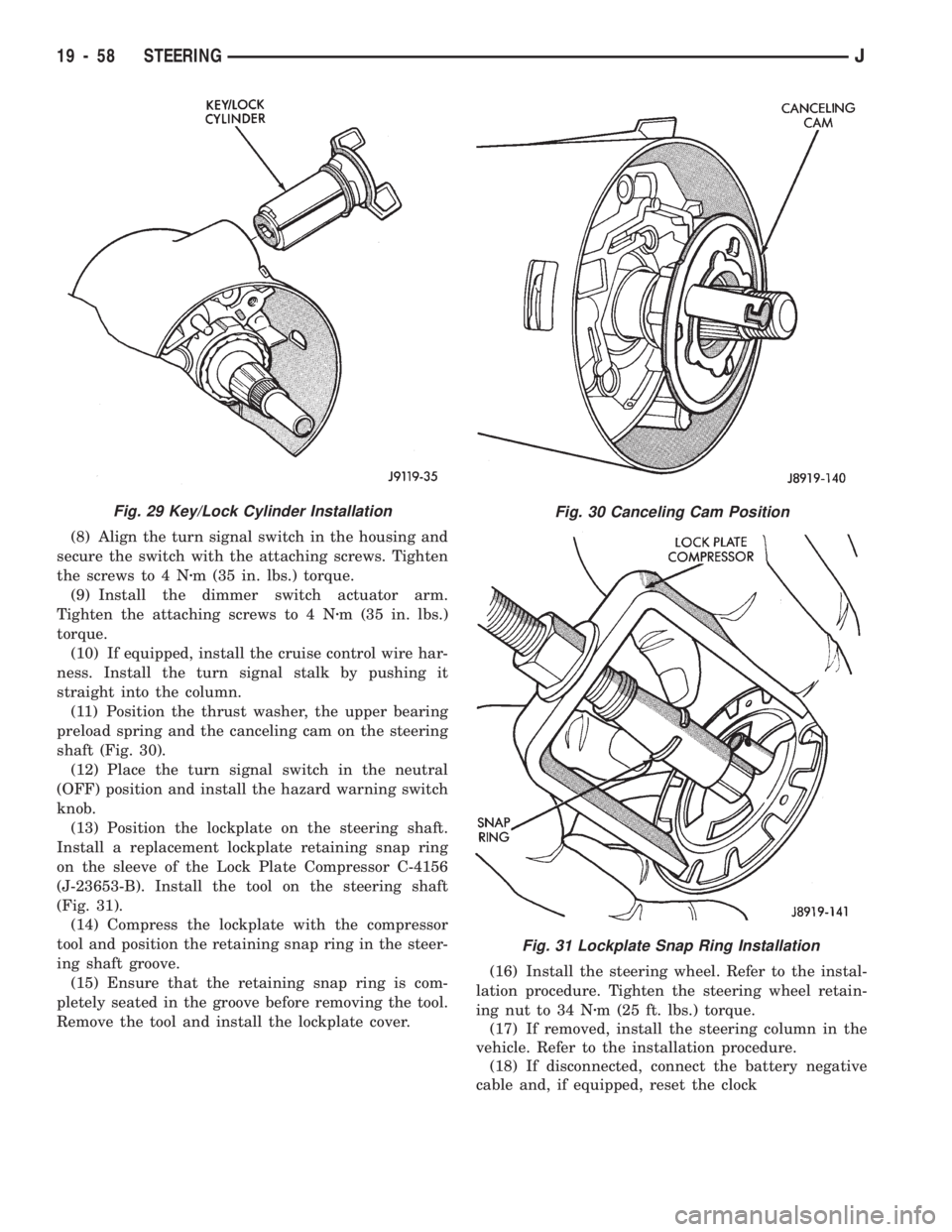

(8) Align the turn signal switch in the housing and

secure the switch with the attaching screws. Tighten

the screws to 4 Nzm (35 in. lbs.) torque.

(9) Install the dimmer switch actuator arm.

Tighten the attaching screws to 4 Nzm (35 in. lbs.)

torque.

