trailer JEEP CHEROKEE 1994 Service User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 1994, Model line: CHEROKEE, Model: JEEP CHEROKEE 1994Pages: 1784, PDF Size: 77.09 MB

Page 947 of 1784

The retaining screws and the steering gear

skid plate must be removed before the left strap

can be removed from the sillmember.

(6) Detach the tow hook straps from the sillmem-

ber.

(7) Remove the support and the bumper from the

vehicle.

(8) Remove the nuts and bolts that attach the tow

hooks to the bumper support brackets.

(9) Remove the tow hook from the bumper support

bracket (Fig. 4).

(10) Remove the support bracket from the bumper

rail.

INSTALLATION

(1) If equipped, install the bumper guard and

bumper support bracket on the bumper rail. Tighten

the retaining hardware in the sequence indicated in

Figure 7. Tighten locknuts to 20 Nzm (15 ft-lbs)

torque. Tighten bolts to 56 Nzm (41 ft-lbs) torque.

(2) If not equipped with bumper guards, install the

bumper support bracket on the bumper rail. Tighten

bolts to 56 Nzm (41 ft-lbs) torque.

(3) Position the tow hook at the support bracket.

Install the bolts and nuts that attach tow hook to the

bumper support bracket. (Fig. 4). Tighten nuts to 100

Nzm (74 ft-lbs) torque.

(4) Position and support the bumper at the front of

the vehicle.

(5) Attach the bumper support brackets to the

right and left sillmembers and reinforcement brack-

ets. Tighten screws and bolts to 56 Nzm (41 ft-lbs)

torque.

(6) If equipped, install the Torx-head bolts and

locknuts that attach the tow hook straps to the un-

derbody sillmember. Tighten locknuts to 30 Nzm (22

ft-lbs) torque.

Install the steering gear skid plate and screws

after the left tow hook strap has been installed.

(7) If equipped, connect the fog lamp wire harness

connectors. Connect the vacuum reservoir tube har-

ness connectors.

(8) Remove the bumper support.

REAR BUMPER

REMOVAL

(1) For vehicles equipped with a trailer hitch, re-

move the hitch before removing the bumper. If nec-

essary, refer to the removal procedure within Group

23ÐBody Components.

(2) Raise and support the rear of the vehicle.

(3) Support the bumper.

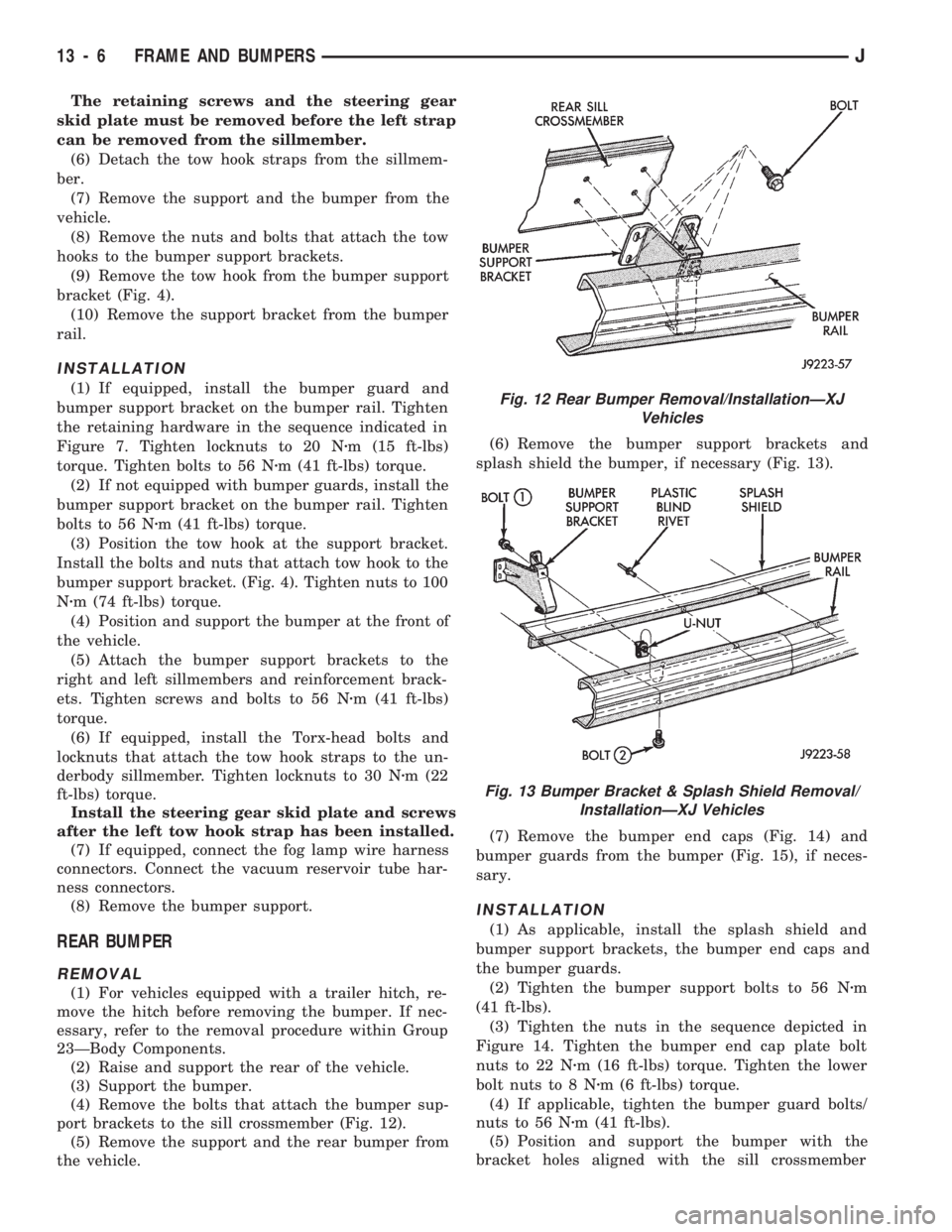

(4) Remove the bolts that attach the bumper sup-

port brackets to the sill crossmember (Fig. 12).

