width JEEP CHEROKEE 1994 Service Owner's Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 1994, Model line: CHEROKEE, Model: JEEP CHEROKEE 1994Pages: 1784, PDF Size: 77.09 MB

Page 984 of 1784

SPEED CONTROLÐPCM INPUT

The speed control system provides three separate

inputs to the powertrain control module (PCM); On/

Off, Set and Resume. The On/Off input informs the

PCM that the speed control system has been acti-

vated. The Set input informs the PCM that a fixed

vehicle speed has been selected. The Resume input

indicates to the PCM that the previous fixed speed is

requested.

The speed control operating range is from 50 km/h

to 142 km/h (35 to 85 mph). Inputs that effect speed

control operation are:

²Park/neutral switch

²Vehicle speed sensor

²Throttle position sensor

Refer to Group 8H for further speed control infor-

mation.

SENSOR RETURNÐPCM INPUT

Sensor Return provides a low noise ground refer-

ence for all system sensors.

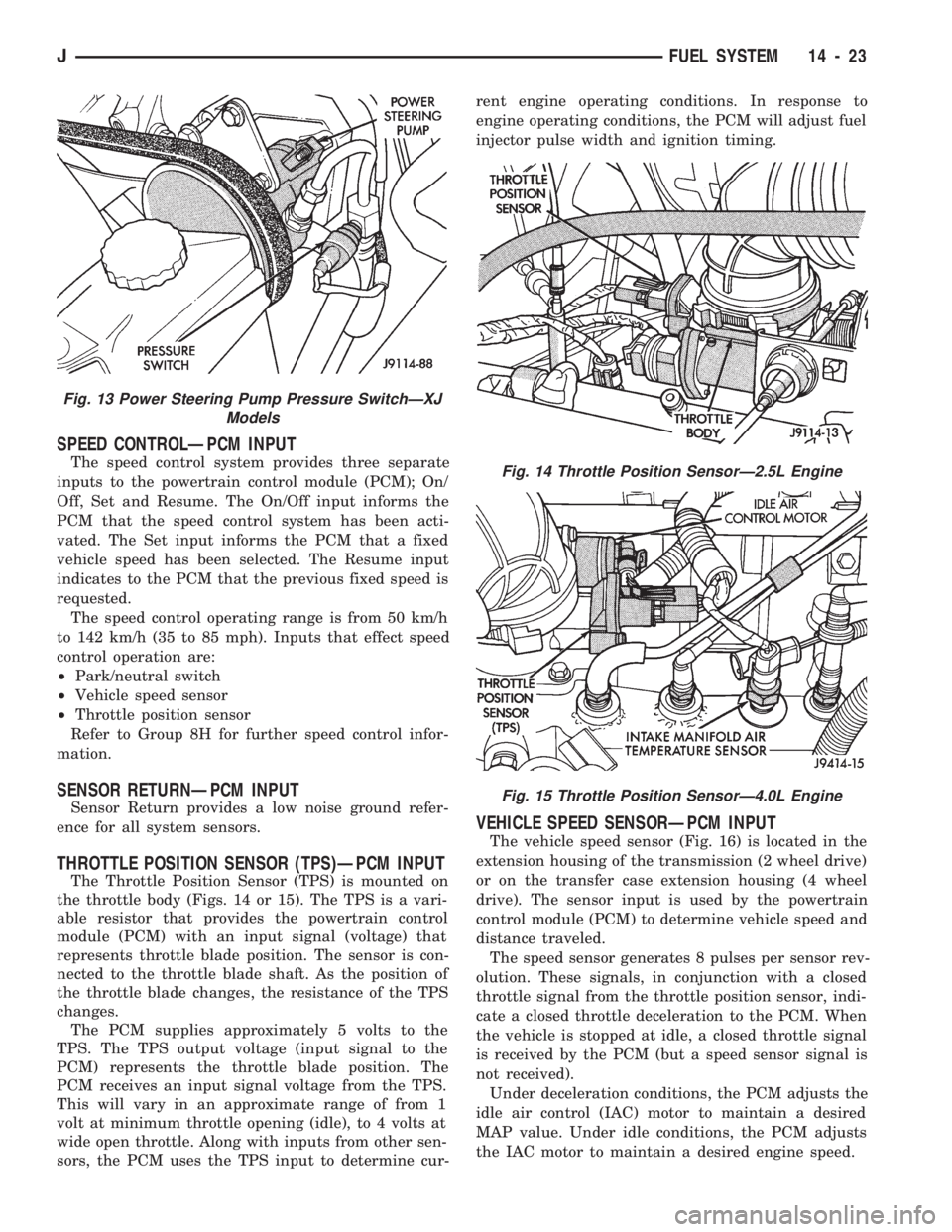

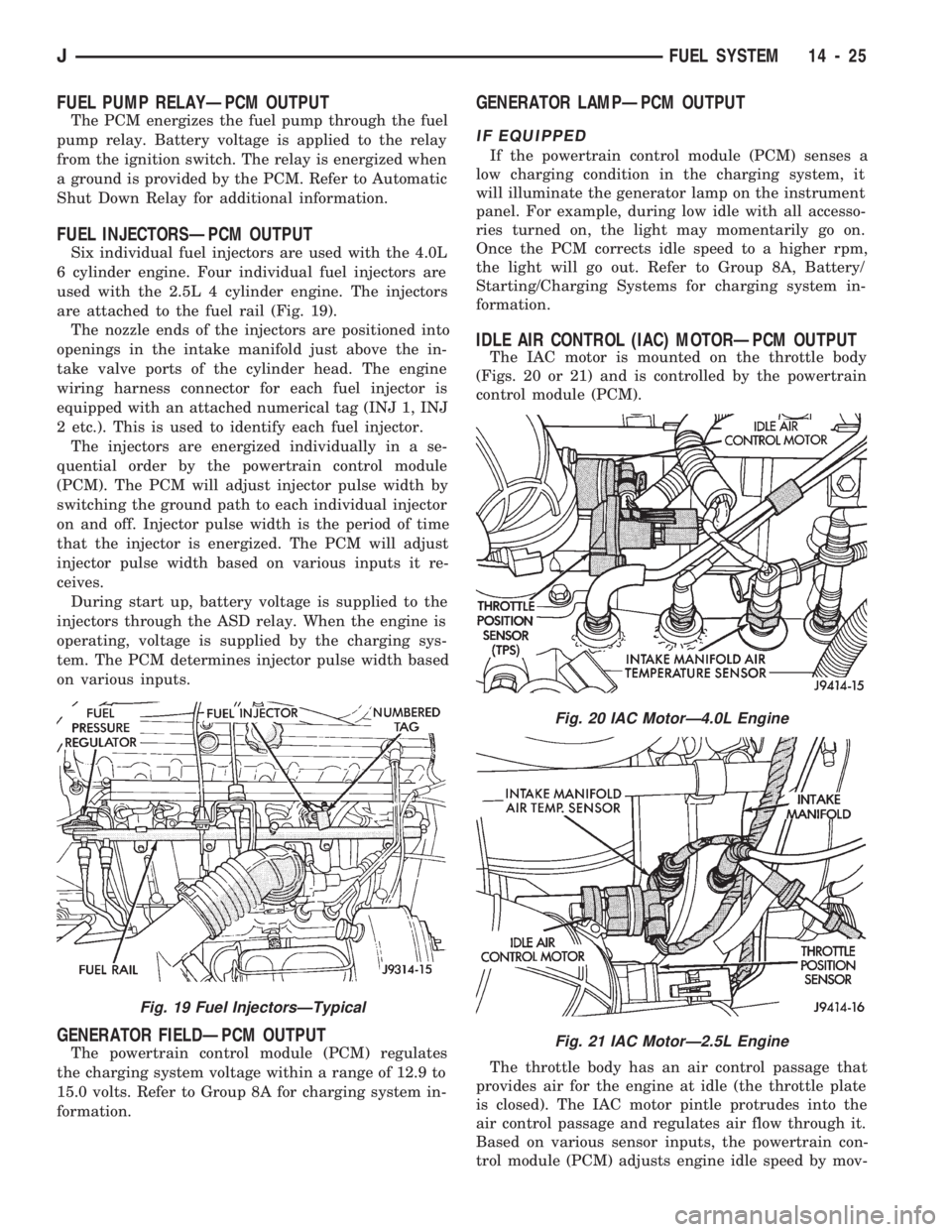

THROTTLE POSITION SENSOR (TPS)ÐPCM INPUT

The Throttle Position Sensor (TPS) is mounted on

the throttle body (Figs. 14 or 15). The TPS is a vari-

able resistor that provides the powertrain control

module (PCM) with an input signal (voltage) that

represents throttle blade position. The sensor is con-

nected to the throttle blade shaft. As the position of

the throttle blade changes, the resistance of the TPS

changes.