(10) If equipped, install the cruise control wire har-

ness. Install the turn signal stalk by pushing it

straight into the column.

(11) Position the thrust washer, the upper bearing

preload spring and the canceling cam on the steering

shaft (Fig. 30).

(12) Place the turn signal switch in the neutral

(OFF) position and install the hazard warning switch

knob.

(13) Position the lockplate on the steering shaft.

Install a replacement lockplate retaining snap ring

on the sleeve of the Lock Plate Compressor C-4156

(J-23653-B). Install the tool on the steering shaft

(Fig. 31).

(14) Compress the lockplate with the compressor

tool and position the retaining snap ring in the steer-

ing shaft groove.

(15) Ensure that the retaining snap ring is com-

pletely seated in the groove before removing the tool.

Remove the tool and install the lockplate cover.(16) Install the steering wheel. Refer to the instal-

lation procedure. Tighten the steering wheel retain-

ing nut to 34 Nzm (25 ft. lbs.) torque.

(17) If removed, install the steering column in the

vehicle. Refer to the installation procedure.

(18) If disconnected, connect the battery negative

cable and, if equipped, reset the clock

Fig. 30 Canceling Cam Position

Fig. 31 Lockplate Snap Ring Installation

Fig. 29 Key/Lock Cylinder Installation

19 - 58 STEERINGJ

Page 1281 of 1784

(8) Shift transmission into D range and record

time it takes for engagement. Repeat test two more

times.

(9) Reset stop watch and shift transmission back to

Neutral.

(10) Shift transmission into Reverse and record

time it takes for engagement. Repeat test two more

times.

(11) Engagement time in D range should be a max-

imum of 1.2 seconds. Engagement time for Reverse

should be a maximum of 1.5 seconds.

TIME LAG TEST ANALYSIS

If engagement time is longer than specified for D

range, check for the following:²shift cable misadjusted

²line pressure low

²forward clutch worn

²overdrive clutch worn or damaged

If engagement time is longer than specified for Re-

verse, check for the following:

²shift cable misadjusted

²line pressure low

²direct clutch worn

²first/reverse brake worn

²overdrive clutch worn or damaged

21 - 170 AW-4 TRANSMISSION DIAGNOSISJ

Page 1543 of 1784

The reinforcement bracket is held on the

frame rail with two blind rivets.

(2) Remove the bracket and tow hook from frame

rail.

INSTALLATION

(1) Position bracket and tow hook on the frame

rail.

(2) Install bolts that attach tow hook bracket to

frame rail and reinforcement bracket. Tighten bolts

to 75 Nzm (55 ft-lbs) torque.

TRAILER HITCHES

CLASS III HITCHÐXJ VEHICLES

A class III weight-distributing/equalizer type hitch

can be used to tow a trailer:

²having a maximum gross weight of 5,000 lbs/2250

kg, and

²having a maximum tongue weight of 750 lbs/332

kg).

The following vehicle basic equipment is required

for class III trailer towing:

²P205/75R15 or larger tires;

²full size spare tire;

²trailer sway control;

²trailer tow wire harness and connector;

²heavy duty turn signal flasher element;

²heavy duty axle (with synthetic lubricant);²heavy duty cooling system;

²heavy duty generator/battery;

²auxiliary automatic transmission fluid cooler; and

²I-6, 4.0L engine.

Wide-angle type door mirrors are recommended but

not required.