(5) Remove the support and the rear bumper from

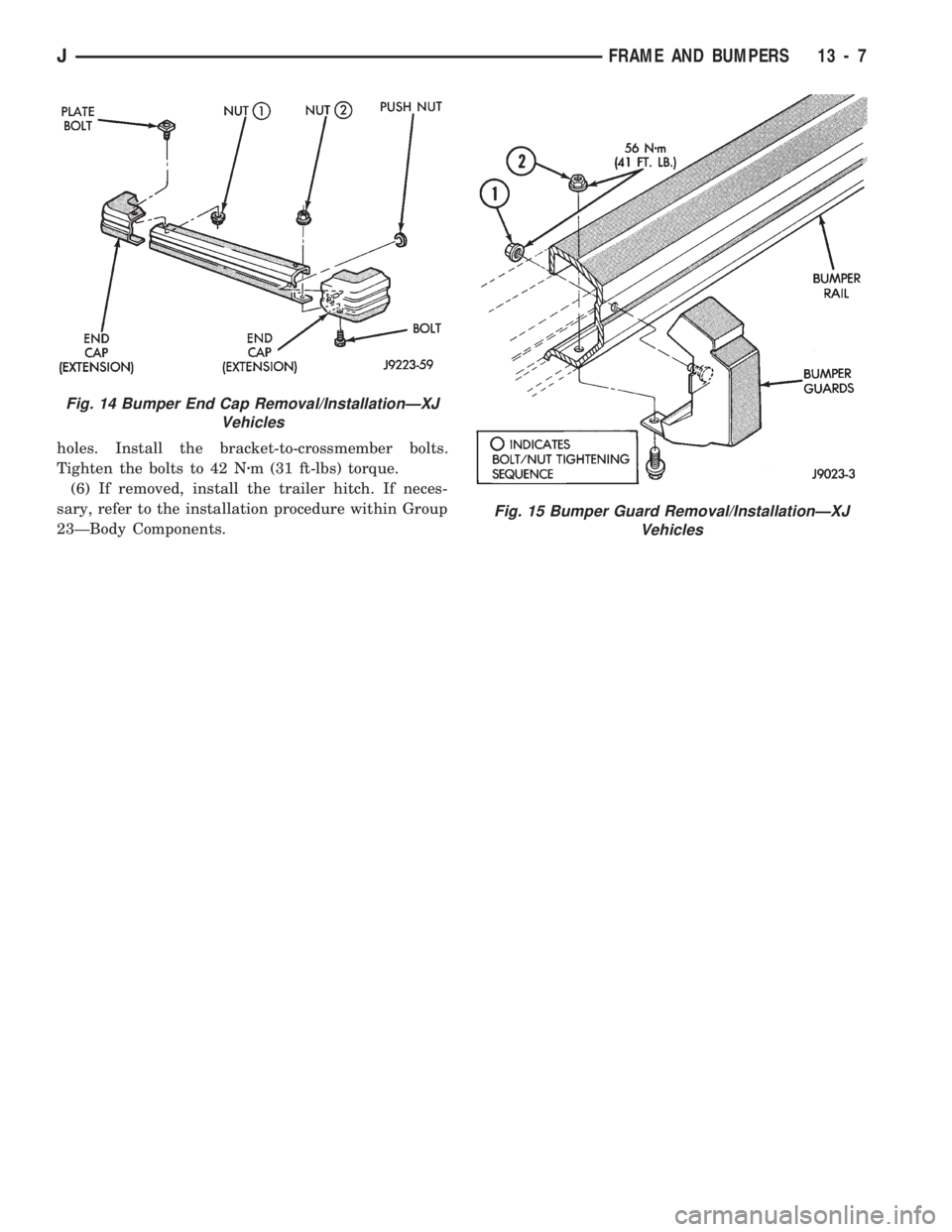

the vehicle.(6) Remove the bumper support brackets and

splash shield the bumper, if necessary (Fig. 13).

(7) Remove the bumper end caps (Fig. 14) and

bumper guards from the bumper (Fig. 15), if neces-

sary.

INSTALLATION

(1) As applicable, install the splash shield and

bumper support brackets, the bumper end caps and

the bumper guards.

(2) Tighten the bumper support bolts to 56 Nzm

(41 ft-lbs).

(3) Tighten the nuts in the sequence depicted in

Figure 14. Tighten the bumper end cap plate bolt

nuts to 22 Nzm (16 ft-lbs) torque. Tighten the lower

bolt nuts to 8 Nzm (6 ft-lbs) torque.

(4) If applicable, tighten the bumper guard bolts/

nuts to 56 Nzm (41 ft-lbs).

(5) Position and support the bumper with the

bracket holes aligned with the sill crossmember

Fig. 12 Rear Bumper Removal/InstallationÐXJ

Vehicles

Fig. 13 Bumper Bracket & Splash Shield Removal/

InstallationÐXJ Vehicles

13 - 6 FRAME AND BUMPERSJ

Page 948 of 1784

holes. Install the bracket-to-crossmember bolts.

Tighten the bolts to 42 Nzm (31 ft-lbs) torque.

(6) If removed, install the trailer hitch. If neces-

sary, refer to the installation procedure within Group

23ÐBody Components.

Fig. 14 Bumper End Cap Removal/InstallationÐXJ

Vehicles

Fig. 15 Bumper Guard Removal/InstallationÐXJ

Vehicles

JFRAME AND BUMPERS 13 - 7

Page 1539 of 1784

UNDERBODY COMPONENTS

INDEX

page page

Catalytic Converter/Muffler/Tailpipe Support

Brackets............................. 85

Front Skid Plate......................... 84

Fuel and Brake Fluid Tube Retainer Clip....... 86

Fuel Filler Hose Splash ShieldÐXJ Vehicles.... 86

Fuel Filter Bracket........................ 86Fuel Tank Skid Plate...................... 84

Fuel Tank Support Strap................... 86

Rear Tow HookÐXJ Vehicles............... 87

Service Information....................... 84

Trailer Hitches........................... 88

Transfer Case Skid Plate.................. 84

SERVICE INFORMATION

In some cases, components in the following proce-

dures either support, or are concealed by other com-

ponents. When necessary, refer to component

removal procedure for service access.

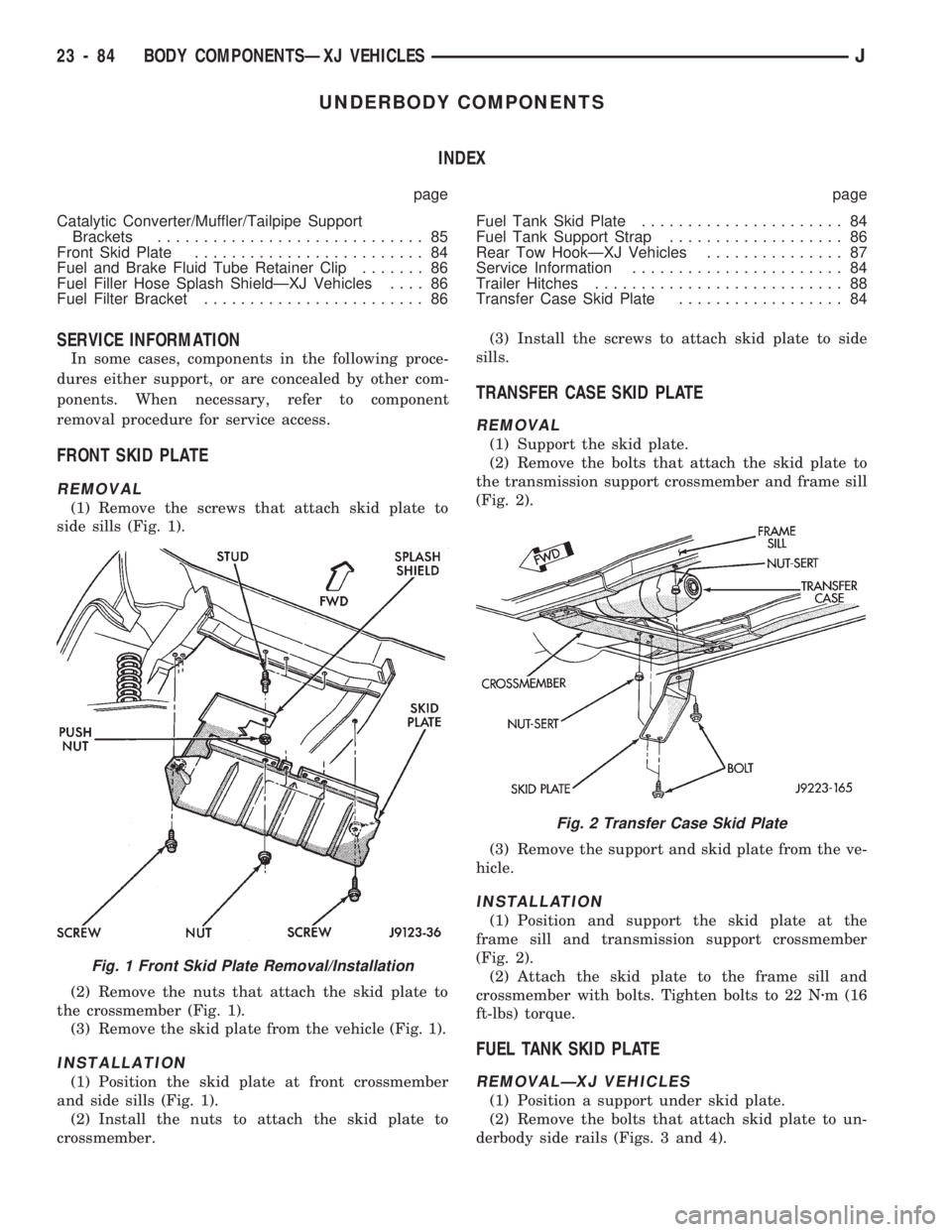

FRONT SKID PLATE

REMOVAL

(1) Remove the screws that attach skid plate to

side sills (Fig. 1).

(2) Remove the nuts that attach the skid plate to

the crossmember (Fig. 1).

(3) Remove the skid plate from the vehicle (Fig. 1).

INSTALLATION

(1) Position the skid plate at front crossmember

and side sills (Fig. 1).