The PCM supplies approximately 5 volts to the

TPS. The TPS output voltage (input signal to the

PCM) represents the throttle blade position. The

PCM receives an input signal voltage from the TPS.

This will vary in an approximate range of from 1

volt at minimum throttle opening (idle), to 4 volts at

wide open throttle. Along with inputs from other sen-

sors, the PCM uses the TPS input to determine cur-rent engine operating conditions. In response to

engine operating conditions, the PCM will adjust fuel

injector pulse width and ignition timing.

VEHICLE SPEED SENSORÐPCM INPUT

The vehicle speed sensor (Fig. 16) is located in the

extension housing of the transmission (2 wheel drive)

or on the transfer case extension housing (4 wheel

drive). The sensor input is used by the powertrain

control module (PCM) to determine vehicle speed and

distance traveled.

The speed sensor generates 8 pulses per sensor rev-

olution. These signals, in conjunction with a closed

throttle signal from the throttle position sensor, indi-

cate a closed throttle deceleration to the PCM. When

the vehicle is stopped at idle, a closed throttle signal

is received by the PCM (but a speed sensor signal is

not received).

Under deceleration conditions, the PCM adjusts the

idle air control (IAC) motor to maintain a desired

MAP value. Under idle conditions, the PCM adjusts

the IAC motor to maintain a desired engine speed.

Fig. 13 Power Steering Pump Pressure SwitchÐXJ

Models

Fig. 14 Throttle Position SensorÐ2.5L Engine

Fig. 15 Throttle Position SensorÐ4.0L Engine

JFUEL SYSTEM 14 - 23

Page 986 of 1784

FUEL PUMP RELAYÐPCM OUTPUT

The PCM energizes the fuel pump through the fuel

pump relay. Battery voltage is applied to the relay

from the ignition switch. The relay is energized when

a ground is provided by the PCM. Refer to Automatic

Shut Down Relay for additional information.

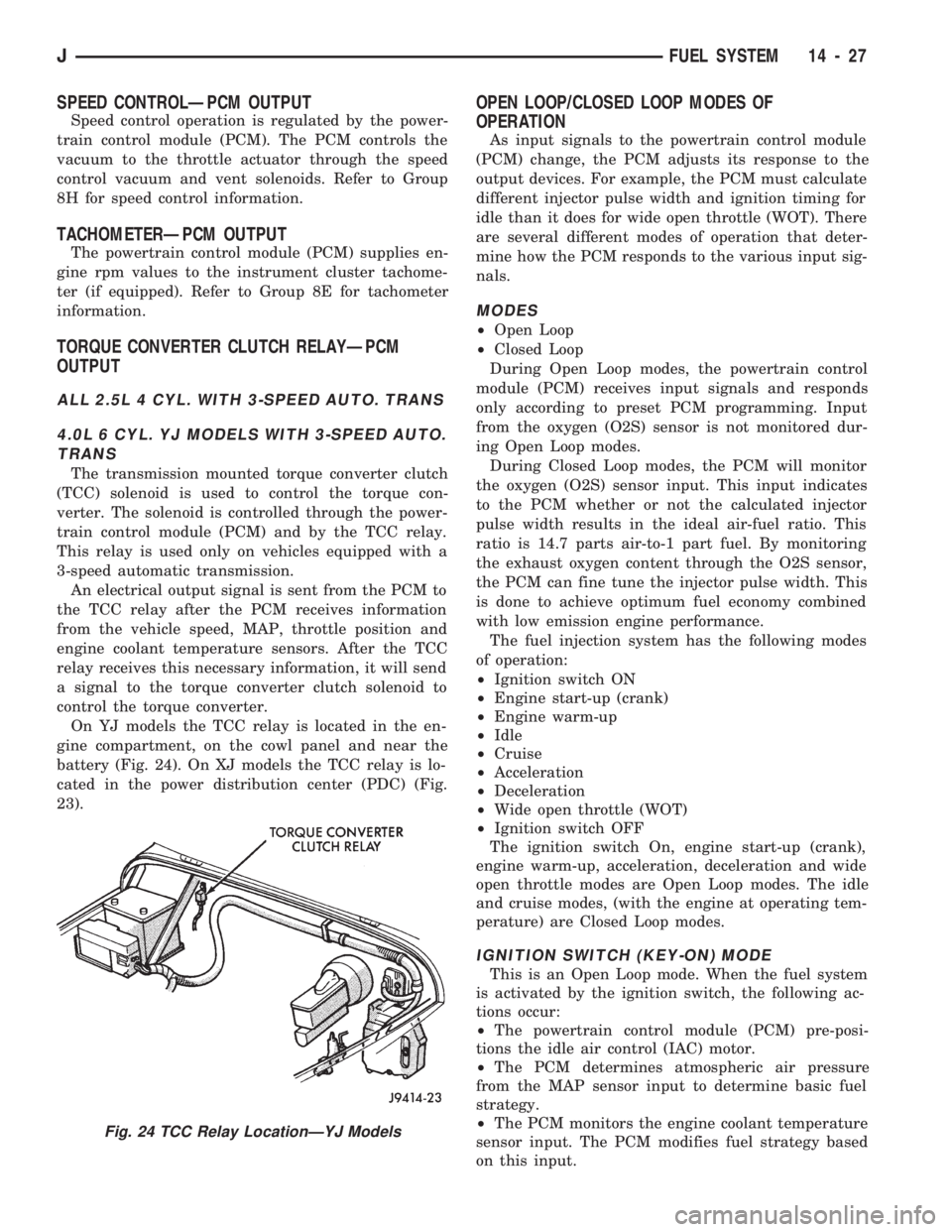

FUEL INJECTORSÐPCM OUTPUT

Six individual fuel injectors are used with the 4.0L

6 cylinder engine. Four individual fuel injectors are

used with the 2.5L 4 cylinder engine. The injectors

are attached to the fuel rail (Fig. 19).

The nozzle ends of the injectors are positioned into

openings in the intake manifold just above the in-

take valve ports of the cylinder head. The engine

wiring harness connector for each fuel injector is

equipped with an attached numerical tag (INJ 1, INJ

2 etc.). This is used to identify each fuel injector.

The injectors are energized individually in a se-

quential order by the powertrain control module

(PCM). The PCM will adjust injector pulse width by

switching the ground path to each individual injector

on and off. Injector pulse width is the period of time

that the injector is energized. The PCM will adjust

injector pulse width based on various inputs it re-

ceives.

During start up, battery voltage is supplied to the

injectors through the ASD relay. When the engine is

operating, voltage is supplied by the charging sys-

tem. The PCM determines injector pulse width based

on various inputs.

GENERATOR FIELDÐPCM OUTPUT

The powertrain control module (PCM) regulates

the charging system voltage within a range of 12.9 to

15.0 volts. Refer to Group 8A for charging system in-

formation.

