mirror JEEP CHEROKEE 1994 Service Owner's Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1994, Model line: CHEROKEE, Model: JEEP CHEROKEE 1994Pages: 1784, PDF Size: 77.09 MB

Page 1530 of 1784

INTERIOR REARVIEW MIRROR SUPPORT

BRACKET REPLACEMENT

PREPARATION

(1) Mark reference lines for the mirror support

bracket on the outside of windshield glass with a wax

pencil.

(2) If the vinyl pad remained on the windshield

glass, soften and remove it with a heat gun.

(3) Clean the support bracket surface area on the

glass. Use a mild abrasive cleaning powder on a cloth

saturated with isopropyl (rubbing) alcohol.

(4) Lightly sand the contact surface on the support

bracket with fine grit sandpaper. Wipe bracket con-

tact surface clean with a paper towel and alcohol.

INSTALLATION

(1) Apply adhesive to the act surface on the sup-

port bracket according as follows:

²crush the vial in the plastic housing of the accel-

erator to saturate the felt applicator;

²remove the paper sleeve;

²apply a generous amount of accelerator to the con-

tact surface on the mirror support bracket;

²do not touch the support bracket contact surface

after the accelerator has been applied.

²allow the accelerator to dry for at least five min-

utes; and

(2) Apply accelerator to the support bracket con-

tact surface on the windshield glass. Allow the accel-

erator to dry for one minute.

(3) Install the mirror bracket on the windshield

glass follows:

²apply one drop of adhesive at the center of support

bracket contact surface on windshield glass;

²immediately apply an even coat of adhesive to the

contact surface on the support bracket;

²align the support bracket with the position refer-

ence lines on the windshield glass, then

²press and hold the support bracket in-place for at

least one minute.

Ensure that the mirror support bracket is

correctly aligned because the adhesive will

cure rapidly.

(4) Allow the adhesive to cure for 8-10 minutes,

then remove any residue adhesive with an alcohol-

dampened cloth.

(5) Allow the adhesive to cure for an additional

8-10 minutes before installing the mirror base on the

support bracket.

WINDSHIELD SERVICE INFORMATION

URETHANE ADHESIVE BONDING

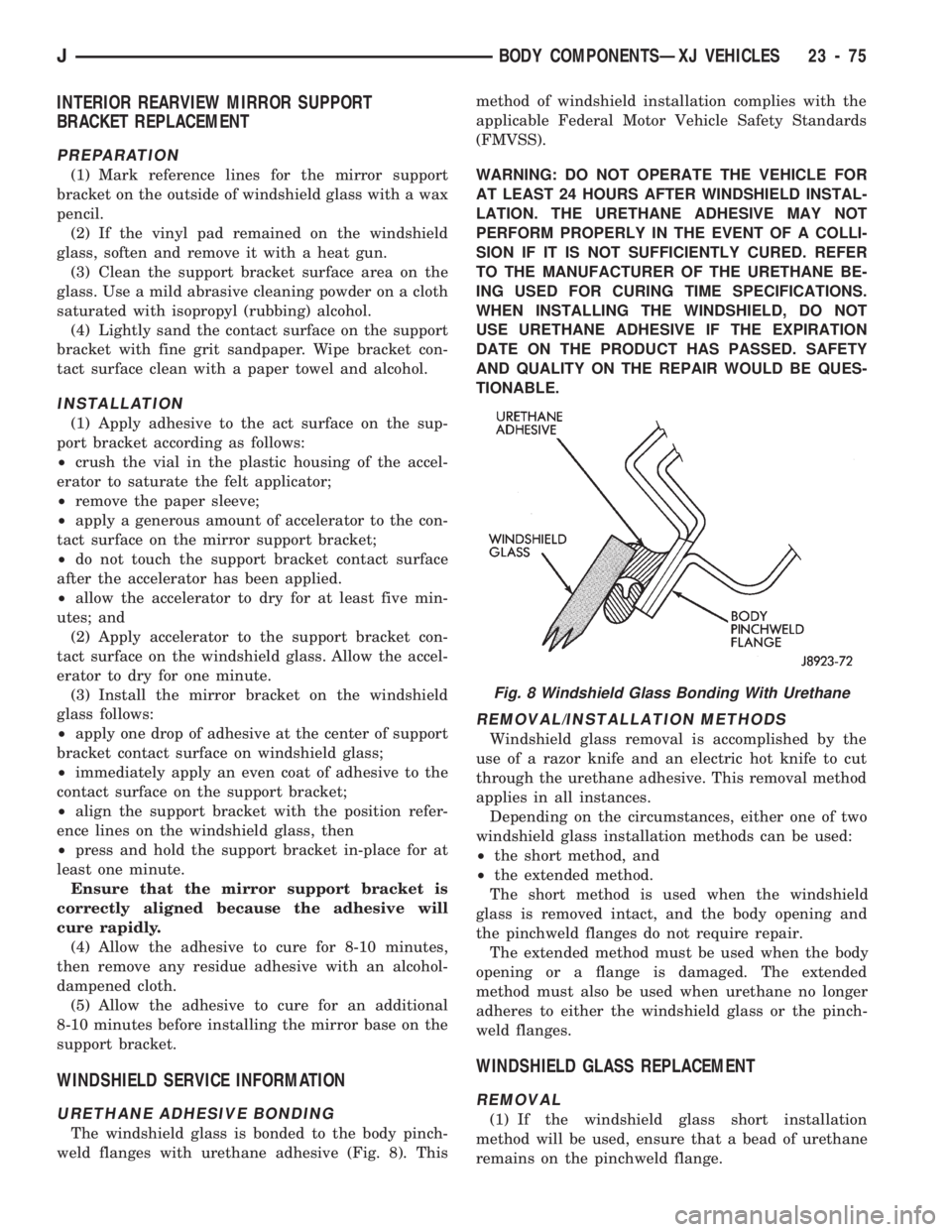

The windshield glass is bonded to the body pinch-

weld flanges with urethane adhesive (Fig. 8). Thismethod of windshield installation complies with the

applicable Federal Motor Vehicle Safety Standards

(FMVSS).

WARNING: DO NOT OPERATE THE VEHICLE FOR

AT LEAST 24 HOURS AFTER WINDSHIELD INSTAL-

LATION. THE URETHANE ADHESIVE MAY NOT

PERFORM PROPERLY IN THE EVENT OF A COLLI-

SION IF IT IS NOT SUFFICIENTLY CURED. REFER

TO THE MANUFACTURER OF THE URETHANE BE-

ING USED FOR CURING TIME SPECIFICATIONS.

WHEN INSTALLING THE WINDSHIELD, DO NOT

USE URETHANE ADHESIVE IF THE EXPIRATION

DATE ON THE PRODUCT HAS PASSED. SAFETY

AND QUALITY ON THE REPAIR WOULD BE QUES-

TIONABLE.

REMOVAL/INSTALLATION METHODS

Windshield glass removal is accomplished by the

use of a razor knife and an electric hot knife to cut

through the urethane adhesive. This removal method

applies in all instances.

Depending on the circumstances, either one of two

windshield glass installation methods can be used:

²the short method, and

²the extended method.

The short method is used when the windshield

glass is removed intact, and the body opening and

the pinchweld flanges do not require repair.

The extended method must be used when the body

opening or a flange is damaged. The extended

method must also be used when urethane no longer

adheres to either the windshield glass or the pinch-

weld flanges.

WINDSHIELD GLASS REPLACEMENT

REMOVAL

(1) If the windshield glass short installation

method will be used, ensure that a bead of urethane

remains on the pinchweld flange.