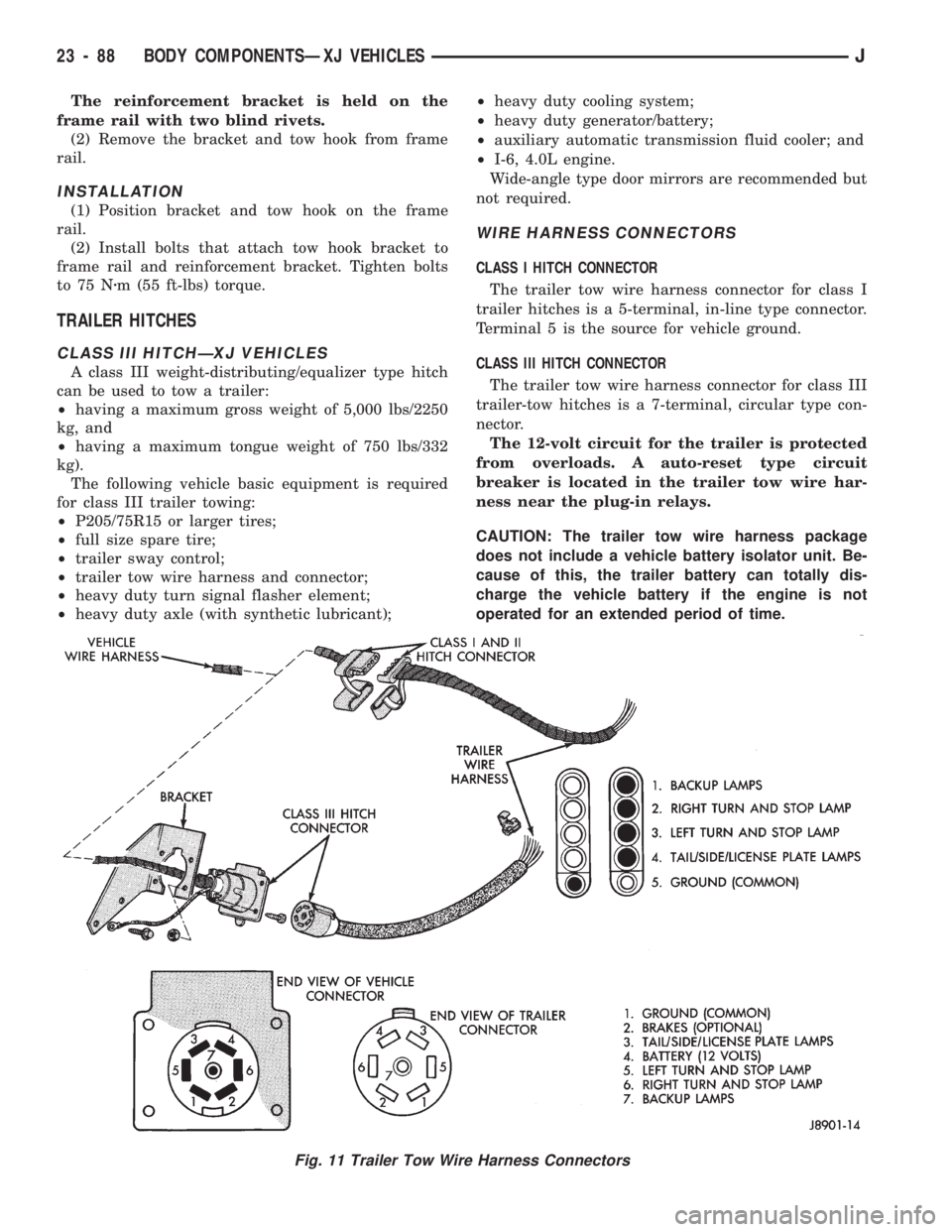

WIRE HARNESS CONNECTORS

CLASS I HITCH CONNECTOR

The trailer tow wire harness connector for class I

trailer hitches is a 5-terminal, in-line type connector.

Terminal 5 is the source for vehicle ground.

CLASS III HITCH CONNECTOR

The trailer tow wire harness connector for class III

trailer-tow hitches is a 7-terminal, circular type con-

nector.

The 12-volt circuit for the trailer is protected

from overloads. A auto-reset type circuit

breaker is located in the trailer tow wire har-

ness near the plug-in relays.

CAUTION: The trailer tow wire harness package

does not include a vehicle battery isolator unit. Be-

cause of this, the trailer battery can totally dis-

charge the vehicle battery if the engine is not

operated for an extended period of time.

Fig. 11 Trailer Tow Wire Harness Connectors

23 - 88 BODY COMPONENTSÐXJ VEHICLESJ