GENERATOR LAMPÐPCM OUTPUT

IF EQUIPPED

If the powertrain control module (PCM) senses a

low charging condition in the charging system, it

will illuminate the generator lamp on the instrument

panel. For example, during low idle with all accesso-

ries turned on, the light may momentarily go on.

Once the PCM corrects idle speed to a higher rpm,

the light will go out. Refer to Group 8A, Battery/

Starting/Charging Systems for charging system in-

formation.

IDLE AIR CONTROL (IAC) MOTORÐPCM OUTPUT

The IAC motor is mounted on the throttle body

(Figs. 20 or 21) and is controlled by the powertrain

control module (PCM).

The throttle body has an air control passage that

provides air for the engine at idle (the throttle plate

is closed). The IAC motor pintle protrudes into the

air control passage and regulates air flow through it.

Based on various sensor inputs, the powertrain con-

trol module (PCM) adjusts engine idle speed by mov-

Fig. 19 Fuel InjectorsÐTypical

Fig. 20 IAC MotorÐ4.0L Engine

Fig. 21 IAC MotorÐ2.5L Engine

JFUEL SYSTEM 14 - 25

Page 988 of 1784

SPEED CONTROLÐPCM OUTPUT

Speed control operation is regulated by the power-

train control module (PCM). The PCM controls the

vacuum to the throttle actuator through the speed

control vacuum and vent solenoids. Refer to Group

8H for speed control information.

TACHOMETERÐPCM OUTPUT

The powertrain control module (PCM) supplies en-

gine rpm values to the instrument cluster tachome-

ter (if equipped). Refer to Group 8E for tachometer

information.

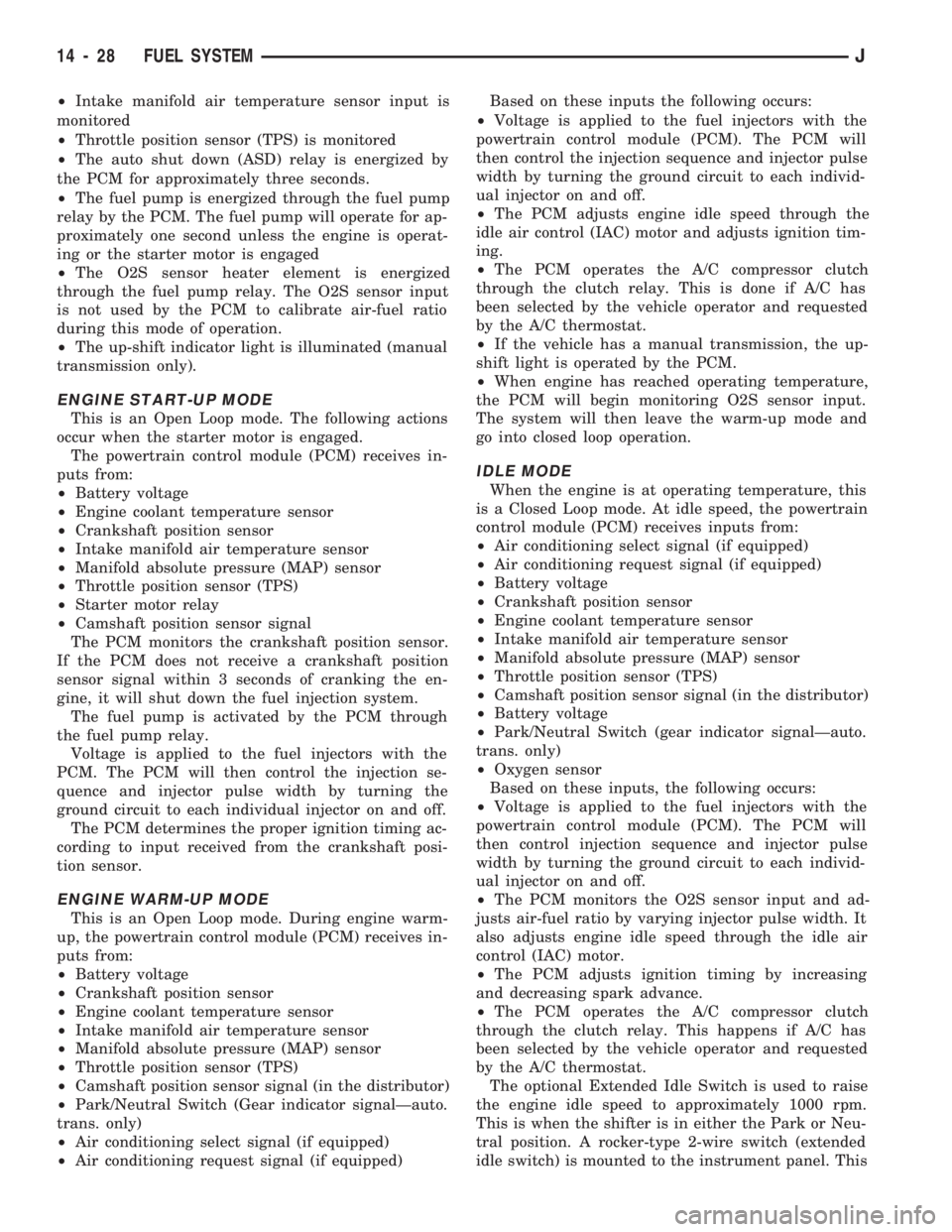

TORQUE CONVERTER CLUTCH RELAYÐPCM

OUTPUT

ALL 2.5L 4 CYL. WITH 3-SPEED AUTO. TRANS

4.0L 6 CYL. YJ MODELS WITH 3-SPEED AUTO.

TRANS

The transmission mounted torque converter clutch

(TCC) solenoid is used to control the torque con-

verter. The solenoid is controlled through the power-

train control module (PCM) and by the TCC relay.

This relay is used only on vehicles equipped with a

3-speed automatic transmission.

An electrical output signal is sent from the PCM to

the TCC relay after the PCM receives information

from the vehicle speed, MAP, throttle position and

engine coolant temperature sensors. After the TCC

relay receives this necessary information, it will send

a signal to the torque converter clutch solenoid to

control the torque converter.

On YJ models the TCC relay is located in the en-

gine compartment, on the cowl panel and near the

battery (Fig. 24). On XJ models the TCC relay is lo-

cated in the power distribution center (PDC) (Fig.

23).

OPEN LOOP/CLOSED LOOP MODES OF

OPERATION

As input signals to the powertrain control module

(PCM) change, the PCM adjusts its response to the

output devices. For example, the PCM must calculate

different injector pulse width and ignition timing for

idle than it does for wide open throttle (WOT). There

are several different modes of operation that deter-

mine how the PCM responds to the various input sig-

nals.

MODES

²Open Loop

²Closed Loop

During Open Loop modes, the powertrain control

module (PCM) receives input signals and responds

only according to preset PCM programming. Input

from the oxygen (O2S) sensor is not monitored dur-

ing Open Loop modes.

During Closed Loop modes, the PCM will monitor

the oxygen (O2S) sensor input. This input indicates

to the PCM whether or not the calculated injector

pulse width results in the ideal air-fuel ratio. This

ratio is 14.7 parts air-to-1 part fuel. By monitoring

the exhaust oxygen content through the O2S sensor,

the PCM can fine tune the injector pulse width. This

is done to achieve optimum fuel economy combined

with low emission engine performance.

The fuel injection system has the following modes

of operation:

²Ignition switch ON

²Engine start-up (crank)

²Engine warm-up

²Idle

²Cruise

²Acceleration

²Deceleration

²Wide open throttle (WOT)

²Ignition switch OFF

The ignition switch On, engine start-up (crank),

engine warm-up, acceleration, deceleration and wide

open throttle modes are Open Loop modes. The idle

and cruise modes, (with the engine at operating tem-

perature) are Closed Loop modes.