Fig. 8 Windshield Glass Bonding With Urethane

JBODY COMPONENTSÐXJ VEHICLES 23 - 75

Page 1531 of 1784

(2) Cover the interior and exterior body surface ar-

eas with a protective covering.

(3) Remove the windshield wiper arms, reveal

moulding, interior trim mouldings and rearview mir-

ror.

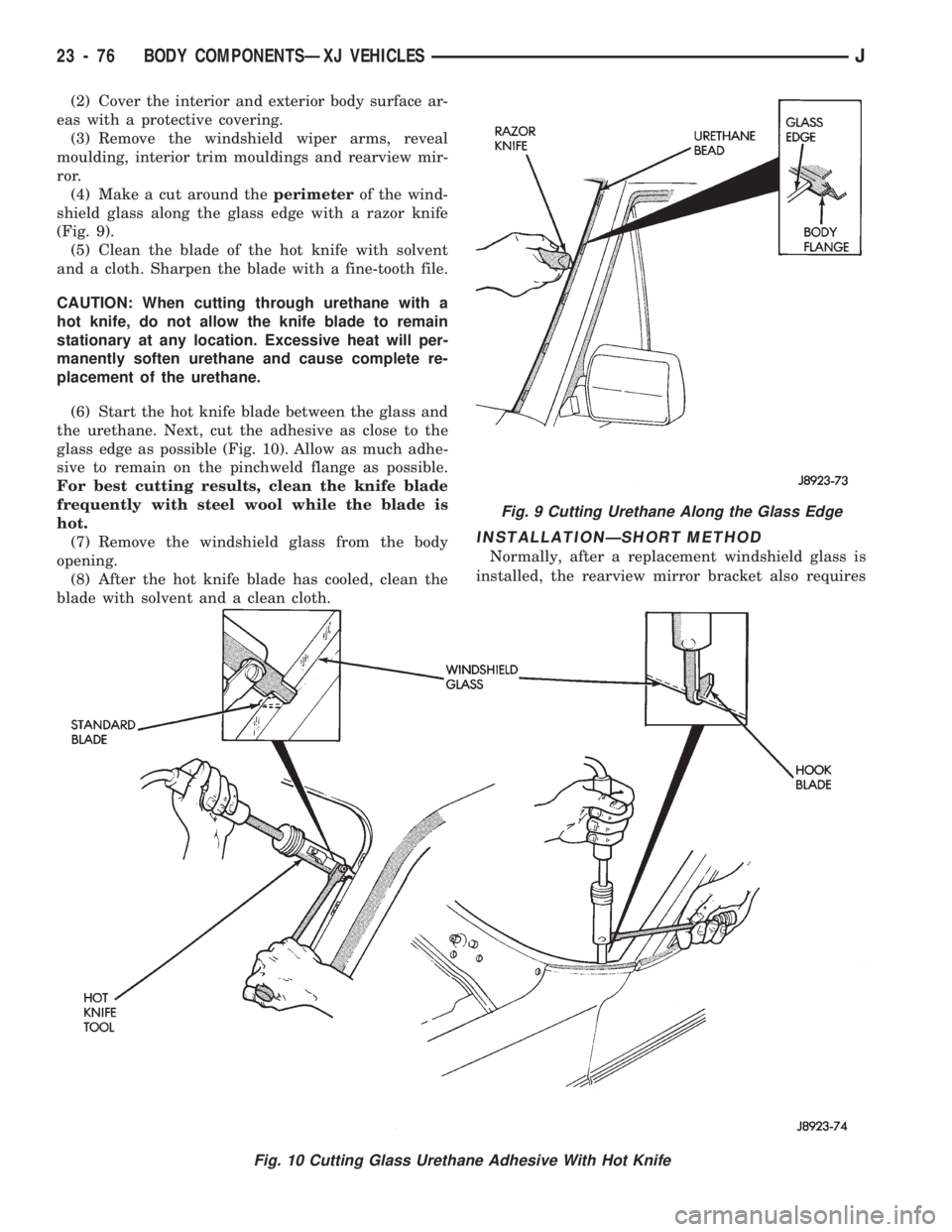

(4) Make a cut around theperimeterof the wind-

shield glass along the glass edge with a razor knife

(Fig. 9).

(5) Clean the blade of the hot knife with solvent

and a cloth. Sharpen the blade with a fine-tooth file.

CAUTION: When cutting through urethane with a

hot knife, do not allow the knife blade to remain

stationary at any location. Excessive heat will per-

manently soften urethane and cause complete re-

placement of the urethane.

(6) Start the hot knife blade between the glass and

the urethane. Next, cut the adhesive as close to the

glass edge as possible (Fig. 10). Allow as much adhe-

sive to remain on the pinchweld flange as possible.

For best cutting results, clean the knife blade

frequently with steel wool while the blade is

hot.

(7) Remove the windshield glass from the body

opening.

(8) After the hot knife blade has cooled, clean the

blade with solvent and a clean cloth.

INSTALLATIONÐSHORT METHOD

Normally, after a replacement windshield glass is

installed, the rearview mirror bracket also requires

Fig. 9 Cutting Urethane Along the Glass Edge

Fig. 10 Cutting Glass Urethane Adhesive With Hot Knife

23 - 76 BODY COMPONENTSÐXJ VEHICLESJ

Page 1533 of 1784

CAUTION: Avoid spilling or dripping primer on

painted surfaces. Clean spills or drips immediately.

The primer will damage the paint if it remains on

the surface for any length of time.