(2) Install the nuts to attach the skid plate to

crossmember.(3) Install the screws to attach skid plate to side

sills.

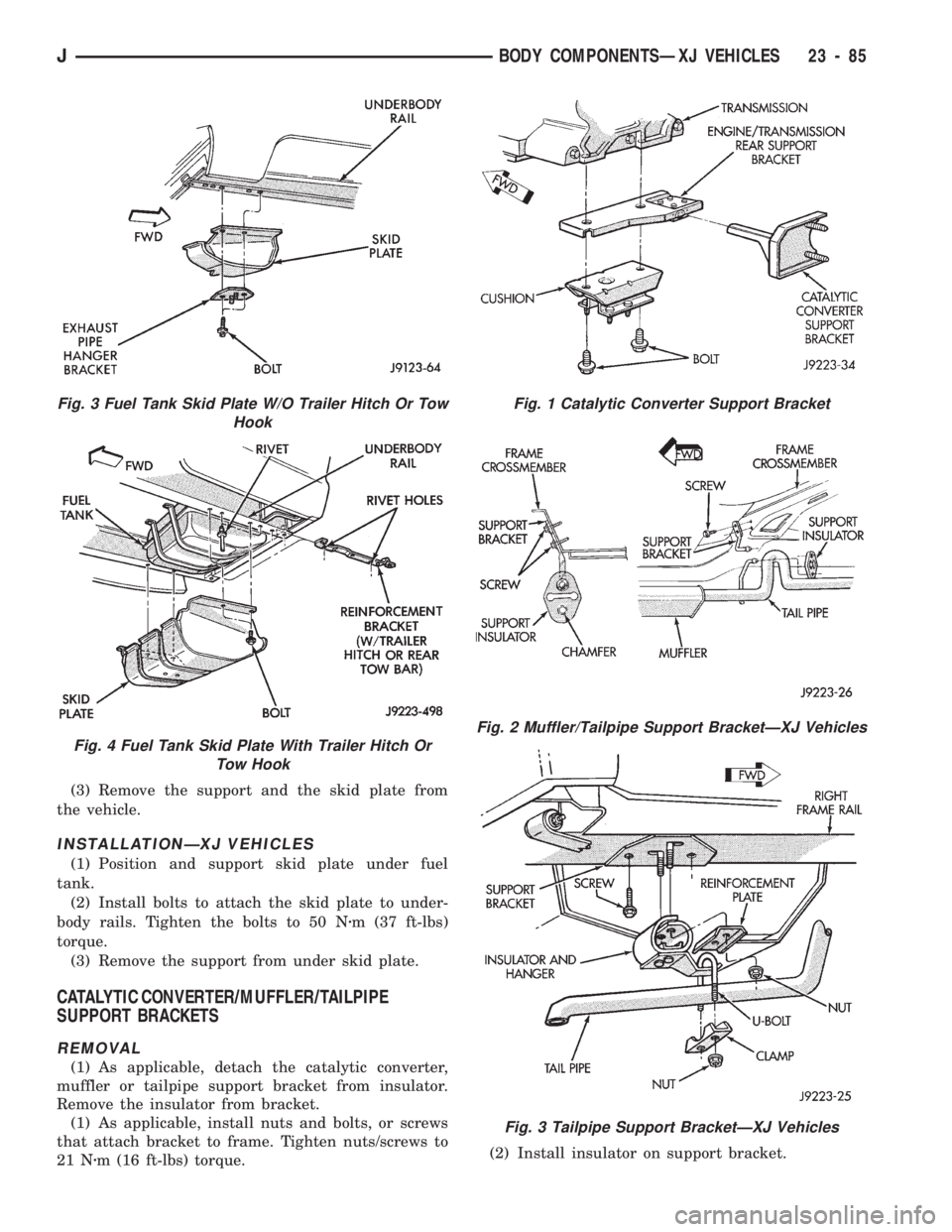

TRANSFER CASE SKID PLATE

REMOVAL

(1) Support the skid plate.

(2) Remove the bolts that attach the skid plate to

the transmission support crossmember and frame sill

(Fig. 2).

(3) Remove the support and skid plate from the ve-

hicle.

INSTALLATION

(1) Position and support the skid plate at the

frame sill and transmission support crossmember

(Fig. 2).

(2) Attach the skid plate to the frame sill and

crossmember with bolts. Tighten bolts to 22 Nzm (16

ft-lbs) torque.

FUEL TANK SKID PLATE

REMOVALÐXJ VEHICLES

(1) Position a support under skid plate.

(2) Remove the bolts that attach skid plate to un-

derbody side rails (Figs. 3 and 4).

Fig. 1 Front Skid Plate Removal/Installation

Fig. 2 Transfer Case Skid Plate

23 - 84 BODY COMPONENTSÐXJ VEHICLESJ

Page 1540 of 1784

(3) Remove the support and the skid plate from

the vehicle.

INSTALLATIONÐXJ VEHICLES

(1) Position and support skid plate under fuel

tank.

(2) Install bolts to attach the skid plate to under-

body rails. Tighten the bolts to 50 Nzm (37 ft-lbs)

torque.

(3) Remove the support from under skid plate.

CATALYTIC CONVERTER/MUFFLER/TAILPIPE

SUPPORT BRACKETS

REMOVAL

(1) As applicable, detach the catalytic converter,

muffler or tailpipe support bracket from insulator.

Remove the insulator from bracket.

(1) As applicable, install nuts and bolts, or screws

that attach bracket to frame. Tighten nuts/screws to

21 Nzm (16 ft-lbs) torque.(2) Install insulator on support bracket.

Fig. 1 Catalytic Converter Support Bracket

Fig. 2 Muffler/Tailpipe Support BracketÐXJ Vehicles

Fig. 3 Tailpipe Support BracketÐXJ Vehicles

Fig. 3 Fuel Tank Skid Plate W/O Trailer Hitch Or Tow

Hook

Fig. 4 Fuel Tank Skid Plate With Trailer Hitch Or

Tow Hook

JBODY COMPONENTSÐXJ VEHICLES 23 - 85

Page 1543 of 1784

The reinforcement bracket is held on the

frame rail with two blind rivets.

(2) Remove the bracket and tow hook from frame

rail.

INSTALLATION

(1) Position bracket and tow hook on the frame

rail.

(2) Install bolts that attach tow hook bracket to

frame rail and reinforcement bracket. Tighten bolts

to 75 Nzm (55 ft-lbs) torque.

TRAILER HITCHES

CLASS III HITCHÐXJ VEHICLES

A class III weight-distributing/equalizer type hitch

can be used to tow a trailer:

²having a maximum gross weight of 5,000 lbs/2250

kg, and

²having a maximum tongue weight of 750 lbs/332

kg).

The following vehicle basic equipment is required

for class III trailer towing:

²P205/75R15 or larger tires;

²full size spare tire;

²trailer sway control;

²trailer tow wire harness and connector;

²heavy duty turn signal flasher element;

²heavy duty axle (with synthetic lubricant);²heavy duty cooling system;

²heavy duty generator/battery;

²auxiliary automatic transmission fluid cooler; and

²I-6, 4.0L engine.

Wide-angle type door mirrors are recommended but

not required.