IGNITION SWITCH (KEY-ON) MODE

This is an Open Loop mode. When the fuel system

is activated by the ignition switch, the following ac-

tions occur:

²The powertrain control module (PCM) pre-posi-

tions the idle air control (IAC) motor.

²The PCM determines atmospheric air pressure

from the MAP sensor input to determine basic fuel

strategy.

²The PCM monitors the engine coolant temperature

sensor input. The PCM modifies fuel strategy based

on this input.

Fig. 24 TCC Relay LocationÐYJ Models

JFUEL SYSTEM 14 - 27

Page 989 of 1784

²Intake manifold air temperature sensor input is

monitored

²Throttle position sensor (TPS) is monitored

²The auto shut down (ASD) relay is energized by

the PCM for approximately three seconds.

²The fuel pump is energized through the fuel pump

relay by the PCM. The fuel pump will operate for ap-

proximately one second unless the engine is operat-

ing or the starter motor is engaged

²The O2S sensor heater element is energized

through the fuel pump relay. The O2S sensor input

is not used by the PCM to calibrate air-fuel ratio

during this mode of operation.

²The up-shift indicator light is illuminated (manual

transmission only).

ENGINE START-UP MODE

This is an Open Loop mode. The following actions

occur when the starter motor is engaged.

The powertrain control module (PCM) receives in-

puts from:

²Battery voltage

²Engine coolant temperature sensor

²Crankshaft position sensor

²Intake manifold air temperature sensor

²Manifold absolute pressure (MAP) sensor

²Throttle position sensor (TPS)

²Starter motor relay

²Camshaft position sensor signal

The PCM monitors the crankshaft position sensor.

If the PCM does not receive a crankshaft position

sensor signal within 3 seconds of cranking the en-

gine, it will shut down the fuel injection system.

The fuel pump is activated by the PCM through

the fuel pump relay.

Voltage is applied to the fuel injectors with the

PCM. The PCM will then control the injection se-

quence and injector pulse width by turning the

ground circuit to each individual injector on and off.

The PCM determines the proper ignition timing ac-

cording to input received from the crankshaft posi-

tion sensor.

ENGINE WARM-UP MODE

This is an Open Loop mode. During engine warm-

up, the powertrain control module (PCM) receives in-

puts from:

²Battery voltage

²Crankshaft position sensor

²Engine coolant temperature sensor

²Intake manifold air temperature sensor

²Manifold absolute pressure (MAP) sensor

²Throttle position sensor (TPS)

²Camshaft position sensor signal (in the distributor)

²Park/Neutral Switch (Gear indicator signalÐauto.

trans. only)

²Air conditioning select signal (if equipped)

²Air conditioning request signal (if equipped)Based on these inputs the following occurs:

²Voltage is applied to the fuel injectors with the

powertrain control module (PCM). The PCM will

then control the injection sequence and injector pulse

width by turning the ground circuit to each individ-

ual injector on and off.

²The PCM adjusts engine idle speed through the

idle air control (IAC) motor and adjusts ignition tim-

ing.

²The PCM operates the A/C compressor clutch

through the clutch relay. This is done if A/C has

been selected by the vehicle operator and requested

by the A/C thermostat.

²If the vehicle has a manual transmission, the up-

shift light is operated by the PCM.

²When engine has reached operating temperature,

the PCM will begin monitoring O2S sensor input.

The system will then leave the warm-up mode and

go into closed loop operation.

IDLE MODE

When the engine is at operating temperature, this

is a Closed Loop mode. At idle speed, the powertrain

control module (PCM) receives inputs from:

²Air conditioning select signal (if equipped)

²Air conditioning request signal (if equipped)

²Battery voltage

²Crankshaft position sensor

²Engine coolant temperature sensor

²Intake manifold air temperature sensor

²Manifold absolute pressure (MAP) sensor

²Throttle position sensor (TPS)

²Camshaft position sensor signal (in the distributor)

²Battery voltage

²Park/Neutral Switch (gear indicator signalÐauto.

trans. only)

²Oxygen sensor

Based on these inputs, the following occurs:

²Voltage is applied to the fuel injectors with the

powertrain control module (PCM). The PCM will

then control injection sequence and injector pulse

width by turning the ground circuit to each individ-

ual injector on and off.

²The PCM monitors the O2S sensor input and ad-

justs air-fuel ratio by varying injector pulse width. It

also adjusts engine idle speed through the idle air

control (IAC) motor.

²The PCM adjusts ignition timing by increasing

and decreasing spark advance.

²The PCM operates the A/C compressor clutch

through the clutch relay. This happens if A/C has

been selected by the vehicle operator and requested

by the A/C thermostat.

The optional Extended Idle Switch is used to raise

the engine idle speed to approximately 1000 rpm.

This is when the shifter is in either the Park or Neu-

tral position. A rocker-type 2-wire switch (extended

idle switch) is mounted to the instrument panel. This

14 - 28 FUEL SYSTEMJ

Page 990 of 1784

switch will supply a ground circuit to the powertrain

control module (PCM).The switch is available

only with 4.0L engine when supplied with the

optional police package.

CRUISE MODE

When the engine is at operating temperature, this

is a Closed Loop mode. At cruising speed, the power-

train control module (PCM) receives inputs from:

²Air conditioning select signal (if equipped)

²Air conditioning request signal (if equipped)

²Battery voltage

²Engine coolant temperature sensor

²Crankshaft position sensor

²Intake manifold air temperature sensor

²Manifold absolute pressure (MAP) sensor

²Throttle position sensor (TPS)

²Camshaft position sensor signal (in the distributor)

²Park/Neutral switch (gear indicator signalÐauto.

trans. only)

²Oxygen (O2S) sensor

Based on these inputs, the following occurs:

²Voltage is applied to the fuel injectors with the

PCM. The PCM will then adjust the injector pulse

width by turning the ground circuit to each individ-

ual injector on and off.

²The PCM monitors the O2S sensor input and ad-

justs air-fuel ratio. It also adjusts engine idle speed

through the idle air control (IAC) motor.

²The PCM adjusts ignition timing by turning the

ground path to the coil on and off.

²The PCM operates the A/C compressor clutch

through the clutch relay. This happens if A/C has

been selected by the vehicle operator and requested

by the A/C thermostat.

ACCELERATION MODE

This is an Open Loop mode. The powertrain control

module (PCM) recognizes an abrupt increase in

throttle position or MAP pressure as a demand for

increased engine output and vehicle acceleration.

The PCM increases injector pulse width in response

to increased throttle opening.

DECELERATION MODE

When the engine is at operating temperature, this

is an Open Loop mode. During hard deceleration, the

powertrain control module (PCM) receives the follow-

ing inputs.

²Air conditioning select signal (if equipped)

²Air conditioning request signal (if equipped)

²Battery voltage

²Engine coolant temperature sensor

²Crankshaft position sensor

²Intake manifold air temperature sensor

²Manifold absolute pressure (MAP) sensor

²Throttle position sensor (TPS)

²Camshaft position sensor signal (in the distributor)²Park/Neutral switch (gear indicator signalÐauto.

trans. only)

If the vehicle is under hard deceleration with the

proper rpm and closed throttle conditions, the PCM

will ignore the oxygen sensor input signal. The PCM

will enter a fuel cut-off strategy in which it will not

supply battery voltage to the injectors. If a hard de-

celeration does not exist, the PCM will determine the

proper injector pulse width and continue injection.

Based on the above inputs, the PCM will adjust en-

gine idle speed through the idle air control (IAC) mo-

tor.

The PCM adjusts ignition timing by turning the

ground path to the coil on and off.

The PCM opens the ground circuit to the A/C

clutch relay to disengage the A/C compressor clutch.

This is done until the vehicle is no longer under de-

celeration (if the A/C system is operating).

WIDE OPEN THROTTLE MODE

This is an Open Loop mode. During wide open

throttle operation, the powertrain control module

(PCM) receives the following inputs.