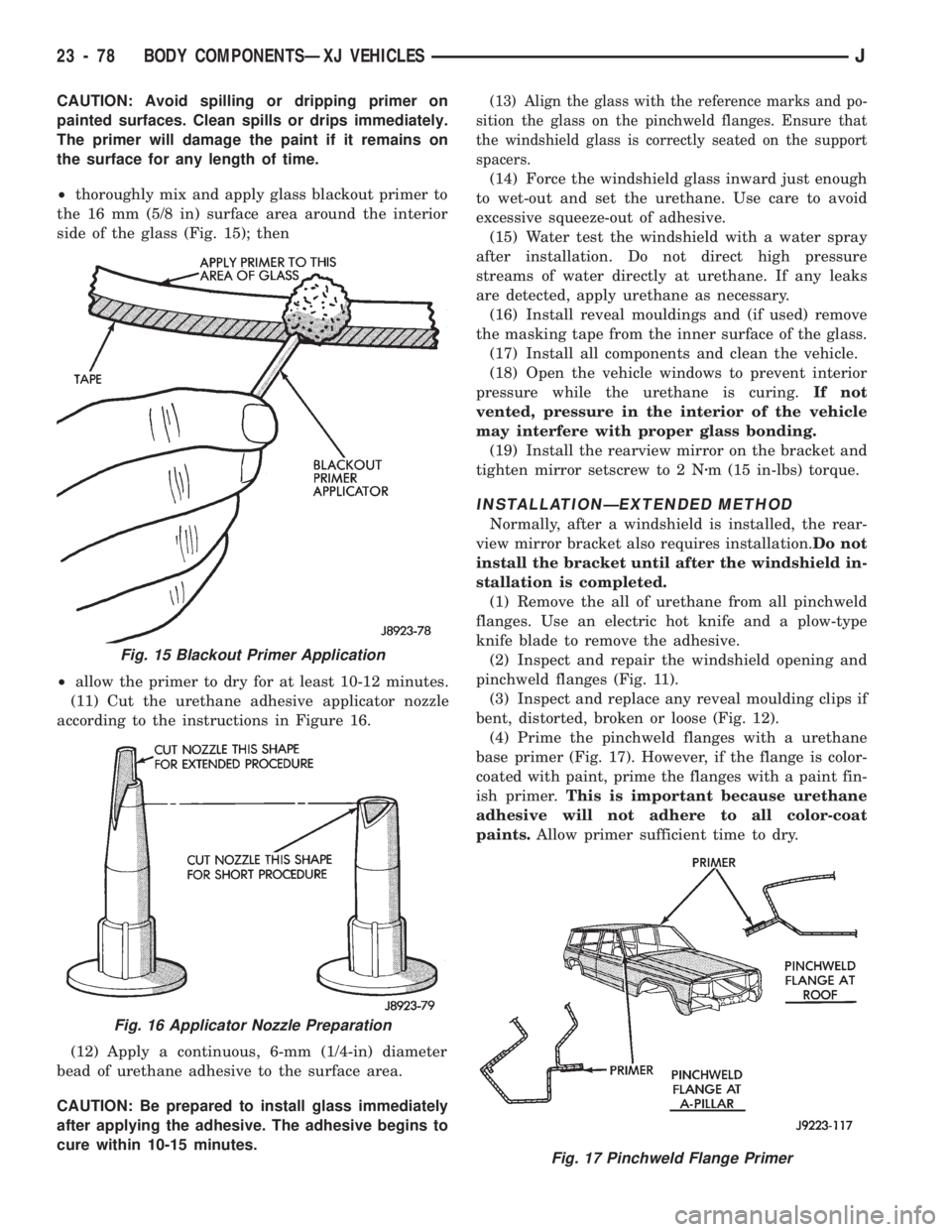

²thoroughly mix and apply glass blackout primer to

the 16 mm (5/8 in) surface area around the interior

side of the glass (Fig. 15); then

²allow the primer to dry for at least 10-12 minutes.

(11) Cut the urethane adhesive applicator nozzle

according to the instructions in Figure 16.

(12) Apply a continuous, 6-mm (1/4-in) diameter

bead of urethane adhesive to the surface area.

CAUTION: Be prepared to install glass immediately

after applying the adhesive. The adhesive begins to

cure within 10-15 minutes.(13) Align the glass with the reference marks and po-

sition the glass on the pinchweld flanges. Ensure that

the windshield glass is correctly seated on the support

spacers.

(14) Force the windshield glass inward just enough

to wet-out and set the urethane. Use care to avoid

excessive squeeze-out of adhesive.

(15) Water test the windshield with a water spray

after installation. Do not direct high pressure

streams of water directly at urethane. If any leaks

are detected, apply urethane as necessary.

(16) Install reveal mouldings and (if used) remove

the masking tape from the inner surface of the glass.

(17) Install all components and clean the vehicle.

(18) Open the vehicle windows to prevent interior

pressure while the urethane is curing.If not

vented, pressure in the interior of the vehicle

may interfere with proper glass bonding.

(19) Install the rearview mirror on the bracket and

tighten mirror setscrew to 2 Nzm (15 in-lbs) torque.

INSTALLATIONÐEXTENDED METHOD

Normally, after a windshield is installed, the rear-

view mirror bracket also requires installation.Do not

install the bracket until after the windshield in-

stallation is completed.

(1) Remove the all of urethane from all pinchweld

flanges. Use an electric hot knife and a plow-type

knife blade to remove the adhesive.

(2) Inspect and repair the windshield opening and

pinchweld flanges (Fig. 11).

(3) Inspect and replace any reveal moulding clips if

bent, distorted, broken or loose (Fig. 12).

(4) Prime the pinchweld flanges with a urethane

base primer (Fig. 17). However, if the flange is color-

coated with paint, prime the flanges with a paint fin-

ish primer.This is important because urethane

adhesive will not adhere to all color-coat

paints.Allow primer sufficient time to dry.

Fig. 15 Blackout Primer Application

Fig. 16 Applicator Nozzle Preparation

Fig. 17 Pinchweld Flange Primer

23 - 78 BODY COMPONENTSÐXJ VEHICLESJ

Page 1535 of 1784

(18) Install the rearview mirror on the bracket and

tighten the mirror setscrew to 2 Nzm (15 in-lbs) torque.

REAR QUARTER VENT WINDOW GLASSÐXJ

VEHICLES

REMOVAL

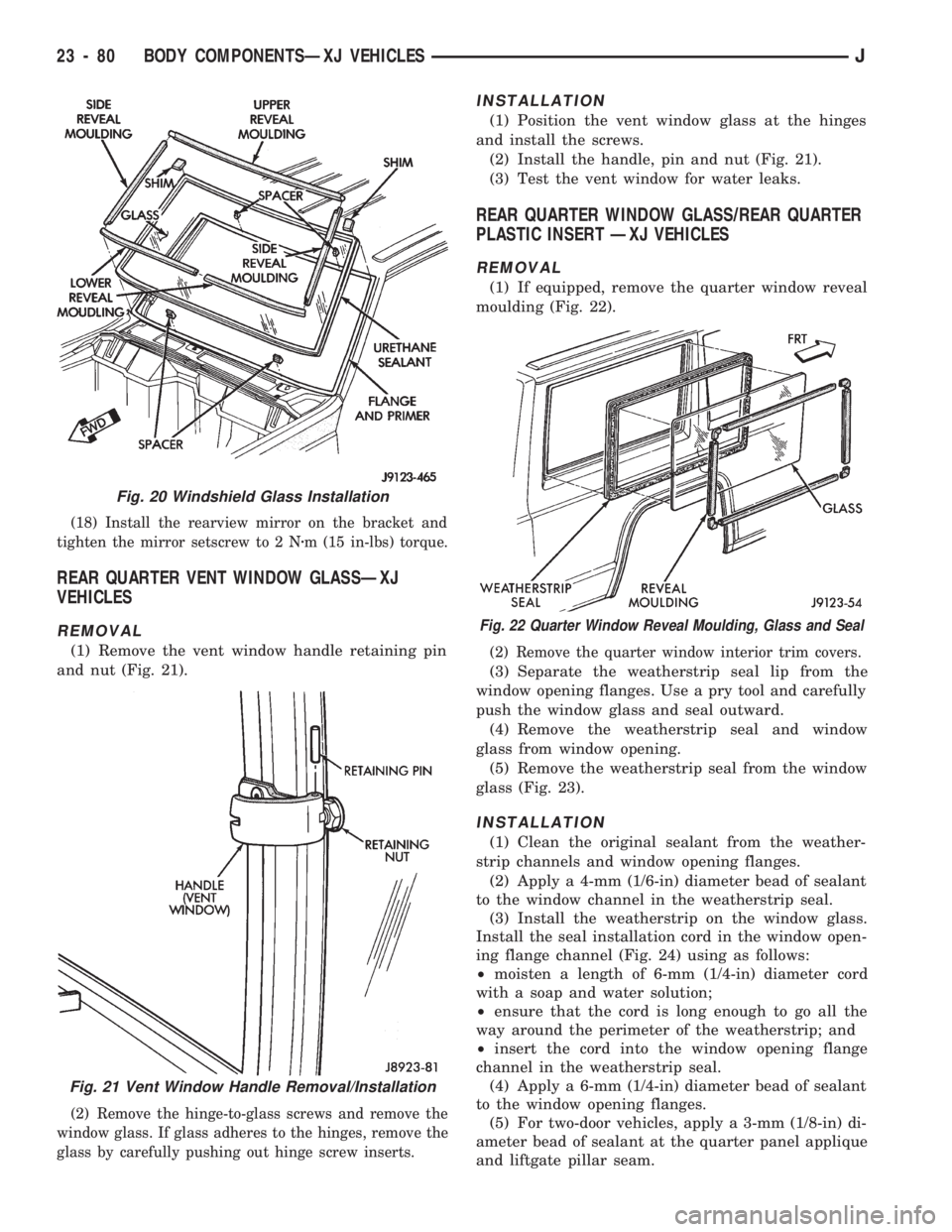

(1) Remove the vent window handle retaining pin

and nut (Fig. 21).