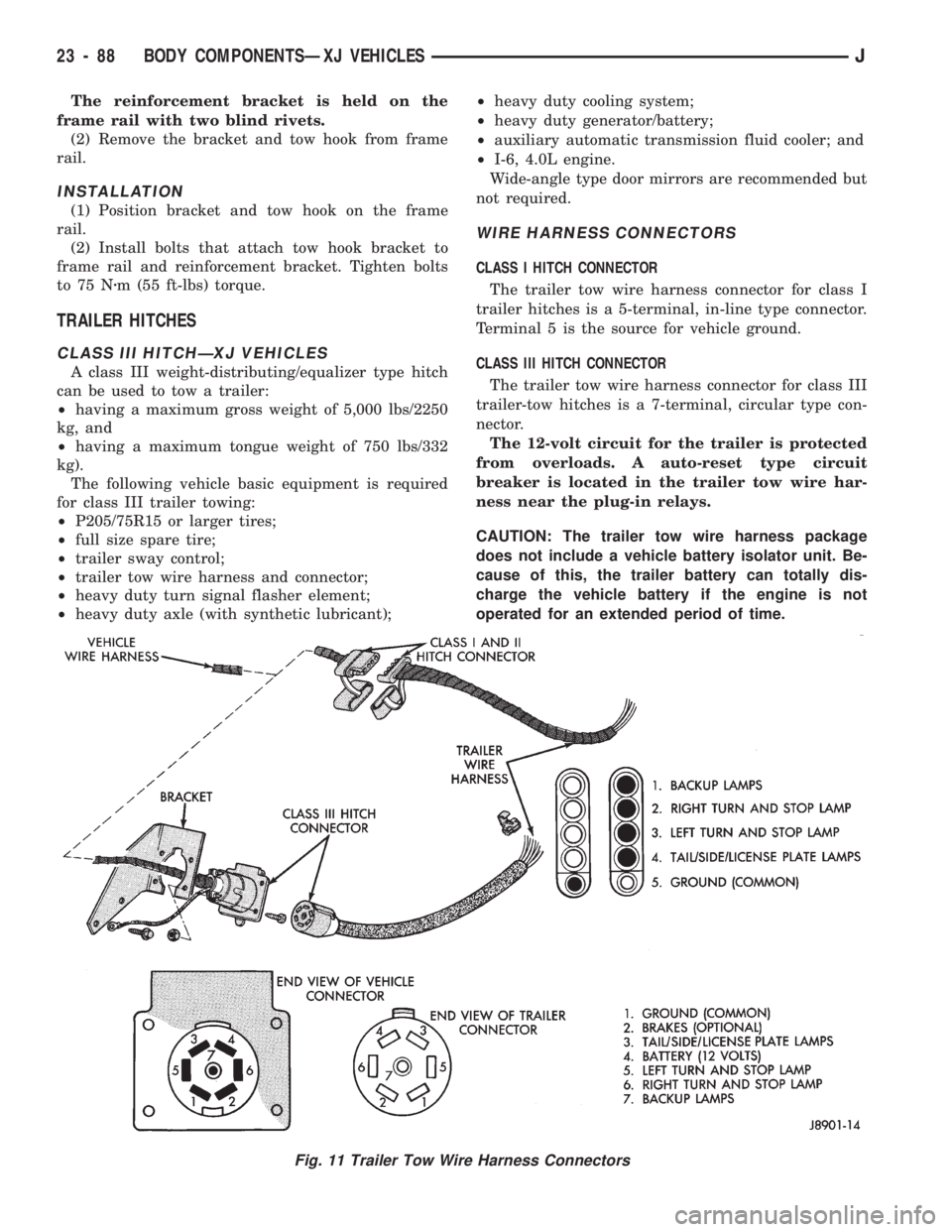

WIRE HARNESS CONNECTORS

CLASS I HITCH CONNECTOR

The trailer tow wire harness connector for class I

trailer hitches is a 5-terminal, in-line type connector.

Terminal 5 is the source for vehicle ground.

CLASS III HITCH CONNECTOR

The trailer tow wire harness connector for class III

trailer-tow hitches is a 7-terminal, circular type con-

nector.

The 12-volt circuit for the trailer is protected

from overloads. A auto-reset type circuit

breaker is located in the trailer tow wire har-

ness near the plug-in relays.

CAUTION: The trailer tow wire harness package

does not include a vehicle battery isolator unit. Be-

cause of this, the trailer battery can totally dis-

charge the vehicle battery if the engine is not

operated for an extended period of time.

Fig. 11 Trailer Tow Wire Harness Connectors

23 - 88 BODY COMPONENTSÐXJ VEHICLESJ

Page 1544 of 1784

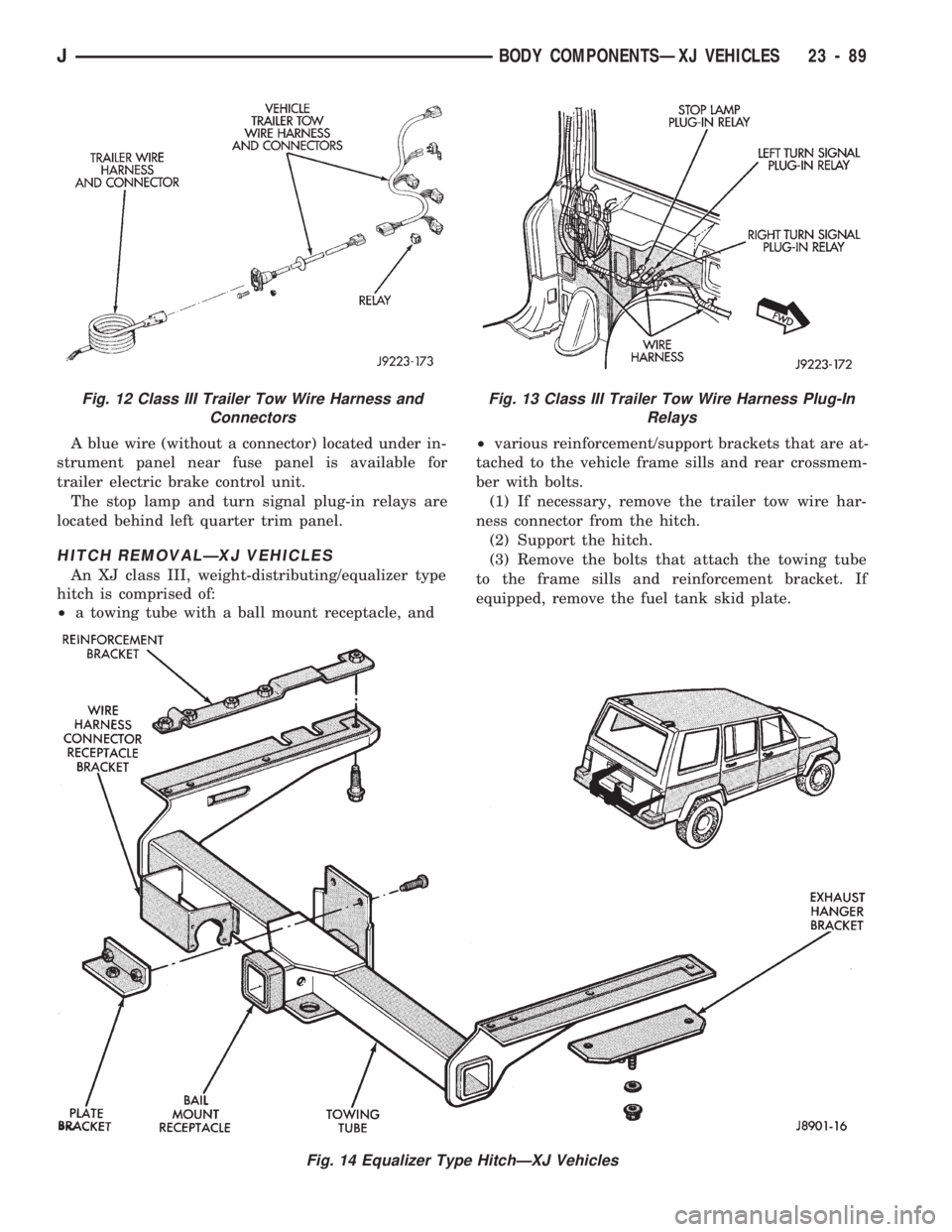

A blue wire (without a connector) located under in-

strument panel near fuse panel is available for

trailer electric brake control unit.

The stop lamp and turn signal plug-in relays are

located behind left quarter trim panel.

HITCH REMOVALÐXJ VEHICLES

An XJ class III, weight-distributing/equalizer type

hitch is comprised of:

²a towing tube with a ball mount receptacle, and²various reinforcement/support brackets that are at-

tached to the vehicle frame sills and rear crossmem-

ber with bolts.

(1) If necessary, remove the trailer tow wire har-

ness connector from the hitch.

(2) Support the hitch.

(3) Remove the bolts that attach the towing tube

to the frame sills and reinforcement bracket. If

equipped, remove the fuel tank skid plate.