²Battery voltage

²Crankshaft position sensor

²Engine coolant temperature sensor

²Intake manifold air temperature sensor

²Manifold absolute pressure (MAP) sensor

²Throttle position sensor (TPS)

²Camshaft position sensor signal (in the distributor)

During wide open throttle conditions, the following

occurs:

²Voltage is applied to the fuel injectors with the

powertrain control module (PCM). The PCM will

then control the injection sequence and injector pulse

width by turning the ground circuit to each individ-

ual injector on and off. The PCM ignores the oxygen

sensor input signal and provides a predetermined

amount of additional fuel. This is done by adjusting

injector pulse width.

²The PCM adjusts ignition timing by turning the

ground path to the coil on and off.

²The PCM opens the ground circuit to the A/C

clutch relay to disengage the A/C compressor clutch.

This will be done for approximately 15 seconds (if the

air conditioning system is operating).

If the vehicle has a manual transmission, the up-

shift light is operated by the PCM.

IGNITION SWITCH OFF MODE

When ignition switch is turned to OFF position,

the PCM stops operating the injectors, ignition coil,

ASD relay and fuel pump relay.

THROTTLE BODY

Filtered air from the air cleaner enters the intake

manifold through the throttle body (Fig. 25). Fuel

does not enter the intake manifold through the throt-

JFUEL SYSTEM 14 - 29

Page 1446 of 1784

²Noise

²Handling

²Durability

²Tread life

²Traction

²Rolling resistance

²Speed capability

Original equipment tires should be used when re-

placement is needed.

Refer to the placard on the vehicle or the

Owner's Manual for the correct replacement

tire.

Failure to use original or equivalent replacement

tires may adversely affect the handling of the vehi-

cle.

The use of oversize tiresis not recommended.

They may cause interference with vehicle suspension

and steering travel. This can cause tire damage or

failure.

WARNING: FAILURE TO EQUIP THE VEHICLE WITH

TIRES HAVING ADEQUATE LOAD CAPABILITY CAN

RESULT IN SUDDEN TIRE FAILURE.

ROTATION

Tires on the front and rear axles operate at differ-

ent loads and perform different steering, driving, and

braking functions. For these reasons, the tires wear

at unequal rates. They may also develop irregular

wear patterns. These effects can be reduced by rotat-

ing the tires according to the maintenance schedule

in the Owners Manual. This will improve tread life,

traction and maintain a smooth quiet ride.

The suggested method of tire rotation is thesame

side front to rearpattern (Fig. 4). Other rotation

methods can be used, but may not provide the same

tire longevity benefits.

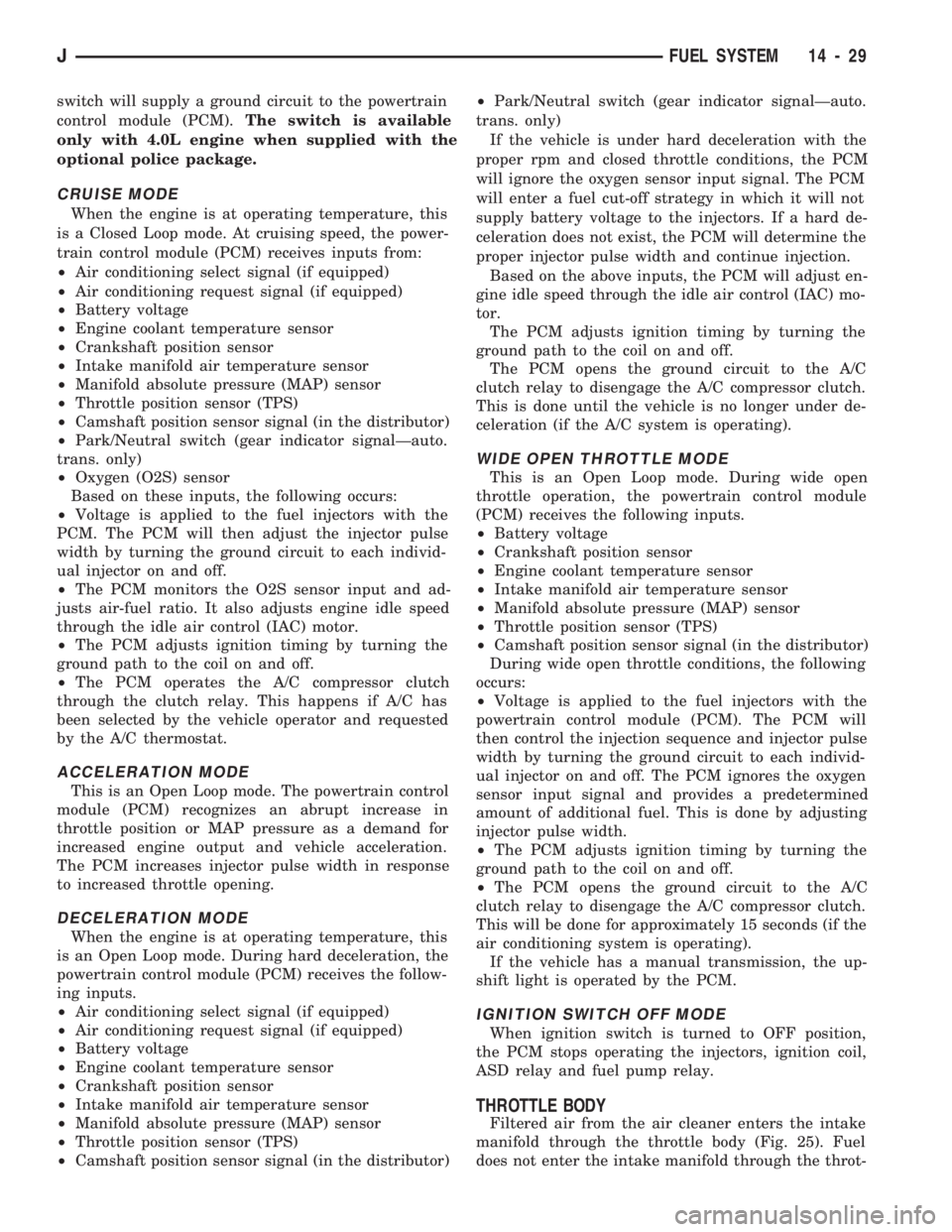

TREAD WEAR INDICATORS

Tread wear indicators are molded into the bottom

of the tread grooves. When tread is 1.6 mm (1/16 in.),

the tread wear indicators will appear as a 13 mm

(1/2 in.) band across the tread width.

Tire replacement is necessary when indicators ap-

pear in two or more grooves Fig. 5).

REPAIRING LEAKS

For proper repairing, a radial tire it must be re-

moved from the wheel. Repairs should only be made

if the puncture is in thetread area(Fig. 6). If out-

side the tread area the tire should be replaced.

Deflate tire completely before dismounting tire

from the wheel. Use lubrication such as a mild soap

solution when dismounting or mounting tire. Use

tools free of burrs or sharp edges.

Before mounting tire on wheel, make sure all rust

scale is removed from the rim. Repaint or seal if nec-

essary.