(2) Remove the hinge-to-glass screws and remove the

window glass. If glass adheres to the hinges, remove the

glass by carefully pushing out hinge screw inserts.

INSTALLATION

(1) Position the vent window glass at the hinges

and install the screws.

(2) Install the handle, pin and nut (Fig. 21).

(3) Test the vent window for water leaks.

REAR QUARTER WINDOW GLASS/REAR QUARTER

PLASTIC INSERT ÐXJ VEHICLES

REMOVAL

(1) If equipped, remove the quarter window reveal

moulding (Fig. 22).

(2) Remove the quarter window interior trim covers.

(3) Separate the weatherstrip seal lip from the

window opening flanges. Use a pry tool and carefully

push the window glass and seal outward.

(4) Remove the weatherstrip seal and window

glass from window opening.

(5) Remove the weatherstrip seal from the window

glass (Fig. 23).

INSTALLATION

(1) Clean the original sealant from the weather-

strip channels and window opening flanges.

(2) Apply a 4-mm (1/6-in) diameter bead of sealant

to the window channel in the weatherstrip seal.

(3) Install the weatherstrip on the window glass.

Install the seal installation cord in the window open-

ing flange channel (Fig. 24) using as follows:

²moisten a length of 6-mm (1/4-in) diameter cord

with a soap and water solution;

²ensure that the cord is long enough to go all the

way around the perimeter of the weatherstrip; and

²insert the cord into the window opening flange

channel in the weatherstrip seal.

(4) Apply a 6-mm (1/4-in) diameter bead of sealant

to the window opening flanges.

(5) For two-door vehicles, apply a 3-mm (1/8-in) di-

ameter bead of sealant at the quarter panel applique

and liftgate pillar seam.

Fig. 20 Windshield Glass Installation

Fig. 21 Vent Window Handle Removal/Installation

Fig. 22 Quarter Window Reveal Moulding, Glass and Seal

23 - 80 BODY COMPONENTSÐXJ VEHICLESJ

Page 1543 of 1784

The reinforcement bracket is held on the

frame rail with two blind rivets.

(2) Remove the bracket and tow hook from frame

rail.

INSTALLATION

(1) Position bracket and tow hook on the frame

rail.

(2) Install bolts that attach tow hook bracket to

frame rail and reinforcement bracket. Tighten bolts

to 75 Nzm (55 ft-lbs) torque.

TRAILER HITCHES

CLASS III HITCHÐXJ VEHICLES

A class III weight-distributing/equalizer type hitch

can be used to tow a trailer:

²having a maximum gross weight of 5,000 lbs/2250

kg, and

²having a maximum tongue weight of 750 lbs/332

kg).

The following vehicle basic equipment is required

for class III trailer towing:

²P205/75R15 or larger tires;

²full size spare tire;

²trailer sway control;

²trailer tow wire harness and connector;

²heavy duty turn signal flasher element;

²heavy duty axle (with synthetic lubricant);²heavy duty cooling system;

²heavy duty generator/battery;

²auxiliary automatic transmission fluid cooler; and

²I-6, 4.0L engine.

Wide-angle type door mirrors are recommended but

not required.

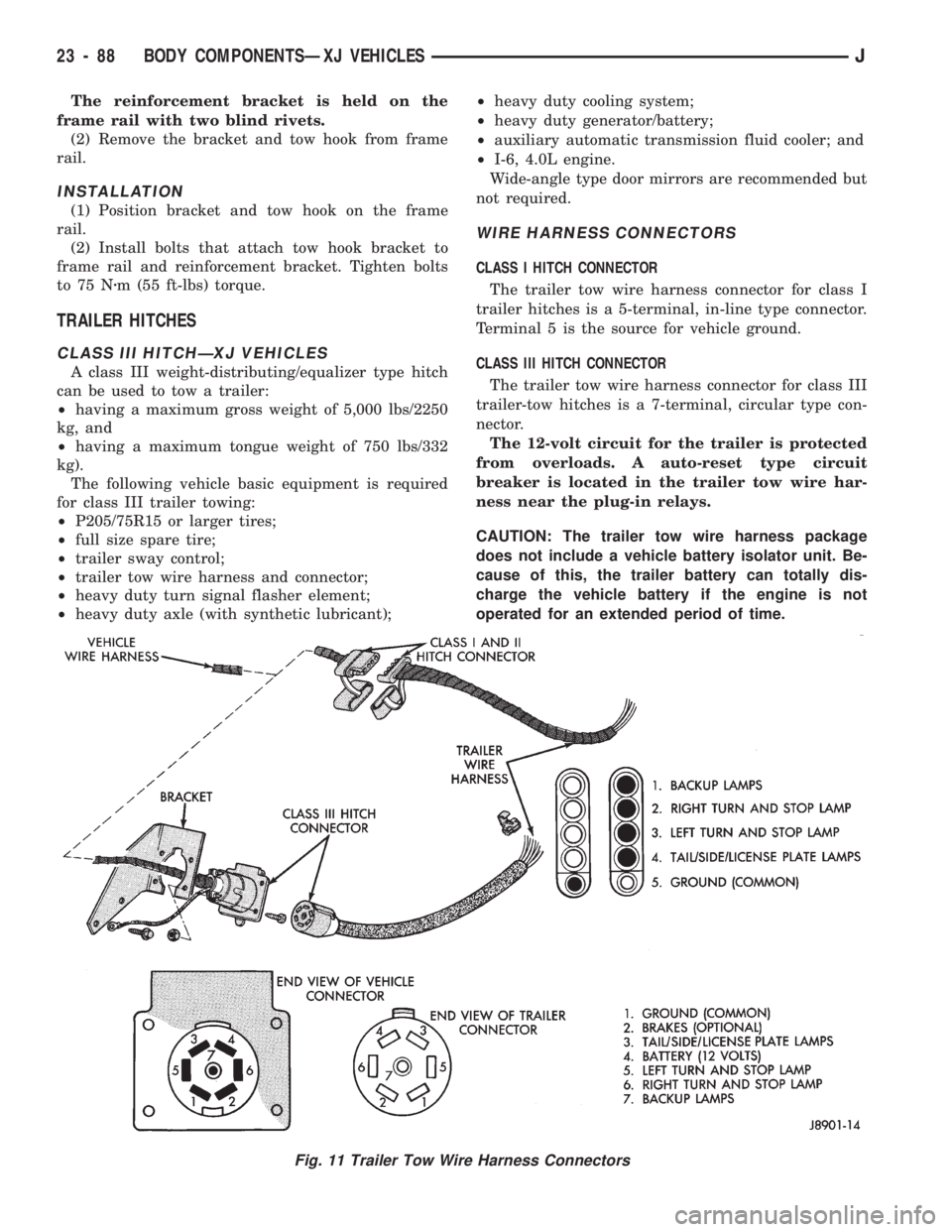

WIRE HARNESS CONNECTORS

CLASS I HITCH CONNECTOR

The trailer tow wire harness connector for class I

trailer hitches is a 5-terminal, in-line type connector.

Terminal 5 is the source for vehicle ground.

CLASS III HITCH CONNECTOR

The trailer tow wire harness connector for class III

trailer-tow hitches is a 7-terminal, circular type con-

nector.

The 12-volt circuit for the trailer is protected

from overloads. A auto-reset type circuit

breaker is located in the trailer tow wire har-

ness near the plug-in relays.