Fig. 14 Equalizer Type HitchÐXJ Vehicles

Fig. 12 Class III Trailer Tow Wire Harness and

ConnectorsFig. 13 Class III Trailer Tow Wire Harness Plug-In

Relays

JBODY COMPONENTSÐXJ VEHICLES 23 - 89

Page 1545 of 1784

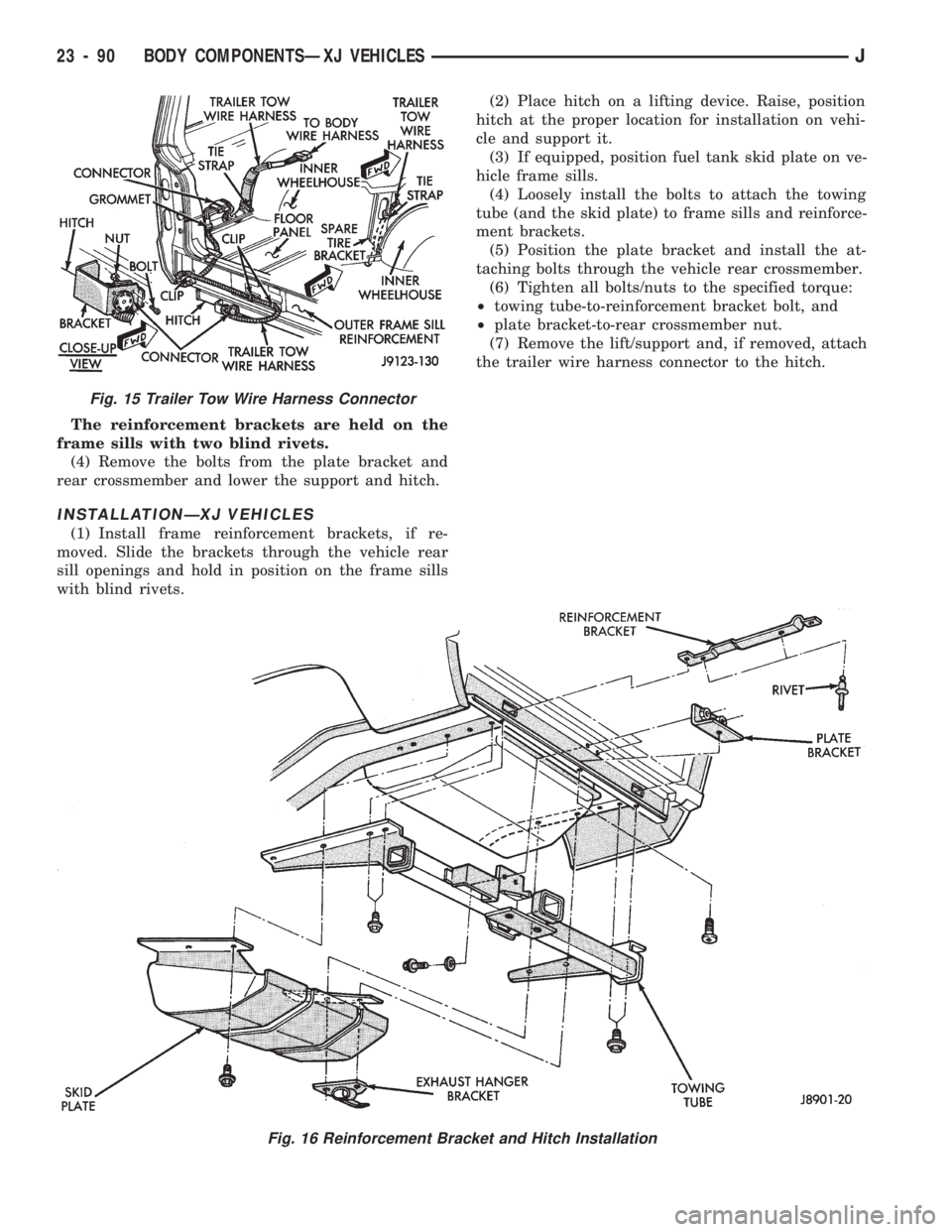

The reinforcement brackets are held on the

frame sills with two blind rivets.

(4) Remove the bolts from the plate bracket and

rear crossmember and lower the support and hitch.

INSTALLATIONÐXJ VEHICLES

(1) Install frame reinforcement brackets, if re-

moved. Slide the brackets through the vehicle rear

sill openings and hold in position on the frame sills

with blind rivets.(2) Place hitch on a lifting device. Raise, position

hitch at the proper location for installation on vehi-

cle and support it.

(3) If equipped, position fuel tank skid plate on ve-

hicle frame sills.

(4) Loosely install the bolts to attach the towing

tube (and the skid plate) to frame sills and reinforce-

ment brackets.

(5) Position the plate bracket and install the at-

taching bolts through the vehicle rear crossmember.

(6) Tighten all bolts/nuts to the specified torque:

²towing tube-to-reinforcement bracket bolt, and

²plate bracket-to-rear crossmember nut.

(7) Remove the lift/support and, if removed, attach

the trailer wire harness connector to the hitch.