Fig. 4 Tire Rotation Pattern

Fig. 5 Tread Wear Indicators

Fig. 6 Tire Repair Area

JWHEELS AND TIRES 22 - 3

Page 1449 of 1784

WHEELS

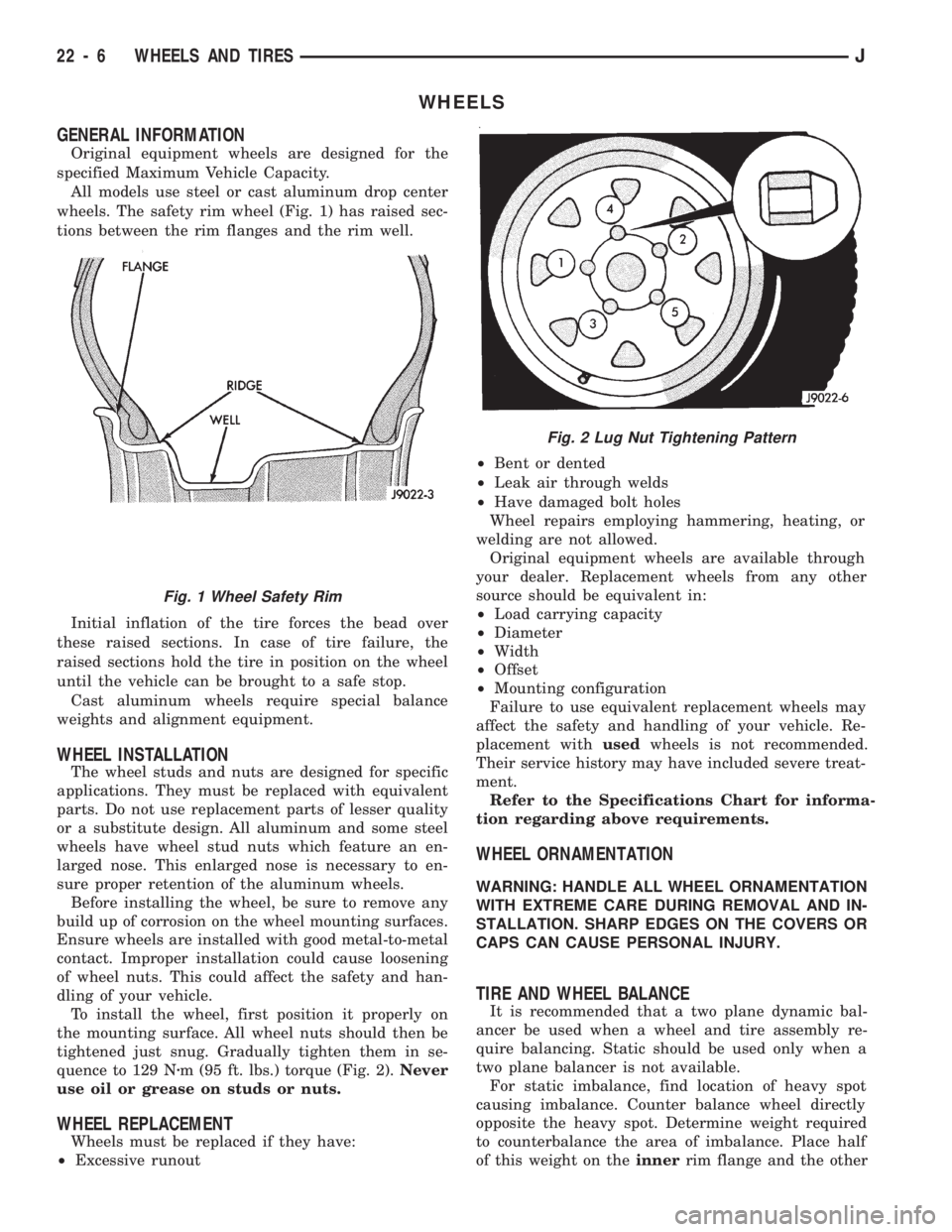

GENERAL INFORMATION

Original equipment wheels are designed for the

specified Maximum Vehicle Capacity.

All models use steel or cast aluminum drop center

wheels. The safety rim wheel (Fig. 1) has raised sec-

tions between the rim flanges and the rim well.

Initial inflation of the tire forces the bead over

these raised sections. In case of tire failure, the

raised sections hold the tire in position on the wheel

until the vehicle can be brought to a safe stop.

Cast aluminum wheels require special balance

weights and alignment equipment.

WHEEL INSTALLATION

The wheel studs and nuts are designed for specific

applications. They must be replaced with equivalent

parts. Do not use replacement parts of lesser quality

or a substitute design. All aluminum and some steel

wheels have wheel stud nuts which feature an en-

larged nose. This enlarged nose is necessary to en-

sure proper retention of the aluminum wheels.

Before installing the wheel, be sure to remove any

build up of corrosion on the wheel mounting surfaces.

Ensure wheels are installed with good metal-to-metal

contact. Improper installation could cause loosening

of wheel nuts. This could affect the safety and han-

dling of your vehicle.

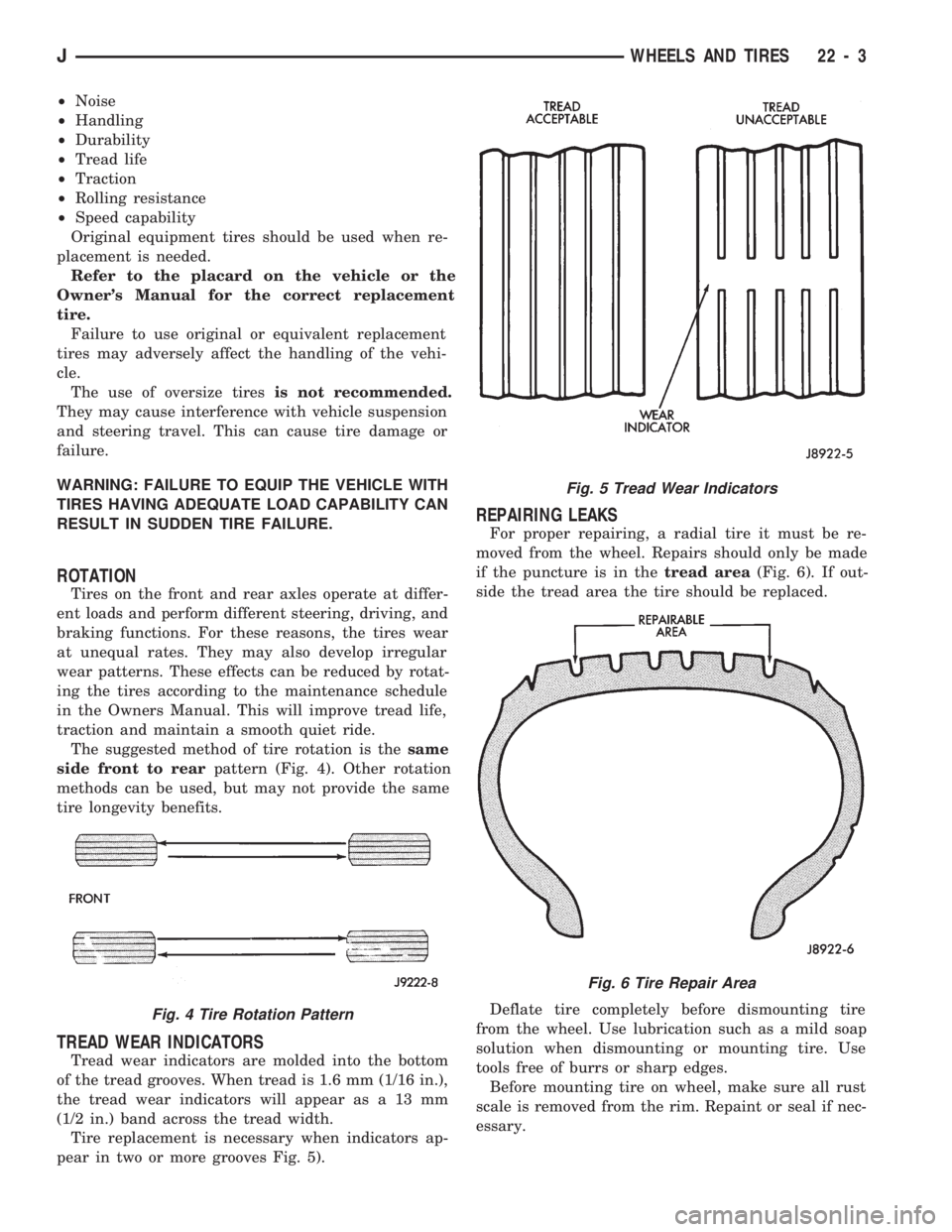

To install the wheel, first position it properly on

the mounting surface. All wheel nuts should then be

tightened just snug. Gradually tighten them in se-

quence to 129 Nzm (95 ft. lbs.) torque (Fig. 2).Never

use oil or grease on studs or nuts.