CAUTION: The trailer tow wire harness package

does not include a vehicle battery isolator unit. Be-

cause of this, the trailer battery can totally dis-

charge the vehicle battery if the engine is not

operated for an extended period of time.

Fig. 11 Trailer Tow Wire Harness Connectors

23 - 88 BODY COMPONENTSÐXJ VEHICLESJ

Page 1580 of 1784

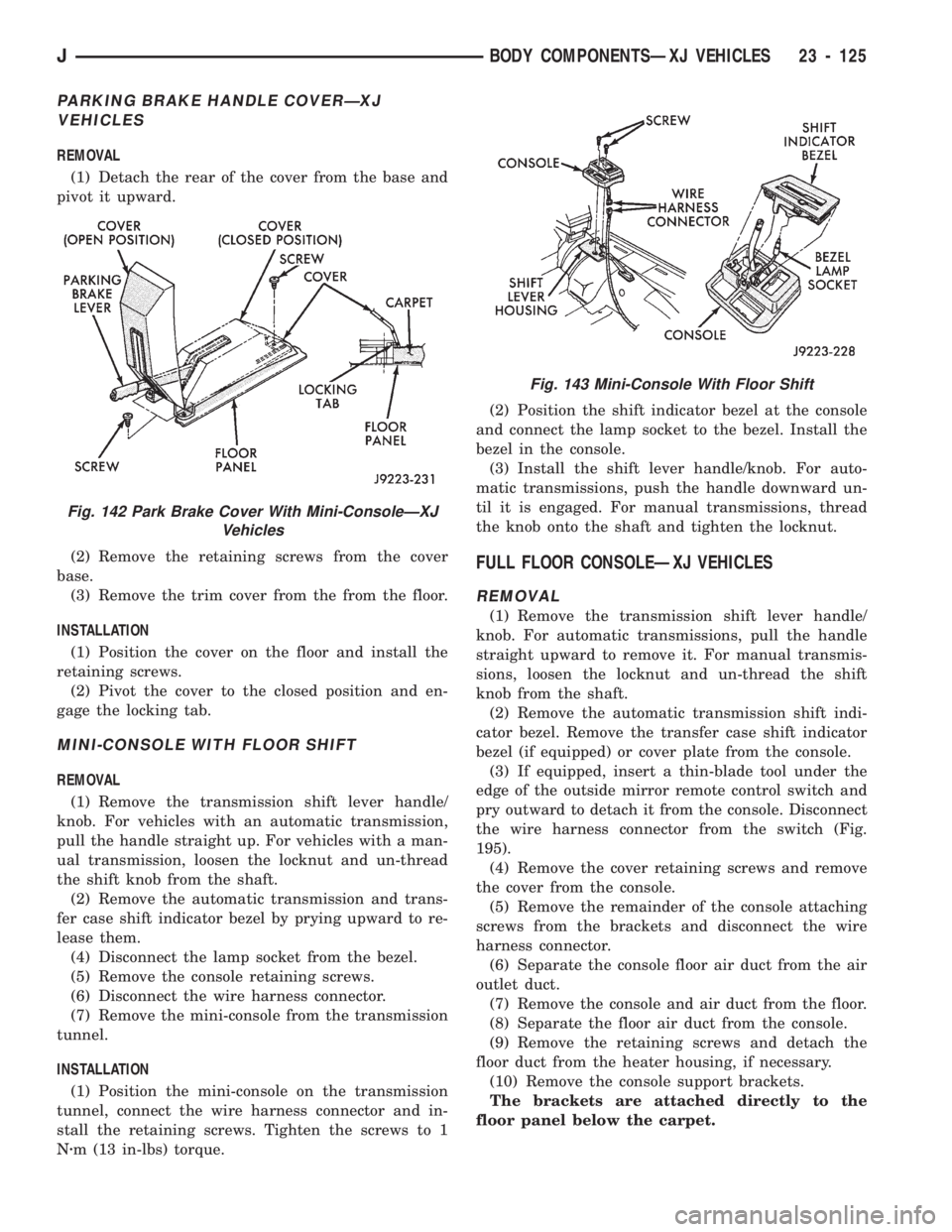

PARKING BRAKE HANDLE COVERÐXJ

VEHICLES

REMOVAL

(1) Detach the rear of the cover from the base and

pivot it upward.

(2) Remove the retaining screws from the cover

base.

(3) Remove the trim cover from the from the floor.

INSTALLATION

(1) Position the cover on the floor and install the

retaining screws.

(2) Pivot the cover to the closed position and en-

gage the locking tab.

MINI-CONSOLE WITH FLOOR SHIFT

REMOVAL

(1) Remove the transmission shift lever handle/

knob. For vehicles with an automatic transmission,

pull the handle straight up. For vehicles with a man-

ual transmission, loosen the locknut and un-thread

the shift knob from the shaft.

(2) Remove the automatic transmission and trans-

fer case shift indicator bezel by prying upward to re-

lease them.

(4) Disconnect the lamp socket from the bezel.

(5) Remove the console retaining screws.

(6) Disconnect the wire harness connector.

(7) Remove the mini-console from the transmission

tunnel.

INSTALLATION

(1) Position the mini-console on the transmission

tunnel, connect the wire harness connector and in-

stall the retaining screws. Tighten the screws to 1

Nzm (13 in-lbs) torque.(2) Position the shift indicator bezel at the console

and connect the lamp socket to the bezel. Install the

bezel in the console.

(3) Install the shift lever handle/knob. For auto-

matic transmissions, push the handle downward un-

til it is engaged. For manual transmissions, thread

the knob onto the shaft and tighten the locknut.