Fig. 15 Trailer Tow Wire Harness Connector

Fig. 16 Reinforcement Bracket and Hitch Installation

23 - 90 BODY COMPONENTSÐXJ VEHICLESJ

Page 1755 of 1784

GRILLE OPENING PANEL (GOP), GRILLE.....23-3

GRILLEÐXJ VEHICLES, AIR EXHAUST.....23-30

GROUND, POWER.....................14-22

GROUP INDEX; ELECTRICAL..............8A-1

GUARD, BRUSH........................23-3

GUARD/EDGE PROTECTOR STRIP, DOOR

EDGE..............................23-61

GUIDES AND CHARTS, DIAGNOSIS........21-76

HALF METAL DOOR MIRROR (EXTERNAL) . . 23-158

HALF-METAL DOOR LATCH STRIKER......23-175

HALF-METAL SOFT TOP DOOR..........23-173

HAND DRIVE, BATTERY CLASSIFICATIONS

AND RATINGSÐLEFT.................8B-10

HAND DRIVE, BATTERY CLASSIFICATIONS

AND RATINGSÐRIGHT................8B-10

HAND DRIVE, BATTERY REPLACEMENTÐ

LEFT...............................8B-1

HAND DRIVE, BATTERY REPLACEMENTÐ

RIGHT..............................8B-2

HAND DRIVE, BELT SERVICEÐEXCEPT

RIGHT..............................7-34

HAND DRIVE, BELT SERVICEÐWITH

RIGHT..............................7-35

HAND DRIVE, DRIVERS DOOR POWER

LOCK SWITCHÐ2-DOOR LEFT...........8P-2

HAND DRIVE, DRIVERS DOOR POWER

LOCK SWITCHÐ2-DOOR RIGHT..........8P-3

HAND DRIVE, DRIVERS DOOR POWER

WINDOW SWITCHÐ2-DOOR LEFT........8S-6

HAND DRIVE, DRIVERS DOOR POWER

WINDOW SWITCHÐ2-DOOR RIGHT......8S-7

HAND DRIVE, GENERATOR

REPLACEMENTÐLEFT.................8B-7

HAND DRIVE, GENERATOR

REPLACEMENTÐRIGHT................8B-9

HAND DRIVE (RHD), BELT TENSIONÐ

EXCEPT RIGHT.......................7-33

HAND DRIVE (RHD), BELT TENSIONÐ

RIGHT..............................7-34

HAND DRIVE VEHICLES, RIGHT............23-1

HAND DRIVE, WASHER PUMP

REPLACEMENTÐLEFT.................8K-2

HAND DRIVE, WASHER PUMP

REPLACEMENTÐRIGHT................8K-3

HANDLE, DOOR EXTERNAL..............23-55

HANDLE, FULL-METAL DOOR ASSIST.....23-175

HANDLE, FULL-METAL DOOR LATCH

EXTERNAL RELEASE.................23-178

HANDLE, FULL-METAL DOOR LATCH

INSIDE RELEASE AND LOCK...........23-175

HANDLE, FULL-METAL DOOR WINDOW

GLASS REGULATOR.................23-175

HANDLE, TAILGATE LATCH AND

RELEASE..........................23-160

HANDLEÐXJ VEHICLES, ASSIST.........23-118

HANGER BRACKET, MUFFLER/TAILPIPE.....13-16

HARD TOP DOME/CARGO LAMP BULB

REPLACEMENTÐYJ VEHICLES..........8L-20

HARD TOP LIFTGATE GLASS............23-162

HARD TOP QUARTER WINDOW GLASS....23-188

HARD TOP REPAIR....................23-165

HARD TOP ROOF VENT................23-165

HARD TOP SERVICE...................23-164

HARD TOP SERVICE INFORMATION.......23-164

HAZARD LAMPSÐXJ....................8J-1

HAZARD LAMPSÐYJ....................8J-2

HCU DIAGNOSIS........................5-4

HCU INSTALLATIONÐXJ.................5-54

HCU INSTALLATIONÐYJ.................5-54

HCU PUMP AND PEDAL TRAVEL

SENSOR OPERATION...................5-44

HCU REMOVALÐXJ.....................5-53

HCU REMOVALÐYJ.....................5-54

HCU SOLENOID VALVE OPERATION.........5-43

HEAD COVER, ENGINE CYLINDER......9-18,9-59

HEAD, ENGINE CYLINDER............9-19,9-60

HEAD GASKET FAILURE DIAGNOSIS,

ENGINE CYLINDER.....................9-5

HEADLAMP BEAM ADJUSTMENT...........8L-3

HEADLAMP BULB REPLACEMENT

..........8L-3

HEADLAMP DELAY FUNCTION TROUBLE

DIAGNOSISÐXJ VEHICLES

.............8L-16

HEADLAMP DELAY MODULE

REPLACEMENTÐXJ VEHICLES

..........8L-16

HEADLAMP DELAY MODULEÐXJ

VEHICLES, SENTINEL

.................8L-15HEADLAMP DIMMER SWITCH

REPLACEMENT.......................8L-6

HEADLAMP SWITCH REPLACEMENT........8L-4

HEADLAMP SWITCH/ILLUMINATION

RHEOSTAT..........................8E-21

HEADLAMP TROUBLE DIAGNOSISÐ

XJ VEHICLES.........................8L-1

HEADLAMP TROUBLE DIAGNOSISÐYJ

VEHICLES...........................8L-2

HEADLAMPS...........................0-35

HEADLINER.........................23-121

HEAT SHIELDS........................14-12

HEAT SHIELDS, EXHAUST................11-1

HEAT SHIELDS, MUFFLER AND TAILPIPE . . . 13-17

HEATER AND A/C CONTROL PANEL

REPLACEMENT......................24-26

HEATER CONTROL CABLE REPLACEMENT . . . 24-30

HEATER CONTROL PANEL REPLACEMENT . . . 24-39

HEATER CORE........................24-28

HEATER CORE AND HOUSING............24-40

HEATER CORE HOUSING REPLACEMENT . . . 24-29

HEATER, ENGINE BLOCK.................7-37

HEATER/DEFROSTER OPERATION.........24-37

HEATER/DEFROSTER/INSTRUMENT

PANEL OUTLET DOOR VACUUM MOTOR

REPLACEMENT......................24-30

HEATING ELEMENT TEST, OXYGEN

SENSOR (O2S)......................14-45

HEATING SCHEMATIC...................24-24

HEATING SYSTEM DIAGNOSIS............24-11

HEATING SYSTEMÐYJ VEHICLES.........24-14

HIGH LINE CLUSTER...................8E-12

HIGH MOUNTED STOP LAMP (CHMSL)Ð

XJ, CENTER.........................8L-10

HIGH MOUNTED STOP LAMP (CHMSL)Ð

YJ, CENTER.........................8L-11

HINGE, LIFTGATE......................23-67

HINGE REPLACEMENT, HOOD.............23-9

HINGE, TAILGATE.....................23-159

HINGE/HINGE PIN REPLACEMENT, DOOR . . . 23-58

HINGES, FULL-METAL DOOR............23-179

HITCHES, TRAILER.....................23-88

HOISTING AND TOWING, JUMP

STARTING,............................0-7

HOLDDOWN AND FLOOR BRACKETSÐ

XJ VEHICLES, SPARE TIRE/WHEEL......23-128

HONING CYLINDER BORES................9-2

HOOD..........................23-6,23-137

HOOD ADJUSTMENT....................23-9

HOOD ALIGNMENT....................23-138

HOOD HINGE REPLACEMENT..............23-9

HOOD INSULATOR PANEL..............23-138

HOOD LATCH REPLACEMENT............23-10

HOOD LATCH STRIKER REPLACEMENT.....23-10

HOOD SAFETY LATCH.................23-139

HOOKÐXJ VEHICLES, REAR TOW.........23-87

HOOKS, FRONT TOW....................13-5

HOOKS, TOW.........................13-14

HORN PAD REPLACEMENT, HORN SWITCH . . . 8G-3

HORN SWITCH (HORN PAD)

REPLACEMENT.......................8G-3

HOSE REPLACEMENT, PRESSURE AND

RETURN............................19-9

HOSE ROUTING SCHEMATICS,

VACUUM............................25-1

HOSE SPLASH SHIELDÐXJ VEHICLES,

FUEL FILLER........................23-86

HOSES, BRAKE BLEEDINGÐBRAKE FLUID

AND LEVELÐBRAKELINES..............5-13

HOSES, BRAKELINES....................5-15

HOSES, COOLING SYSTEM...............7-26

HOSES/TUBING, RUBBER AND PLASTIC.....0-28

HOUSING, AIR CLEANER; EMISSION

CONTROL SYSTEMS...................25-8

HOUSING, AIR CLEANER; FUEL SYSTEM....14-54

HOUSING AND PARK LOCK COMPONENT

OVERHAUL, ADAPTER................21-120

HOUSING END PLUG...................19-26

HOUSING, EVAPORATOR................24-42

HOUSING, EVAPORATOR/BLOWER.........24-33

HOUSING, HEATER CORE................24-40

HOUSING LEAK DIAGNOSIS, CONVERTER

. . . 21-73

HOUSING, LIFTGATE LICENSE PLATE

LAMP

..............................23-72

HOUSING REPLACEMENT, CLUTCH

.........6-11

HOUSING REPLACEMENT, HEATER CORE

. . . 24-29HOUSING SEAL REPLACEMENT,

ADAPTER..........................21-182

HOUSINGS, INSTRUMENT CLUSTER

AND GAUGE........................23-190

HUB BEARING AND AXLE SHAFT...........2-24

HYDRAULIC CLUTCH....................0-22

HYDRAULIC COMPONENTS................5-1

HYDRAULIC CONTROL UNIT (HCU).........5-39

HYDRAULIC FLOW DURING FULL

THROTTLE 3-2 DOWNSHIFT............21-92

HYDRAULIC FLOW DURING PART

THROTTLE 3-2 DOWNSHIFT............21-91

HYDRAULIC FLOW IN D RANGE FIRST

GEAR..............................21-87

HYDRAULIC FLOW IN D RANGE SECOND

GEAR..............................21-88

HYDRAULIC FLOW IN D RANGE THIRD

GEAR..............................21-89

HYDRAULIC FLOW IN MANUAL FIRST

GEAR (1) POSITION..................21-94

HYDRAULIC FLOW IN MANUAL SECOND

(2) RANGE..........................21-93

HYDRAULIC FLOW IN PARK AND NEUTRAL . . . 21-86

HYDRAULIC FLOW IN REVERSE..........21-95

HYDRAULIC FLOW IN THIRD GEAR

(CONVERTER CLUTCH ENGAGED)........21-90

HYDRAULIC LINKAGE INSTALLATION,

CLUTCH.............................6-12

HYDRAULIC LINKAGE REMOVAL,

CLUTCH.............................6-11

HYDRAULIC PRESSURE TEST......21-71,21-168

HYDRAULIC SYSTEM..................21-160

HYDRAULIC TAPPETS...............9-24,9-65

HYDROMETER TEST....................8A-3

IDENTIFICATION, AW-4 VALVE AND

SPRING...........................21-330

IDENTIFICATION, CIRCUIT................8W-2

IDENTIFICATION, COMPONENT............8W-2

IDENTIFICATION, ENGINE AND

TRANSMISSION/TRANSFER CASE.....INTRO.-3

IDENTIFICATION, MAJOR COMPONENT . . INTRO.-3

IDENTIFICATION NUMBER (VIN)