WHEEL REPLACEMENT

Wheels must be replaced if they have:

²Excessive runout²Bent or dented

²Leak air through welds

²Have damaged bolt holes

Wheel repairs employing hammering, heating, or

welding are not allowed.

Original equipment wheels are available through

your dealer. Replacement wheels from any other

source should be equivalent in:

²Load carrying capacity

²Diameter

²Width

²Offset

²Mounting configuration

Failure to use equivalent replacement wheels may

affect the safety and handling of your vehicle. Re-

placement withusedwheels is not recommended.

Their service history may have included severe treat-

ment.

Refer to the Specifications Chart for informa-

tion regarding above requirements.

WHEEL ORNAMENTATION

WARNING: HANDLE ALL WHEEL ORNAMENTATION

WITH EXTREME CARE DURING REMOVAL AND IN-

STALLATION. SHARP EDGES ON THE COVERS OR

CAPS CAN CAUSE PERSONAL INJURY.

TIRE AND WHEEL BALANCE

It is recommended that a two plane dynamic bal-

ancer be used when a wheel and tire assembly re-

quire balancing. Static should be used only when a

two plane balancer is not available.

For static imbalance, find location of heavy spot

causing imbalance. Counter balance wheel directly

opposite the heavy spot. Determine weight required

to counterbalance the area of imbalance. Place half

of this weight on theinnerrim flange and the other

Fig. 2 Lug Nut Tightening Pattern

Fig. 1 Wheel Safety Rim

22 - 6 WHEELS AND TIRESJ

Page 1725 of 1784

EXHAUST EMISSION CONTROLS

INDEX

page page

Air Cleaner.............................. 7Oxygen (O2S) Sensor...................... 7

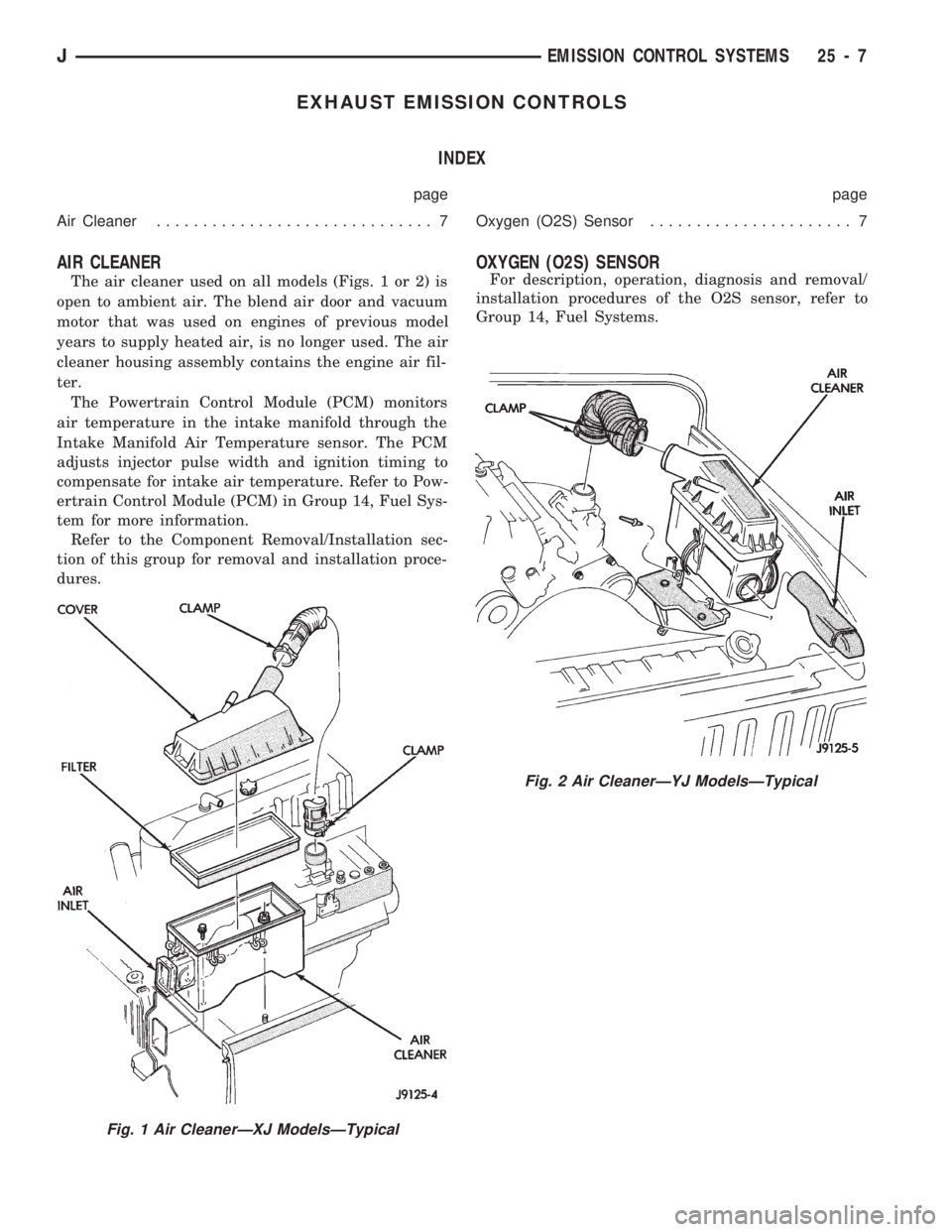

AIR CLEANER

The air cleaner used on all models (Figs. 1 or 2) is

open to ambient air. The blend air door and vacuum

motor that was used on engines of previous model

years to supply heated air, is no longer used. The air

cleaner housing assembly contains the engine air fil-

ter.

The Powertrain Control Module (PCM) monitors

air temperature in the intake manifold through the

Intake Manifold Air Temperature sensor. The PCM

adjusts injector pulse width and ignition timing to

compensate for intake air temperature. Refer to Pow-

ertrain Control Module (PCM) in Group 14, Fuel Sys-

tem for more information.

Refer to the Component Removal/Installation sec-

tion of this group for removal and installation proce-

dures.

OXYGEN (O2S) SENSOR

For description, operation, diagnosis and removal/

installation procedures of the O2S sensor, refer to

Group 14, Fuel Systems.

Fig. 2 Air CleanerÐYJ ModelsÐTypical

Fig. 1 Air CleanerÐXJ ModelsÐTypical

JEMISSION CONTROL SYSTEMS 25 - 7

Page 1783 of 1784

Page 9

03/30/99

Rev. 0

4.0 Using The Acrobat Reader

4.1 Acrobat Reader On-Line Help

The complete user help file can be accessed by selecting the

Help Menu option and then Reader Online Guide option within

the Acrobat Reader application.