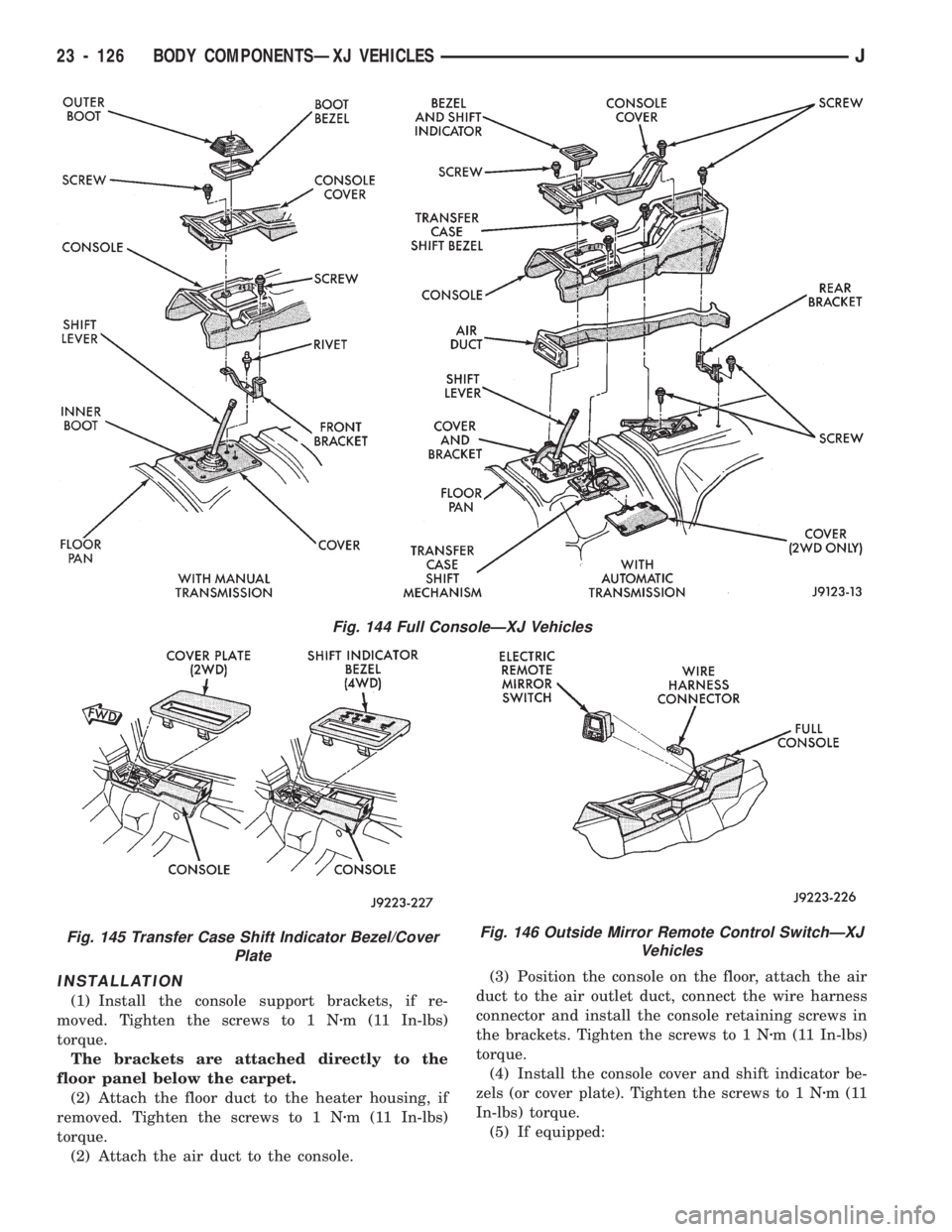

FULL FLOOR CONSOLEÐXJ VEHICLES

REMOVAL

(1) Remove the transmission shift lever handle/

knob. For automatic transmissions, pull the handle

straight upward to remove it. For manual transmis-

sions, loosen the locknut and un-thread the shift

knob from the shaft.

(2) Remove the automatic transmission shift indi-

cator bezel. Remove the transfer case shift indicator

bezel (if equipped) or cover plate from the console.

(3) If equipped, insert a thin-blade tool under the

edge of the outside mirror remote control switch and

pry outward to detach it from the console. Disconnect

the wire harness connector from the switch (Fig.

195).

(4) Remove the cover retaining screws and remove

the cover from the console.

(5) Remove the remainder of the console attaching

screws from the brackets and disconnect the wire

harness connector.

(6) Separate the console floor air duct from the air

outlet duct.

(7) Remove the console and air duct from the floor.

(8) Separate the floor air duct from the console.

(9) Remove the retaining screws and detach the

floor duct from the heater housing, if necessary.

(10) Remove the console support brackets.

The brackets are attached directly to the

floor panel below the carpet.

Fig. 142 Park Brake Cover With Mini-ConsoleÐXJ

Vehicles

Fig. 143 Mini-Console With Floor Shift

JBODY COMPONENTSÐXJ VEHICLES 23 - 125

Page 1581 of 1784

INSTALLATION

(1) Install the console support brackets, if re-

moved. Tighten the screws to 1 Nzm (11 In-lbs)

torque.

The brackets are attached directly to the

floor panel below the carpet.

(2) Attach the floor duct to the heater housing, if

removed. Tighten the screws to 1 Nzm (11 In-lbs)

torque.

(2) Attach the air duct to the console.(3) Position the console on the floor, attach the air

duct to the air outlet duct, connect the wire harness

connector and install the console retaining screws in

the brackets. Tighten the screws to 1 Nzm (11 In-lbs)

torque.

(4) Install the console cover and shift indicator be-

zels (or cover plate). Tighten the screws to 1 Nzm(11

In-lbs) torque.

(5) If equipped:

Fig. 146 Outside Mirror Remote Control SwitchÐXJ

Vehicles

Fig. 144 Full ConsoleÐXJ Vehicles

Fig. 145 Transfer Case Shift Indicator Bezel/Cover

Plate

23 - 126 BODY COMPONENTSÐXJ VEHICLESJ

Page 1582 of 1784

²connect the wire harness connector to the outside

mirror remote control switch,

²insert the switch into the console hole, and

²push inward to engage the retaining clips.

(6) Install the shift lever handle/knob.

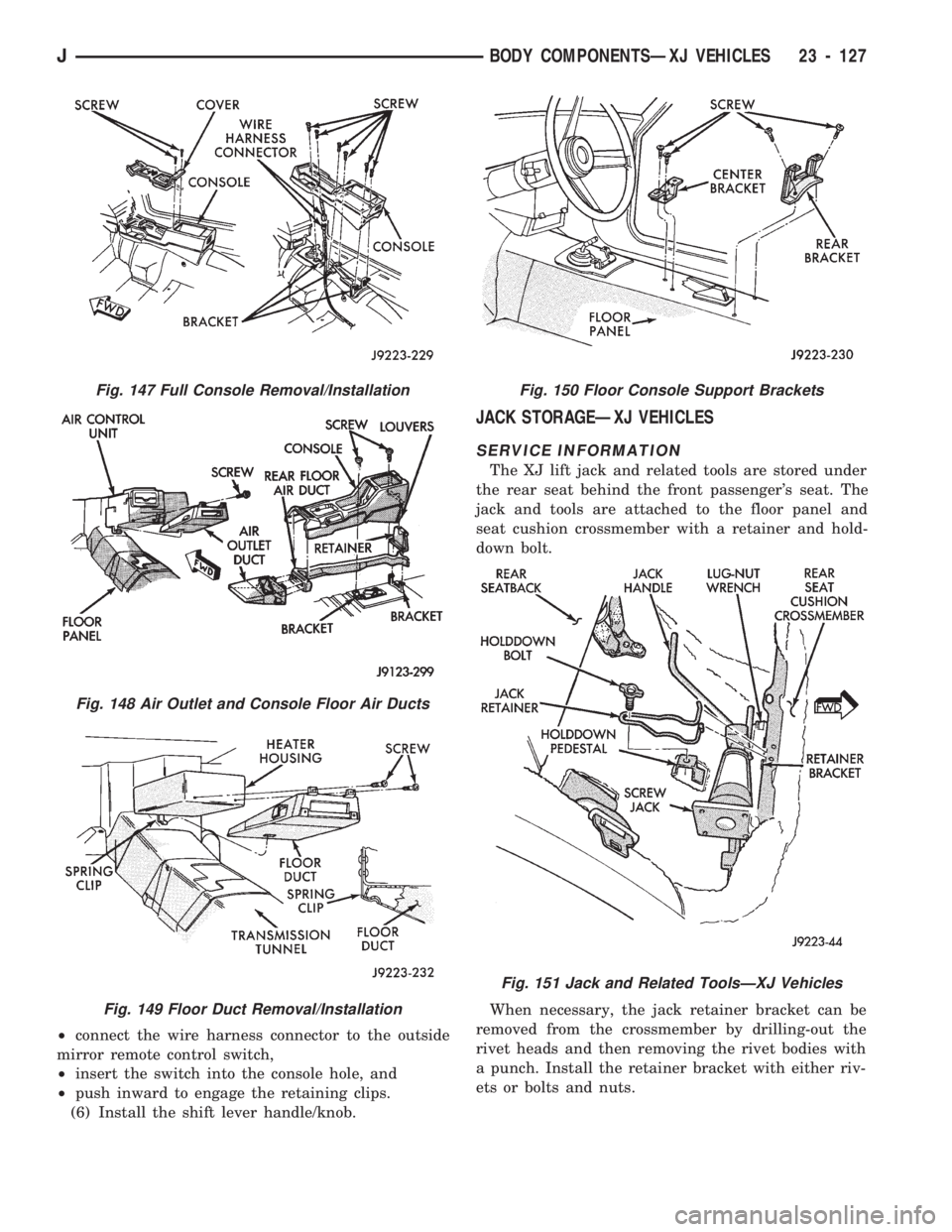

JACK STORAGEÐXJ VEHICLES

SERVICE INFORMATION

The XJ lift jack and related tools are stored under

the rear seat behind the front passenger's seat. The

jack and tools are attached to the floor panel and

seat cushion crossmember with a retainer and hold-

down bolt.