DECODING, VEHICLE...............INTRO.-2

IDENTIFICATION NUMBER (VIN) PLATE,

VEHICLE.........................INTRO.-1

IDENTIFICATION, TRANSFER CASE

. 21-273,21-293

IDENTIFICATION, TRANSMISSION

.....21-1,21-32,

21-66,21-157

IDENTIFICATION, WIRE CODE

.............8W-2

IDENTIFICATION, WIRING AND

COMPONENT

.......................8W-13

IDLE AIR CONTROL (IAC) MOTOR

.........14-56

IDLE AIR CONTROL (IAC) MOTORÐPCM

OUTPUT

............................14-25

IDLE AIR CONTROL MOTOR TEST

.........14-46

IDLE SWITCHÐPCM INPUT, EXTENDED

....14-21

IDLE SWITCH TEST, EXTENDED

...........14-45

IGNITION CABLES, DISTRIBUTOR CAP

AND ROTOR

.........................0-18

IGNITION CIRCUIT SENSEÐPCM INPUT

....14-21

IGNITION COIL; FUEL SYSTEM

...........14-57

IGNITION COIL; IGNITION SYSTEMS

. . 8D-4,8D-11,

8D-26

IGNITION COILÐPCM OUTPUT

...........14-26

IGNITION COIL RESISTANCE

.............8D-11

IGNITION KEY WARNING SWITCH

REPLACEMENT

.......................8U-4

IGNITION OFF DRAW (IOD) DIAGNOSIS

.....8A-8

IGNITION SECONDARY CIRCUIT

DIAGNOSIS

.........................8D-12

IGNITION SWITCH; BRAKES

...............5-42

IGNITION SWITCH CONTINUITY TESTS

.....8D-31

IGNITION SWITCH; IGNITION SYSTEMS

....8D-30

IGNITION SWITCH INSTALLATION/

ADJUSTMENT

.......................8D-31

IGNITION SWITCH REMOVAL

............8D-30

IGNITION SWITCH TESTING

.............8D-30

IGNITION TIMING

......................8D-14

IGNITION WIRING, SECONDARY

...........8W-1

ILLUMINATED ENTRY SYSTEM SERVICE

INFORMATION

.......................8L-20

ILLUMINATED ENTRY SYSTEM TROUBLE

DIAGNOSIS

....................8L-21,8L-22

JINDEX11

Description Group-Page Description Group-Page Description Group-Page

Page 1768 of 1784

TRAILER HITCHES.....................23-88

TRANSFER CASE...........0-25,21-292,21-319...........