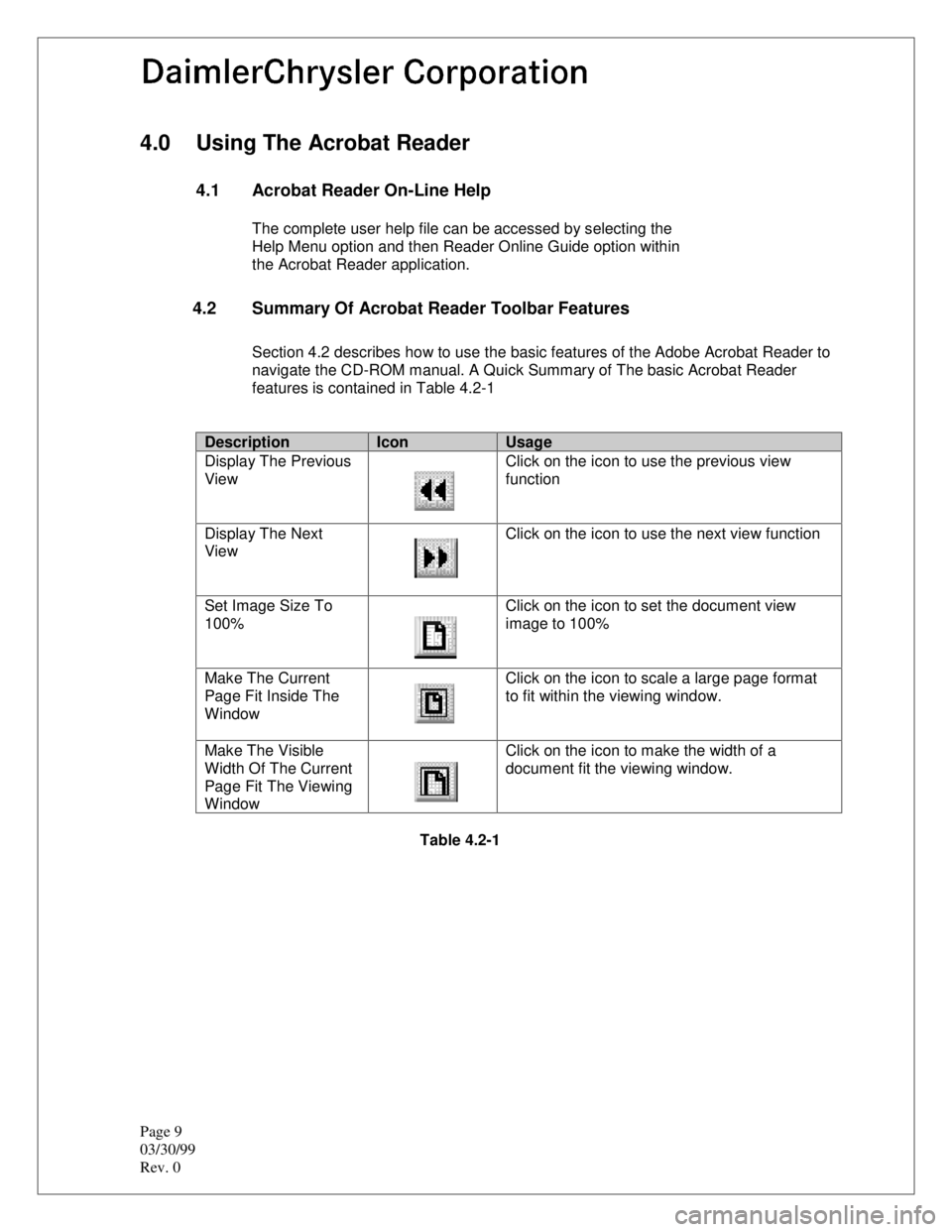

4.2 Summary Of Acrobat Reader Toolbar Features

Section 4.2 describes how to use the basic features of the Adobe Acrobat Reader to

navigate the CD-ROM manual. A Quick Summary of The basic Acrobat Reader

features is contained in Table 4.2-1

DescriptionIconUsage

Display The Previous

ViewClick on the icon to use the previous view

function

Display The Next

ViewClick on the icon to use the next view function

Set Image Size To

100%Click on the icon to set the document view

image to 100%

Make The Current

Page Fit Inside The

WindowClick on the icon to scale a large page format

to fit within the viewing window.

Make The Visible

Width Of The Current

Page Fit The Viewing

WindowClick on the icon to make the width of a

document fit the viewing window.

Table 4.2-1

Page 1784 of 1784

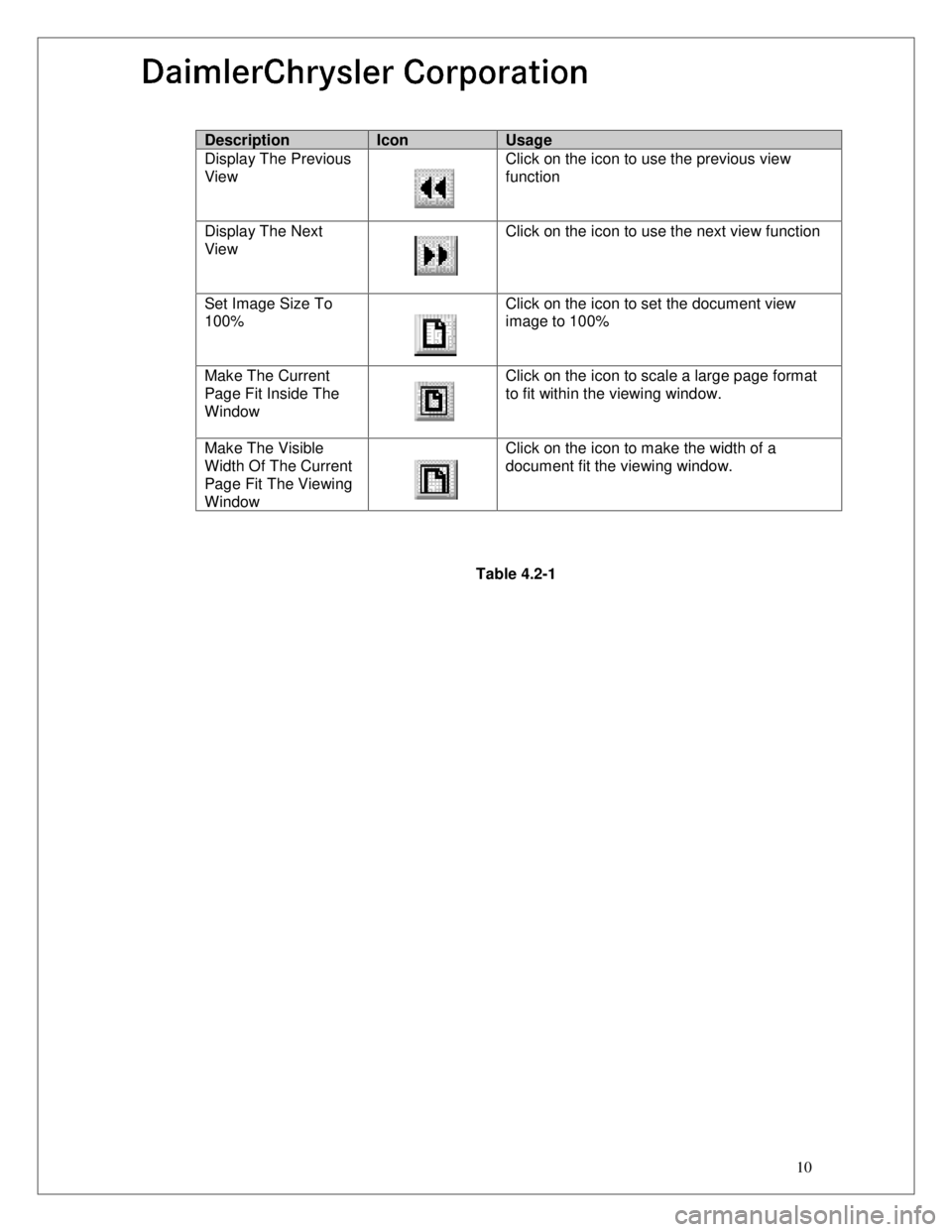

10

DescriptionIconUsage

Display The Previous

ViewClick on the icon to use the previous view

function

Display The Next

ViewClick on the icon to use the next view function

Set Image Size To

100%Click on the icon to set the document view

image to 100%

Make The Current

Page Fit Inside The

WindowClick on the icon to scale a large page format

to fit within the viewing window.

Make The Visible

Width Of The Current

Page Fit The Viewing

WindowClick on the icon to make the width of a

document fit the viewing window.

Table 4.2-1