When necessary, the jack retainer bracket can be

removed from the crossmember by drilling-out the

rivet heads and then removing the rivet bodies with

a punch. Install the retainer bracket with either riv-

ets or bolts and nuts.

Fig. 147 Full Console Removal/Installation

Fig. 148 Air Outlet and Console Floor Air Ducts

Fig. 149 Floor Duct Removal/Installation

Fig. 150 Floor Console Support Brackets

Fig. 151 Jack and Related ToolsÐXJ Vehicles

JBODY COMPONENTSÐXJ VEHICLES 23 - 127

Page 1589 of 1784

EXTERIOR COMPONENTS

INDEX

page page

Battery Tray........................... 140

Body Extension Panels and FasciasÐYJ

Renegade Vehicles..................... 147

Body Side Step Moulding................. 145

Body Stripes/Decals..................... 153

Cowl Grille and Screen................... 139

Cowl Weatherstrip Seal................... 139

Exterior Nameplates (Adhesive-Backed)....... 158

External Spare/Wheel Tire Carrier........... 172

Fender Flare........................... 144

Fender Inner Splash Shields............... 147

Fender Splash Aprons.................... 147

Fenders............................... 141

Fog LampÐYJ Renegade Vehicles.......... 150

Front Fascia and Skid PlateÐYJ Renegade

Vehicles............................. 148

Front Fender Extension PanelÐYJ Renegade

Vehicles............................. 149

Fuel Filler Protector/Nozzle................ 158

Half Metal Door Mirror (External)............ 158

Hard Top Liftgate Glass.................. 162

Hard Top Repair........................ 165

Hard Top Roof Vent..................... 165

Hard Top Service....................... 164

Hard Top Service Information.............. 164Hood................................. 137

Hood Alignment......................... 138

Hood Insulator Panel..................... 138

Hood Safety Latch....................... 139

Liftgate Glass Weatherstrip Seal Replacement . . 163

Radiator Grille Applique................... 134

Rear Fascia and Skid PlateÐYJ Renegade

Vehicles............................. 152

Rear Quarter Extension PanelÐYJ Renegade

Vehicles............................. 151

Rocker Extension PanelÐYJ Renegade

Vehicles............................. 150

Soft Top Service........................ 167

Soft Top Service Information............... 166

Sport Bar............................. 171

Tailgate Adjustment...................... 160

Tailgate Hinge.......................... 159

Tailgate Latch and Release Handle.......... 160

Tailgate Latch Striker..................... 161

Tailgate Lock Cylinder.................... 160

Tailgate Service......................... 159

Tailgate Service Information................ 159

Tailgate Weatherstrip Seal................. 161

Wheelhouse Splash Liners................ 146

RADIATOR GRILLE APPLIQUE

REMOVAL

(1) Raise the hood.

(2) Remove the headlamp bezels (Fig. 1).

(3) Remove the headlamp bulb retainer screws

(Fig. 2).

(4) Disconnect and remove the headlamps and

buckets as a unit (Fig. 2).

(5) Remove the parking lamp retaining screws

(Fig. 2).

(6) Disconnect the wire harness connectors and re-

move the parking lamps (Fig. 2).

(7) Remove the front crossmember cover.

(8) Remove the retaining screws and the bumper

inserts at the top of the grille panel (Fig. 1).

(9) Detach the grille applique from the grille panel

(Fig. 1).

(10) Remove the double faced foam adhesive tape

at the bottom of the grille applique (Fig. 1).

INSTALLATION

(1) Install double faced foam tape at the bottom,

interior side of the grille applique (Fig. 1).

(2) Position the grille applique over the grille

panel and press inward along the bottom where the

tape is located (Fig. 1).

(3) Install the grille applique retaining screws and

the bumper inserts (Fig. 1).(4) Connect the wire harness connectors and posi-

tion the headlamp buckets and headlamps in the

grille panel (Fig. 2).

(5) Install the headlamp bulb retainer and the

screws (Fig. 1). Tighten the screws to 2 Nzm (18 in-

lbs) torque.

(6) Install the headlamp bezels and the retaining

screws (Fig. 1). Tighten the screws securely.

(7) Connect the wire harness connectors and in-

stall the parking lamps (Fig. 2).

(8) Install the parking lamp retaining screws.

Tighten the screws to 2 Nzm (18 in-lbs) torque.

(9) Close the hood.

(10) Install the front crossmember cover.

23 - 134 BODY COMPONENTSÐXJ VEHICLESJ

Page 1613 of 1784

area and re-align stripe/decal with panel character

line.Do not lift the tape stripe/decal if only a

few air bubbles exist.

(10) Where applicable, allow 12 mm (1/2 in) extra

tape stripe/decal to extend beyond the edges to be

folded over.

(11) Fold the excess tape stripe/decal back onto in-

side flange area.Use care to avoid trapping air

under the tape stripe/decal.Where necessary,

trim excess tape stripe/decal.

(12) Inspect tape installation with reflected light to

detect any defects that could have developed during

the installation.

(13) Remove all air and moisture bubbles from the

tape stripe/decal with a needle or pin.

(14) Install any removed components and clean the

vehicle as necessary.