TRANSFER CASE ASSEMBLY......21-282,21-306

TRANSFER CASE DISASSEMBLY AND

OVERHAUL..................21-277,21-297

TRANSFER CASE FILL LEVEL............21-294

TRANSFER CASE IDENTIFICATION . . 21-273,21-293

TRANSFER CASE INSTALLATION . . . 21-276,21-296

TRANSFER CASE LUBRICANT.....21-273,21-294

TRANSFER CASE, NP231.........21-272,21-291

TRANSFER CASE, NP242...............21-293

TRANSFER CASE REMOVAL.......21-276,21-296

TRANSFER CASE SKID PLATE; BODY

COMPONENTSÐXJ VEHICLES.....13-15,23-84

TRANSMISSION, 30RH/32RH AUTOMATIC . . . 21-66

TRANSMISSION AND CONVERTER

INSTALLATION......................21-109

TRANSMISSION AND CONVERTER

REMOVAL.........................21-108

TRANSMISSION AND TORQUE

CONVERTER INSTALLATION...........21-190

TRANSMISSION AND TORQUE

CONVERTER REMOVAL...............21-189

TRANSMISSION APPLICATION............21-66

TRANSMISSION ASSEMBLY AND

ADJUSTMENT............21-15,21-51,21-255

TRANSMISSION ASSEMBLY AND

ADJUSTMENT PROCEDURES..........21-146

TRANSMISSION ASSEMBLY TIPS........21-146

TRANSMISSION, AUTOMATIC.............0-23

TRANSMISSION, AW-4 AUTOMATIC.......21-156

TRANSMISSION, AX 15 MANUAL.........21-32

TRANSMISSION, AX 4/5 MANUAL..........21-1

TRANSMISSION CASE CLEANING AND

INSPECTION.......................21-118

TRANSMISSION CASE OVERHAUL, FIRST-

REVERSE BRAKE PISTON.............21-237

TRANSMISSION CONTROL MODULE

(TCM) SERVICE.....................21-173

TRANSMISSION CONTROLS

AND COMPONENTS...................21-66

TRANSMISSION COOLER FLOW TESTING . . 21-106

TRANSMISSION COOLER LINE FITTINGS . . 21-187

TRANSMISSION COOLER LINES AND

FITTINGS, SERVICING................21-106

TRANSMISSION COOLER REVERSE

FLUSHING.........................21-105

TRANSMISSION COOLER SERVICE.......21-187

TRANSMISSION DIAGNOSIS, 30RH/32RH . . 21-69,

21-77,21-77,21-79,21-80,21-81,21-82,21-83,21-84,

21-85

TRANSMISSION DIAGNOSIS, AW-4.......21-167

TRANSMISSION DISASSEMBLY....21-112,21-192

TRANSMISSION DISASSEMBLY AND

OVERHAUL.....................21-5,21-36

TRANSMISSION GEAR RATIOS...........21-33

TRANSMISSION IDENTIFICATION.....21-1,21-32,

21-66,21-157

TRANSMISSION INSTALLATION............21-4

TRANSMISSION INSTALLATIONÐAX 15....21-35

TRANSMISSION LUBRICANT.............21-33

TRANSMISSION OIL COOLERS............7-29

TRANSMISSION OVERHAUL, 30RH/32RH . . 21-112

TRANSMISSION OVERHAUL, AW-4.......21-192

TRANSMISSION RANGES AND SHIFT

LEVER POSITIONS

...................21-157

TRANSMISSION REMOVALÐAX 4/5

........21-3

TRANSMISSION REMOVAL AND

INSTALLATION, 30RH/32RH

...........21-108

TRANSMISSION REMOVAL AND

INSTALLATION, AW-4

................21-189

TRANSMISSION REMOVALÐAX 15

........21-34

TRANSMISSION, SELECTIVE SNAP RING

CHARTÐAX 15 MANUAL

.............21-321

TRANSMISSION SHIFT PATTERNÐAX 15

. . . 21-33

TRANSMISSION SWITCH AND PLUG

LOCATIONS

.........................21-33

TRANSMISSION THROTTLE CABLE

ADJUSTMENT

......................21-185

TRANSMISSION THROTTLE CABLE

ADJUSTMENT

.......................21-98

TRANSMISSION THROTTLE CABLE

REPLACEMENT

.....................21-184

TRANSMISSION THROTTLE VALVE CABLE

ADJUSTMENT

.......................21-70TRANSMISSION, TORQUE

SPECIFICATIONSÐ AX 15 MANUAL.....21-320

TRANSMISSION VALVE BODY

INSTALLATION......................21-177

TRANSMISSION VALVE BODY OVERHAUL . . 21-240

TRANSMISSION VALVE BODY REMOVAL . . . 21-176

TRANSMISSION VALVE BODY

SOLENOIDS........................21-175

TRANSMISSION/TRANSFER CASE

IDENTIFICATION, ENGINE............INTRO.-3

TRANSMISSION/TRANSFER CASE

SPECIFICATIONS....................21-320

TRANSMITÐPCM OUTPUT, SCI...........14-26

TRANSMITTER.........................8P-8

TRANSMITTER PROGRAMMING...........8P-9

TRANSMITTER SERVICE.................8P-9

TRAVEL SENSOR OPERATION, HCU

PUMP AND PEDAL....................5-44

TRAVEL SENSOR, PEDAL.................5-41

TRAVEL SENSOR SERVICE, PEDAL.........5-51

TRAY, BATTERY.................23-13,23-140

TRAY LAMP, I/P ASH RECEIVER..........23-92

TREAD WEAR INDICATORS...............22-3

TRIM COVERSÐXJ VEHICLES, B/C-

PILLAR AND LIFTGATE PILLAR.........23-116

TRIM PANEL, DOOR....................23-35

TRIM PANEL EXTENSIONÐXJ VEHICLES,

QUARTER.........................23-115

TRIM PANEL, FULL-METAL DOOR........23-175

TRIM PANEL, LIFTGATE.................23-66

TRIM PANELÐXJ VEHICLES, FRONT

INNER SCUFF PLATE/COWL SIDE.......23-114

TRIM PANELS AND SCUFF PLATESÐXJ

VEHICLES, INTERIOR................23-112

TRIM PANELSÐXJ VEHICLES, QUARTER

AND WHEELHOUSE..................23-115

TROUBLE CODE, CHECKING FOR

DIAGNOSTIC.........................8H-5

TROUBLE CODE (DTC), DIAGNOSTIC.......14-51

TROUBLE CODE (DTC), GENERATOR

DIAGNOSTIC........................8A-19

TROUBLE CODES, INDICATOR (CHECK

ENGINE) LAMP FOR DIAGNOSTIC.......8A-19

TROUBLE DIAGNOSIS, DOME/COURTESY

LAMP..............................8L-19

TROUBLE DIAGNOSIS, FOG LAMP.........8L-12

TROUBLE DIAGNOSIS, ILLUMINATED

ENTRY SYSTEM; LAMPS..........8L-21,8L-22

TROUBLE DIAGNOSIS, LIGHTED VANITY

MIRROR...........................8L-19

TROUBLE DIAGNOSISÐHEADLAMP....8L-1,8L-2

TROUBLE DIAGNOSISÐXJ VEHICLES,

HEADLAMP DELAY FUNCTION..........8L-16

TROUBLESHOOTING WIRING PROBLEMS . . . 8W-3

TUBE AXLE (2WD), MODEL 30 AXLE........2-20

TUBE CAP, FUEL TANK FILLER;

EMISSION CONTROL SYSTEMS......25-4,25-9

TUBE CAP, FUEL TANK FILLER; FUEL

SYSTEM............................14-12

TUBE, NO-LEAD FUEL TANK FILLER.......14-12

TUBE RETAINER CLIP, FUEL AND BRAKE

FLUID; BODY COMPONENTSÐXJ VEHICLES . 23-86

TUBE RETAINER CLIP, FUEL AND BRAKE

FLUID; FRAME AND BUMPERS..........13-16

TUBES/LINES/HOSES AND CLAMPS,

FUEL..........................14-9,14-56

TURN/HAZARD SWITCH REPLACEMENT -

ALL MODELS.........................8J-3

TURN SIGNAL LEVER TEST, SPEED

CONTROL SWITCH....................8H-7

TURN SIGNALSÐXJ.....................8J-1

TURN SIGNALSÐYJ.....................8J-2

TURN SIGNAL/TAIL LAMP BULB

REPLACEMENT, BACK-UP/REAR..........8L-9

TWEETER SPEAKER/COURTESY LAMP

SUPPORT BRACKET, I/P...............23-95

U-JOINT, AXLE SHAFTÐCARDAN..........2-25

U-JOINTS, PROPELLER SHAFTS..........16-14

UNBALANCE...........................16-3

UNDERBODY COMPONENTS.............23-84

UNDERCOAT, BODY...................23-203

UNDERHOOD LAMP BULB REPLACEMENT

. . . 8L-18

UNDERHOOD LAMP REPLACEMENT

.......8L-18

UNDERHOOD LAMP SERVICE

INFORMATION

.......................8L-17

UNIBODY CONSTRUCTION, XJ

.............13-1UNIT (ECU), ELECTRONIC CONTROL........5-41

UNIT, FUEL GAUGE SENDING.............14-15

UNIT (HCU), HYDRAULIC CONTROL........5-39

UNIVERSAL JOINT ANGLE

MEASUREMENT.......................16-4

UNIVERSAL JOINT REPLACEMENT.........16-9

UNIVERSAL JOINTS.....................16-2

UPPER SUSPENSION ARM...............2-11

UPSHIFT INDICATOR INOPERATIVE.........8E-4

UPSHIFT INDICATOR LAMP; INSTRUMENT

PANELAND GAUGESÐXJ...............8E-2

UPSHIFT INDICATOR LAMP; INSTRUMENT

PANELAND GAUGESÐYJ..............8E-16

USAGE STATEMENT, FUEL................14-1

USAGE STATEMENTÐGAS ENGINES, FUEL . . . 0-17

USING ON-BOARD DIAGNOSTIC SYSTEM . . . 8A-19

VACUUM DISCONNECT AXLE Ð YJ

VEHICLES...........................2-26

VACUUM HOSE ROUTING SCHEMATICS......25-1

VACUUM MOTOR, FRESH AIR DOOR.......24-41

VACUUM MOTOR REPLACEMENT, A/C

RECIRCULATING AIR DOOR............24-31

VACUUM MOTOR REPLACEMENT,

HEATER/DEFROSTER/INSTRUMENT

PANEL OUTLET DOOR.................24-30

VACUUM ROUTING SCHEMATICÐ2.5L 4

CYLINDER ENGINE....................25-2

VACUUM ROUTING SCHEMATICÐ4.0L 6

CYLINDER ENGINE....................25-3

VACUUM SUPPLY TEST..................8H-7

VACUUM TEST, POWER BOOSTER..........5-12

VALUES, CONVERSION FORMULAS AND

EQUIVALENT.....................INTRO.-8

VALUES, GAUGE CALIBRATION...........8E-22

VALUES, STANDARD TORQUE.........INTRO.-9

VALVE AND SPRING IDENTIFICATION, AW-

4 ................................21-330

VALVE BODY ASSEMBLY AND

ADJUSTMENT......................21-144

VALVE BODY CHECK BALL DIMENSIONS,

AW-4 .............................21-328

VALVE BODY DISASSEMBLY AND

INSPECTION.......................21-138

VALVE BODY INSTALLATION............21-101

VALVE BODY INSTALLATION,

TRANSMISSION.....................21-177

VALVE BODY OVERHAUL, TRANSMISSION . . 21-240

VALVE BODY REMOVAL................21-100

VALVE BODY REMOVAL, TRANSMISSION . . 21-176

VALVE BODY SERVICE.................21-100

VALVE BODY SOLENOIDS,

TRANSMISSION.....................21-175

VALVE CABLE ADJUSTMENT,

TRANSMISSION THROTTLE............21-70

VALVE, COMBINATION; BRAKES.......5-15,5-42

VALVE, EXPANSION (H); HEATING AND

AIR CONDITIONING..............24-35,24-43

VALVE FITTING O-RING SEAL, FLOW

CONTROL..........................19-12

VALVE, FUEL TANK PRESSURE

RELIEF/ROLLOVER..............14-15,14-56

VALVE OPERATION, HCU SOLENOID........5-43

VALVE PLATEÐLEAK TESTS, COMPRESSOR . . 24-8

VALVE, PRESSURE RELIEF/ROLLOVER;

EMISSION CONTROL SYSTEMS......25-5,25-9

VALVE REPLACEMENT..................19-28

VALVE REPLACEMENT, CHECK............19-33

VALVE REPLACEMENTÐXJ, COMBINATION . . . 5-55

VALVE REPLACEMENTÐYJ, COMBINATION . . . 5-55

VALVE SHAFT OVERHAUL, MANUAL......21-205

VALVE SHAFT SEAL REPLACEMENT,

MANUAL..........................21-178

VALVE SPRINGS AND OIL SEALS......9-21,9-62

VALVE SPRINGS, VALVES............9-22,9-63

VALVE TEST, POWER BOOSTER CHECK......5-11

VALVE TIMING.....................9-26,9-66

VALVES AND VALVE SPRINGS.........9-22,9-63

VALVES, SERVICE.......................24-3

VANITY MIRROR, LIGHTED

..............8L-19

VANITY MIRROR TROUBLE DIAGNOSIS,

LIGHTED

...........................8L-19

VARIANCE, PINION GEAR DEPTH;

FRONT SUSPENSION AND AXLE

..........2-38

VARIANCE, PINION GEAR DEPTH; REAR

SUSPENSION AND AXLES

...........3-20,3-38

24 INDEXJ

Description Group-Page Description Group-Page Description Group-Page