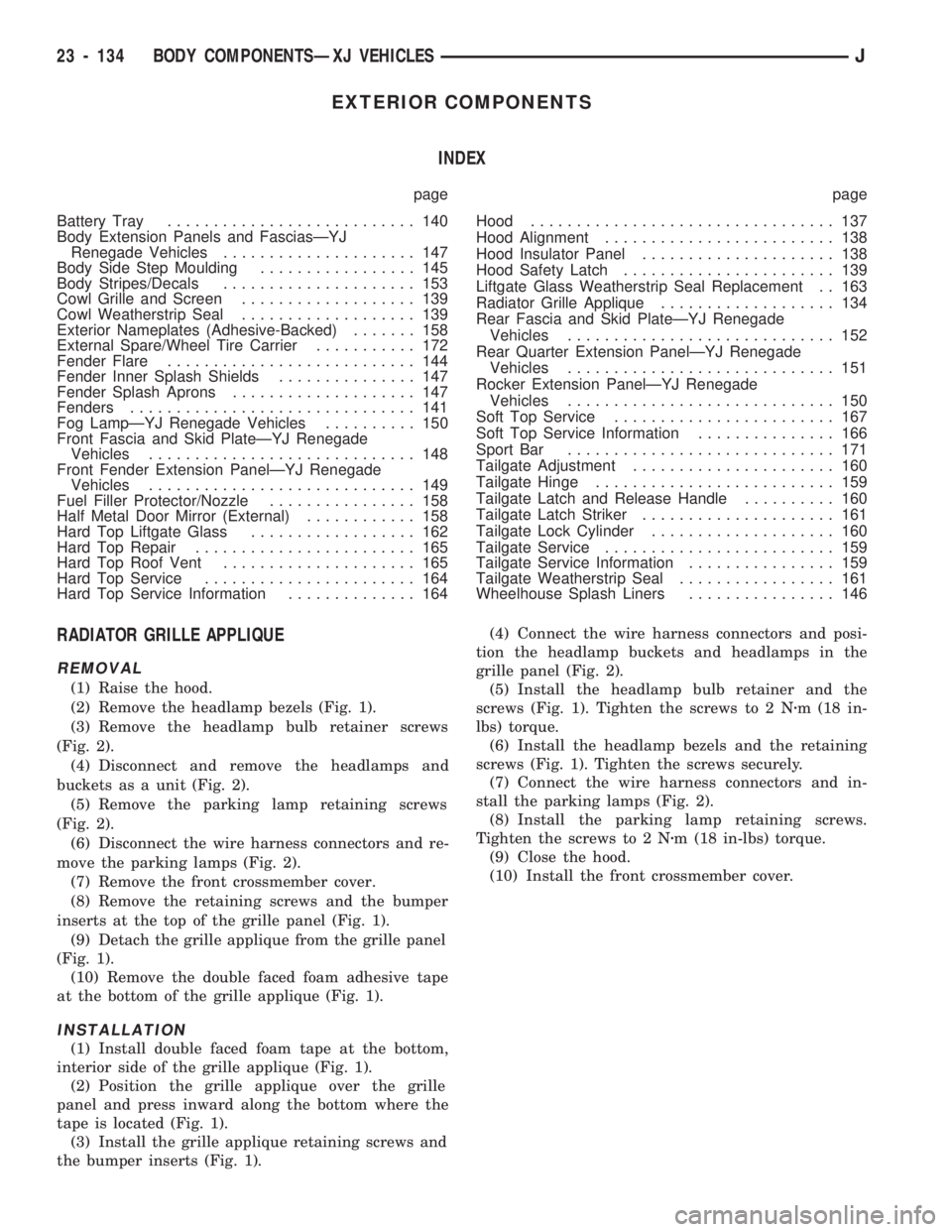

EXTERIOR NAMEPLATES (ADHESIVE-BACKED)

All of the YJ exterior nameplates (Fig. 75) are at-

tached to the vehicle panels with adhesive.

REMOVAL/INSTALLATION

(1) Carefully pry the nameplate (Fig. 75) from the

body outer panel.

(2) Clean the panel surface.

(3) Position the replacement nameplate (Fig. 75)

on the panel and apply inward force to seat it.

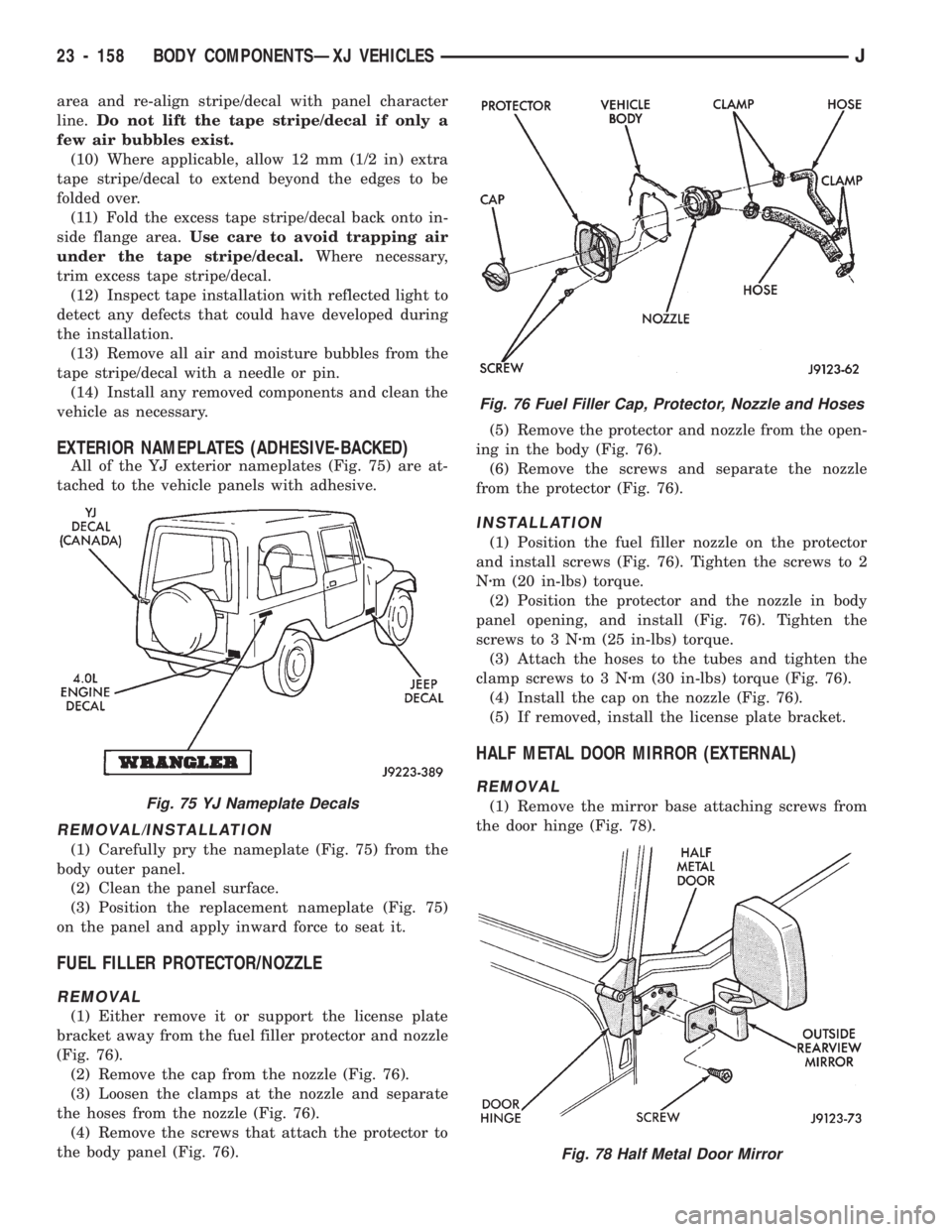

FUEL FILLER PROTECTOR/NOZZLE

REMOVAL

(1) Either remove it or support the license plate

bracket away from the fuel filler protector and nozzle

(Fig. 76).

(2) Remove the cap from the nozzle (Fig. 76).

(3) Loosen the clamps at the nozzle and separate

the hoses from the nozzle (Fig. 76).

(4) Remove the screws that attach the protector to

the body panel (Fig. 76).(5) Remove the protector and nozzle from the open-

ing in the body (Fig. 76).

(6) Remove the screws and separate the nozzle

from the protector (Fig. 76).

INSTALLATION

(1) Position the fuel filler nozzle on the protector

and install screws (Fig. 76). Tighten the screws to 2

Nzm (20 in-lbs) torque.

(2) Position the protector and the nozzle in body

panel opening, and install (Fig. 76). Tighten the

screws to 3 Nzm (25 in-lbs) torque.

(3) Attach the hoses to the tubes and tighten the

clamp screws to 3 Nzm (30 in-lbs) torque (Fig. 76).

(4) Install the cap on the nozzle (Fig. 76).

(5) If removed, install the license plate bracket.

HALF METAL DOOR MIRROR (EXTERNAL)

REMOVAL

(1) Remove the mirror base attaching screws from

the door hinge (Fig. 78).

Fig. 76 Fuel Filler Cap, Protector, Nozzle and Hoses

Fig. 78 Half Metal Door Mirror

Fig. 75 YJ Nameplate Decals

23 - 158 BODY COMPONENTSÐXJ VEHICLESJ